Automatic lamination, detection and boxing production line of stator and rotor

A production line, stator-rotor technology, applied in the field of stator-rotor automatic stacking detection and packing production line, can solve the problems of affecting production efficiency, low operation efficiency, batch abnormal parts, etc., and achieve the goal of improving production efficiency, reducing quantity and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

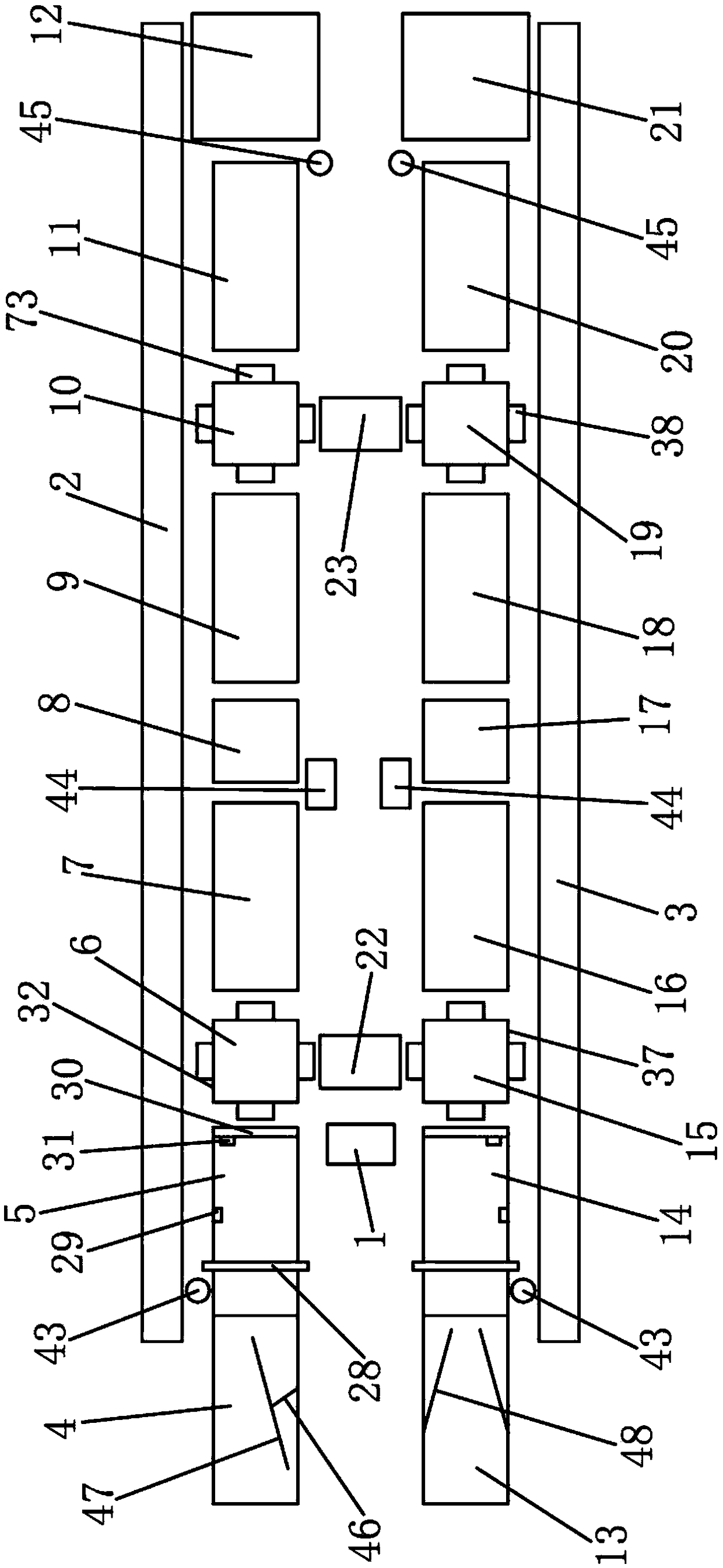

[0021] Embodiment: A stator-rotor automatic stacking detection packing production line, such as Figure 1-Figure 7As shown, it includes the stator production line, the rotor production line, the control unit, the stator defective product conveying line and the rotor defective product conveying line. The control unit is controlled by PLC and connected with a visual operation man-machine interface and sound and light alarm devices. Control the work of the stator production line, the rotor production line, the stator defective product conveying line and the rotor defective product conveying line. According to the transmission direction of the stator production line, the stator slideway, the stator feeding mechanism, the stator first screening mechanism, and the stator first conveyor belt are arranged in sequence. , Stator pressure riveting mechanism, stator second conveyor belt, stator second screening mechanism, stator third conveyor belt and stator collection box, according to the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap