Method for detecting leakage flow of automobile oil tank cover

A leakage flow and detection method technology, which is applied in the field of measuring force, torque and pressure devices, can solve the problems of complex operation process, high price and long detection time, and achieve high detection accuracy, good stability and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A method for detecting the leakage flow rate of the fuel tank cap of an automobile, which is carried out sequentially according to the following steps:

[0019] a. Prepare test instruments, b. Detect torque, c. Detect negative pressure flow, d. Detect leakage and e. Detect positive pressure flow, characterized by:

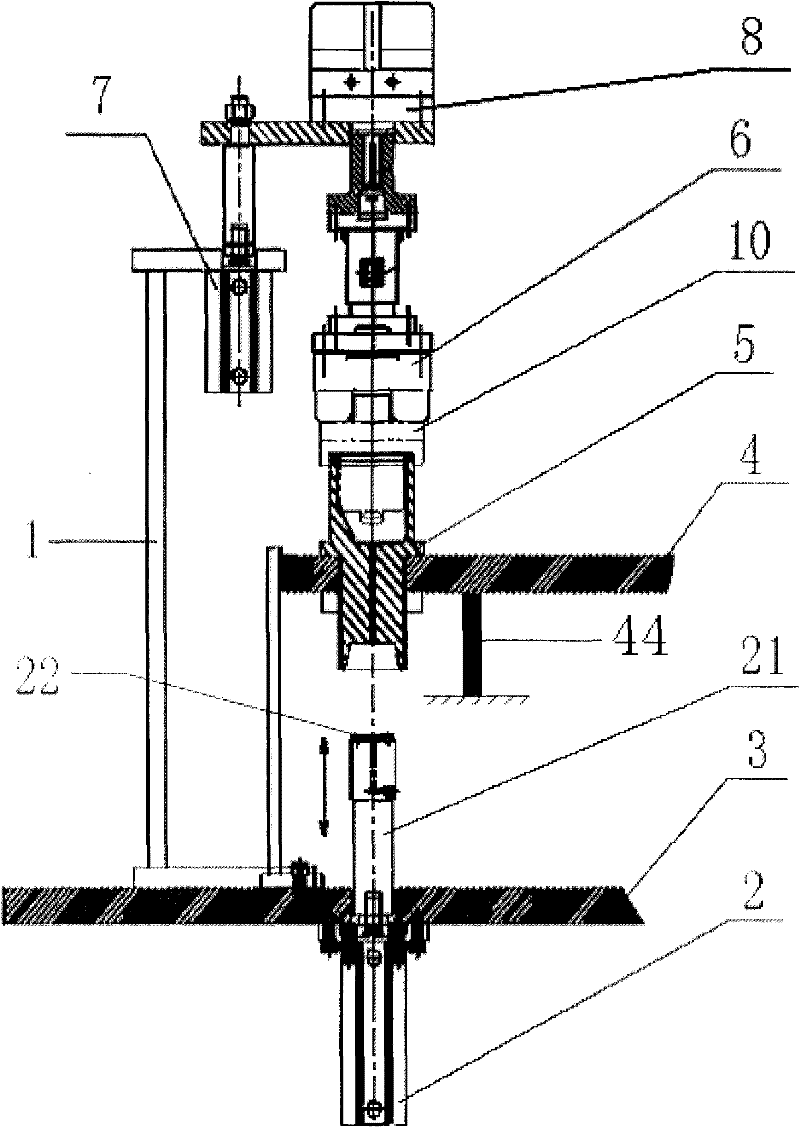

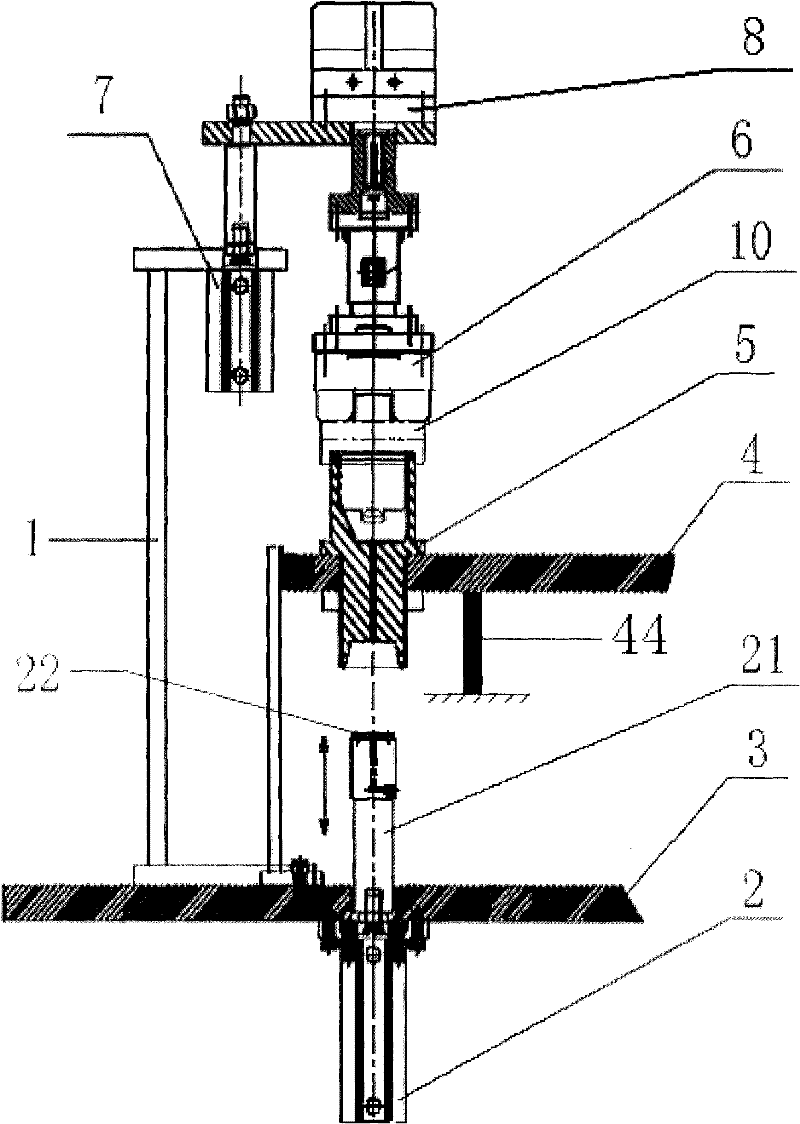

[0020] When preparing the test instrument in step a, proceed as follows: figure 1 and figure 2 As shown, the test instrument includes a bracket 1, a bottom plate telescopic cylinder 2, a piston 21, a sealing ring 22, a bottom plate 3, a rotating disc 4, an indexing rotator 41, a base 5, a tightening torque claw 6, a bracket telescopic cylinder 7 and a rotating Cylinder 8, bracket 1 is fixed on the base plate 3, the base plate telescopic cylinder 2 is vertically fixed below the base plate 3, a through hole is opened on the base plate 3, the piston 21 slides up and down along the inner wall of the base plate telescopic cylinder 2 and the top of the piston 21 pa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap