Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130 results about "Polypropylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat resistant. It is a white, mechanically rugged material and has a high chemical resistance. Polypropylene is the second-most widely produced commodity plastic (after polyethylene) and it is often used in packaging and labeling. In 2013, the global market for polypropylene was about 55 million tonnes.

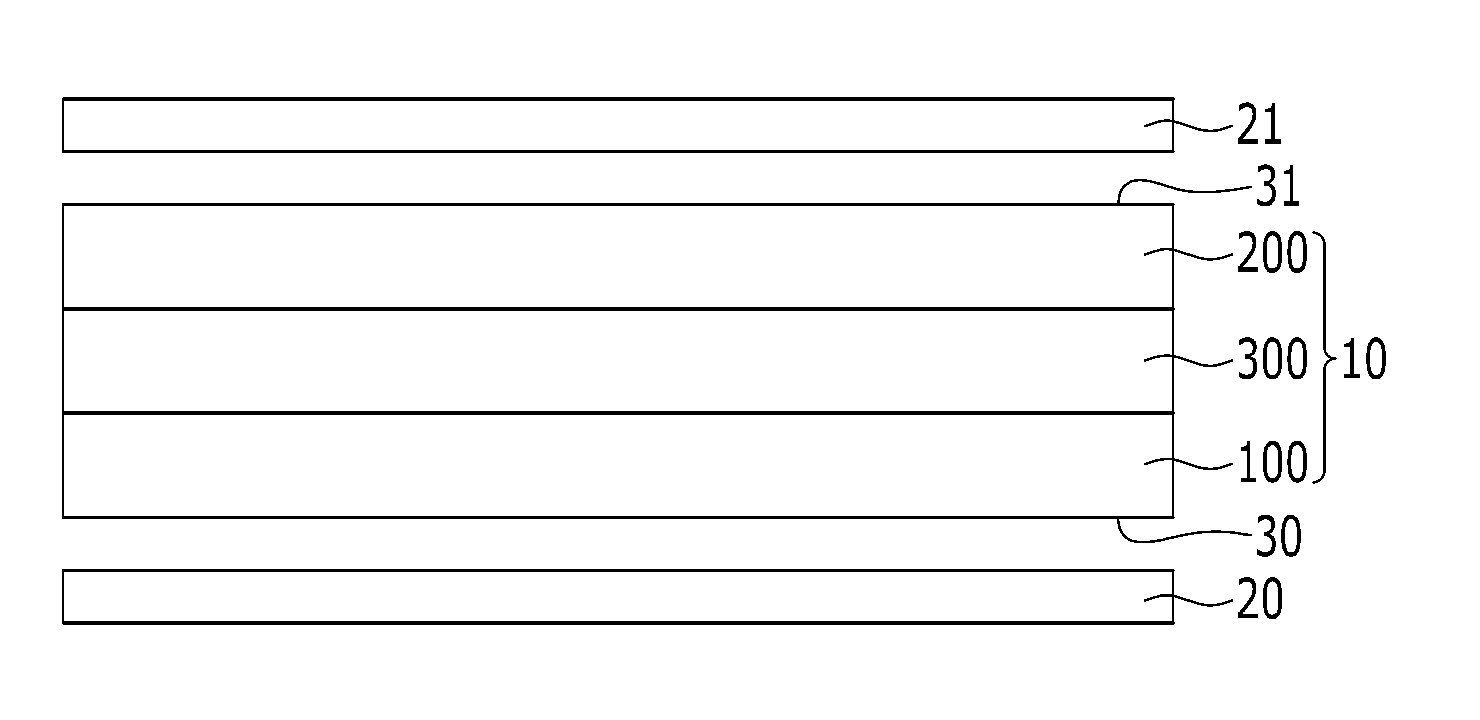

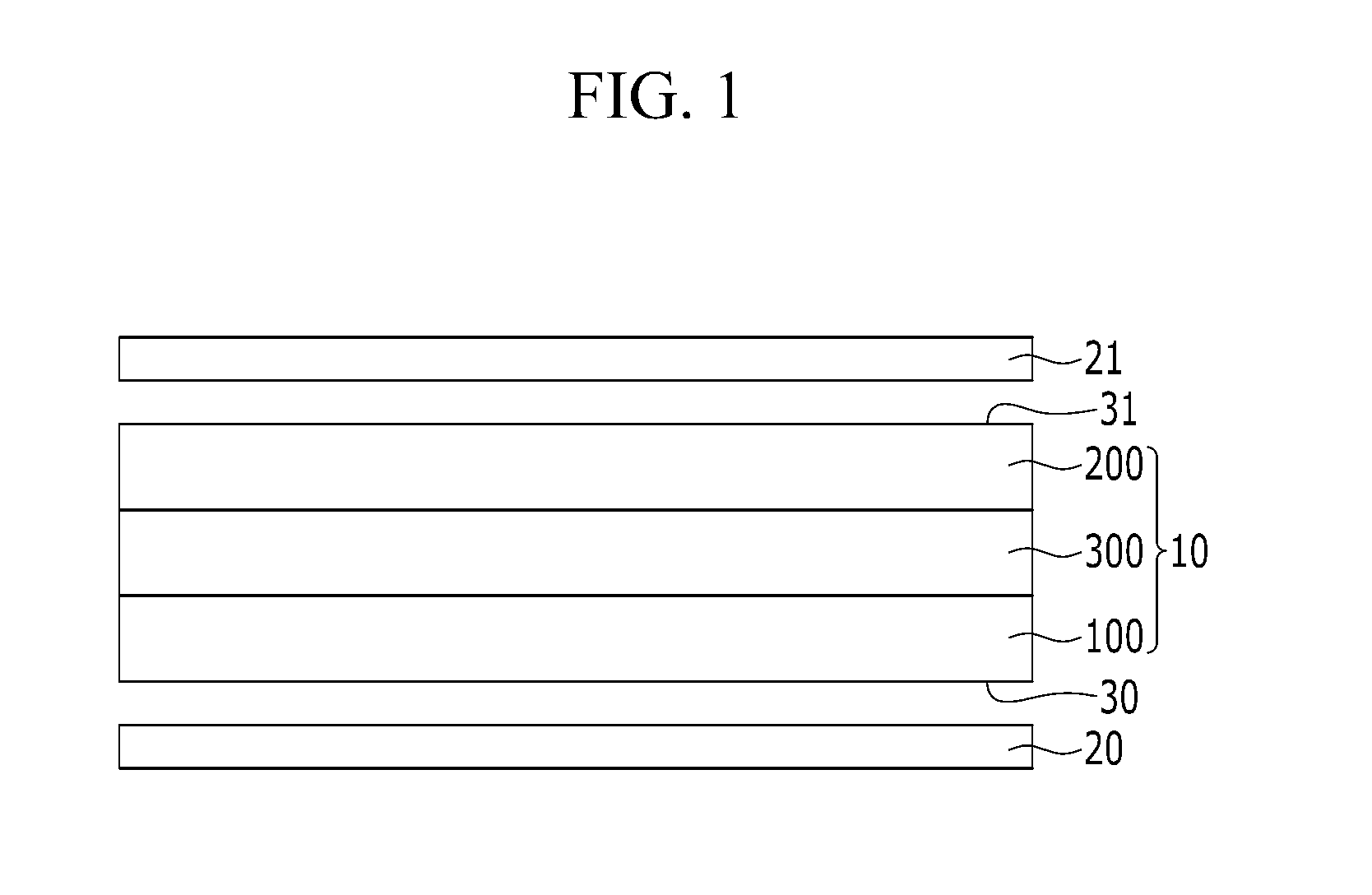

Composition for polarizing film, polarizing film, method of manufacturing the same, and liquid crystal display provided with the polarizing film

Owner:SAMSUNG ELECTRONICS CO LTD

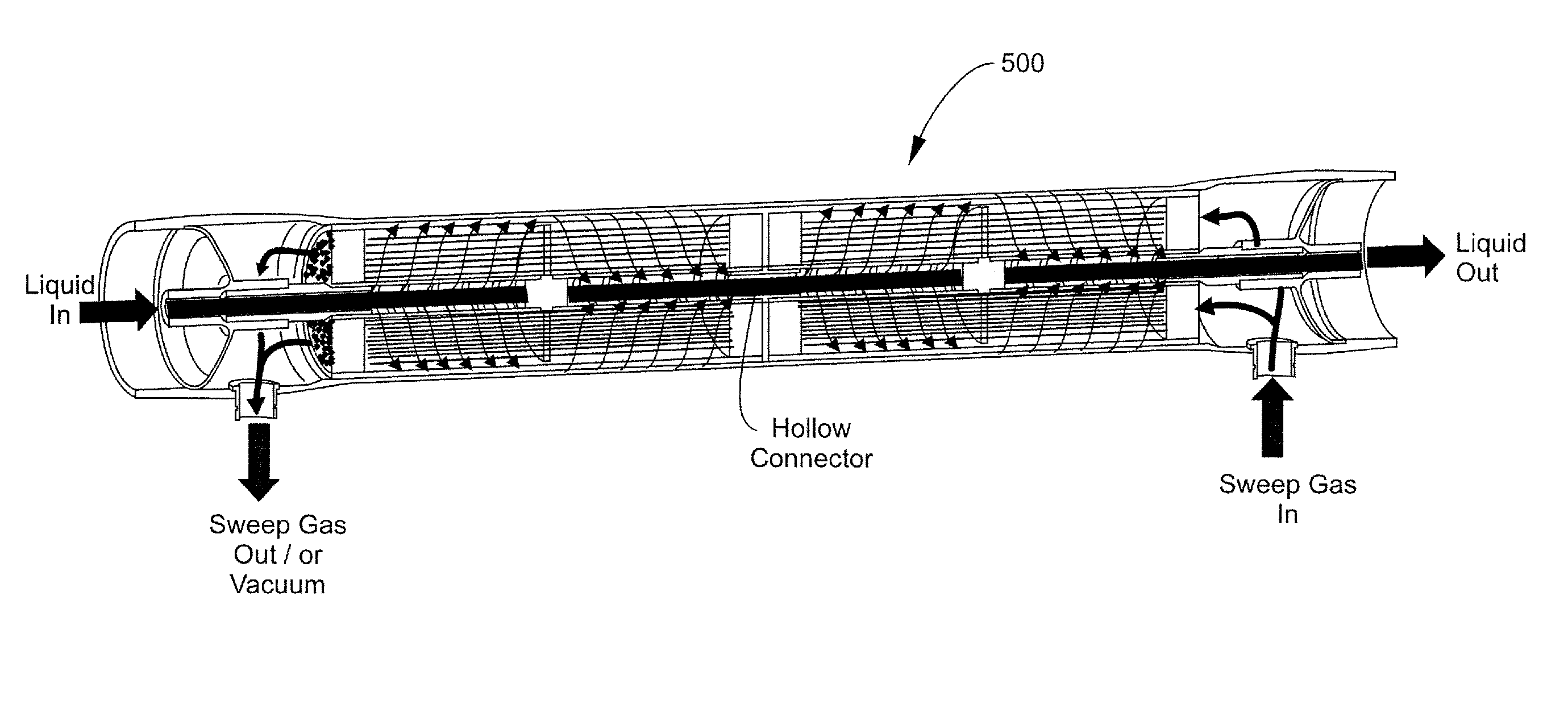

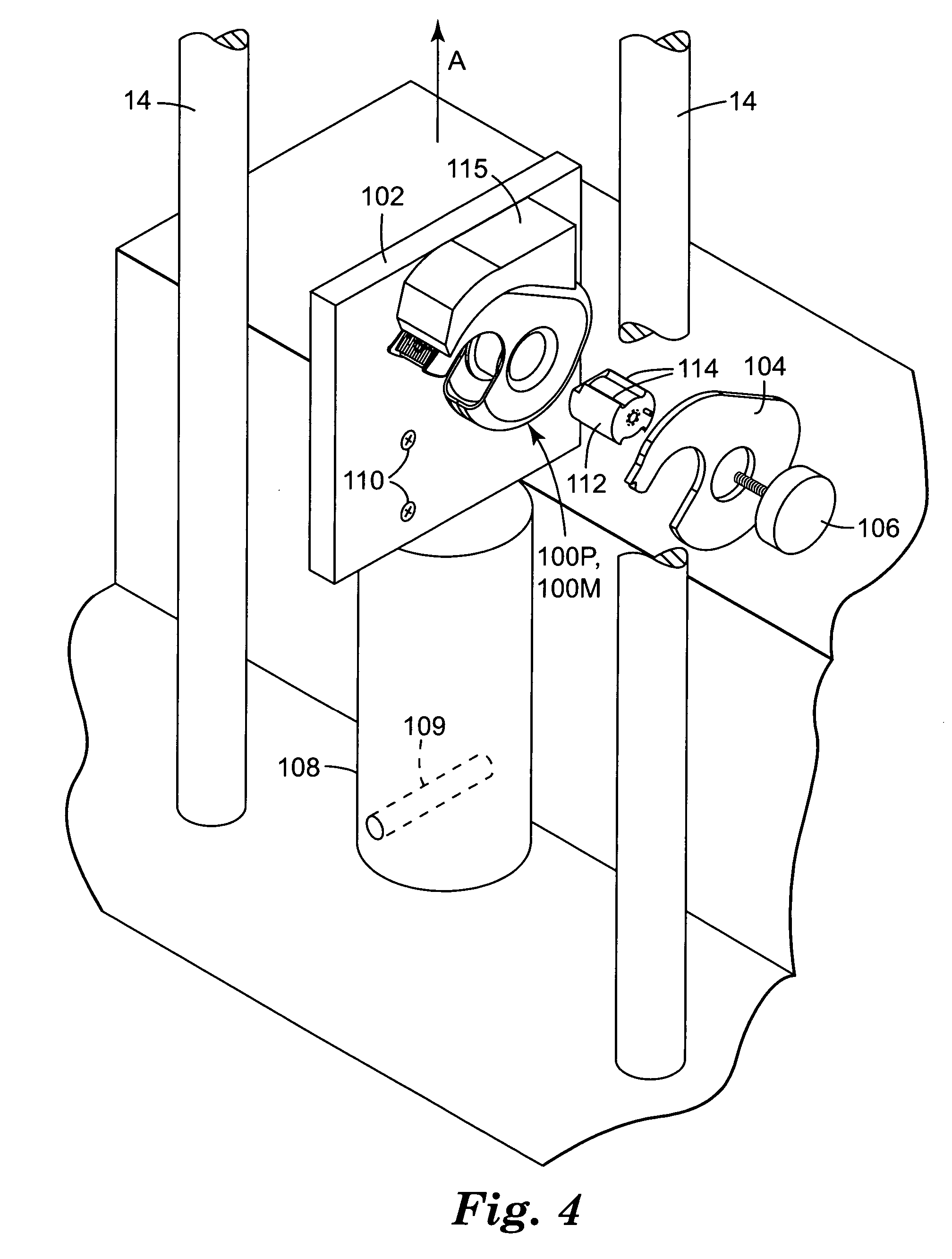

High pressure liquid degassing membrane contactors and methods of manufacturing and use

ActiveUS20110036240A1Fast displacementCost-effectiveMembranesIsotope separationPolypropyleneCorrosion resistant

Owner:3M INNOVATIVE PROPERTIES CO

Heat-proof bottle cap sealing material and preparation method thereof

Owner:EAST CHINA UNIV OF SCI & TECH

Superhigh melt index polypropene and preparing process thereof

Owner:DONGHUA UNIV

Phase change energy storage thermoplastic composite material and preparation method thereof

ActiveCN102070845AHas processing propertiesHigh elongation at breakHeat-exchange elementsPolymer scienceVulcanization

Owner:KINGFA SCI & TECH CO LTD +2

High abrasion-proof PU printing ink for silicon rubber surface

Owner:东莞市贝特利新材料有限公司

Fibers capable of heat storage and temperature adjustment

InactiveCN101845683AReduce leakageImprove thermal stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolyesterCore component

Owner:YINGBAO FIBER TECH RENHUA

Lithium battery flexible packaging film and its manufacturing method

Owner:上海紫江彩印包装有限公司

Fresh-keeping processing and packaging process for berry like strawberry and blueberry berry

InactiveCN102763715ALower oxygen levelsInhibition of reproductionFruits/vegetable preservation by freezing/coolingFragariaSoft materials

Owner:SUZHOU RENXIANGQUAN PRESERVATION SCI & TECH

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

High bath-strength polypropylene and method for preparing same

Owner:SHANGHAI JIAO TONG UNIV

Ultrahigh-toughness concrete and a preparing method thereof

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Super-hydrophobic polypropylene film and preparation method thereof

Owner:ZHEJIANG UNIV

Highly flame-retardant polypropylene foaming sheet and preparation method thereof

Owner:北京斯维浩特新材料科技有限公司

Highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method

InactiveCN1765970AAdd lessLong-term stabilityAntistatic agentBiaxial tension

The invention relates to a highly effective antistatic agglomerate for biaxial tension polypropylene and its preparation method, wherein the agglomerate comprises raw materials of the following constituents (by weight proportion): polypropylene 70-90%, antistatic agent 8-30%, grinding agent 0.1-1%, dispersing agent 0.1-2%, anti-oxidant 0.1-1%, inhibiting agent 0.1-0.5%, anti-ageing 0.1-0.5%.

Owner:SHANGHAI SUNNY

Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

ActiveCN107266685AOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolymer science

Owner:宁波塑之华塑化有限公司

Mildew-resistant and antibacterial nano-silver decorative laminated board

ActiveCN103862988AAdequate defense against invasionImprove adhesionNon-macromolecular adhesive additivesSpecial ornamental structuresPolymer sciencePolyolefin

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Flame-retardant wear-resisting modified polypropylene material and preparation method thereof

Owner:解波

Method for preparing high-temperature resistant microporous membrane

ActiveCN103811704AClearly definedEasy to understandCell component detailsPolymer sciencePolypropylene

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

Aluminum plastic plate flame-retardant core layer and aluminum-plastic plate

ActiveCN109111617AReduce corrosionExtended service lifeSynthetic resin layered productsMetal layered productsLow-density polyethyleneAntioxidant

Owner:台州市佳信新材料科技有限公司

Ink resin composite used for plastic gravure printing and preparation method thereof

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Preparation method of waterborne polyurethane emulsion and waterborne polyurethane emulsion prepared by preparation method

InactiveCN104211902AImprove waterproof performanceGood solvent resistanceHydroxybutyric acidPolymer science

Owner:内蒙古源创绿能节能环保产业创业投资合伙企业(有限合伙)

Novel halogen-free flame retardant composite material and preparation method thereof

Owner:广州敬信高聚物科技有限公司

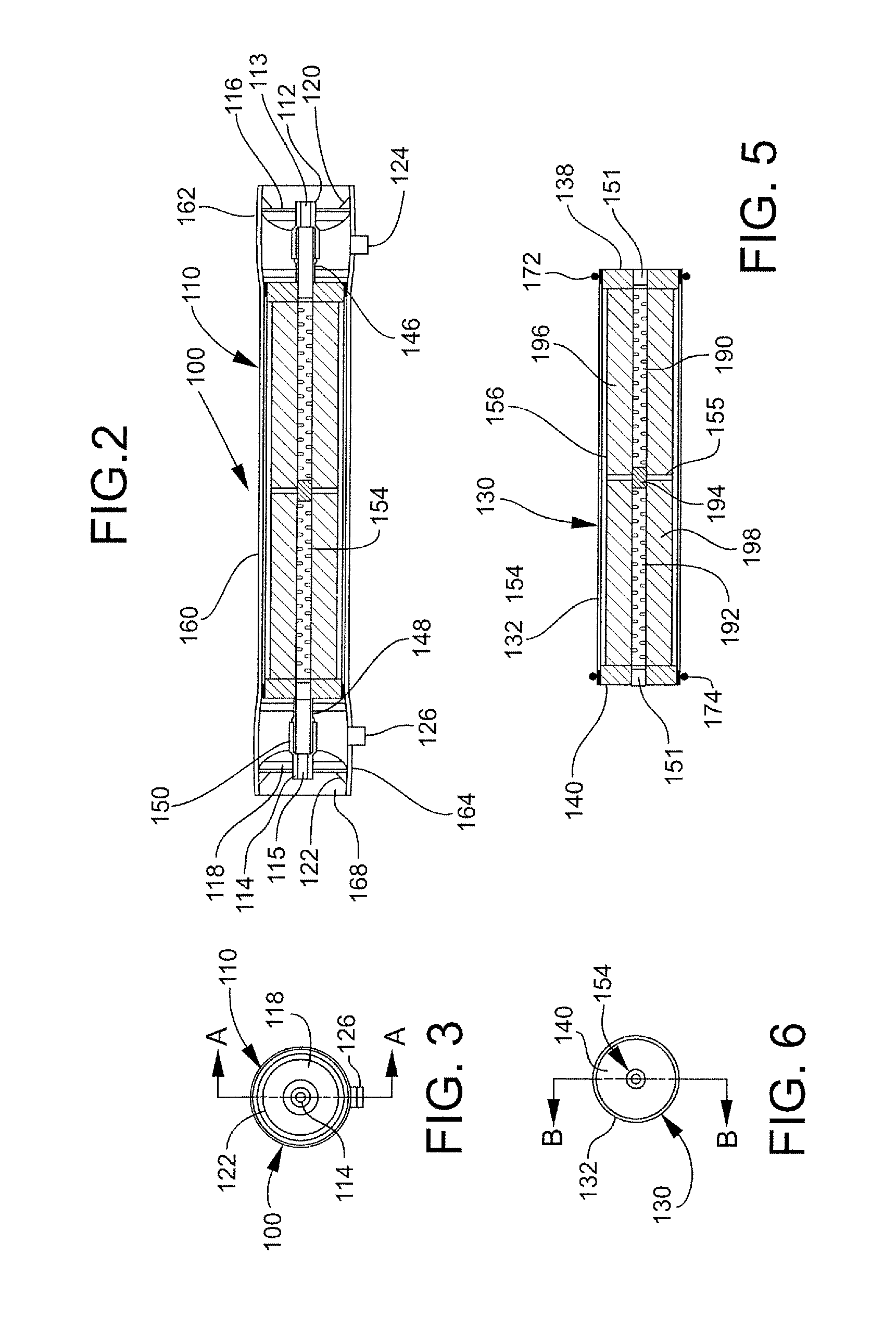

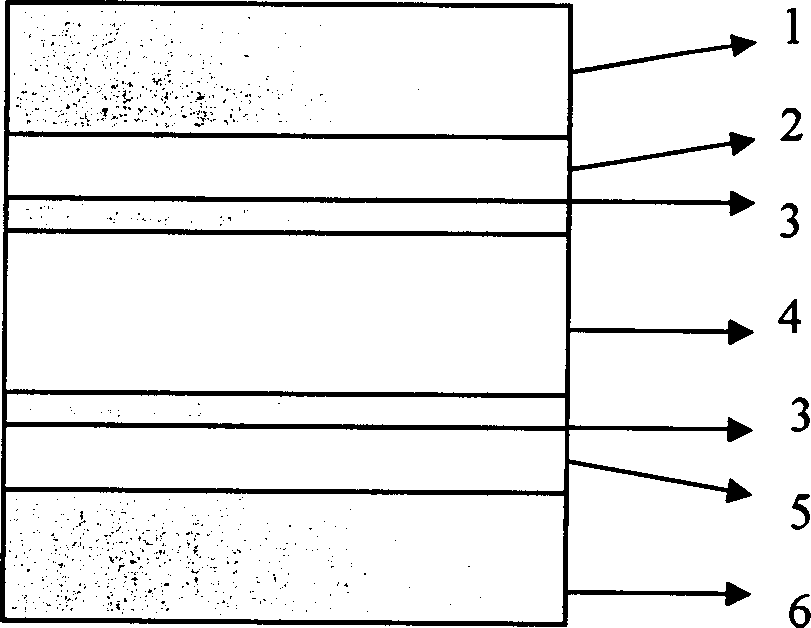

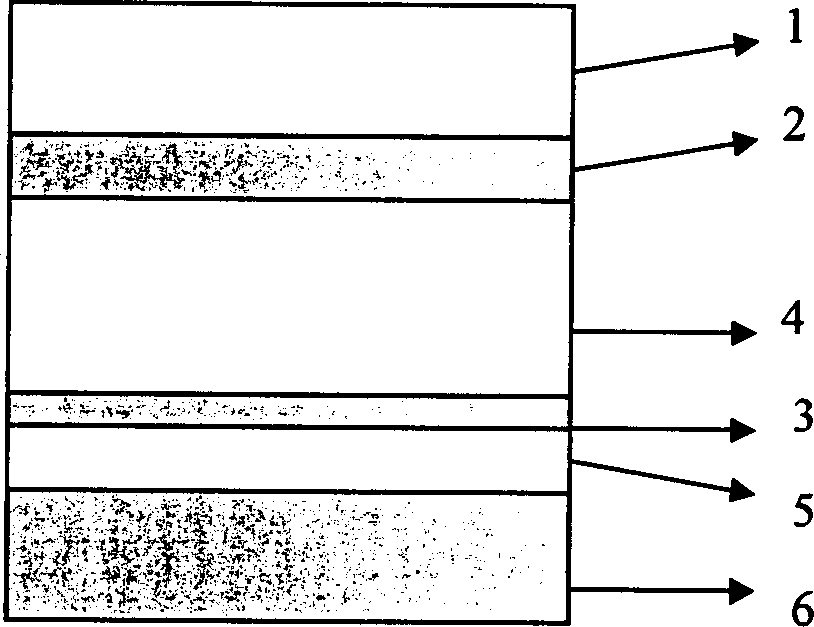

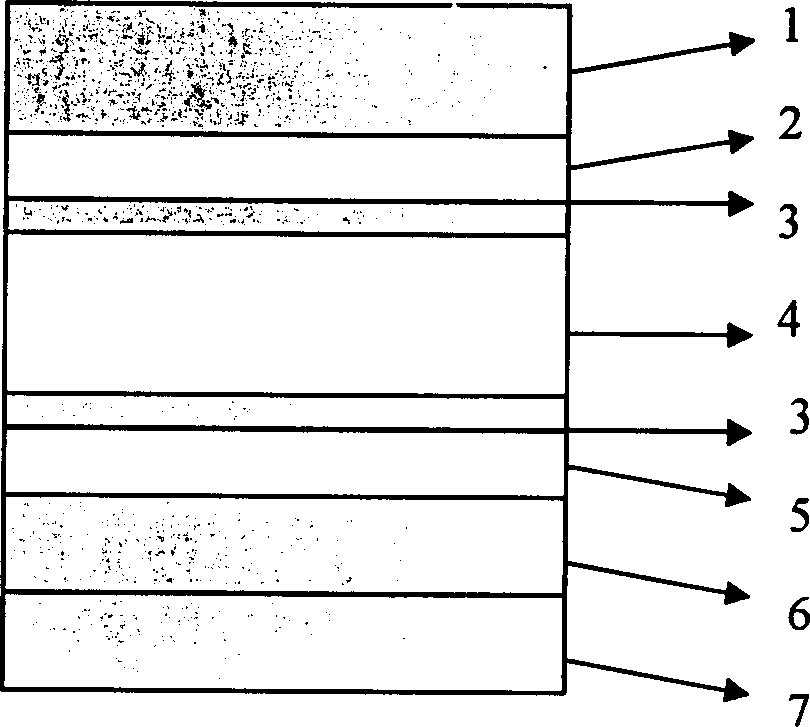

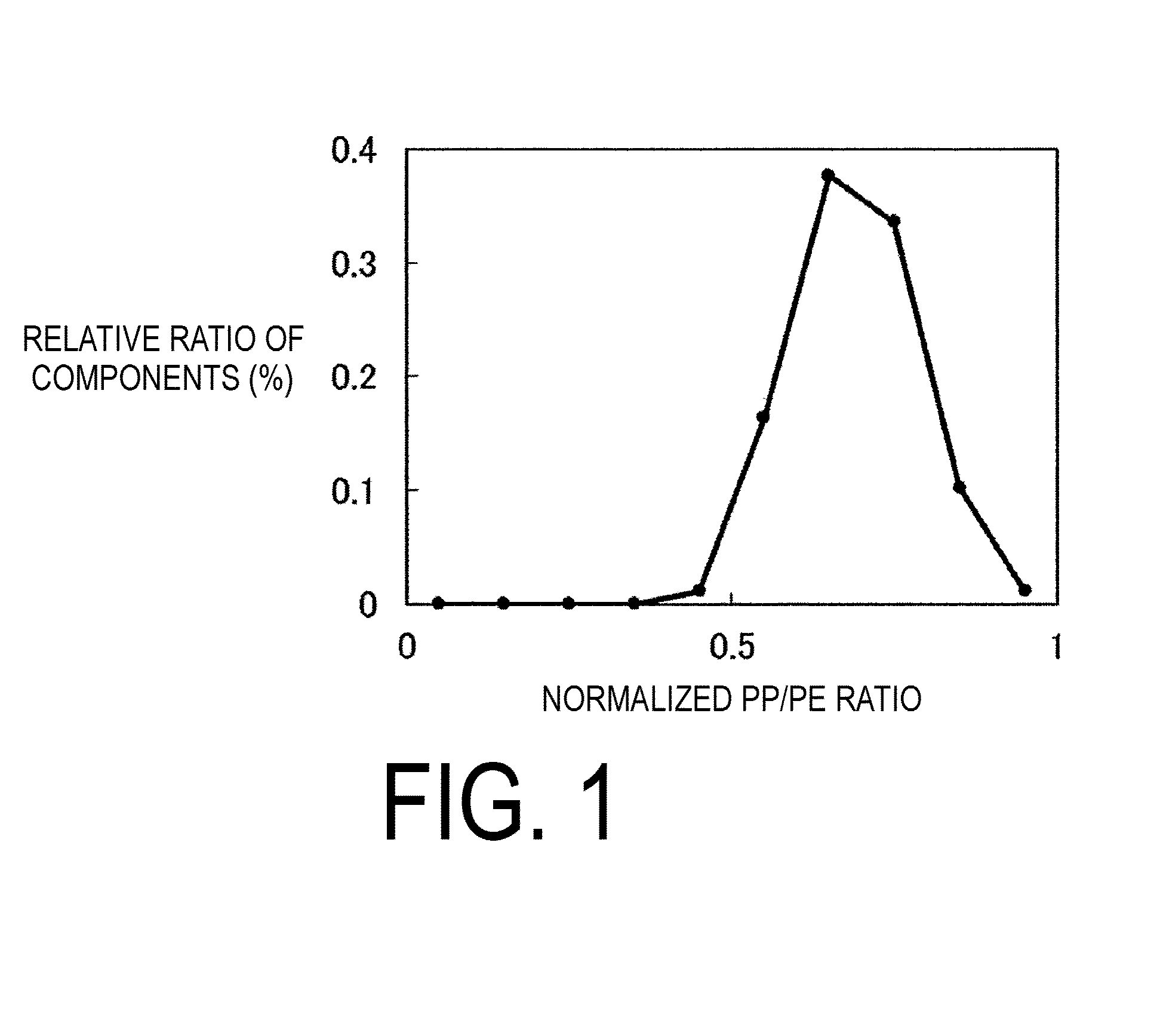

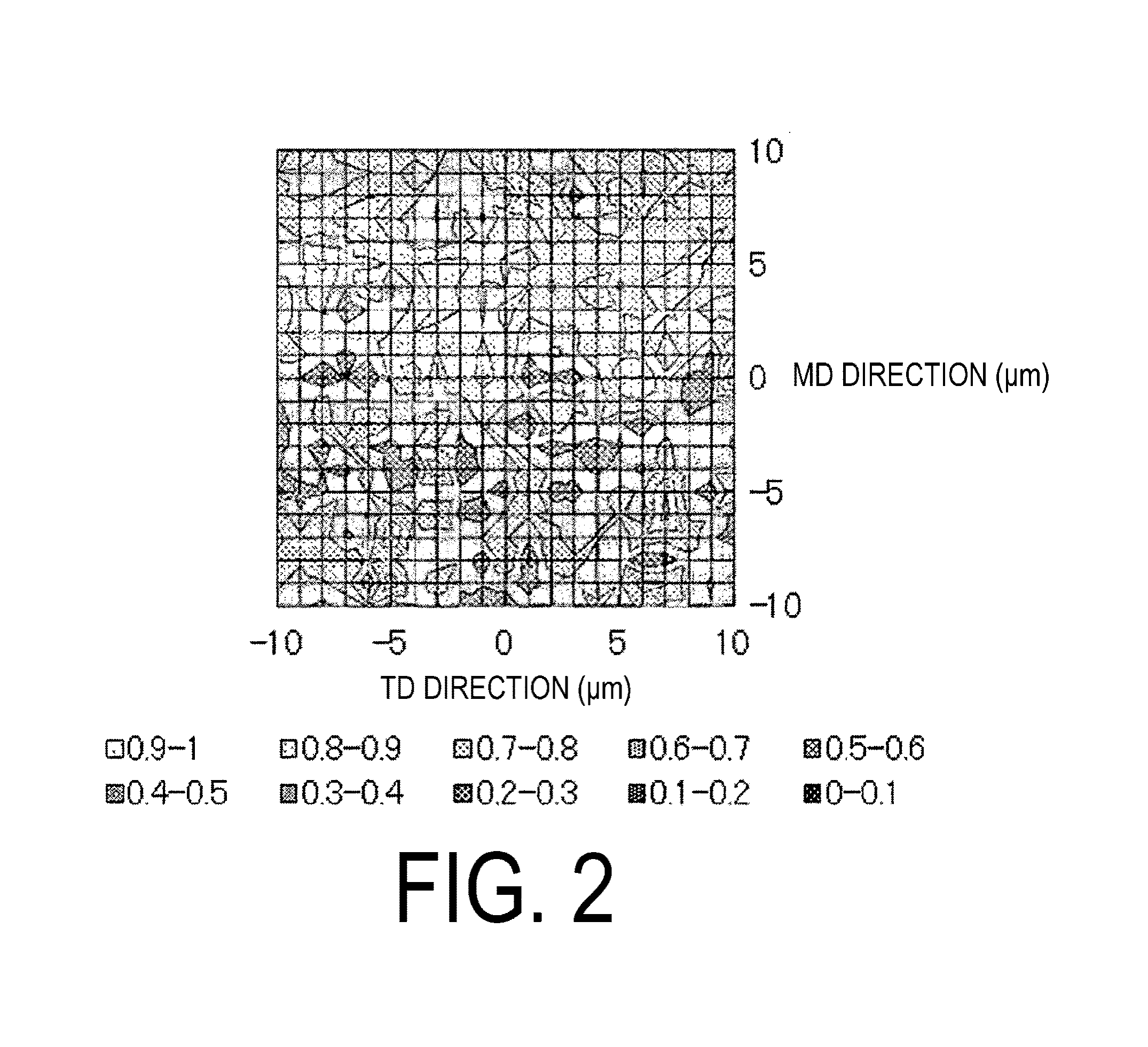

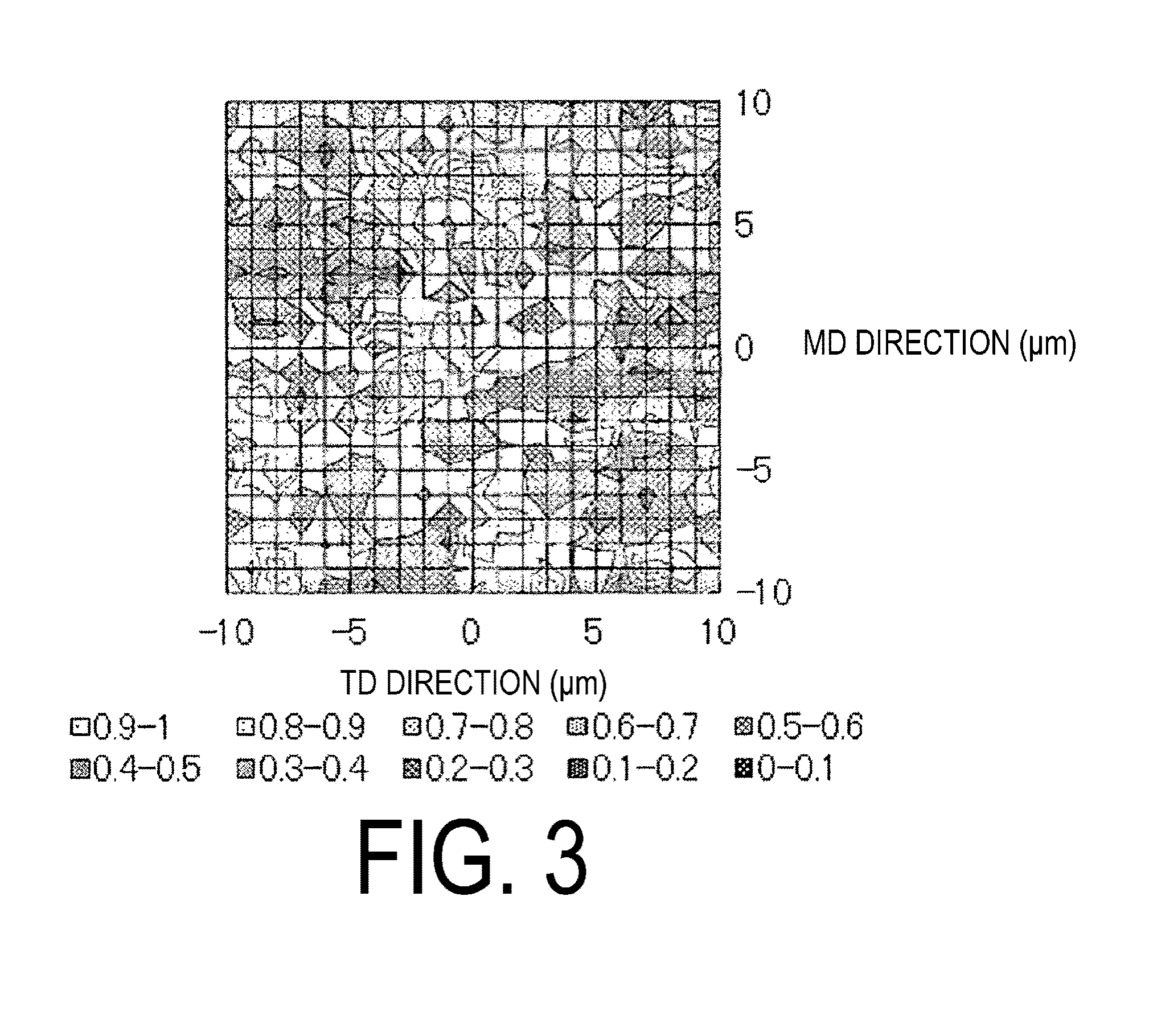

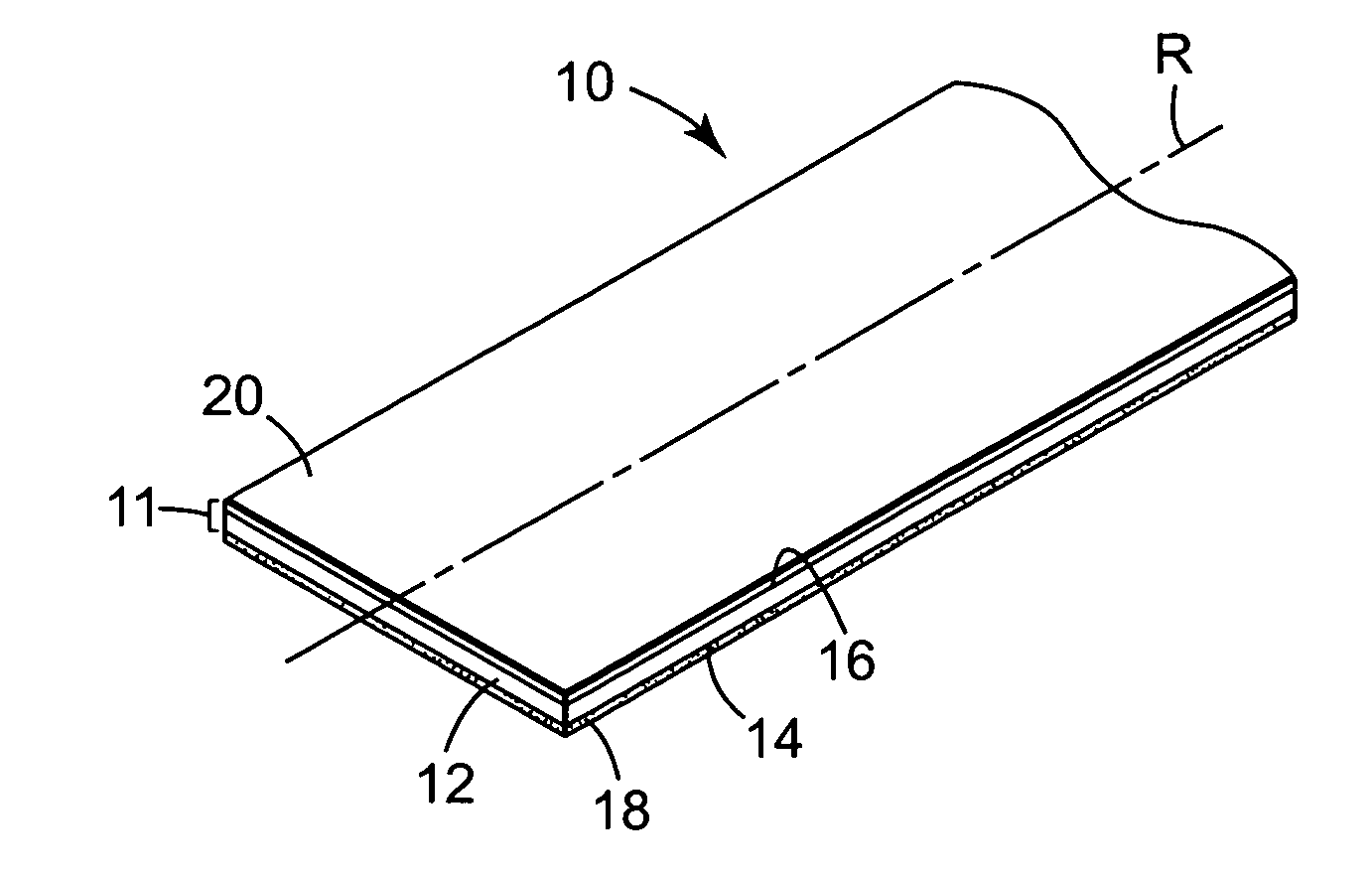

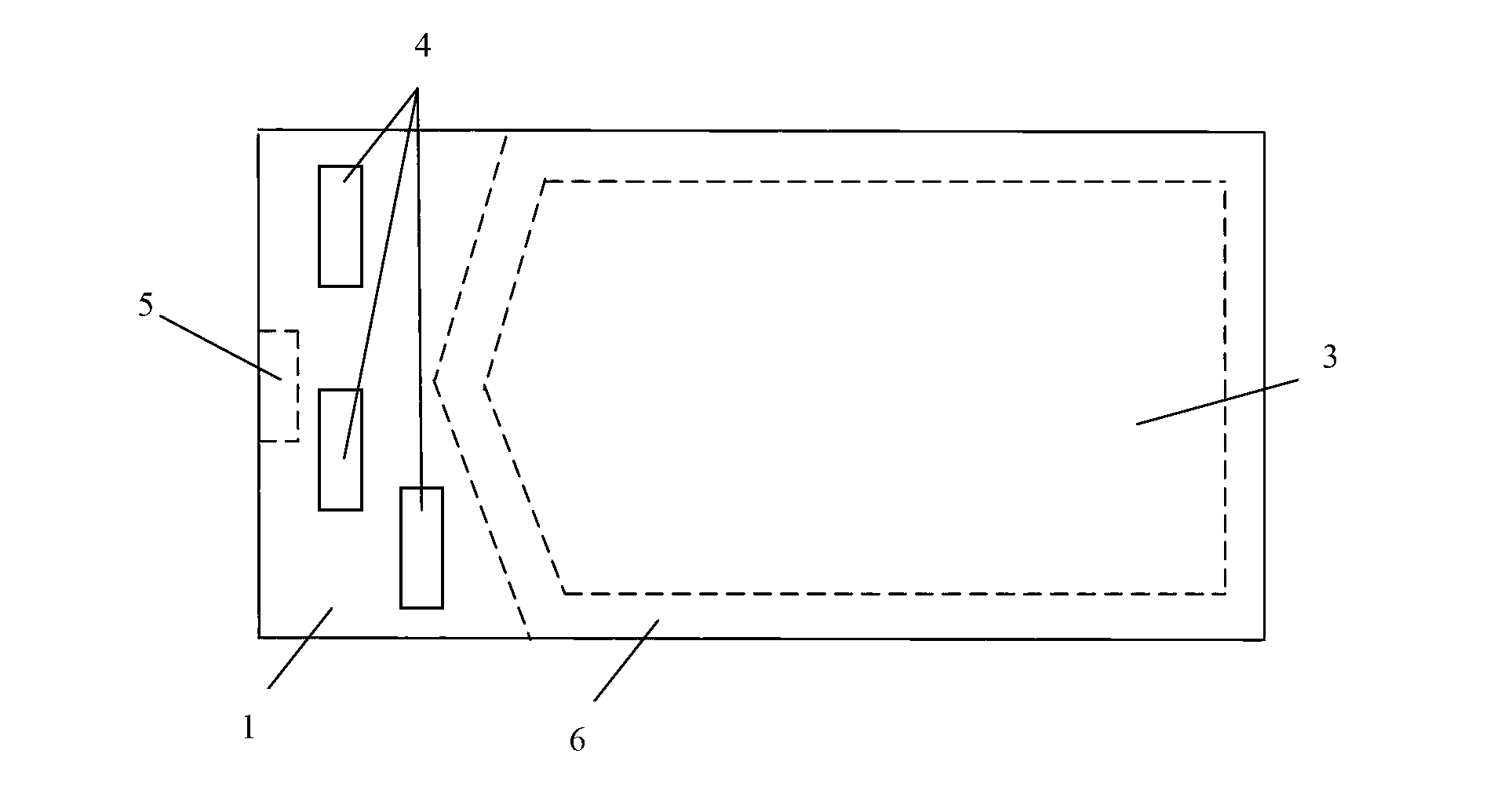

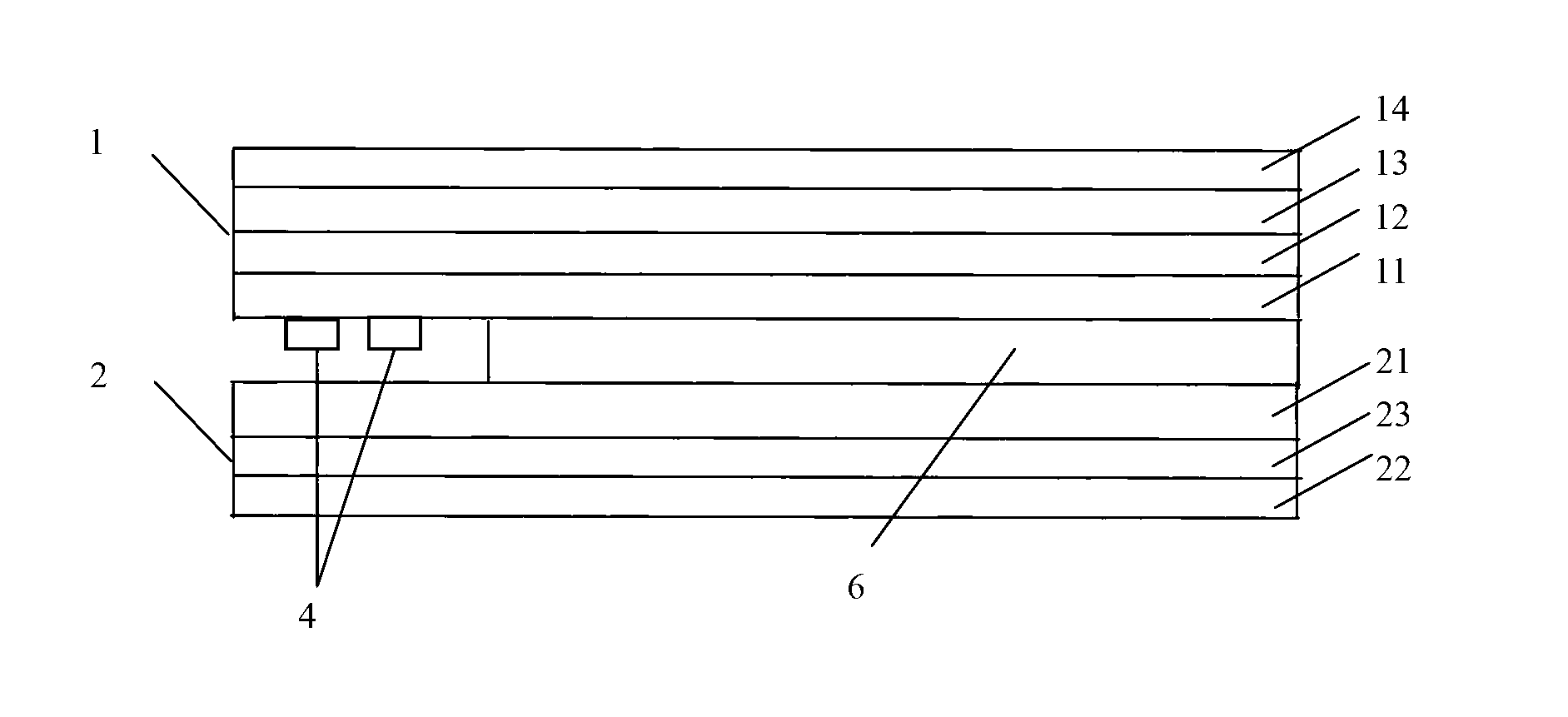

Multilayer, microporous polyolefin membrane, and production method thereof

ActiveUS20160118639A1Improve permeabilityHigh strengthSemi-permeable membranesMembranesIn planePolymer science

Owner:TORAY IND INC

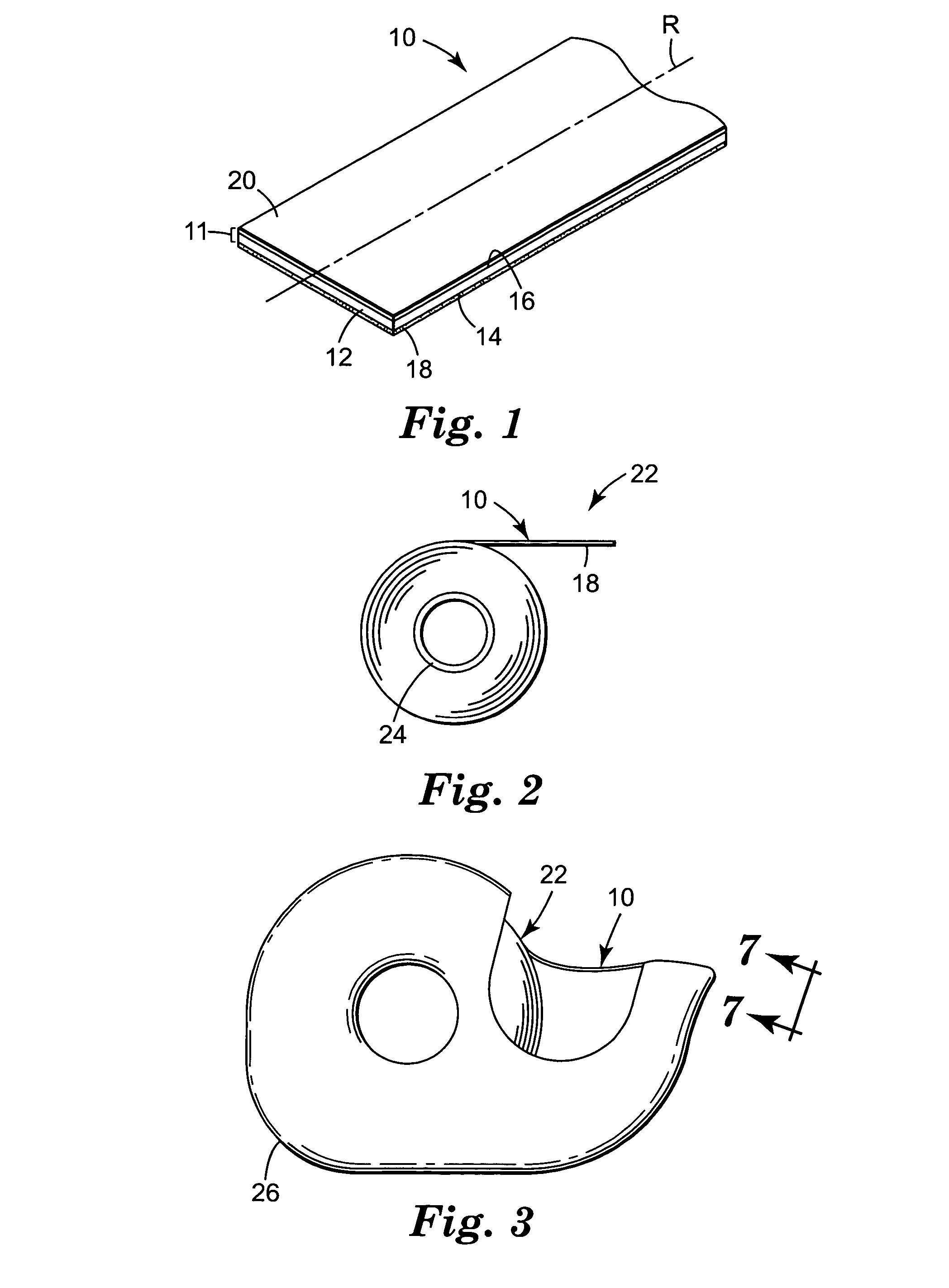

Oriented polypropylene films for adhesive tape

Owner:3M INNOVATIVE PROPERTIES CO

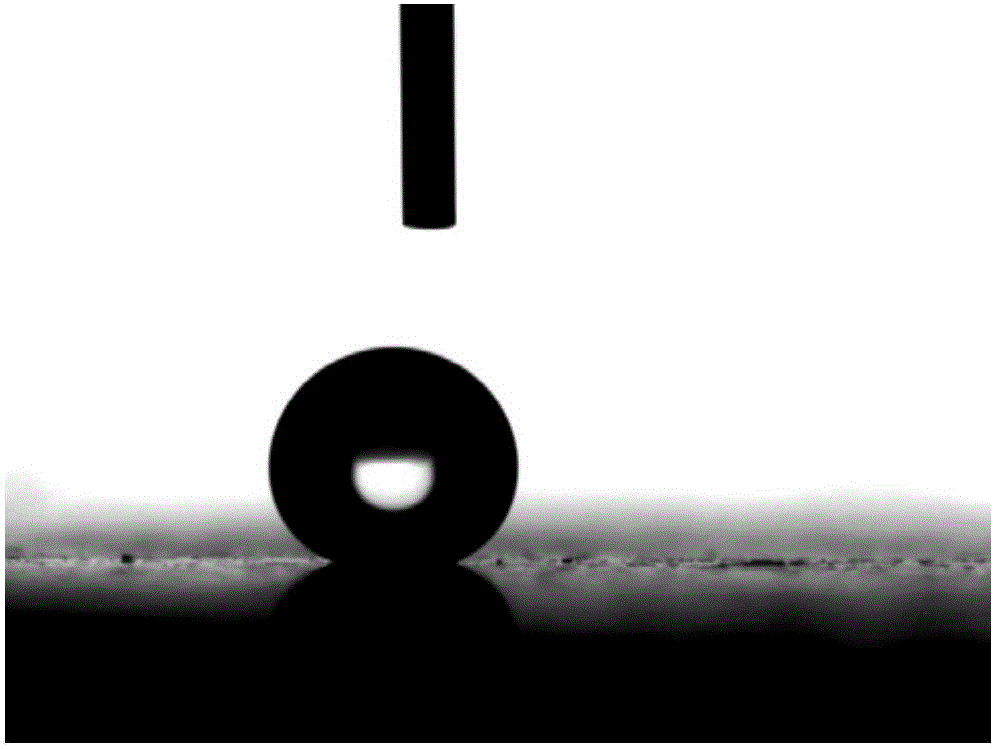

Preparation method for durable aluminum and aluminum alloy superhydrophobic surface coating

InactiveCN102527619AExtended service lifeGood antifoulingSpecial surfacesCoatingsSuperhydrophobic coatingPolypropylene

Owner:HUNAN UNIV OF TECH

Medical sterilization packaging bag

ActiveCN103072739AImprove packaging antibacterial rateGuarantee the safety of useBagsSacksSurface layerNonwoven fabric

Owner:SHANGHAI JIANZHONG MEDICAL PACKAGING

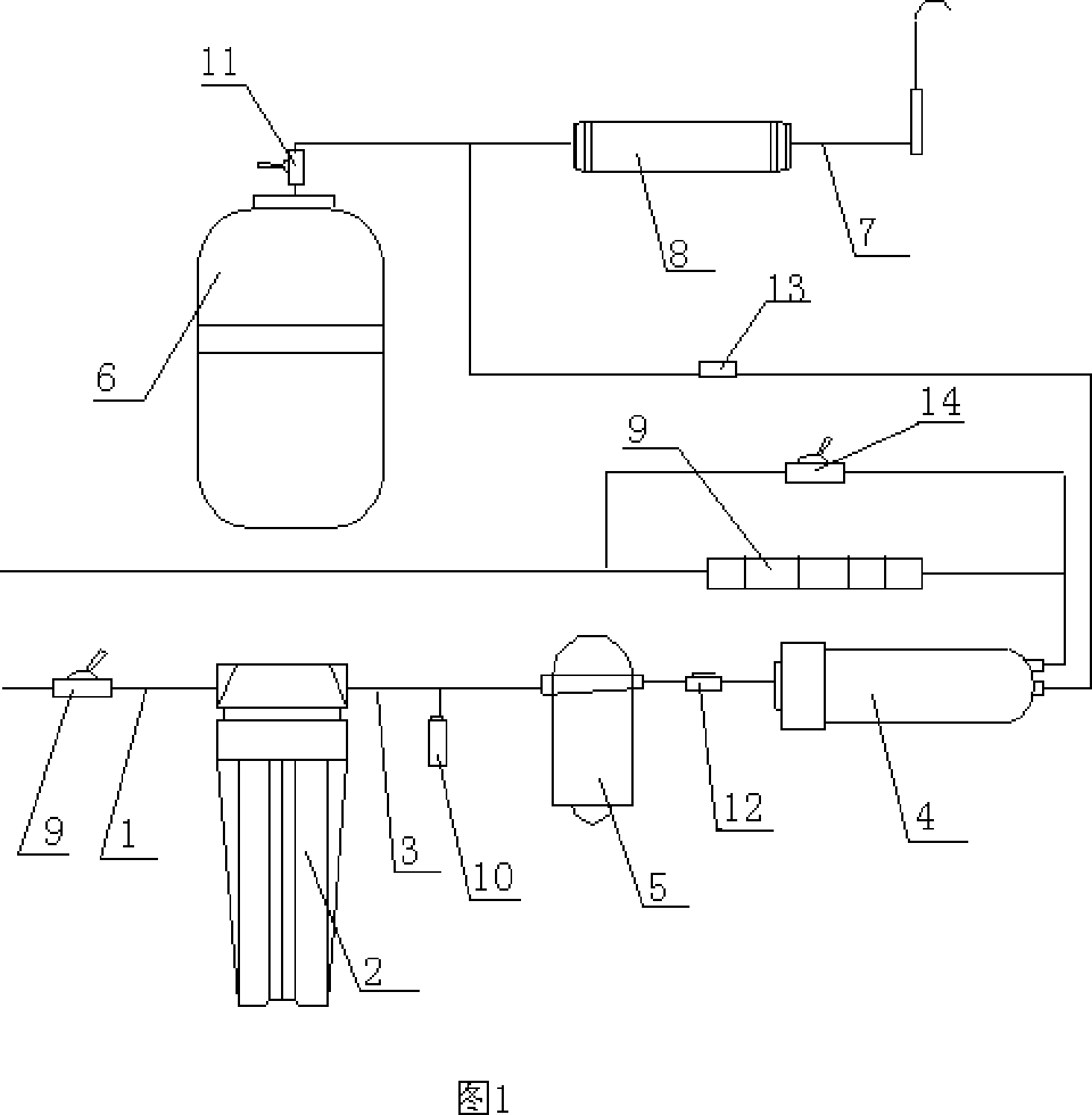

Household water purifying process and system

ActiveCN101066790AWater/sewage treatment bu osmosis/dialysisWater/sewage treatment using germicide/oligodynamic-processPolypropyleneChemistry

Owner:VONTRON TECH CO LTD

Anti-bacterial and mouldproof plastic

The invention discloses anti-bacterial and mouldproof plastic. The anti-bacterial and mouldproof plastic comprises the following substances by weight: 14-18 parts of cinnamyl aldehyde, 18-28 parts of POE, 2-5 parts of copper, 2-3 parts of glycerol triglycerate, 4-7 parts of polyvinyl ester, 3-7 parts of magnesium sulfate, 3-12 parts of polypropylene, 6-10 parts of a bisphenol A type polycarbonate, 5-8 parts of an active resin binder, 6-12 parts of triethanolamine, 2-6 parts of vinyl triethoxysilane and 8-16 parts of a drier. With the above technical solution, raw materials are easily available, and cost is low. By adding the drier, the surface of the plastic can be maintained relatively dry; an environment for microbial growth is broken; propagation of microbes is effectively suppressed; and mouldiness can be prevented.

Owner:JIANGSU XINRUN PLASTIC CO LTD

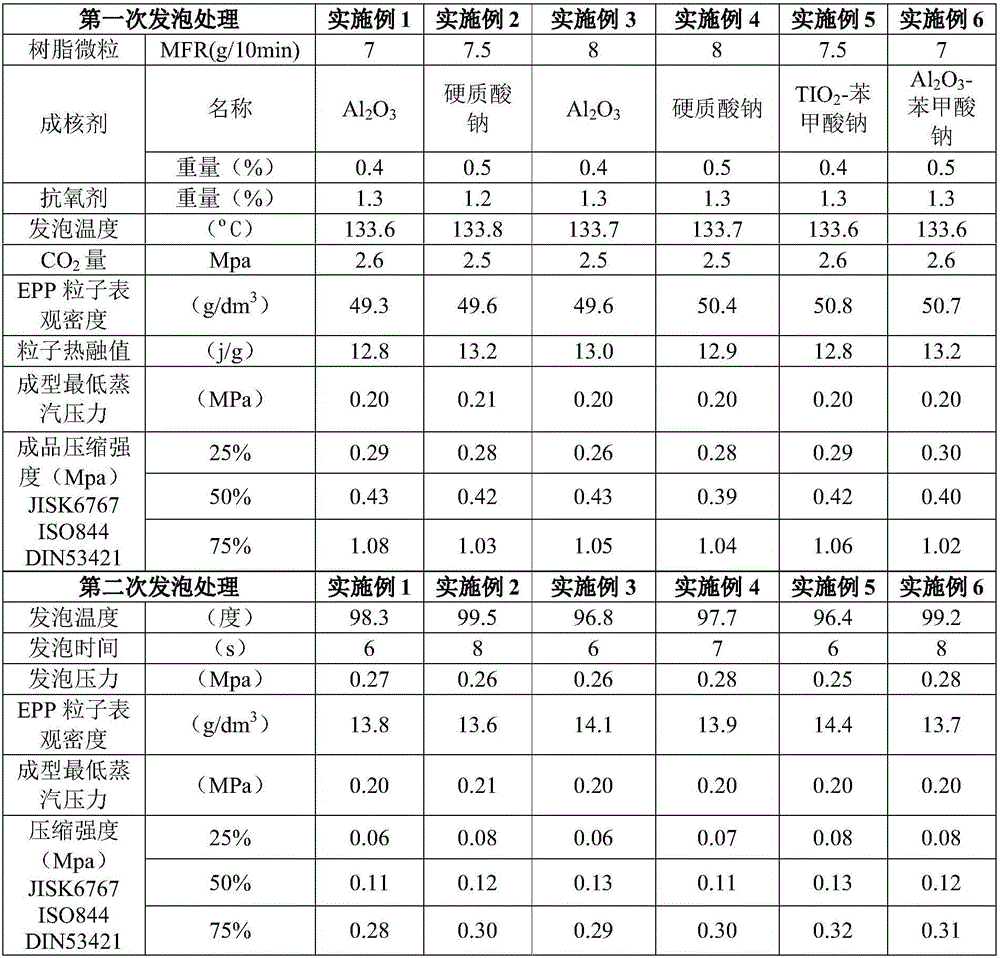

Foamed polypropylene bead and preparation method thereof

Owner:中广核博繁新材料(南通)有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap