Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Alkane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry, an alkane, or paraffin (a historical name that also has other meanings), is an acyclic saturated hydrocarbon. In other words, an alkane consists of hydrogen and carbon atoms arranged in a tree structure in which all the carbon–carbon bonds are single. Alkanes have the general chemical formula CₙH₂ₙ₊₂. The alkanes range in complexity from the simplest case of methane (CH₄), where n = 1 (sometimes called the parent molecule), to arbitrarily large and complex molecules, like pentacontane (C₅₀H₁₀₂) or 6-ethyl-2-methyl-5-(1-methylethyl) octane, an isomer of tetradecane (C₁₄H₃₀).

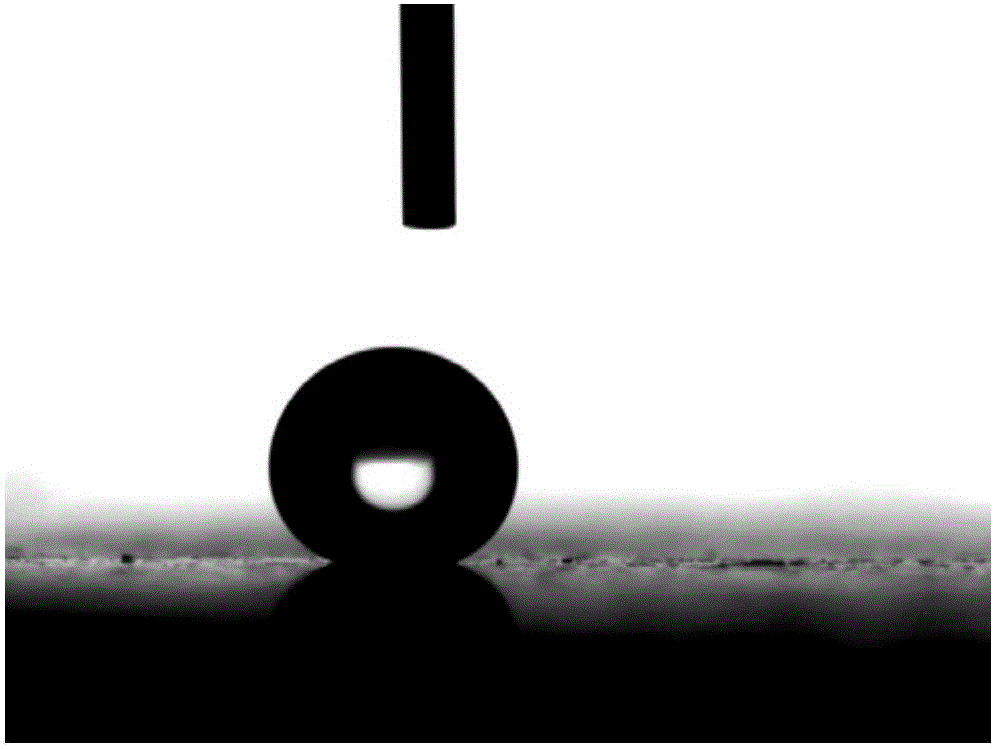

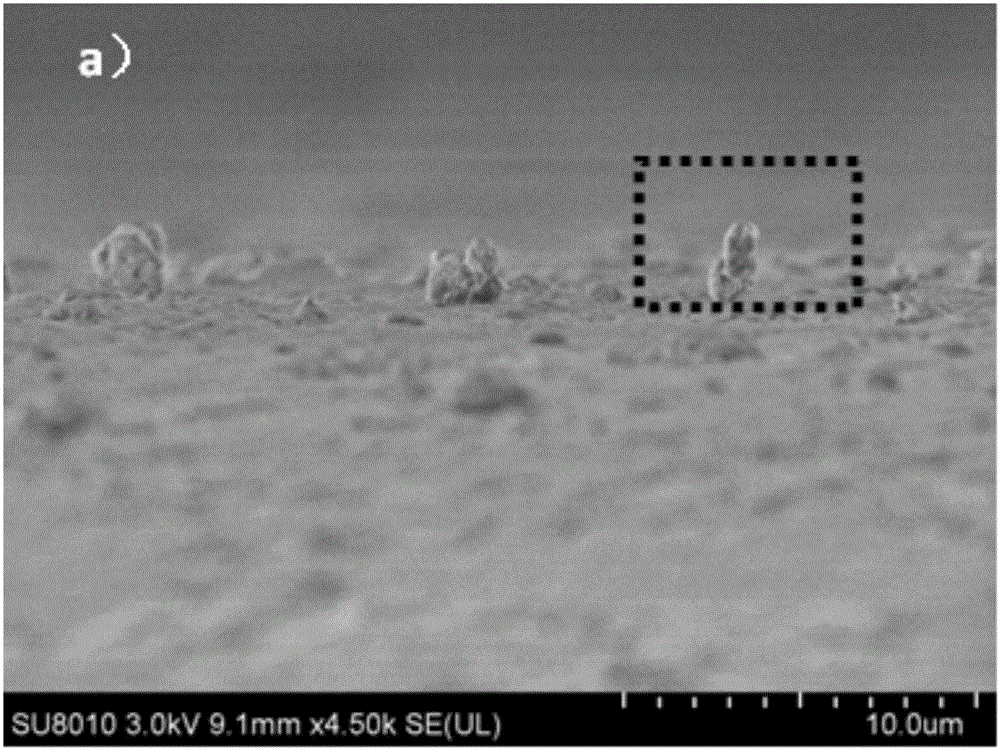

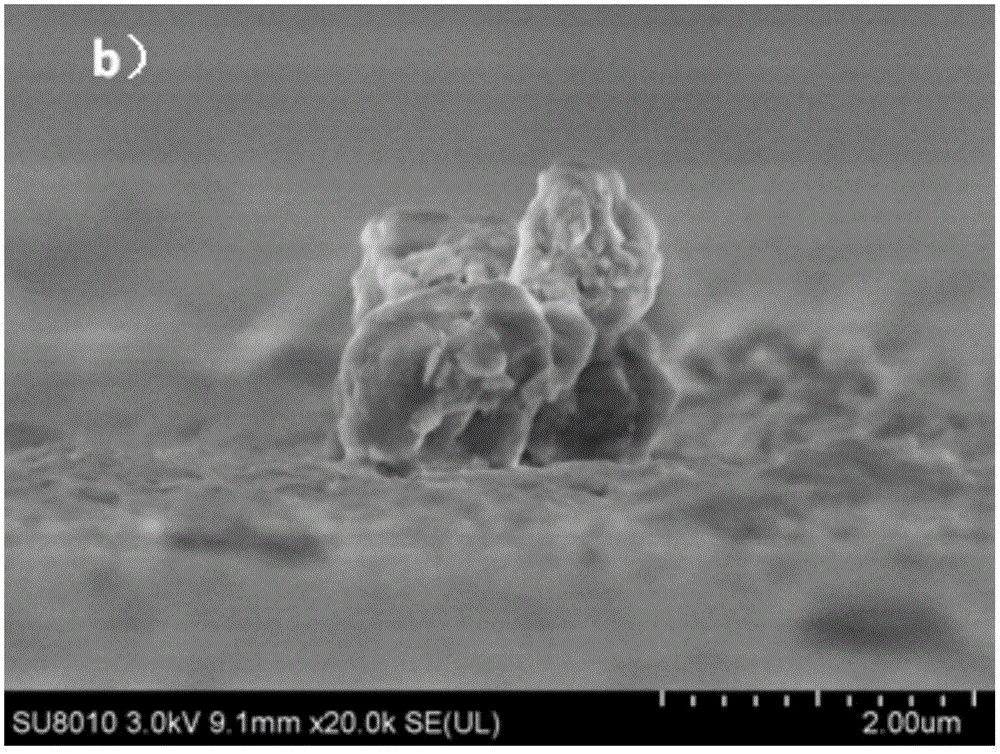

Super-hydrophobic polypropylene film and preparation method thereof

Owner:ZHEJIANG UNIV

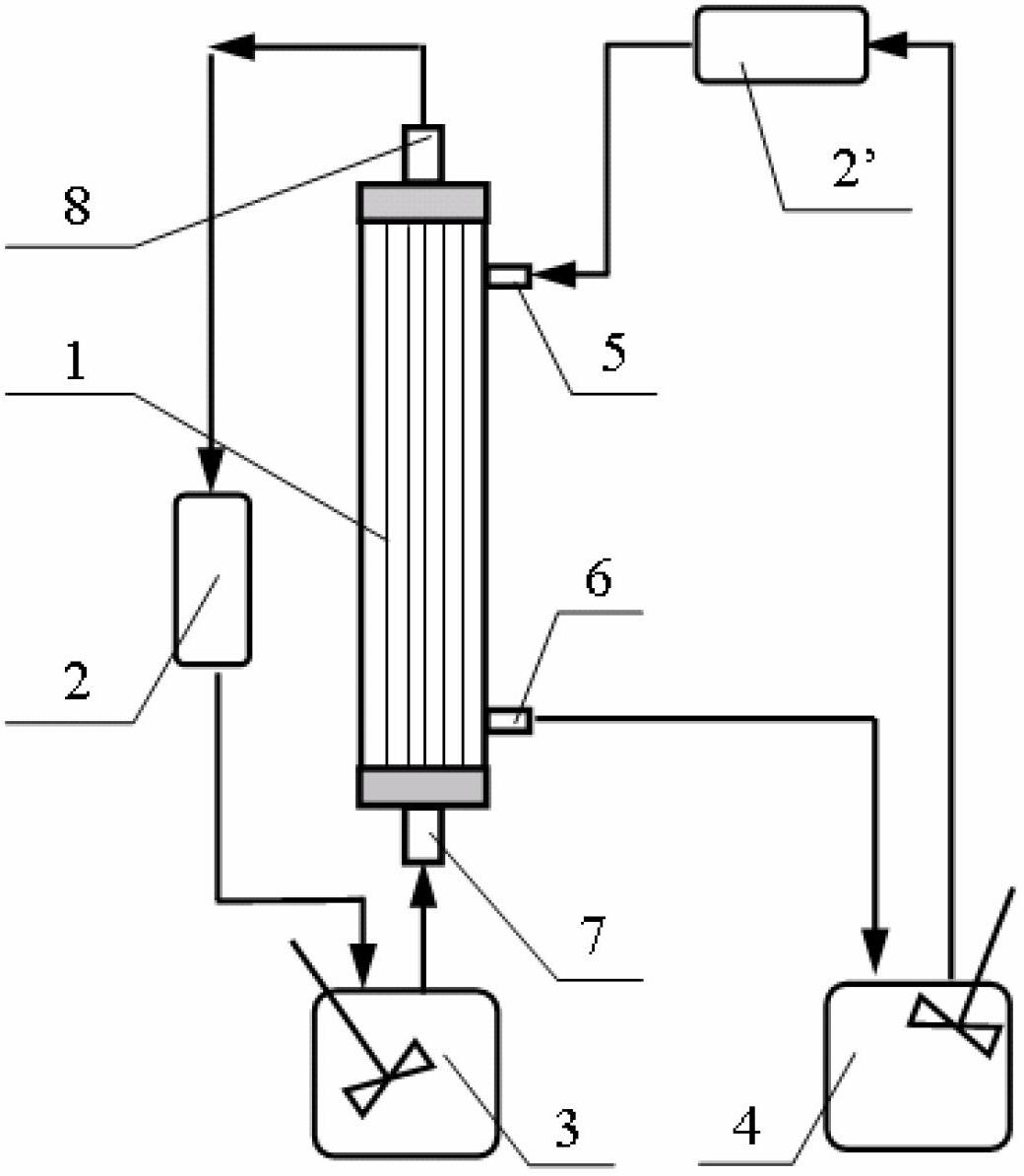

Method for separating aromatic hydrocarbon from alkane by ionic liquid and membrane process coupling technology

InactiveCN102688708AHigh separation selectivityAchieve the purpose of separationSemi-permeable membranesLiquid solutions solvent extractionAlkaneAromatic hydrocarbon

Owner:BEIJING UNIV OF CHEM TECH

Environment-friendly concentrated liquid detergent for clothing materials

InactiveCN106047529AEasy to rinseConserve waterInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlkaneSodium bicarbonate

The invention provides an environment-friendly concentrated liquid detergent for clothing materials. The liquid detergent is environmentally friendly and easily degradable, does not stimulate the human body and has multiple functions of purifying, softening, fragrance depositing and the like. The environment-friendly concentrated liquid detergent comprises the following components in percentage by weight: 10%-15% of fatty alcohol-polyoxyethylene ether, 15%-20% of alkyl glycoside, 10%-12% of dodecyl dimethyl betaine, 6%-8% of seconary alkane sulphonate sodium, 3%-6% of fatty acid alkanol amide, 0-2% of citric acid, 0-2% of sodium carbonate, 0-2% of sodium bicarbonate, 0-1% of a flavoring agent and the balance of softened water.

Owner:ANHUI TAILONG CHENGYA GRP CO LTD

Method for preparing bis(diphenylphosphino)alkane palladium dichloride complex

ActiveCN103265581AReduce productionThe synthesis process is simpleOrganic chemistryAlkaneN dimethylformamide

The invention discloses a method for preparing a bis(diphenylphosphino)alkane palladium dichloride complex. The method comprises the steps of: (1) preparing a chloropalladite solution; (2) adding bis(diphenylphosphino) alkane into N,N-dimethylformamide so as to prepare a N,N-dimethylformamide solution of bis(diphenylphosphino) alkane; (3) dropwise adding the chloropalladite solution to the N,N-dimethylformamide solution of bis(diphenylphosphino) alkane while stirring, carrying out stirring reaction after the dropwise adding process is completed, and filtering after cooling so as to obtain a filter cake; and (4) washing the filter cake, and carrying out vacuum drying on the washed filter cake, thereby obtaining the bis(diphenylphosphino)alkane palladium dichloride complex. According to the method, palladium sponge is directly adopted as a palladium source, the target product is synthesized from chloropalladite and a ligand, namely the bis(diphenylphosphino) alkane, in a DMF (N,N-dimethylformamide) solvent in one step, and a process for preparing intermediates, namely palladium chloride and acetonitrile palladium chloride, is avoided, so that the method has the characteristics of simple synthesis process, short cycle, low cost and the like.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

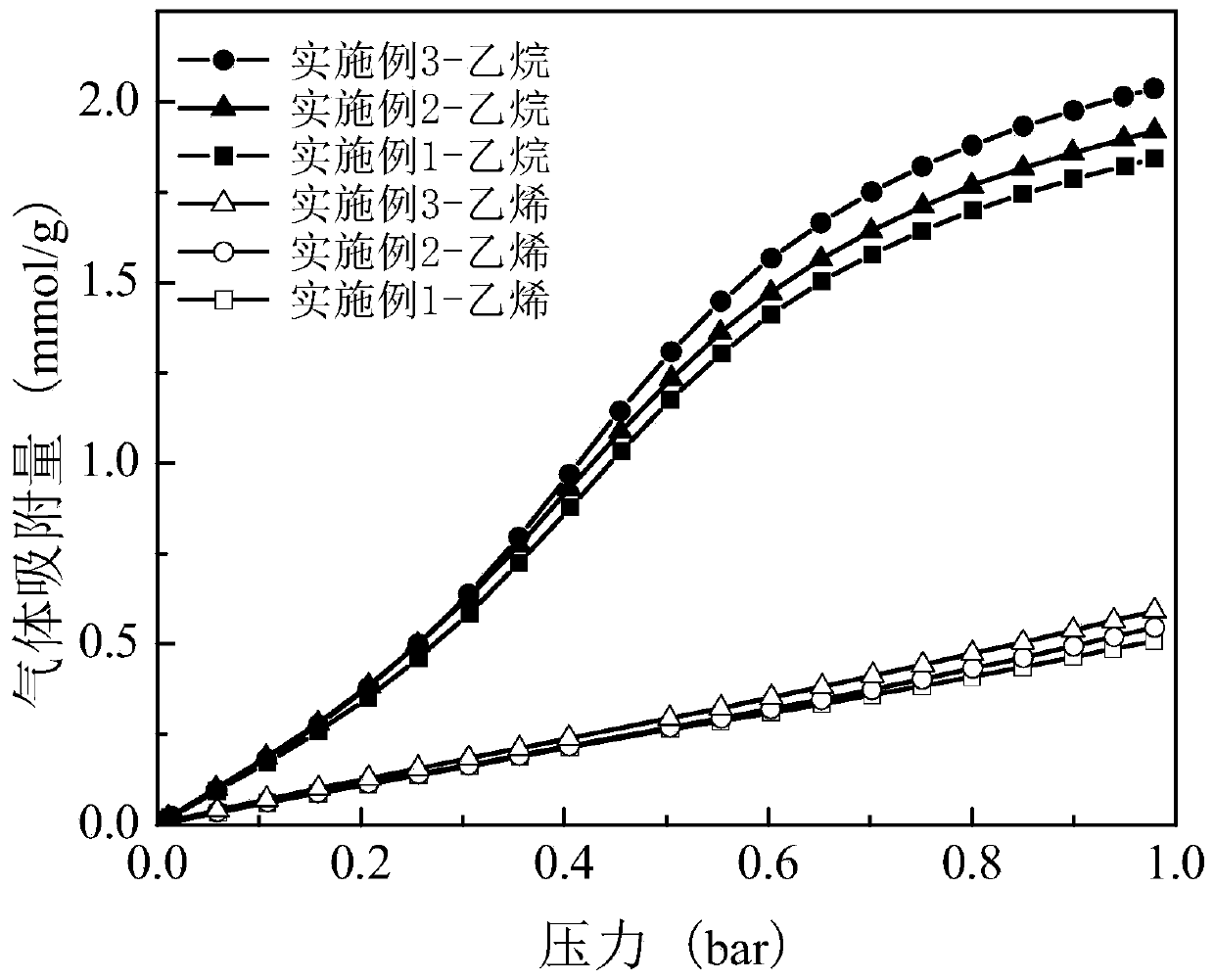

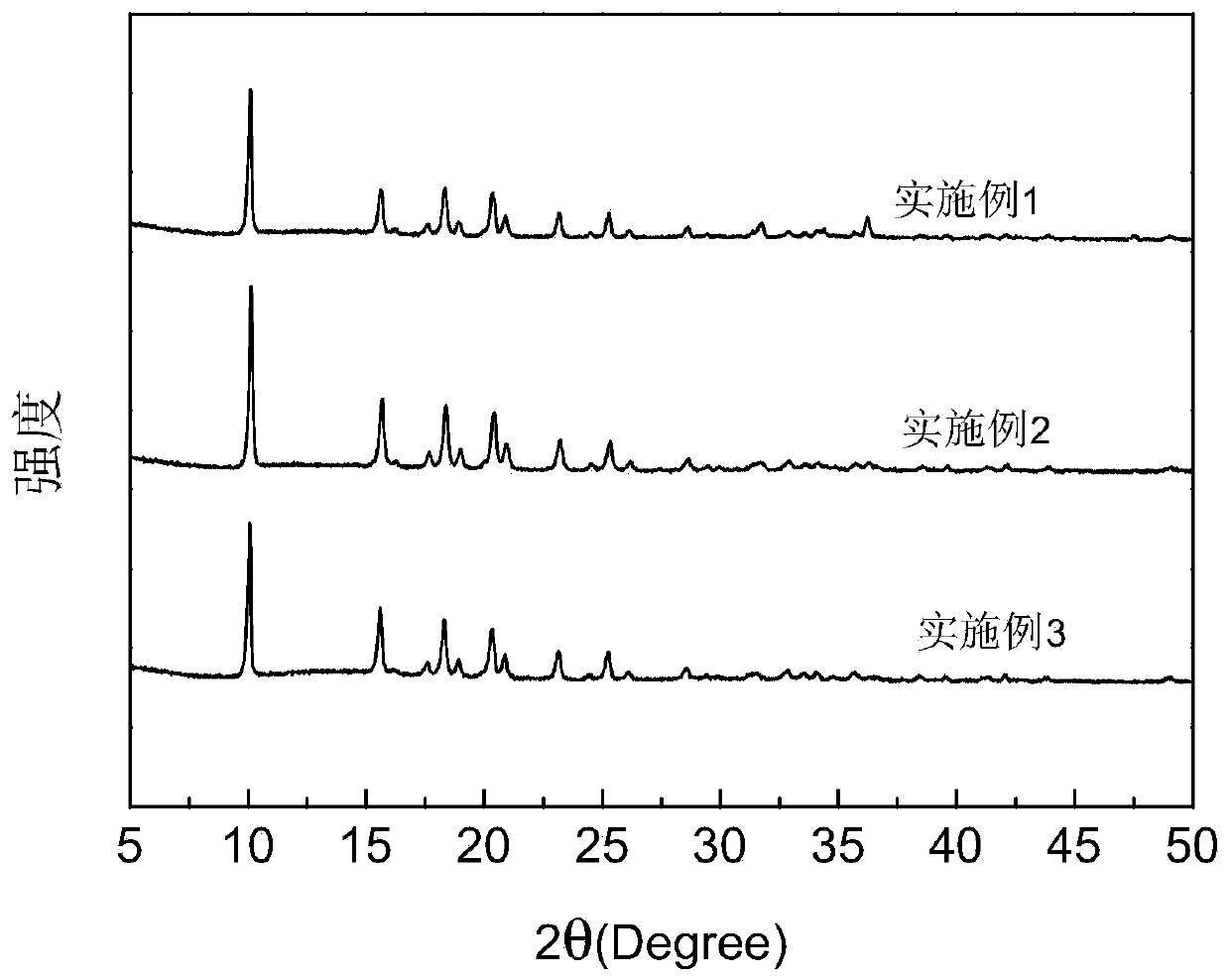

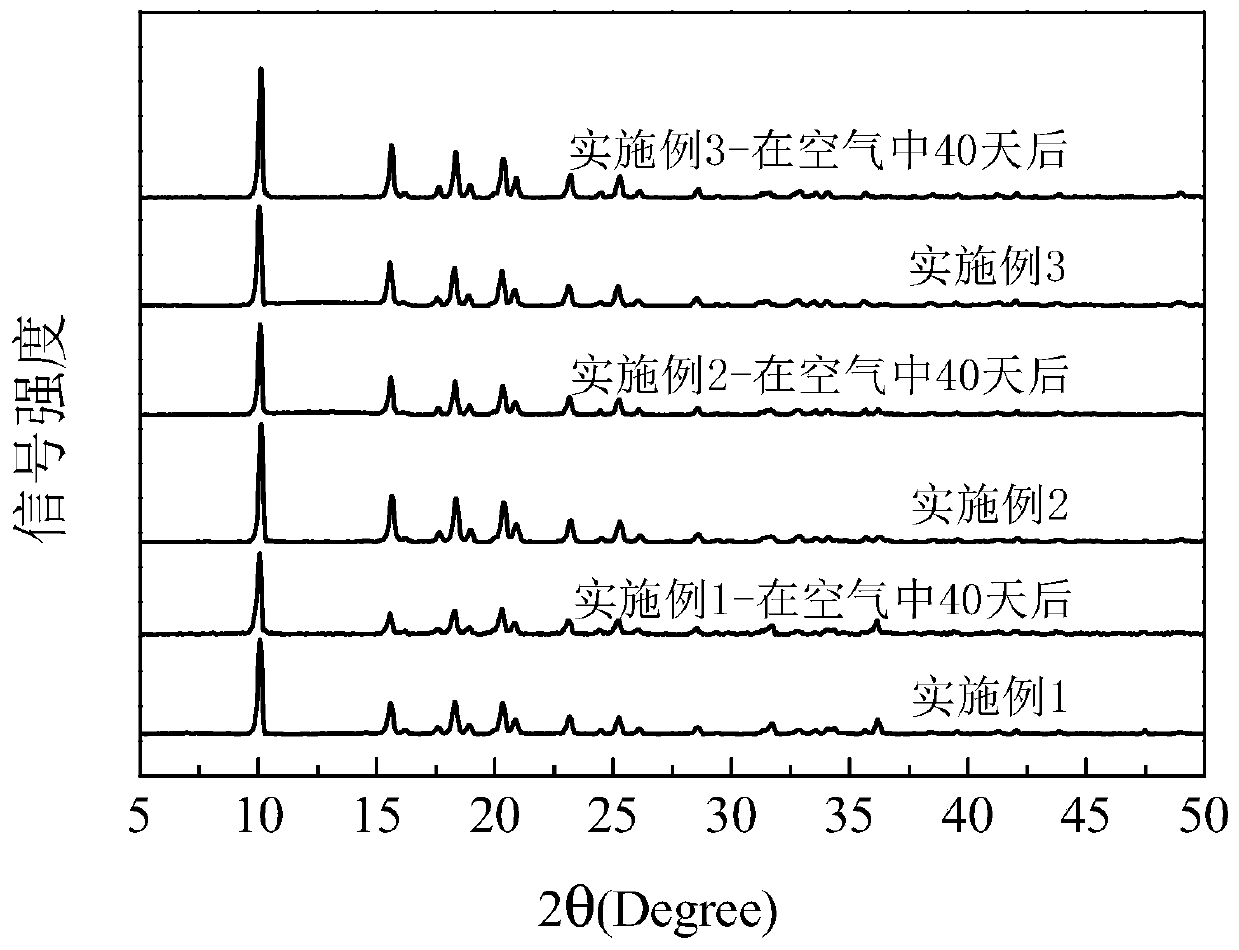

Room-temperature preparation method of metal-organic framework material preferentially adsorbing ethane

PendingCN110075805AGood alkane selectivityGood adsorption and separation performanceGas treatmentOther chemical processesAlkaneN dimethylformamide

Owner:SOUTH CHINA UNIV OF TECH

Tunnel kiln brick-making method

ActiveCN104279865AReduce pollutionReduce consumptionFurnace typesIncreasing energy efficiencyAlkaneTunnel kiln

The invention provides a tunnel kiln brick-making method. A tunnel kiln comprises a preheating section, a sintering section, a cooling section, a fuel and combustion-assisting air conveying system, a temperature control system, a heat exchange system and a smoke discharging system. The tunnel kiln brick-making method includes that a mixture of smoke containing polluting gas like pyrolytic gas, volatile gas gas and alkane generated by the preheating section and combustion-assisting air is fed into the sintering section to be mixed with fuel for mixed combustion, wherein the polluting gas is fully oxidized and finally generate carbon dioxide, water and the like along with combustion smoke to be cooled through a heat exchanger and then discharged. Hot air generated by the cooling section directly enters the preheating section to serve as preheated air, or the hot air generated by the cooling section together with normal-temperature air is heated through the heat exchanger to be preheated air so as to achieve the objective of waste heat recycling. By the tunnel kiln brick-making method, energy utilization rate of the tunnel kiln in the prior art is increased further, pollution, to surrounding environment, of discharged smoke is reduced, and effect of energy conservation and emission reduction is realized.

Owner:DALIAN UNIV OF TECH

Method for preparing gasoline rich in isoparaffin from methanol and/or dimethyl ether

InactiveCN106867564AImprove qualityBroaden the application marketMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention relates to a method for preparing gasoline rich in isoparaffin from methanol and / or dimethyl ether. A catalyst used in the method is prepared from a molecular sieve-loaded active metal component. Since the catalyst used in the method has excellent selectivity on isoparaffin in a gasoline fraction (hydrocarbons with a carbon atom number of 5 to 11; and low selectivity on olefins and aromatic hydrocarbons, the composition of the gasoline produced by using the method can meet the national gasoline standard VI in China, or even meet requirements on the contents of aromatic hydrocarbons and olefins in world advanced standards for clean fuels (such as the European standard V and standards for motor gasoline in California of the US). The method provides a feasible technical route for direct acquisition of non-petroleum resources and has good market prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing alkane through lignin derivative in ionic liquid system

ActiveCN109294614AOvercome the problem of high pressure in the reaction processReduce pressure requirementsLiquid hydrocarbon mixture productionBio-feedstockAlkaneIonic liquid

The invention discloses a method for preparing a high calorific value alkane by one-step hydrodeoxygenation of a lignin-derived aromatic compound in an ionic liquid system. The method adopts a transition metal supported catalyst and is characterized in that biomass alkane gasoline is prepared through lignin-derived compound high-efficiency hydrodeoxygenation in an intermittent reactor at 100-160 DEG C under hydrogen gas pressure of 1-5MPa for 2-10h. The catalytic system has mild reaction conditions and low energy consumption. The catalyst has good dispersibility in the ionic liquid. The ligninderivative conversion rate is 100%. The selectivity of the product cycloalkane is 95% or more. The method is free of protonic acid in the conventional catalytic system. The extremely low vapor pressure of the ionic liquid keeps the system low pressure during the reaction process, the requirements on the equipment are reduced, cycle performances of the catalytic system are good, and the method hasgood industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

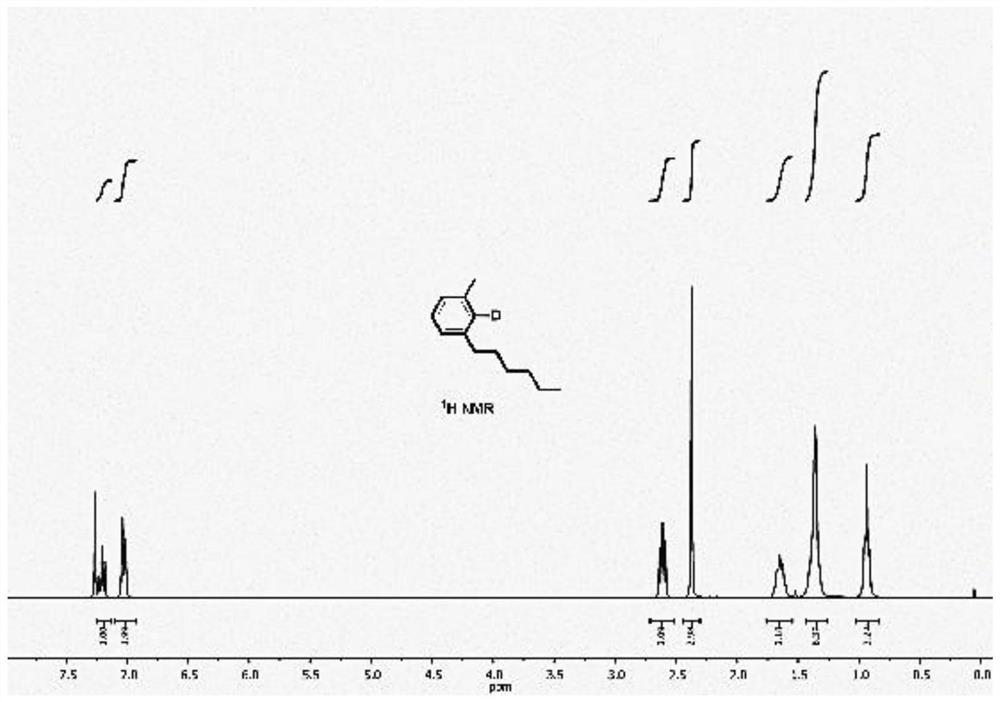

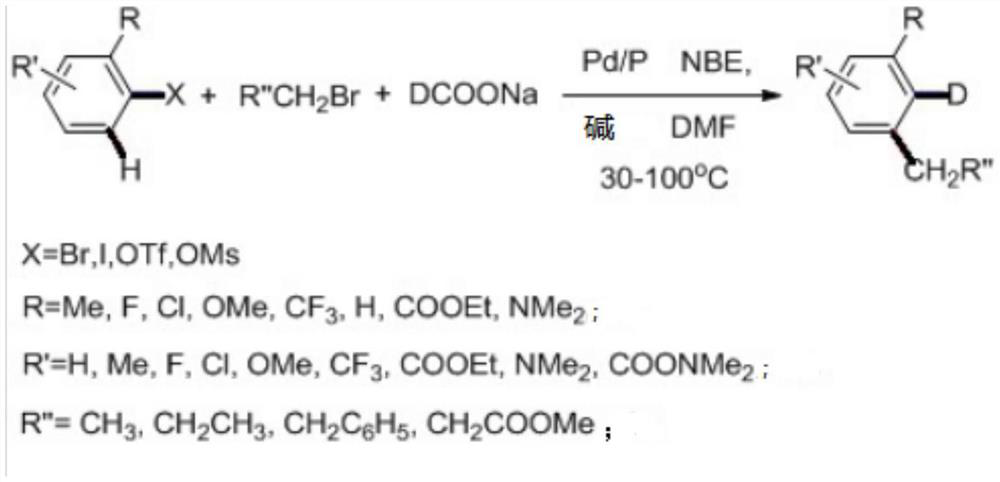

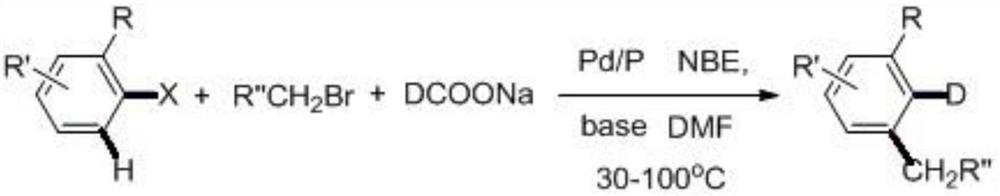

A kind of preparation method of deuterated aromatic compound

ActiveCN110054541BCarboxylic acid nitrile preparationOrganic compound preparationAlkaneCombinatorial chemistry

Owner:安徽秀朗新材料科技有限公司

Preparation method of aryl borate

ActiveCN111875627AReduce pollutionCheap sourceGroup 3/13 element organic compoundsSulfonyl chlorideAlkane

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

Oil stain remover for water pump and preparation method

InactiveCN108285835AImprove antioxidant capacityStrong decontaminationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsChemistryAlkane

The invention provides an oil stain remover for a water pump and a preparation method and relates to the field of cleaning. The oil stain remover comprises the following ingredients: 15-25 parts of sodium metasilicate, 15-20 parts of polyoxyethylene lauryl ether, 5-8 parts of ethanol, 3-5 parts of surfactant, 15-20 parts of sodium pyrophosphate, 5-10 parts of secondary alkane sulphonate, 1-5 partsof metronidazole, 60-80 parts of deionized water and 8-12 parts of biological bacterial remover. According to the oil stain remover for the water pump and the preparation method, the oil stain remover can remove dust on a housing of and oil stains in the water pump, achieves sterilization and odor removal, has a high oxidation resistance effect, strong detergency and wetting power, and is simplein preparation process, low in cost, long in effect and non-stimulating.

Owner:SANLIAN PUMP IND CO LTD

Hydrogenating method of unsaturated alkane based on microwaves

InactiveCN104058918AImprove conversion rateGood hydrogenationHydrocarbon by hydrogenationAlkaneHydrogen

The invention discloses a hydrogenating method of unsaturated alkane based on microwaves. The method comprises the following steps: introducing a certain amount of unsaturated alkane into a 25mL microwave container; after replacing air for three times, introducing 20-100psi unsaturated alkane; finally, introducing hydrogen with pressure being 30-250psi for microwave radiation for 1-5 hours, wherein the microwave radiation power is 10-25w and the reaction temperature is 20-100 DEG C; and carrying out a reaction on the unsaturated alkane with hydrogen under a condition without a catalyst so as to hydrogenate and saturate the unsaturated alkane. The method is mild in reaction condition and high in conversion ratio, thereby facilitating cost-saving.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap