Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43 results about "Autonomation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Autonomation describes a feature of machine design to effect the principle of jidoka (自働化) used in the Toyota Production System (TPS) and Lean manufacturing. It may be described as "intelligent automation" or "Automation with a human touch". This type of automation implements some supervisory functions rather than production functions. At Toyota, this usually means that if an abnormal situation arises; the machine stops and the worker will stop the production line. It is a quality control process that applies the following four principles...

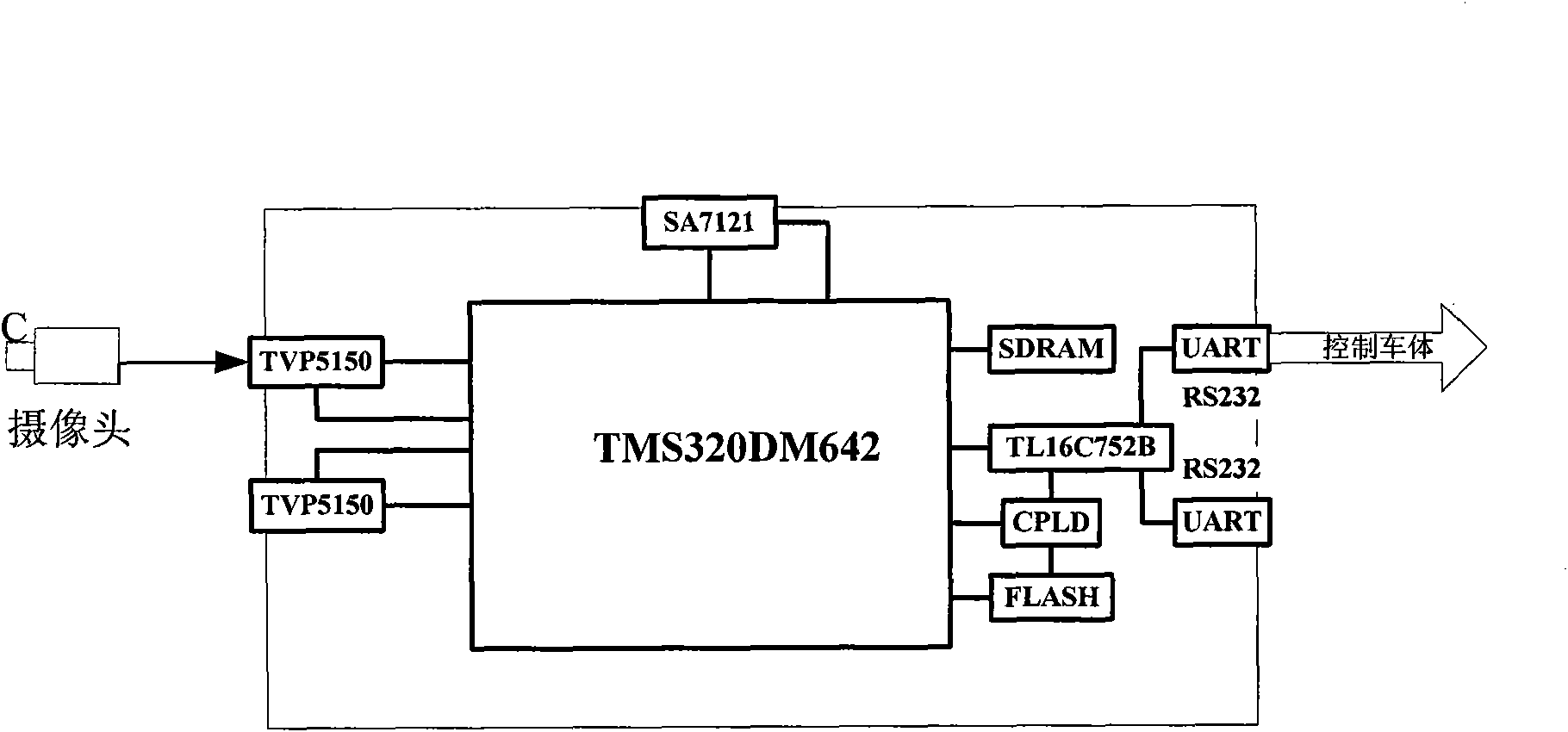

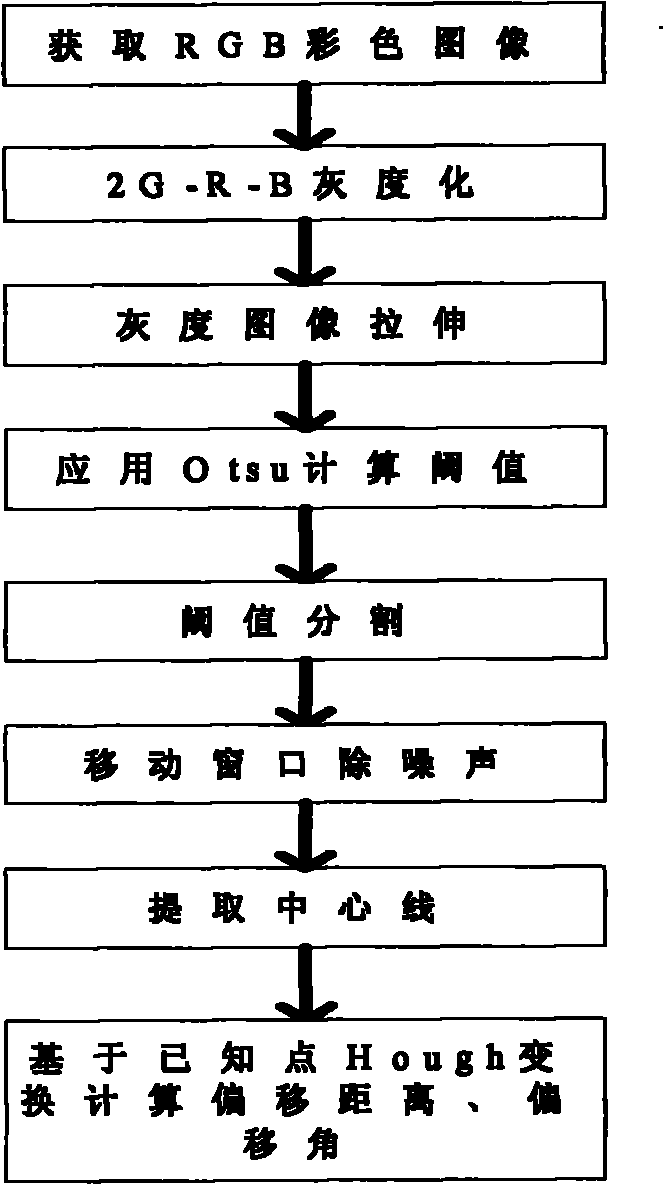

Intelligent navigation control system and method

InactiveCN101976079AImprove environmental adaptabilityImprove work efficiencyInstruments for road network navigationPosition/course control in two dimensionsRobustificationClosed loop

Owner:北京环宇信科技术发展有限公司

Informationized full-intelligent carton production linkage management method

ActiveCN108177946AReduce on-site manpowerReduce lossControl devices for conveyorsStacking articlesPaperboardEnterprise resource planning

The invention belongs to the technical field of intelligent logistics management, and concretely relates to an informationized full-intelligent carton production linkage management method, which comprises the following steps of according to customer orders, forming work order information through decomposing order information, and carrying out carton board purchase operation through an ERP (Enterprise Resource Planning) system according to the work order information; warehousing; feeding a carton board of each tray to an automatic logistics paper feeding area; stacking trays, separating, and feeding the carton boards separated from the trays to corresponding storage belts of a storage area; controlling a feeding shuttle bus for directly taking the carton boards at the storage belt parts onwhich the carton boards are required for the corresponding orders are located, and after taking the carton boards, directly feeding to an inlet of a carton board feeding machine; and passing the carton boards through the carton board feeding machine, a printer, a carton board receiving machine, a carton board transferring machine, a laminating machine, a stacking machine and a labelling machine, and finally packaging. The informationized full-intelligent carton production linkage management method provided by the invention has the advantages of high production continuity degree, high working reliability, compact flow and high automation degree, so that the actual working efficiency of a whole production flow can be effectively improved.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD +1

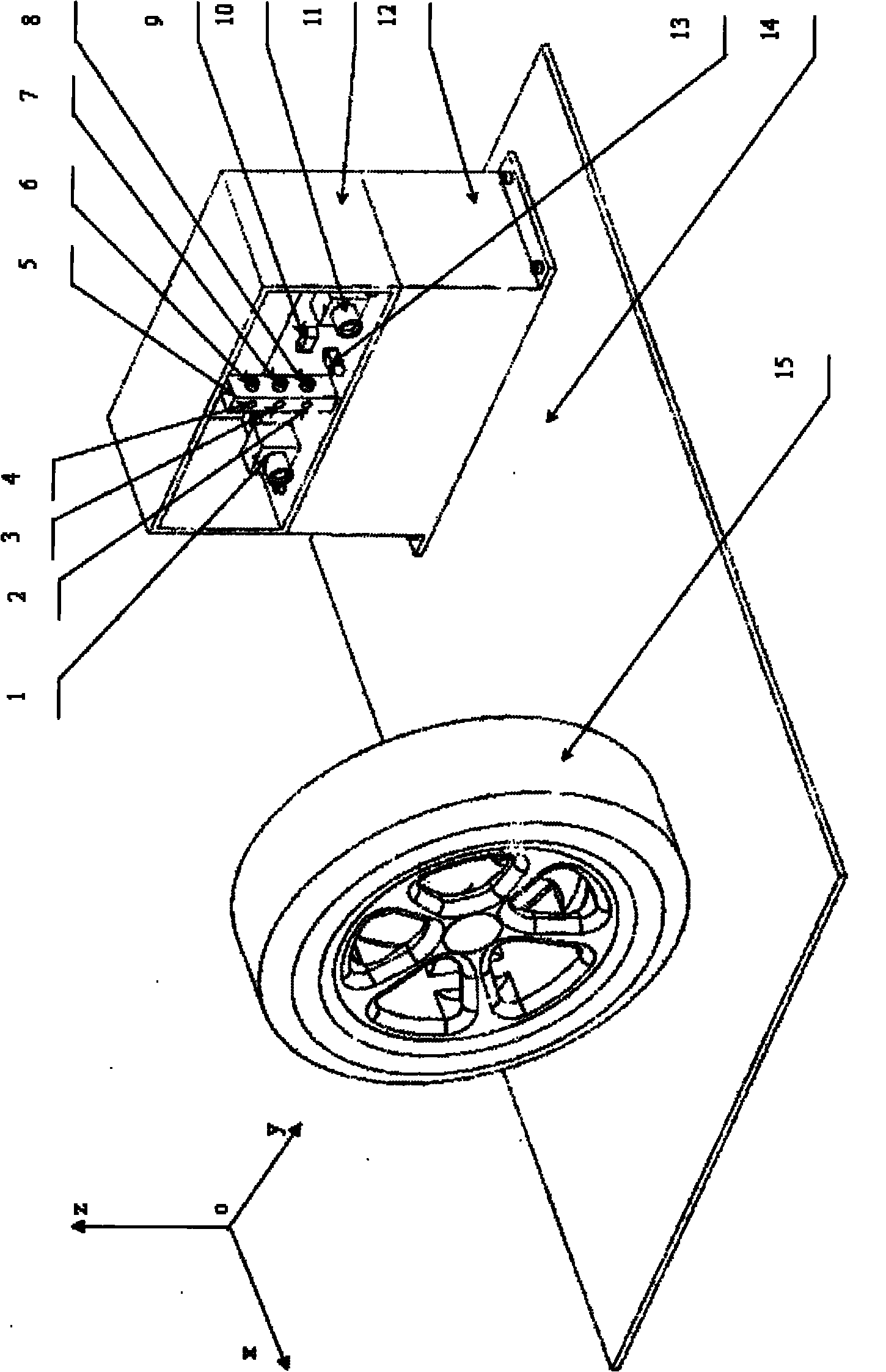

Machine vision-based spatial position detection system for automobile wheel planes and rims

InactiveCN102042806AImprove detection efficiencyImprove detection accuracyUsing optical meansVehicle wheel testingMachine visionVisual perception

Owner:JILIN UNIV

Monitoring method and monitoring device for abnormal state of metering equipment

PendingCN108805296AImprove convenienceAvoid the problem of false positives of abnormal statusData processing applicationsData acquisitionMonitoring system

The invention relates to a monitoring method and a monitoring device for an abnormal state of metering equipment. The monitoring method comprises the steps of collecting operational data of the metering equipment for metering an automatic system; determining abnormal state information of the metering equipment according to the operational data; acquiring equipment information of the metering equipment, and generating an operation and maintenance work order according to the abnormal state information and the equipment information; sending the operation and maintenance work order to a client side; receiving an operation and maintenance state of the metering equipment fed back by the client side; monitoring the abnormal state of the metering equipment according to the operation and maintenance state, and monitoring the abnormal state of the metering equipment by combining the operational data, the operation and maintenance work order and the operation and maintenance state. Therefore, theproblem of misinformation of the abnormal state caused by inaccurate collected operational data of the metering equipment is avoided, the monitoring accuracy is improved, closed loop monitoring processing of data collection, work order generation and equipment operation and maintenance is formed, and the convenience, pertinence and timeliness of monitoring and operation and maintenance are improved. The invention further provides a monitoring system for the abnormal state of the metering equipment.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

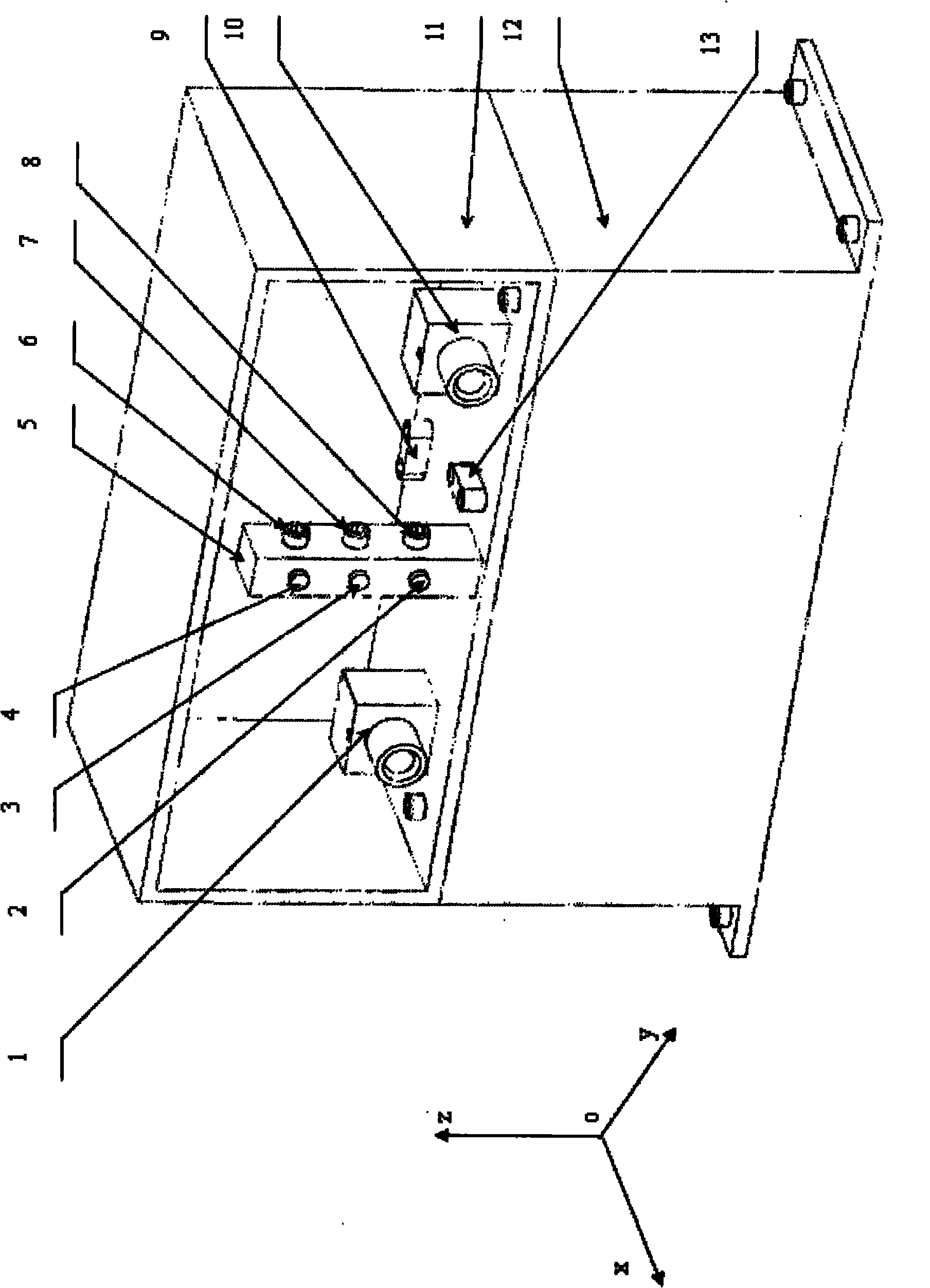

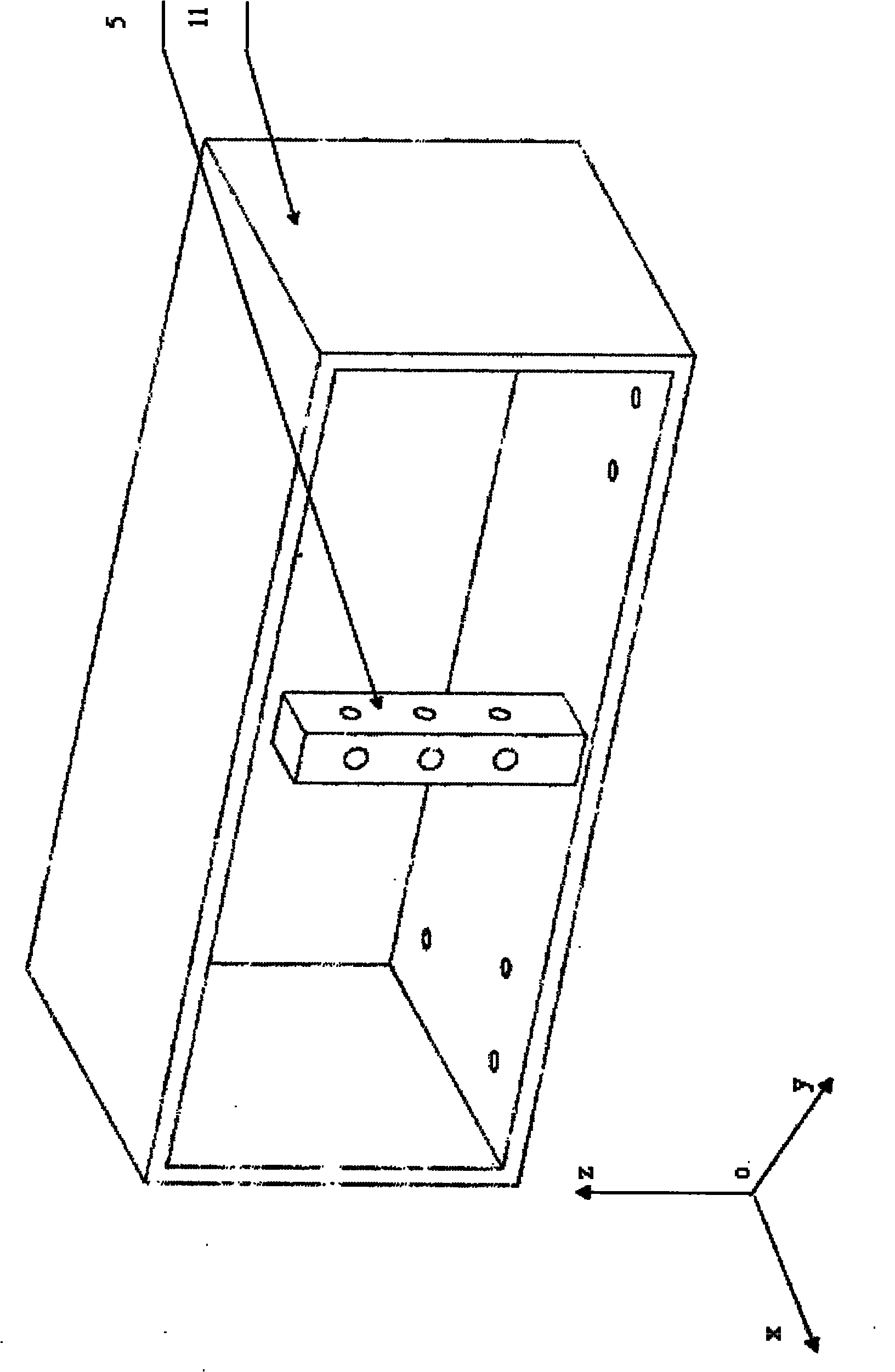

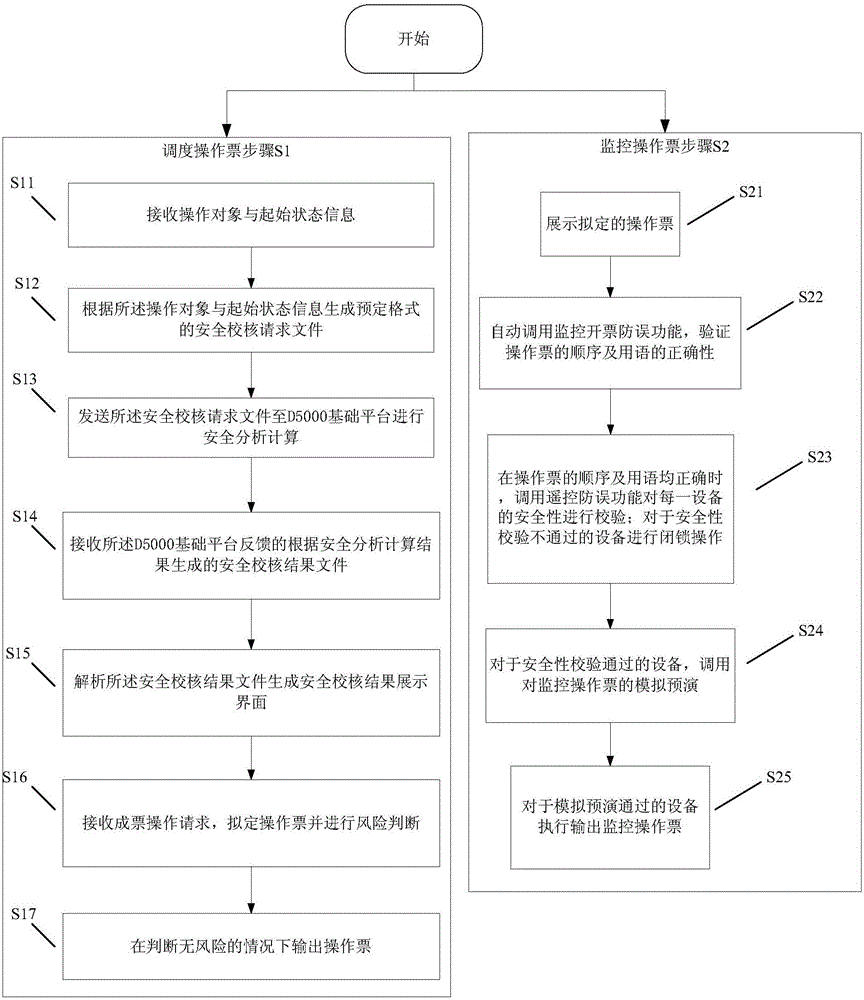

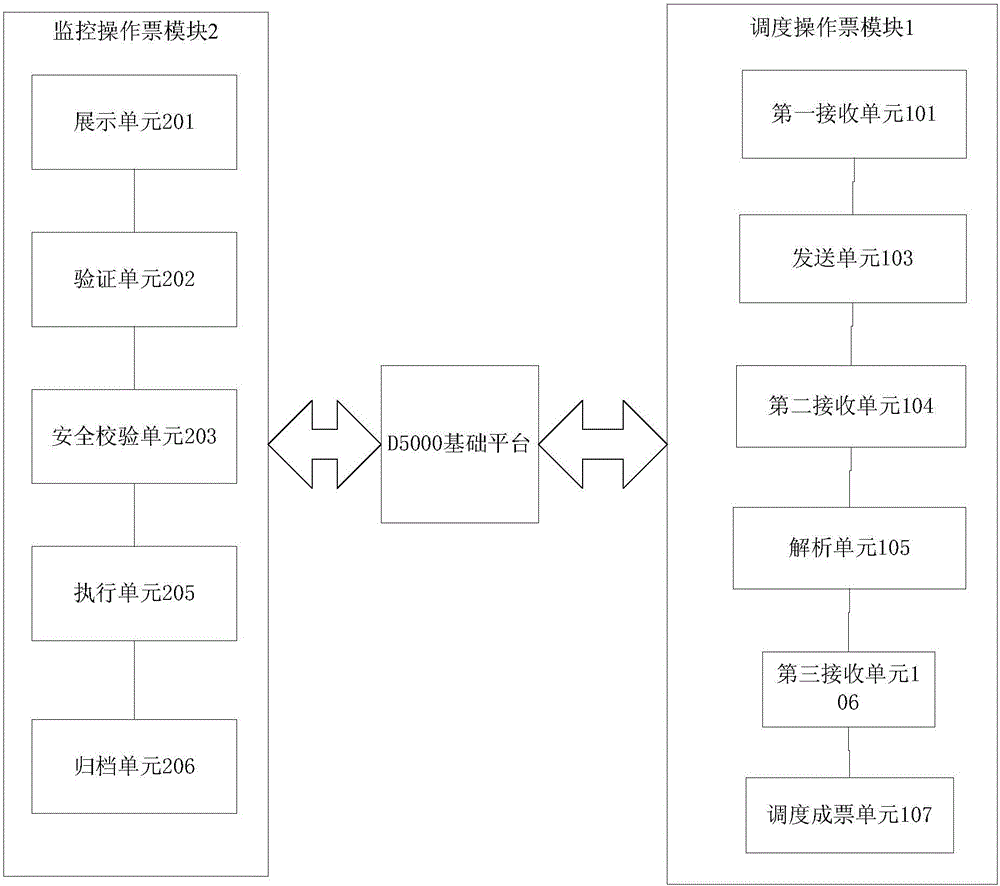

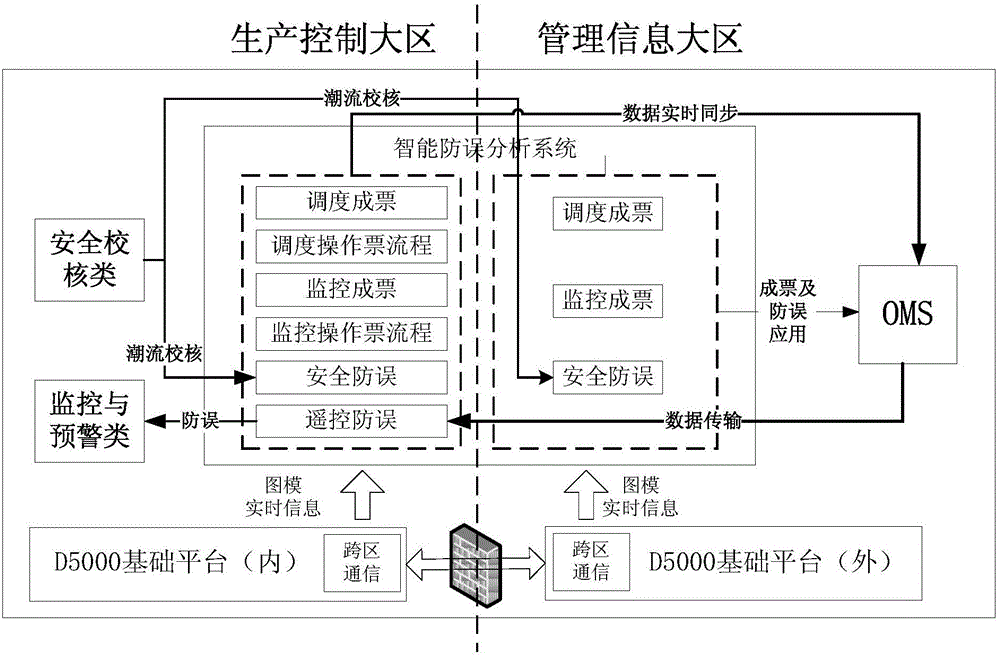

Intelligent anti-error analysis method and system

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

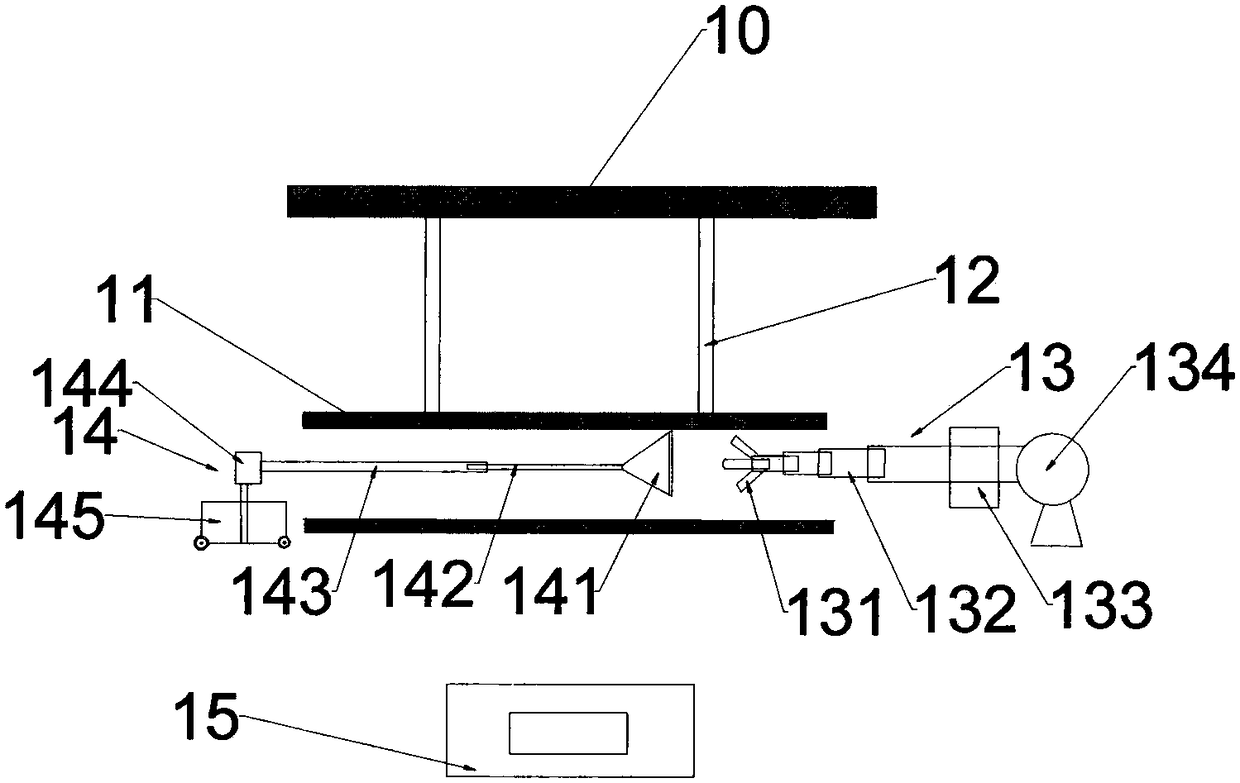

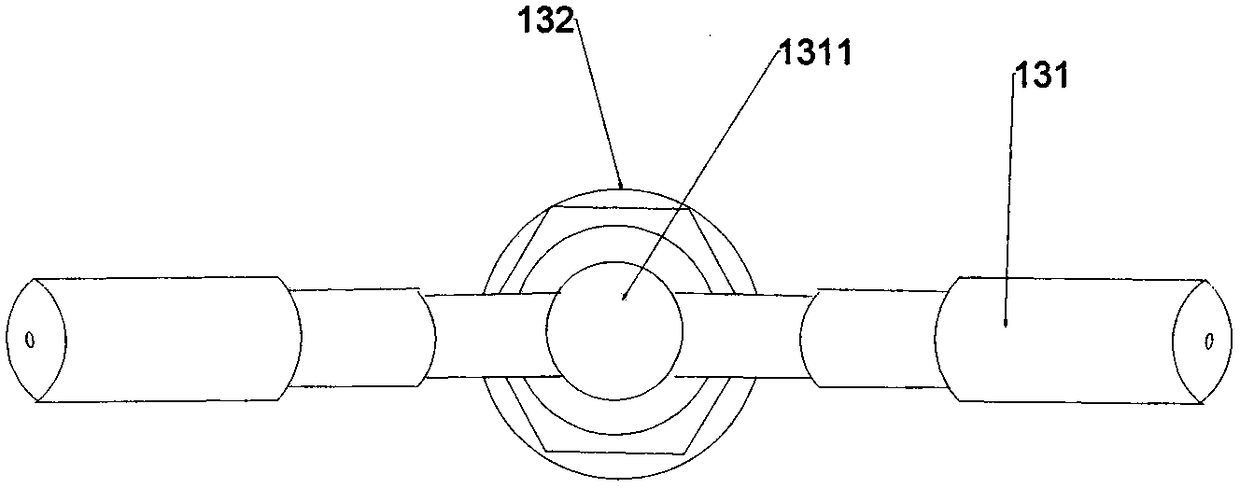

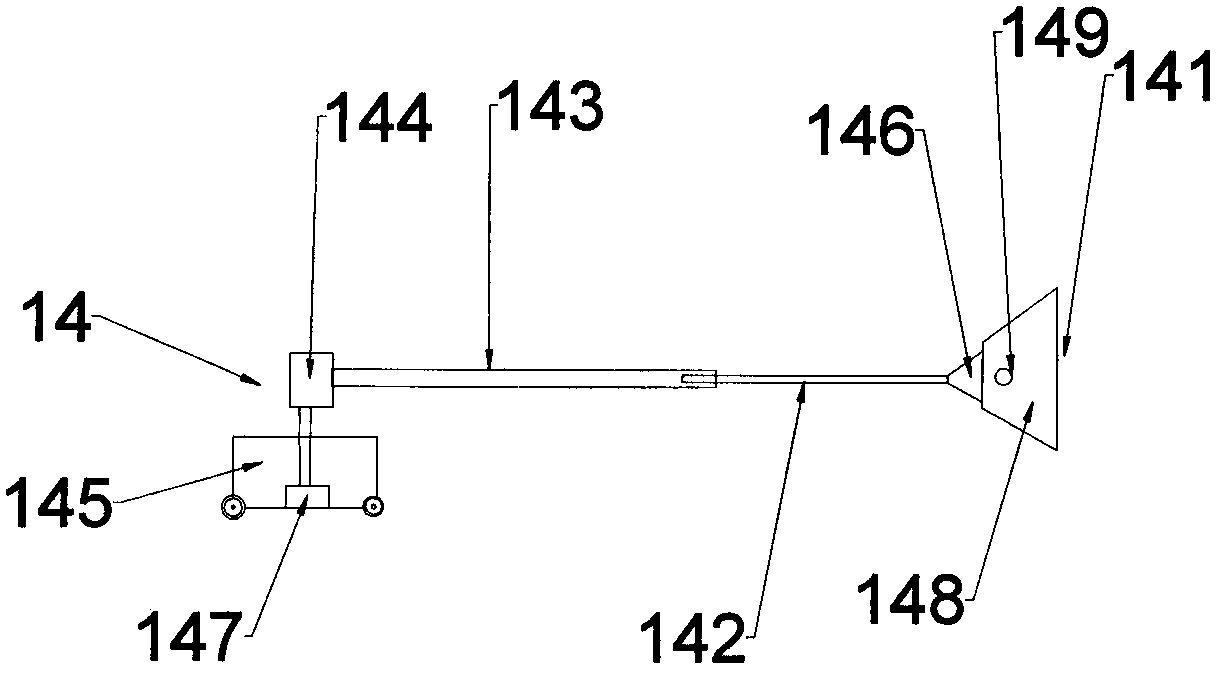

Method for detecting leakage flow of automobile oil tank cover

ActiveCN102183346AImprove the display effectEasy to storeMeasurement of fluid loss/gain rateApparatus for force/torque/work measurementFuel tankEngineering

Owner:SHANGHAI HUF AUTOMOTIVE LOCK CO LTD

Electric control system of hydraulic experiment table

InactiveCN108087388AReasonable designGuaranteed uptimeFluid-pressure actuator testingServometer circuitsAutomatic controlControl system design

The invention discloses an electric control system of a hydraulic experiment table; the purposes of remote monitoring and control can be realized; the functions of voice alarm, statement output and the like are achieved; and automatic control of the system of the hydraulic experiment table is realized. The control system of the hydraulic experiment table is reasonable in design; hardware is selected properly; software is designed to achieve requirement meeting, high operability and powerful functions; detected scene sensor data is matched with actual data; control on a motor, a relay and the like is accurate and timely; and the whole system of the hydraulic experiment table is stable and reliable in operation and excellent in monitoring effect.

Owner:赵江涛

Intelligent tile production equipment for recycling tailings and automatic tile production technology

Owner:佛山市粤祥陶瓷有限公司

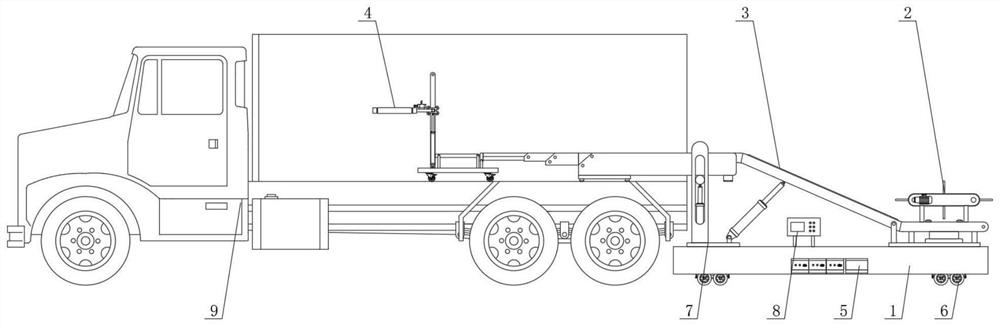

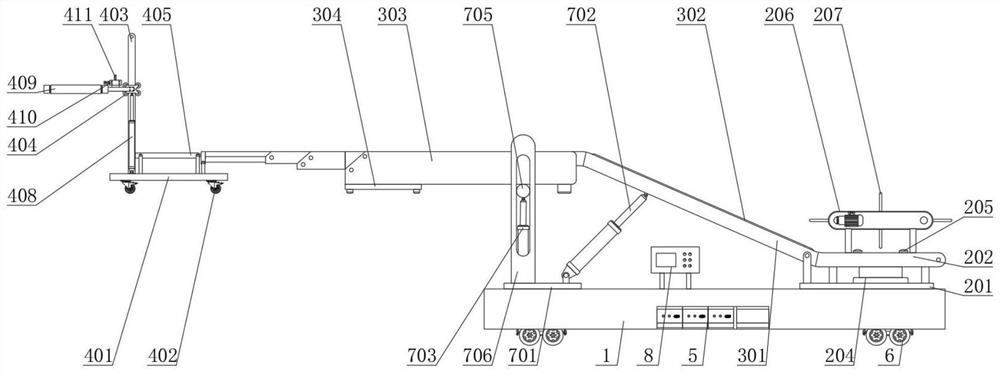

A kind of automatic production method of elastic chain

ActiveCN106507885BReduce consumptionEven and reasonable feedingAmmunition loadingPunchingManufacturing technology

Owner:HEILONGJIANG NORTH TOOLS CO LTD

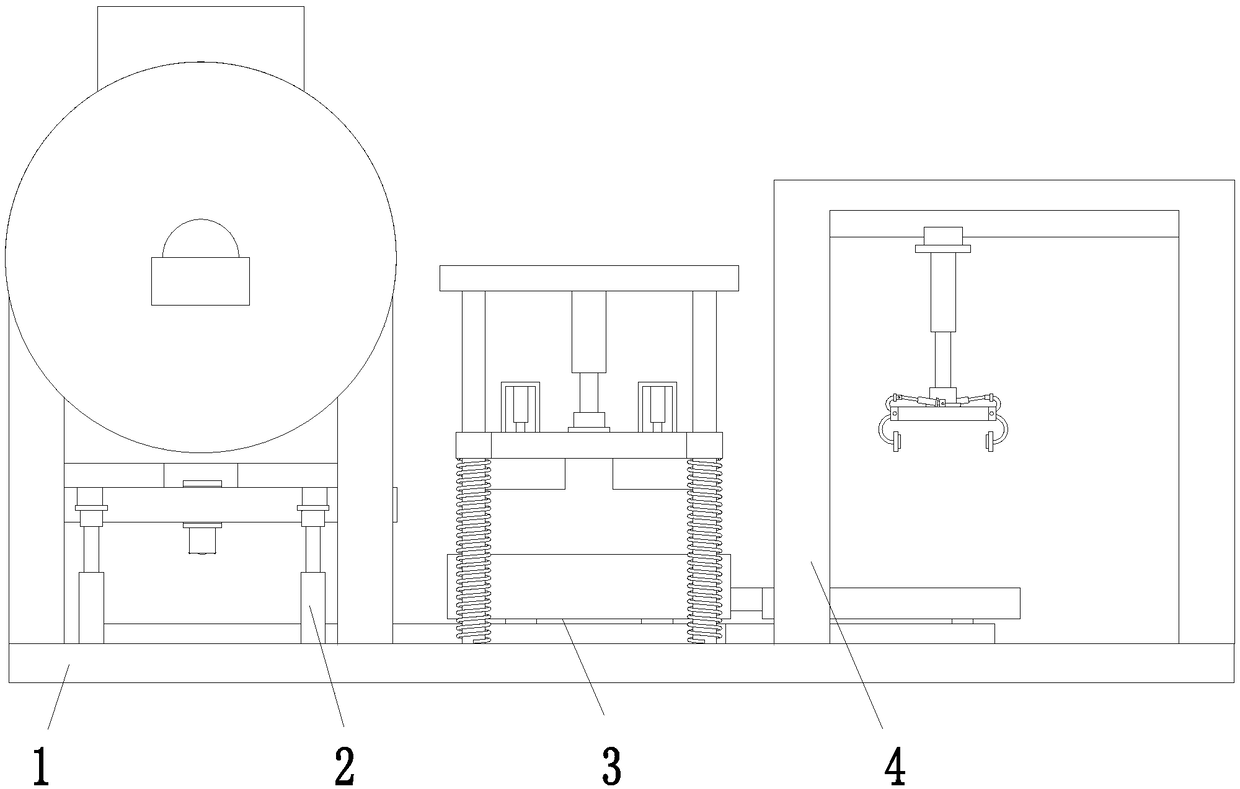

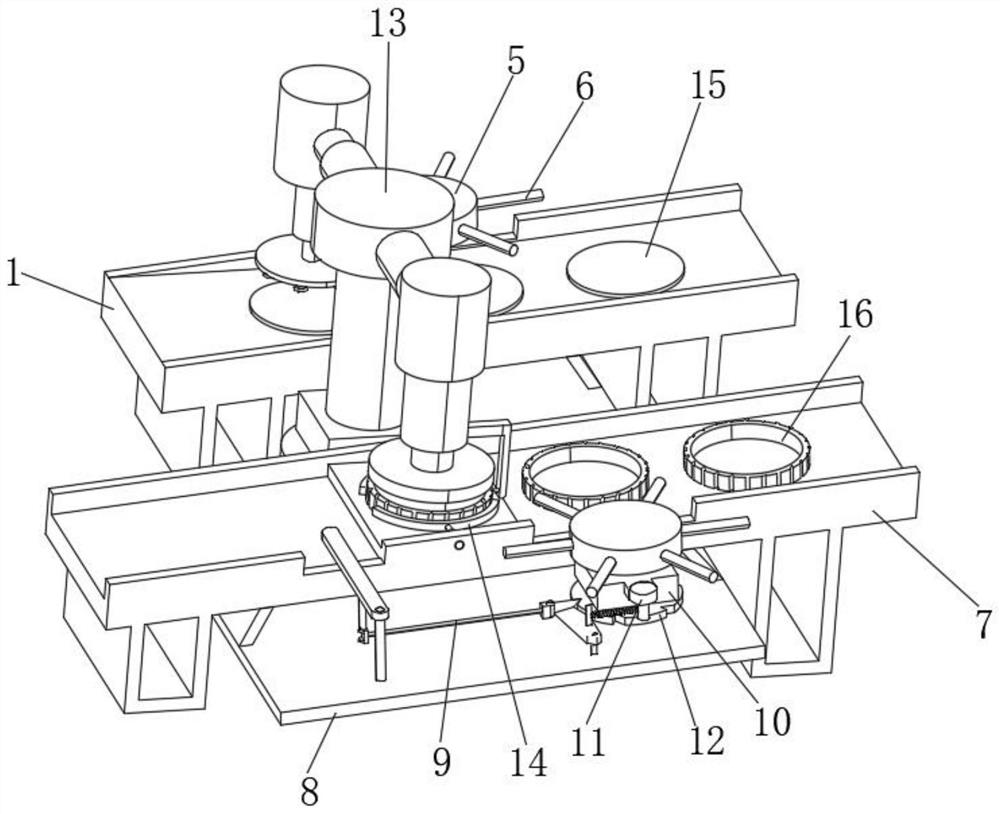

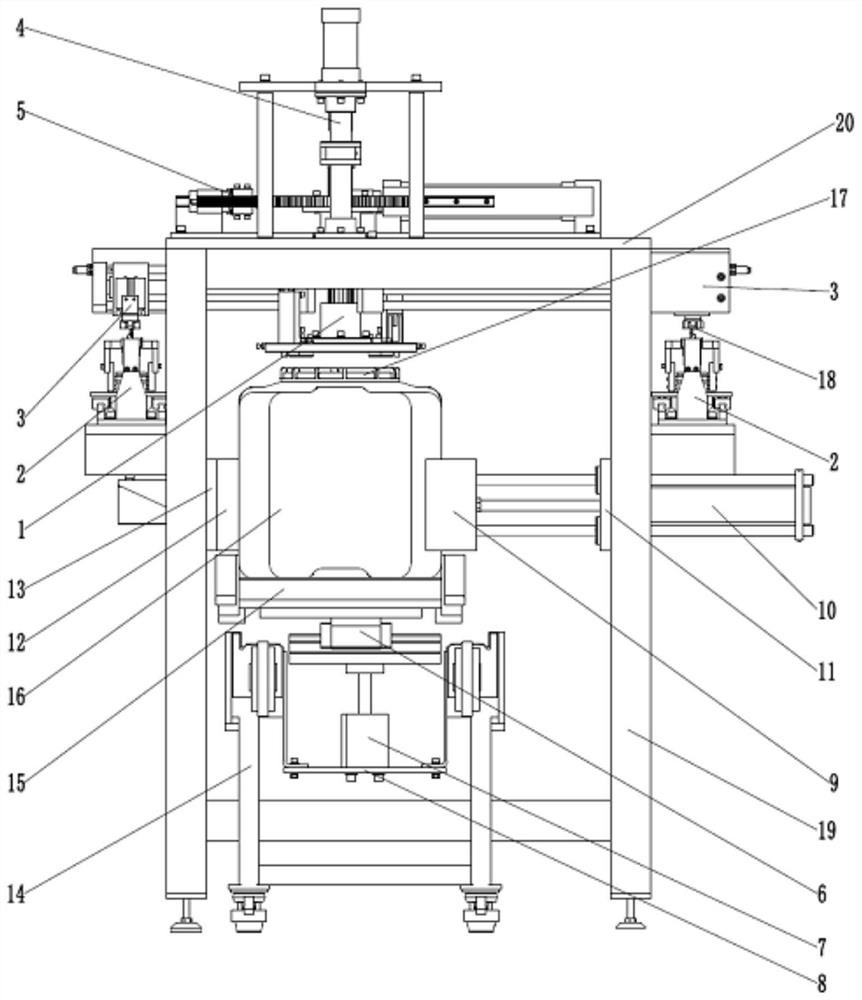

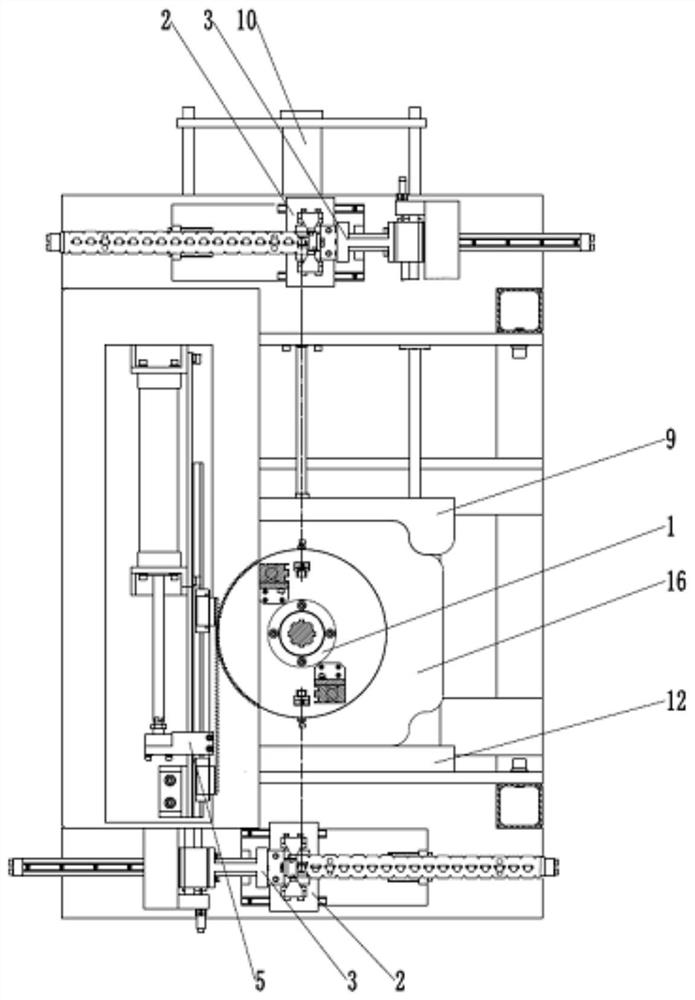

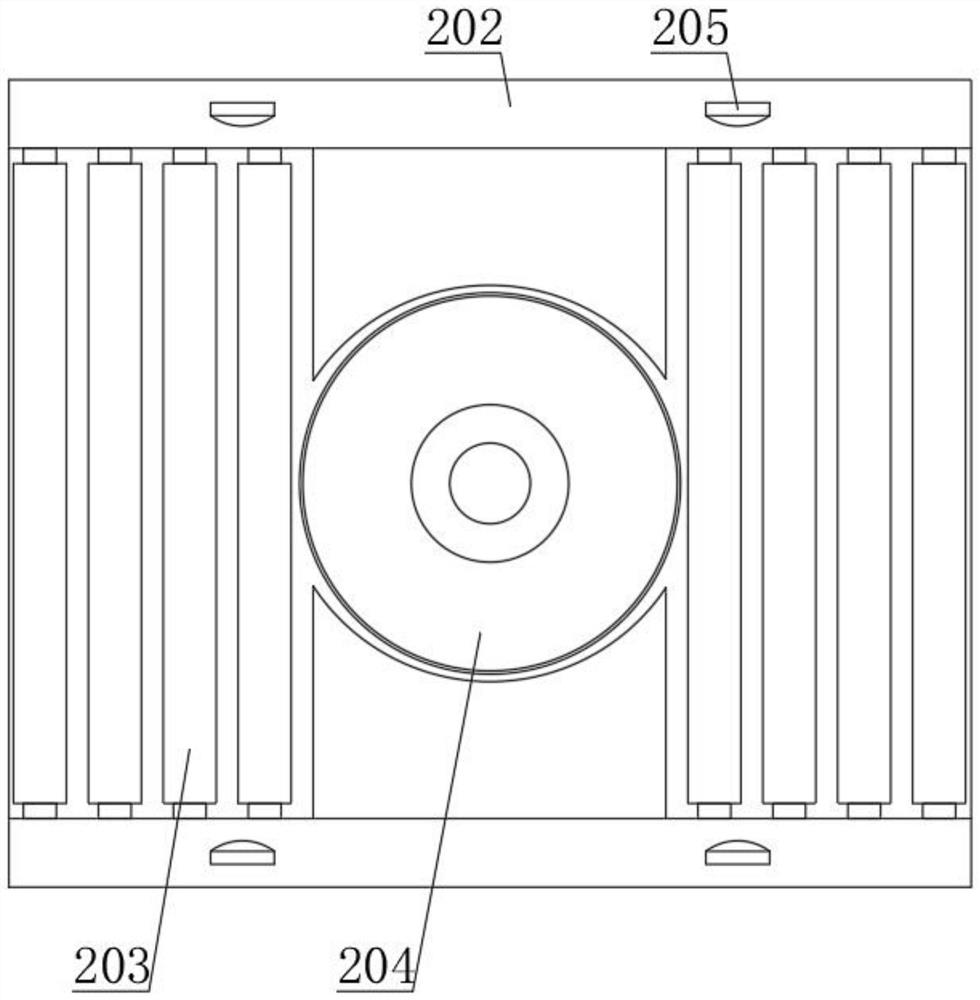

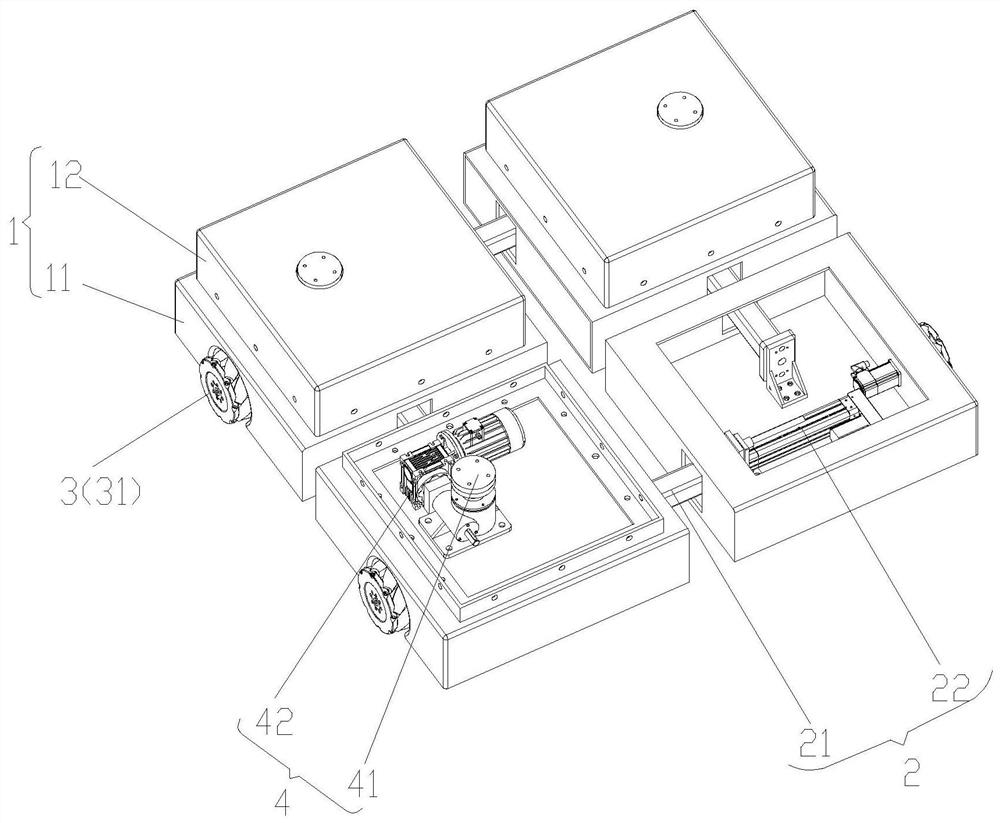

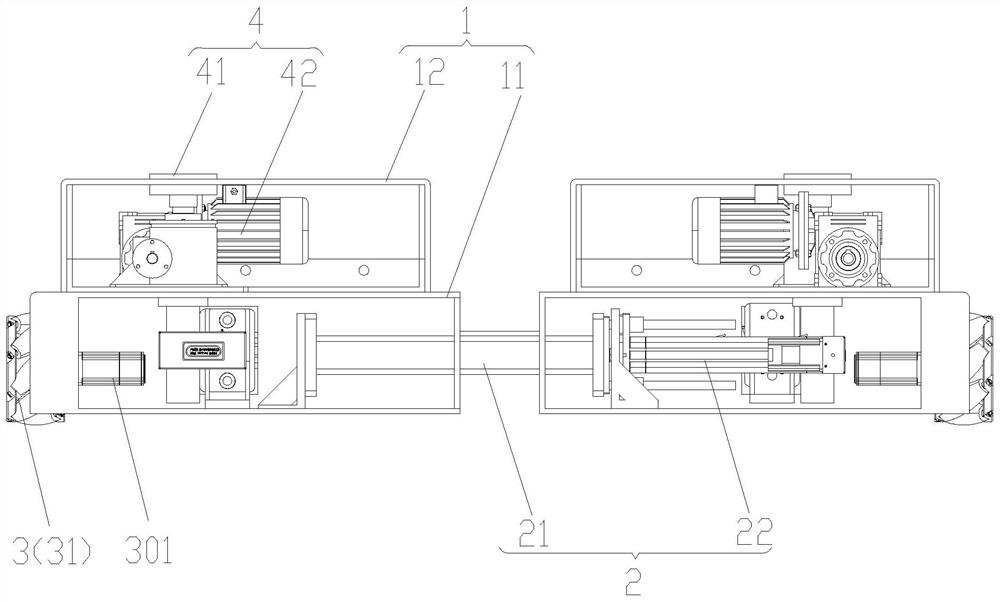

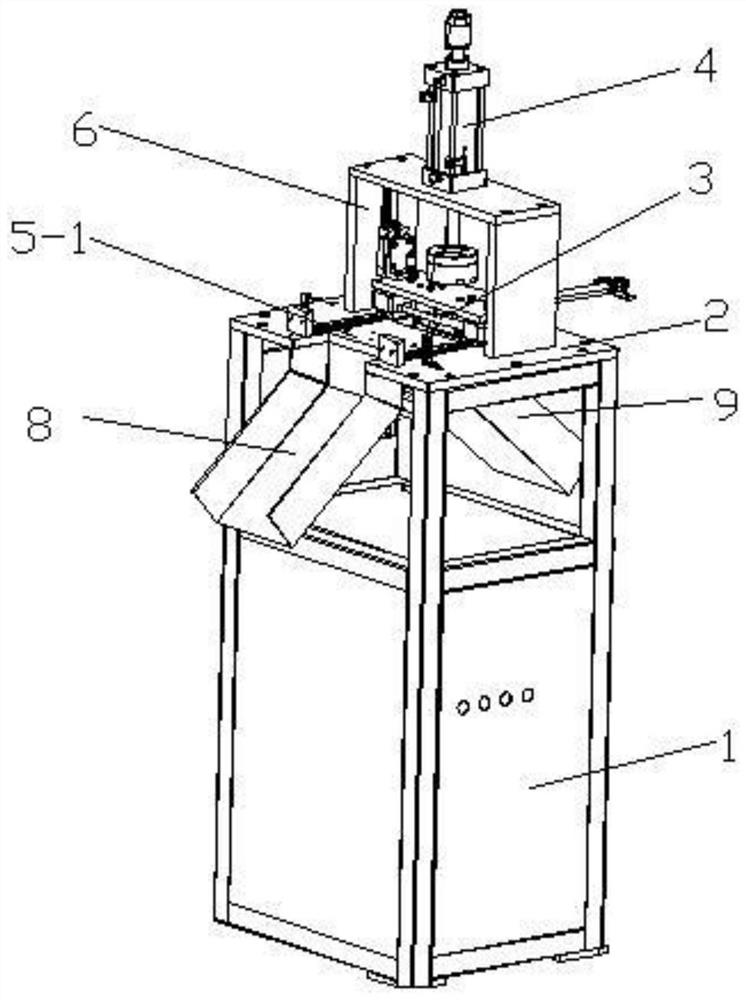

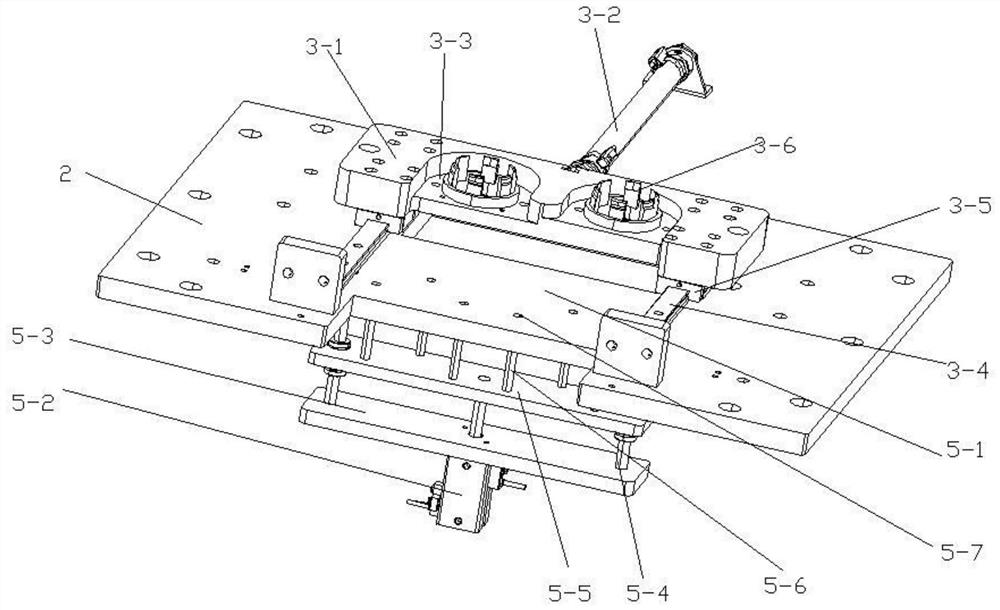

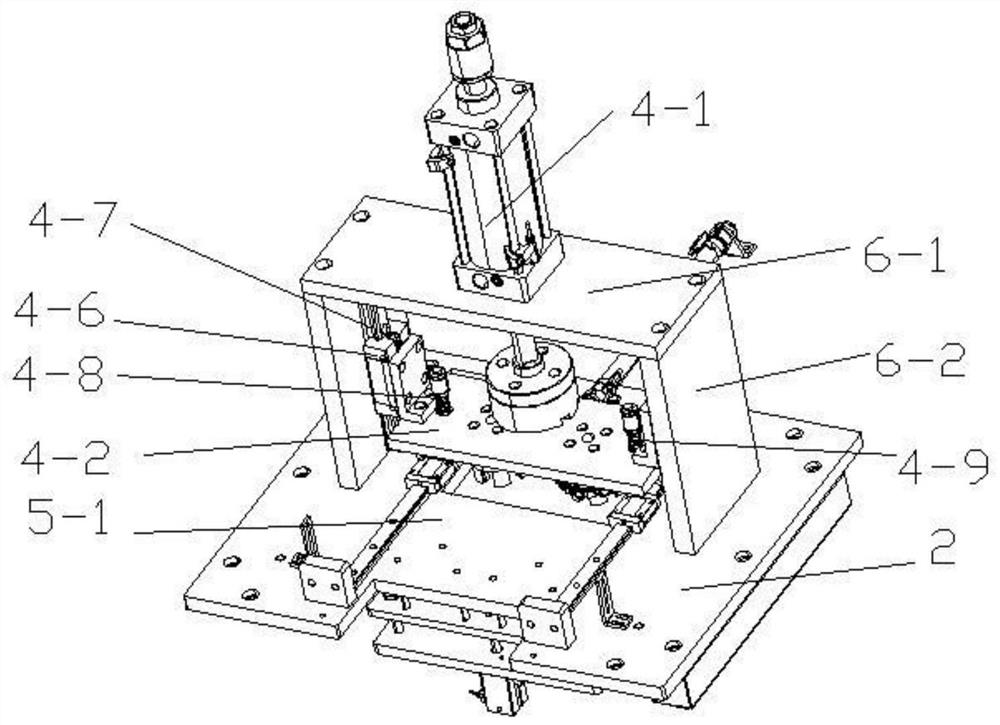

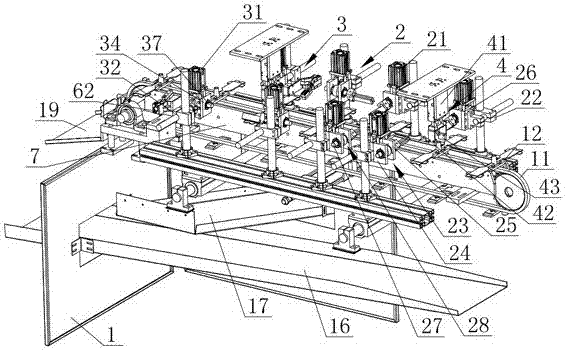

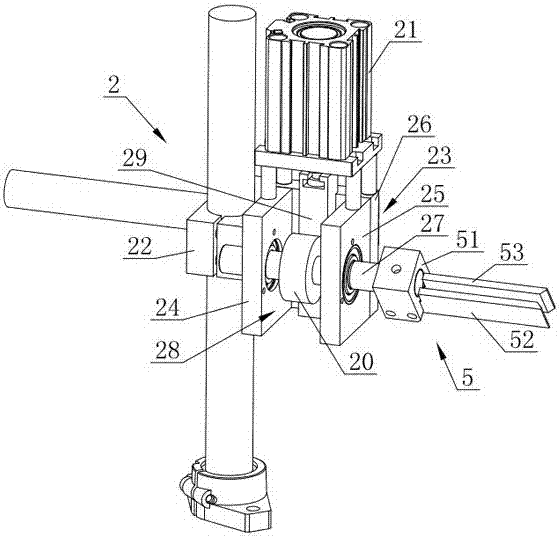

Automatic part taking system

ActiveCN113955506AHigh degree of automationRealize automatic box change functionEdge grinding machinesControl devices for conveyorsEngineeringMachining system

The invention relates to an automatic part taking system. The system comprises a first mechanical arm, a cooling device, a cinder ladle removing device, a deburring device and a second mechanical arm and further comprises an automatic box replacing device arranged at a box filling station and used for replacing part boxes and an automatic stacking device used for stacking the full part boxes. The automatic box replacing device comprises a conveying frame, a conveying roller set rotationally installed on the conveying frame and a driving part for driving the conveying roller set to rotate, and the box filling station is located on the conveying roller set. The automatic stacking device comprises a clamping mechanism used for clamping or loosening the part boxes and a stacking control mechanism used for controlling the clamping mechanism to move between the box filling station and a stacking station in a reciprocating manner and achieving stacking. The automatic part taking system has the effects that the work of replacing and stacking part boxes can be automatically carried out, and the automation degree of a part die-casting machining system is improved.

Owner:AIMI (SHANGHAI) TECH CO LTD

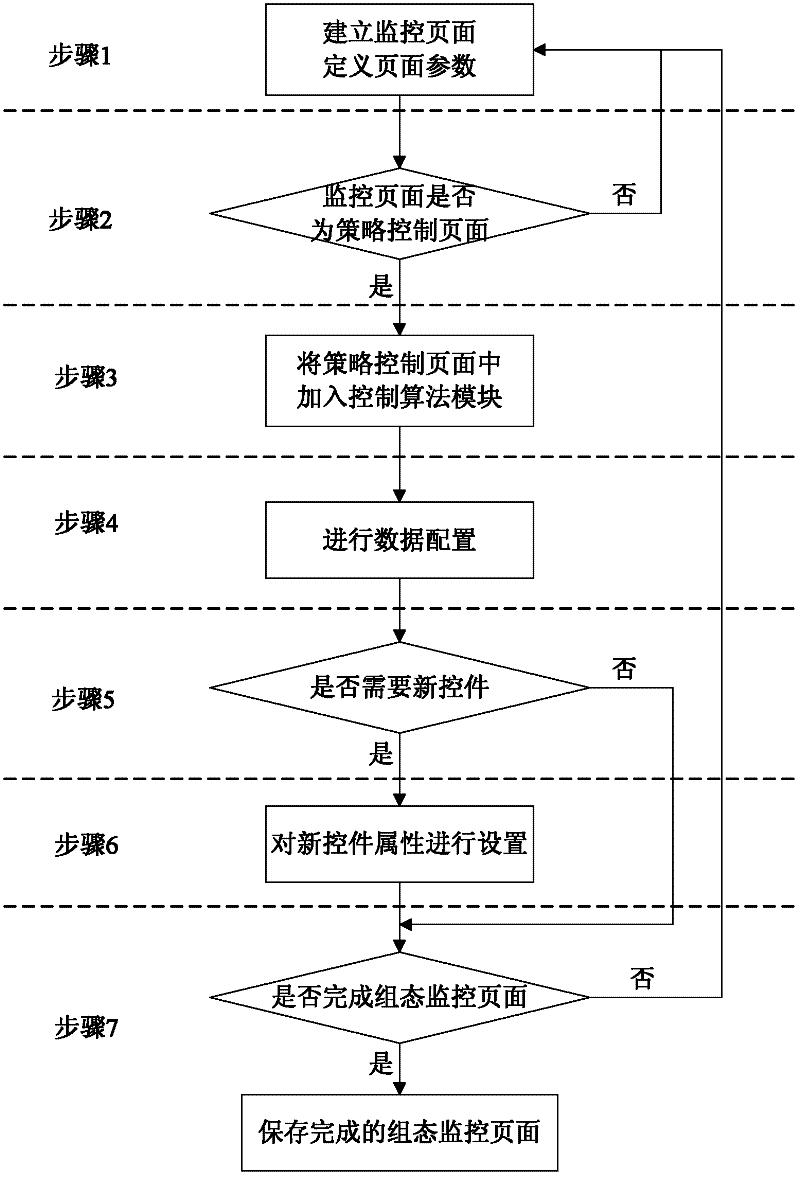

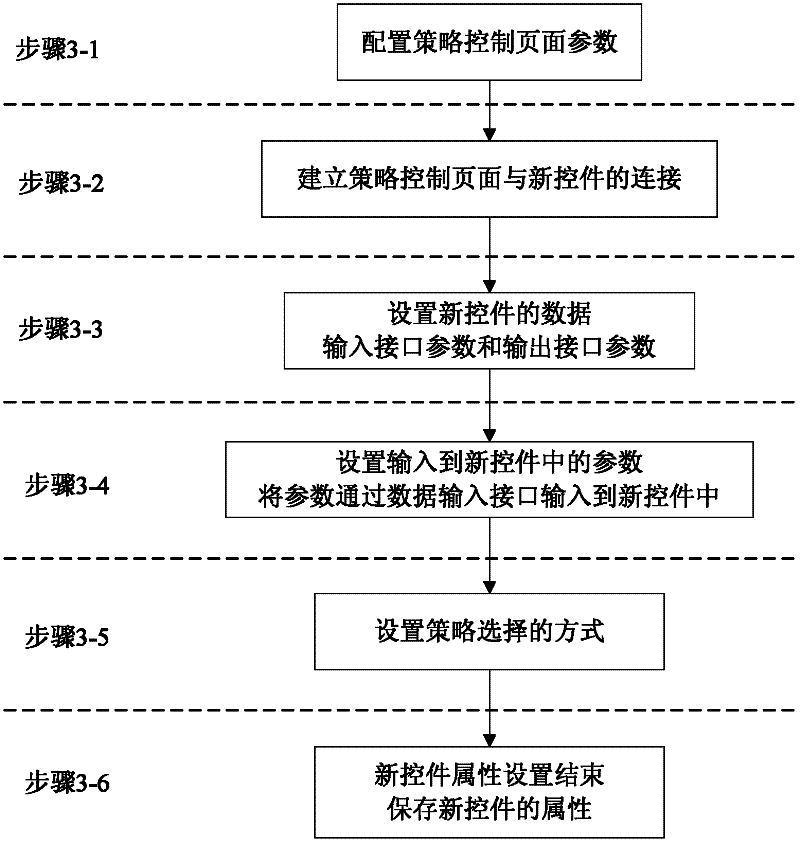

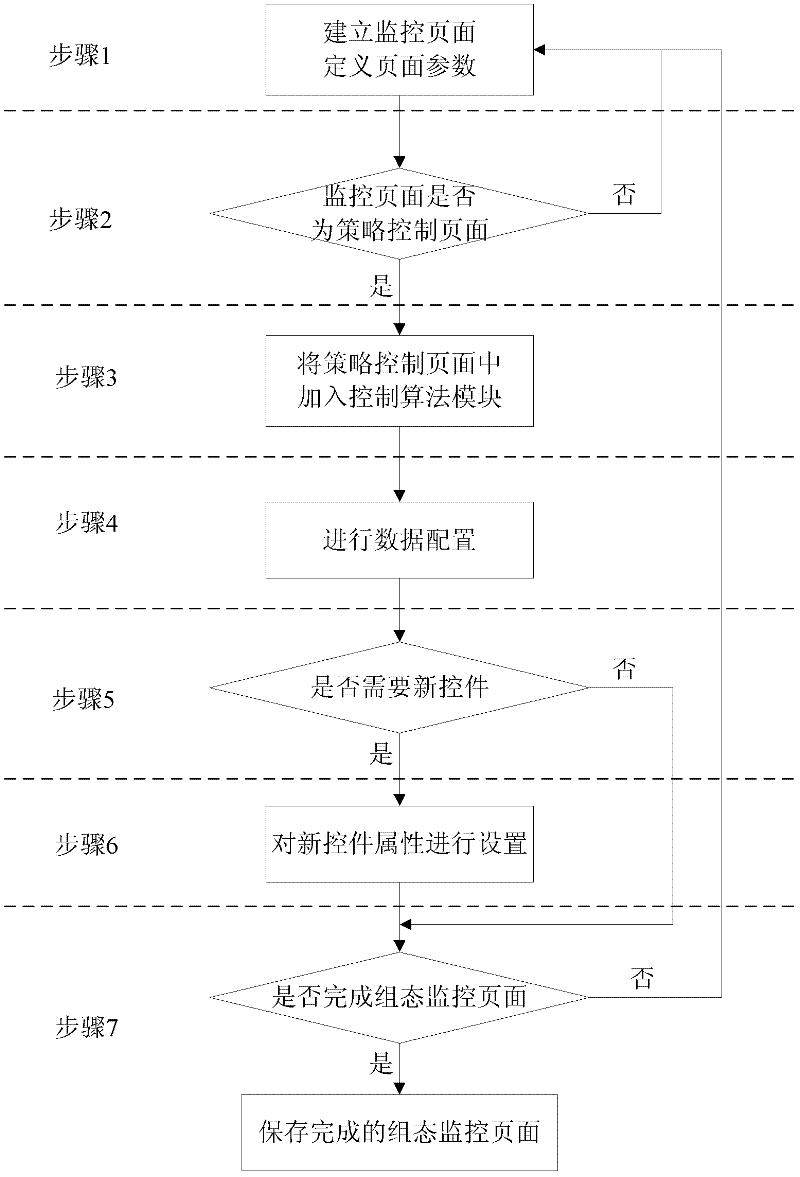

Operation monitoring system configuration monitoring page generation method

InactiveCN102692880ASolve the real problemSolve complex and centralized management problems on industrial sitesProgramme control in sequence/logic controllersComputer moduleMonitoring system

Owner:HARBIN INST OF TECH

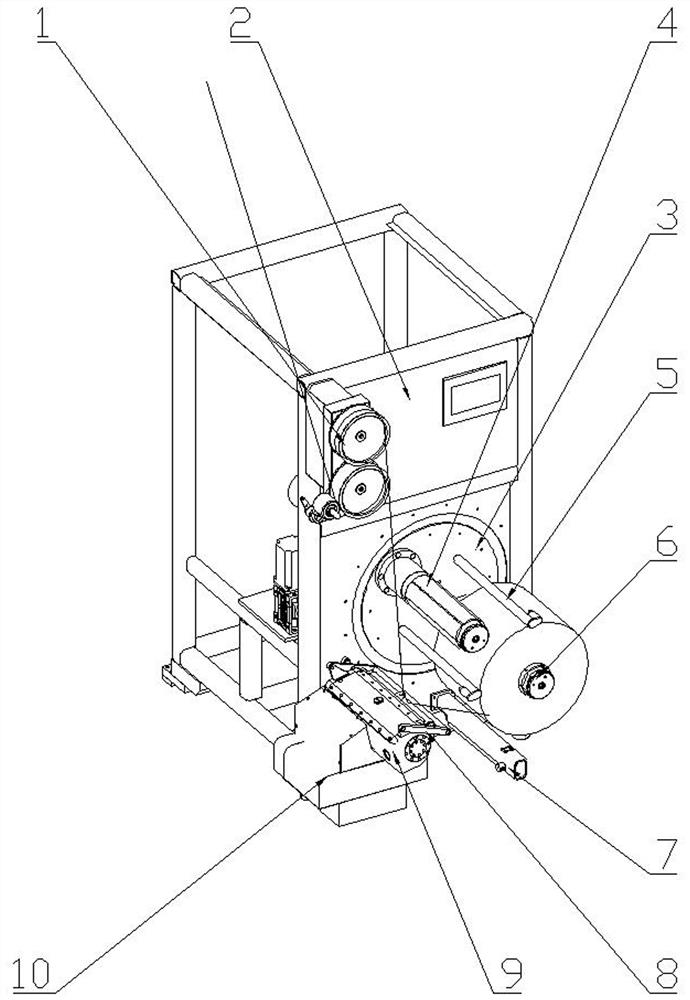

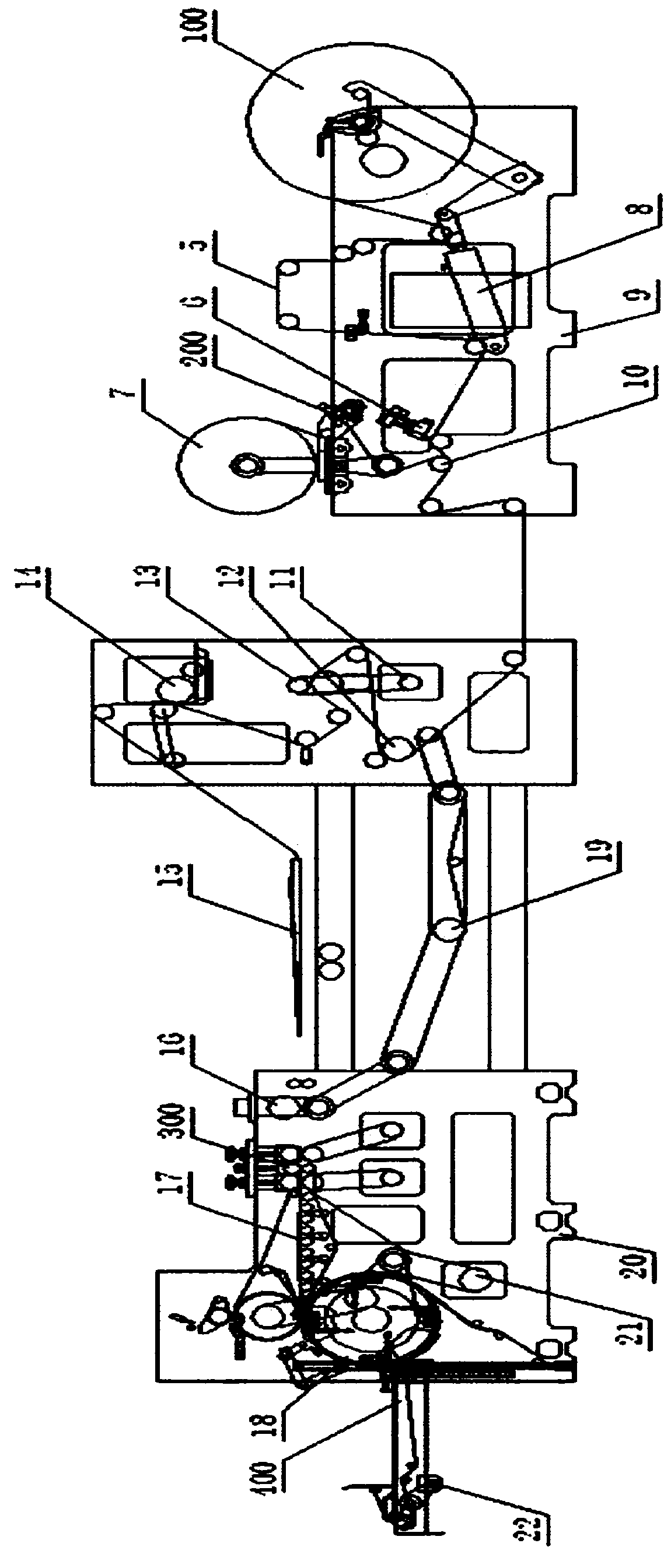

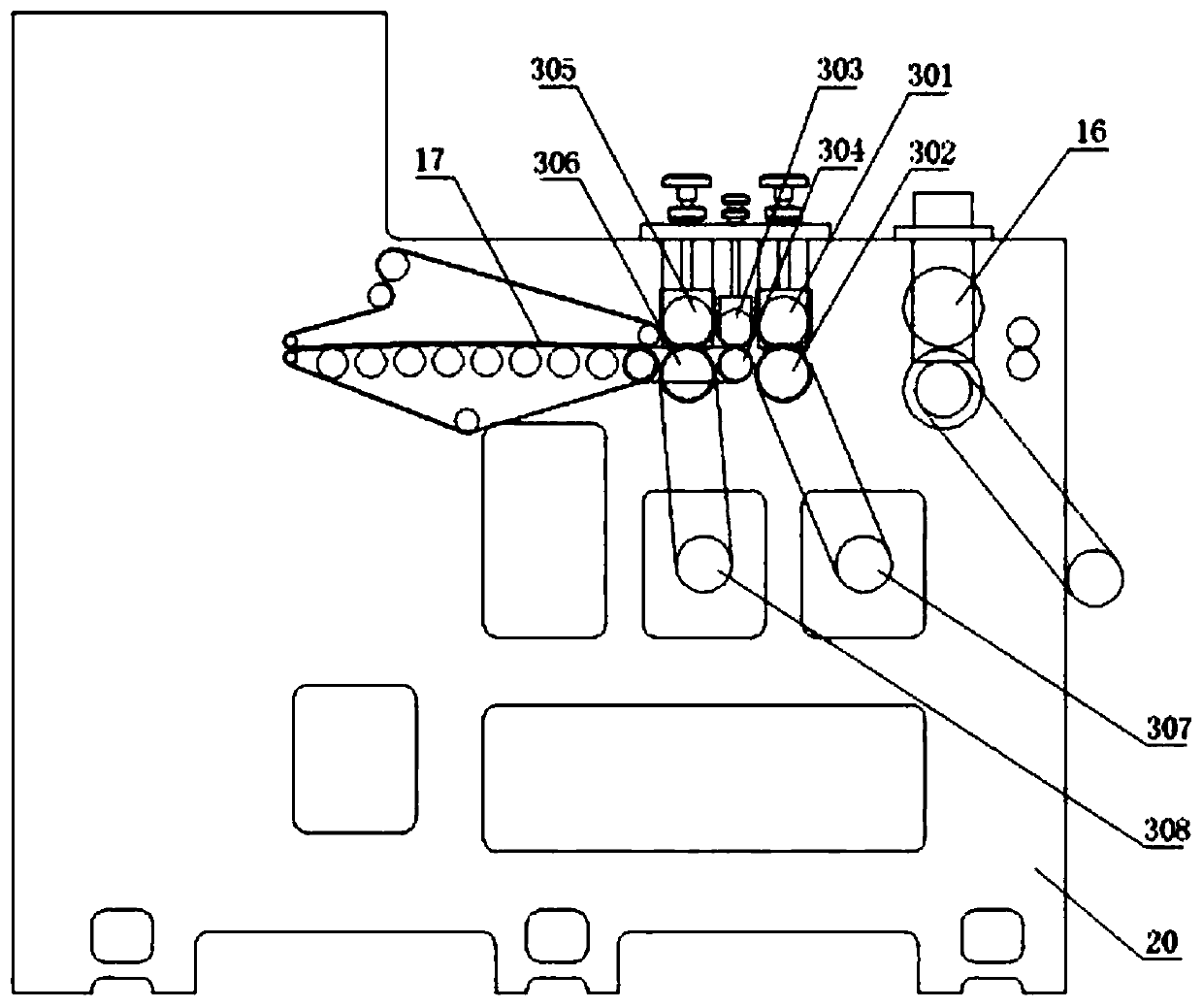

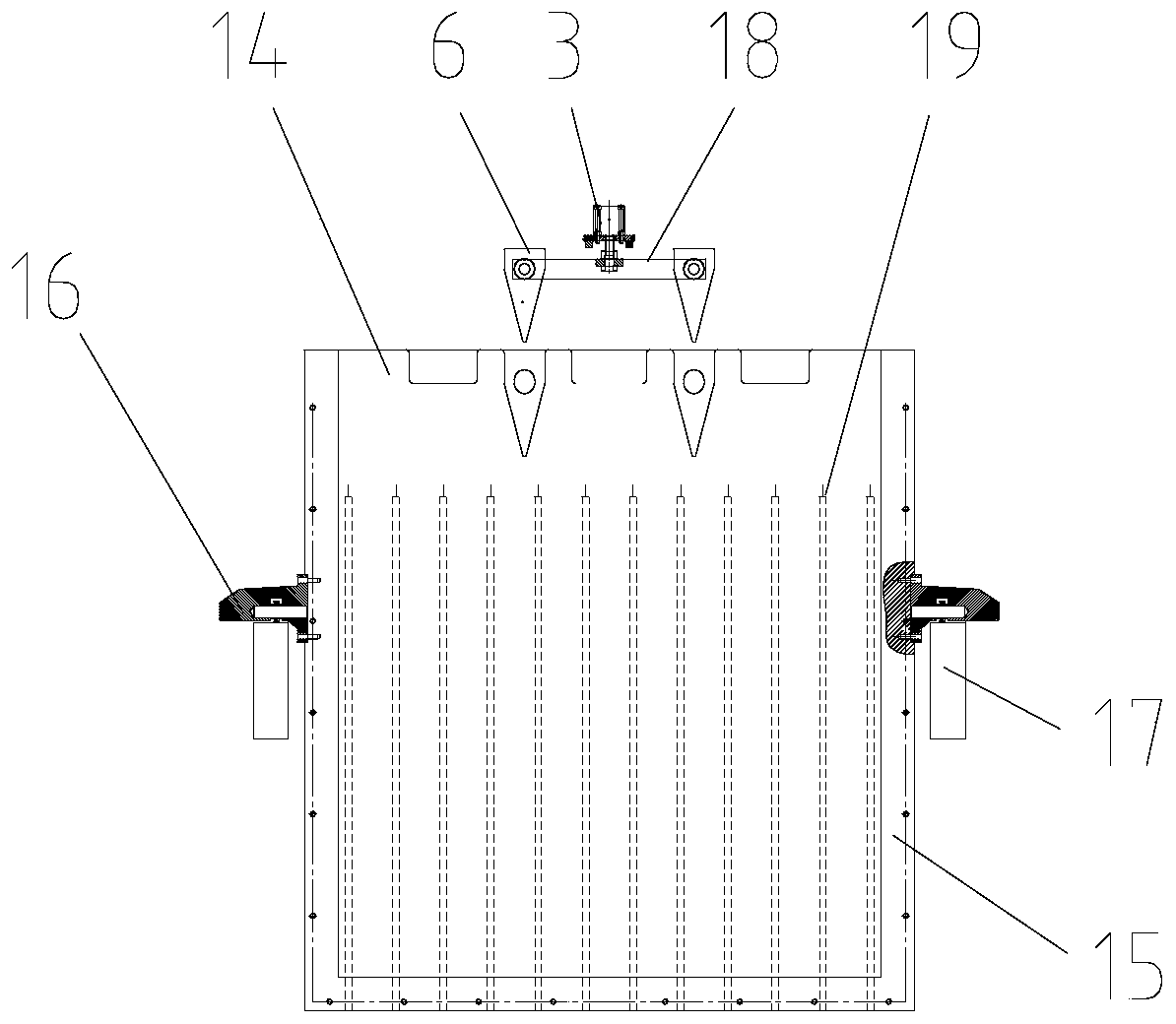

Bottle cap gasket plugging machine

PendingCN114751001ASmooth transmissionProduction rhythm is tightPackagingElectric machineControl engineering

Owner:HEFEI UNIV OF TECH

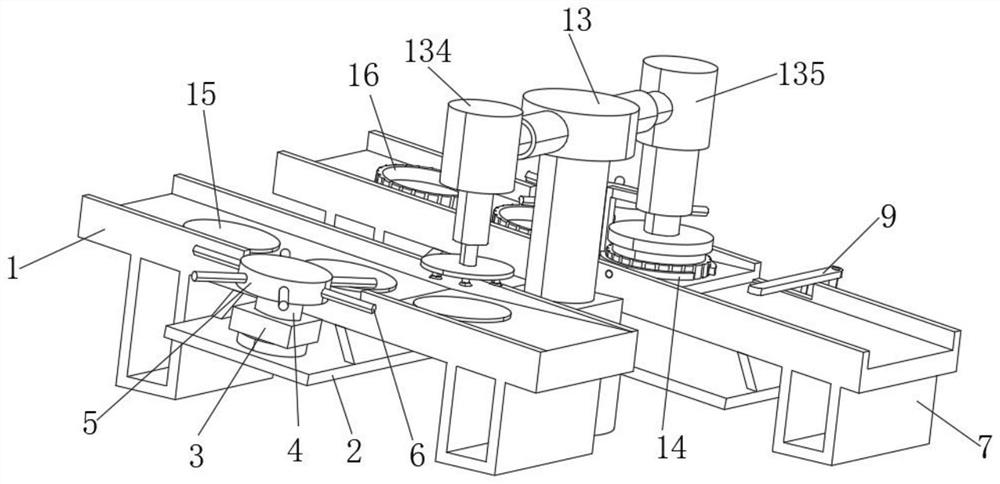

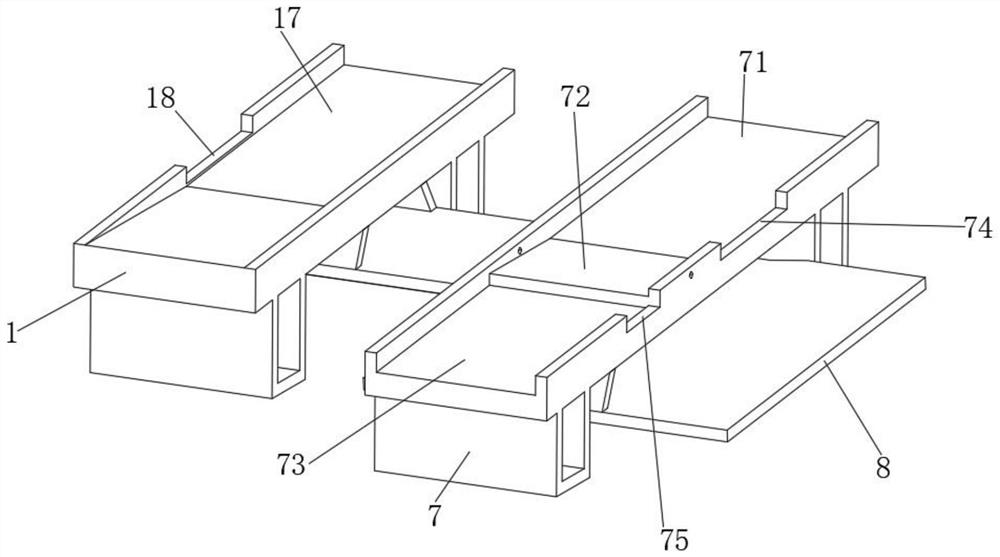

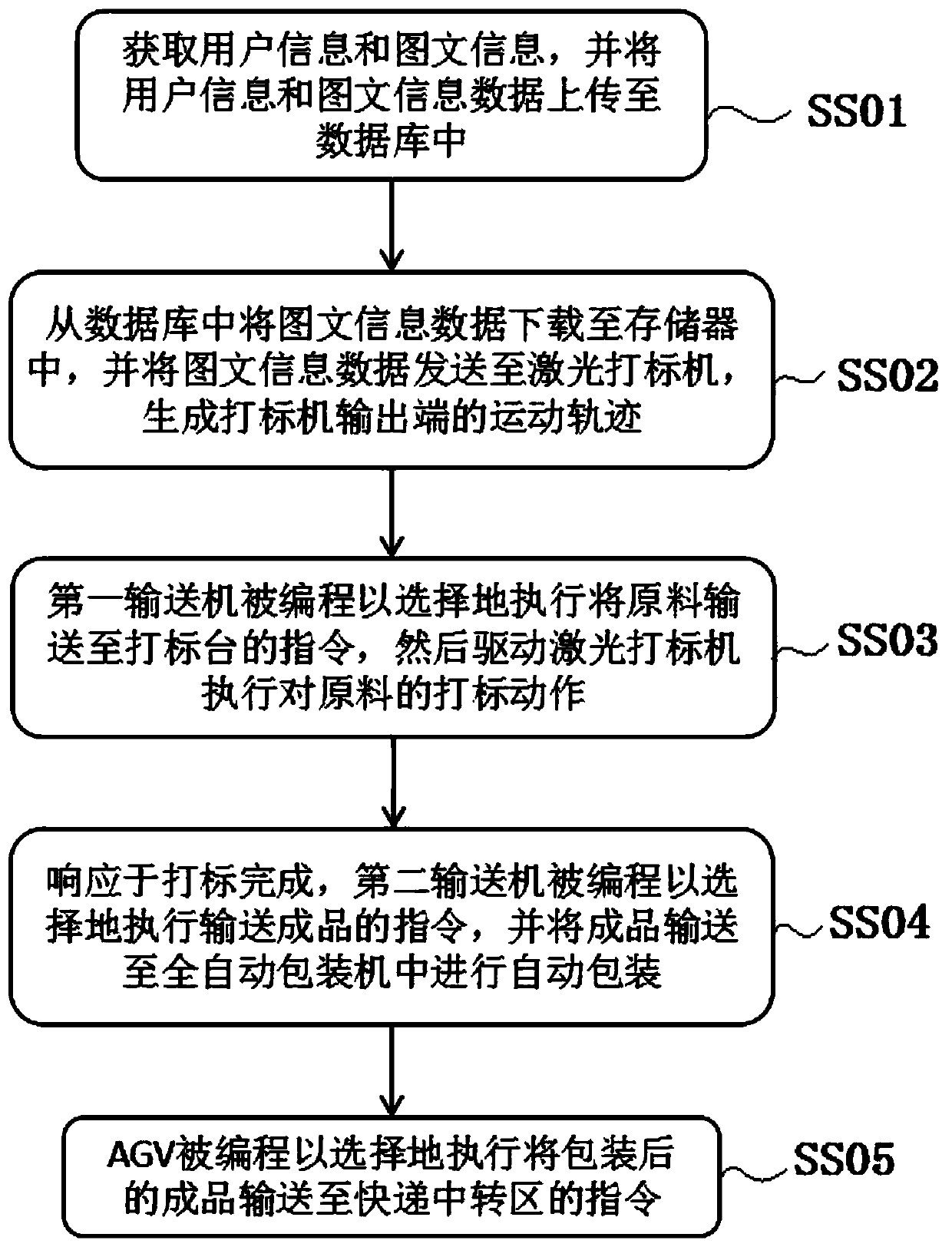

Self-service type laser labelling method and device

InactiveCN109676263AEasy do-it-yourself markingImprove automationLaser beam welding apparatusComputer hardwareGraphics

Owner:合肥齐泰光电科技有限公司

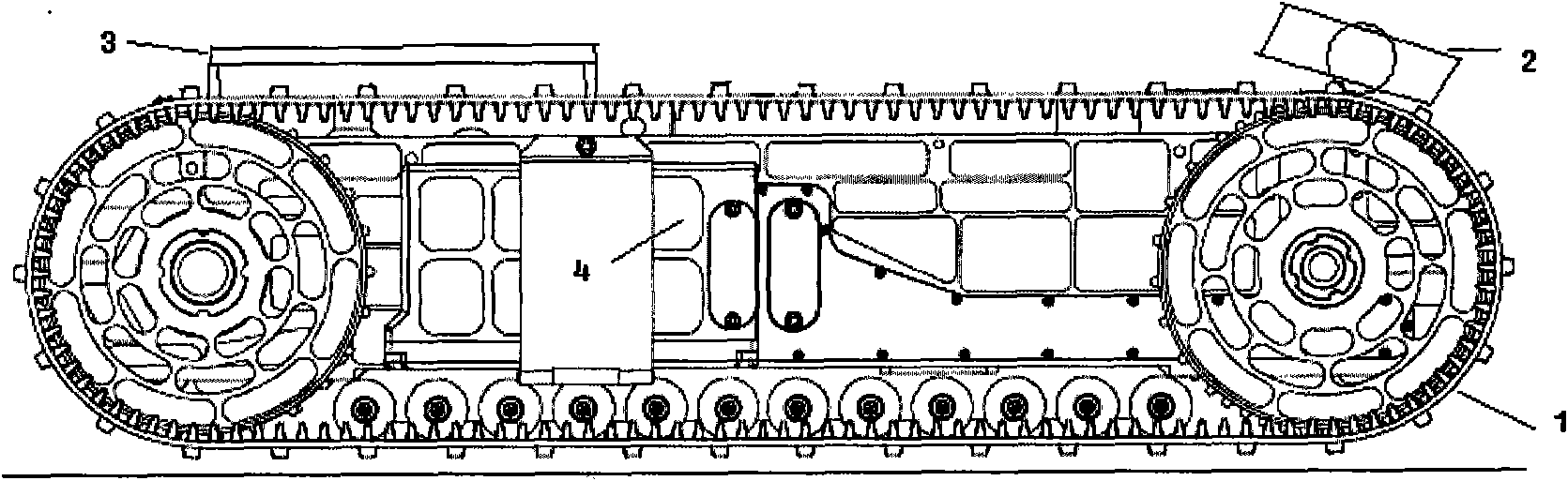

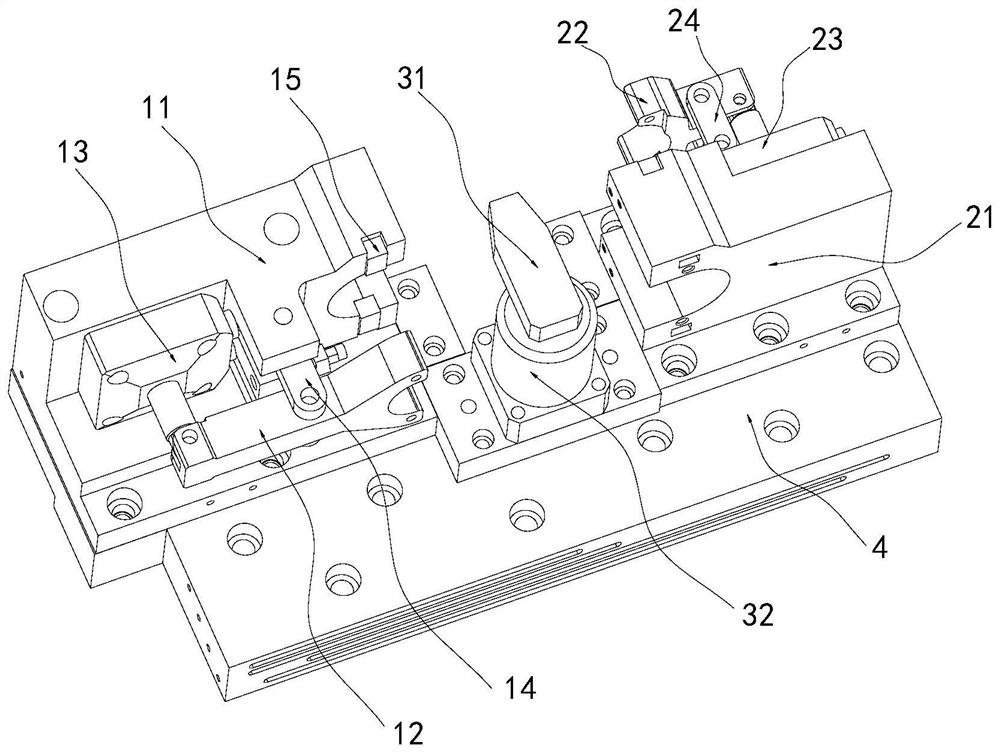

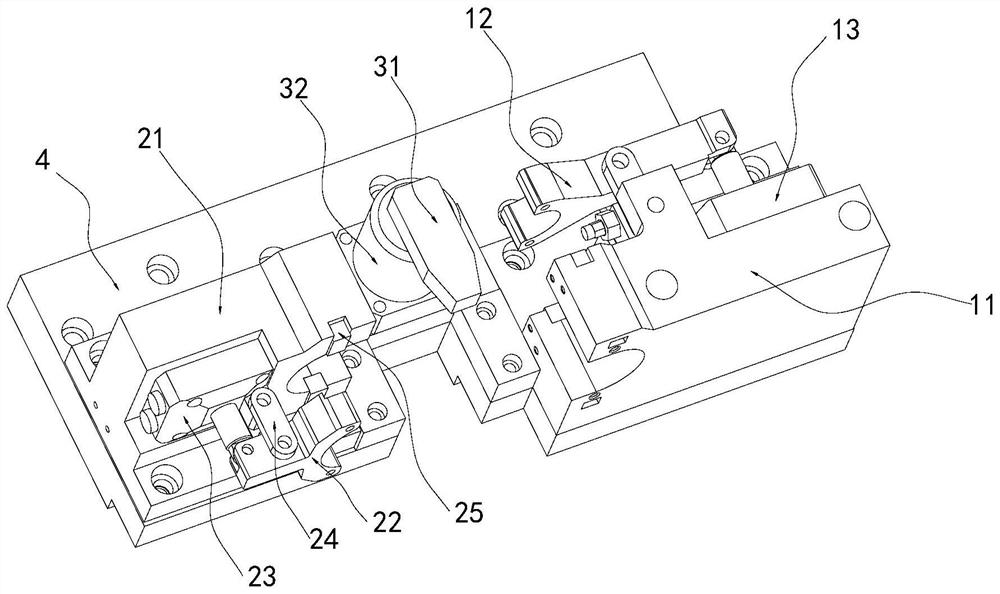

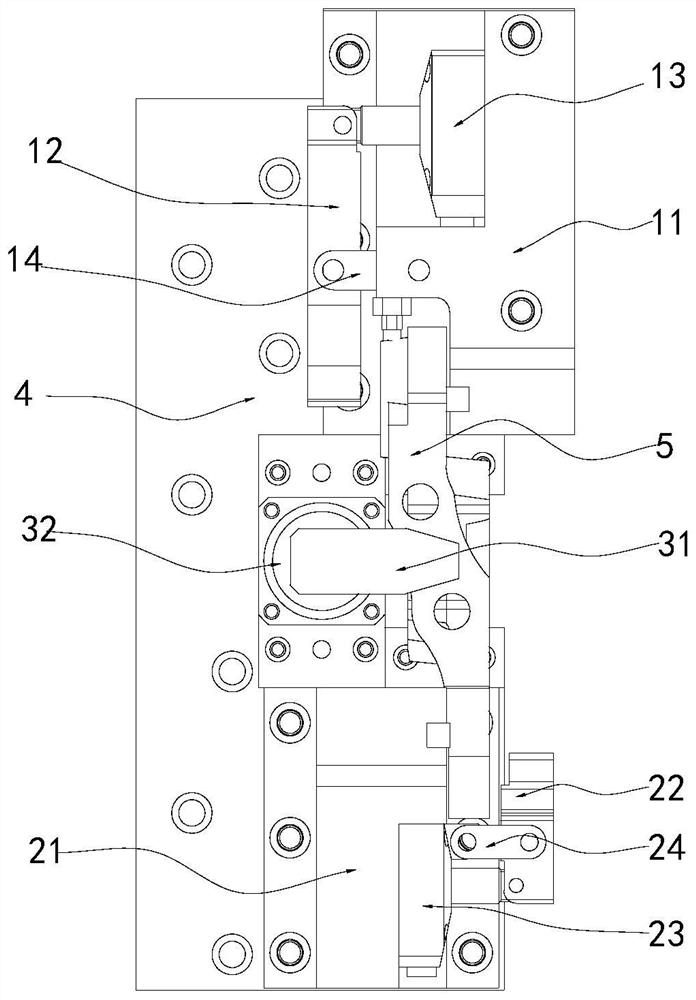

Excavator chassis crawler chain link machining tool clamp

PendingCN113878374AAvoid loosening and slippingEasy to processPositioning apparatusMetal-working holdersExcavatorChain link

Owner:众一机械(福鼎)有限公司

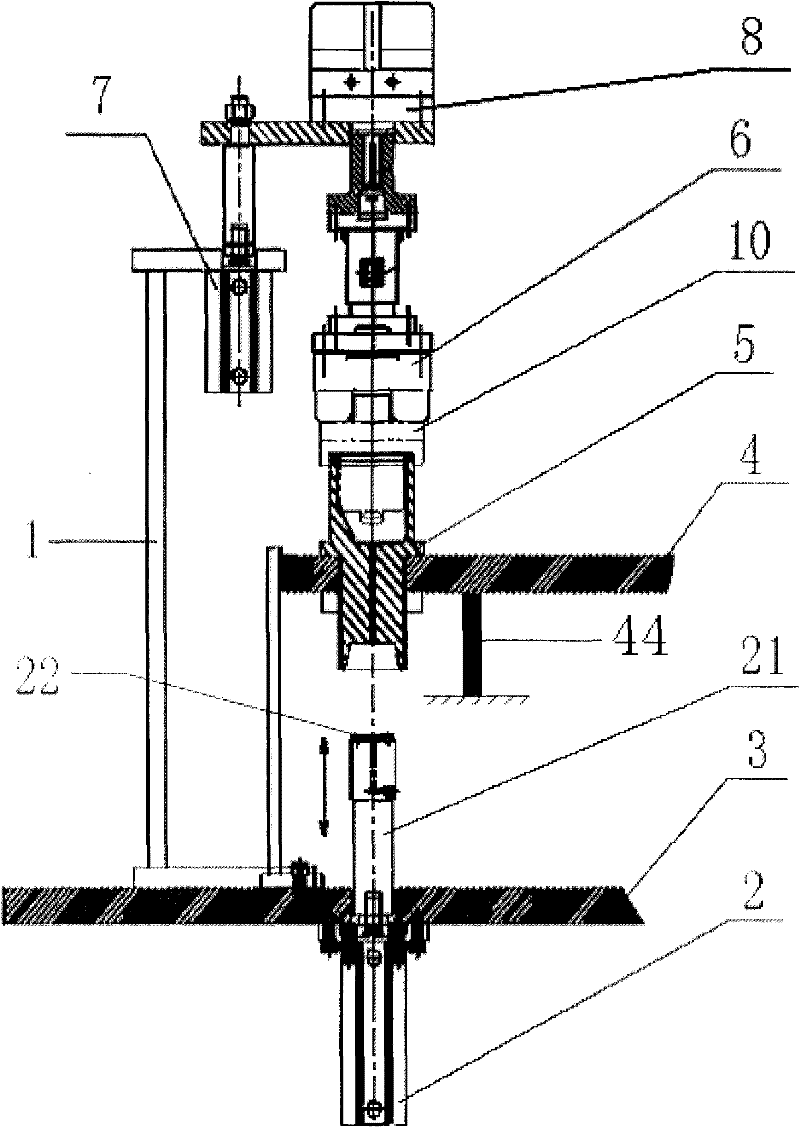

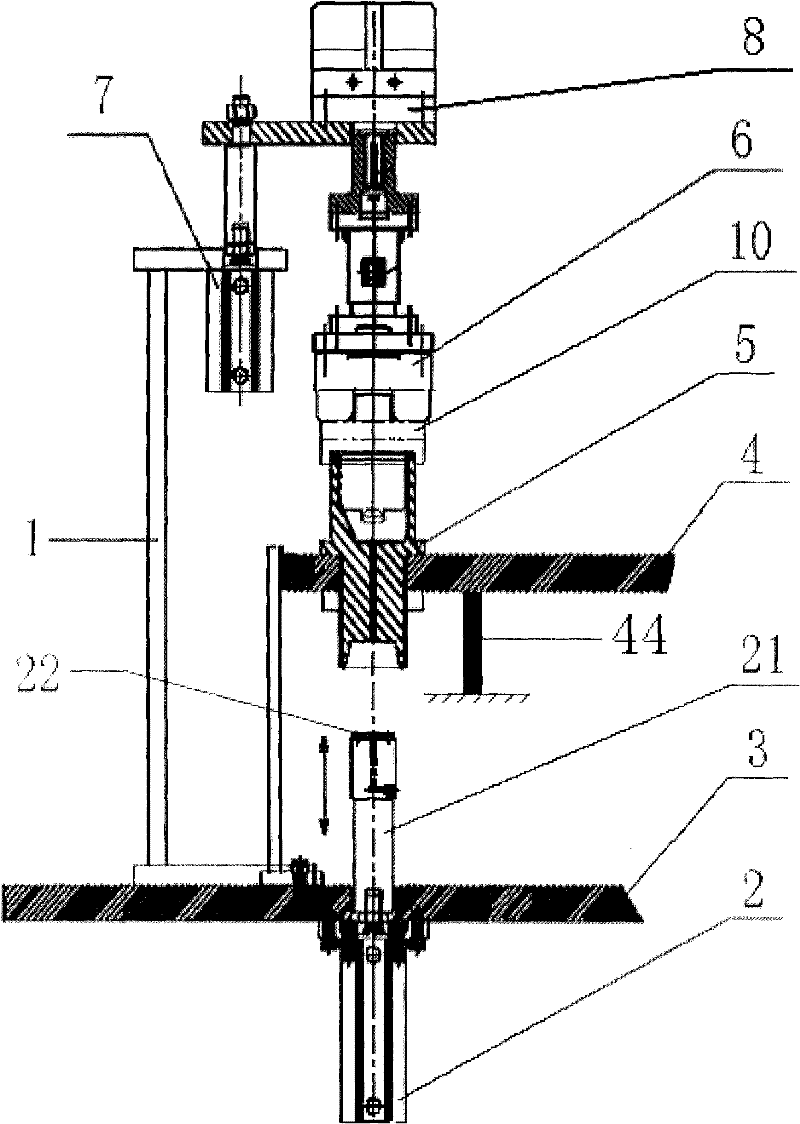

Device for automatically screwing box cover and installing anti-unsealing pin

ActiveCN112404958AGuaranteed uptimeMeet the process requirementsMetal working apparatusStructural engineeringIndustrial engineering

Owner:中国兵器装备集团自动化研究所有限公司

Intelligent automatic sand blast system

Owner:YANCHENG INST OF TECH

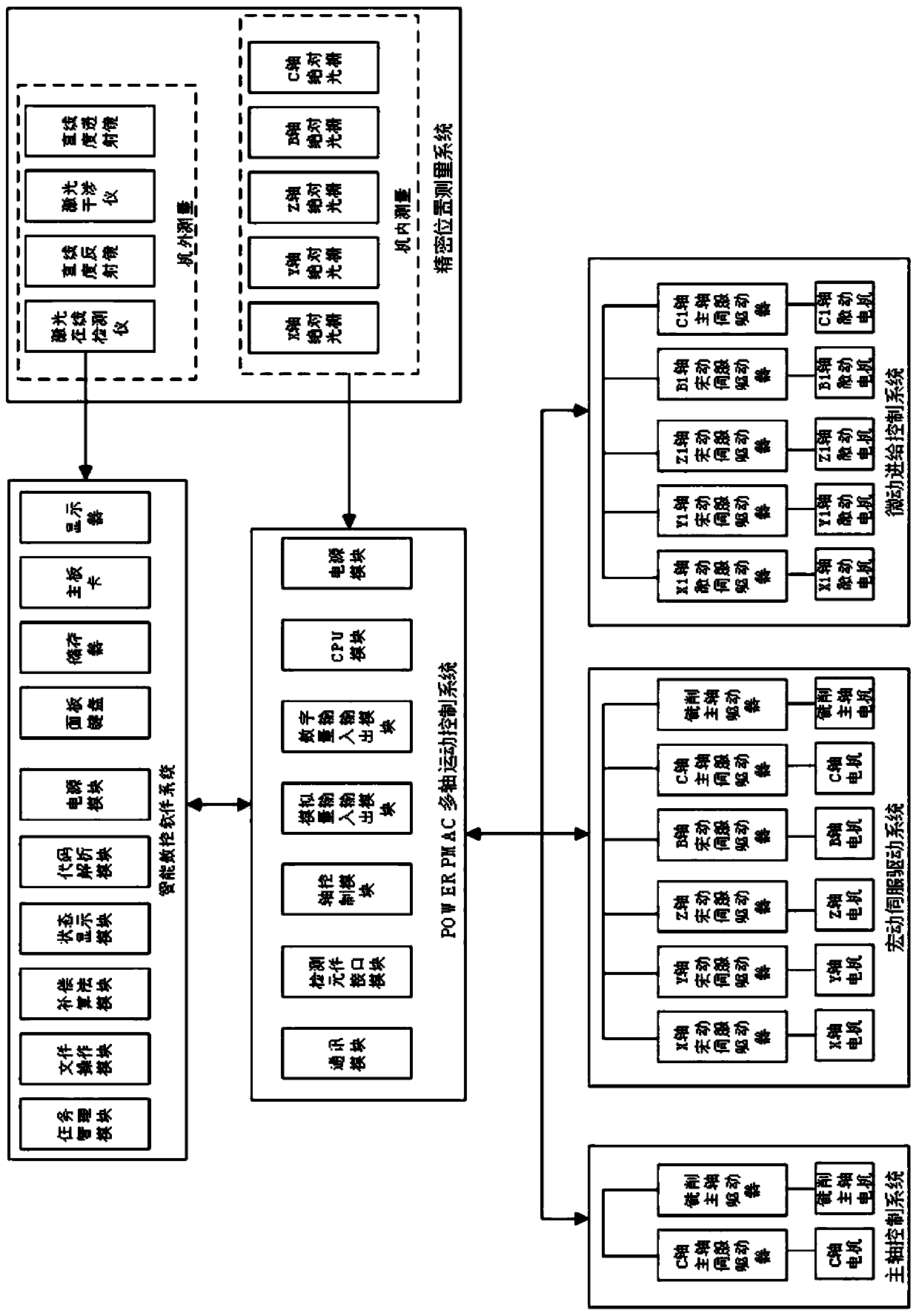

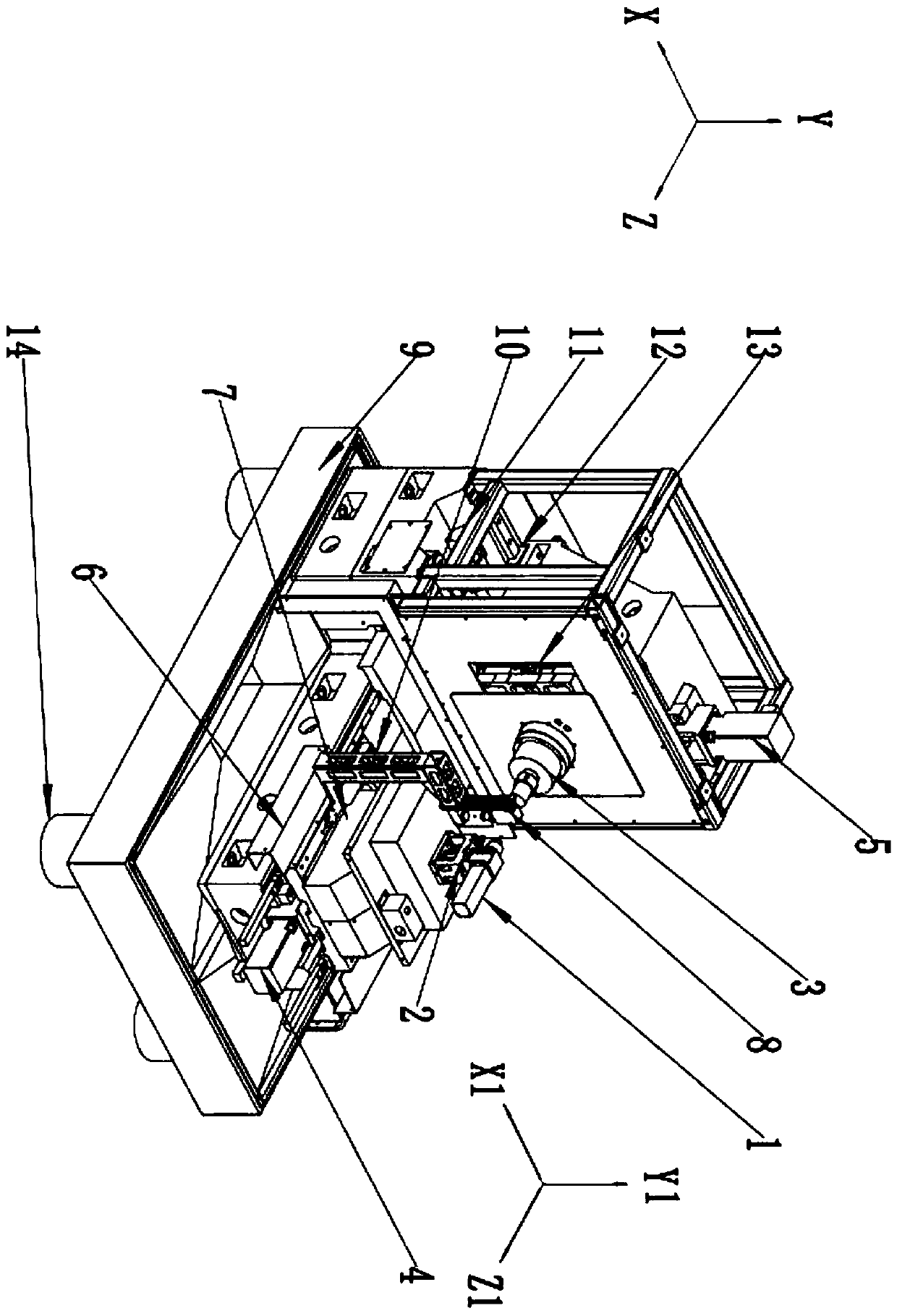

Macro-micro combined multi-precision intelligent numerical control system

PendingCN111552236AHigh degree of automationImprove scalabilityNumerical controlKinematic controllerMachine parts

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

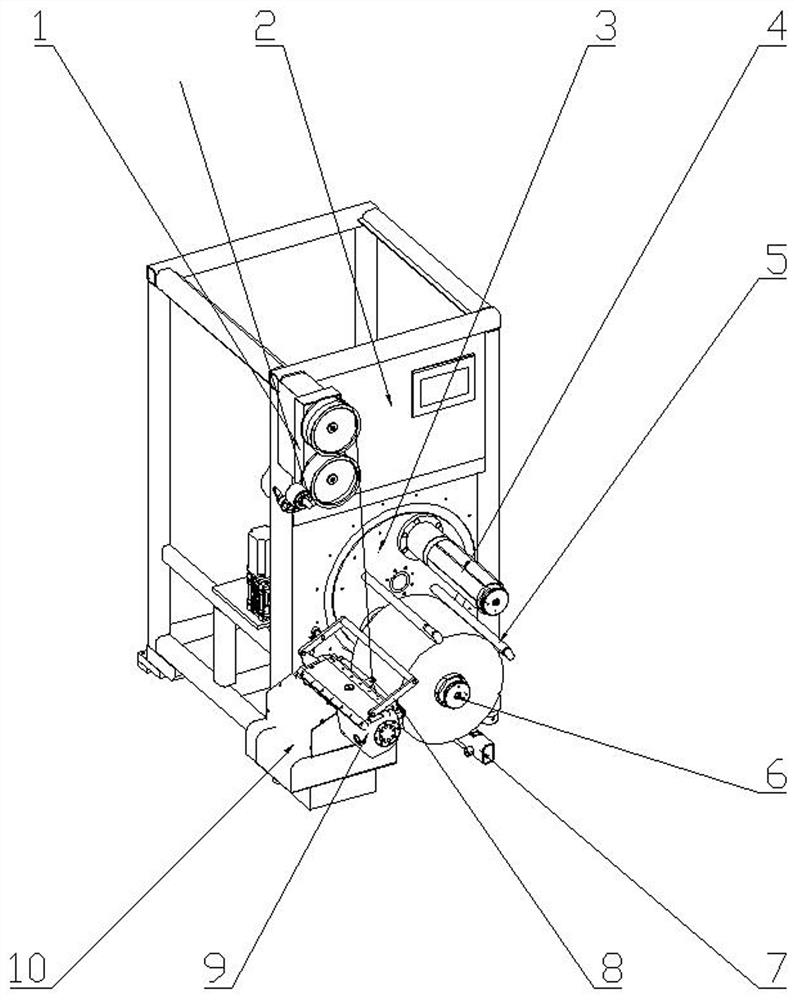

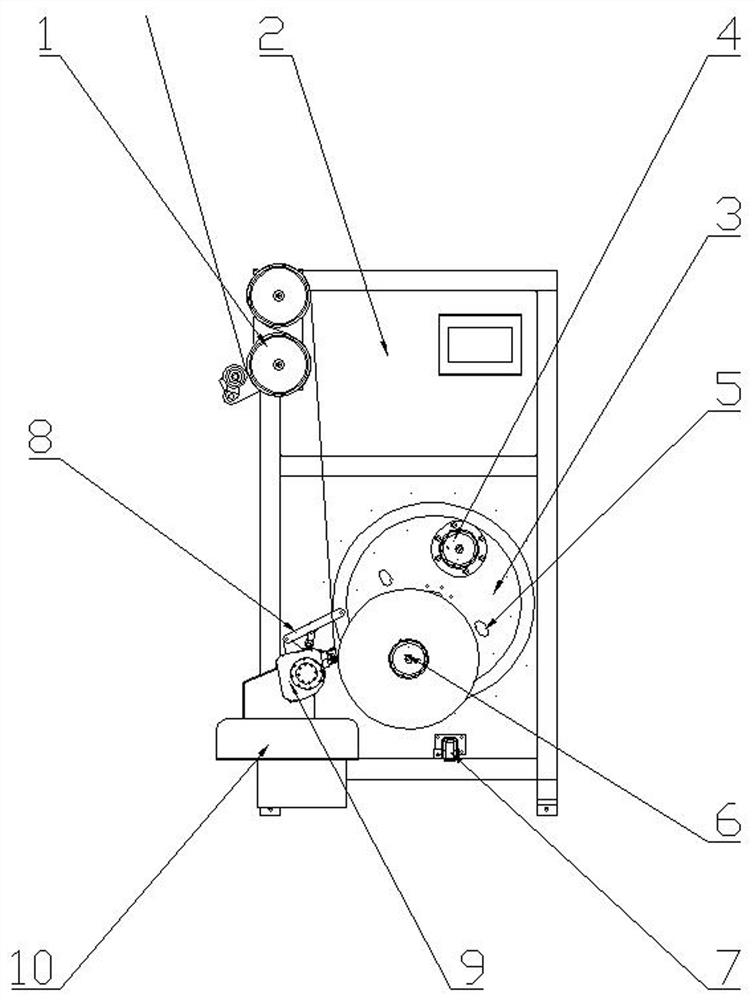

Automatic creeling winder and control method thereof

Owner:杭州天启机械有限公司

Express package loading assembly line with high automation degree

InactiveCN113830579AEasy loadingSave loading spaceConveyorsLoading/unloadingDrive wheelLogistics management

Owner:溆浦县远宏速递有限责任公司

Belt sander

PendingCN112123118AQuick changeEasy to change clothesBelt grinding machinesSanderStructural engineering

Owner:SUNRISE INSTR CO LTD

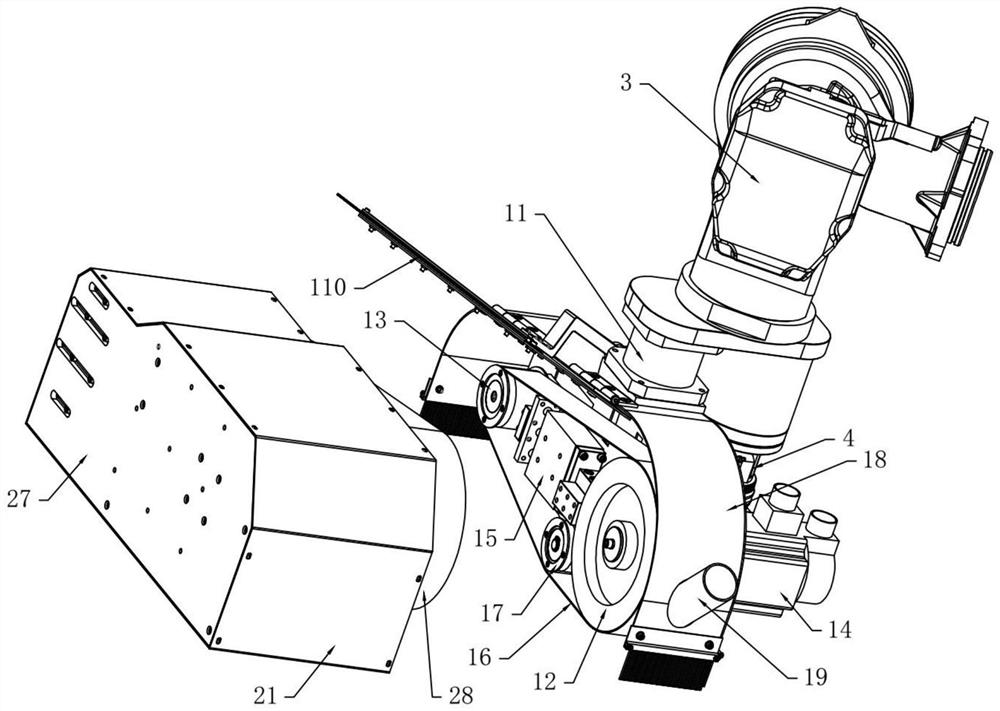

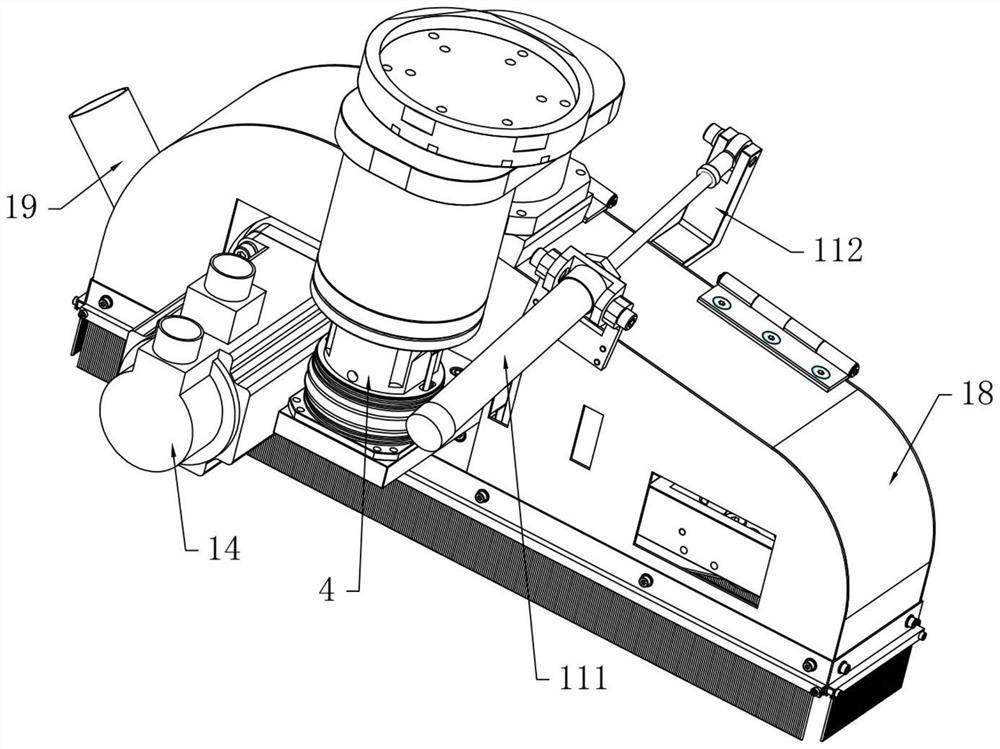

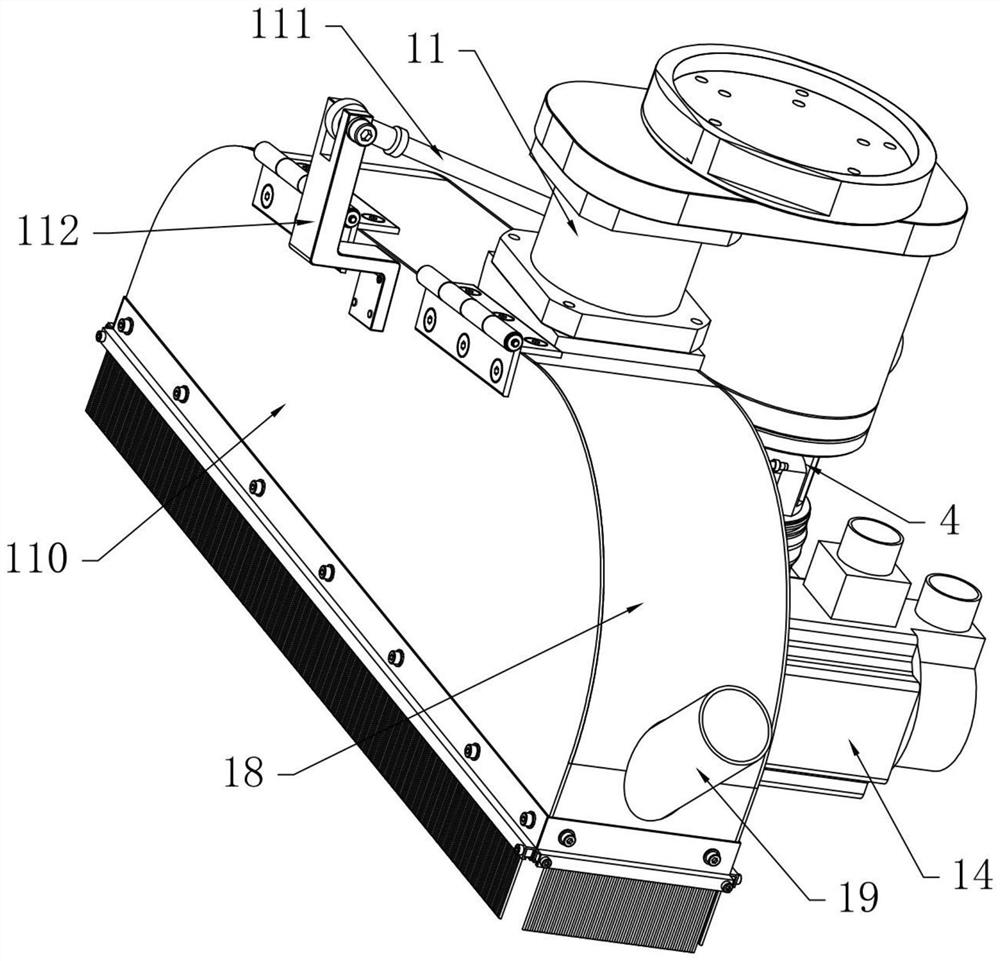

Appearance self-adaptive flexible transfer robot and material management application system

PendingCN112706679ARealize automated handling operationsOvercoming manual searchData processing applicationsTransmission systemsControl engineeringMonitoring system

Owner:苏州云骐智能科技有限公司

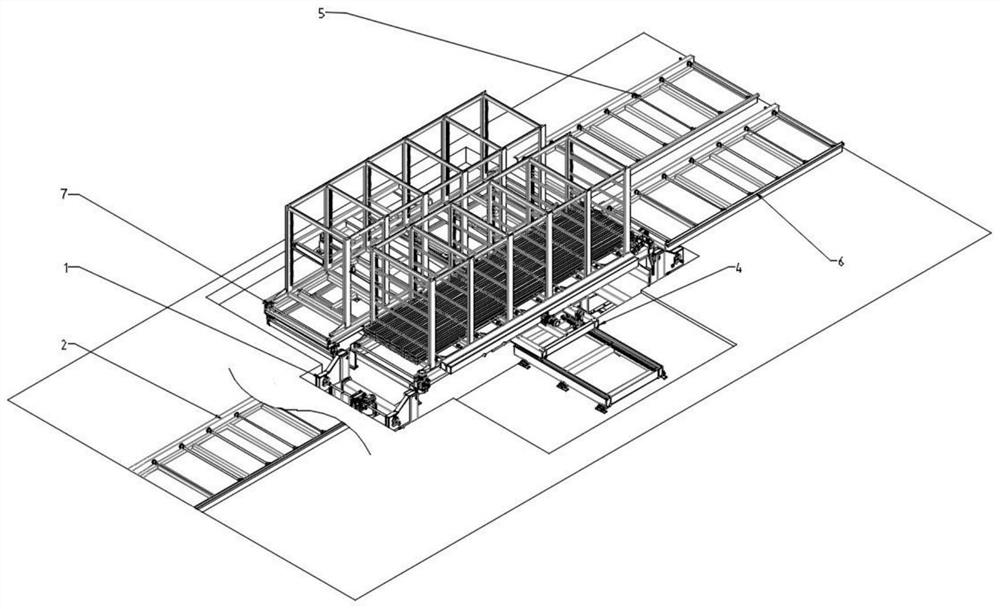

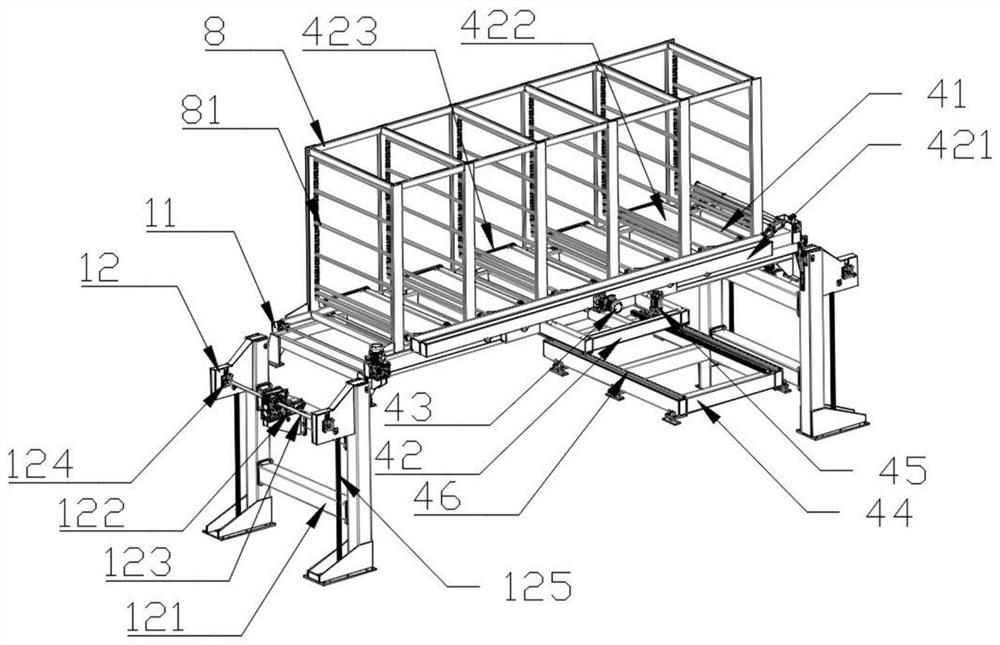

Full-automatic Chinese pastry production line

ActiveCN112960418AOpening and closing effectThere will be no mutual interferenceLoading/unloadingMechanical conveyorsFood safetyProcess engineering

The invention discloses a full-automatic Chinese pastry production line, and relates to the technical field of automatic production. The full-automatic Chinese pastry production line comprises a loading system, a rack car conveying system, a curing system, an unloading system and a car returning system, and the loading system is used for stacking pastry trays loaded with raw pastry and conveyed by an input mechanism on a rack car; after loading is completed, the rack car is conveyed to the curing system through the rack car conveying system to be subjected to fermentation, steaming and cooling, the rack car output by the curing system is conveyed to the unloading system, and the unloading system unloads the pastry trays on the rack car to an output mechanism; and the unloaded empty frame vehicle is conveyed to the loading system by the car returning system for loading. The full-automatic Chinese pastry production line is high in automation degree, does not need manual intervention in the production process, can effectively ensure food safety, can perform whole vehicle steaming processing on the rack vehicle, and is beneficial for improving the yield and the work efficiency.

Owner:SHANGHAI SOONTRUE MACHINERY EQUIP

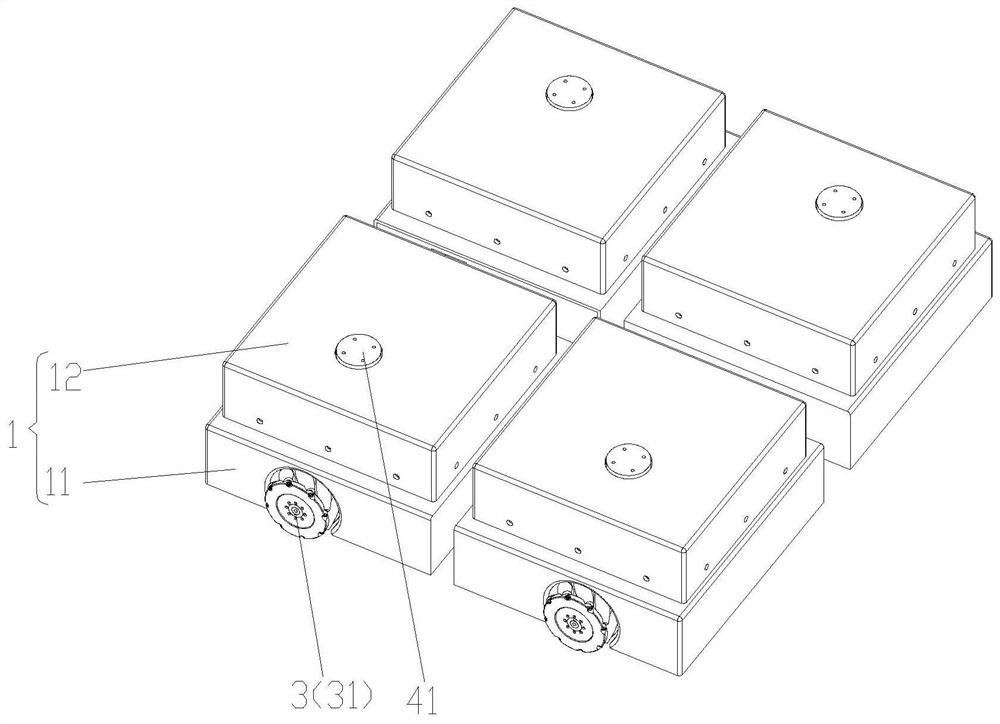

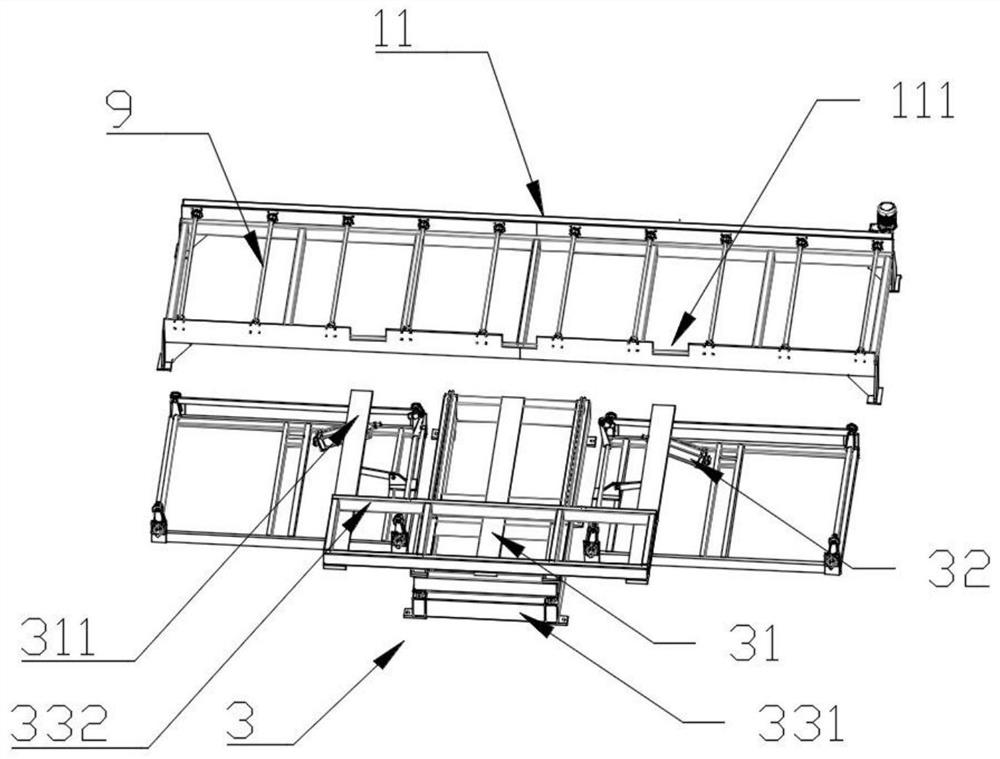

Roll-in type automatic stacking machine

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

Automatic tire water gap cutting machine

Owner:苏州瀚博精密模塑科技有限公司

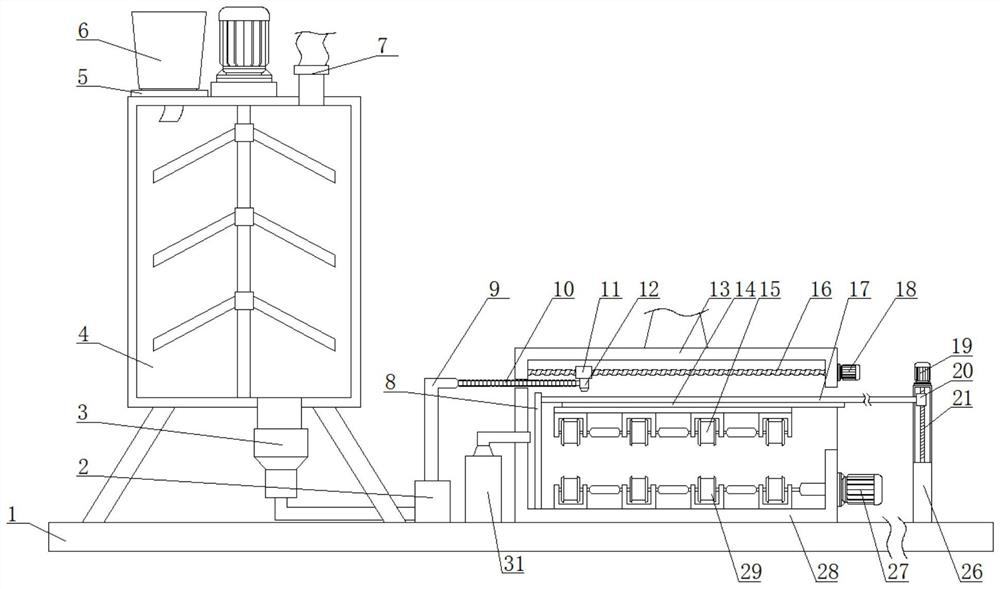

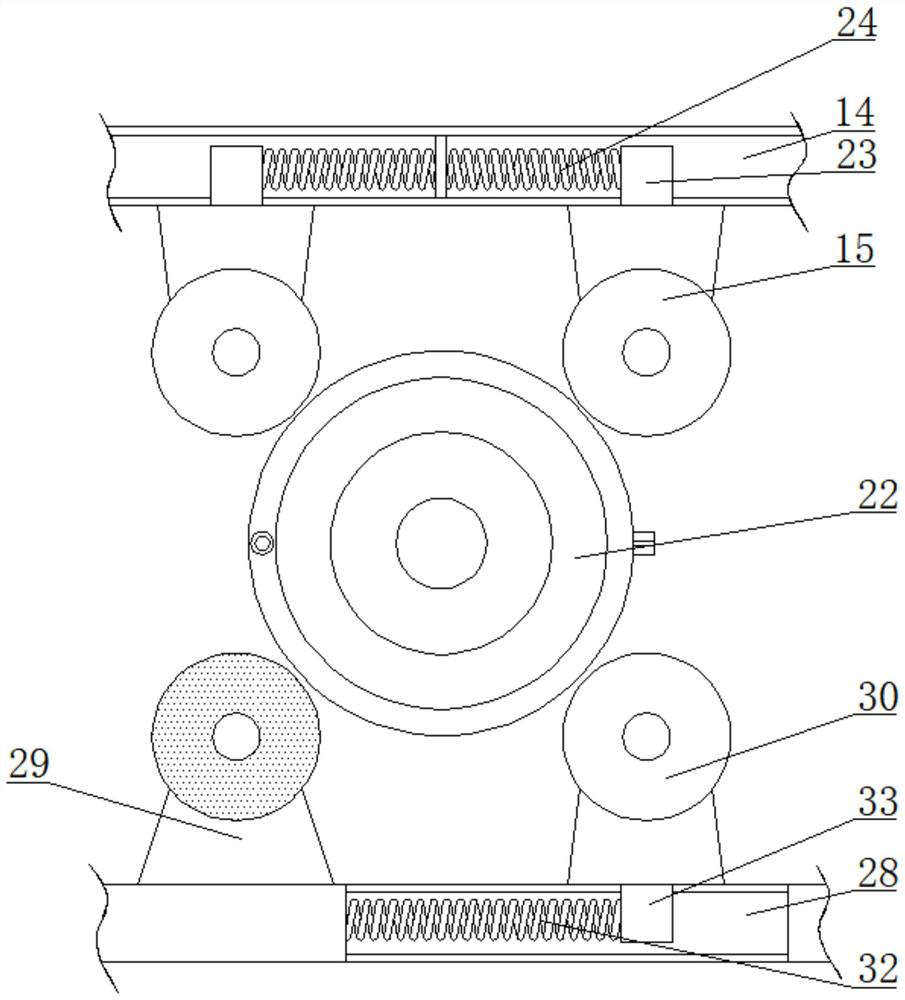

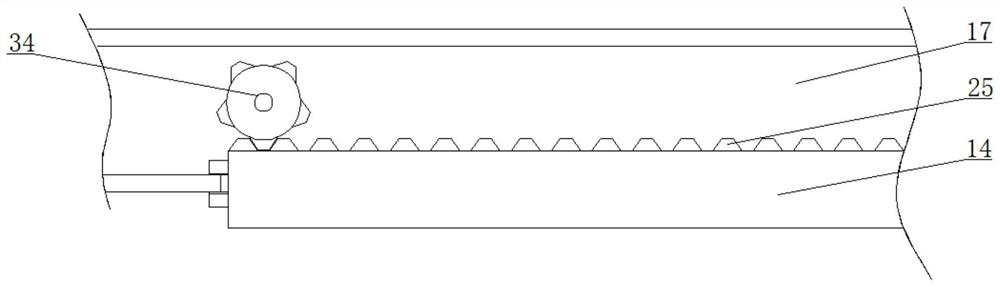

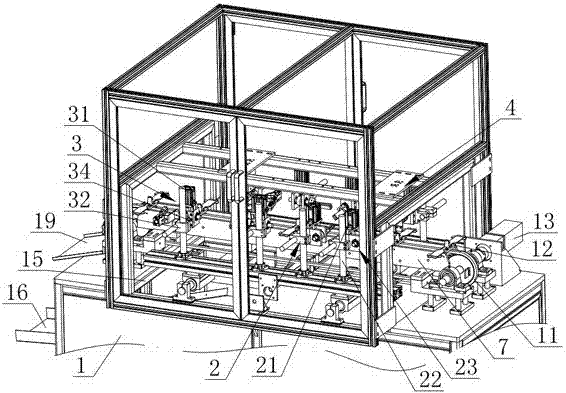

Concrete pole automatic production line

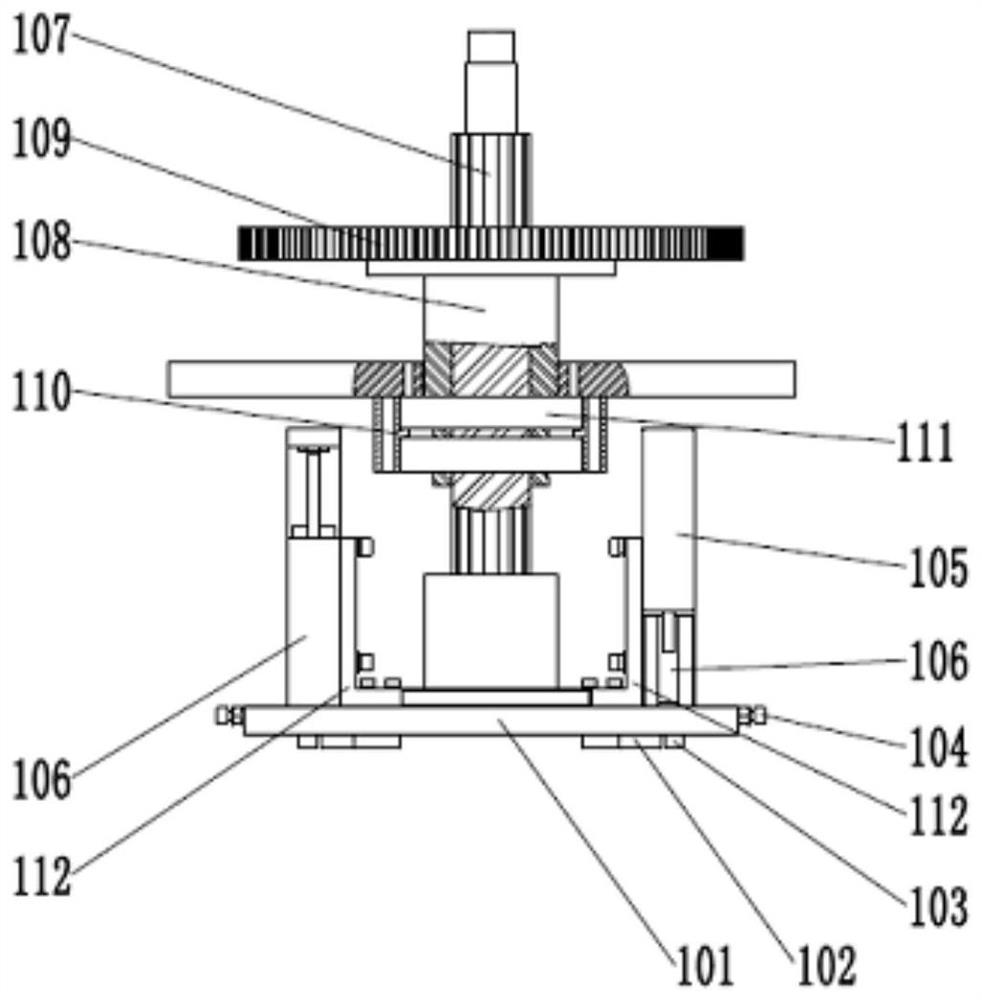

PendingCN112677308APrevent throwing outEasy to fixMixing operation control apparatusFeeding arrangmentsGear wheelEngineering

Owner:广东新荣荣电力科技有限公司

Special landscape architecture three-dimensional slope automatic planting regulation equipment

InactiveCN107187268AOperation diversificationEasy to operateSpecial ornamental structuresAgricultural engineeringSingle type

The invention relates to a special automatic planting and conditioning equipment for the three-dimensional slope of the garden landscape, which includes a mounting plate, a three-dimensional planting device is installed in the middle of the mounting plate, two mobile adjustment devices are installed on the installation plate, and the mobile adjustment device is located on the left side of the installation plate. A traction device is installed on the top, and a clamping device is installed on the mobile adjustment device on the right side of the mounting plate. The three-dimensional planting device, the mobile adjustment device, the traction device and the clamping device cooperate with each other to complete the technology of automatic conditioning and planting of the slope three-dimensional landscape. The invention can solve the problems existing in the planting process of the existing garden landscapes, such as limited plane planting, immature slope three-dimensional planting mode, insufficient utilization of planting space, poor plane and three-dimensional planting effect, single landscape types, requiring manual adjustment of landscape plants, and complicated operation , high labor intensity and low work efficiency, it can realize the function of automatic adjustment and planting of slope three-dimensional garden landscape.

Owner:吴慧

Full-automatic casting edge removing equipment

Owner:DONGGUAN XINTENG ROBOT TECH

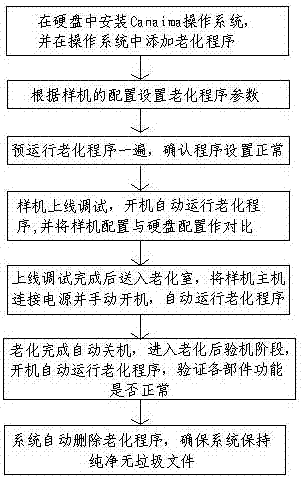

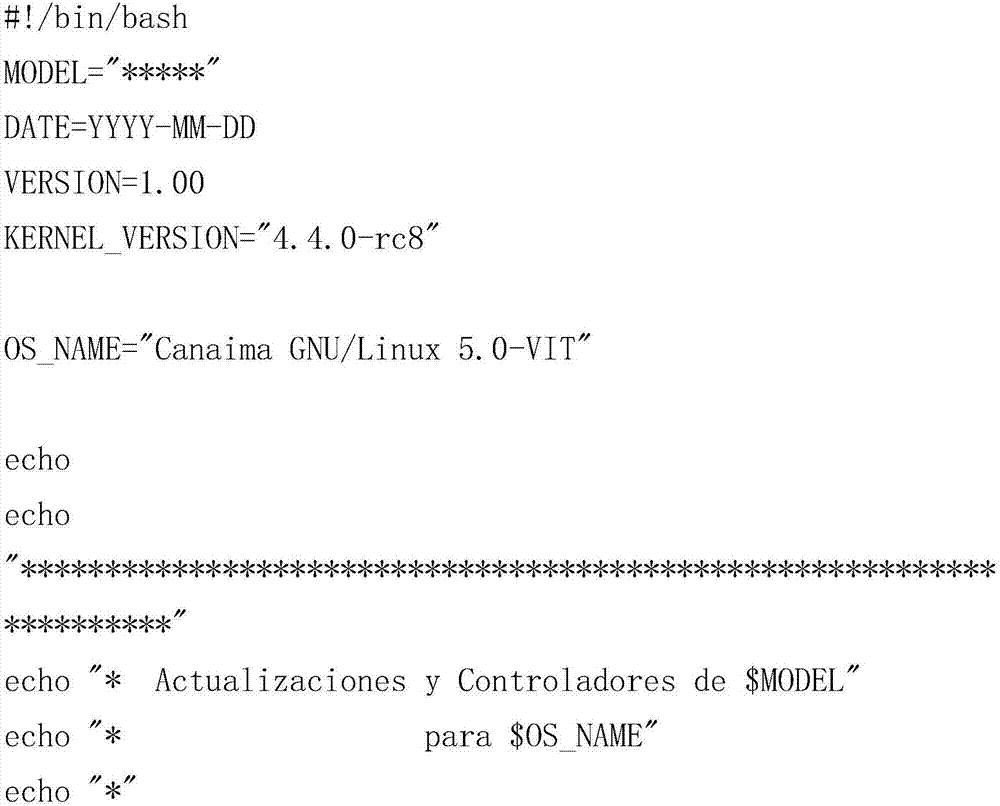

Computer aging program based on Canaima operating system

ActiveCN106874153AReduce demandThe content of the program interface is intuitiveDetecting faulty hardware by power-on testDetecting faulty hardware by configuration testDisplay deviceComputer testing

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

High-performance bag machine

PendingCN111409309ASimple structureGood bag qualityBag making operationsPaper-makingStampingStructural engineering

Owner:杭州环申新材料科技股份有限公司

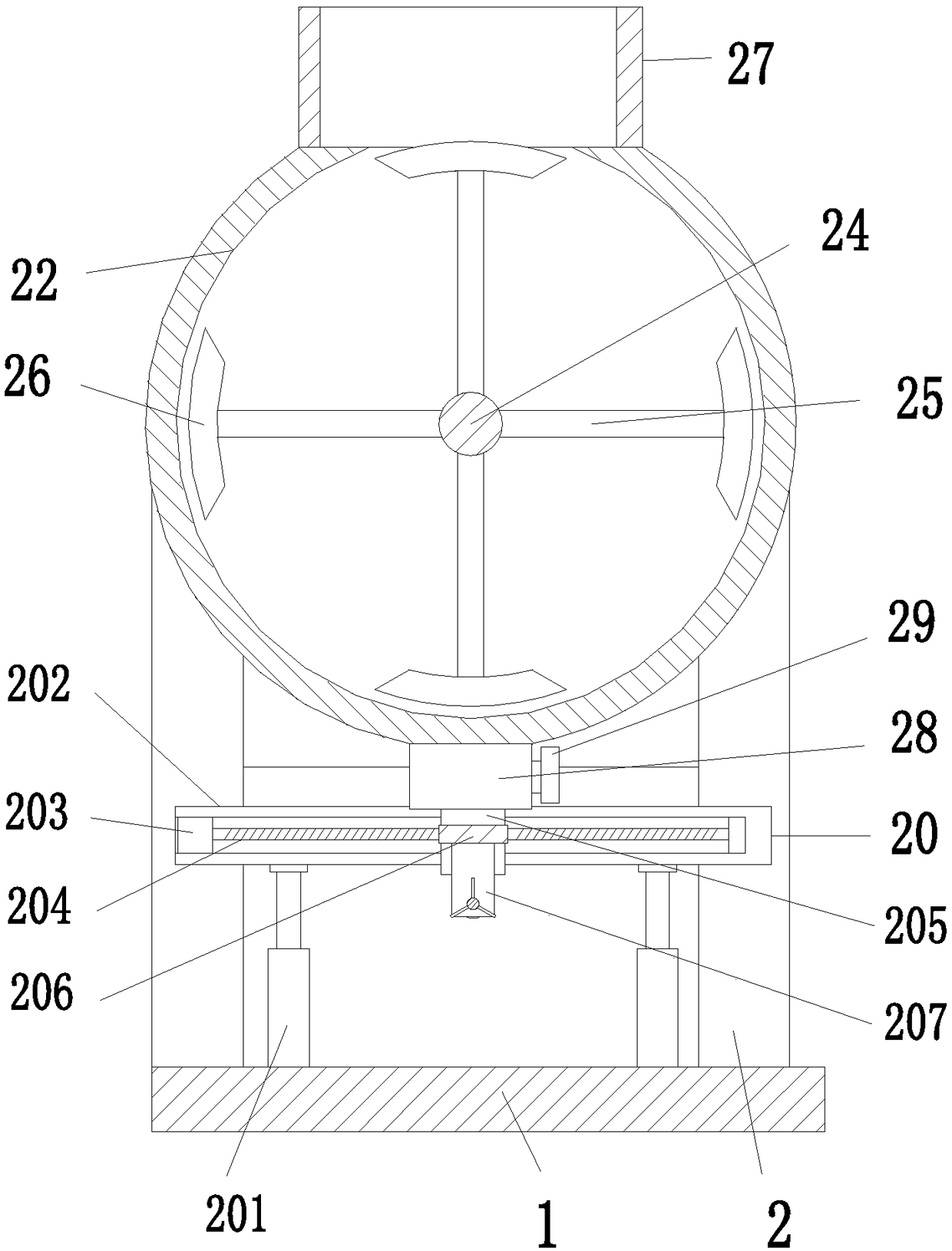

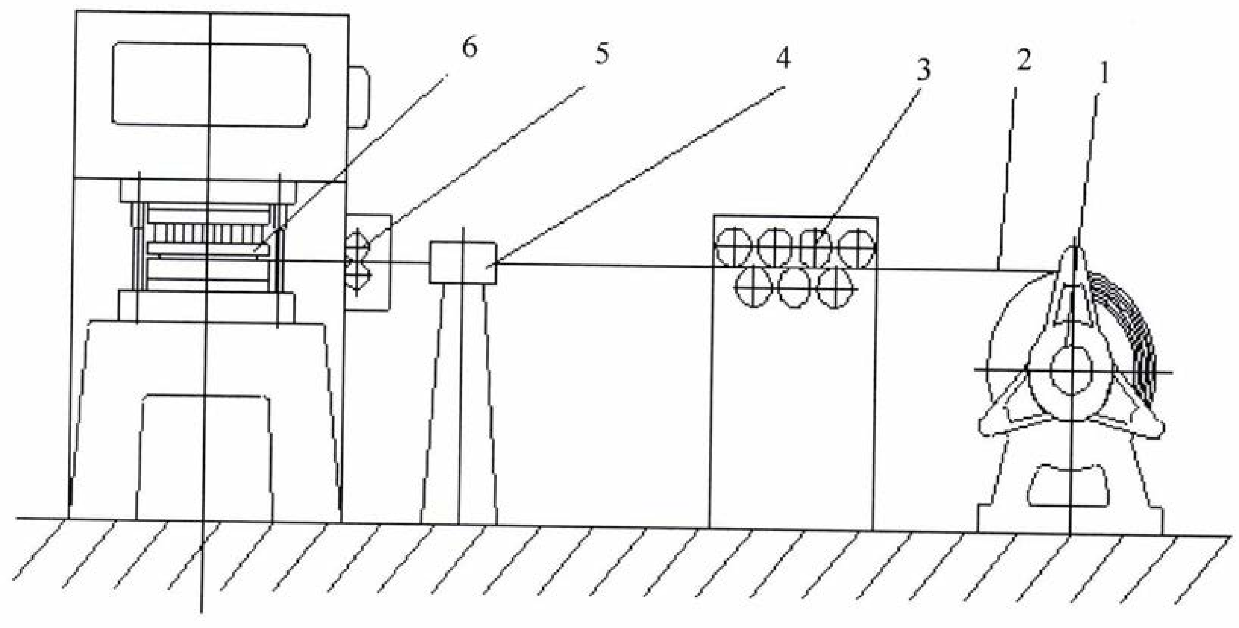

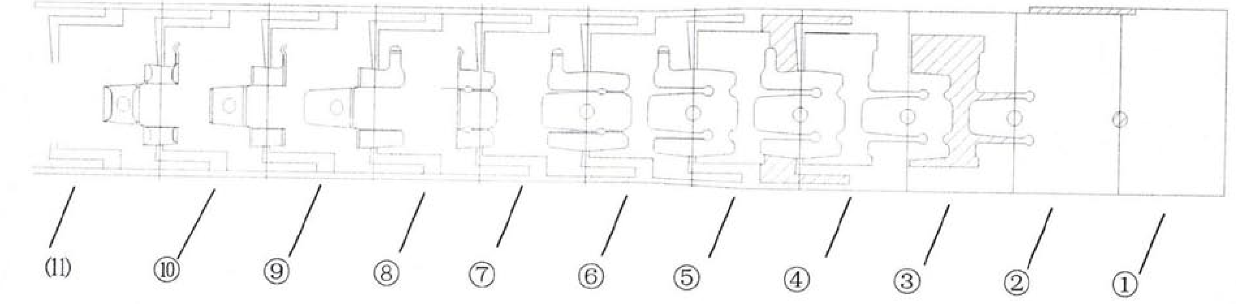

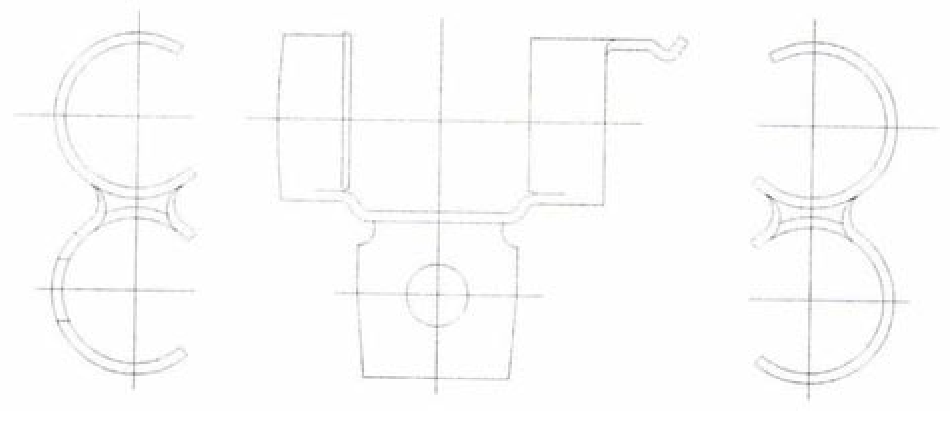

Static casting machine for MC nylon profiles

PendingCN111421727ATo achieve the purpose of constant temperature castingAvoid casting defectsTemperature controlControl system

Owner:合肥通泰晟管道科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap