Online cylinder crimping apparatus and method

A technology of cylinder and crimping dies, which is applied in the direction of connection and connection through deformation, so as to reduce the damage of terminals by pulling, reduce self-engineering defects, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

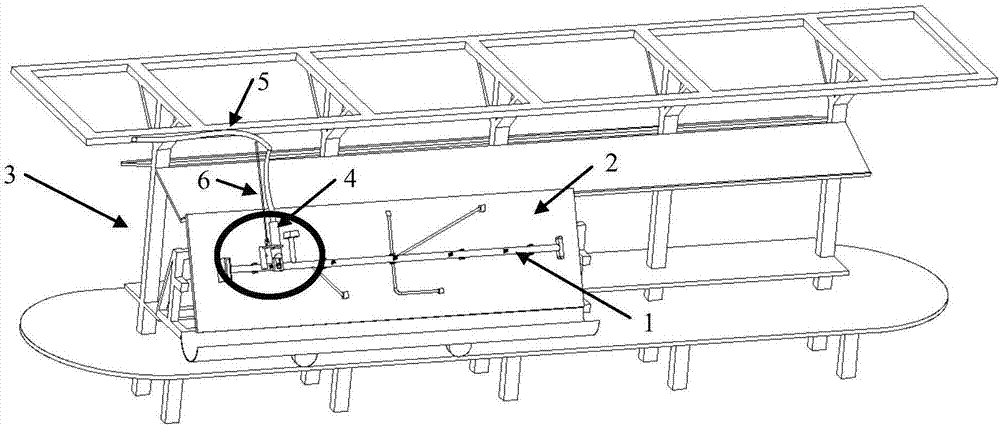

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

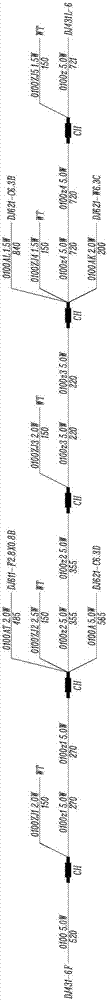

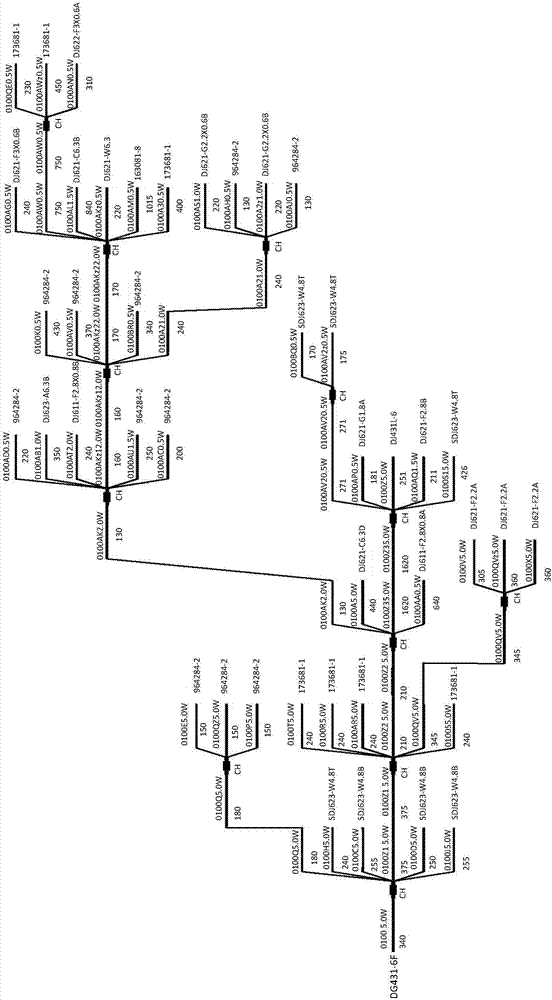

[0013] Such as figure 2 As shown, blanking - crimping - super welding / heat shrinking (all concentrated) - pre-installed head (concentrated) - assembly line - electric inspection - packaging. The 54 branch lines of the existing 0100 ground wires are combined through 12 super-soldering points. The single-match structure is complex and the welding efficiency is low. During the logistics turnover process, it is easy to cause the terminals to pull each other, damage the terminals, scratch the wire skin, and wire the assembly line. And the insertion efficiency is low, and the self-engineering defect is high.

[0014] Such as figure 1 As shown, blanking - crimping - super welding / heat shrinking (partial) - [pre-installed head (line side), online cylinder crimping (partial branch line), assembly line] - 5 electric inspection - 6 packaging

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap