Thermal shoe

A technology for warm shoes and shoe barrels, applied in the field of warm shoes, can solve the problems of overheating or overcooling, surface heating, difficult heating temperature, etc., and achieve the effects of enhancing comfort, enhancing sealing, and enhancing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described with reference to the accompanying drawings.

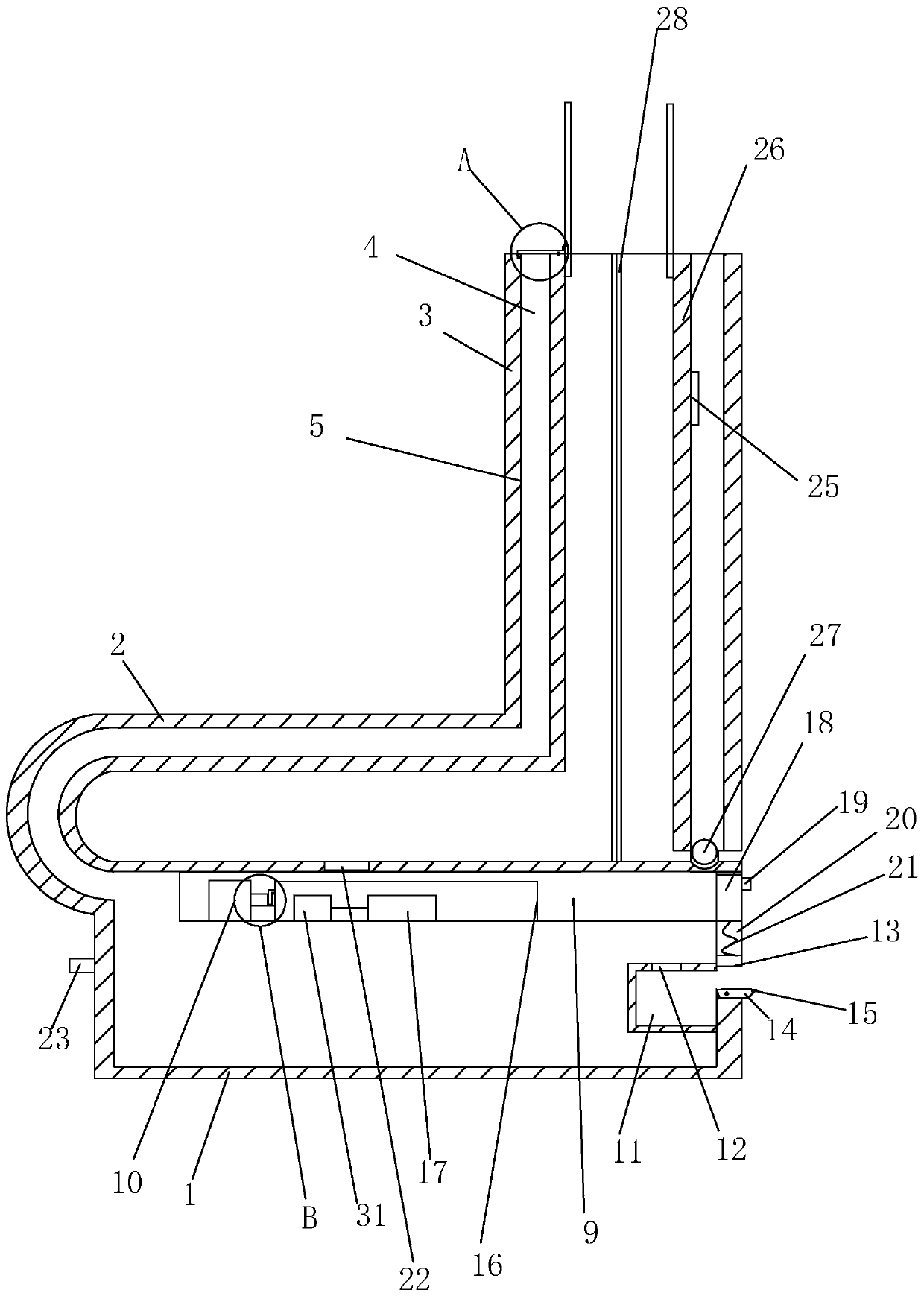

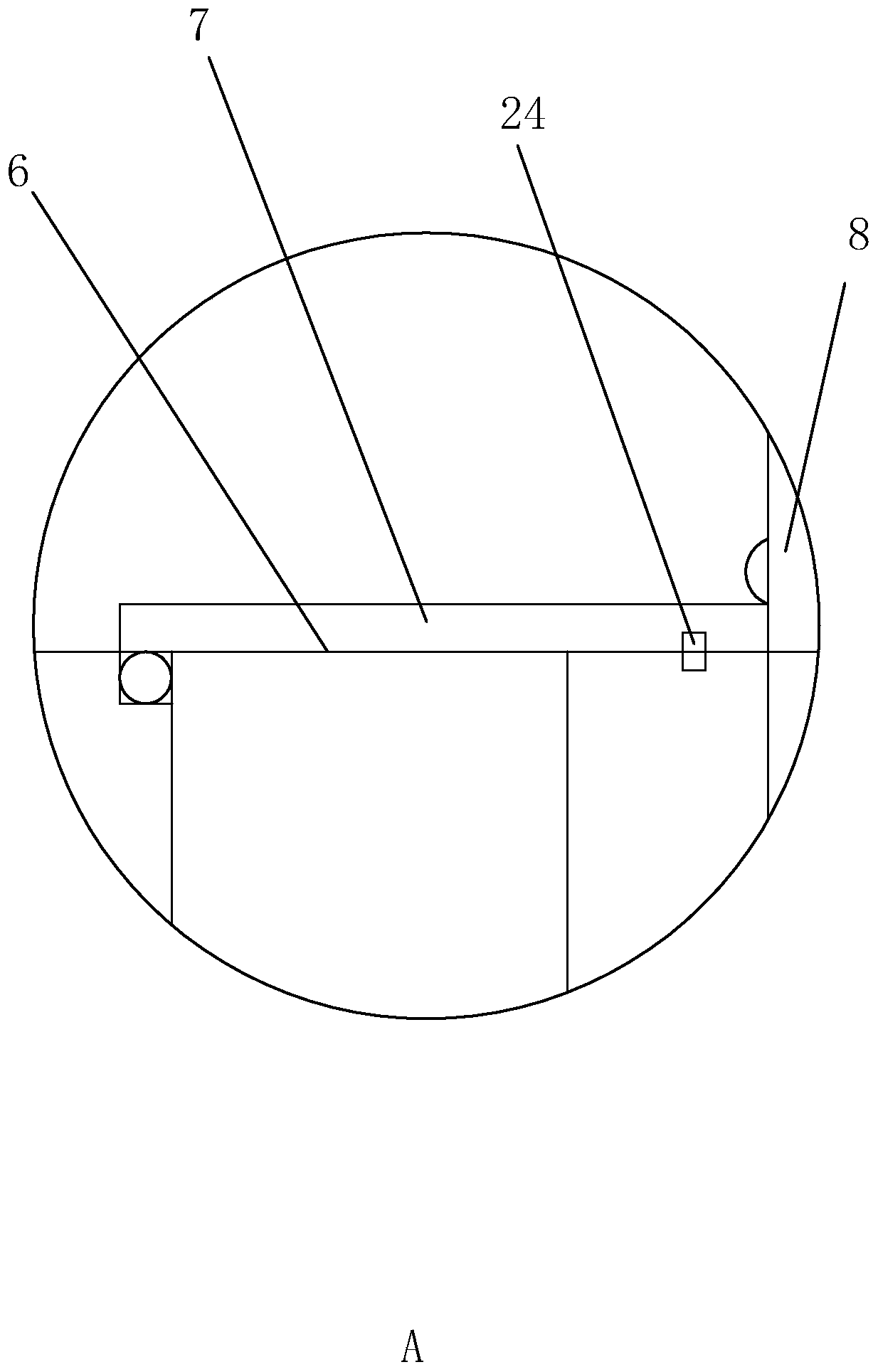

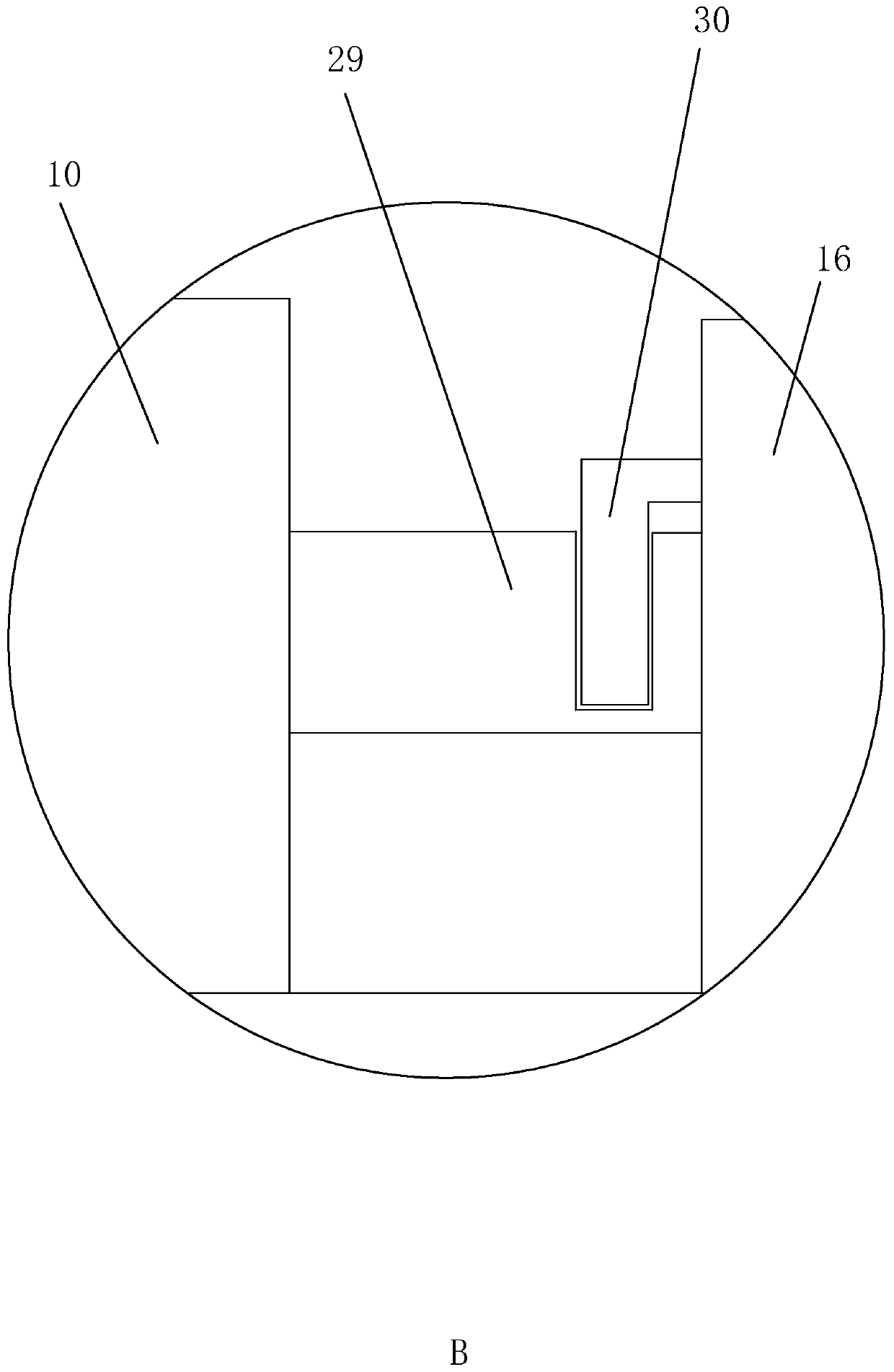

[0030] a warm shoe such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a sole 1, a vamp 2 and a shoe barrel 3. A heating device is arranged inside the sole 1. The sole 1 and the shoe barrel 3 are jointly provided with the same circulation groove 4. The circulation groove 4 is located between the sole 1 and the shoe barrel. A built-in closed space is formed in the cylinder 3 . The tank wall of the circulation tank 4 is provided with a waterproof layer 5, and the waterproof layer 5 restricts the passage of water vapor. The top of the shoe barrel 3 is provided with an exhaust groove 6 communicating with the circulation groove 4, and the notch of the exhaust groove 6 is provided with a grid block 7, and the grid block 7 can limit the communication between the exhaust groove 6 and the outside world. The shoe barrel 3 is integrally connected with a protecti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap