Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Carving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carving is the act of using tools to shape something from a material by scraping away portions of that material. The technique can be applied to any material that is solid enough to hold a form even when pieces have been removed from it, and yet soft enough for portions to be scraped away with available tools. Carving, as a means for making sculpture, is distinct from methods using soft and malleable materials like clay, fruit, and melted glass, which may be shaped into the desired forms while soft and then harden into that form. Carving tends to require much more work than methods using malleable materials.

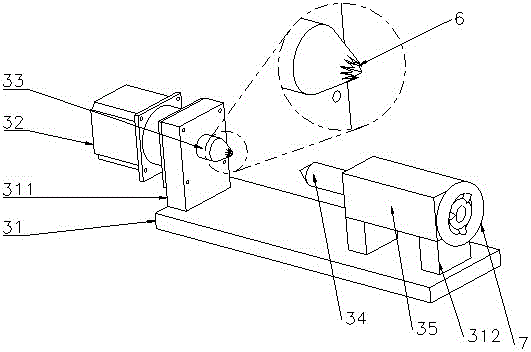

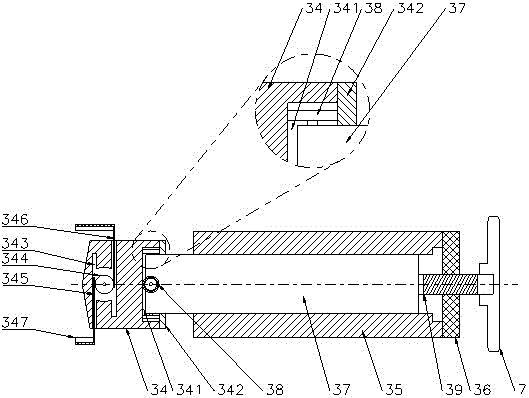

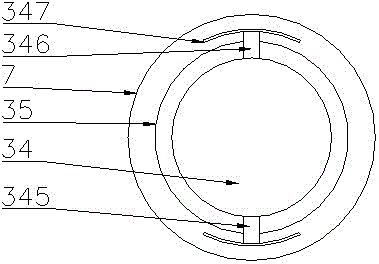

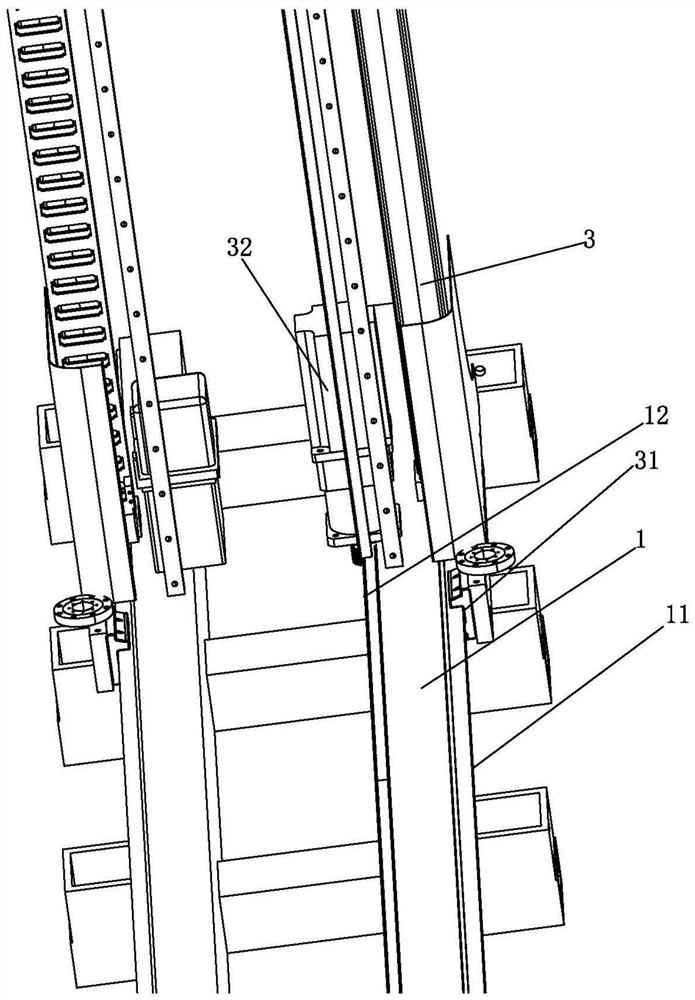

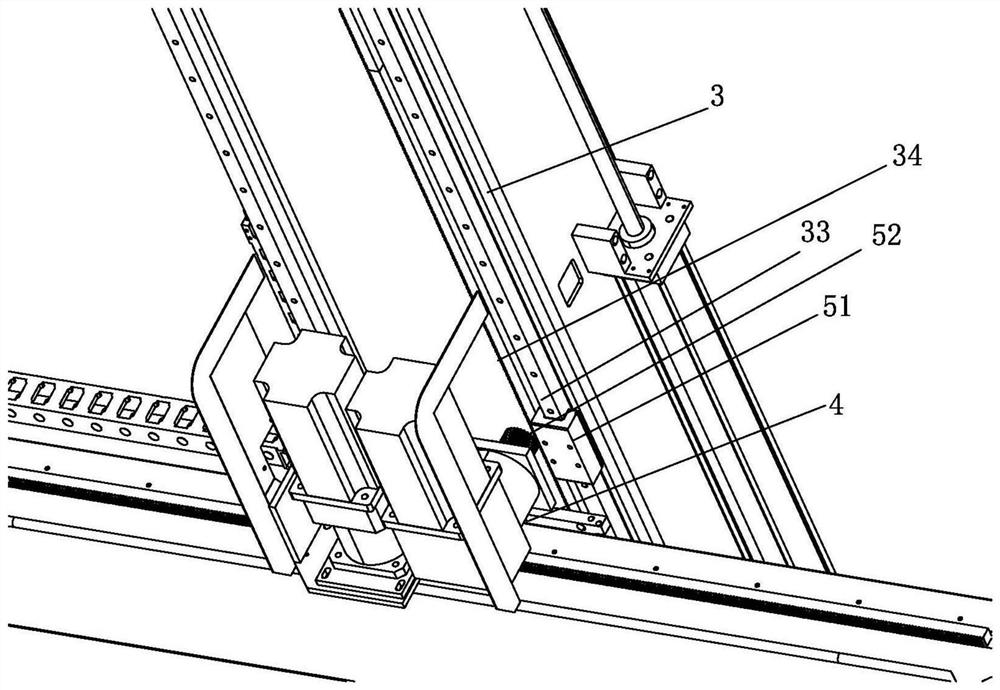

Axis locating device for split type cylindrical carving machine

InactiveCN105799405AAvoid wear and tearIncrease frictionOther artistic work equipmentsModel makingEngineeringCarving

Owner:DIACAM CNC EQUIP TECH CO LTD

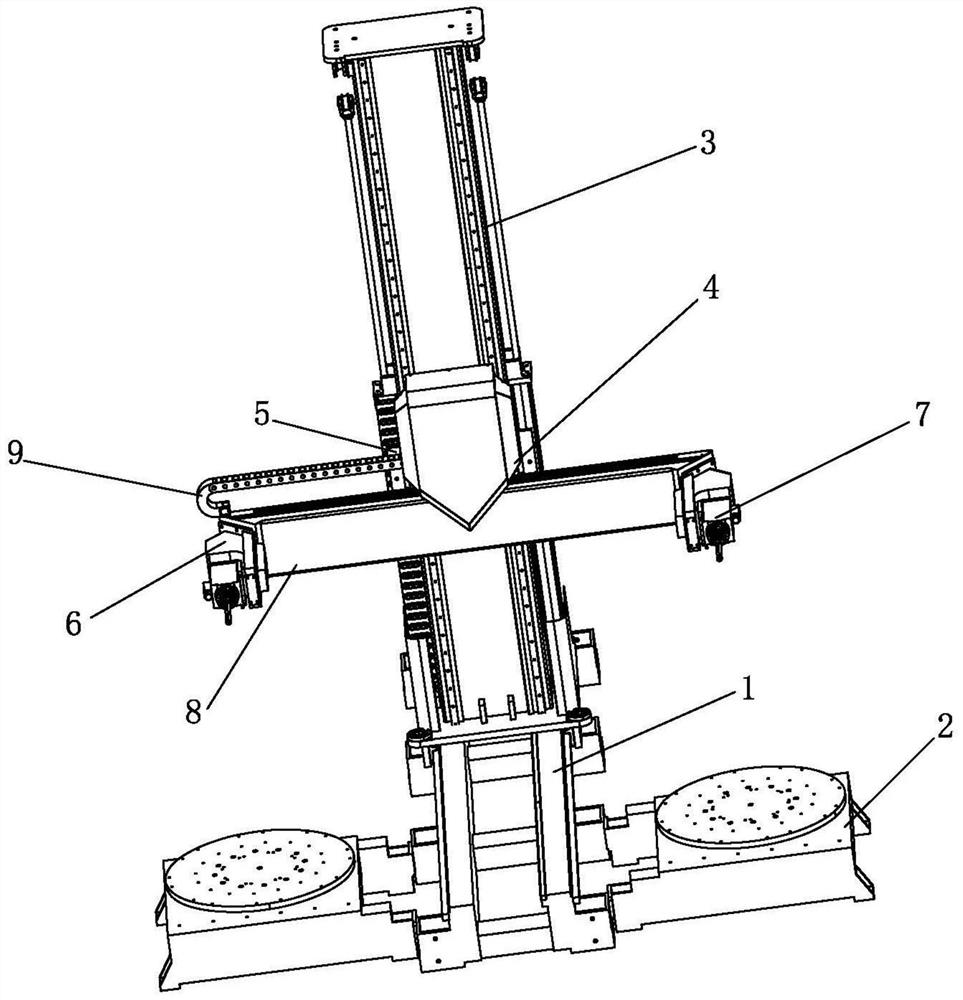

Double-head engraving machine

PendingCN112406384AImprove engraving accuracyImprove engraving efficiencyOther artistic work equipmentsModel makingRotational axisEngineering

The invention discloses a double-head engraving machine. The double-head engraving machine comprises a machine frame, wherein two bases in bilateral symmetry and a lifting support are arranged on themachine frame, an engraving device is arranged on the lifting support, and the engraving device comprises a fixing plate and an engraving assembly movably connected with the fixing plate; and the engraving assembly comprises a connecting shaft and engraving heads arranged at the two ends of the connecting shaft, each engraving head comprises an engraving tool, an engraving bottom plate and a rotating motor, the engraving bottom plates are fixed to the connecting shaft, and rotating shafts are arranged on the engraving tools. According to the double-head engraving machine, embossments are fixedthrough the bases; three-dimensional movement of the engraving heads is achieved through the lifting support, the engraving device and the engraving assembly, the direction of the engraving tools canbe adjusted through the rotating motors, engraving at any position is achieved, the engraving precision is high, a left embossment and a right embossment can be engraved simultaneously, the engravingefficiency is high, engraving functions are diversified, and the occupied space is small.

Owner:厦门特雕科技有限公司

Multi-groove glass clamping jig for fine carving

The invention discloses a multi-groove glass clamping jig for fine carving. The glass clamping jig comprises a positioning base, wherein a plurality of rectangular placement grooves are formed in theupper end of the positioning base in an arrayed mode, rectangular insertion holes penetrating through the lower end face of the positioning base are formed in the bottom surfaces of the placement grooves, a plurality of longitudinal insertion grooves penetrating through the upper end face of the positioning base are formed in the inner walls of the front and rear sides of the rectangular insertionholes, the longitudinal insertion grooves of the positioning base are internally provided with longitudinal carrier rollers in an embedded mode, horizontal grooves are formed in the upper end faces of the positions, between every two longitudinally adjacent placements grooves, of the positioning base, vertical connection plates are inserted into the grooves, the connection plates are inserted onthe carrier rollers in a sleeve mode, horizontal rectangular pressing plates are formed in the middles of the upper end faces of the connection plates, the front and rear side edges of the pressing plates extend out of the inner side walls of the rectangular insertion holes, and the pressing plate presses against the upper end face of the positioning base.

Owner:SHENZHEN SENSELEADER TECH DEV CO LTD

Production and processing equipment with automatic positioning and carving function for helmet pendants

InactiveCN112317968AEasy to passEasy accessWelding/cutting auxillary devicesAuxillary welding devicesLaser engravingManual handling

The invention discloses production and processing equipment with an automatic positioning and carving function for helmet pendants. The production and processing equipment comprises an operation case,and a laser engraving case is fixedly mounted on a right bolt of the top end surface of the operation case. According to the production and processing equipment, a pushing head and the laser engraving case are respectively arranged at the two ends of a guide groove in the top of the operation case; through the arrangement of the pushing head, a helmet can be conveniently pushed to the position below the laser engraving case when being conveyed to the front end of the pushing head through a conveying belt; through the arrangement of an inflation device and an air bag, the air bag can conveniently enter an inner cavity of the helmet to be attached to the helmet to form a clamping and fixing structure; through the arrangement of a rotating base and a laser head, the helmet can be driven to rotate while being engraved, and the helmet can be engraved at different portions; and through the arrangement of a feeding assembly, the helmet can be conveniently pushed out of the guide groove of the operation case after carving is finished, manual operation is avoided, operation steps are reduced, and therefore an automatic carving structure can be formed.

Owner:DONGGUAN UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap