Testing device and method for determining system uniformity by utilizing near-infrared spectrometer

A near-infrared spectrometer and testing device technology, which is applied in the field of analysis and testing, can solve the problems that strain gauges cannot be used for measurement, and there is no method for measuring the expansion pressure of a solid-liquid-gas three-phase mixture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

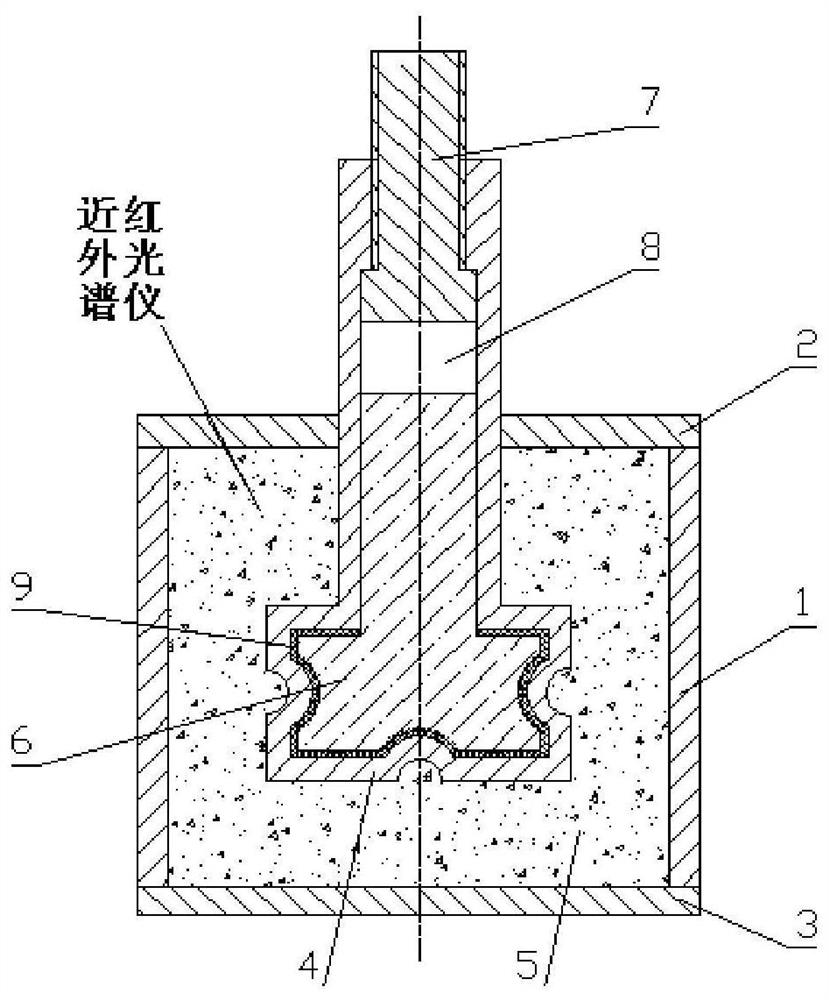

[0060] Such as figure 1 As shown, the present embodiment provides a test device and method for determining system uniformity using a near-infrared spectrometer, including a solid-liquid-gas phase mixture 5, and is characterized in that it also includes a housing 1, an upper end cover 2, a lower end cover 3, a spring chamber 4, Isobaric liquid 6, piston 7, isobaric gas 8, heat insulating layer 9;

[0061] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first cylindrical body of the housing 1 The lower end surface of the cylindrical body is the first lower end concentric annular surface;

[0062] The axis of the rotating body of the casing 1 is perpendicular to the ground, and the casing 1 is a casing filled with a gelled solid-liquid-gas mixture;

[0063] The upper end cover 2 is a second concentric

Embodiment 2

[0133] Such as figure 1 As shown, the present embodiment provides a test device and method for determining system uniformity using a near-infrared spectrometer, including a solid-liquid-gas phase mixture 5, and is characterized in that it also includes a housing 1, an upper end cover 2, a lower end cover 3, a spring chamber 4, Isobaric liquid 6, piston 7, isobaric gas 8, heat insulating layer 9;

[0134] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first cylindrical body of the housing 1 The lower end surface of the cylindrical body is the first lower end concentric annular surface;

[0135] The axis of the rotating body of the casing 1 is perpendicular to the ground, and the casing 1 is a casing filled with a gelled solid-liquid-gas mixture;

[0136] The upper end cover 2 is a second concentric

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap