Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Fuel cells" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for evaluating performance states of automotive power batteries

The invention belongs to the technical field of batteries, and particularly relates to a method for evaluating performance states of automotive power batteries. Through performing second-order equivalent circuit modeling on automotive power batteries (including lead-acid batteries, nickel-metal hydride batteries, lithium ion batteries, fuel batteries, super batteries and the like), the performance states of the batteries (a state of charge (SOC) and a state of health (SOH)) are transformed to parameters of an equivalent circuit model. An impulse charging-discharging experiment result of each automotive power battery is handled by using a second-order exponential damping fitting method in Origin software, so that the parameters of equivalent resistance and equivalent capacitance in the power batteries are obtained. A database of the power battery model parameters and the battery performance states is established as the basis of evaluating the performance states of the batteries in an operating process of an automobile, so that the power management can be optimized, problems can be found timely, and accidents are avoided.

Owner:BEIJING UNIV OF TECH

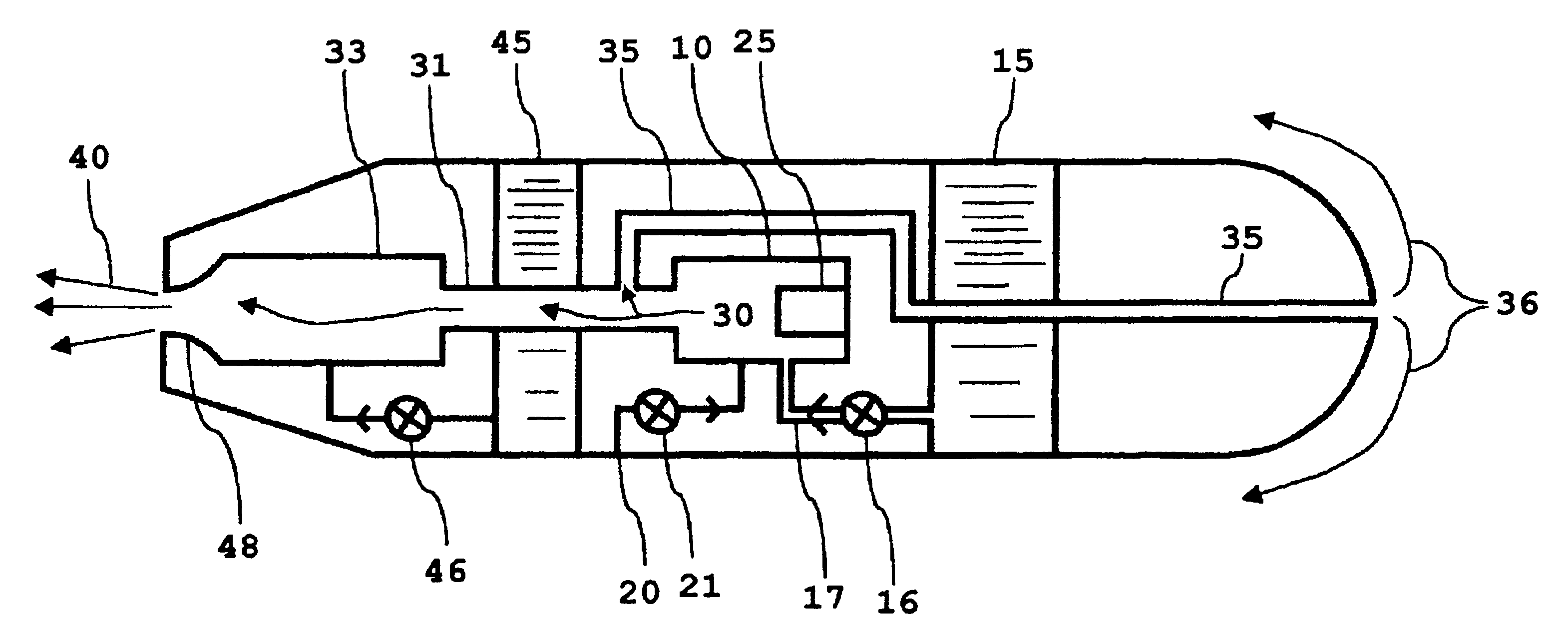

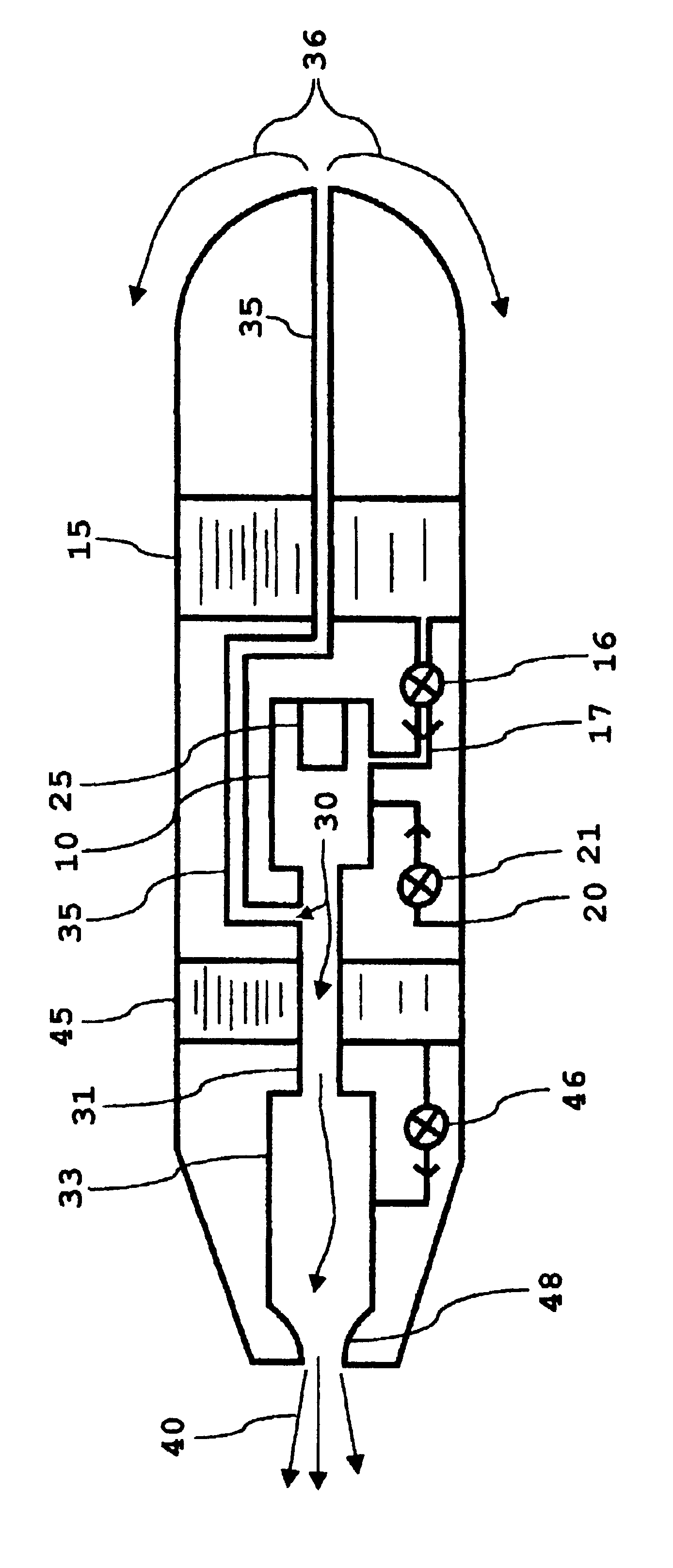

Gas generating process for propulsion and hydrogen production

InactiveUS6849247B1Reduce the temperatureProducing energyLoomsHydrogen productionMetallic materialsSlurry

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

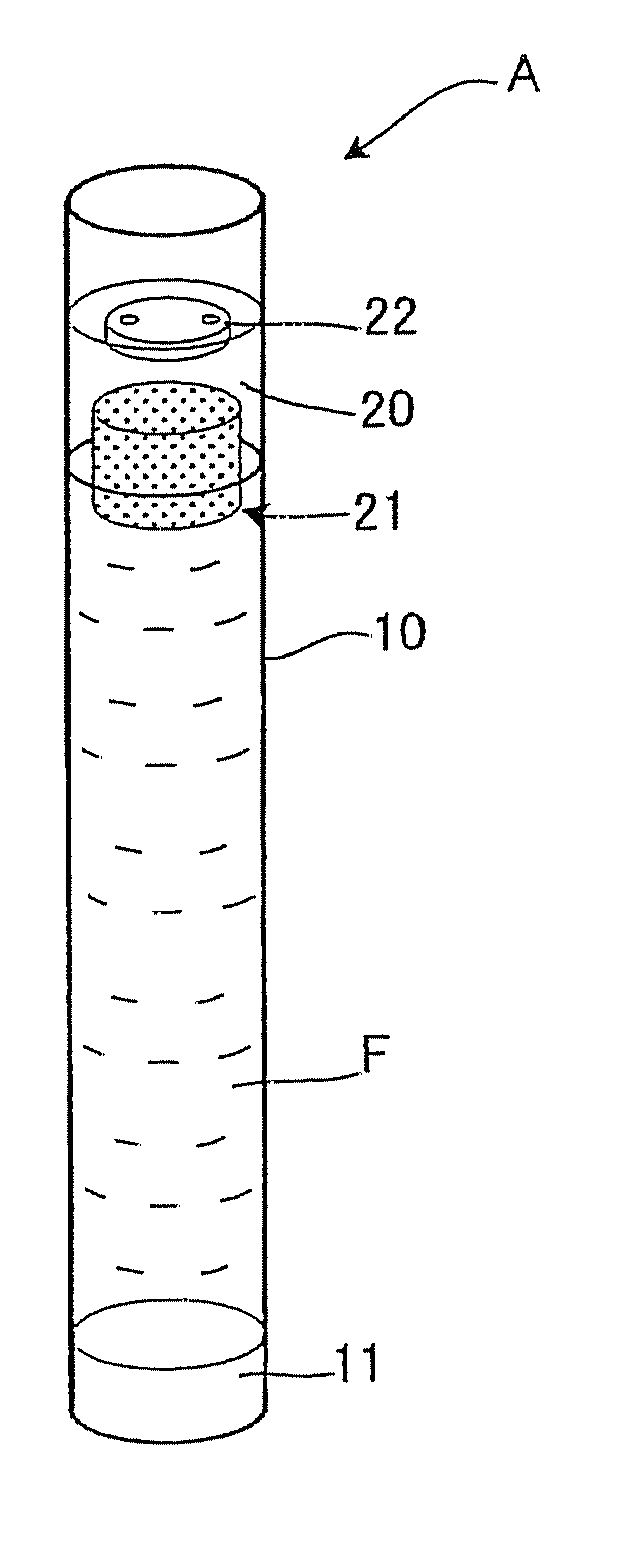

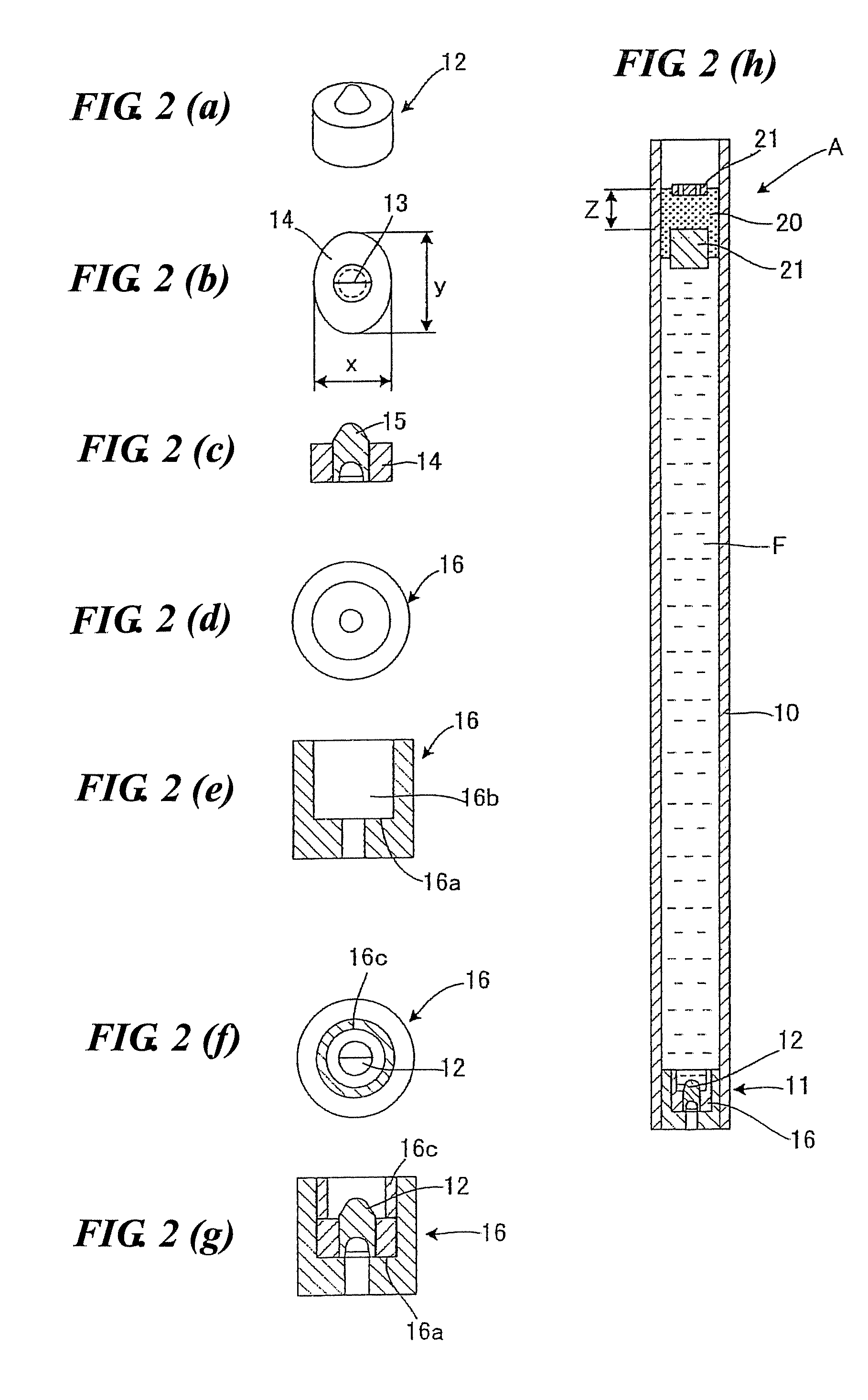

Fuel cartridge

InactiveUS20100012568A1Improve vibration resistanceImprove the immunityReactant parameters controlDistillation regulation/controlFuel cellsLiquid fuel

Owner:MITSUBISHI PENCIL CO LTD +1

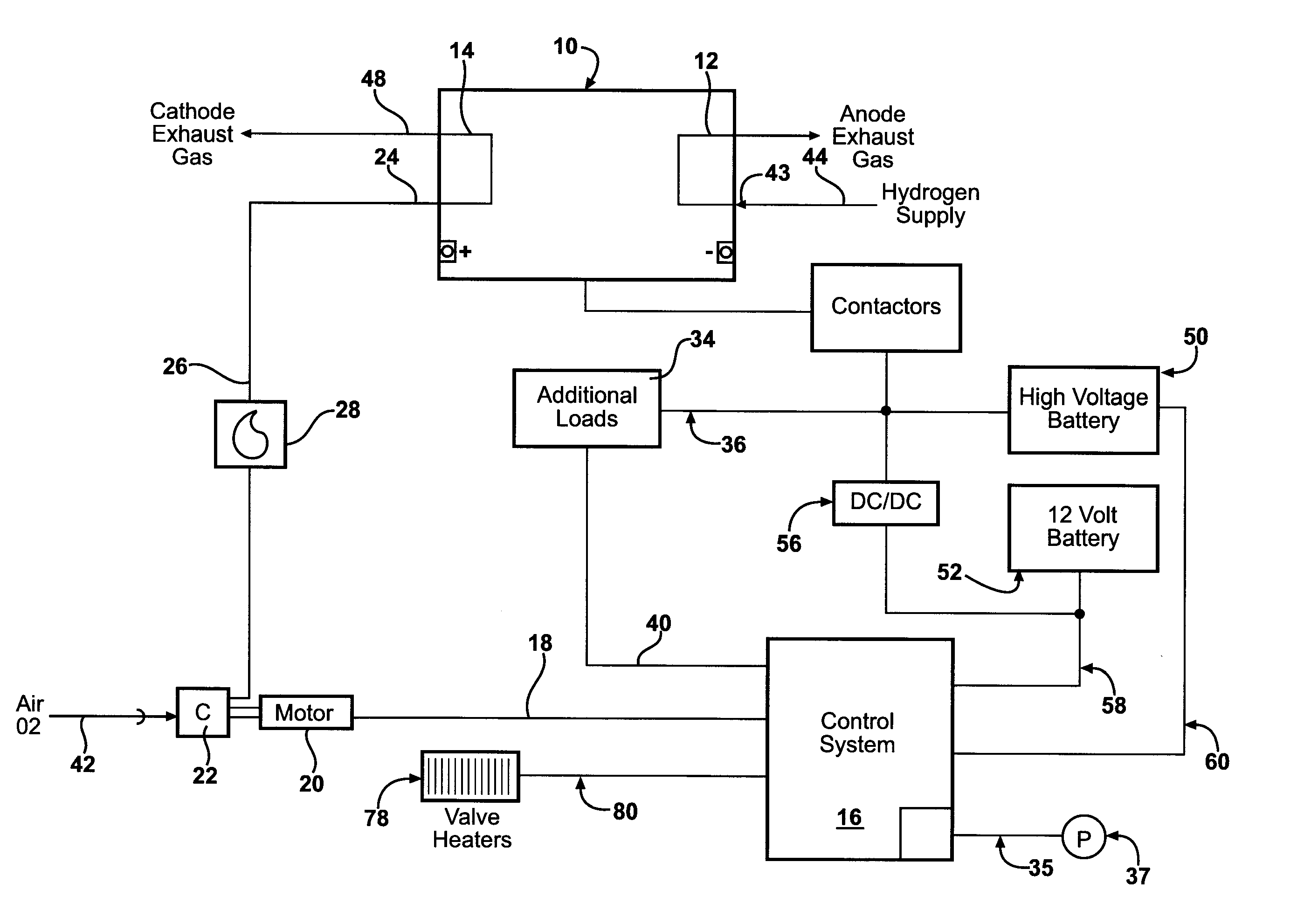

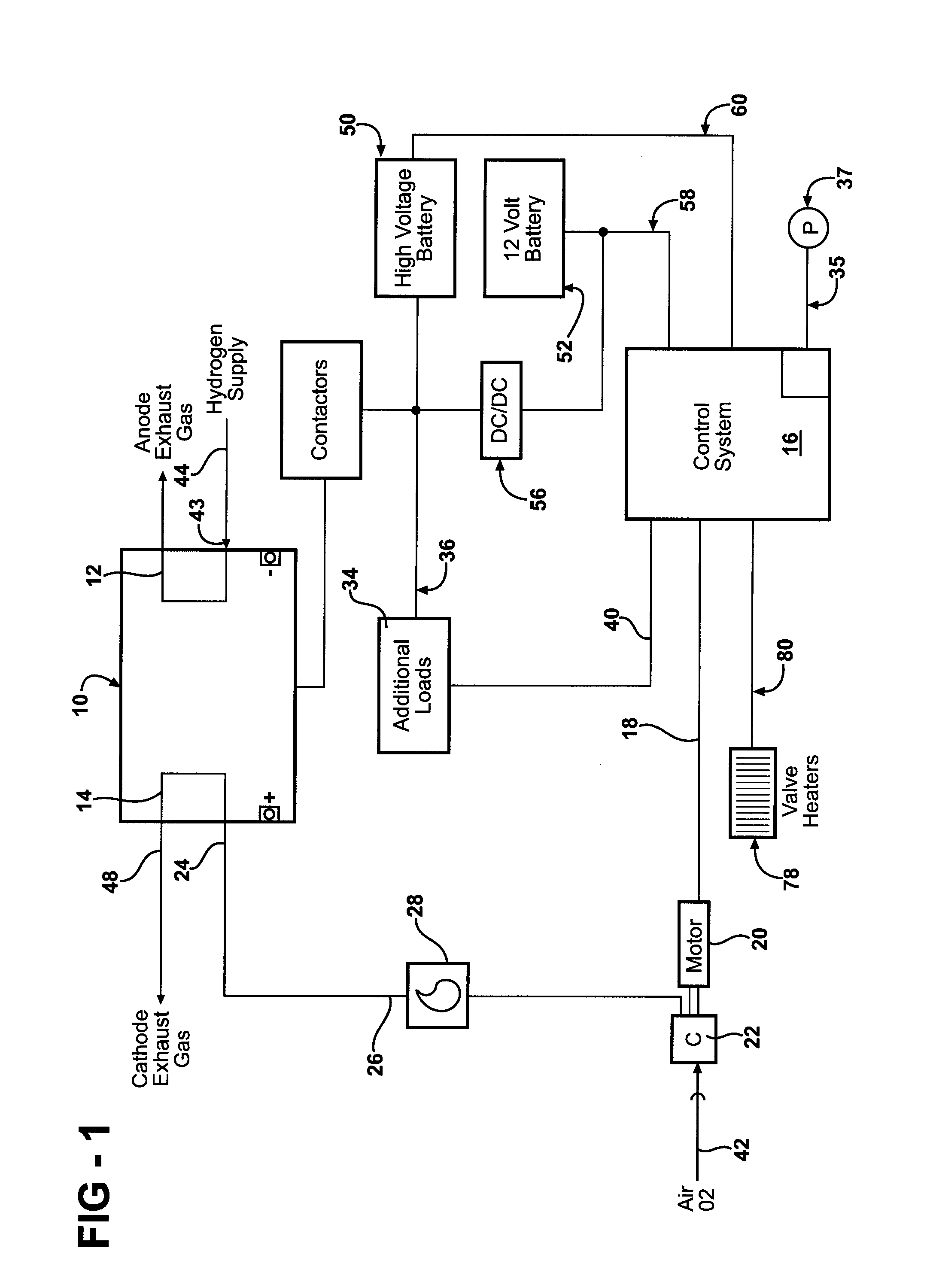

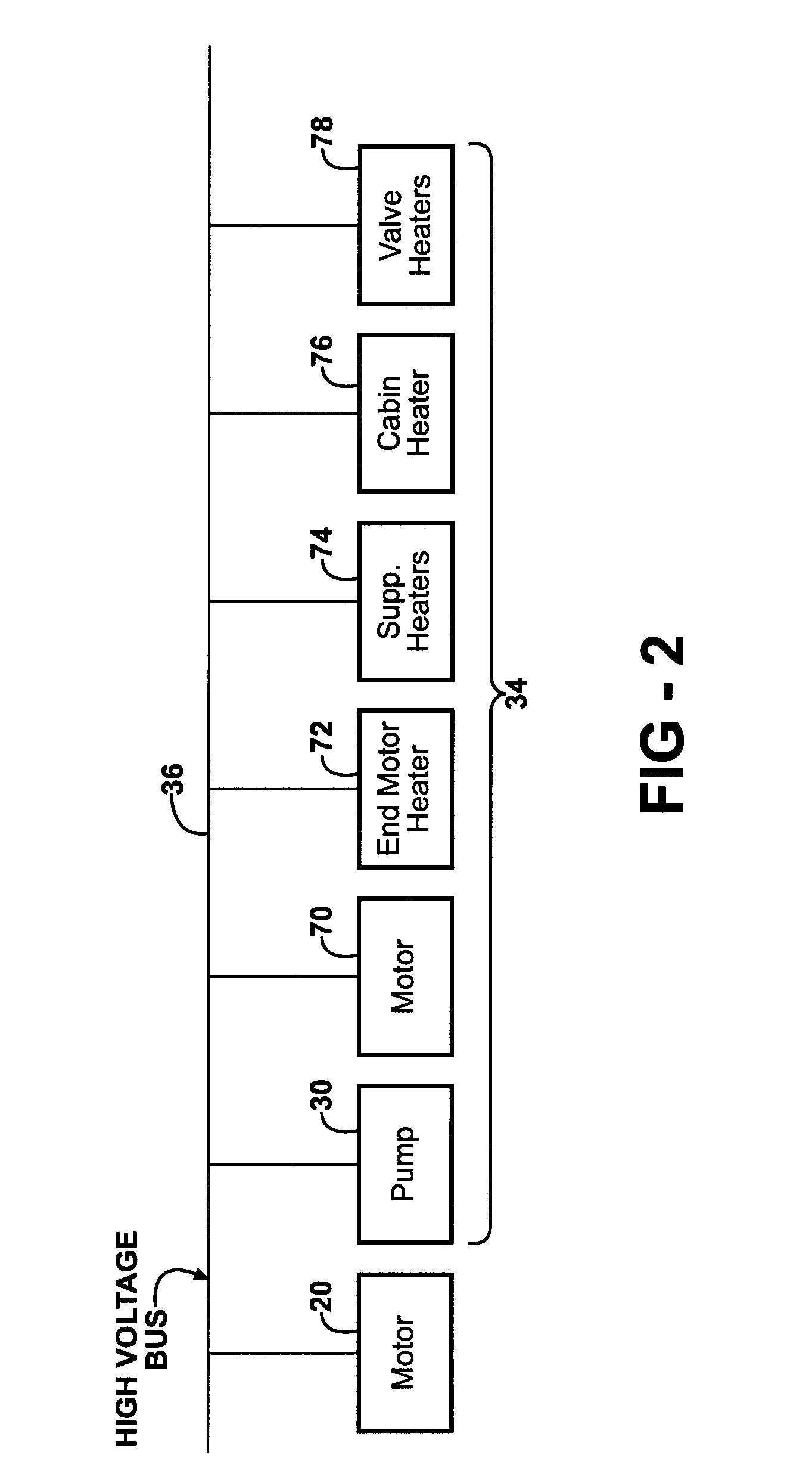

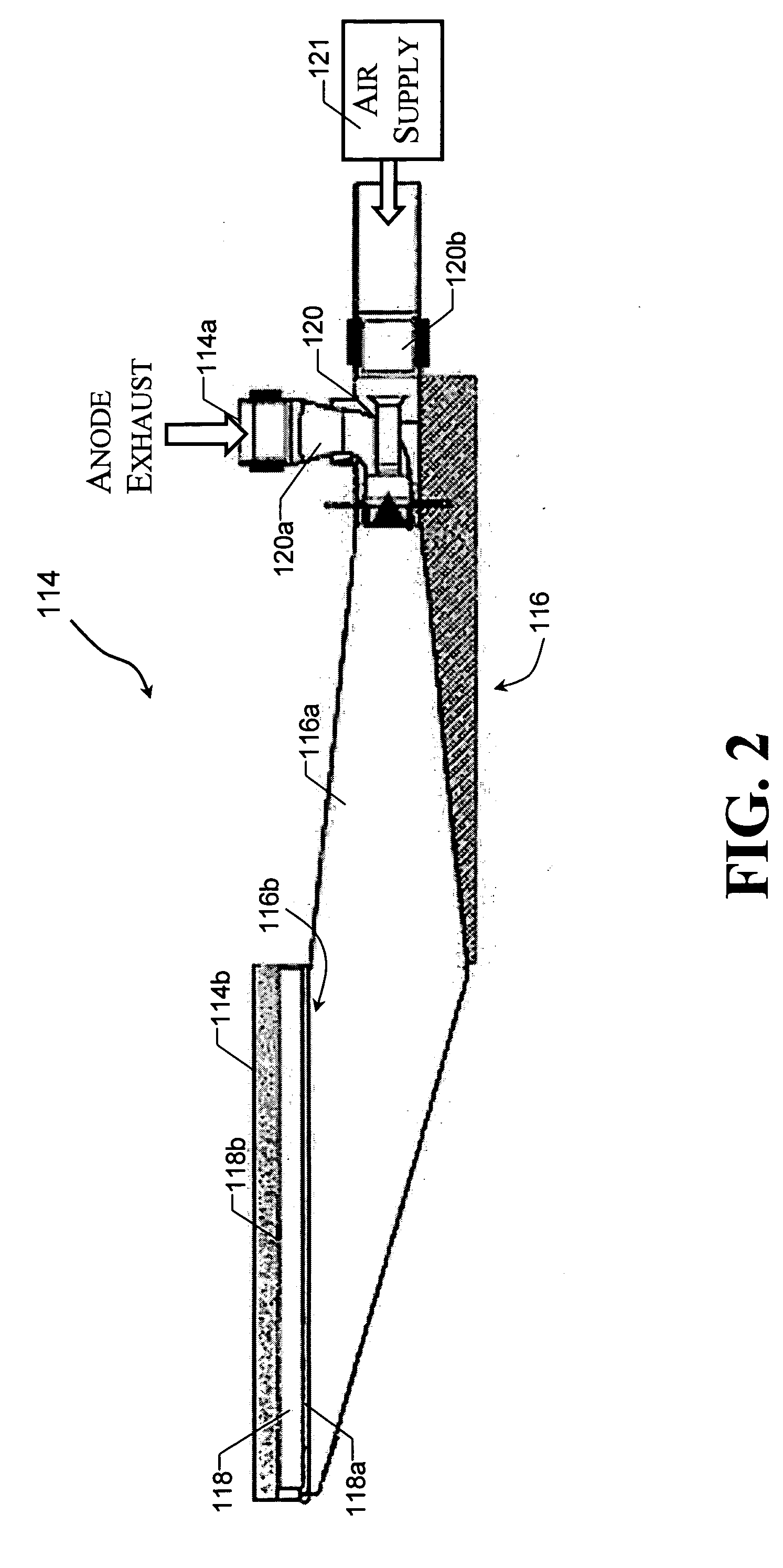

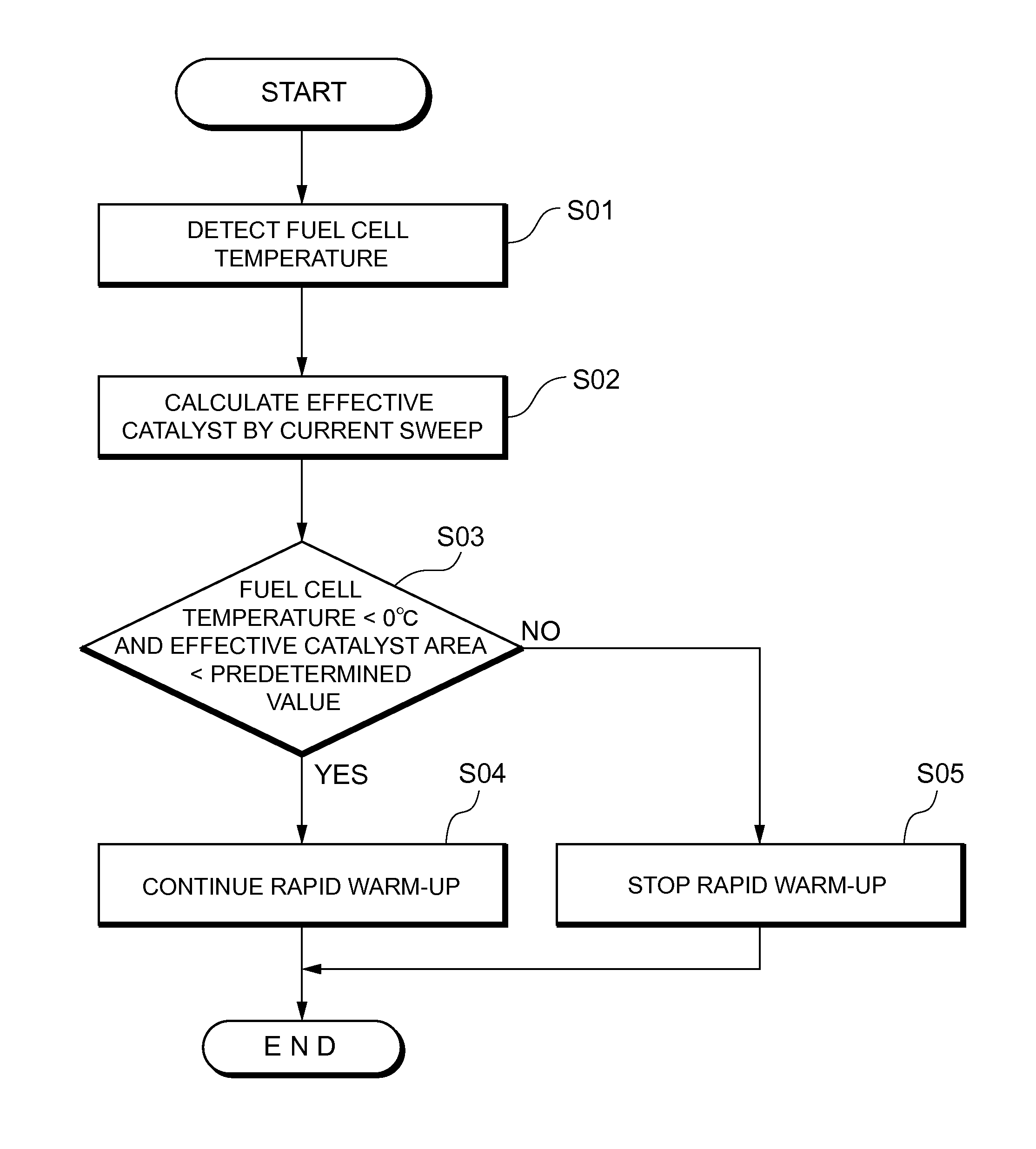

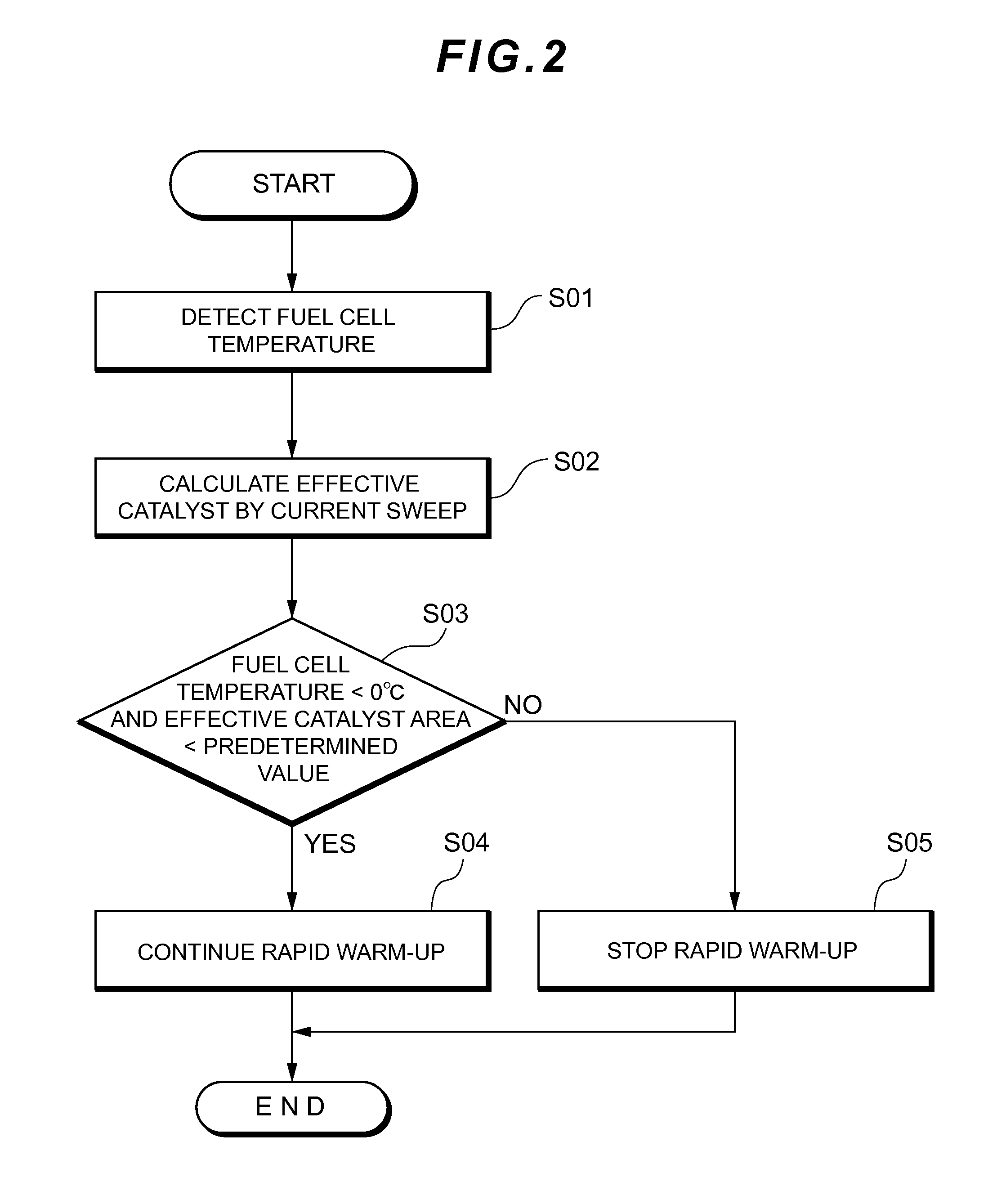

Fuel cell startup method for fast freeze startup

ActiveUS20080081224A1Increase ratingsOptimizes warm-up timeFuel cell heat exchangeConverter typesFuel cellsStart time

Owner:GM GLOBAL TECH OPERATIONS LLC

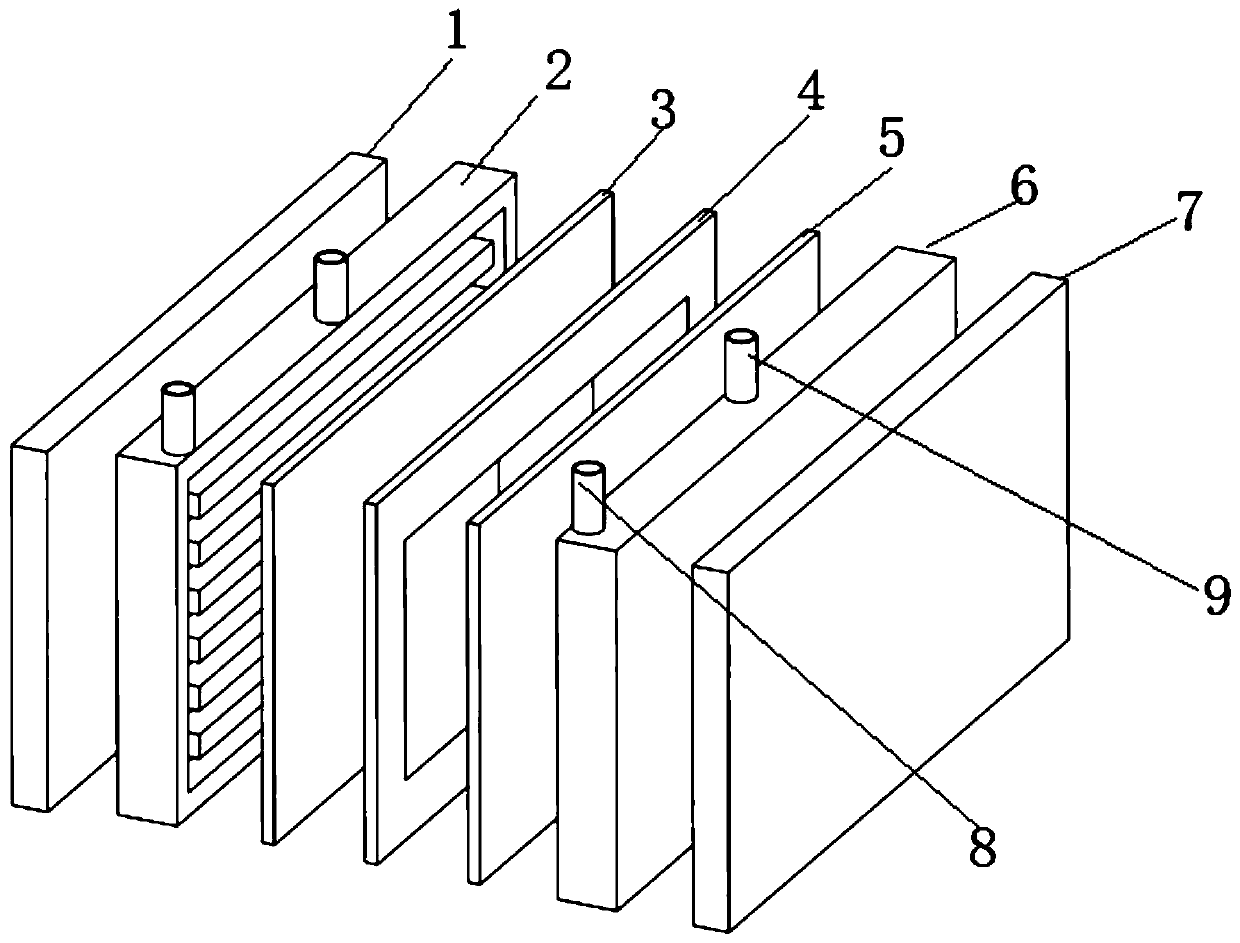

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

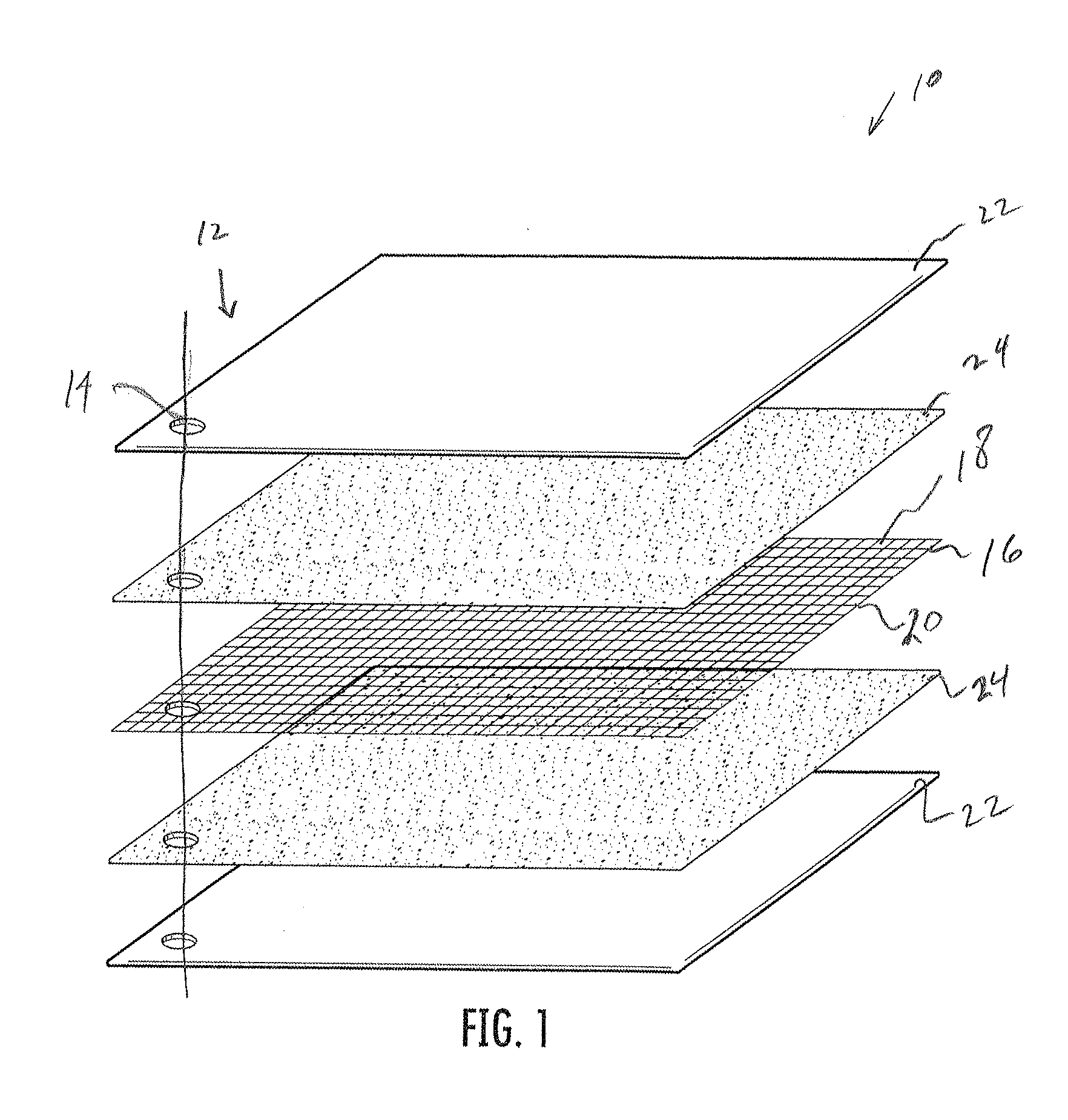

Fuel cell composite flow field element and method of forming the same

InactiveUS20110053052A1High thermalImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsFuel cellsGraphite

Owner:VPJP

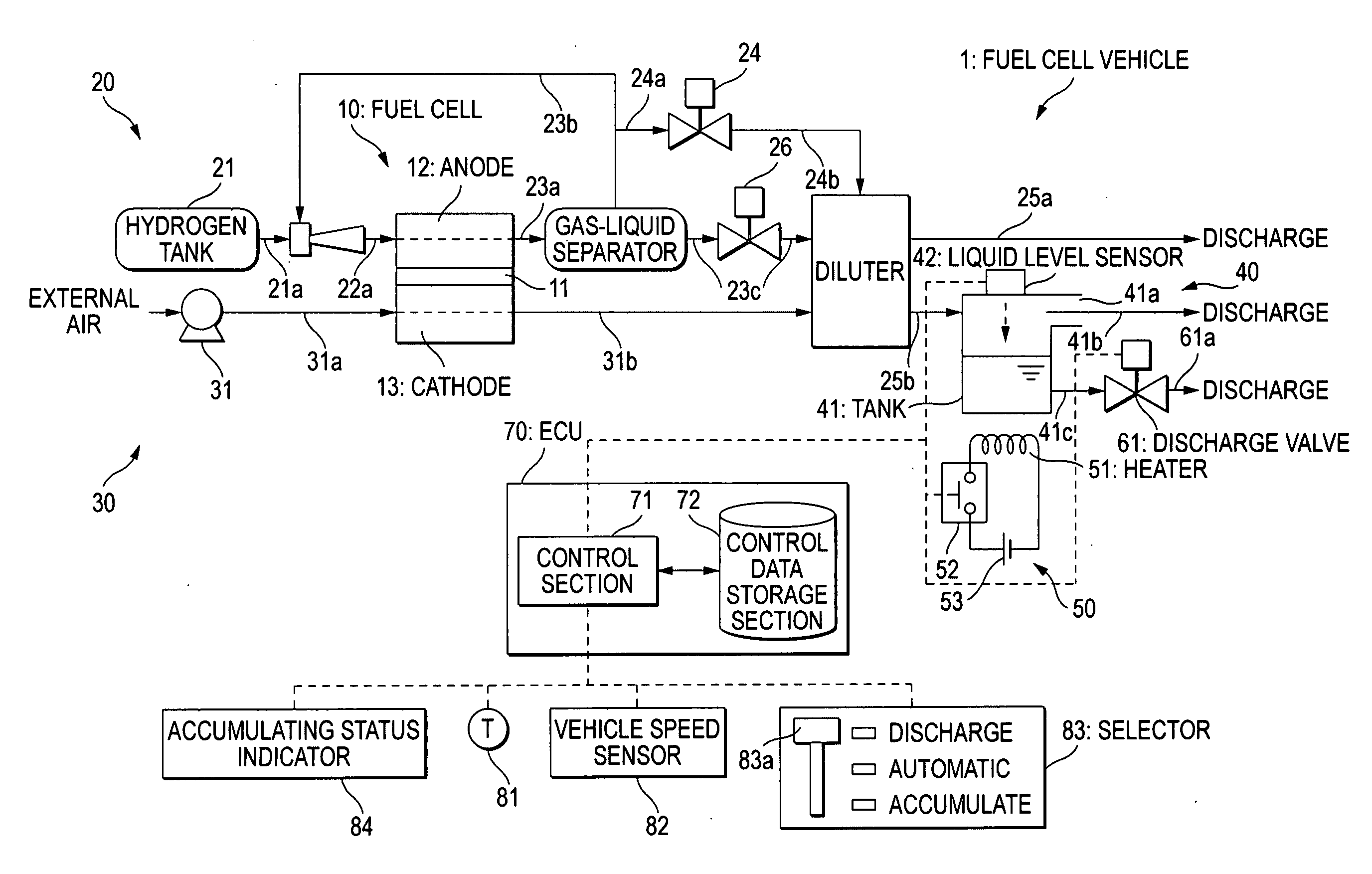

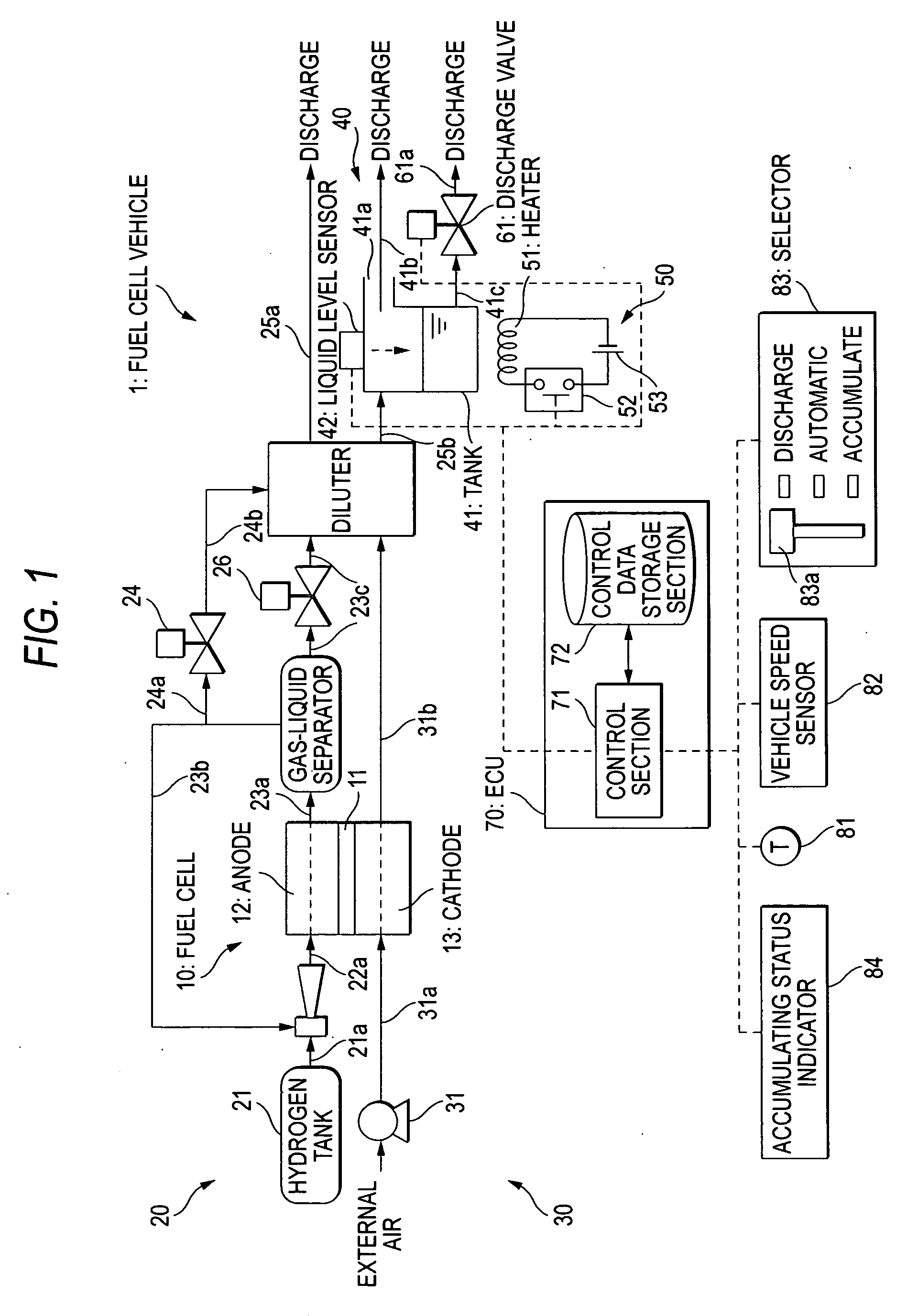

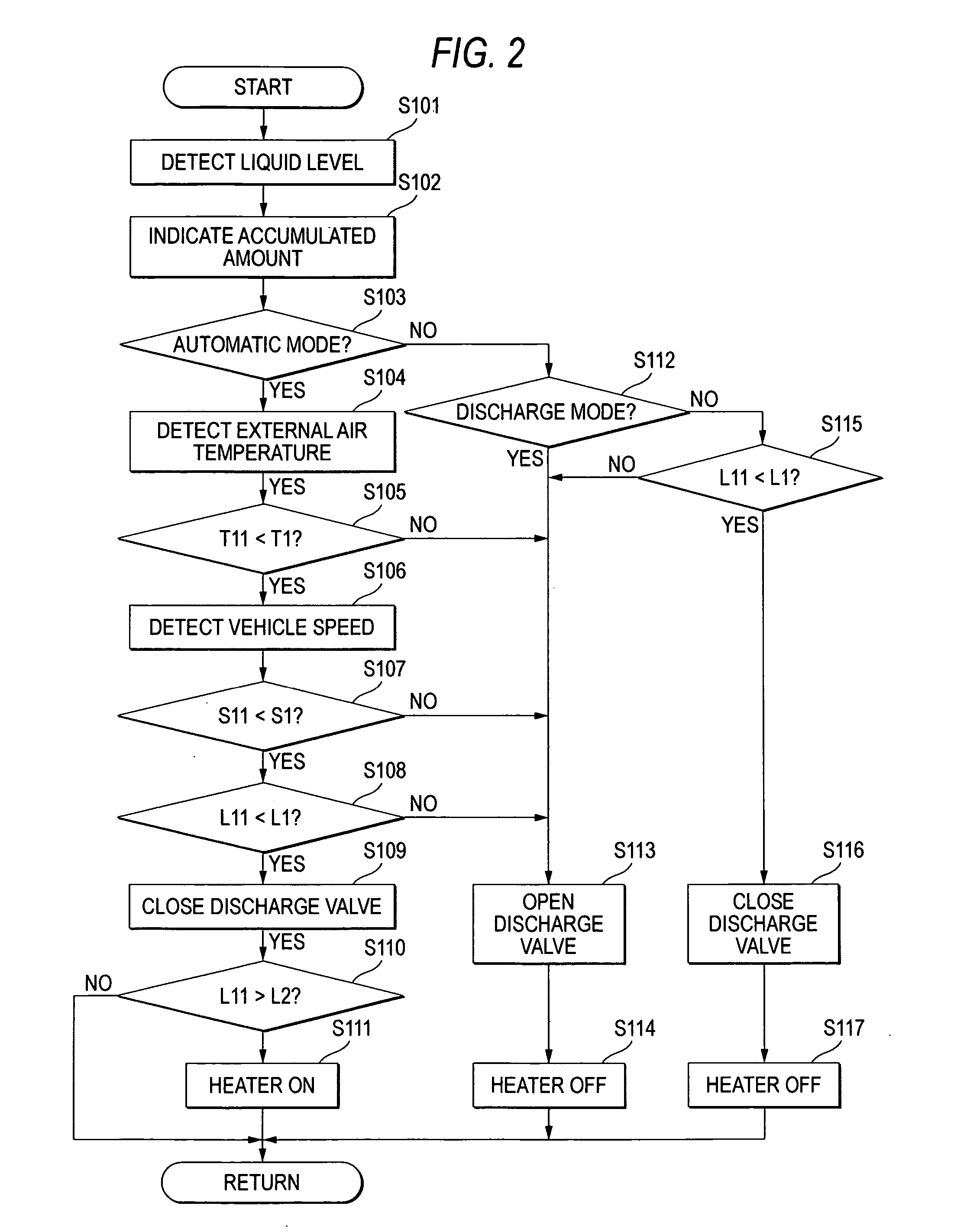

Fuel cell vehicle and water discharging method for fuel cell vehicle

InactiveUS20060240299A1Avoid dischargeWater management in fuel cellsTransportation fuel cell technologyFuel cellsDriver/operator

Owner:HONDA MOTOR CO LTD

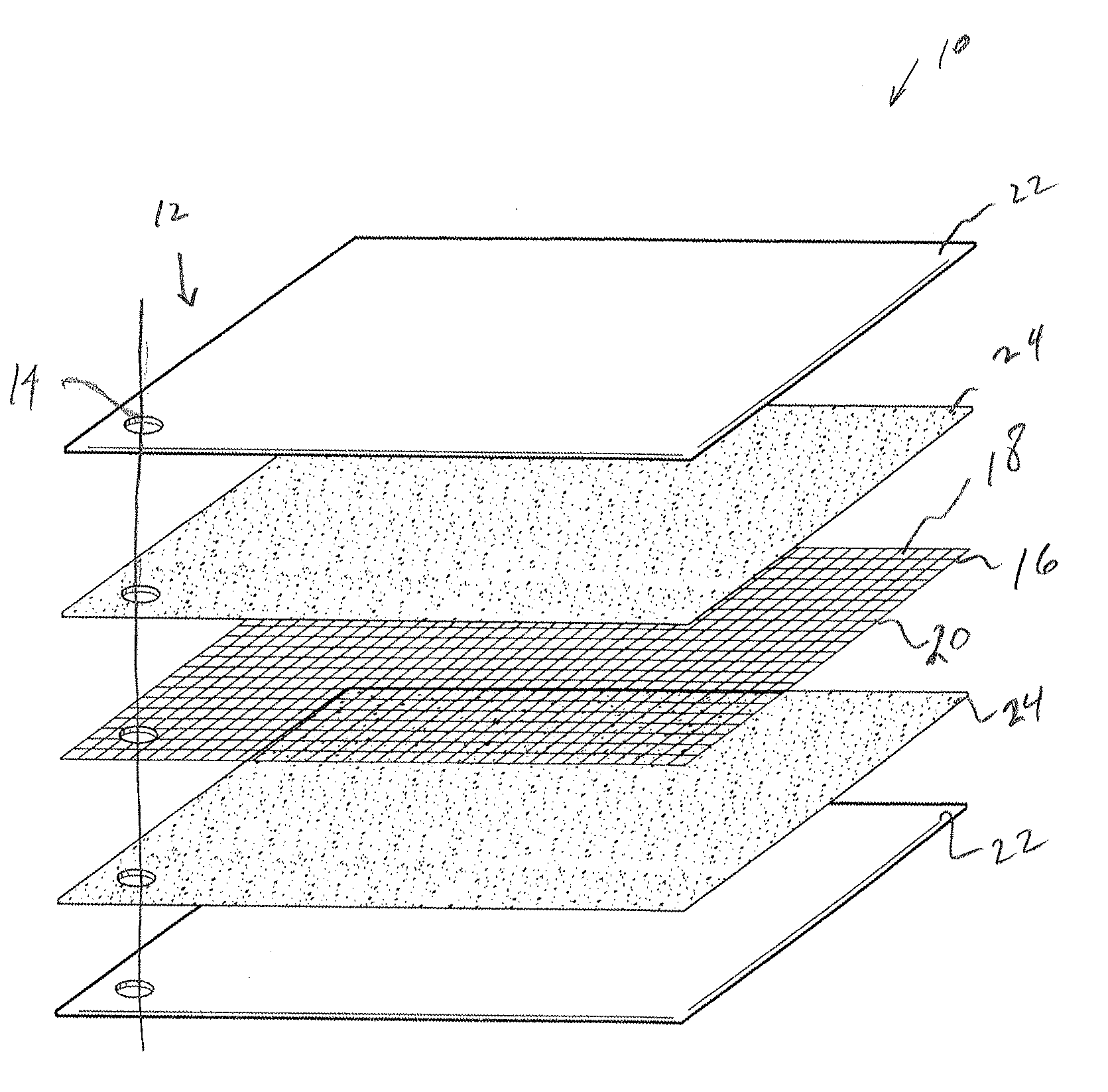

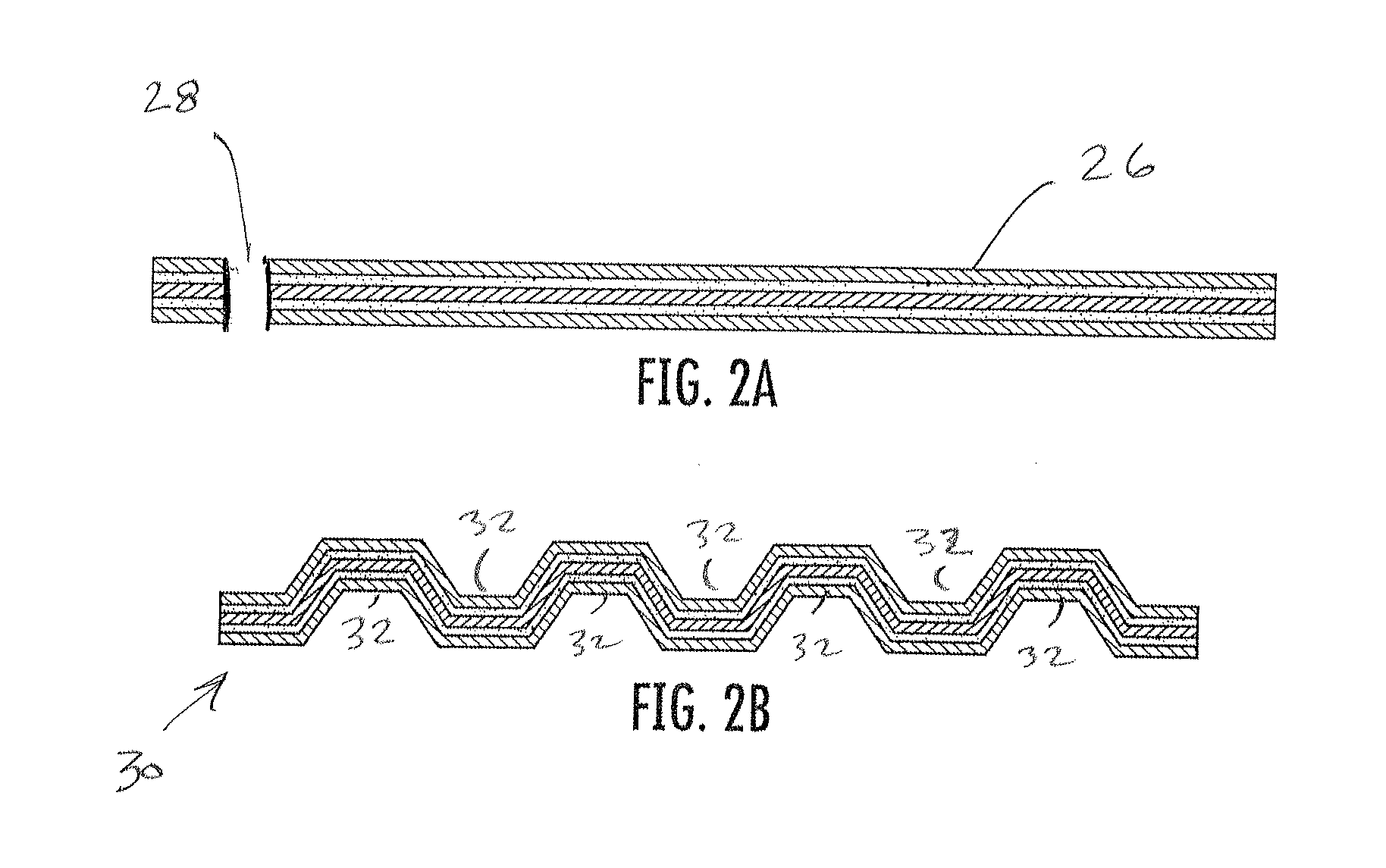

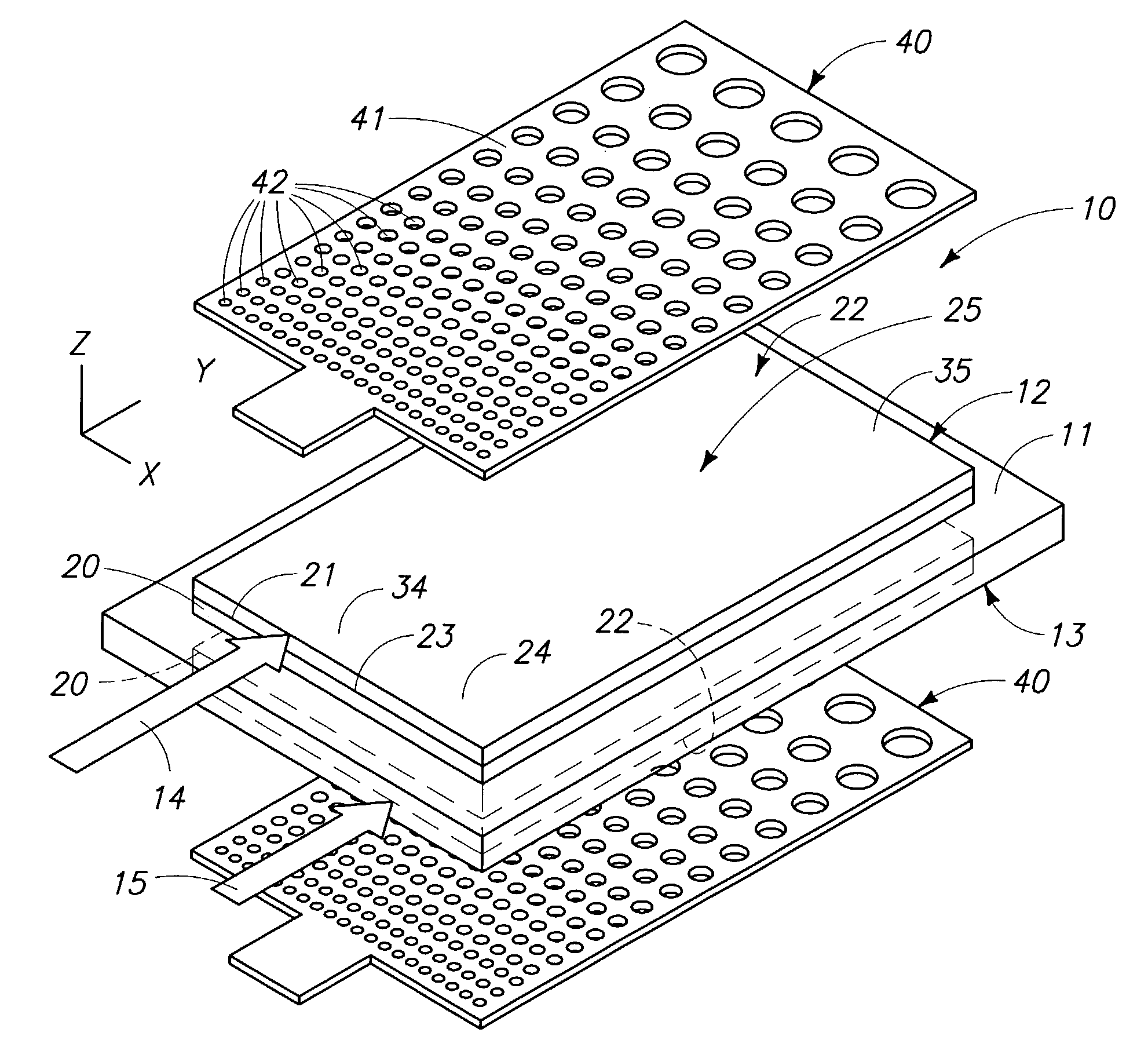

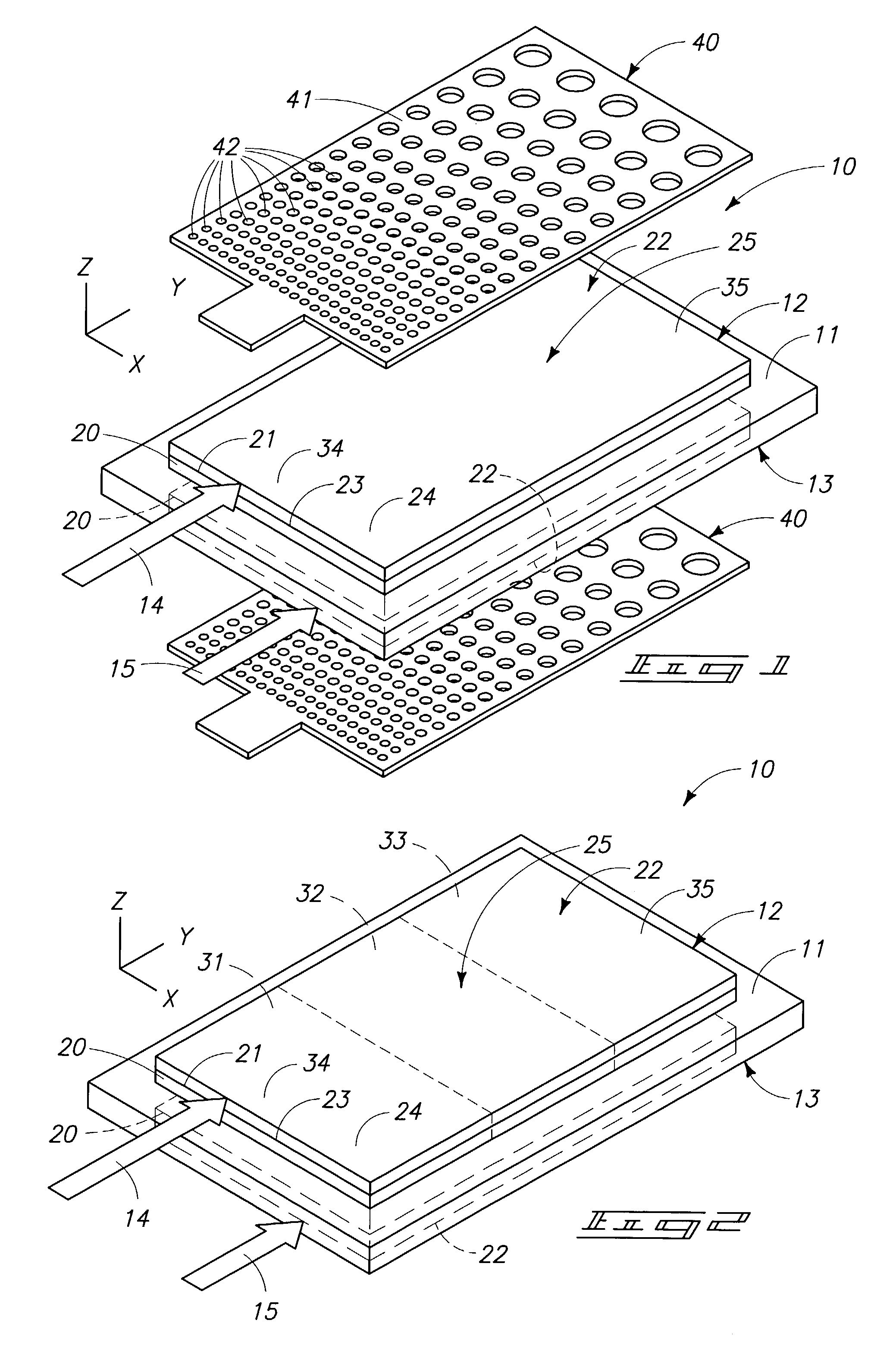

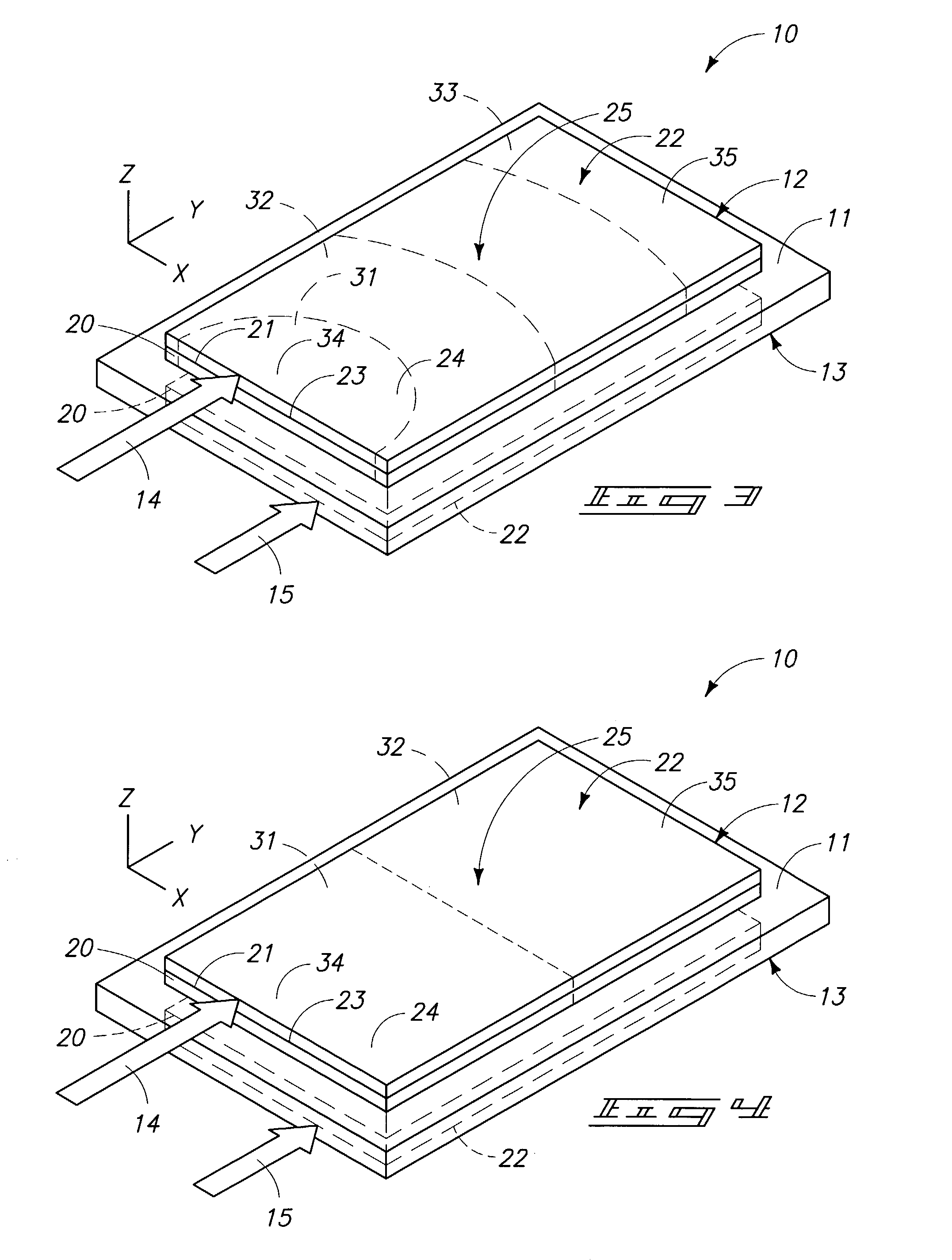

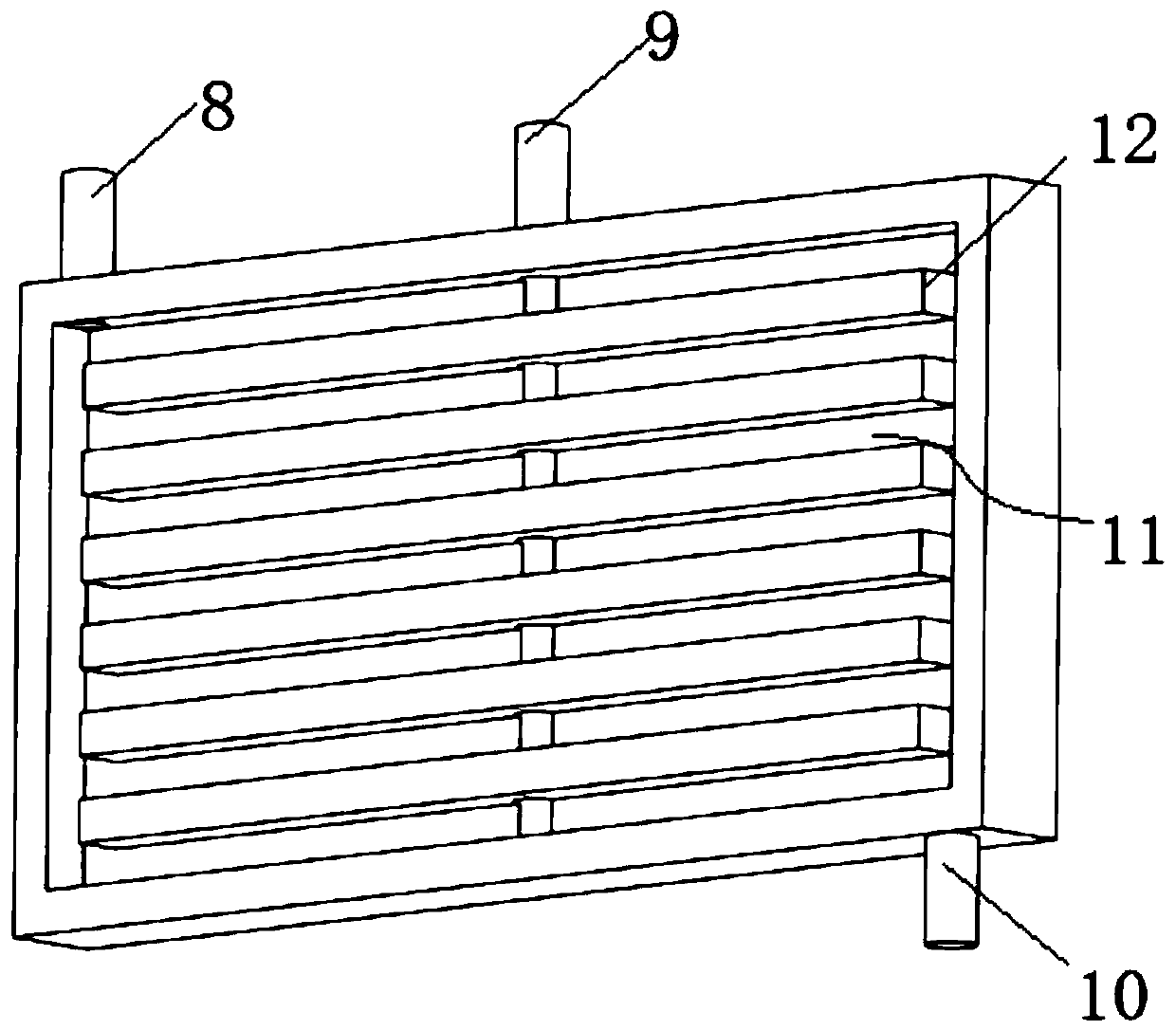

Current collector for use in a fuel cell

ActiveUS7056608B2Improve cooling effectHeat energyElectrode carriers/collectorsFuel cell auxillariesFuel cellsIon-exchange membranes

Owner:EMERGENT POWER

Capacitive liquid level detector for direct methanol fuel cell systems

InactiveUS20080282795A1Improve accuracyHigh precision measurementReactant parameters controlMachines/enginesFuel cellsDielectric layer

Owner:SAMSUNG SDI CO LTD

Hydrogen on demand electrolysis fuel cell system

InactiveUS20140262819A1Improve fuel economyEmission reductionCellsPhotography auxillary processesElectrolysisHydrogen

A hydrogen and oxygen (HHO) gas on-demand electrolysis fuel cell system for use with internal combustion engines is disclosed. This hydrogen on-demand (HOD) system integrates with the engine control module (ECM) or other control system that regulates the operation of an internal combustion engine in order to supply HHO to the engine and improve the engine's overall fuel efficiency. This system includes an electrolyte fluid reservoir outfitted with level, pressure and temperature sensors; a pump and heat exchanger; a uniquely-configured electrolyzer; and a filter. The combined engine and HOD system is controlled and regulated by an electronic control system (ECS) and a combustion control module (CCM). The CCM is installed on the engine such that it actively intercepts the electronic signals from the engine manufacturer's ECM to continuously coordinate the functions and operations of the HOD system and the engine.

Owner:NRG LOGISTICS

Catalyst slurry for fuel cell coating and preparation method thereof

Owner:先进储能材料国家工程研究中心有限责任公司

Fuel cell automobile air supply system based on organic Rankine cycle and control method thereof

ActiveCN109980251AIncrease net output powerReduce parasitic lossFuel cell heat exchangeReactant parameters controlAxial compressorPlate heat exchanger

The invention discloses a fuel cell automobile air supply system based on an organic Rankine cycle. The system comprises a boosting circuit and a waste heat utilization circuit, wherein the boosting circuit comprises a fuel cell stack, a turbine, a first compressor, a second compressor, a first intercooler, an air compressor, a heat exchanger and a second intercooler, which are sequentially connected; the waste heat utilization circuit comprises an organic working fluid pump, a heat exchanger and an expander connected in sequence; the first compressor is connected to the outside air, the expander is connected to the second compressor for driving the second compressor to operate; when the waste heat utilization circuit is opened, the waste heat of the air compressor flows into the heat exchanger to heat the organic working medium and drive the expander to compress the second compressor; when the waste heat utilization circuit is closed, the second compressor does not operate, and the boosting circuit is a low-pressure boosting circuit. The invention also provides a control method for a fuel cell automobile air supply system based on an organic Rankine cycle.

Owner:JILIN UNIV

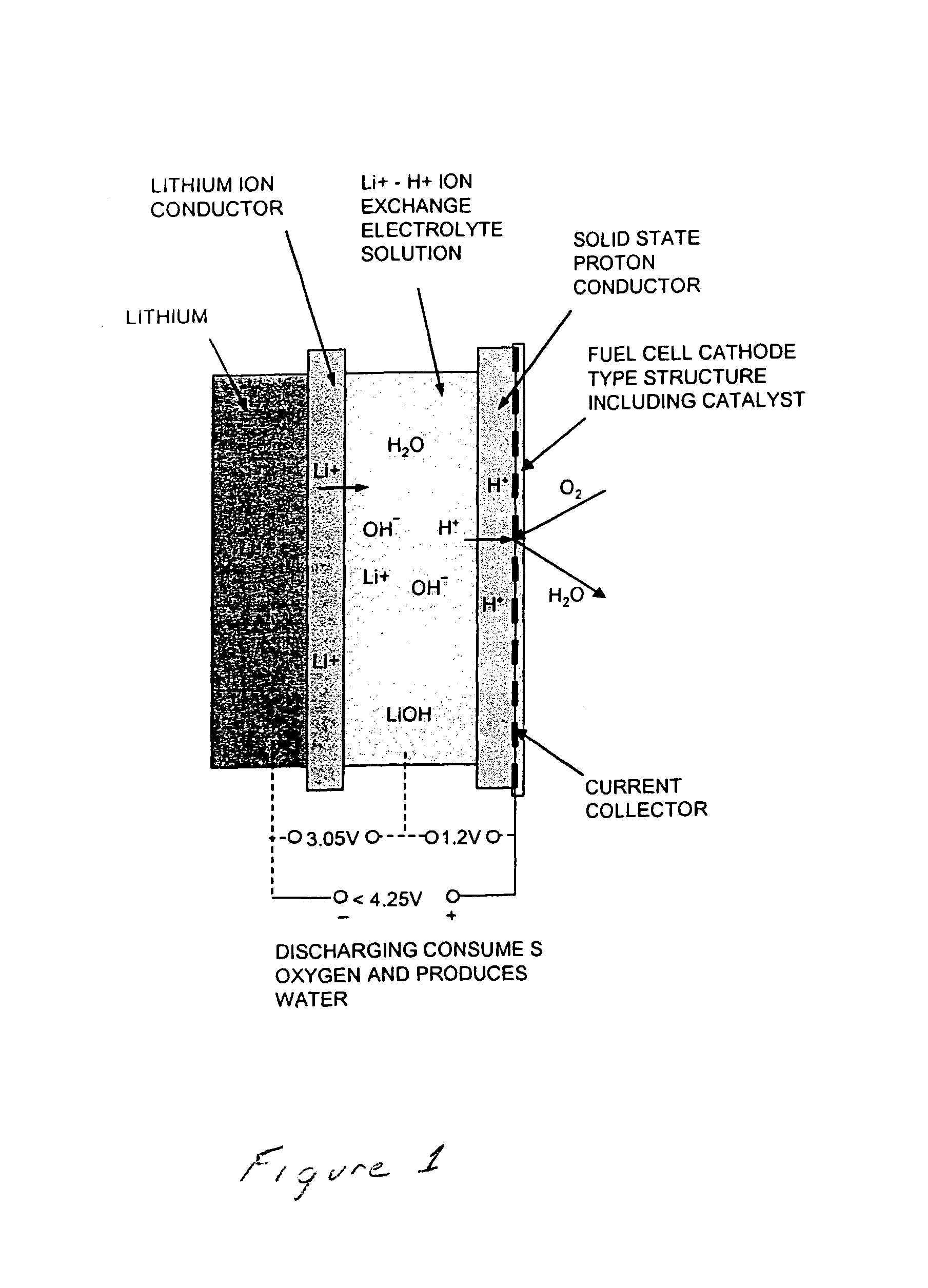

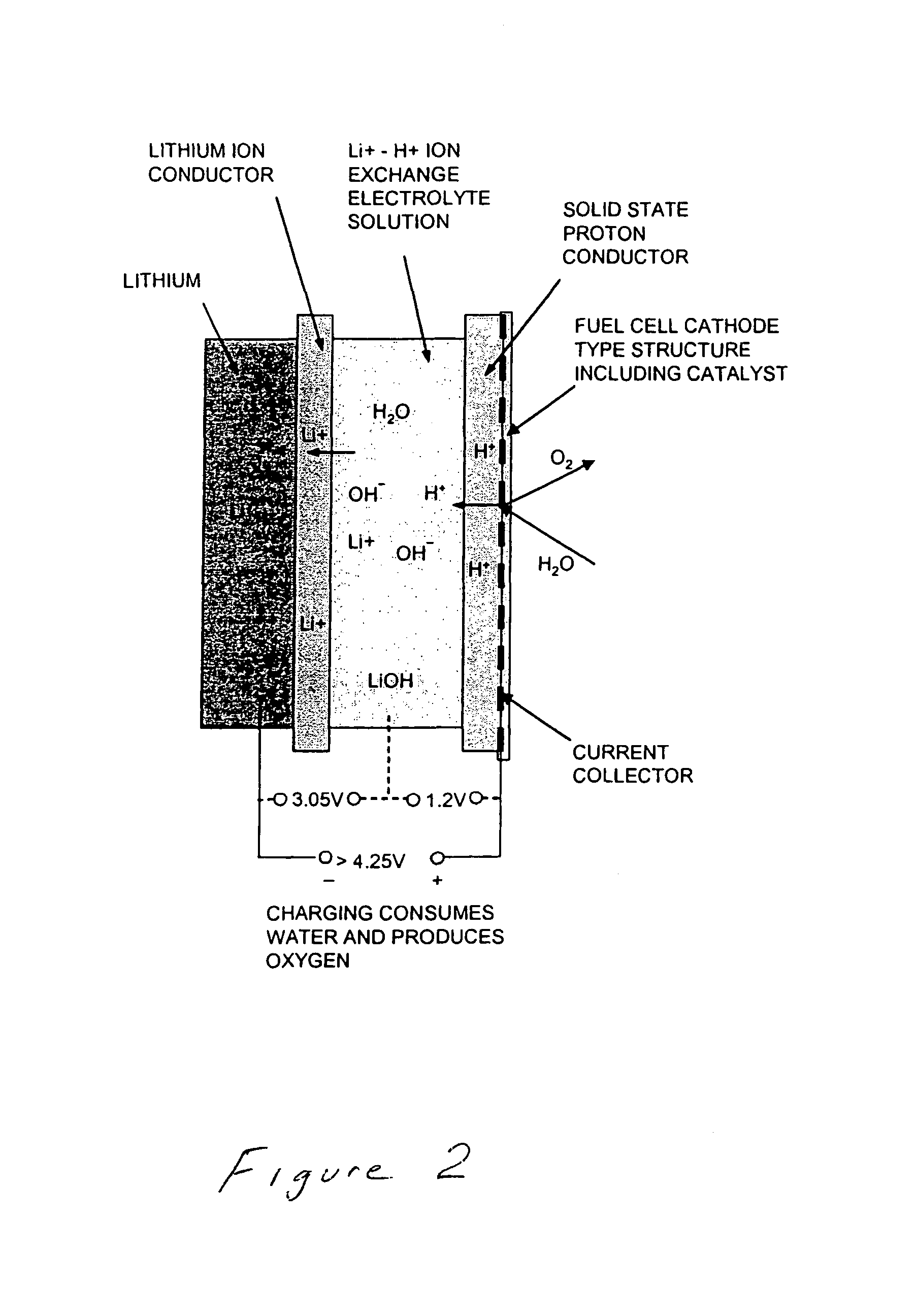

Regenerative ion exchange fuel cell

Owner:EXCELLATRON SOLID STATE

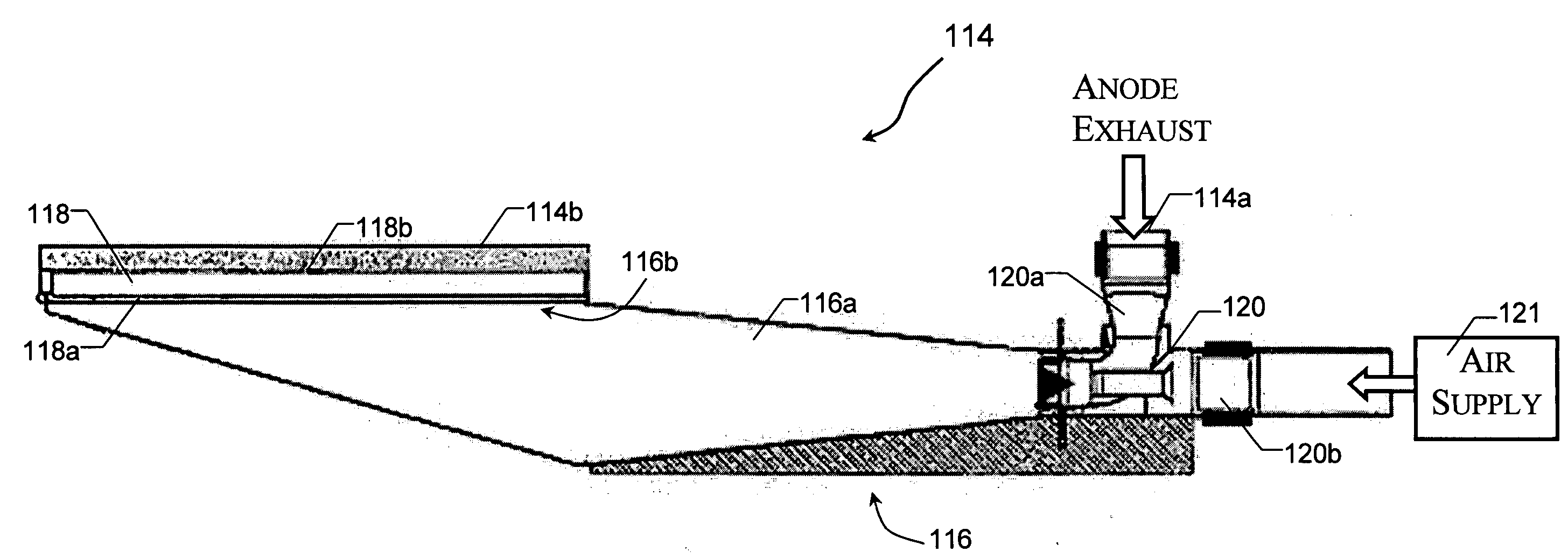

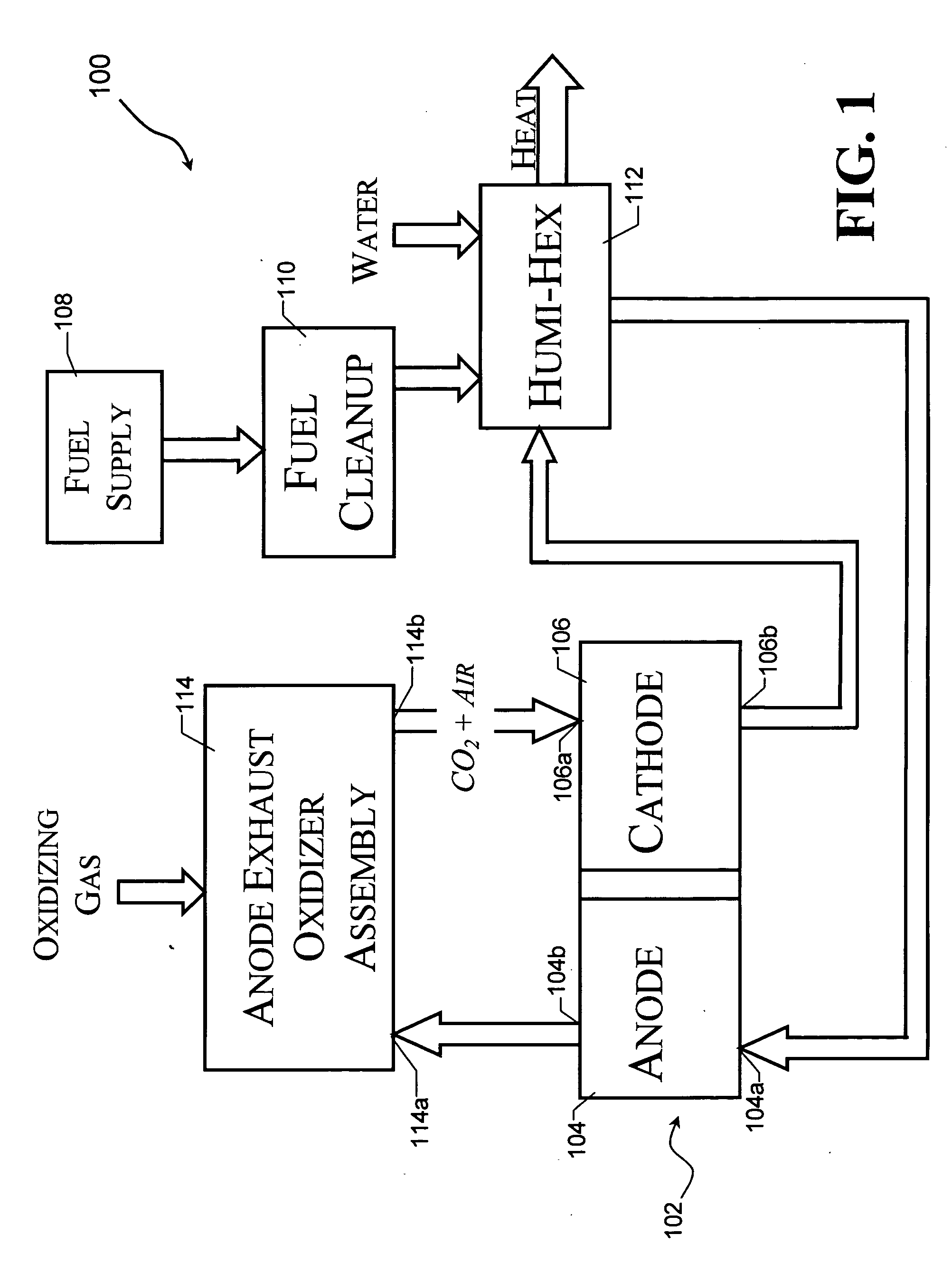

In-situ removal of electrolyte from gas oxidizer

Owner:FUELCELL ENERGY INC

Direct oxidation fuel cells with improved cathode gas diffusion media for low air stoichiometry operation

InactiveUS20080176112A1Promote oxidationSimple methodNanotechFuel cell auxillariesFuel cellsEngineering

A cathode for use in a direct oxidation fuel cell (DOFC) comprises a gas diffusion medium (GDM) including a backing layer and a microporous layer comprising a fluoropolymer and an electrically conductive material, wherein loading of the fluoropolymer in the microporous layer is in the range from about 10 to about 60 wt. %. In use, a concentrated solution of a liquid fuel is supplied to an anode and an oxidant to the cathode of the fuel cell, and the fuel cell may be operated at a low oxidant stoichiometry ξc not greater than about 2.5.

Owner:PANASONIC CORP +1

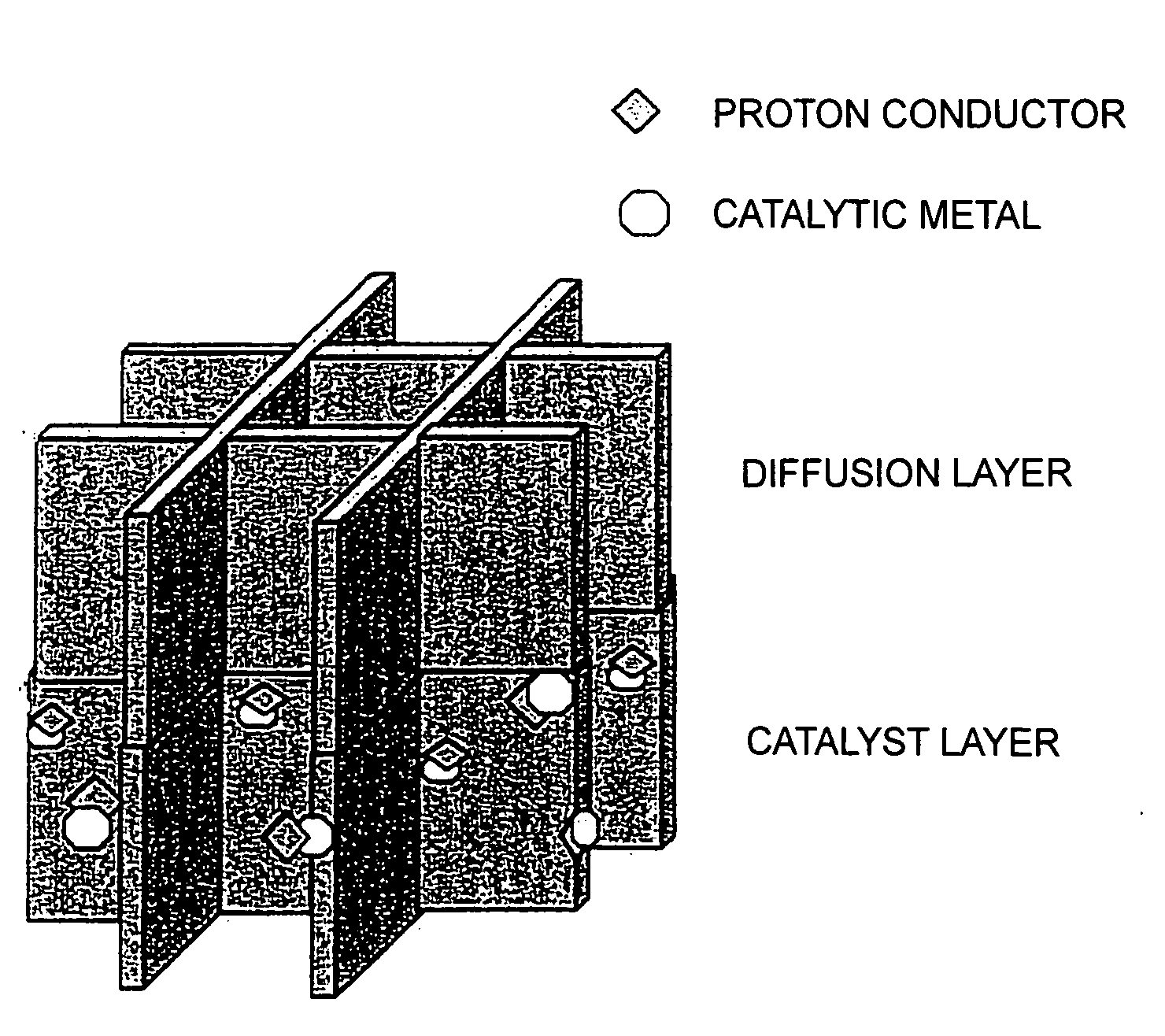

Class of electrocatalysts and a gas diffusion electrode based thereon for fuel cells

InactiveUS6878664B1Organic-compounds/hydrides/coordination-complexes catalystsActive material electrodesFuel cellsConductive polymer

An electrocatalyst based on a highly electroconducting polymer and a transition metal, in which transition metal atoms are covalently bonded to heteroatoms of the backbone monomers of the polymer. The covalently bonded transition metal atoms are nucleation sites for catalytically active transition metal particles. The complex is prepared by complexing a highly electroconducting polymer with transition metal coordination ions and then reducing the transition metal ions to neutral atoms. An electrode for a fuel cell is made by impregnating an electrically conducting sheet with the catalytic complex and drying the impregnated sheet. The scope of the present invention includes such electrodes and the fuel cells that incorporate these electrodes.

Owner:MEDIS EL

Preparation method of paper-graphite-CoPd thin film electrode

InactiveCN103904337AImprove electroreduction performanceSolve the problem of poor cathode activityCell electrodesElectricityThin film electrode

Owner:HARBIN ENG UNIV

Fuel Cell System

InactiveUS20080008913A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesElectricityExhaust valve

The disclosure describes fuel cell systems including a fuel cell stack that generates electricity, an exhaust valve that externally vents a fuel gas from a fuel chamber of the fuel cell stack, and a controller that computes an estimated time to replace an oxidant gas in at least the fuel chamber with a newly supplied fuel gas, wherein at a time of starting-up the fuel cell system the controller maintains the exhaust valve in an open position for the estimated time. In some embodiments, the controller computes the estimated time as a summation of a first time T1 measured from the fuel cell start-up time to a time when contents of a supply conduit are replaced with fuel gas, a second time T2 measured from the when contents of a supply conduit are replaced with fuel gas to a time when contents of the fuel chamber are replaced with fuel gas, and a third time T3 measured from time when contents of the fuel chamber are replaced with fuel gas to a time when contents of the exhaust conduit are replaced with fuel gas. The disclosure further describes methods of operating a fuel cell system, particularly during fuel cell start-up.

Owner:NISSAN MOTOR CO LTD

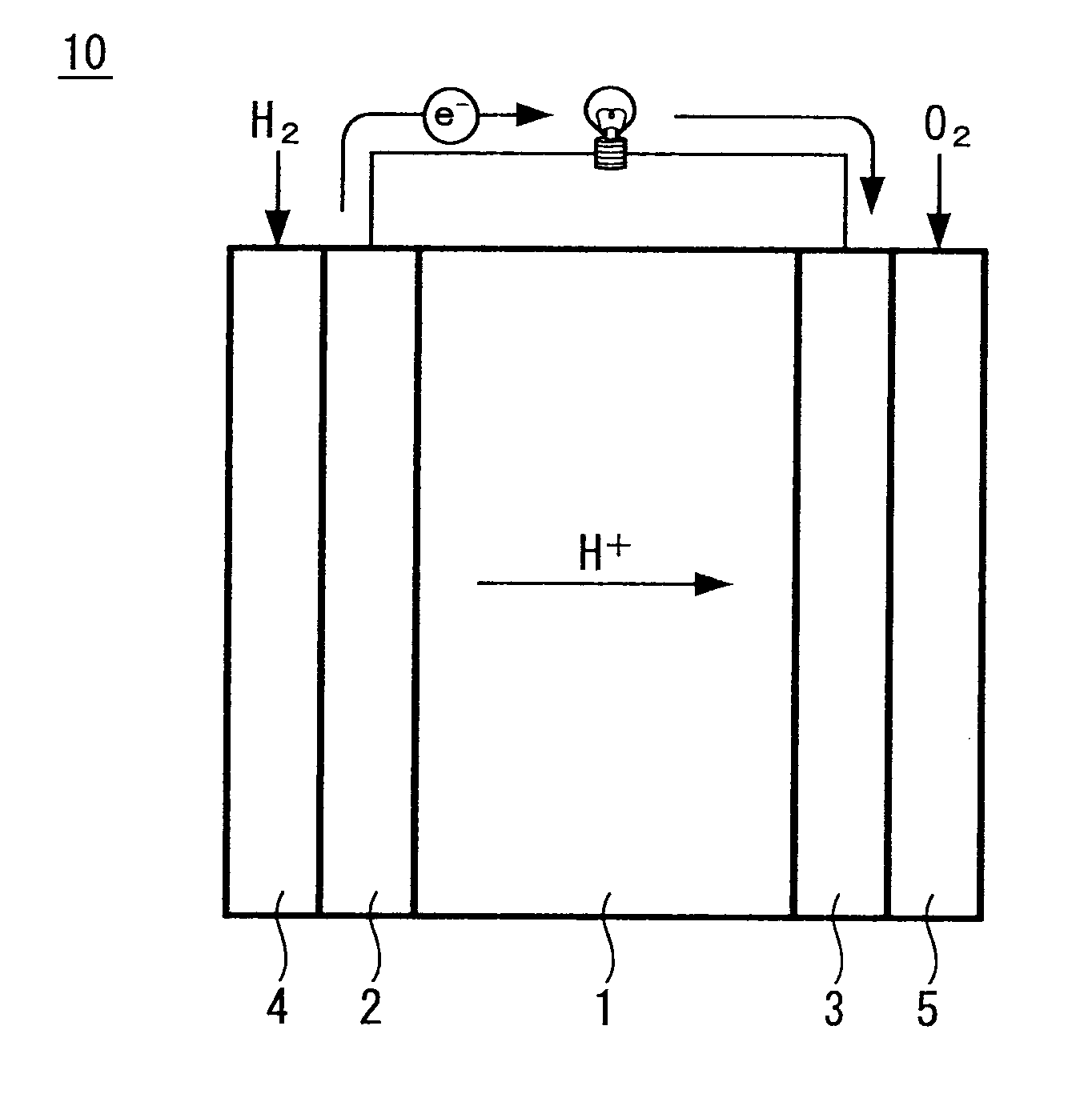

Fuel cell

InactiveUS20120009498A1Complex structureLow costFuel cells groupingCell component detailsCross-linkFuel cells

A fuel cell is provided with a separator that supports an electrolyte / electrode assembly sandwiched therebetween. The separator is provided with: first and second fuel gas supply parts in the center of which fuel gas supply holes are formed; first and second cross-link parts connected to the first and second fuel gas supply parts; and first and second surrounding support parts connected to the first and second cross-link parts. Each first surrounding support part is provided with a set of fuel gas exhaust passages that discharge fuel gas that has gone through a fuel gas passage and been used. The cross-sectional areas of the fuel gas exhaust passages are larger on the downstream sides than on the upstream sides, in terms of the direction of fuel gas flow.

Owner:HONDA MOTOR CO LTD

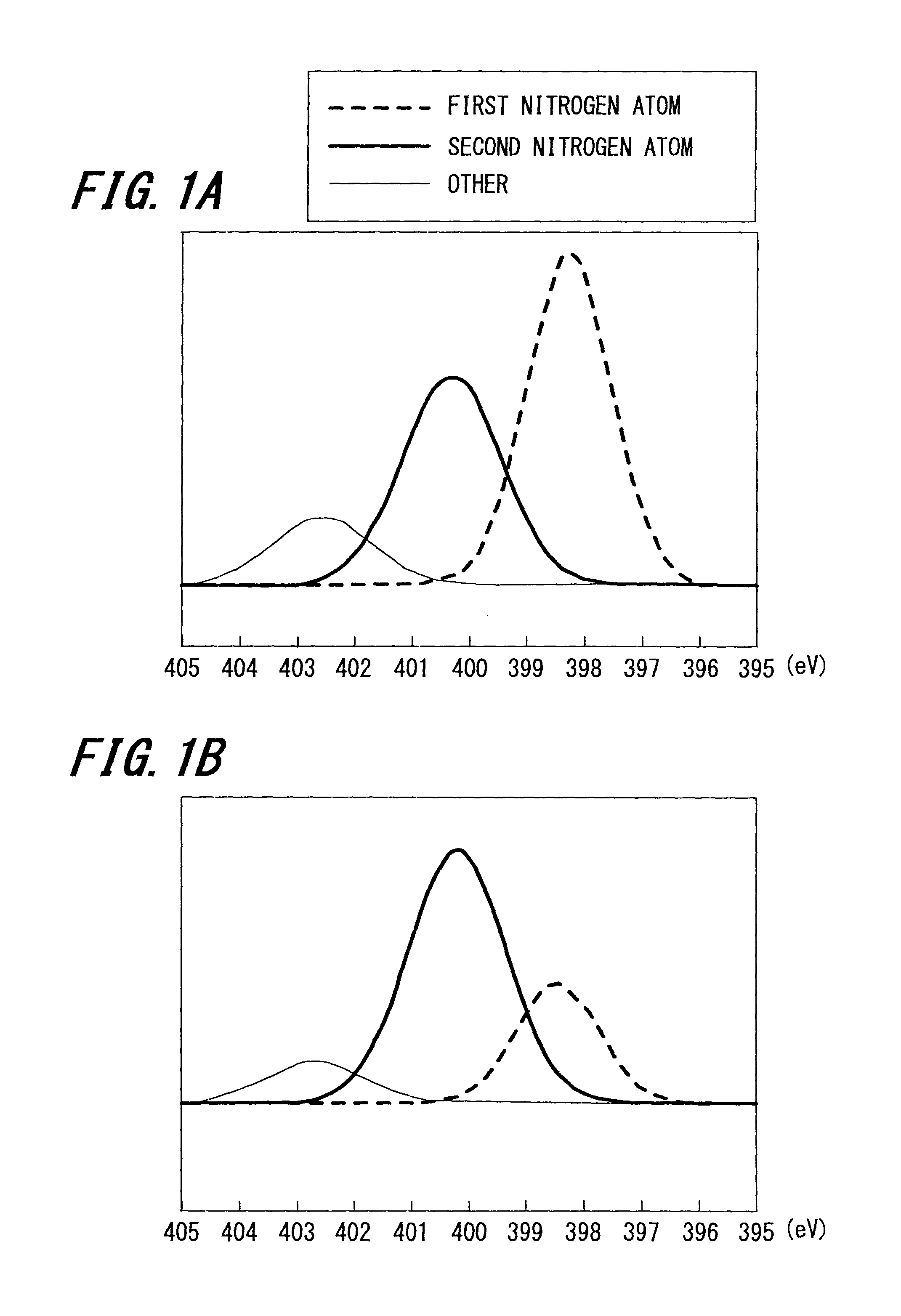

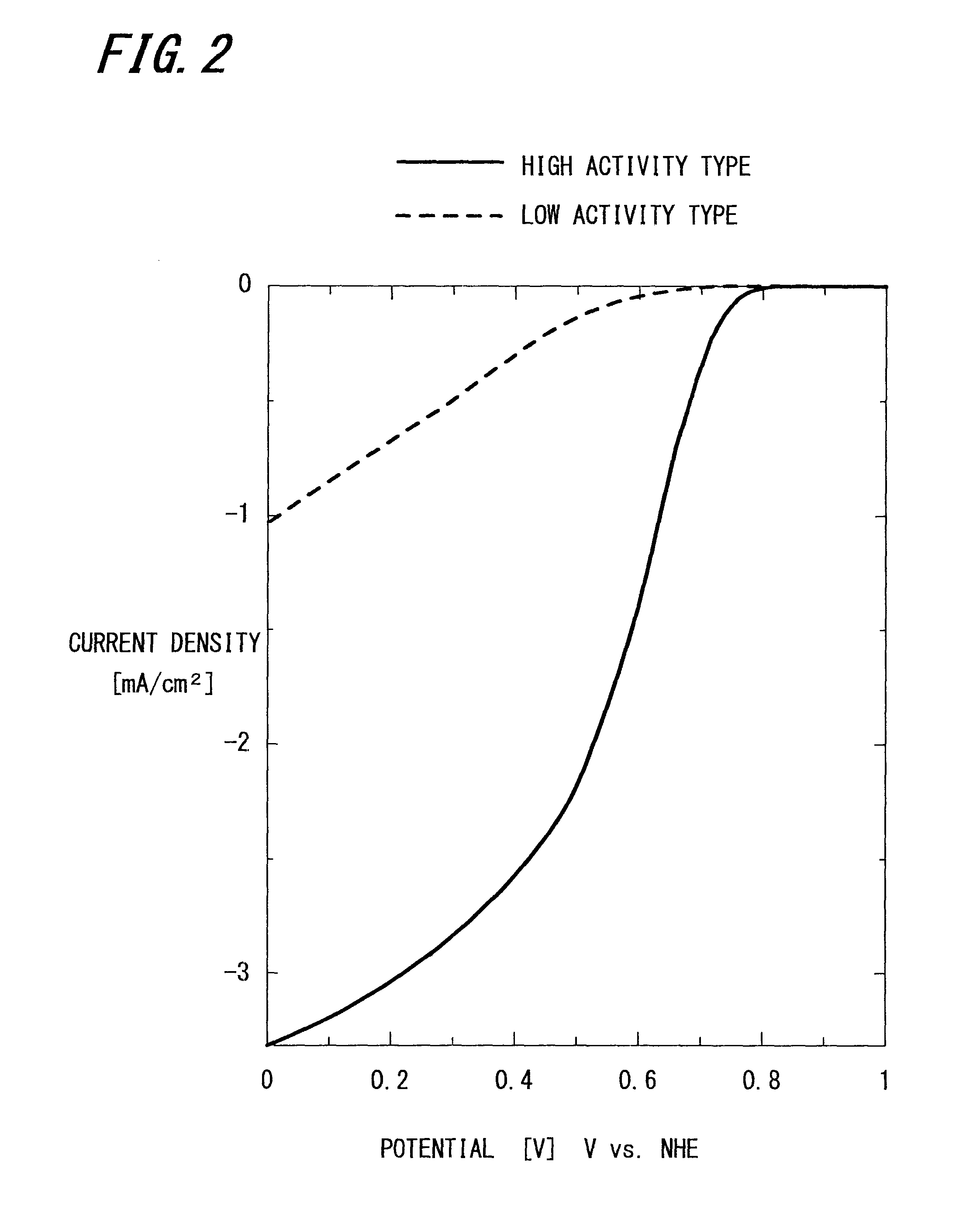

Carbon catalyst, method for producing carbon catalyst, fuel cell, electricity storage device, and use of carbon catalyst

ActiveUS20130288888A1High activitySpeed up chemical reactionsCell electrodesHybrid capacitor electrodesElectricityBinding energy

Owner:ROWANWOOD IP

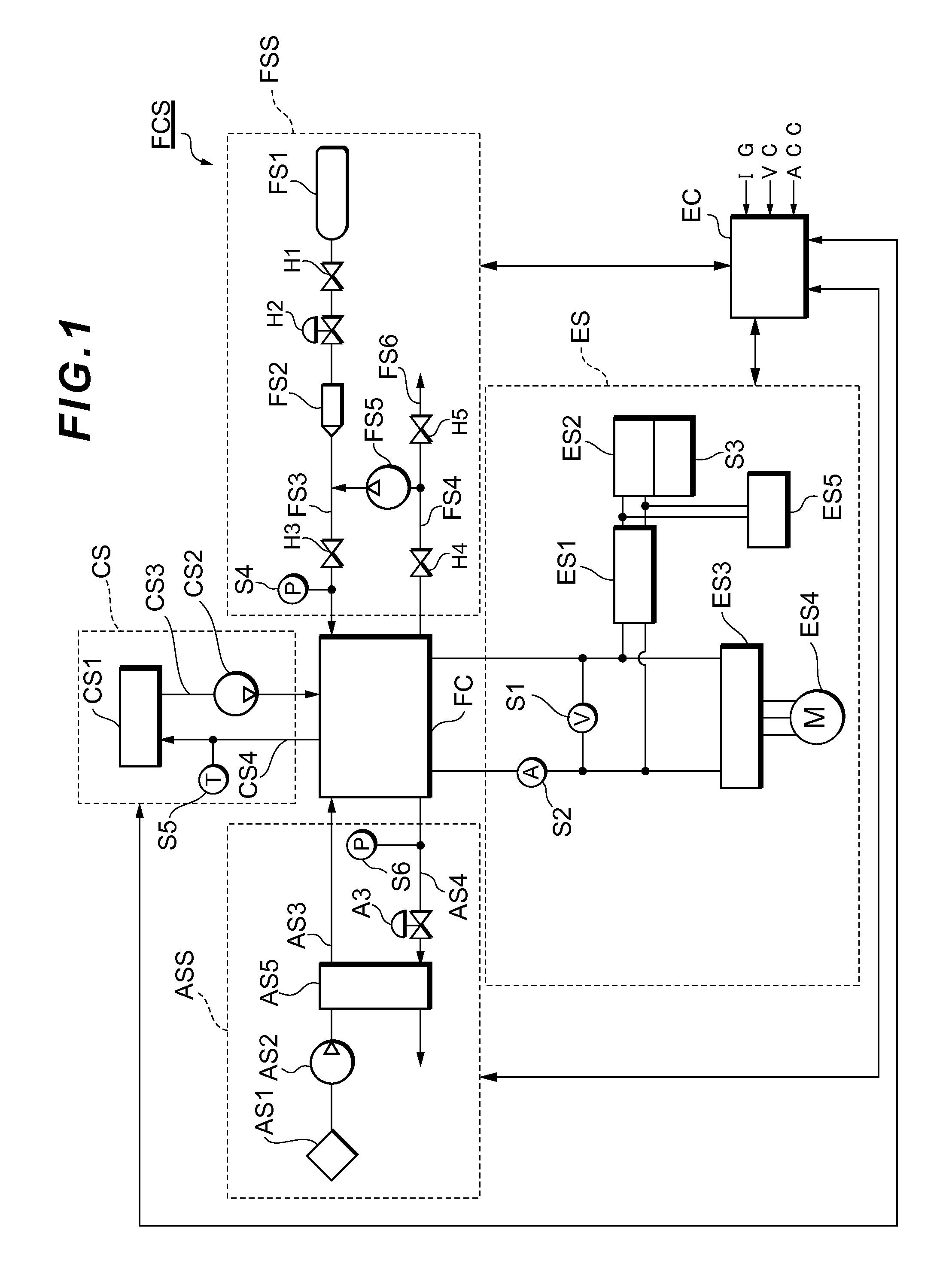

Fuel cell system

ActiveUS8092947B1Find exactlyFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsCurrent voltage

Owner:TOYOTA JIDOSHA KK

Double-screw compression and expansion all-in-one machine for fuel cell

ActiveCN112746958ASolve the problem of low recycling powerReduce speedRotary piston pumpsRotary piston liquid enginesFuel cellsElectric machine

The invention discloses a double-screw compression and expansion all-in-one machine for a fuel cell. According to the all-in-one machine, high-pressure orifices are formed in positions close to the middle of a machine body, and low-pressure orifices are formed in the two ends of the machine body; a female rotor of a compressor and a male rotor of an expander are coaxially connected and fixed, a male rotor of the compressor and a female rotor of the expander are also connected through a rotor shaft, the male rotor of the compressor is fixed to the rotor shaft, and the female rotor of the expander and the rotor shaft are in clearance fit and slide mutually; and the low-pressure side of the expander is connected with a motor. According to the all-in-one machine, the number of bearings is reduced, the size, weight and cost are lowered, the rotating speed of the expander is effectively lowered by the rotor gear ratio, and flow matching of the compressor and the expander is realized; and meanwhile, the load of the bearings is effectively lowered through the stress balance effect of the compressor rotors and the expander rotors, the power loss of the bearings is reduced, and the problem that the recovery work is little when the expander is at a low load is solved.

Owner:XI AN JIAOTONG UNIV

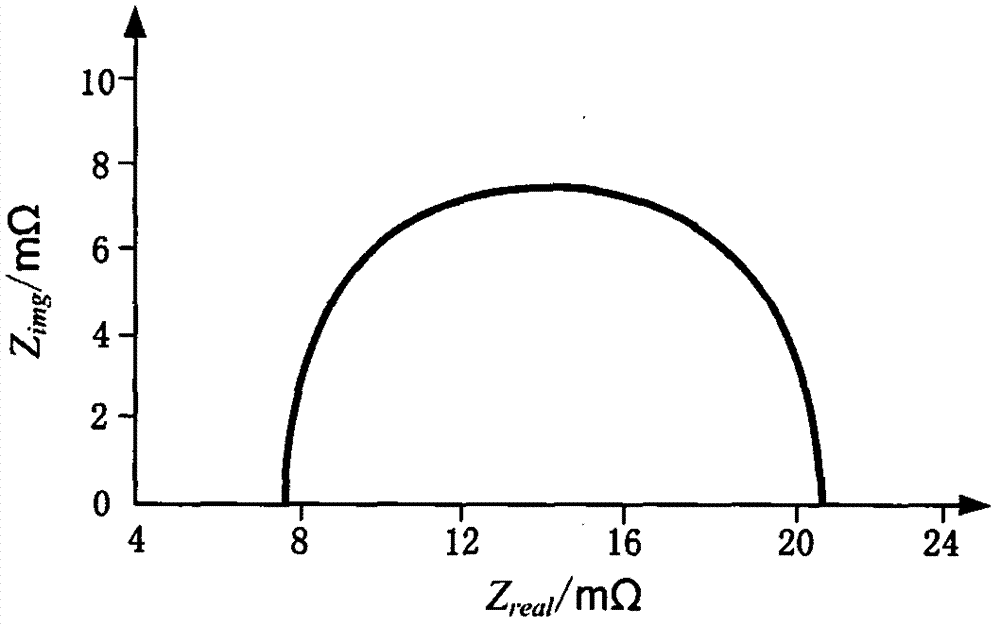

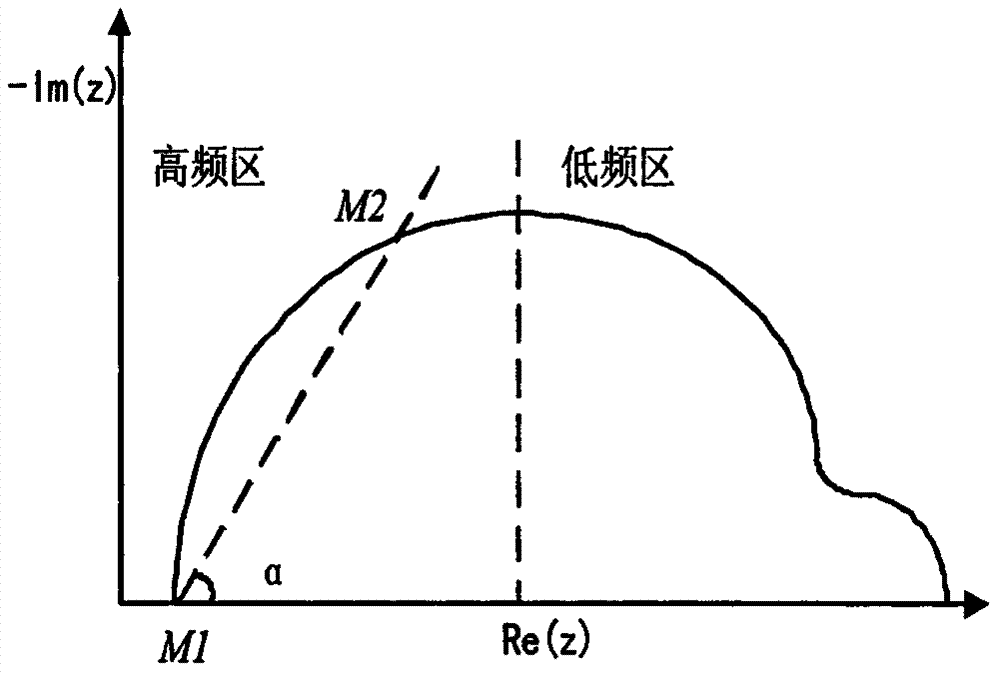

Method for optimizing PEMFC output performance based on frequency secant angle method

InactiveCN107391817AImprove output performanceOvercoming the large hysteresisElectrical testingDesign optimisation/simulationHysteresisInternal resistance

Owner:CHINA JILIANG UNIV

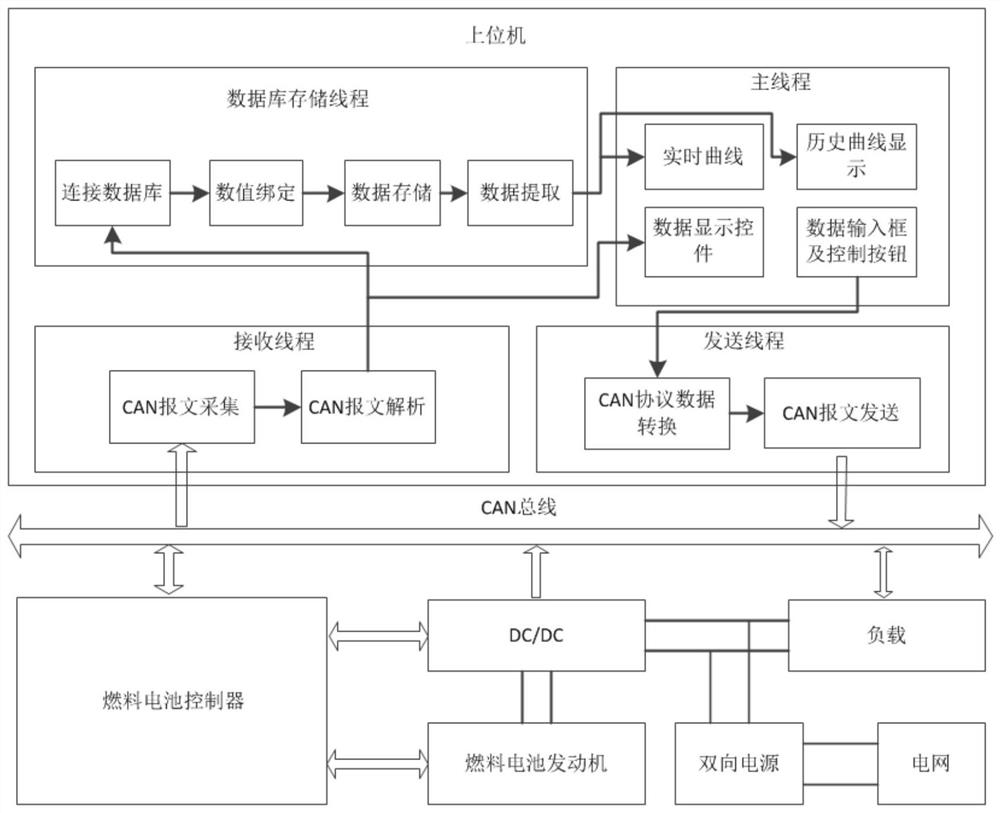

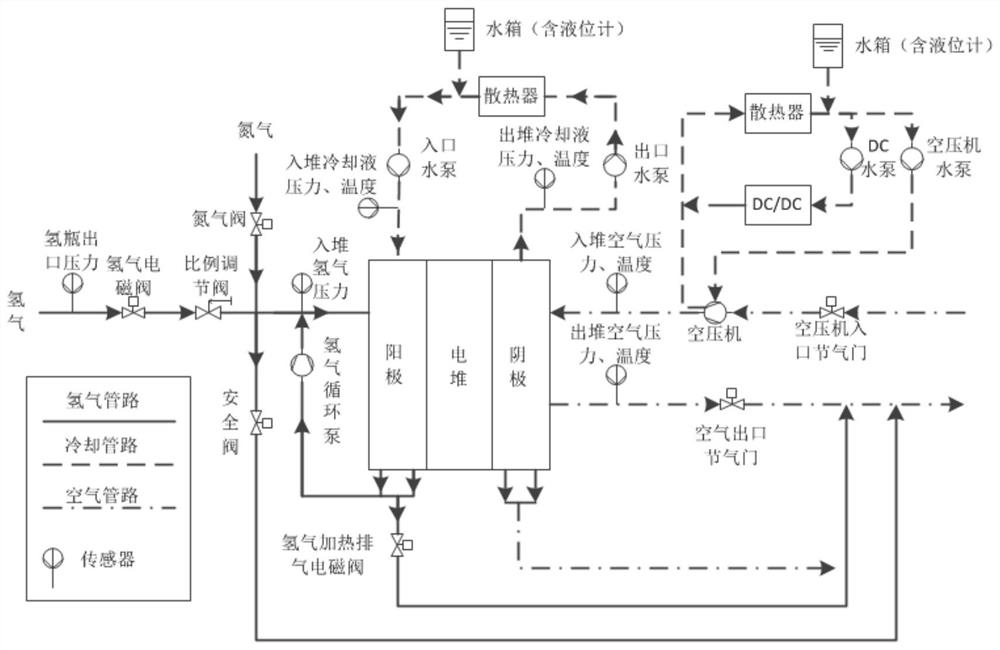

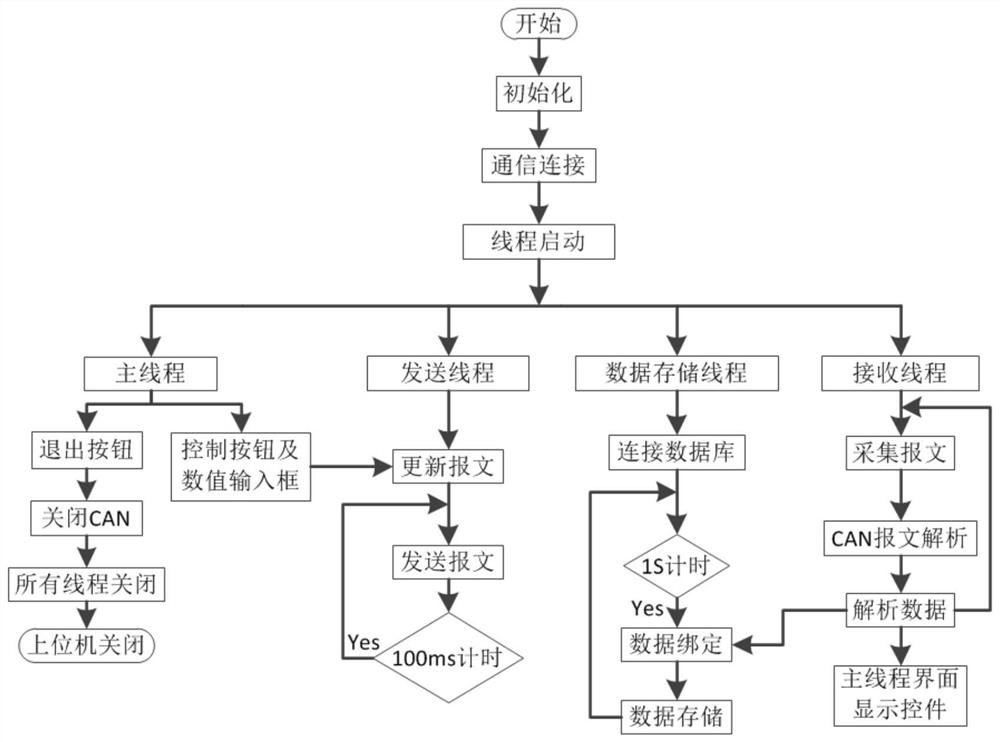

Fuel cell power system platform upper computer monitoring method based on CAN bus

ActiveCN111628197AGood conditionFacilitate energy control strategy debuggingFuel cell controlAutomatic controlComputer monitoring

Owner:瀚锐氢能科技集团有限公司

Power supply device of vacuum pipeline train and vacuum pipeline train

PendingCN111231670AImprove energy conversion efficiencyNo pollution in the processRailway heating/coolingRailway tunnelsFuel cellsElectric power equipment

The invention discloses a power supply device of a vacuum pipeline train and the vacuum pipeline train. The power supply device comprises a hydrogen-oxygen fuel cell which comprises an electrolyte layer, and a first electrode and a second electrode which are respectively arranged on two sides of the electrolyte layer, the first electrode and the second electrode are respectively connected to two ends of a load and used for supplying power to the load of the vacuum pipeline train; a first interface is formed in the outer wall, close to the first electrode, of the hydrogen-oxygen fuel cell, thefirst interface is used for allowing oxygen to flow in, a second interface is formed in the outer wall, close to the second electrode, of the hydrogen-oxygen fuel cell, and the second interface is used for allowing hydrogen to flow in; and a third interface is used for discharging water in the hydrogen-oxygen fuel cell. According to the vacuum pipeline train, the hydrogen-oxygen fuel cell can be used for supplying power to power equipment of the vacuum pipeline train, the requirement for heat loads in the train can be met through the refrigerating capacity of liquid oxygen and liquid hydrogen,in addition, water produced through fuel reaction can be used in carriages, and the vacuum pipeline train has important significance in energy conservation and environmental protection.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Fuel cell with cathode flow channel flow distribution design and catalyst layer Pt content gradient distribution

PendingCN110661013AEvenly distributedSave Pt amountCell electrodesFinal product manufacturePtru catalystChemical physics

Owner:TIANJIN UNIV OF COMMERCE

Fuel Cell Structure and Method of Manufacturing Same

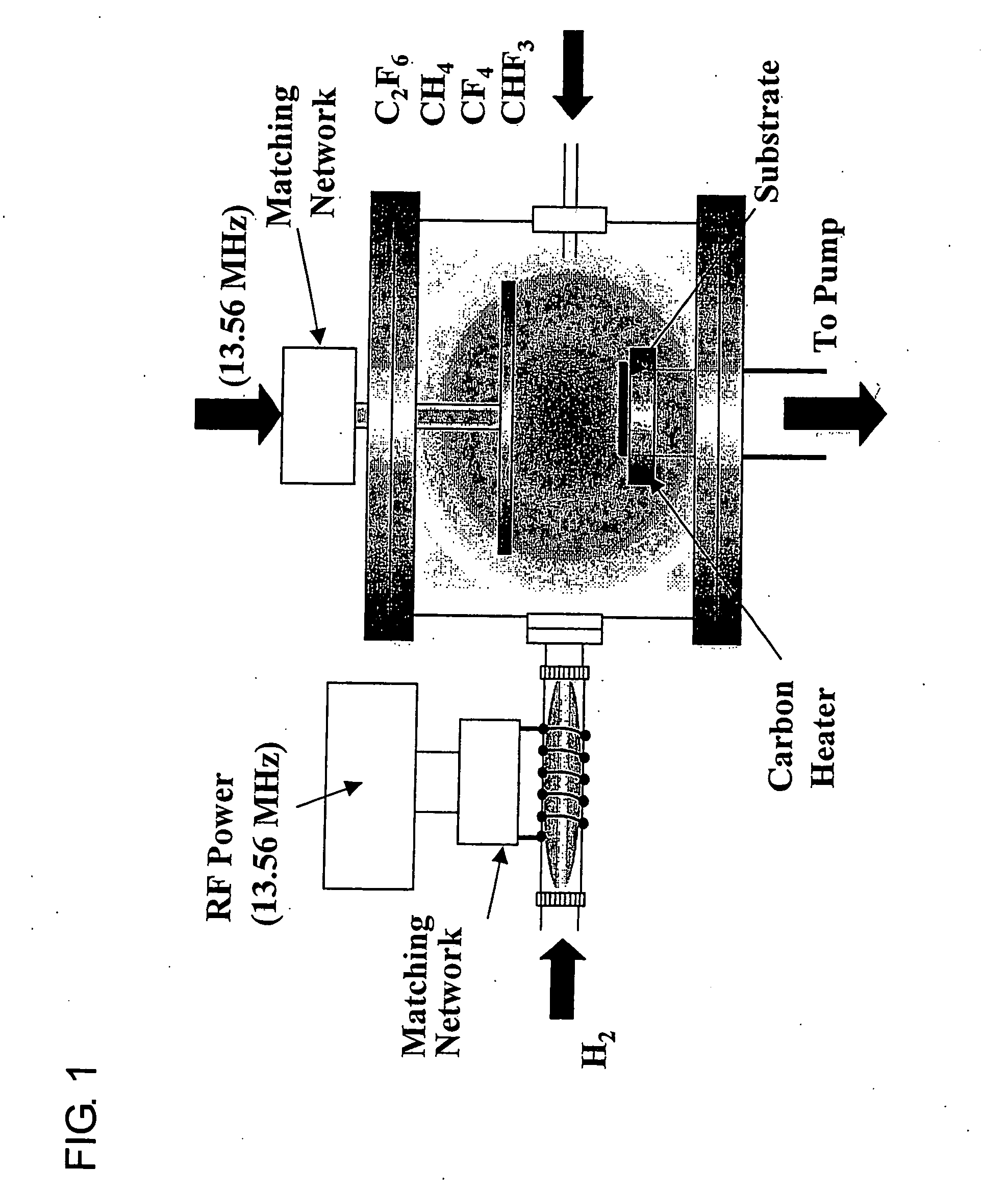

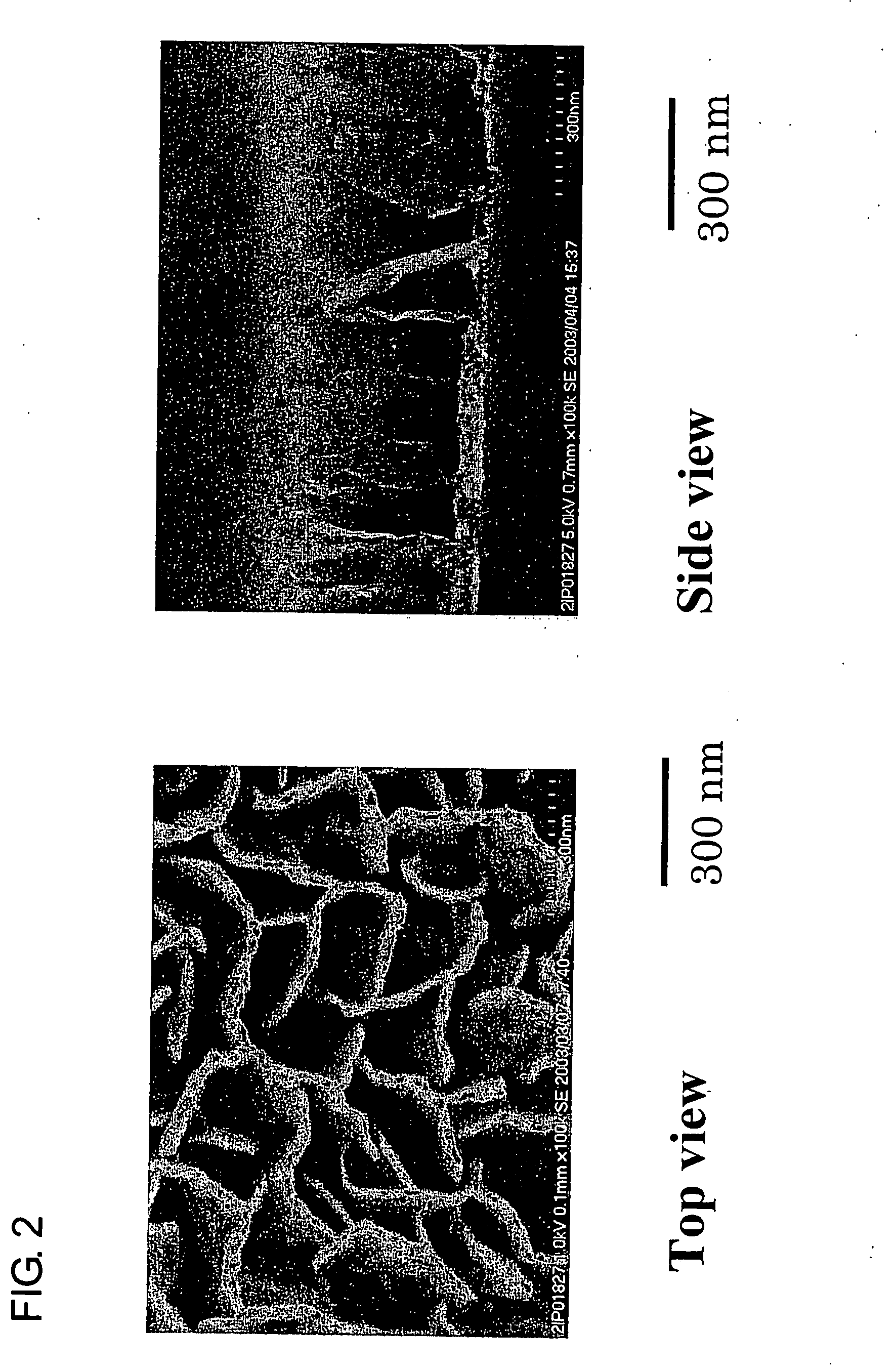

InactiveUS20080187814A1Simplified cell structureReduce manufacturing costFinal product manufactureElectrode carriers/collectorsCarbon nanowallsNano size

Owner:HORI MASARU +2

High-power high-integration-level fuel cell engine system assembly

InactiveCN110323479AImprove utilization efficiencyGuaranteed uptimePropulsion by batteries/cellsTrucksElectricityFuel cells

The invention discloses a high-power high-integration-level fuel cell engine system assembly; the high-power high-integration-level fuel cell engine system assembly comprises a supporting frame, a packaging box, an electric pile assembly, an air inlet assembly, a hydrogen gas inlet assembly and a water system assembly, wherein a lifting lug is arranged at the bottom of the supporting frame; the packaging box, the air inlet assembly, the hydrogen gas inlet assembly and the water system assembly are divided into a plurality of layers by the supporting frame; the packaging box is fixedly arrangedon the top layer of the supporting frame; the electric pile assembly is arranged in the packaging box, and a hole is formed in the side wall of the packaging box; and the air inlet assembly, the hydrogen gas inlet assembly and the water system assembly are positioned below the packing box and are fixedly arranged on the supporting frame and are connected with the electric pile assembly separately. By virtue of reasonable layout of external parts of the whole fuel cell engine system, reasonable design of structural member strength, reasonable distribution of multiple phases of flows of systemair, hydrogen gas, water, electricity and the like, and the reasonable layout of the external auxiliary parts of the engine system, the vehicle can stably and reliably run, and the utilization efficiency of the new energy is improved.

Owner:WUHAN HYDRAV FUEL CELL TECH CO LTD

Method of producing fuel cell separator, and fuel cell

InactiveUS20090098431A1Improve wettabilityStable electromotive forceFuel cells groupingRadiation applicationsPolymer scienceFuel cells

Owner:DAINIPPON INK & CHEM INC

Fuel cell system

ActiveUS20160129808A1Easy to operateAvoid flowFuel cell heat exchangeBattery/fuel cell control arrangementFuel cellsWater flow

A flow control valve 26 can adjust the percentage of the flow rate of cooling water to a radiator 23 to a predetermined value (50%) or smaller. When the temperature of the cooling water in a fuel cell 11 is determined to be a predetermined temperature (0° C.) or higher after the cooling water is supplied to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger, a controller 41 performs a predetermined percentage supply operation for controlling the flow control valve 26 and a pump 22 to supply the cooling water to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger.

Owner:TOYOTA JIDOSHA KK

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap