Lithium battery flexible packaging film and its manufacturing method

A technology of flexible packaging film and manufacturing method, which is applied in the field of composite flexible packaging film and its manufacturing, can solve the problems of high raw material cost, small melting finger, low melt strength, etc., and achieve the effect of low price and cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

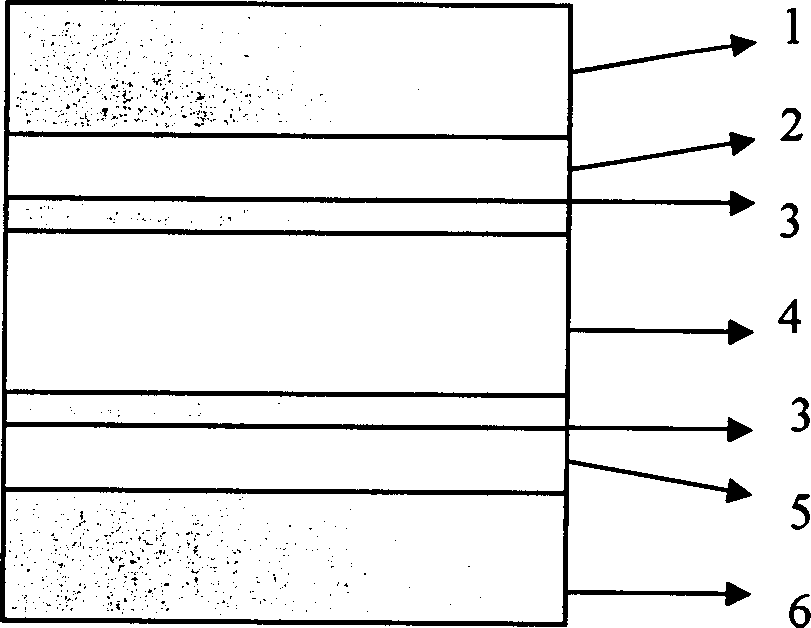

[0032] Such as figure 1 As shown, it is a schematic diagram of a lithium battery flexible packaging film made of base layer / dry compound adhesive / chemical treatment layer / aluminum foil layer / chemical treatment layer / adhesive resin layer / heat sealing layer; the lithium battery flexible packaging film is made of base The bottom layer 1, the dry compound adhesive 2, the chemical conversion treatment layer 3, the aluminum foil layer 4, the chemical conversion treatment layer 3, the adhesive resin layer 5 and the heat sealing layer 6 are composed of seven layers.

[0033] The base layer 1, the aluminum foil layer 4, and the chemical treatment layer 3 can be processed according to existing methods; the base layer 1 is selected from polyamide, the aluminum foil layer 4 is selected from soft aluminum foil with a thickness of 45 microns, and the heat-sealing layer 6 One side used for compounding is polyethylene, metallocene polyethylene resin is selected, the other side used f

Embodiment 2

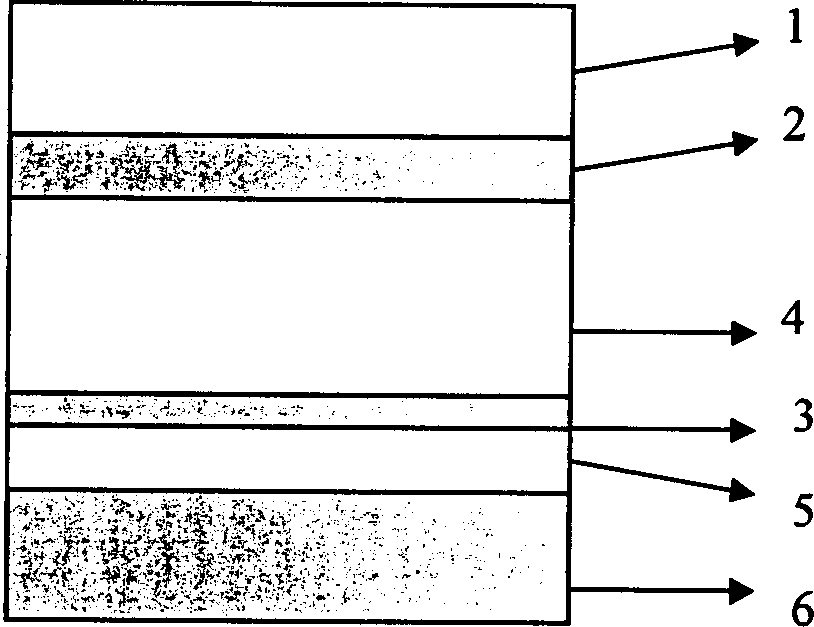

[0040] Such as figure 2 Shown is a schematic diagram of a lithium battery flexible packaging film made of base layer / dry lamination adhesive / aluminum foil layer / chemical treatment layer / adhesive resin layer / heat seal layer, consisting of base layer 1, dry lamination adhesive 2, aluminum foil Layer 4, chemical conversion treatment layer 3, adhesive resin layer 5 and heat sealing layer 6 consist of six layers.

[0041] The selection of materials is the same as in Example 1. The heat-sealing layer 6 is a multi-layer co-extrusion structure, one layer is polyethylene resin, one layer is polypropylene resin layer, and an intermediate layer is added between polyethylene resin and polypropylene resin. layer of resin.

[0042] The manufacture method of lithium battery flexible packaging film is characterized in that it comprises the following steps:

[0043] (1) The metallocene polyethylene resin is used as the composite surface, the polypropylene resin is used as the heat co

Embodiment 3

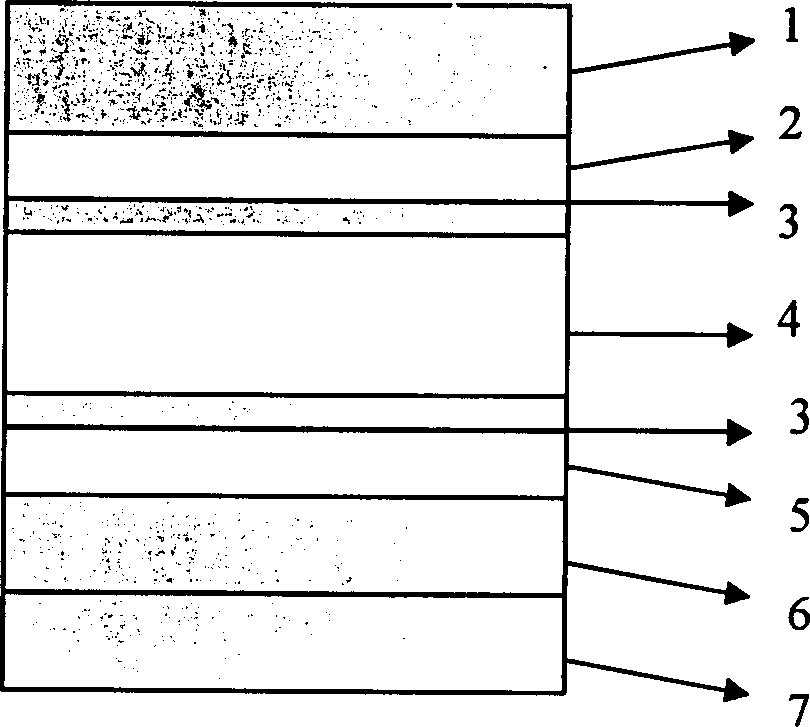

[0048] Such as image 3 Shown is a schematic diagram of a lithium battery flexible packaging film made of base layer / dry compound adhesive / chemical treatment layer / aluminum foil layer / chemical treatment layer / adhesive resin layer / polyethylene resin layer / polypropylene resin layer; Lithium battery flexible packaging film consists of base layer 1, dry compound adhesive 2, chemical conversion treatment layer 3, aluminum foil layer 4, chemical conversion treatment layer 3, adhesive resin layer 5, polyethylene resin layer 6 and polypropylene resin layer 7-8 layer composition.

[0049] The base layer 1, the aluminum foil layer 4, and the chemical treatment layer 3 can be processed according to existing methods; the base layer 1 is made of polyamide, and the aluminum foil layer 4 is made of soft aluminum foil with a thickness of 45 microns; the adhesive resin layer 5 is made of acrylic acid Modified polyethylene; metallocene polyethylene resin is selected for the polyethy

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap