Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Gas pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Gas Pressure. When the molecules of a gas bounce off the walls of their container, they exert a force. Gas pressure is defined as the force per unit area produced by the gas. Depending on the purpose of the measurement, different units are commonly used. In the English system, the unit of pressure is pounds per square inch.

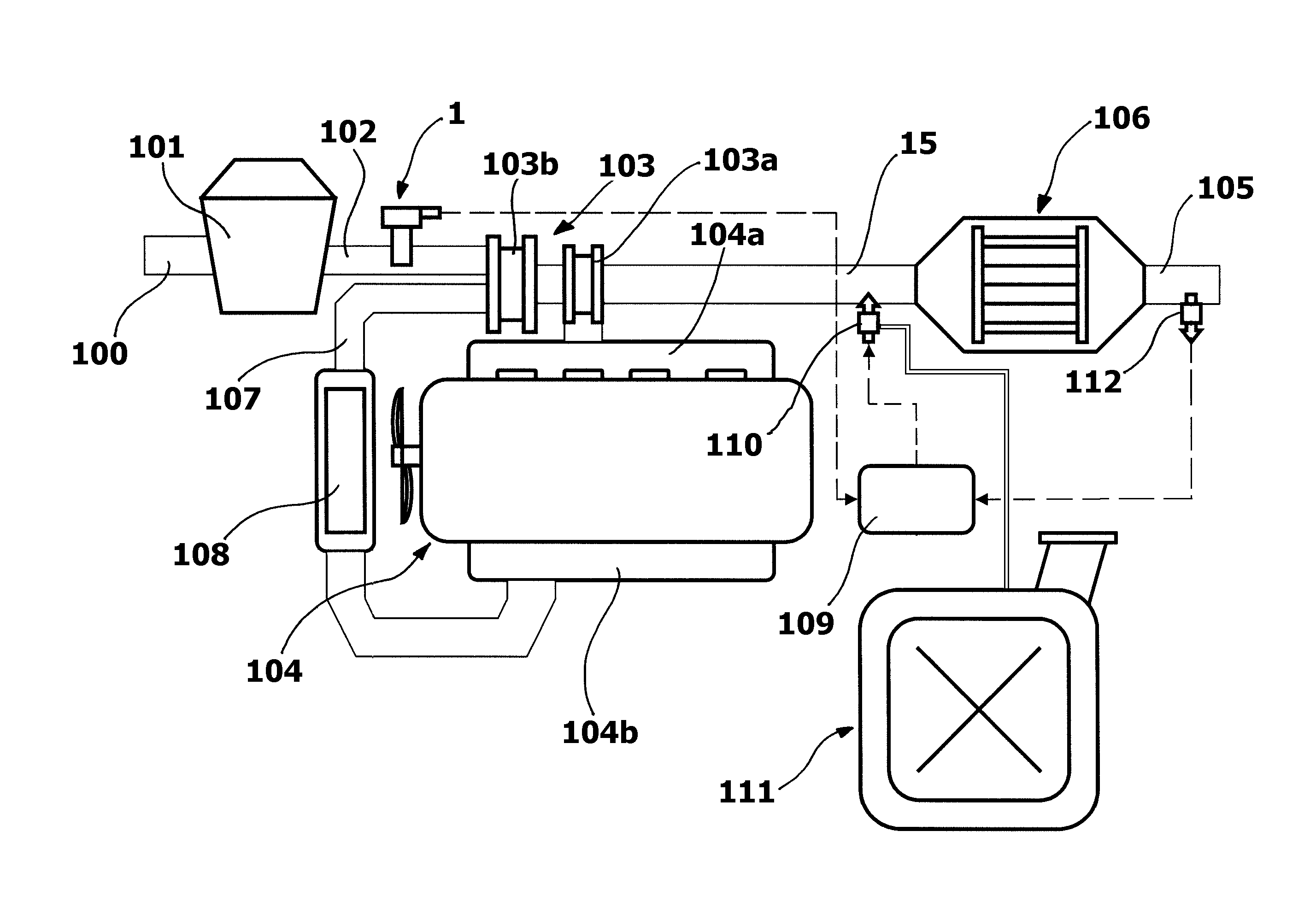

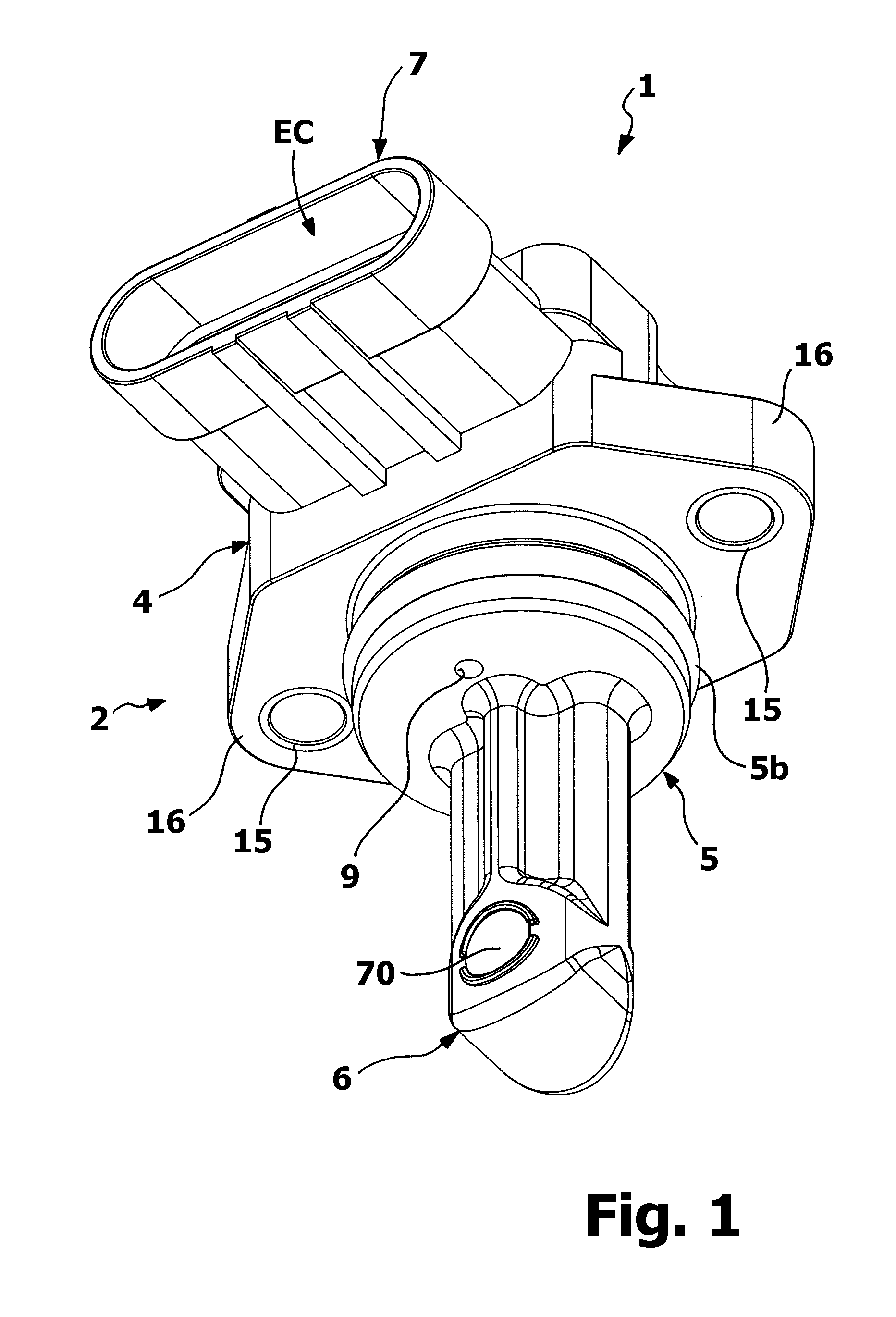

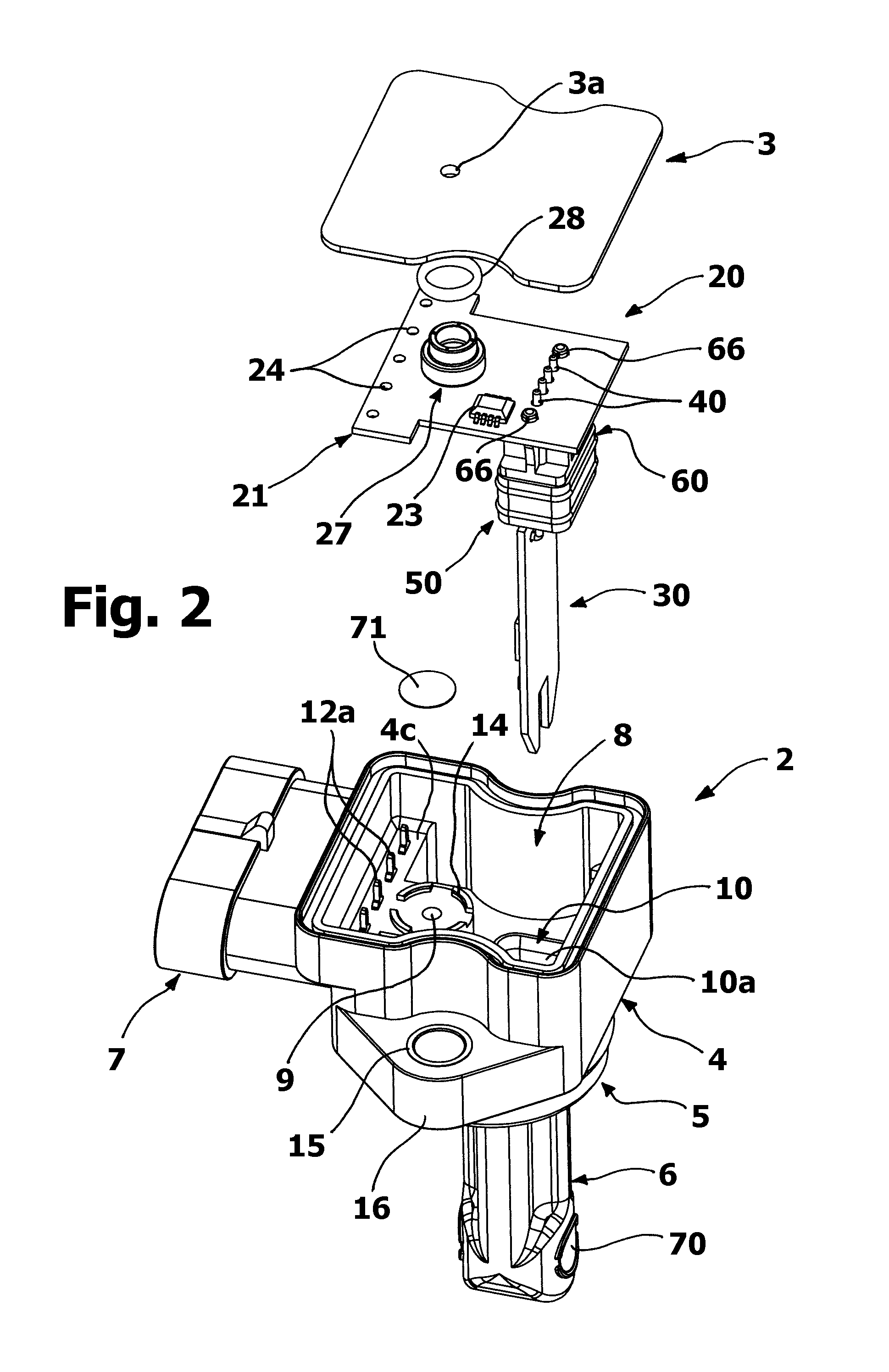

Detection device

InactiveUS20120237402A1Improve accuracyImprove operational reliabilityInternal-combustion engine testingThermometer detailsCombustionEngineering

Owner:ELTEK

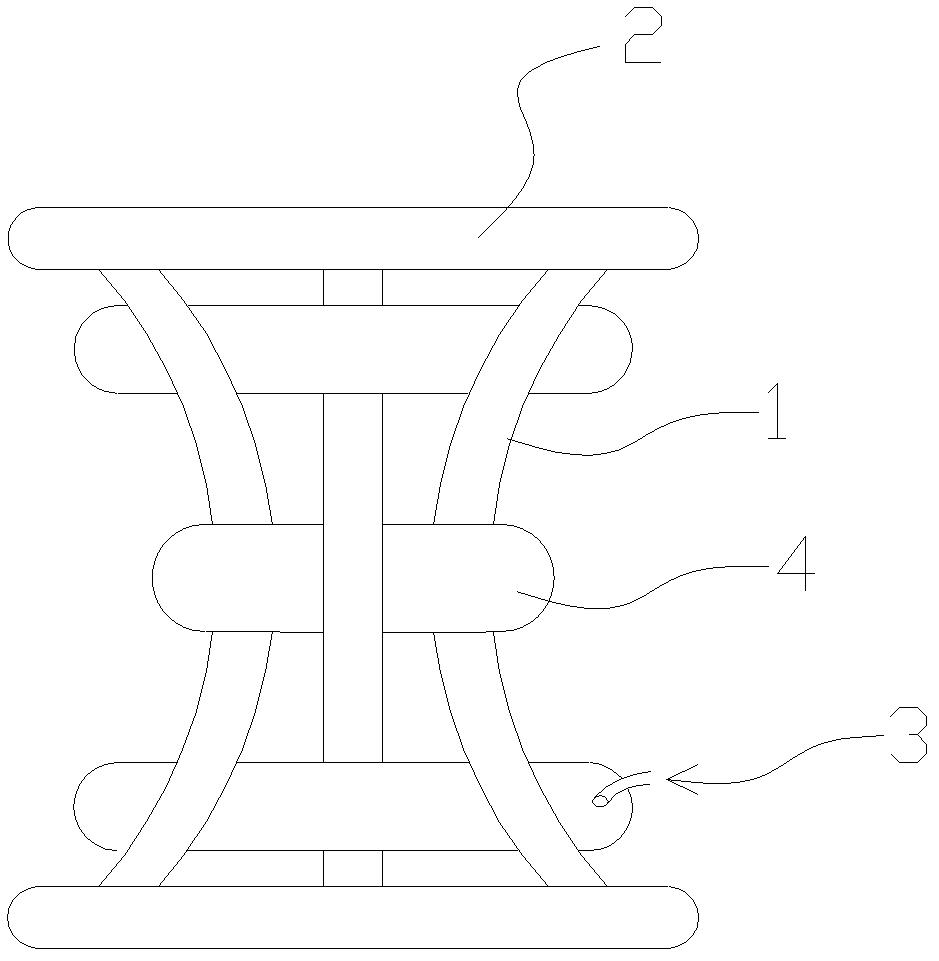

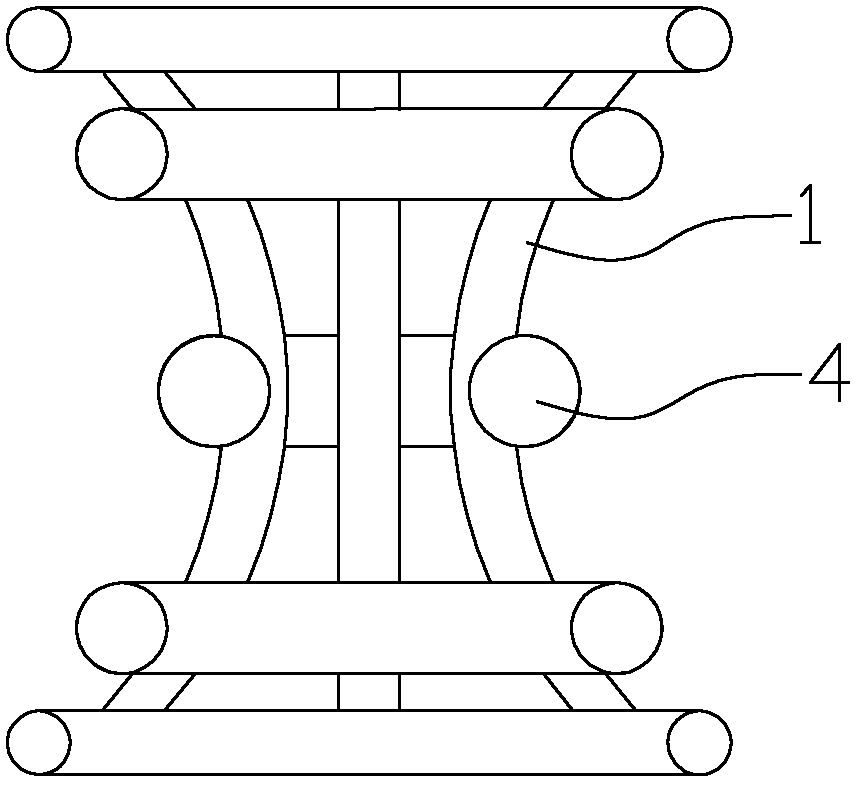

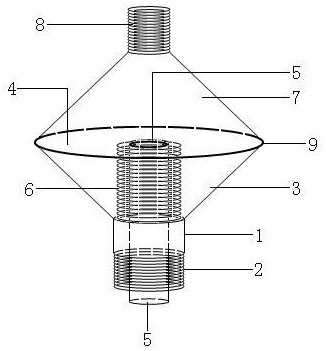

Solid-oxide-fuel-cell cathode gas flow field plate and preparation method thereof

ActiveCN104253280AEfficient use ofFully contactedFinal product manufactureCollectors/separatorsIsosceles trapezoidFuel cells

The invention discloses a solid-oxide-fuel-cell cathode gas flow field plate which is used to uniformly distribute an oxidation gas and collect cathode current. The cathode gas flow field plate is formed by multiple tooth-shaped ripple blocks which are in parallel connection and have same dimension, each tooth-shaped ripple block is formed by two tooth-shaped ripple strips (3 and 4) which are in parallel arrayed connection after being staggered at a distance (7), each tooth-shaped ripple strip (3 and 4) is formed by multiple flat-top bosses (2) and flat plates (1) which are in alternate connection, each flat-top boss (2) has a tooth-shaped contour, the flat plates (1) are connected with the root parts of the flat-top bosses (2) to form tooth-shaped ripples, and the cross section of each flat-top boss (2) has a shape same to the shape of an isosceles trapezoid without a bottom edge. The cathode gas flow field plate of a fuel cell is capable of overcoming the problems that a conventional flow field is large in gas pressure reduction and low in fuel utilization rate. By employing a roll forming technology for preparing the flow field plate, the flow field plate is simple in technology, can be precisely formed and high in product qualified rate.

Owner:HUAZHONG UNIV OF SCI & TECH

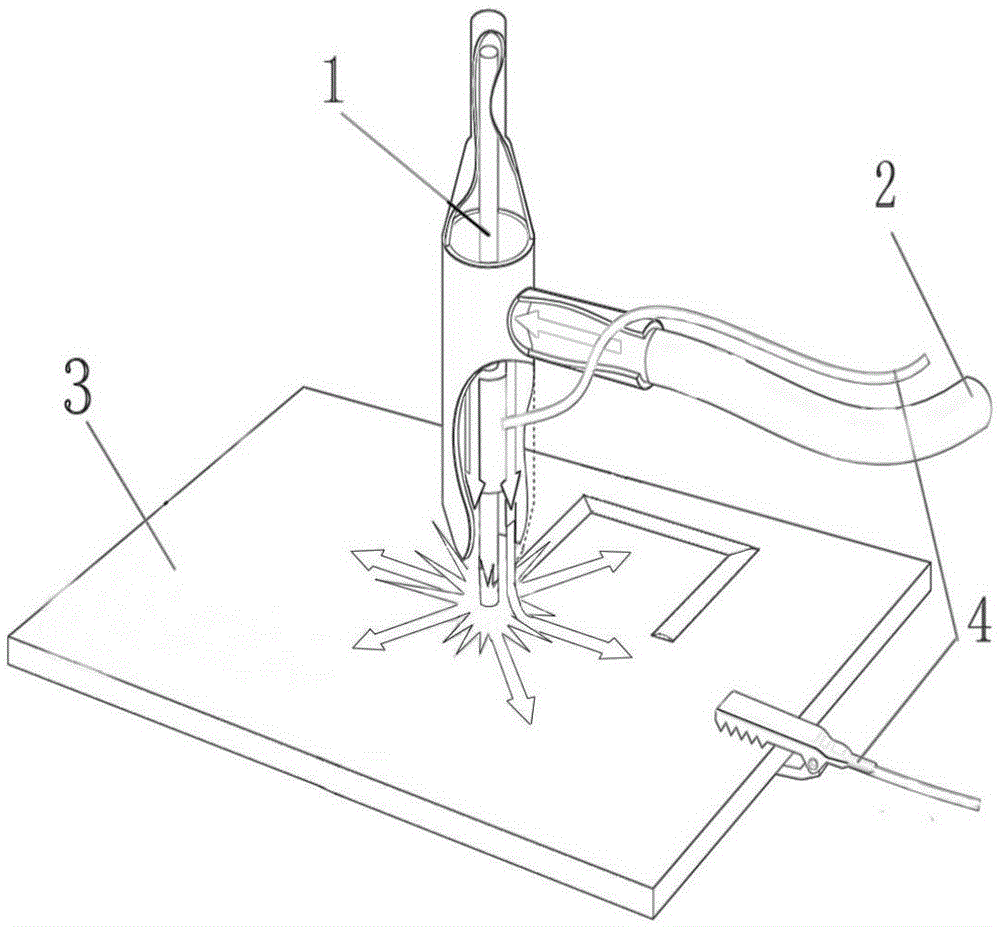

Consumable electrode gas shielded arc deposition three-dimensional printing method

InactiveCN105643053AHigh shape accuracyQuality improvementArc welding apparatusShielding gasEngineering

Owner:GUIZHOU NORMAL UNIVERSITY

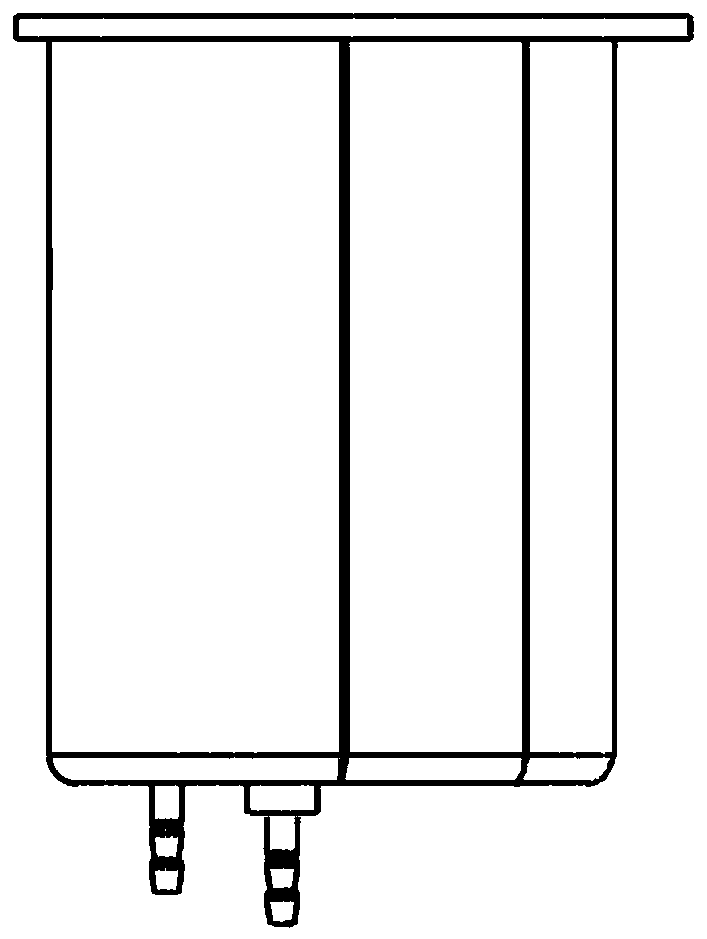

Purge and trap concentrator with sparge vessel

InactiveUS7803635B1Optimize volumeAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationEngineeringOptical transducers

A purge and trap concentrator system that includes a sparge vessel, and includes a variable gas flow valve for controlling the gas pressure in an analytic trap or the sparge vessel; a sensor that detects both a foaming sample state and a high liquid level in the sparge vessel, using one optical sensor; a control scheme that re-directs the purge gases to a second inlet of the sparge vessel during a foaming condition; a control scheme that uses a split flow to enhance the quantity of sample gases passed from an analytic trap; an electrically powered thermal energy source with a fan raising the sparge vessel temperature via thermal convection.

Owner:PROFESSIONAL TECHN SERVICES

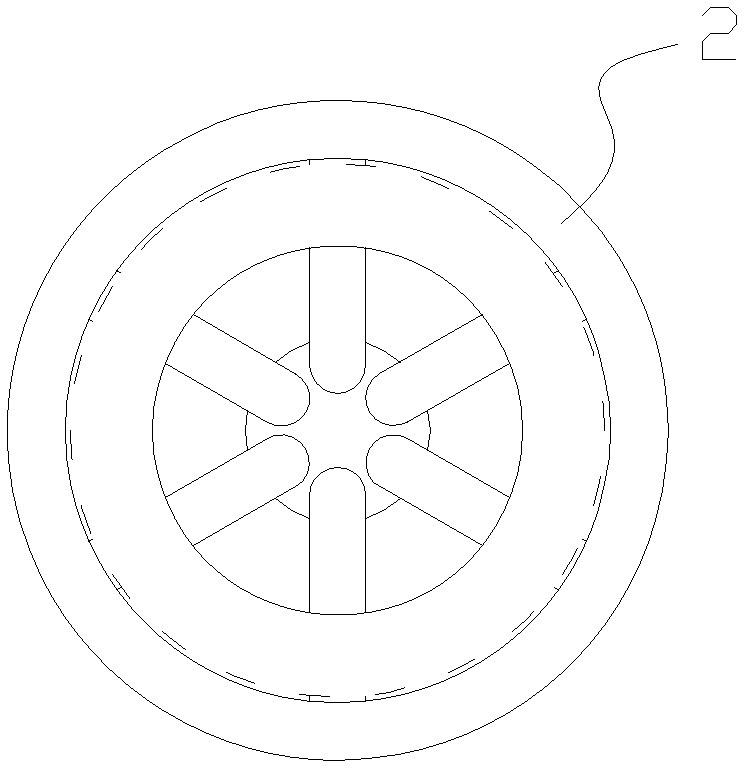

Inner protective gas rod for welded pipe welding

PendingCN111673331AReduce downward forcePlay a protective effectWelding/cutting auxillary devicesAuxillary welding devicesGas passingEngineering

The invention provides an inner protective gas rod for welded pipe welding. The inner protective gas rod comprises a tail end rod section, plugs and a gas outlet rod section, wherein a plurality of gas outlet holes are formed in the gas outlet rod section, the plugs are arranged at two ends of the gas outlet rod section correspondingly, and a gas pressure bin covering the outer side of the gas outlet rod section is formed by the two plugs and the inner wall of a welded pipe; the tail end rod section is provided with a tail end gas hole and communicates with the gas outlet rod section, and gasentering the gas outlet rod section is exhausted through the gas outlet holes and the tail end gas hole; and the inner protective gas rod further comprises a connecting rod section, the connecting rodsection and the tail end rod section communicate with the two plugs correspondingly, and the gas is injected into the gas outlet rod section through the connecting rod section. The inner protective gas rod outputs the stable gas through the gas outlet holes, and the gas pressure bin is formed between the two plugs, so that one lifting force is provided for a weld joint of the welded pipe in the crystallization process, downward acting force borne by liquid metal is reduced, and the effect of protecting the weld joint against subsidence is achieved; and due to the arrangement of the tail end gas hole, the effects of cooling a welded position and preventing the welded position from being oxidized can be achieved.

Owner:HUNAN XIANGTOU GOLDSKY NEW MATERIALS CO LTD

Method for preparing alkane through lignin derivative in ionic liquid system

ActiveCN109294614AOvercome the problem of high pressure in the reaction processReduce pressure requirementsLiquid hydrocarbon mixture productionBio-feedstockAlkaneIonic liquid

The invention discloses a method for preparing a high calorific value alkane by one-step hydrodeoxygenation of a lignin-derived aromatic compound in an ionic liquid system. The method adopts a transition metal supported catalyst and is characterized in that biomass alkane gasoline is prepared through lignin-derived compound high-efficiency hydrodeoxygenation in an intermittent reactor at 100-160 DEG C under hydrogen gas pressure of 1-5MPa for 2-10h. The catalytic system has mild reaction conditions and low energy consumption. The catalyst has good dispersibility in the ionic liquid. The ligninderivative conversion rate is 100%. The selectivity of the product cycloalkane is 95% or more. The method is free of protonic acid in the conventional catalytic system. The extremely low vapor pressure of the ionic liquid keeps the system low pressure during the reaction process, the requirements on the equipment are reduced, cycle performances of the catalytic system are good, and the method hasgood industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

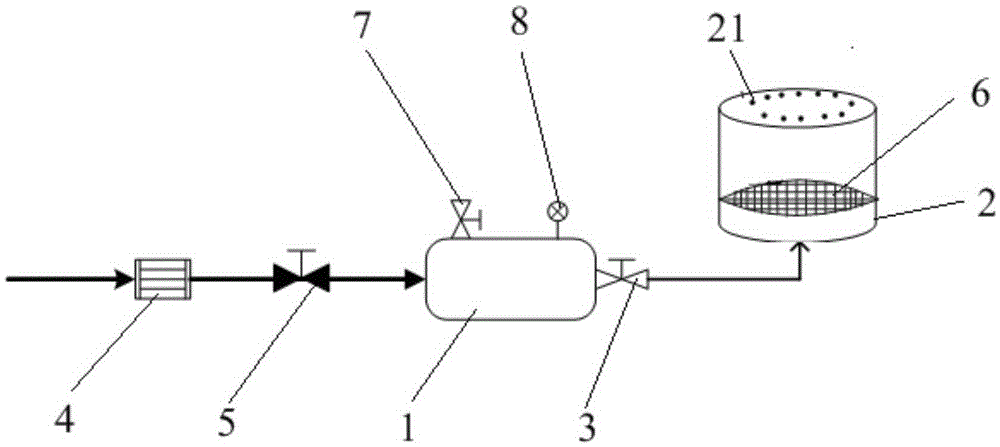

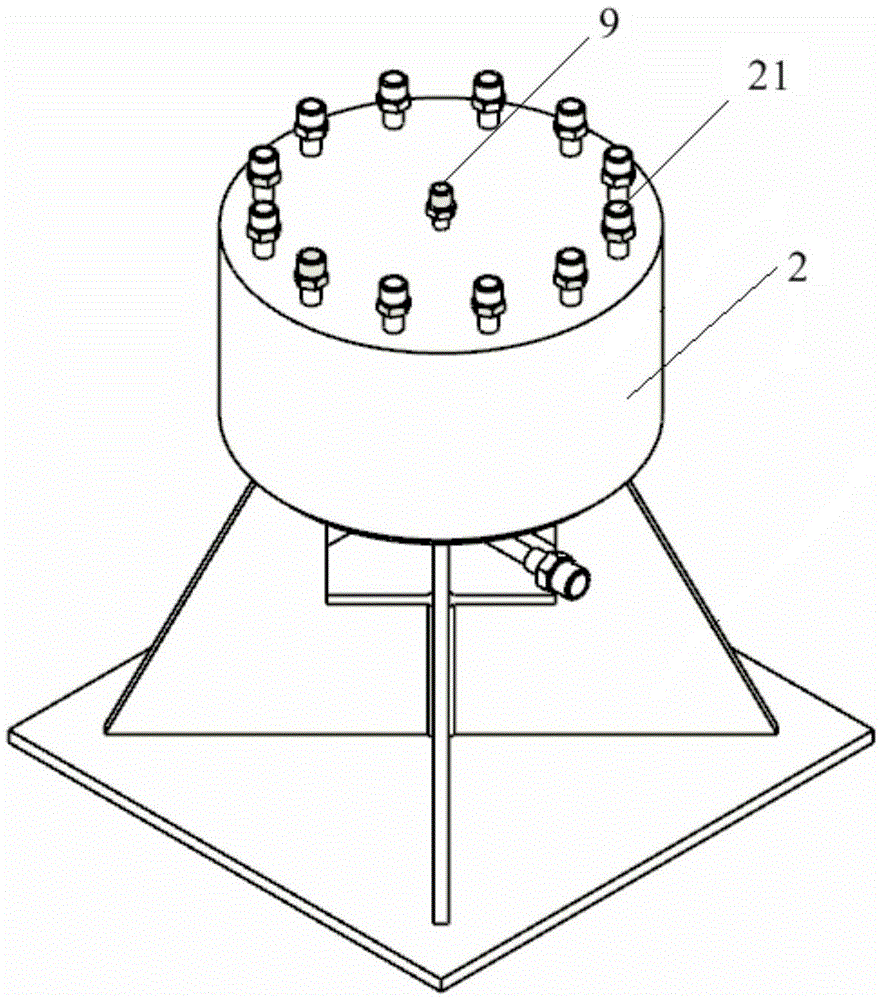

Calibrating device for fire extinguishing agent concentration measuring system

InactiveCN105424876AEnsure final calibration accuracyEnsure consistencyMaterial analysisEngineeringControl valves

Owner:CHINA HELICOPTER RES & DEV INST

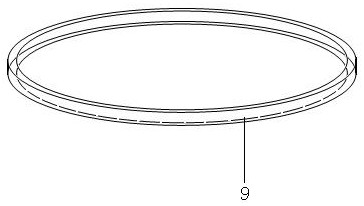

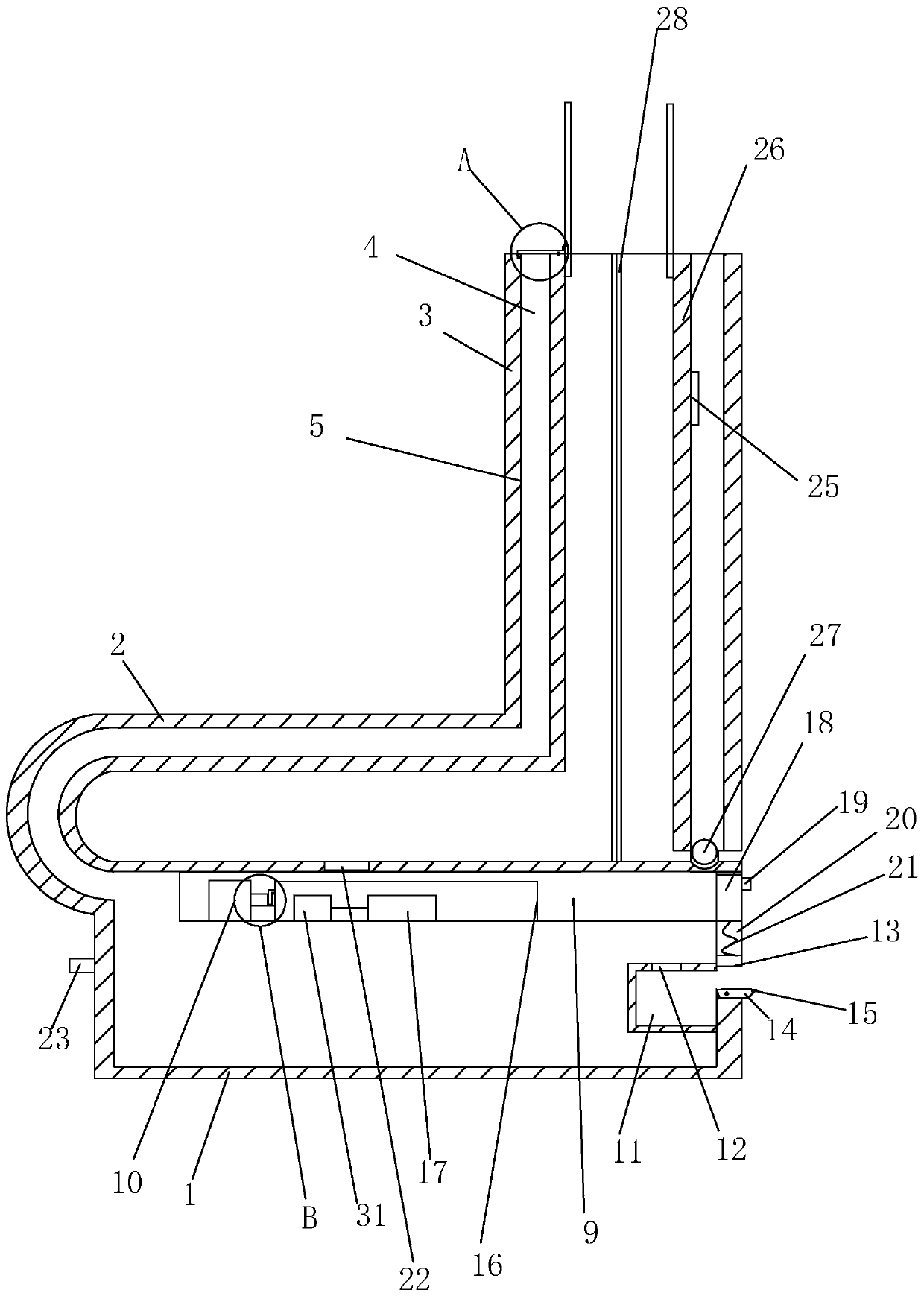

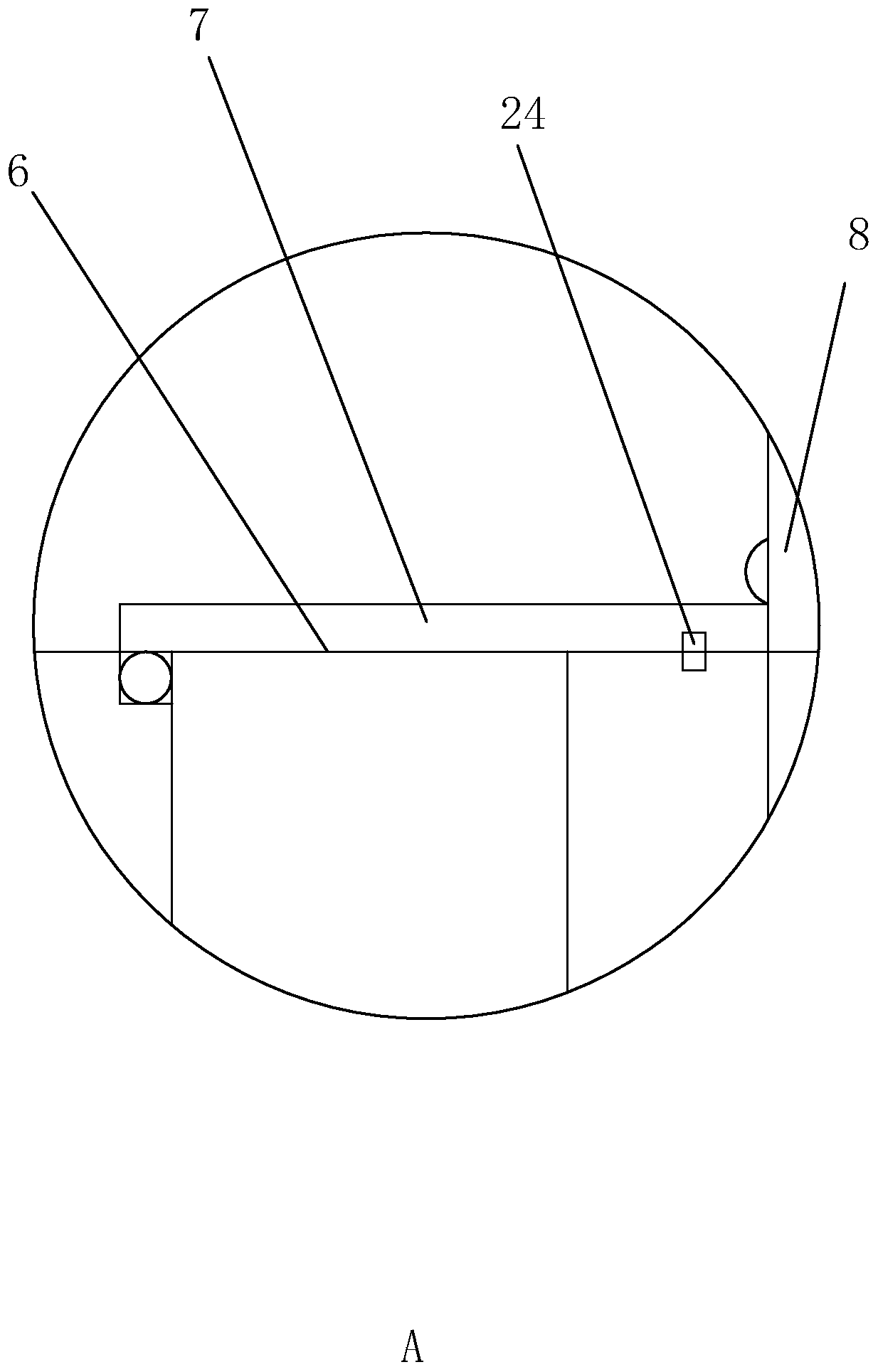

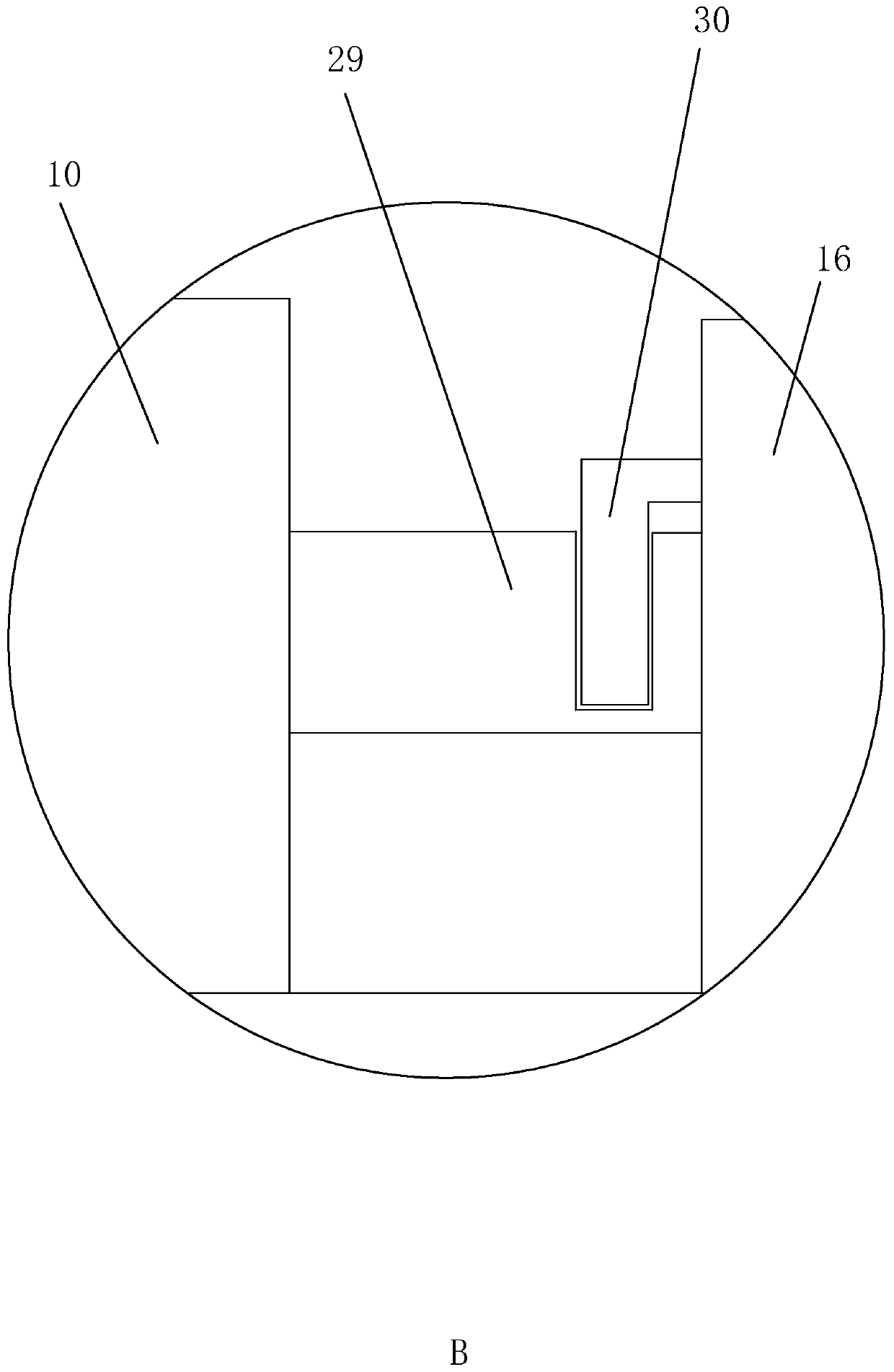

Vertically and horizontally combined gas pressure spring

Owner:XILINMEN FURNITURE

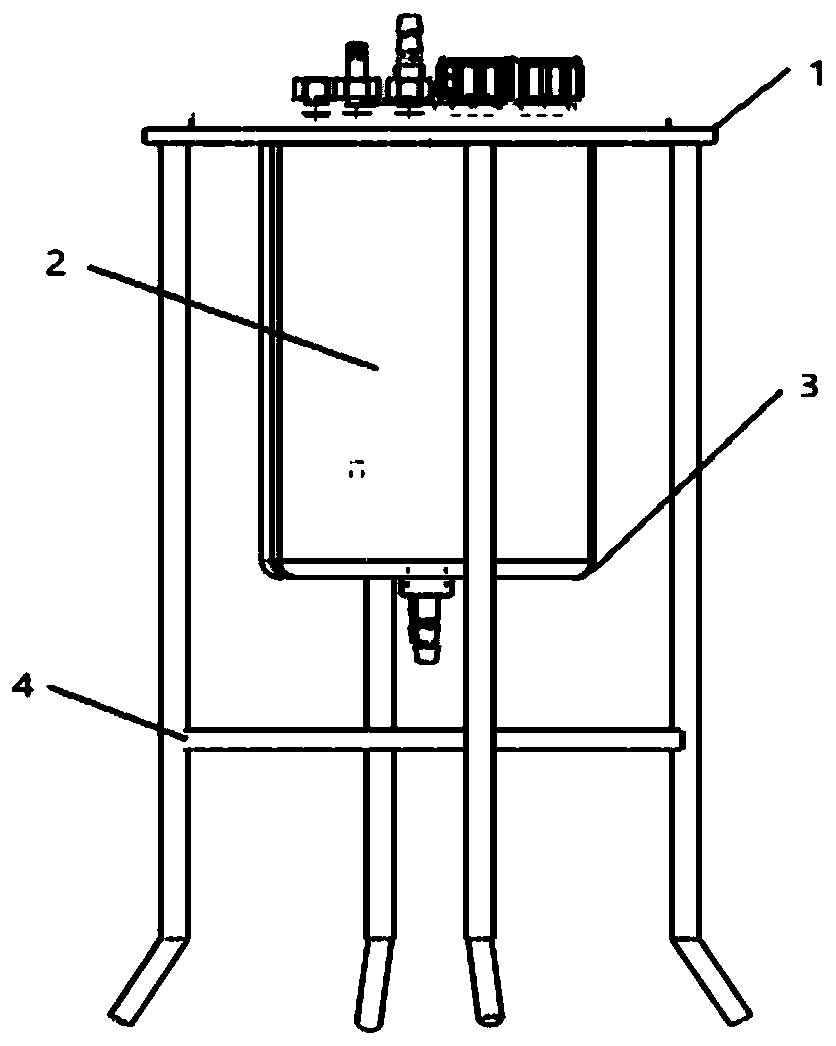

Integrated bioreactor for adherent cell culture

ActiveCN110106085AAdjust liquid levelChange liquid levelBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemEngineering

Owner:SUN YAT SEN UNIV

Gas-liquid separator

InactiveCN111249806AAvoid incomplete separationIncrease flow ratePositive displacement pump componentsDispersed particle separationSeparation technologyEngineering

Owner:罗辉

Air-pressure dredging device

The invention discloses an air-pressure dredging device which comprises air-pressure series and pipe control series components. Air which is pressurized by an inflator arranged in an air bottle shell can flow into an air bag via an air pipe and a skin pipe, and the air bag is communicated with an air pressure gauge, an air valve, an air valve connector, a connecting cap, a hose and an expansion pipe via the air pipe; a flared pipe head is arranged at the lower end of the expansion pipe, and the expansion pipe penetrates a fixing pipe to be connected with a rubber pipe; the upper end of the expansion pipe is closed, is provided with a push-pull rod and is connected with a spiral pipe; the spiral pipe is connected with the upper end of the fixing pipe in a threaded manner. The air-pressure dredging device has the advantages that the push-pull rod and the flared pipe head of the expansion pipe can be driven by the spiral pipe to ascend when a rotary handle upwardly rotates, accordingly, the rubber pipe and sewer pipeline openings can be squeezed to be sealed, standard air-pressure impact force can be kept, and sewer pipelines can be effectively dredged.

Owner:金进

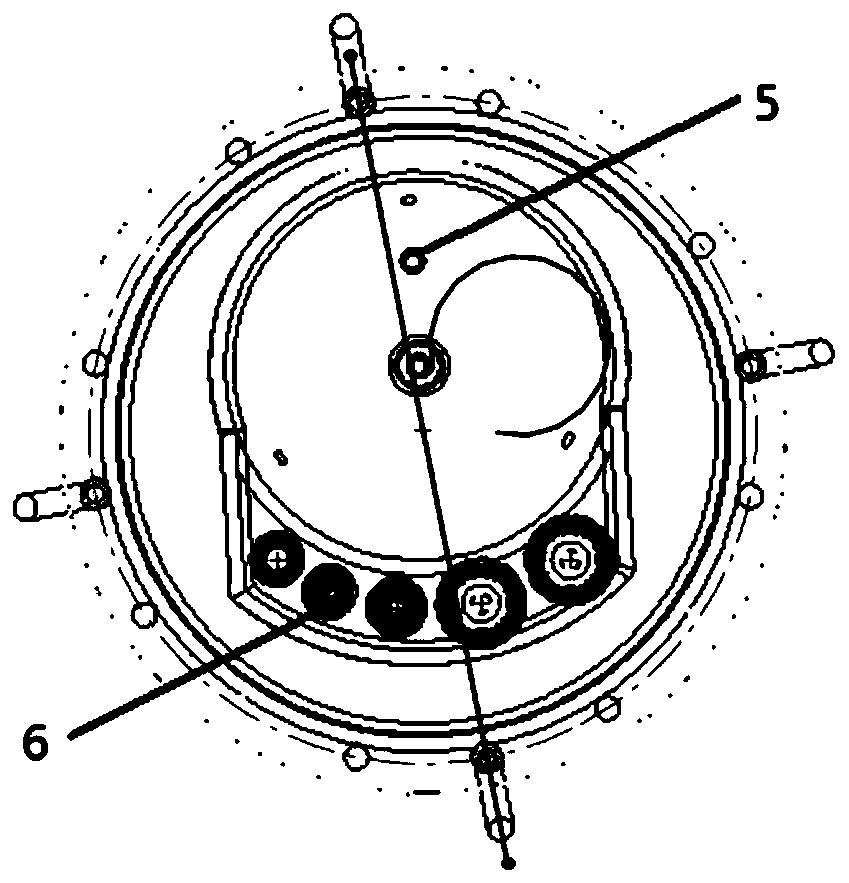

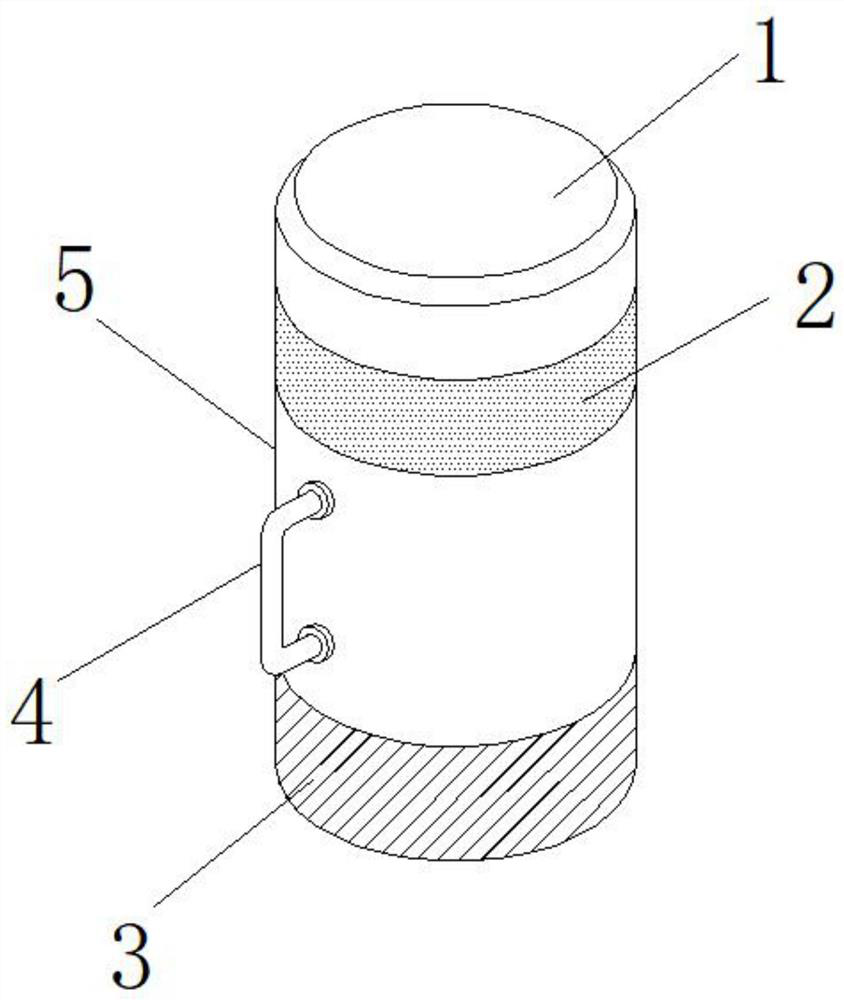

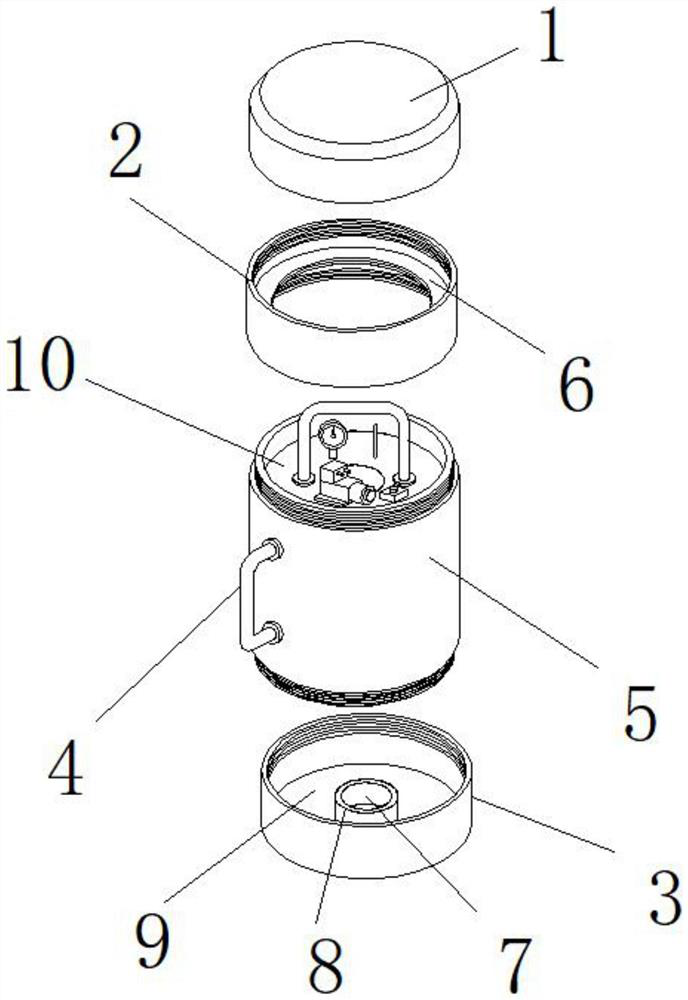

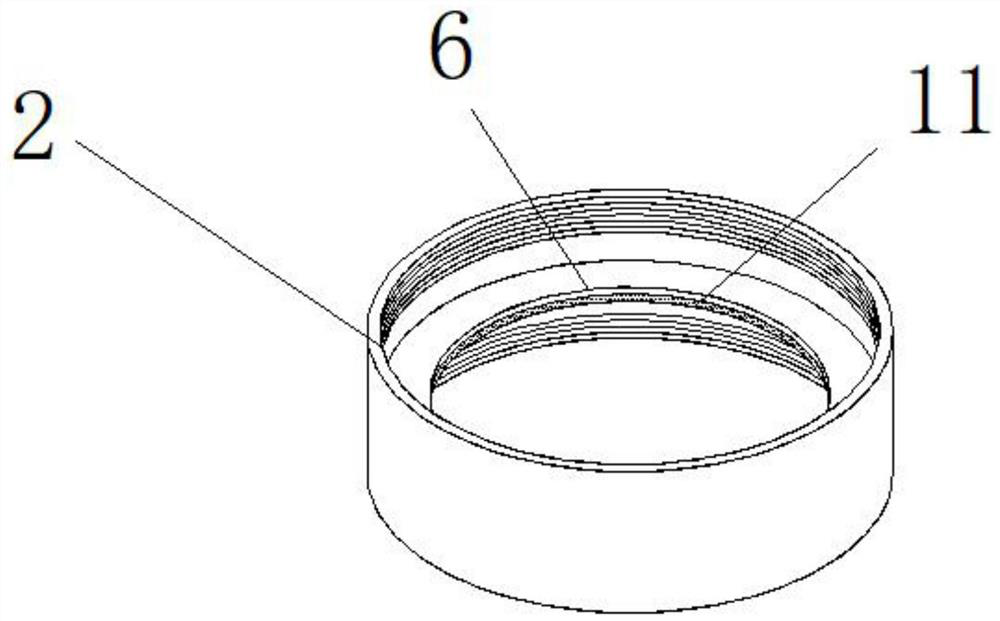

Lifting type interlayer vacuum liquid storage device

ActiveCN112208943ASolve the problem of inconvenient retrievingImprove protectionDomestic cooling apparatusLighting and heating apparatusLiquid storage tankAir pump

Owner:湖南精诚制药机械有限公司

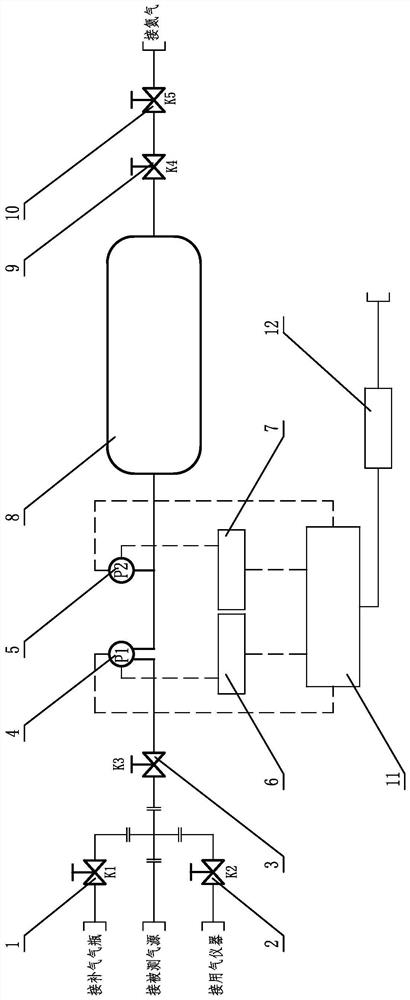

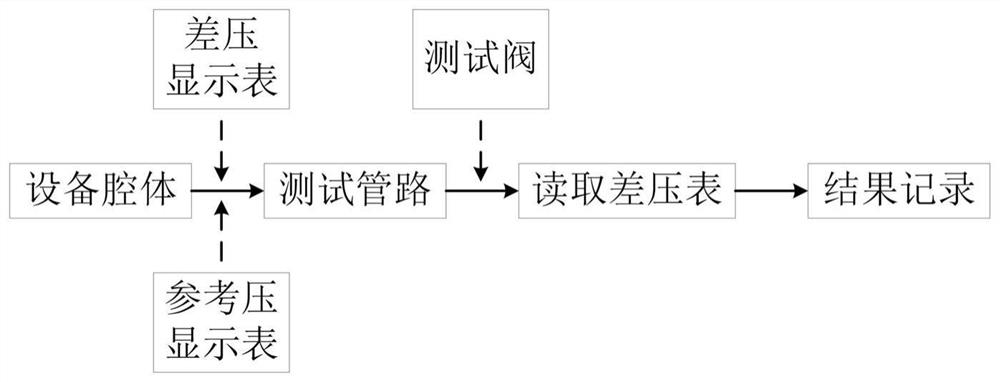

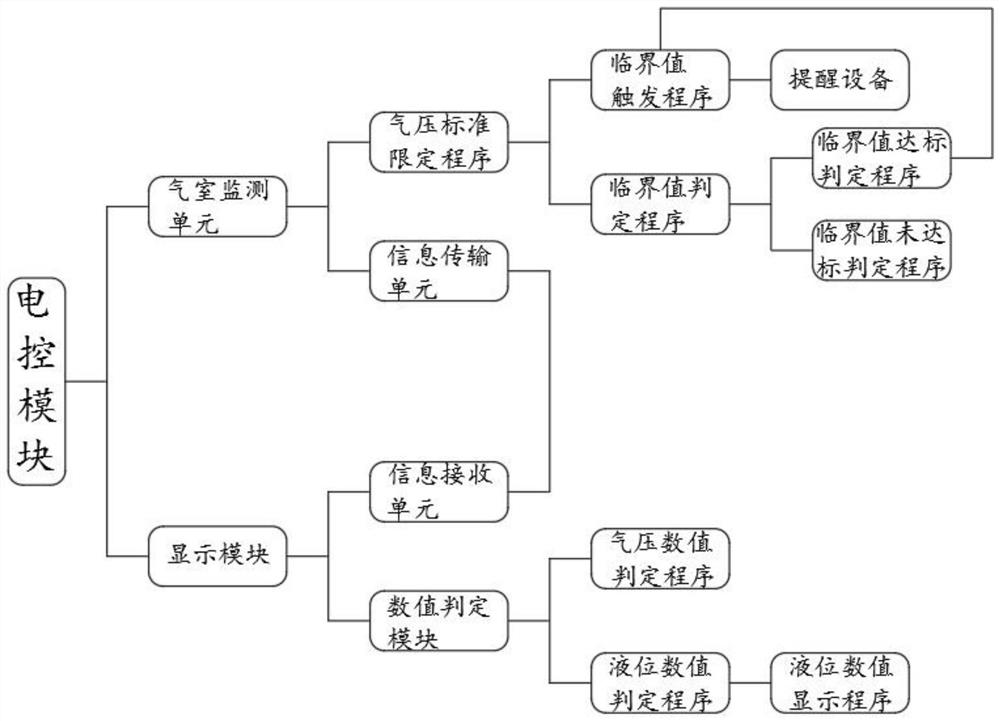

Sulfur hexafluoride decomposition product gas pressure monitoring device based on gas in-situ detection

PendingCN113933467ADetection technology of sulfur hexafluoride decomposition product air pressure monitoring pressure leakageEasy to usePressure difference measurement between multiple valvesMaterial analysisSulfur hexafluorideProcess engineering

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

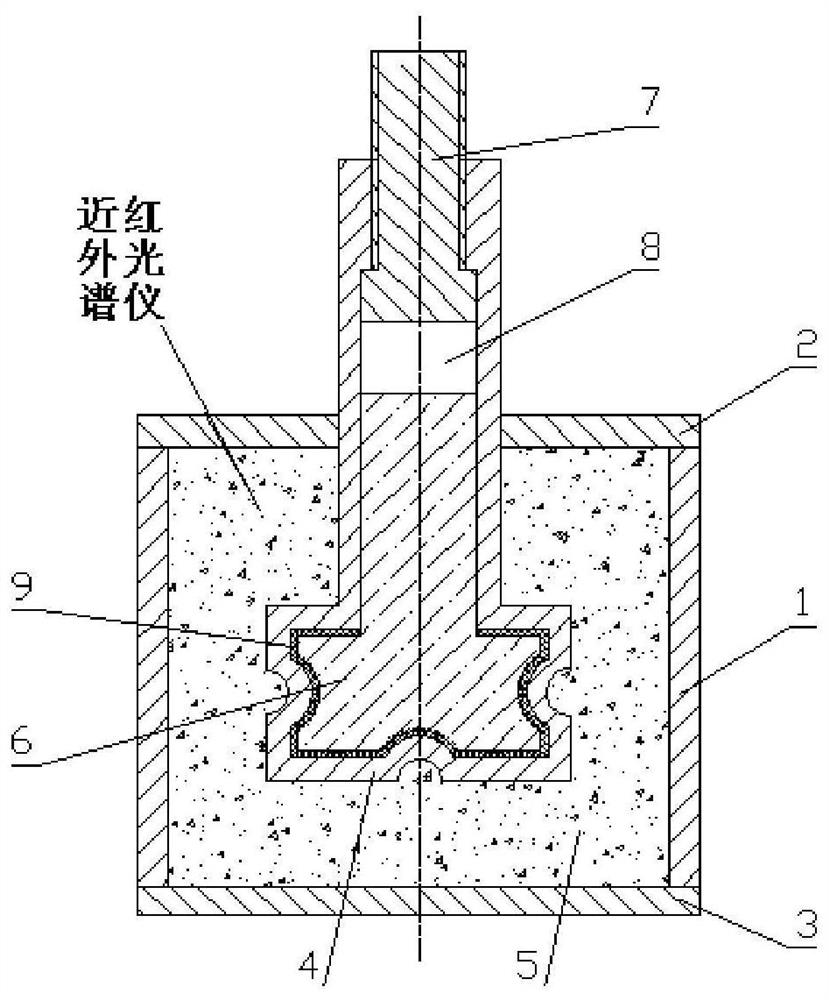

Testing device and method for determining system uniformity by utilizing near-infrared spectrometer

Owner:XIAN MODERN CHEM RES INST

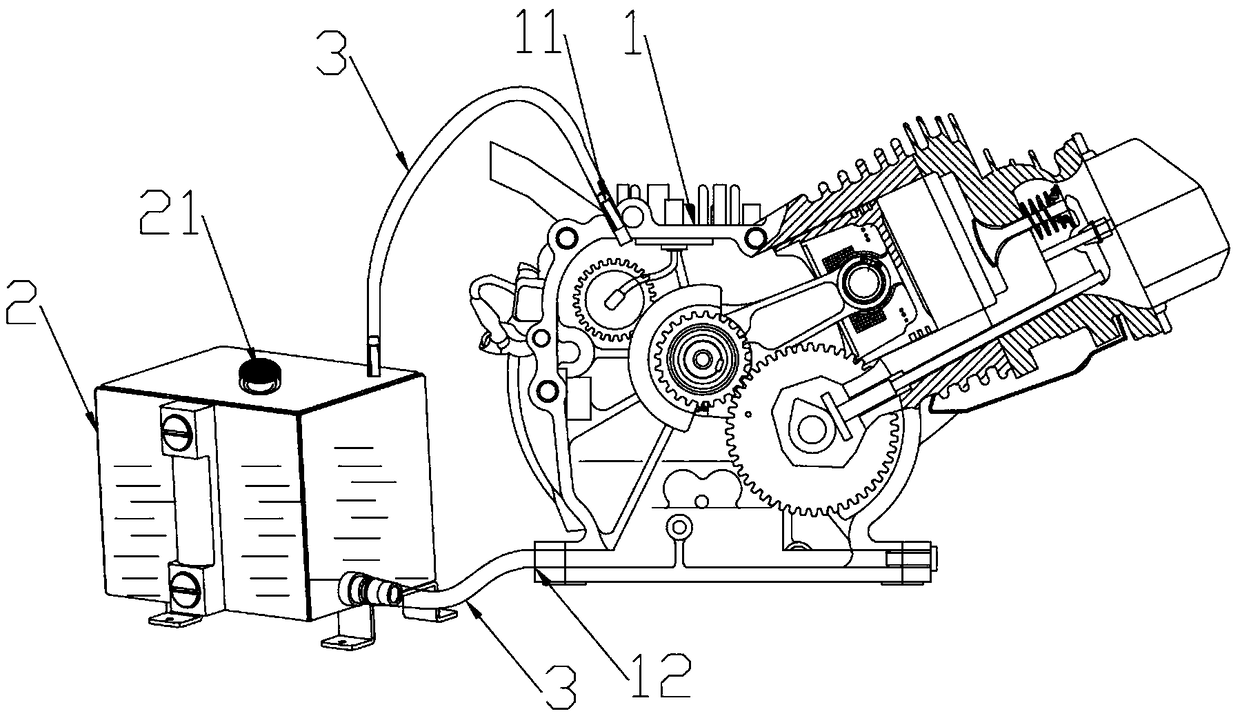

Engine lubricating oil supply device

PendingCN109139180AGuaranteed capacityIncrease in sizeLubricant conduit arrangementsMachines/enginesFuel tankOil consumption

Owner:华建农

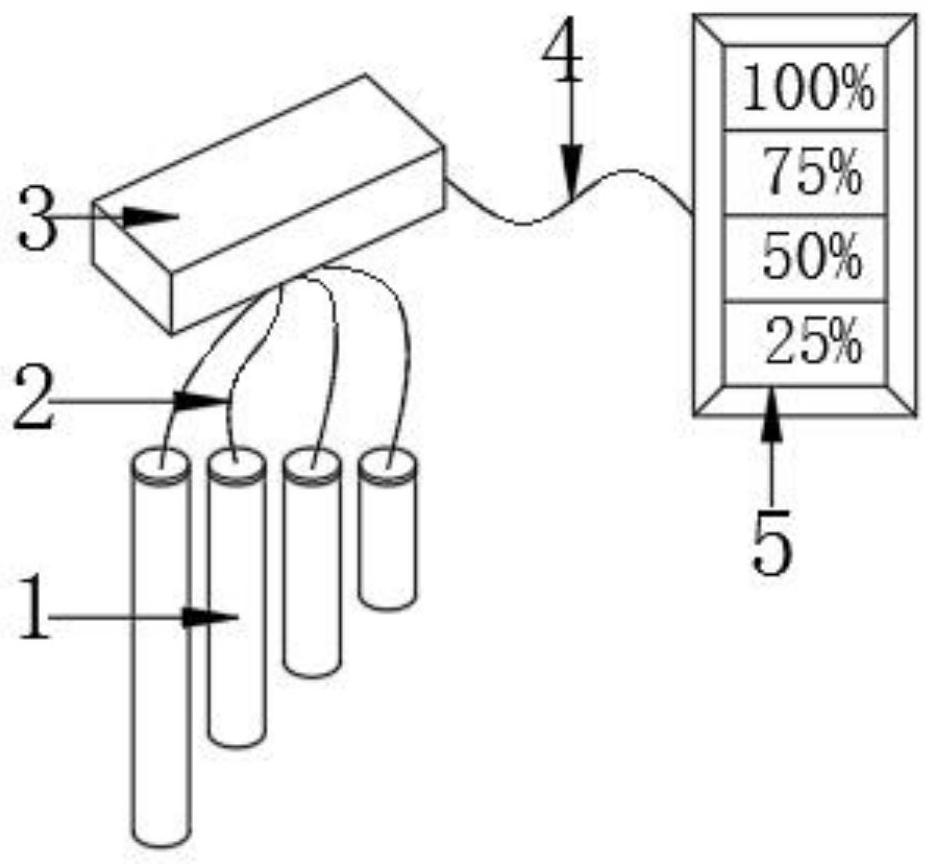

Differential pressure principle non-contact liquid level sensor

PendingCN114858240AReduce manufacturing costAvoid failureTotal factory controlLevel indicators by pressure measurementThermodynamicsLiquid level measurement

Owner:长春市朗瑞斯环保科技有限公司

High-sensitivity pressure-limiting air valve of truck air pump

Owner:房县启扬工贸有限责任公司

Thermal shoe

Owner:WENZHOU POLYTECHNIC

Method, chip and device for preparing SiO2 film

PendingCN114000123AImprove compactnessIncrease stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh frequency powerMoisture resistance

The invention discloses a method for preparing a SiO2 film, which adopts a PECVD (Plasma Enhanced Chemical Vapor Deposition) mode to prepare the SiO2 film: adopting a high-frequency and low-frequency alternating mode to deposit, wherein the high frequency is 13.56 KHz, the low frequency is 50 to 400 KHz, the high-frequency power is 20-100W, and the low-frequency power is 35-100W, the gas for deposition is amixed gas of amixed gas and laughing gas, the gas pressure is 900-1600 mtorr, and the flow ratio of the silane to the laughing gas is (90-300): (600-800), and the deposition temperature is 250-300 DEG C. The SiO2 thin film is grown alternately at high and low frequencies, so that the thin film is relatively high in compactness and high in moisture resistance; and the low-stress SiO2 film is obtained by adjusting process parameters of high and low frequencies, the stable low-stress SiO2 film can be obtained through alternate growth of the high and low frequencies, the process is stable, the operation can be repeated, and the stress value is kept stable and does not drift.

Owner:浙江光特科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap