Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Wrappers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

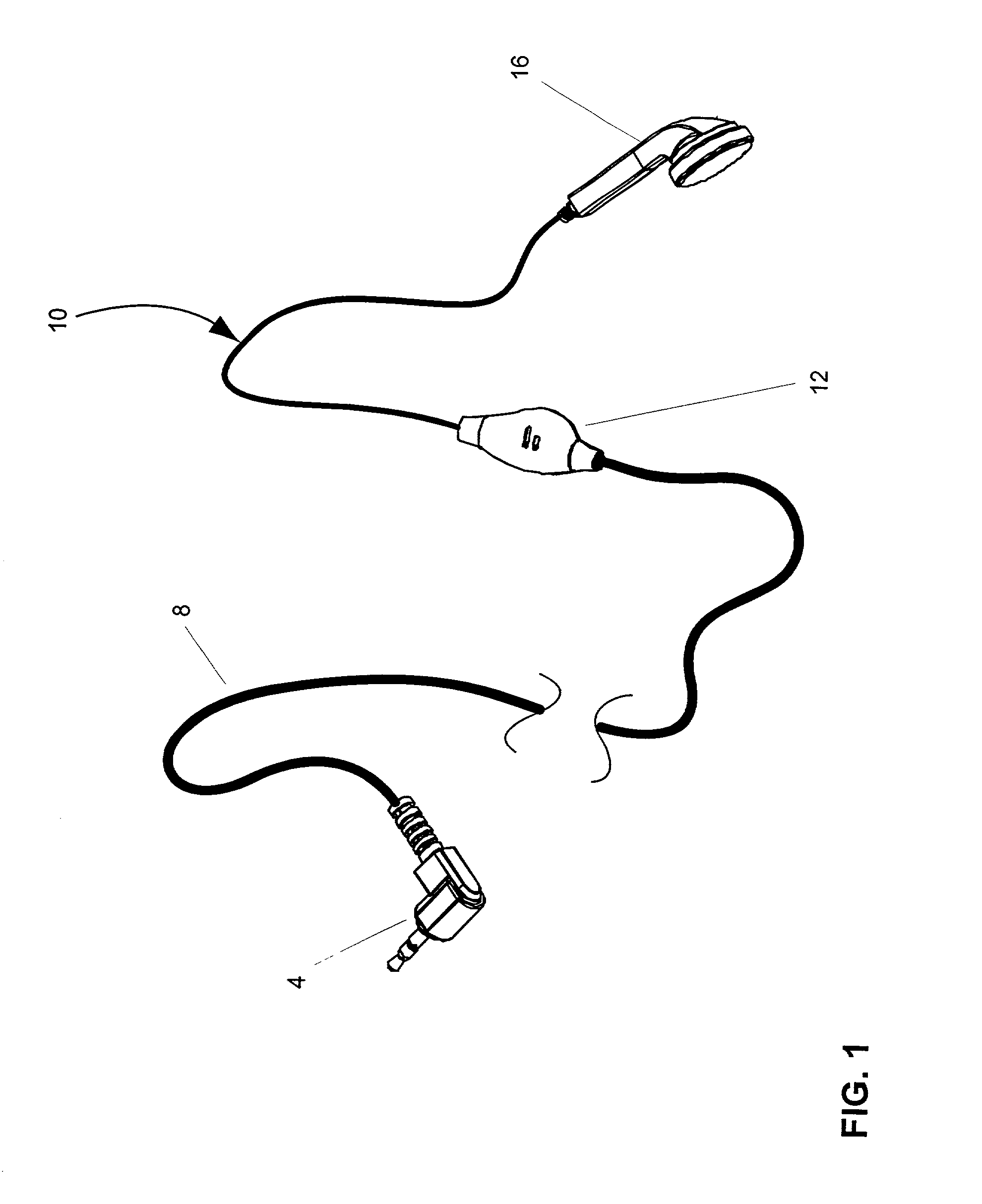

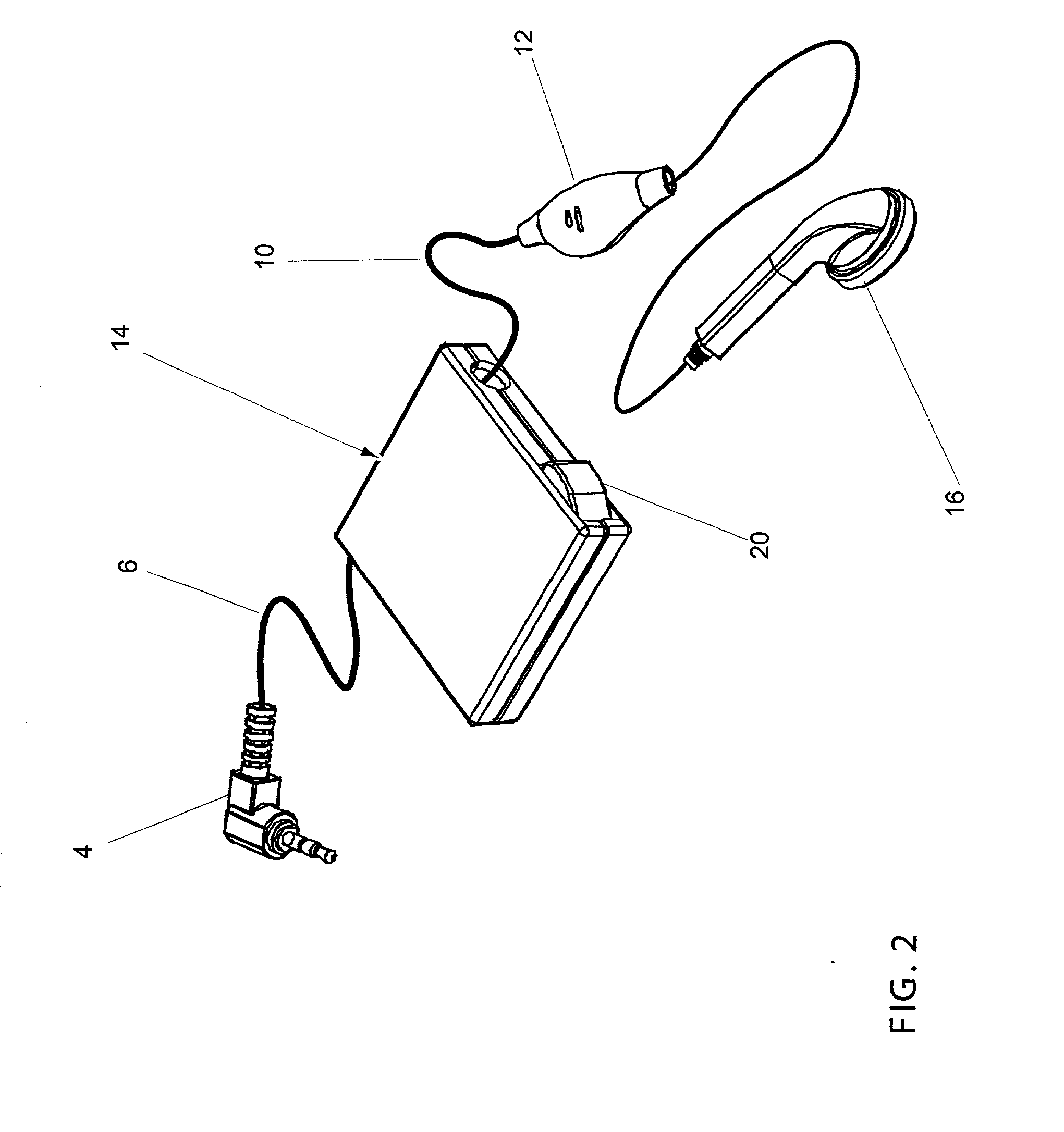

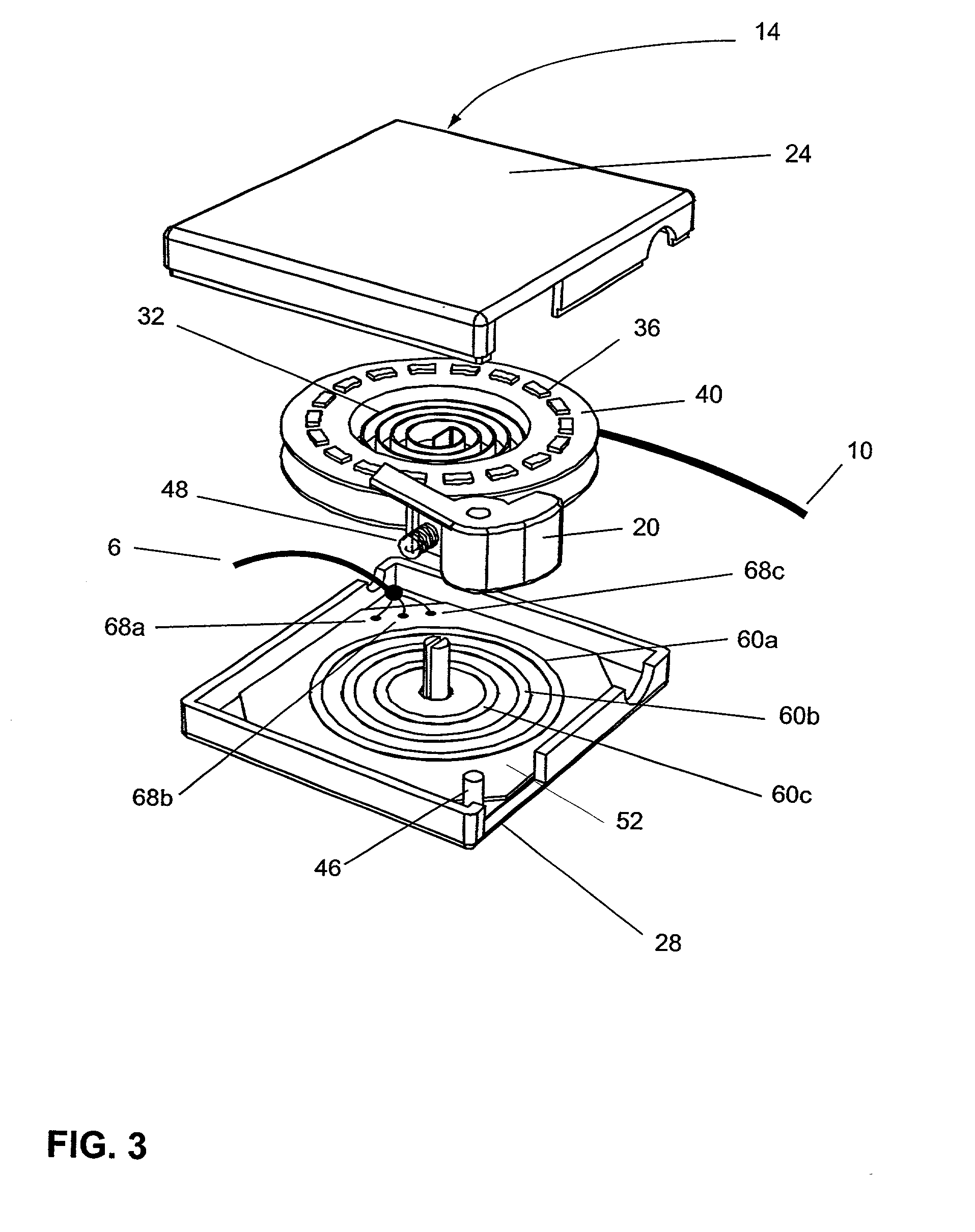

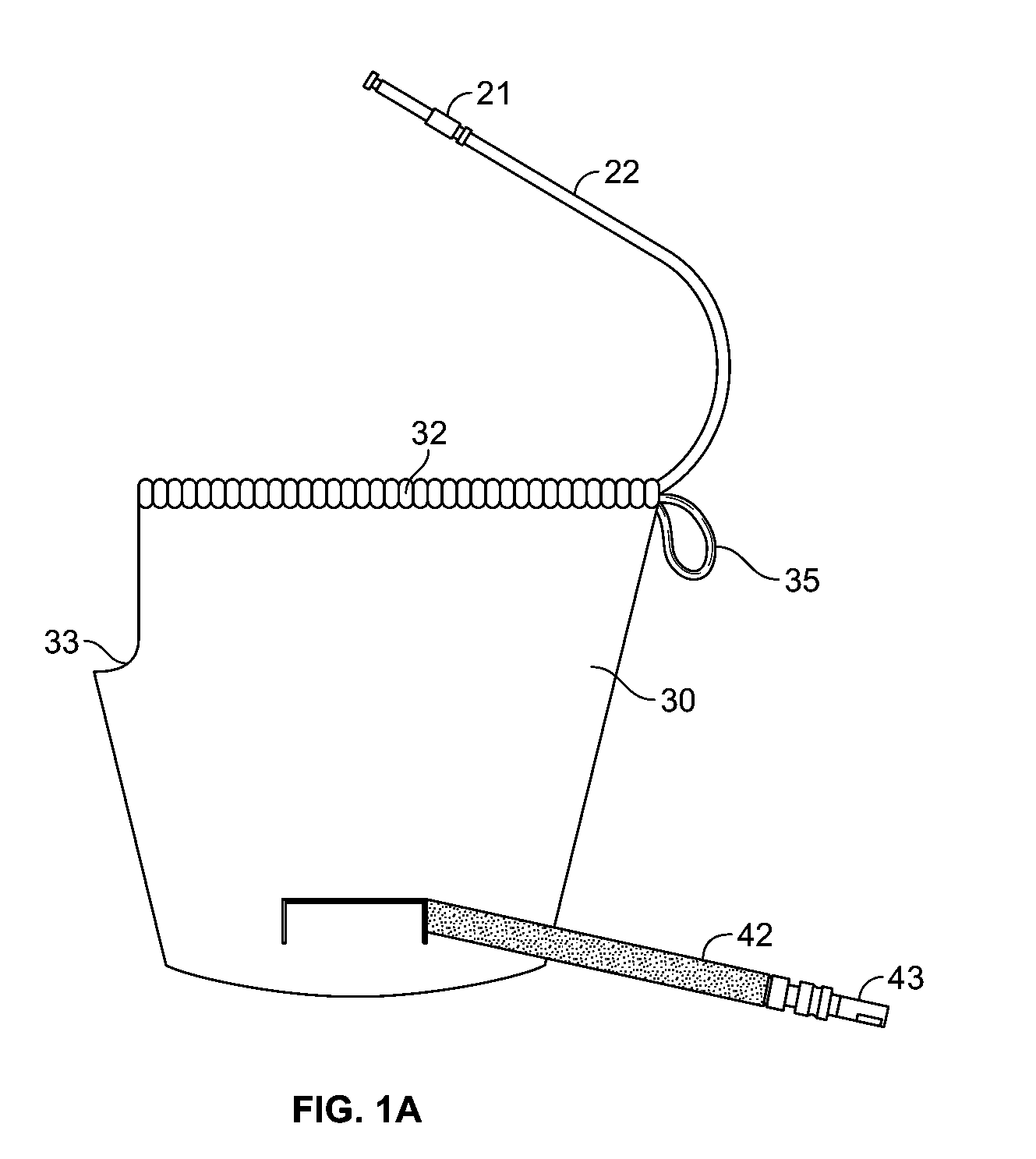

Integrated headset-case for wireless phones

Owner:HUGHS LOUIS S +1

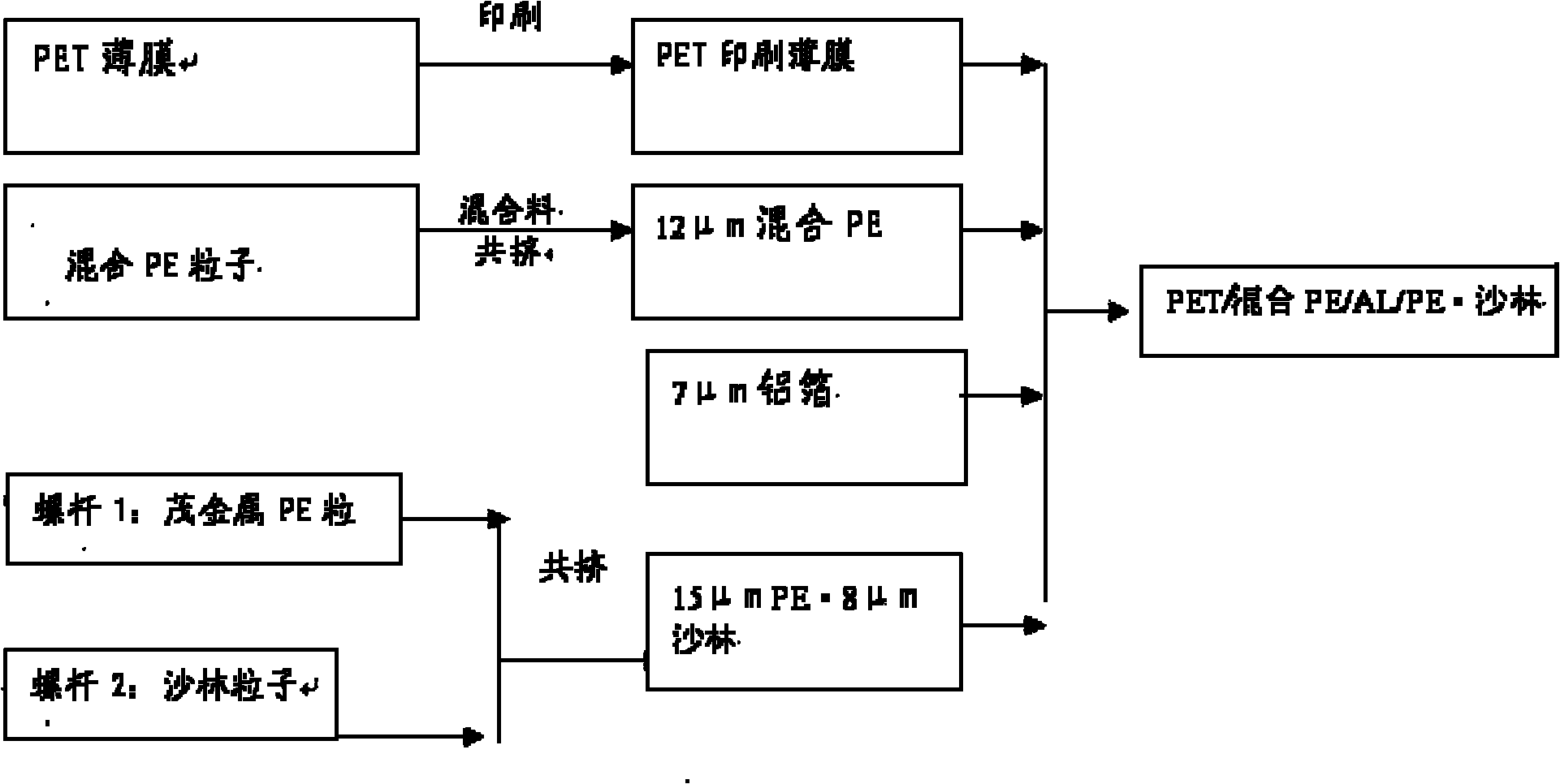

Lithium battery flexible packaging film and its manufacturing method

Owner:上海紫江彩印包装有限公司

Enhanced oxygen barrier performance from modification of ethylene vinyl alcohol copolymers (EVOH)

Owner:CRYOVAC INC

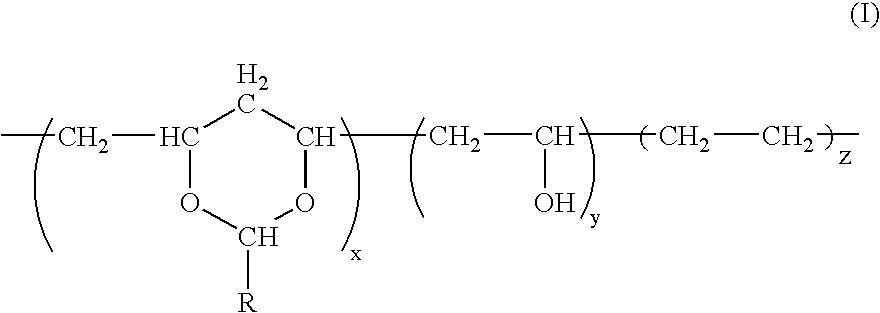

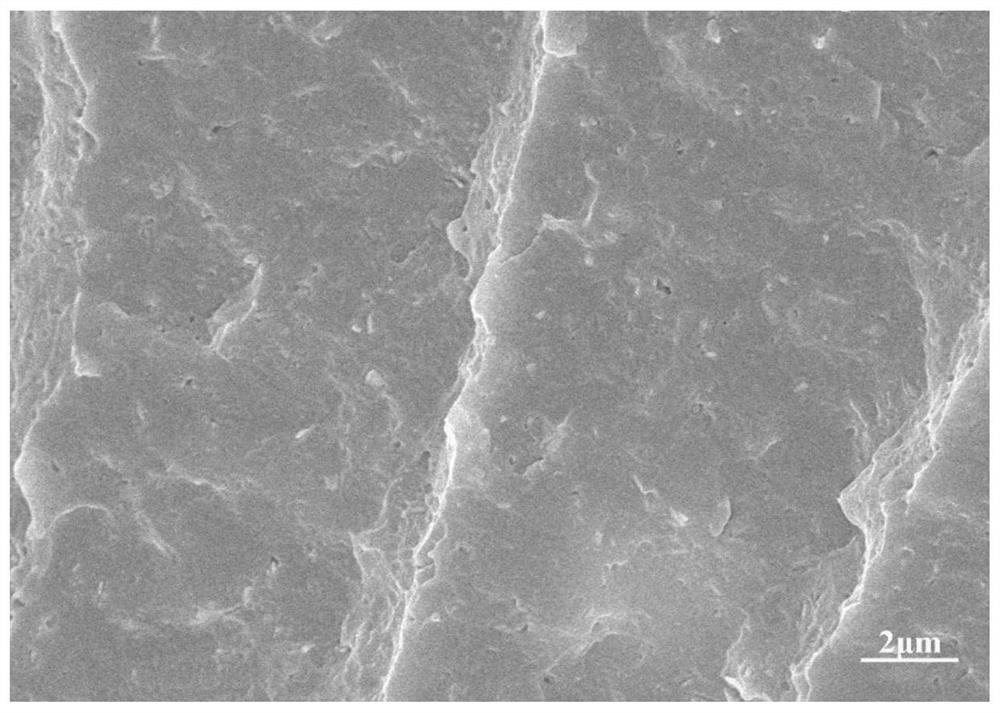

Polyvinyl alcohol/xylan biodegradable composite membrane and preparation method and application thereof

InactiveCN103073738APrevent leakageReduce hydrogen bondingWrappersFlexible coversXylanFood packaging

Owner:SOUTH CHINA UNIV OF TECH

Edible instant flour bag packaging film and preparation method thereof

Owner:ZHEJIANG UNIV

Dual controlled release fruits and vegetables fresh-keeping paper and manufacturing method thereof

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Pitaya peel-based edible packaging film and preparation method thereof

ActiveCN105419370AFull edible medicinal valueAvoid pollutionWrappersFlexible coversCellulosePolymer science

The invention provides a preparation method for a pitaya peel-based edible packaging film. The preparation method is characterized by comprising the following steps: (1) washing and stripping and slicing pitaya peels; (2) performing blanching treatment; (3) adding water and pulping to obtain pitaya peel pulp, wherein the mass ratio of matter obtained in the step (2) to the water is (15 to 45):100; (4) adding a thickening agent and a plasticizer into the pitaya peel pulp, wherein the mass ratio of the thickening agent to the pitaya peel pulp is (0 to 0.4):100, and the mass ratio of the plasticizer to the pitaya peel pulp is (0 to 0.3):100; the thickening agent is sodium alginate or sodium carboxymethylcellulose, and the plasticizer is glycerinum or sorbitol; (5) performing homogenization treatment at a treatment rate of 15000 to 20000 r / min for 5 to 8min; then, performing degassing treatment and standing to obtain shaped pulp; (6) casting and drying, and then performing film uncovering to obtain the pitaya peel-based edible packaging film. The invention also provides the packaging film prepared by the preparation method.

Owner:SICHUAN AGRI UNIV

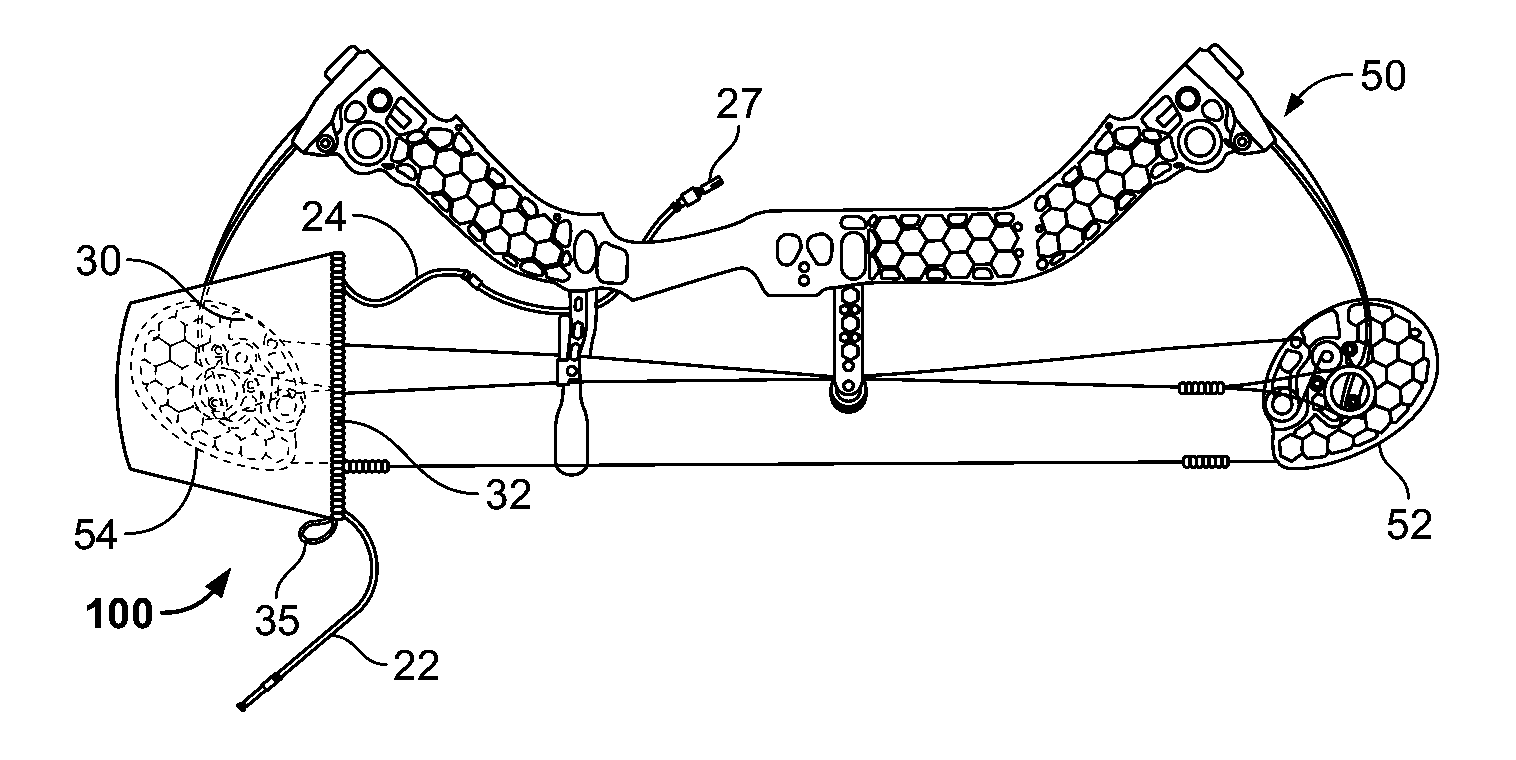

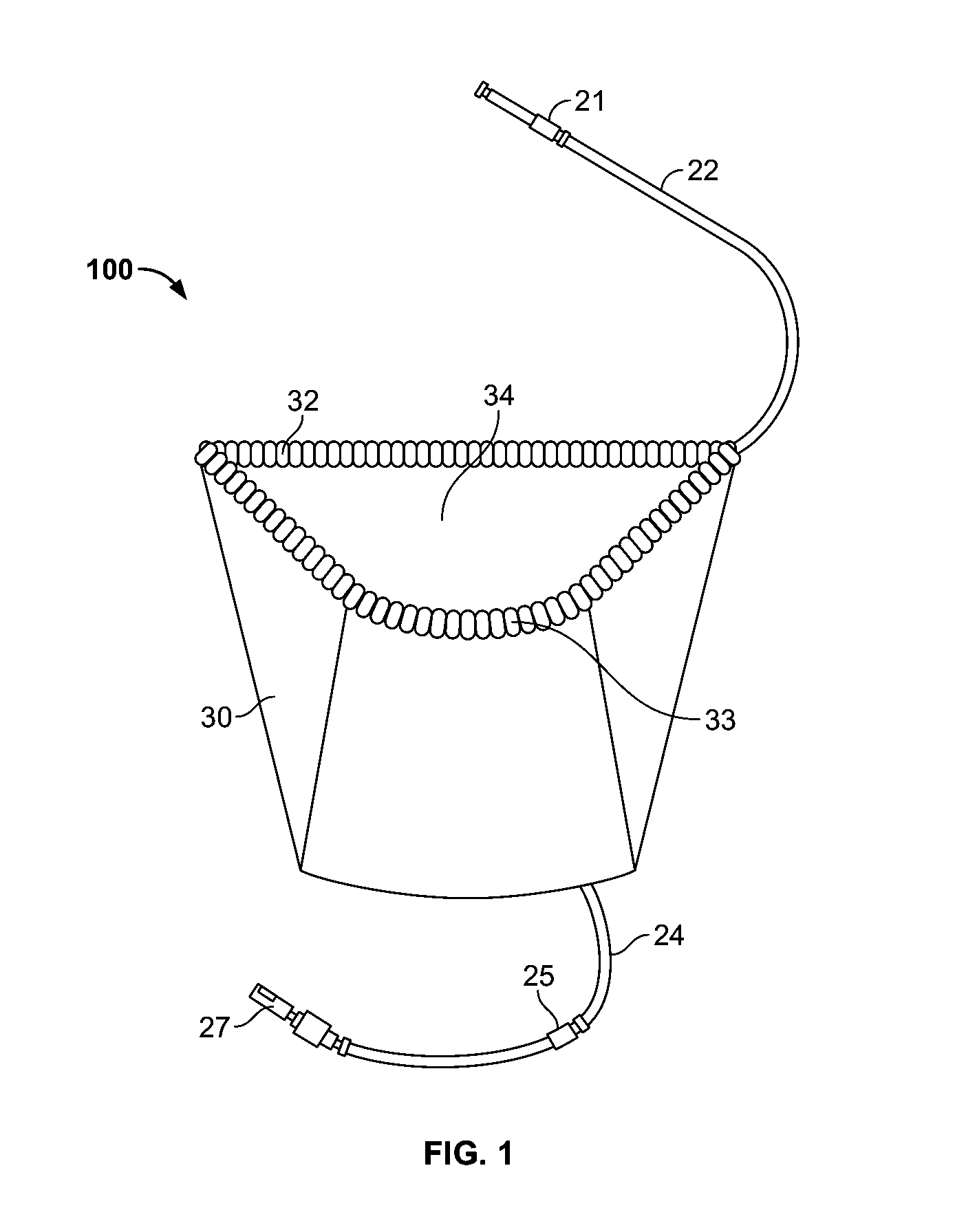

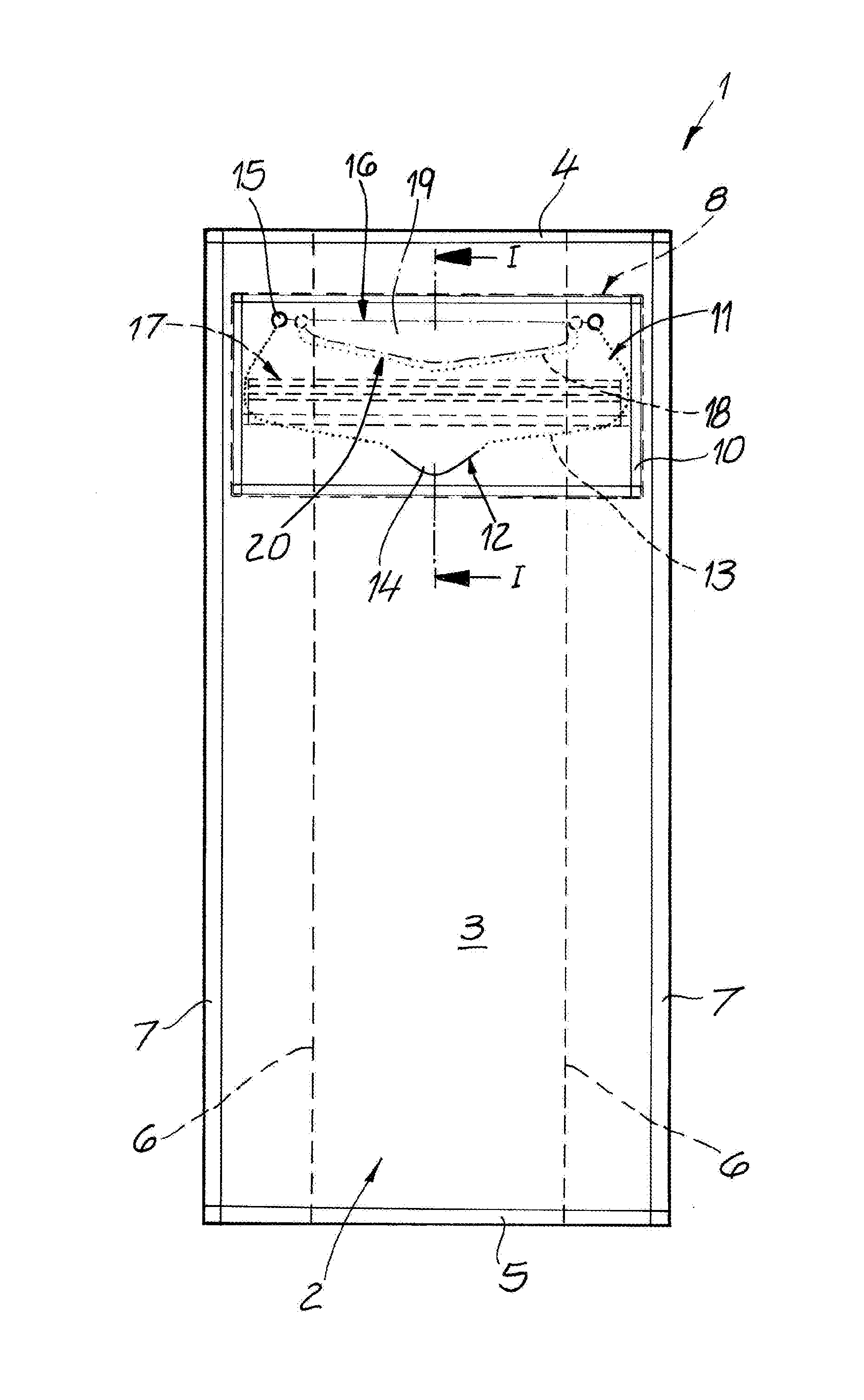

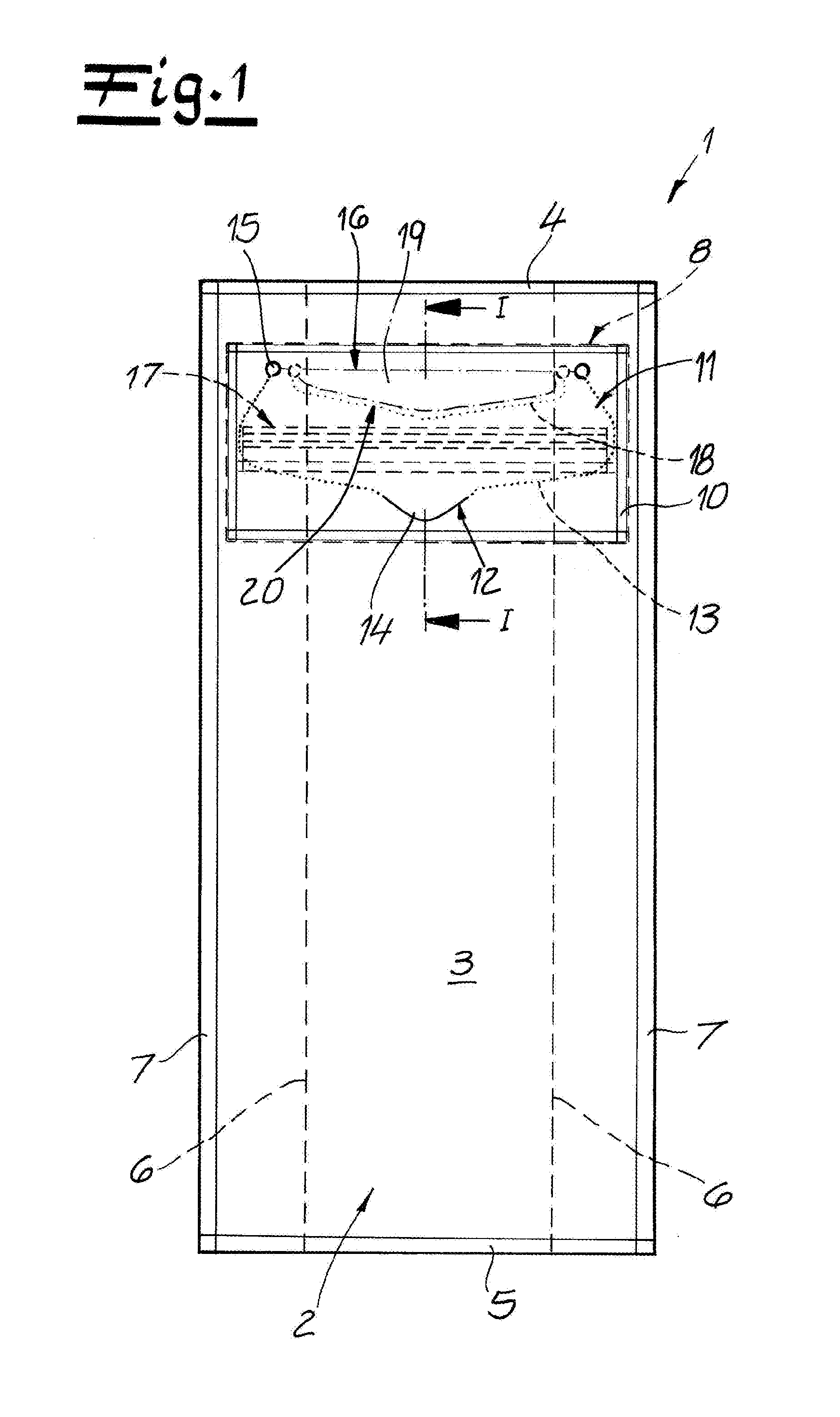

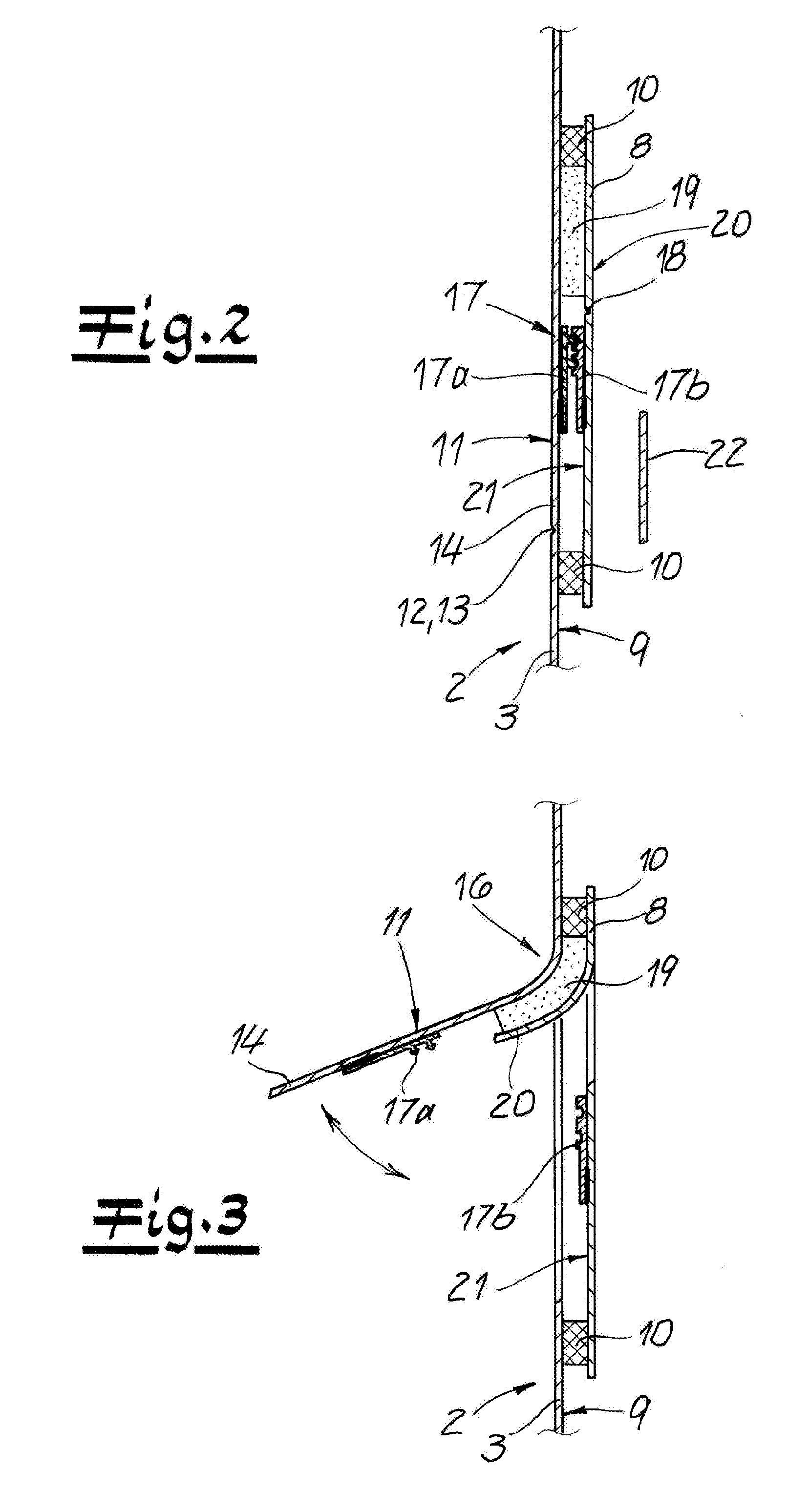

Bow Cam Cover

Owner:EBERSOLE CLAYTON +1

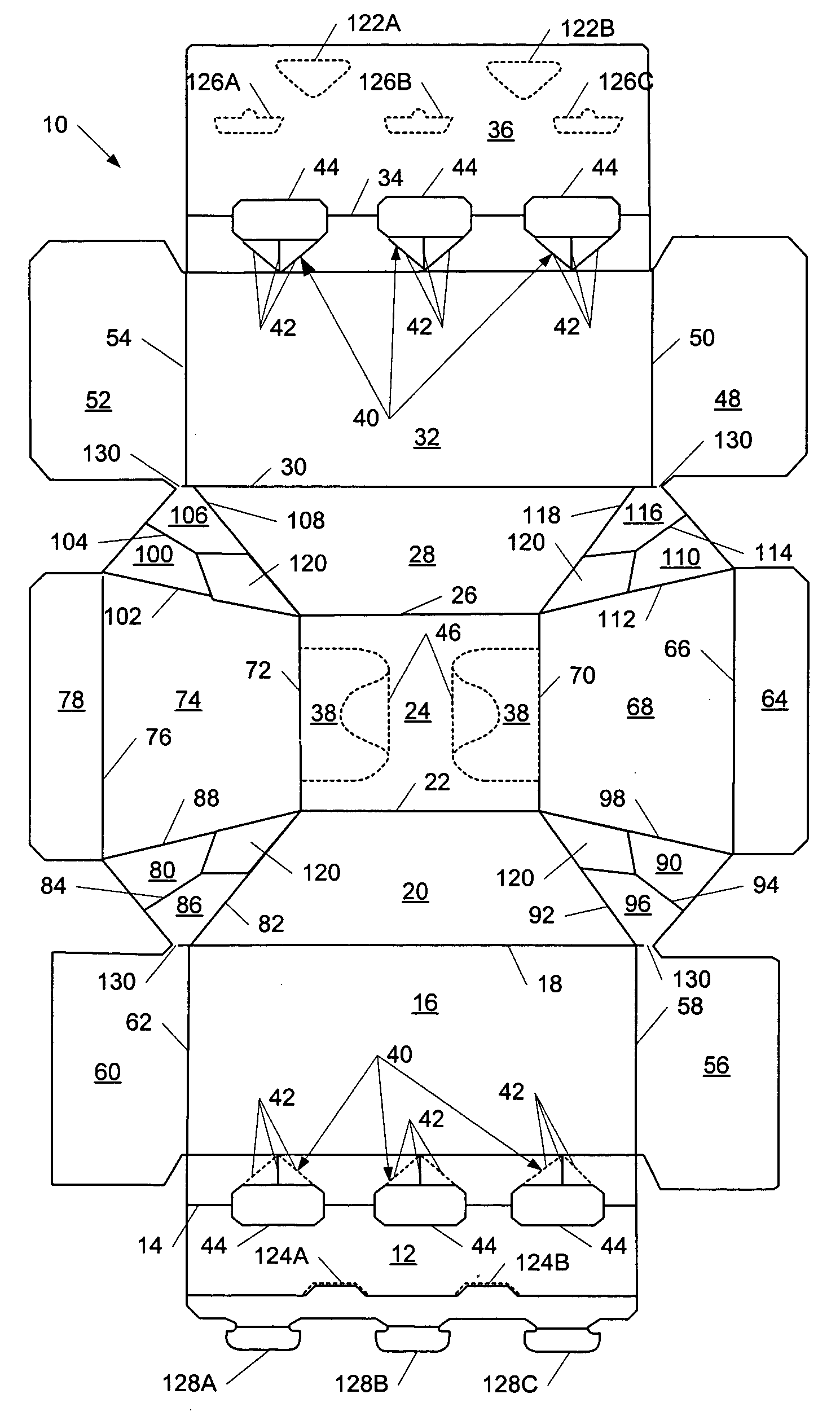

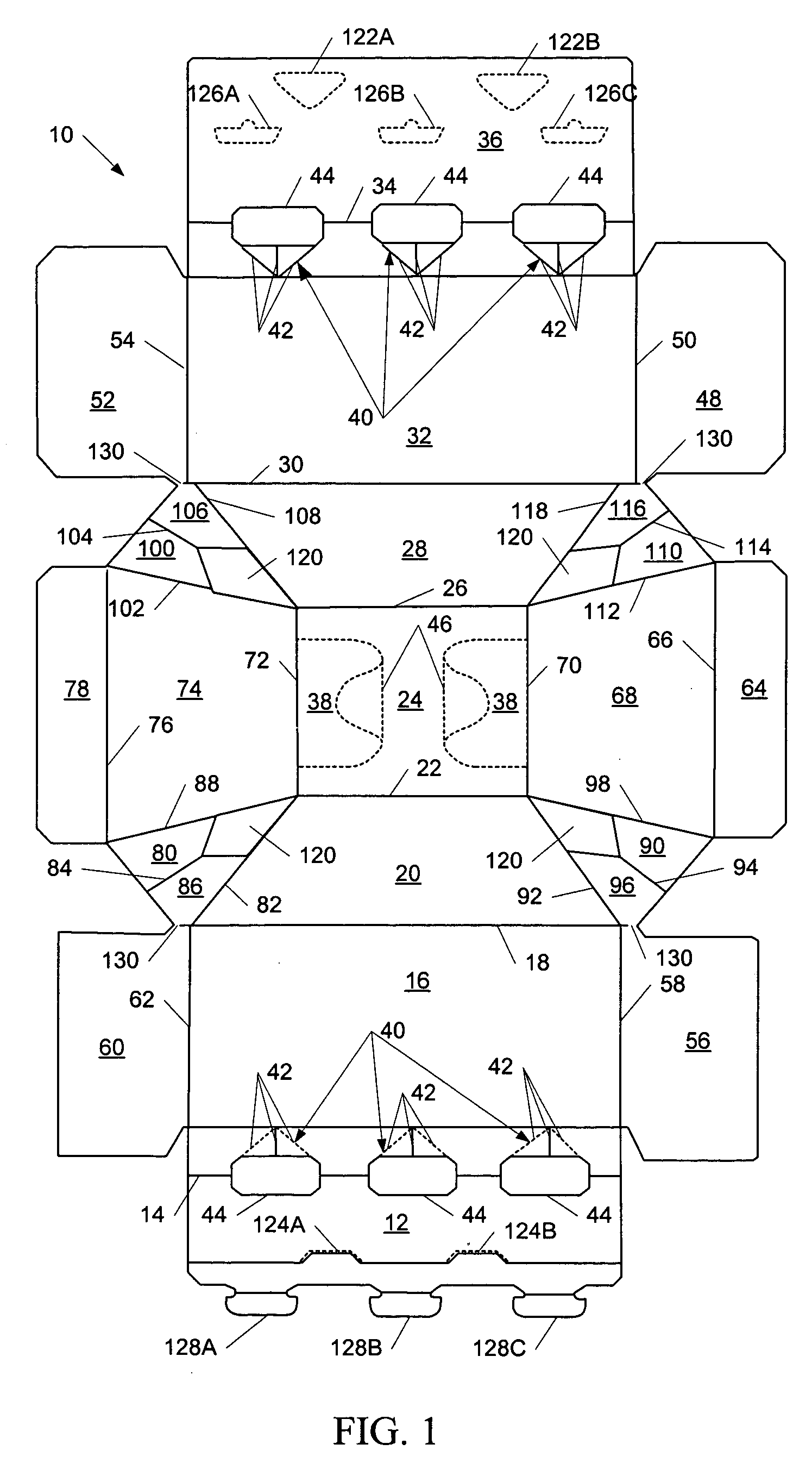

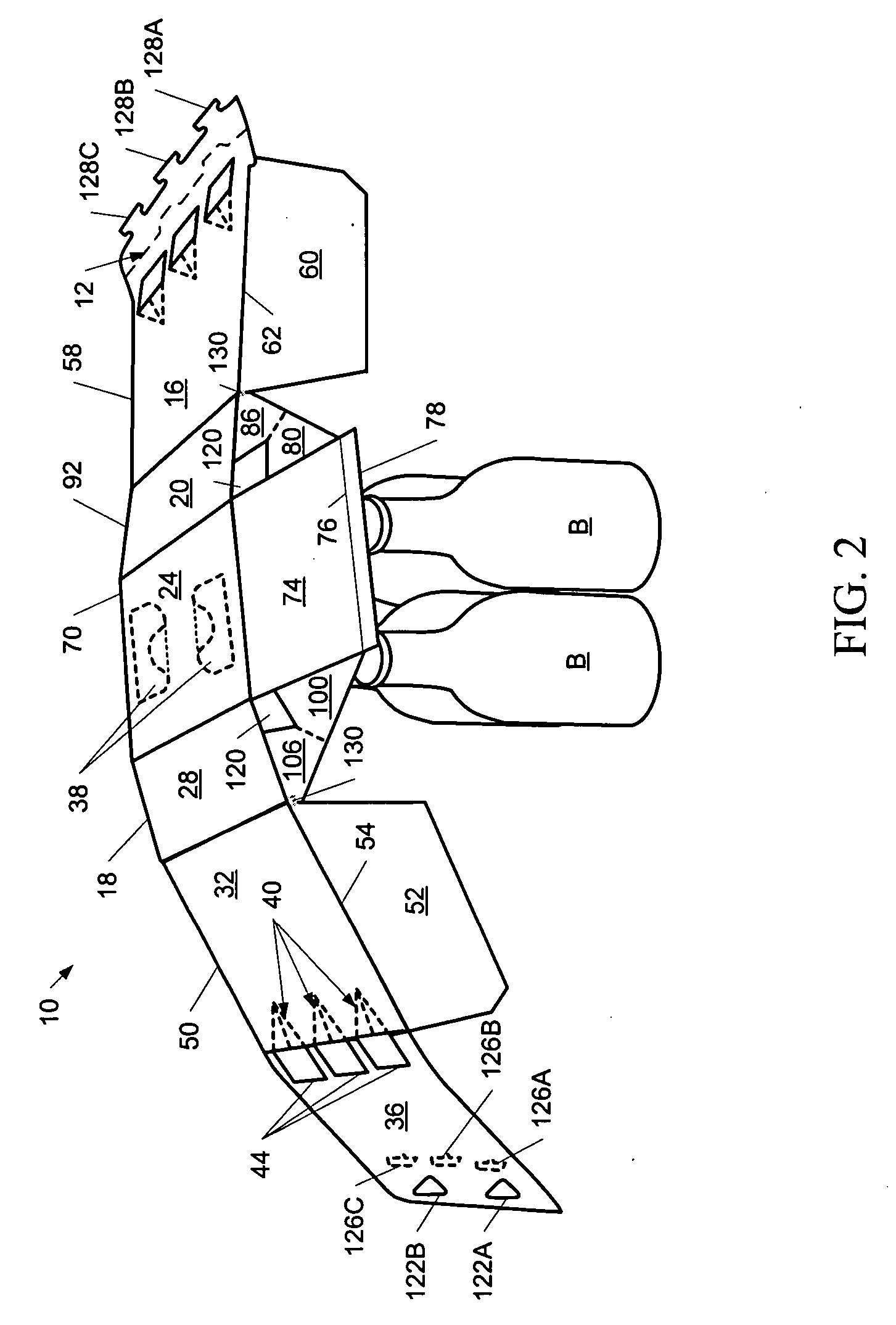

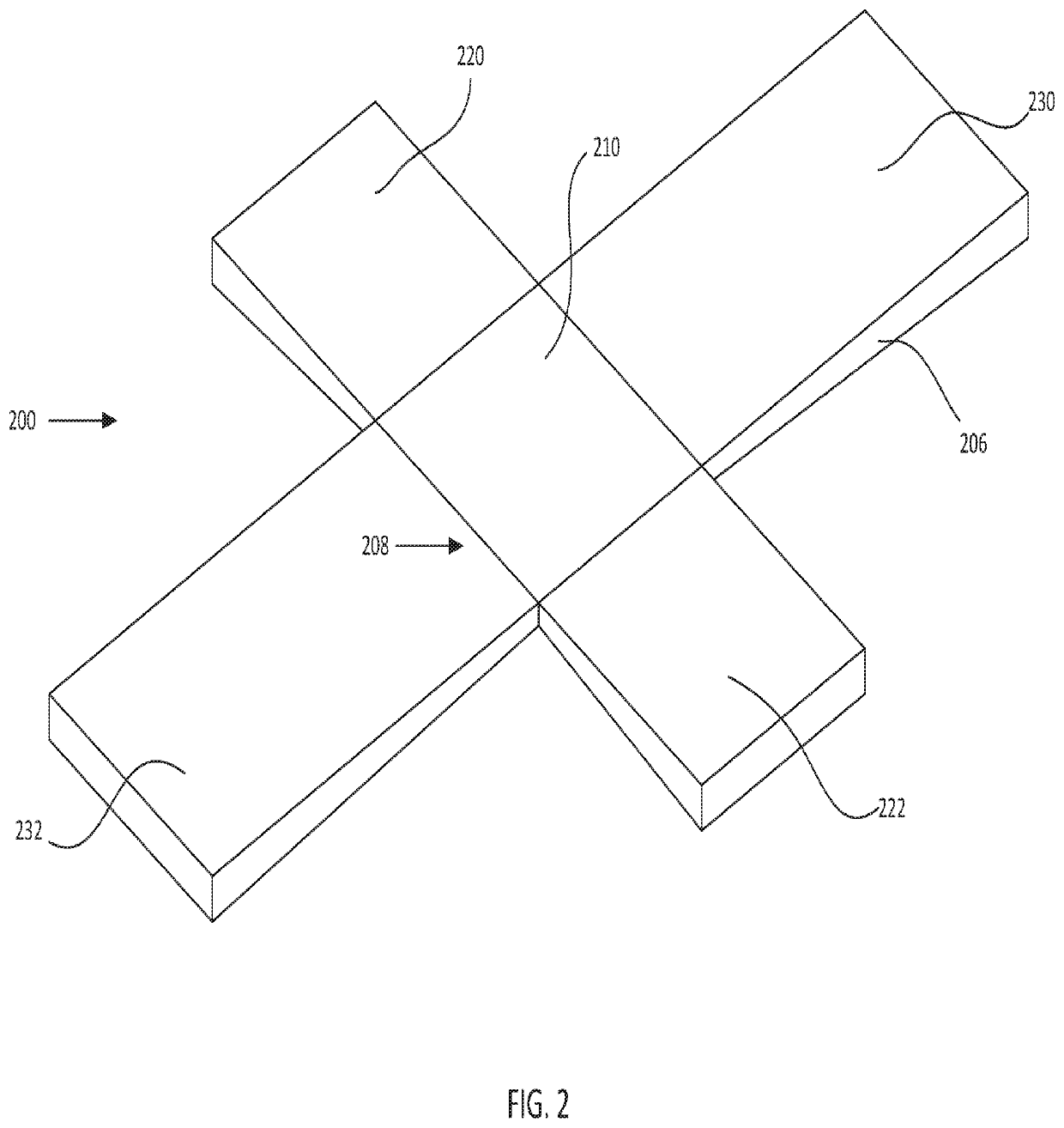

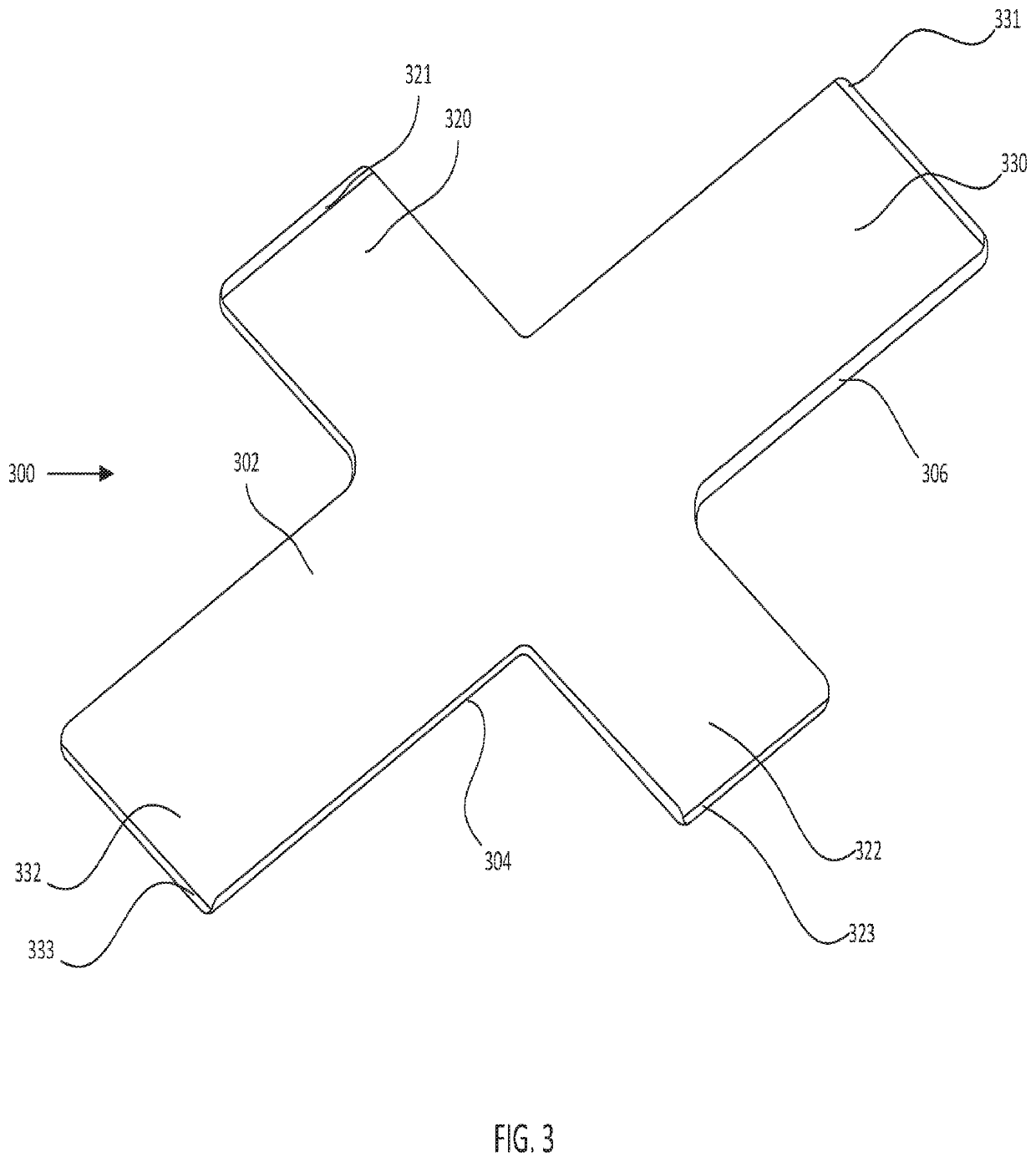

Fully enclosed wrap-around carton

Owner:GRAPHIC PACKAGING INT

Closure arrangement with tear guide for allowing access to zipper flanges in a package

InactiveUS7192192B2Avoid hard activationDifficult to accessSnap fastenersWrappersEngineeringMaterial Perforation

Owner:REYNOLDS CONSUMER PROD INC

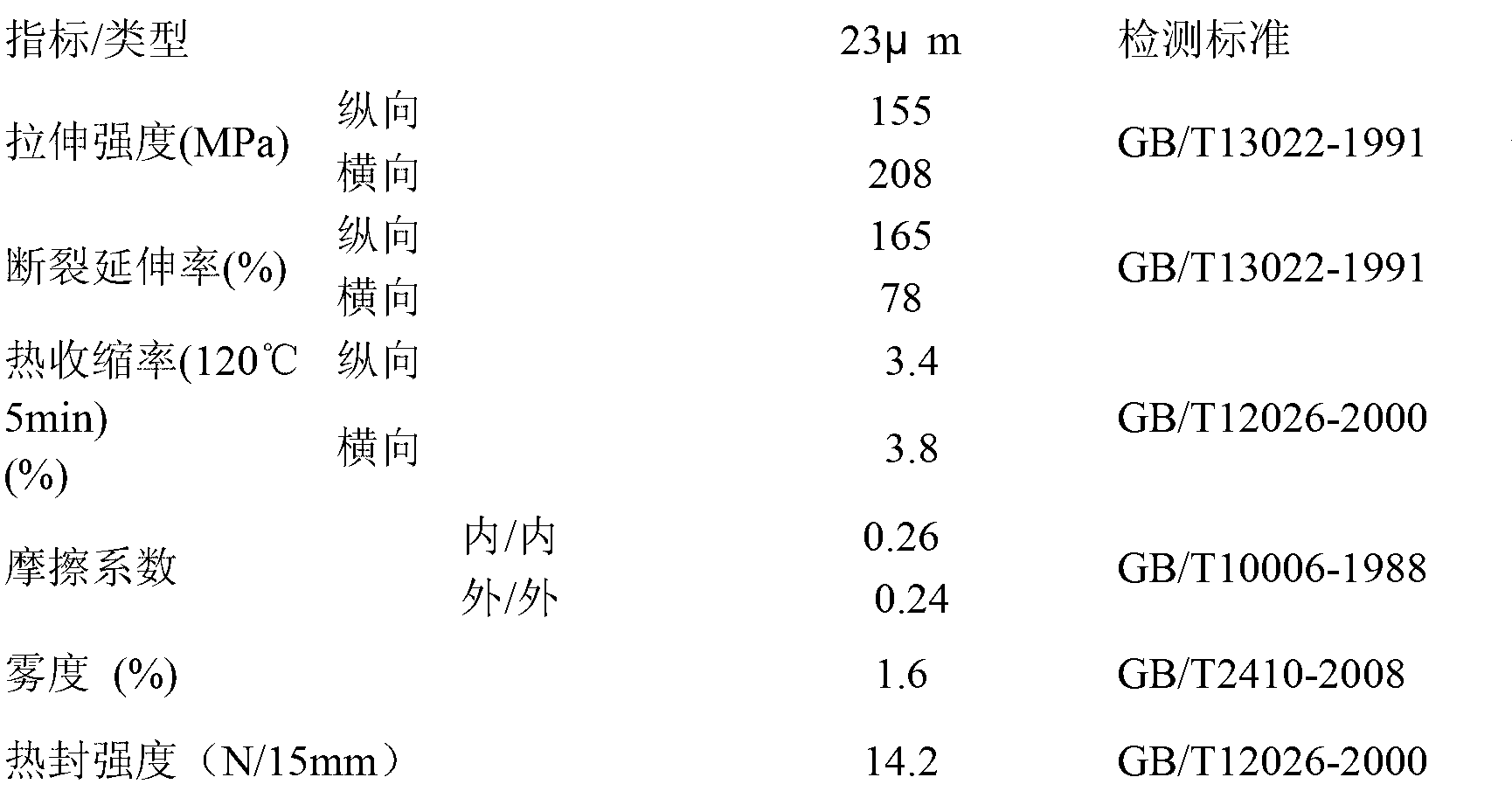

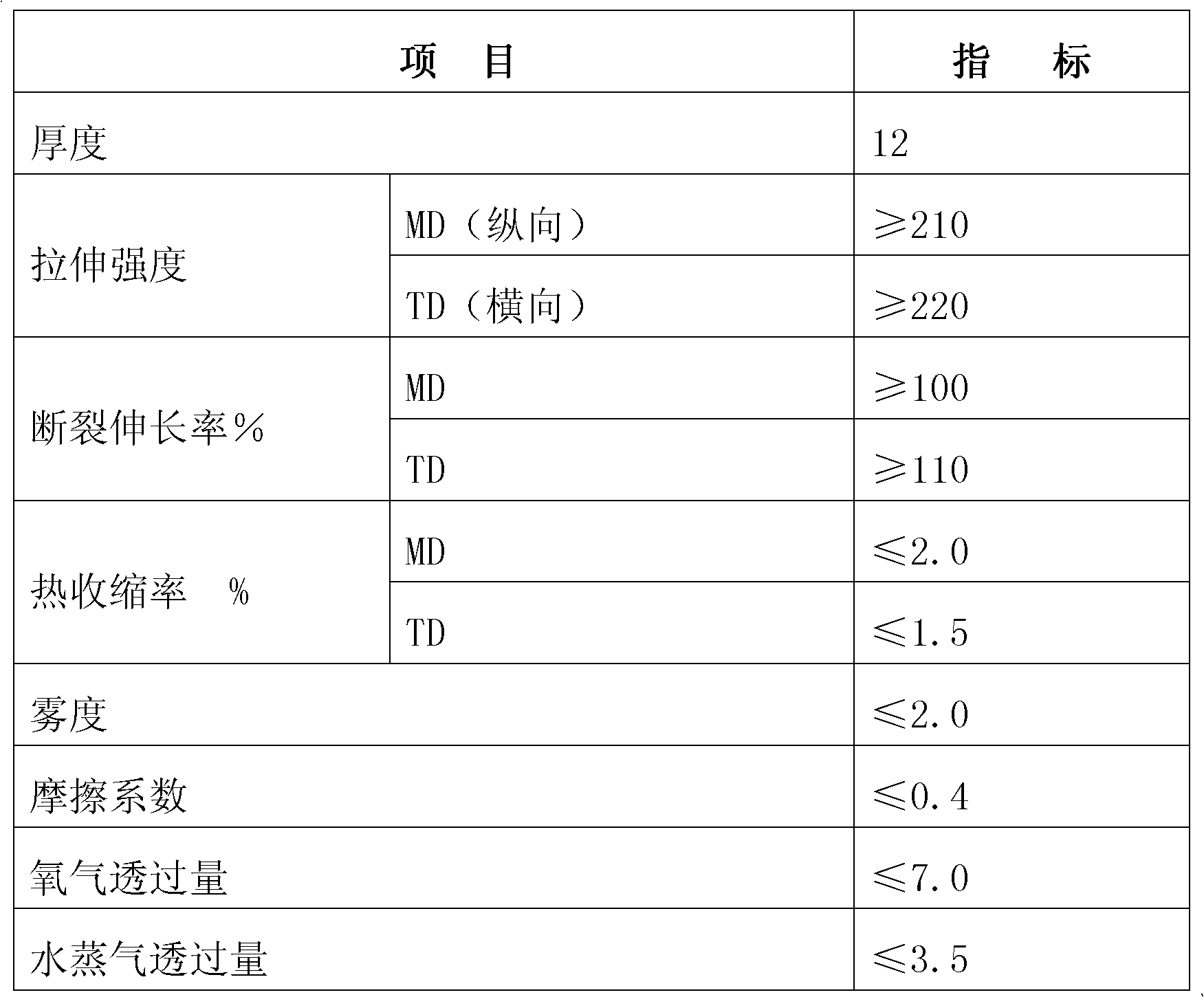

Biaxial stretching polypropylene high heat-seal film and manufacturing method thereof

Owner:HAINAN SHINER IND

Car cover

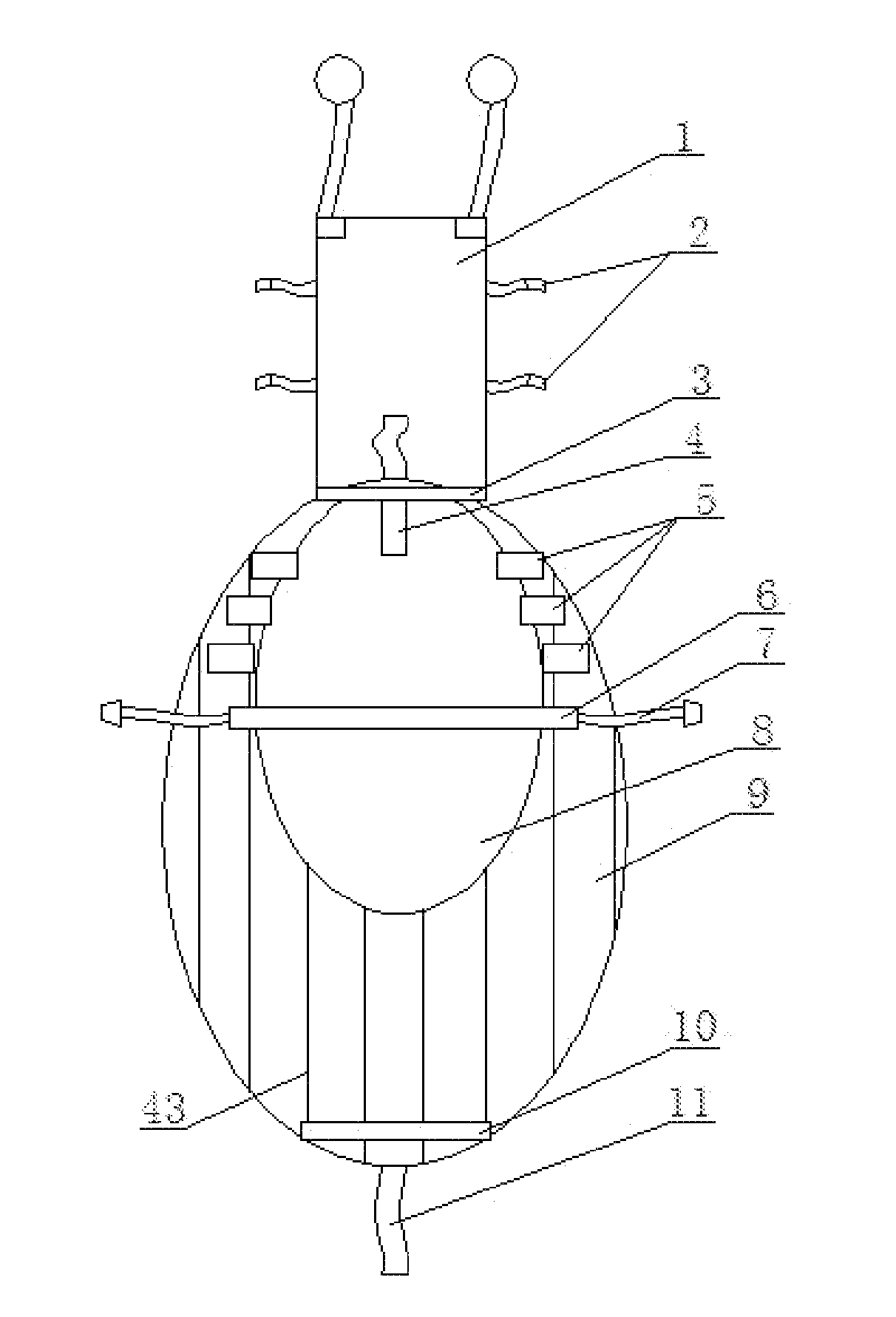

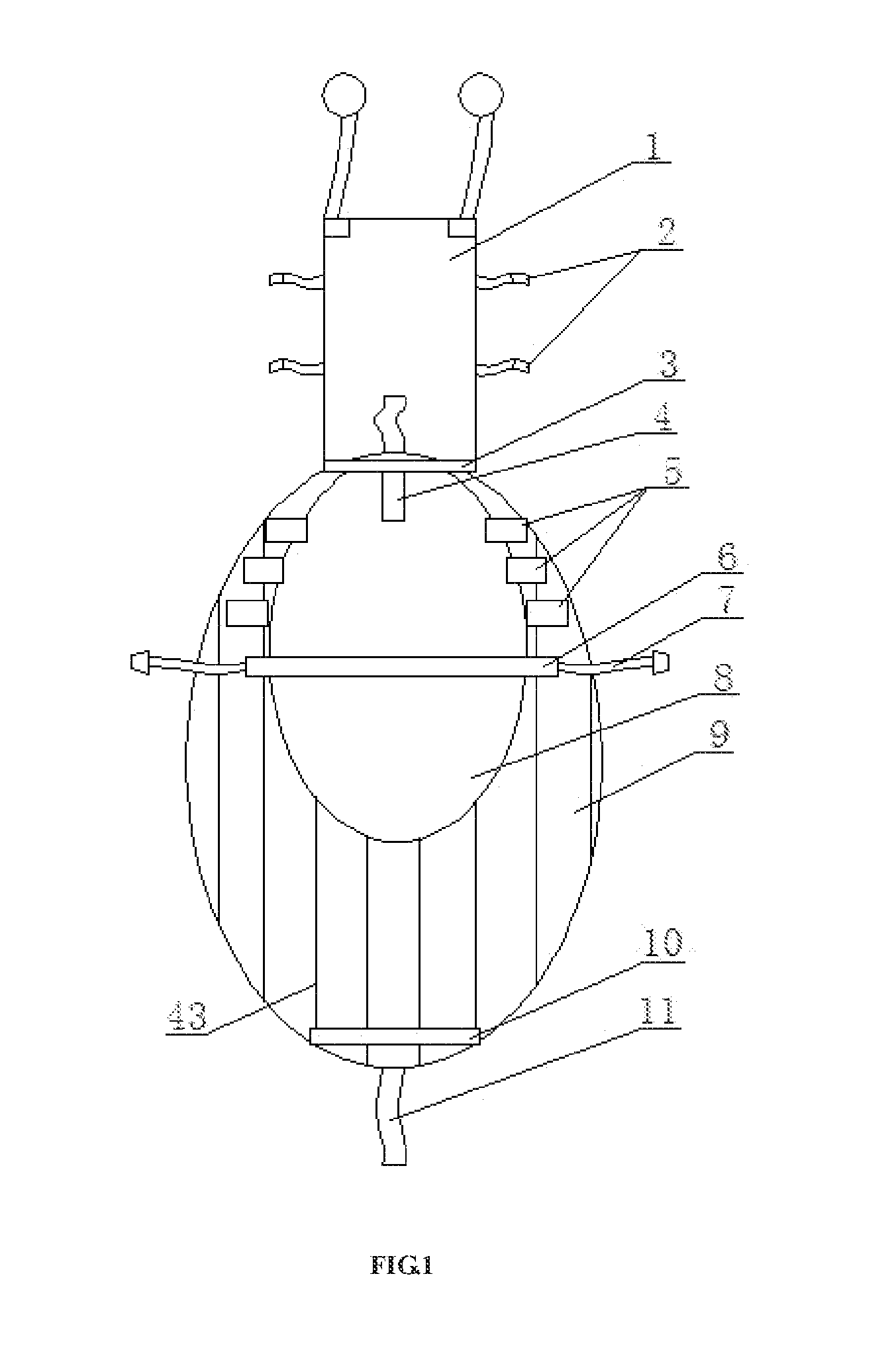

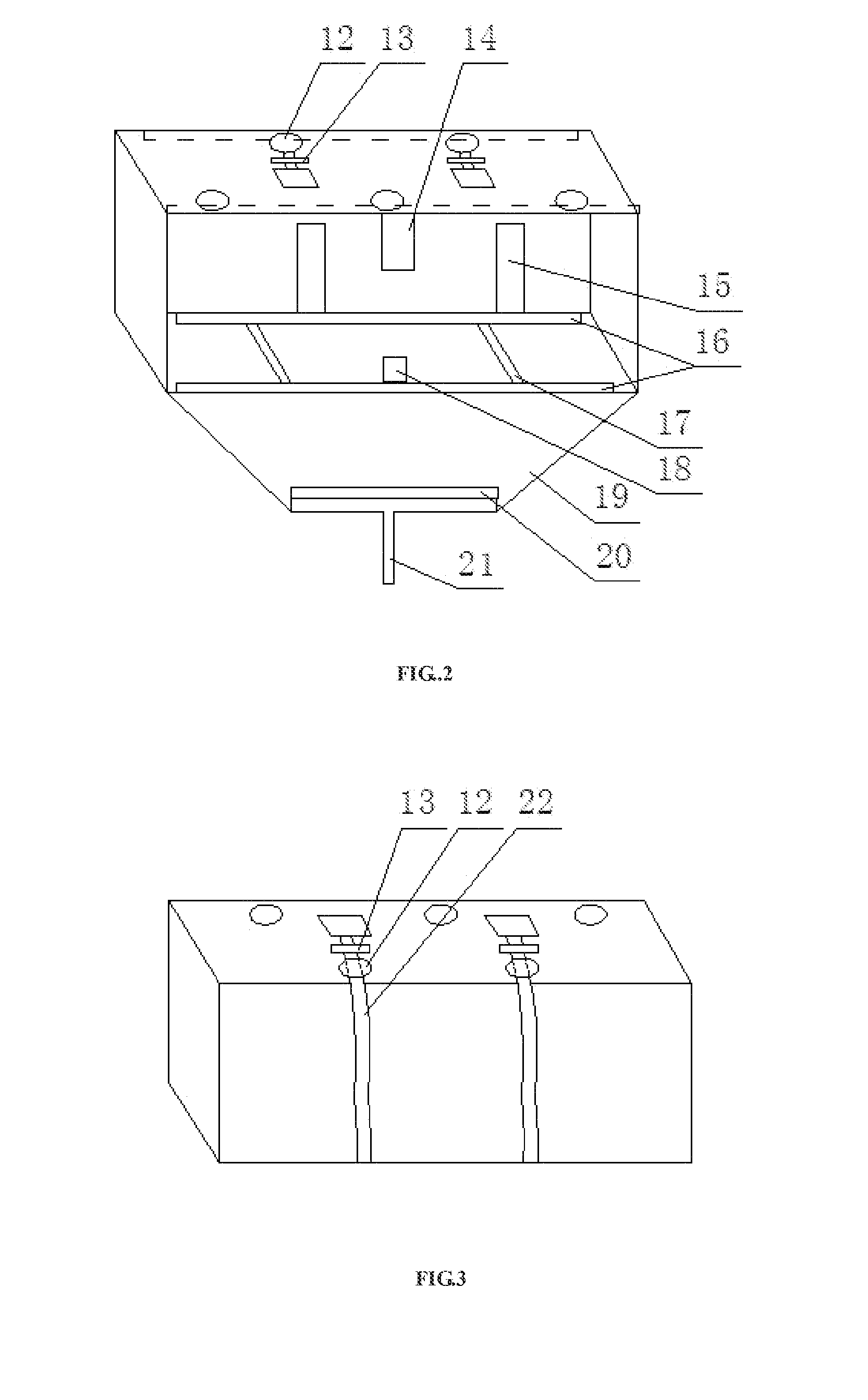

InactiveUS20130118659A1Prevent hailImprove heat transfer performanceWrappersFlexible coversAgricultural engineering

Owner:ZHOU DALU

Flexible package for packing fresh produce made from a biodegradable flexible film

Owner:CHATURVEDI ASHOK

Preparation method of degradable foam packing material

Owner:WUXI HUANGSHENG PACKING PROD

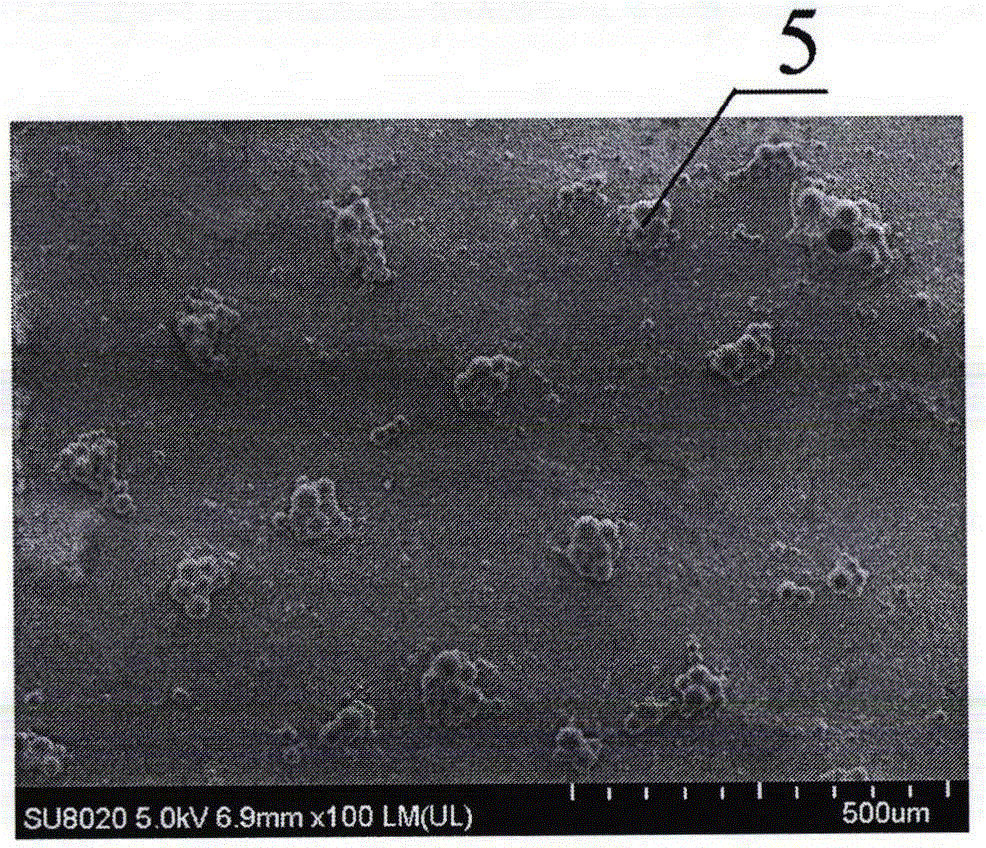

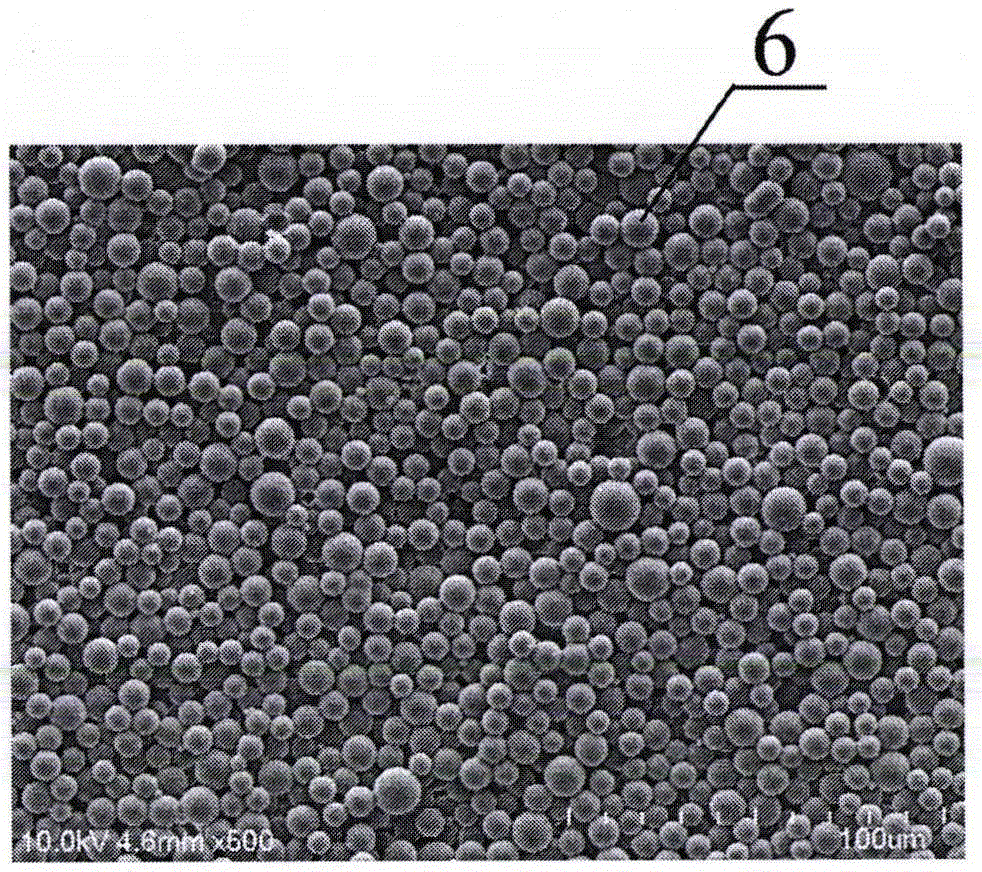

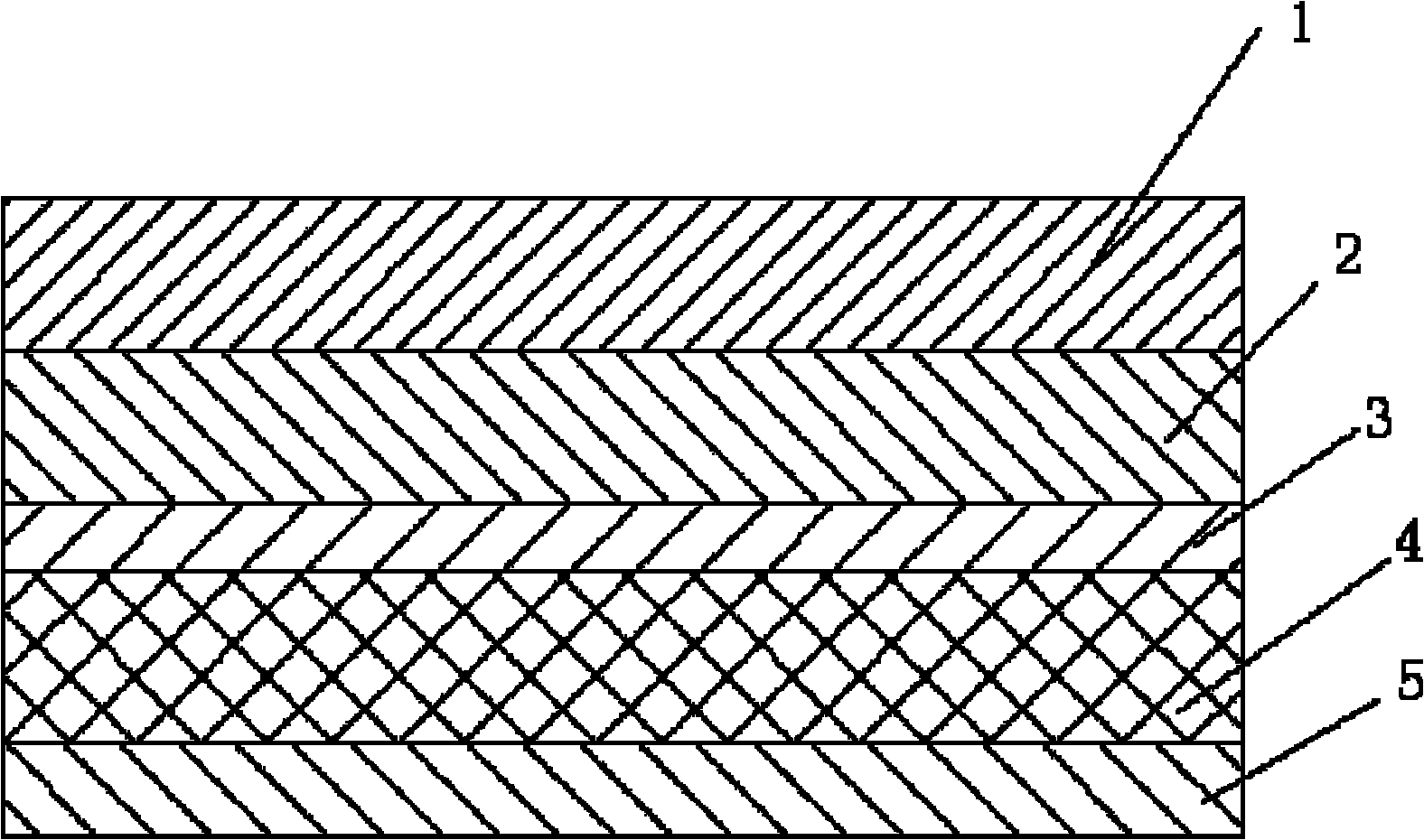

Preparation method of compound aluminum paper and aluminum plastic compound film packaging material with hydrophobic surface

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

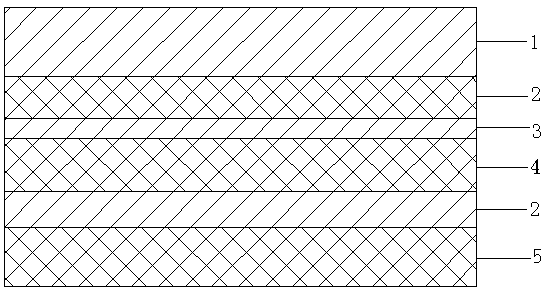

Medical packaging film

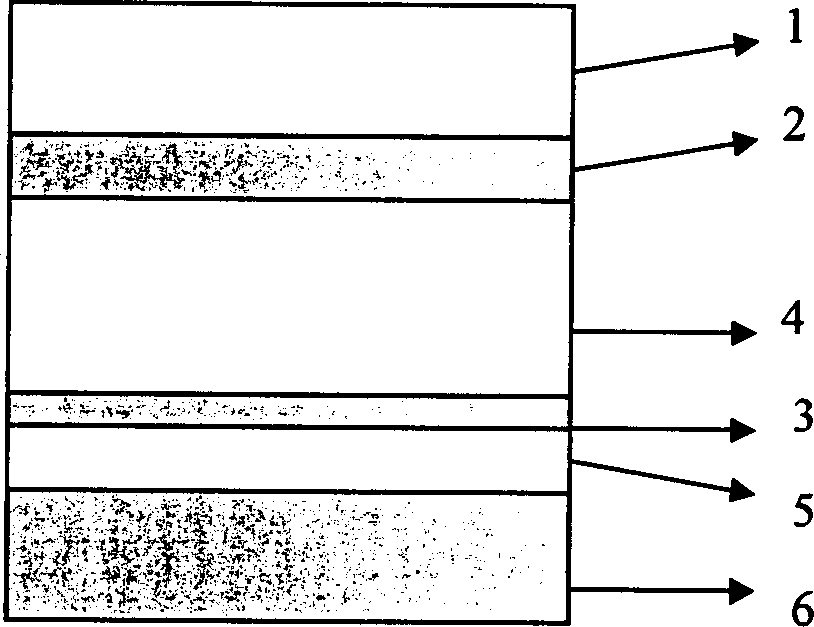

ActiveCN102152542AHigh barrierPrevent brittle and fragile problemsWrappersFlexible coversAdhesiveCost Controls

Owner:HUANGSHAN NOVEL

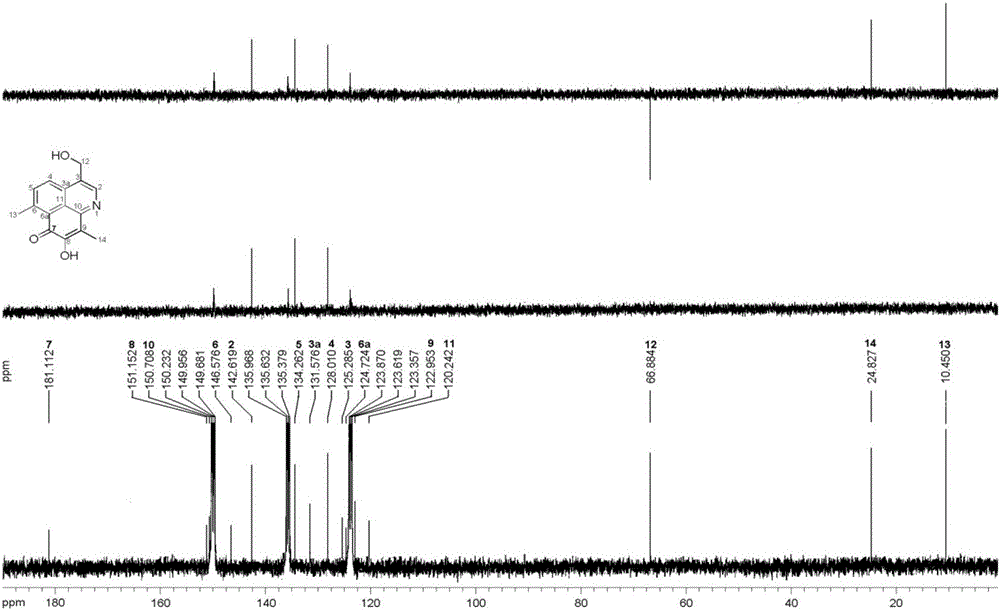

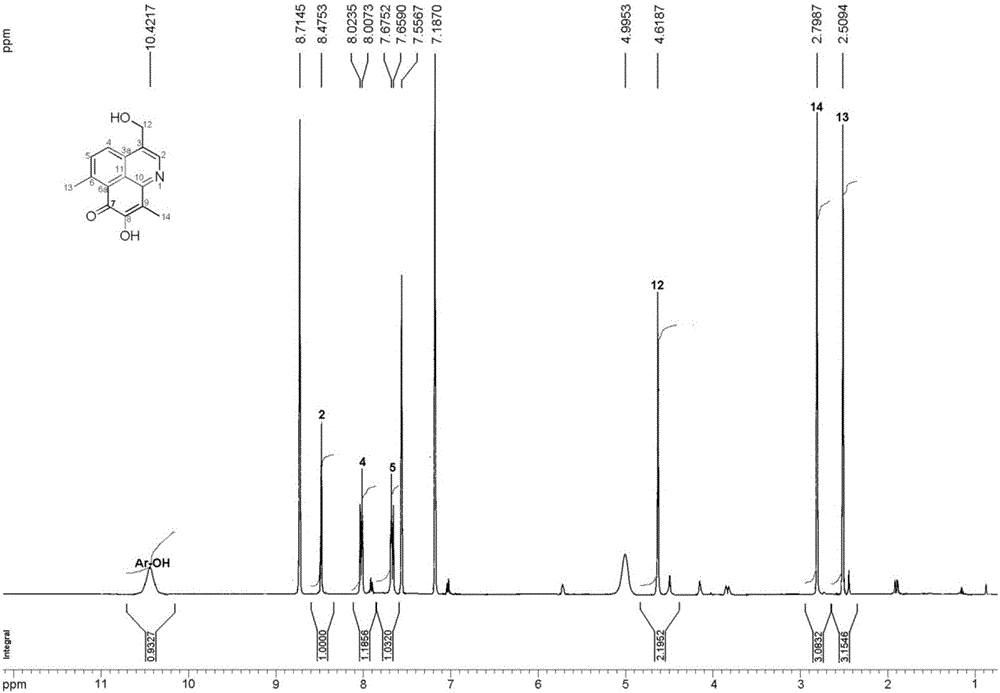

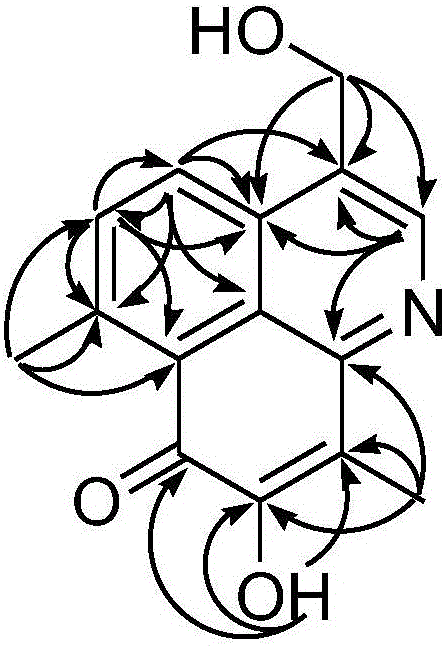

Alkaloid compound with antibacterial activity in tobaccos as well as preparation method and use of alkaloid compound

Owner:CHINA TOBACCO YUNNAN IND

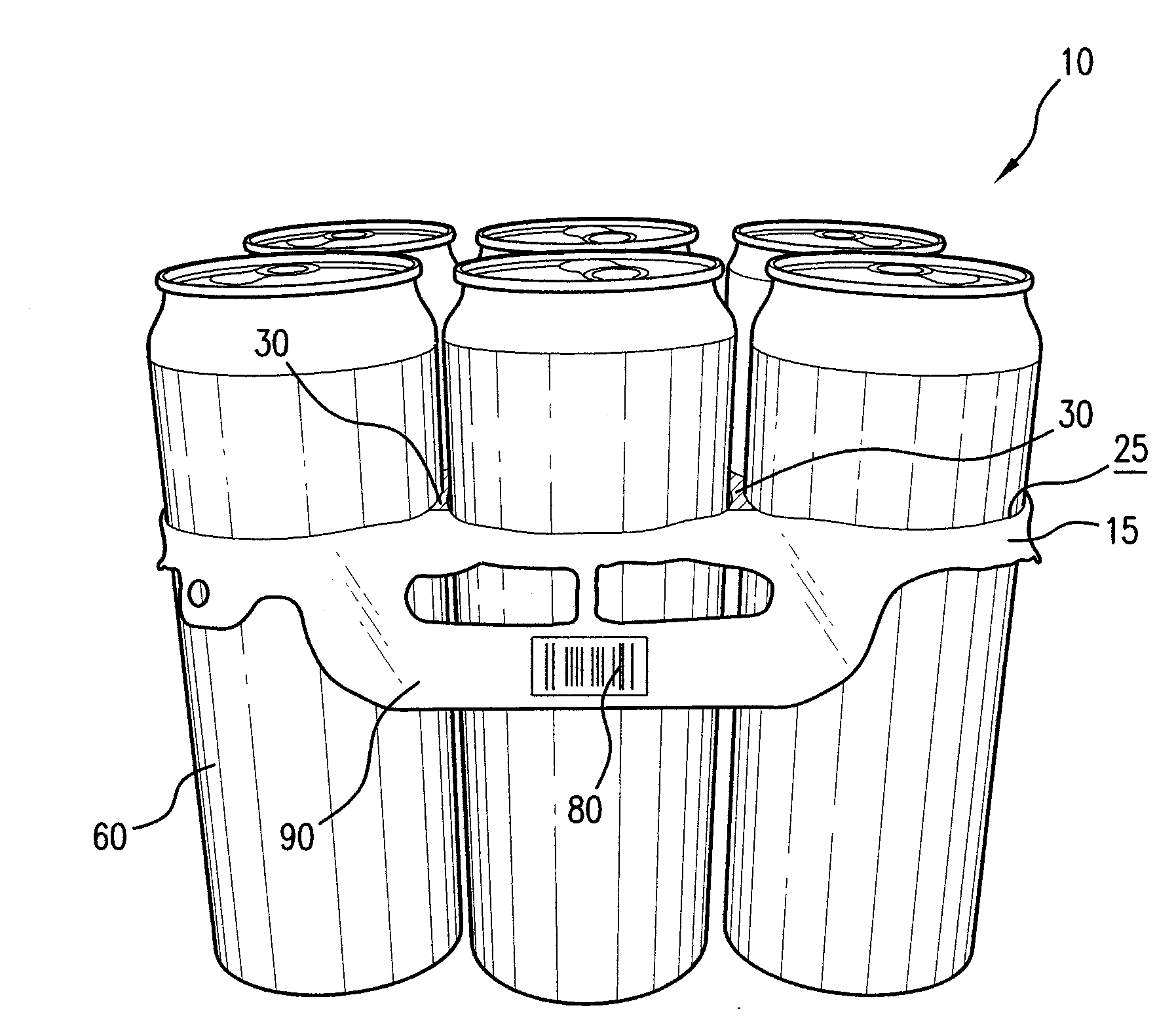

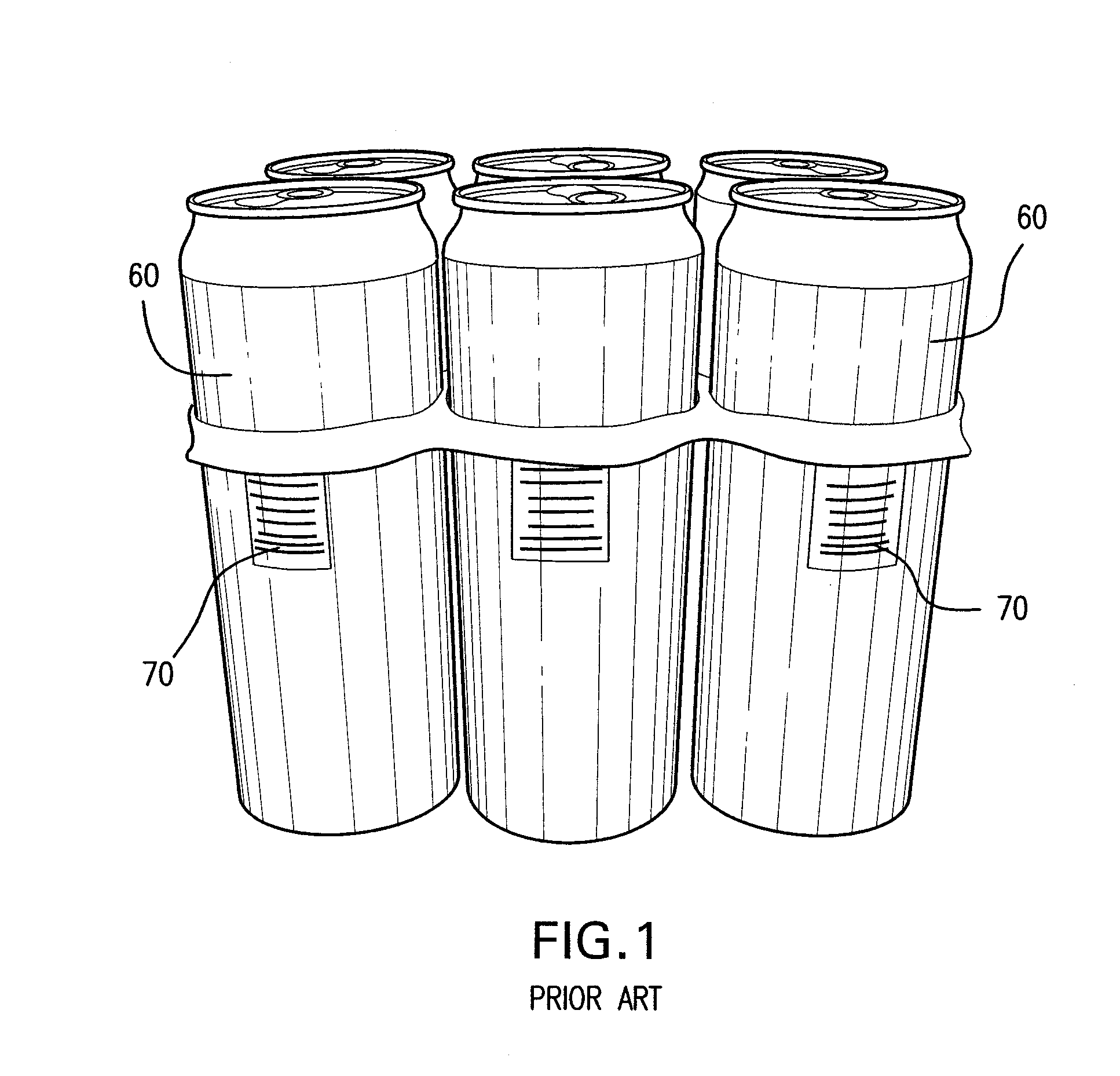

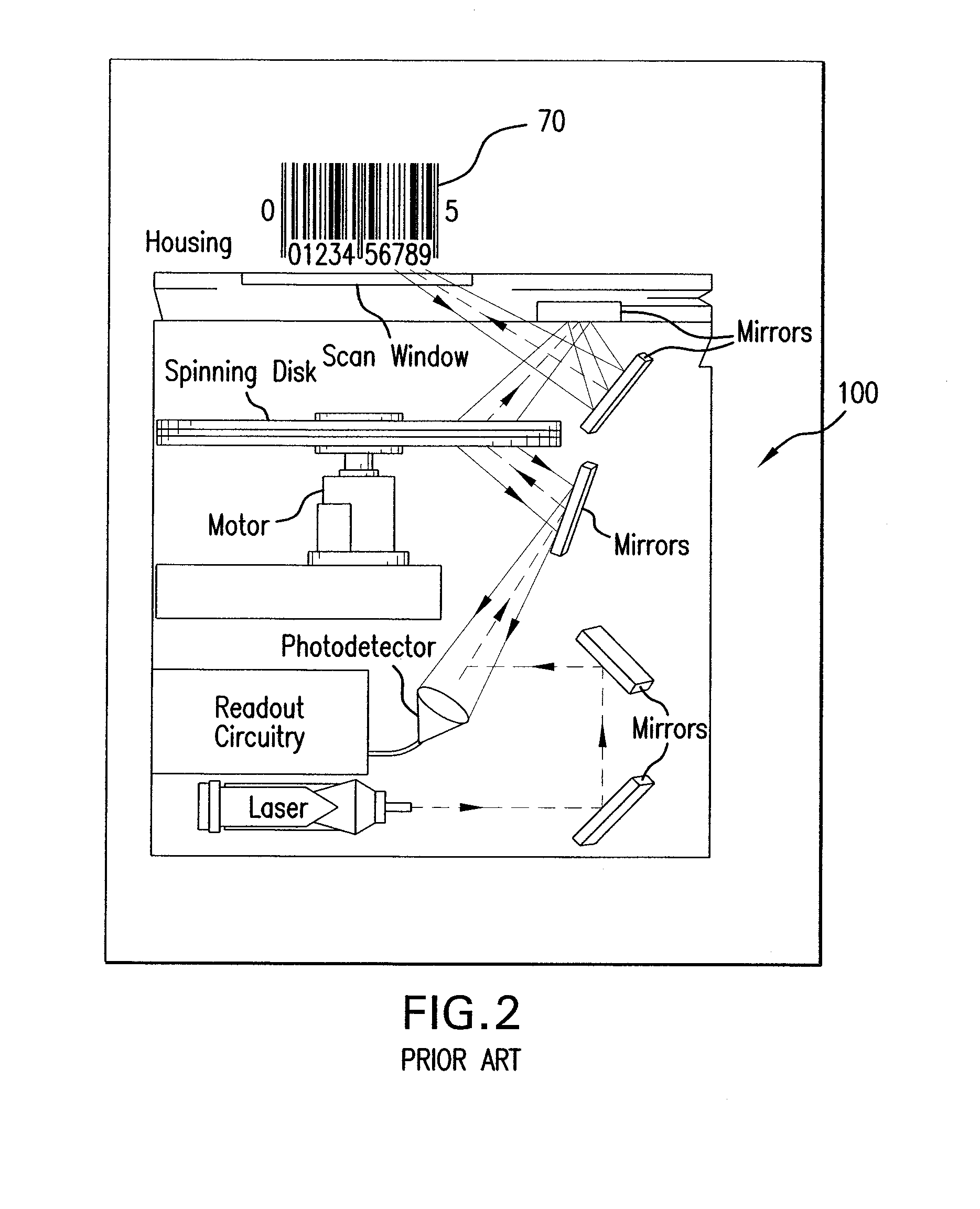

Single color bar code printing on a multi-package

ActiveUS20080164323A1Avoid readingSolve lack of contrastContainer decorationsWrappersFluorescenceBarcode

Owner:ILLINOIS TOOL WORKS INC

Capsule formulation

Owner:CAPSUGEL BELGIUM NV

High-barrier composite membrane applied to thermal baffle

Owner:SICHUAN HUILI IND

Antistatic shielding aluminum-plastic composite packaging material

ActiveCN109397776AImproved ability to resist static shieldingImprove buffering effectWrappersFlexible coversEpoxyAcrylic resin

Owner:西安欣百众复合包装有限公司

Film bag

Owner:MONDI JACKSON

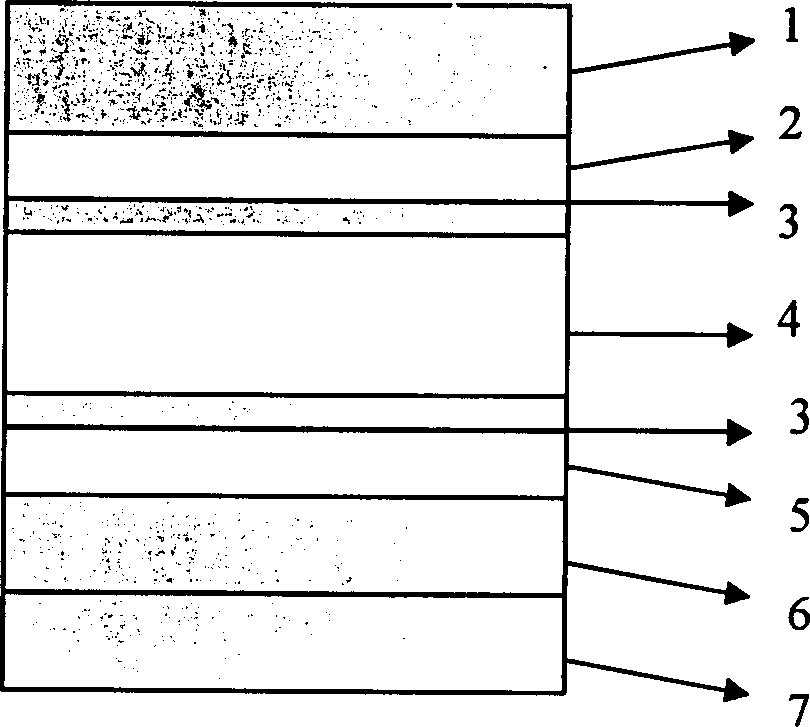

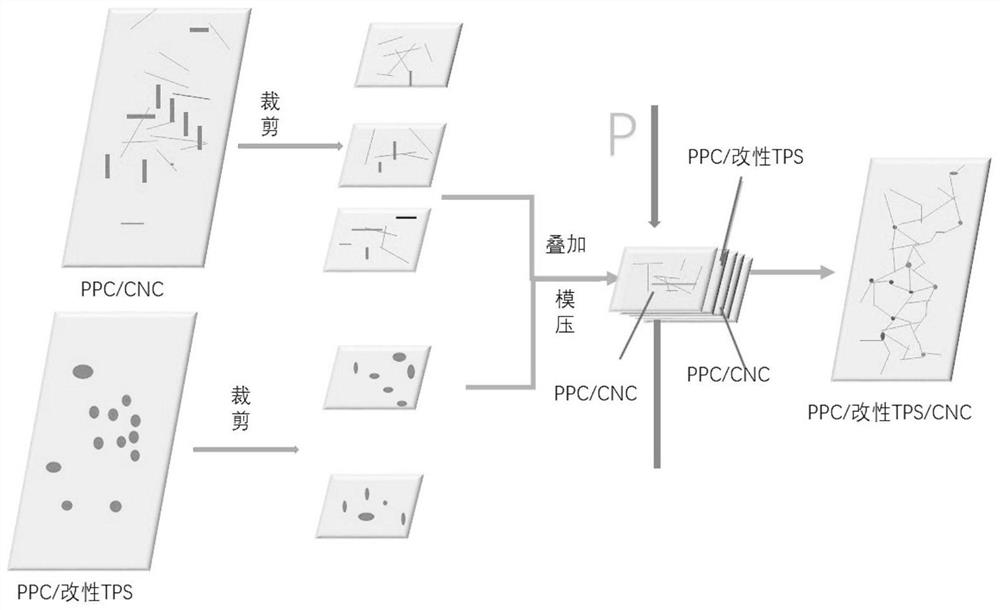

Multi-layer stacked composite material and preparation method and application thereof

Owner:SOUTH CHINA UNIV OF TECH

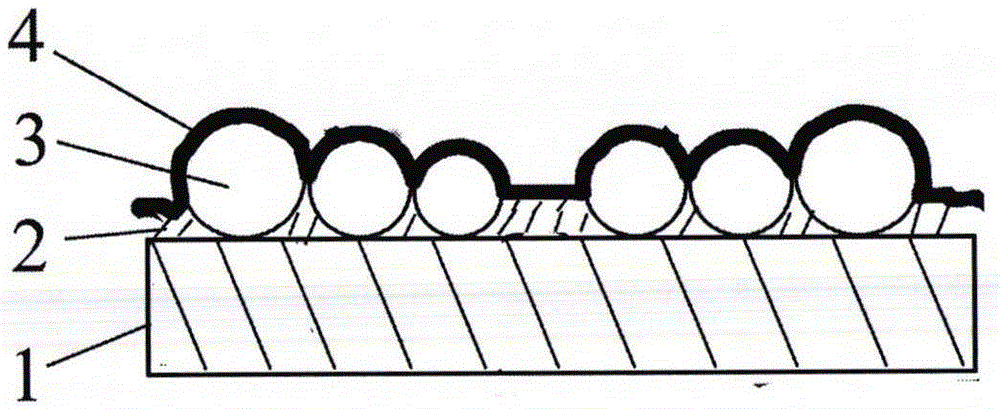

Fire extinguishing air bubble film doped with powdery fire extinguishing medium and manufacturing method thereof

ActiveCN111716854AImprove high temperature resistanceStrong toughnessWrappersFlexible coversFilm baseProcess engineering

The invention discloses a fire extinguishing air bubble film doped with a powdery fire extinguishing medium and a manufacturing method thereof. The fire extinguishing air bubble film comprises a double-layer air bubble film base material and buffer air bubbles which are distributed in the double-layer air bubble film base material and are filled with the powdery fire extinguishing medium, whereinthe air bubble film base material consists of polyethylene serving as a base material and auxiliary materials according to a weight ratio. Compared with the prior art, the fire extinguishing air bubble film doped with the powdery fire extinguishing medium and the manufacturing method thereof in the invention have the following advantages: various kinds of polyethylene can be used as the base material for preparing the air bubble film; by adding a certain proportion of a flame retardant in the mixing process and filling buffering air bubbles with a large amount of the powdery fire extinguishingmedium by using a proper method, the overall high temperature resistance of the bubble film can be improved on the premise of not changing original performance, and flame retardant and fire extinguishing effects are obvious. Meanwhile, through the manufacturing method, the bubble film prepared through the method is high in toughness and not prone to damage, processing process is simple, the produced film has market competitiveness, and better benefits can be brought.

Owner:CIVIL AVIATION UNIV OF CHINA

Preparation method of environment-friendly food packaging material

InactiveCN113698676AExtended service lifeStable structureWrappersFlexible coversBiotechnologyFood grade

Owner:苏州优跃腾信息科技有限公司

Production method of mirror-surface metal leatherette paper

The invention discloses a production method of mirror-surface metal leatherette paper. The method includes the steps of: selecting a raw leatherette basic paper, impregnating the raw leatherette basic paper, finishing the basic paper, performing bottom coating, performing composition, and pressing the paper to form textures. The bottom coating is carried out in a comma blade coating manner, wherein the finished paper surface is uniformly coated with a prime coating, bottom coating quantity being 15-30 g / m<2>. Drying temperature is 110-130 DEG C and machining speed is 20-30 m / min. The method is simple and has low cost. The leatherette paper has a leather texture and has a soft and loose feel, can be folded in any way and has a strong leather hand feel, has beautiful glossiness and is high-grade, can be used various high-grade packages for expensive high-grade luxury products, such as gift boxes, jewel boxes, jewelry boxes, decorative covers of books and albums, high-grade gift boxes and wine boxes, tea boxes, textbooks, etc.

Owner:安徽天艺纸业科技有限公司

Temperature change anti-counterfeiting packaging film for cigarette, and preparation method thereof

InactiveCN110498941ASolve the mildew phenomenon of cigarettesReduce lossesWrappersFlexible coversEngineeringCopolymer

The invention relates to a temperature change anti-counterfeiting packaging film for cigarette, and a preparation method thereof. The temperature change anti-counterfeiting packaging film for cigarette comprises, by weight, 20-40 parts of an ethylene / propylene copolymer, 20-30 parts of a propylene / ethylene / butylene copolymer, 20-40 parts of a mixture of a terpolymer and butylene and 5-10 parts ofa surface additive. The components are reasonably improved, so the packaging film for cigarette of the invention has the advantages of effective solving of the problem of mildew and molds in the shelflife of cigarette, caused by absorption of moist gas due to poor barrier of routine packaging films for cigarette, effective ensuring of the quality of the cigarette, reduction of the loss of enterprises, and non-deformation in case of transient high temperature.

Owner:QINGDAO JUSTO PACKAGING

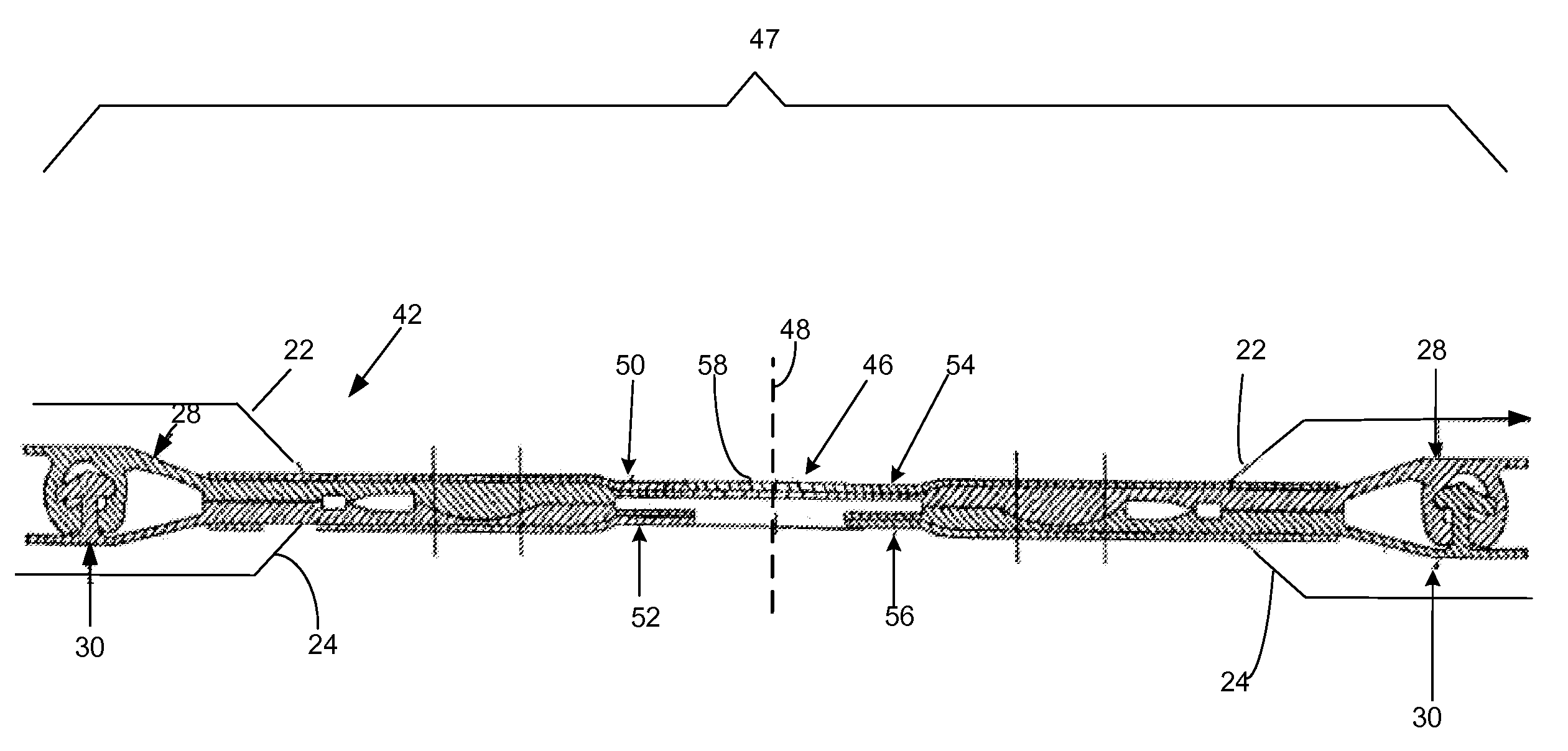

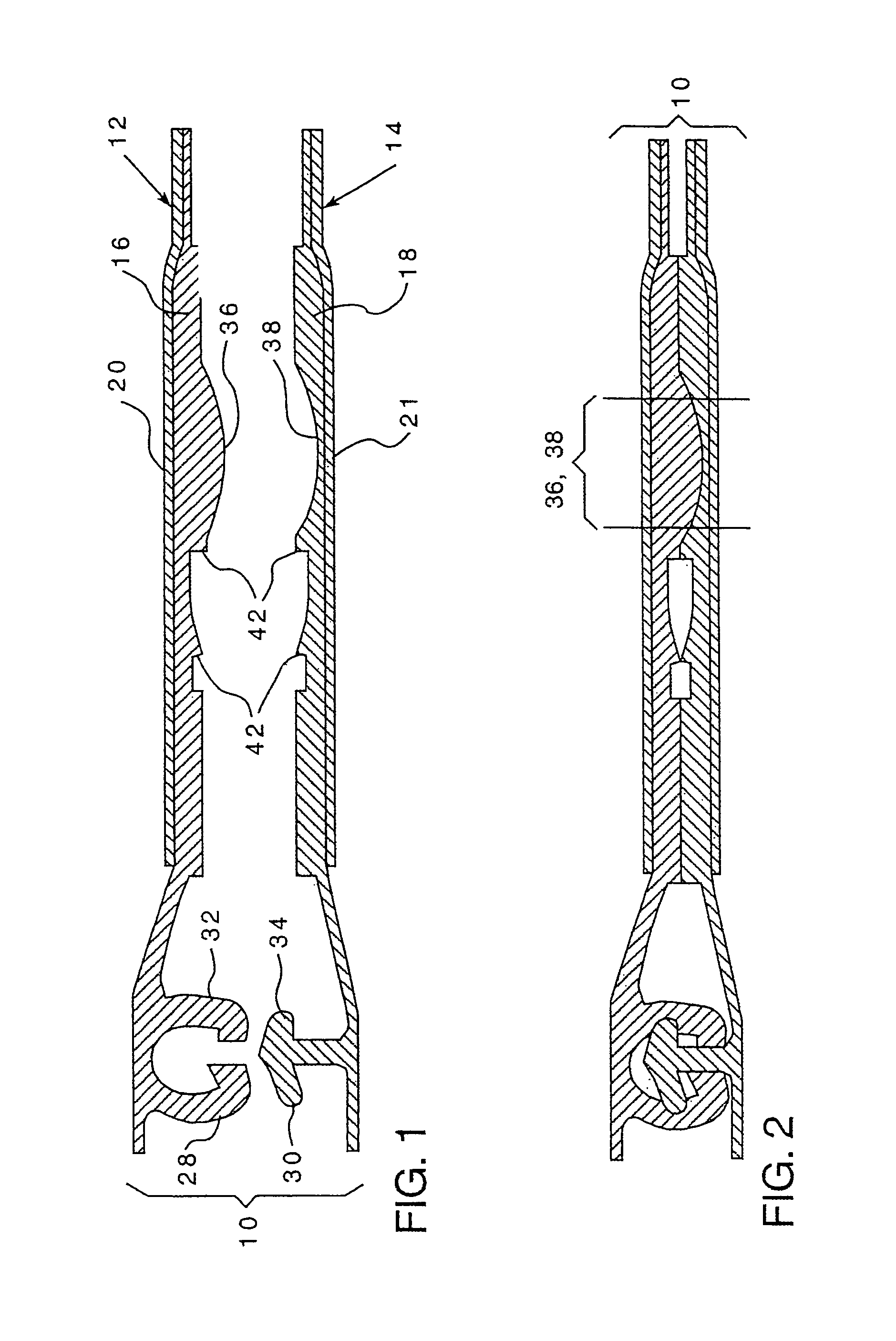

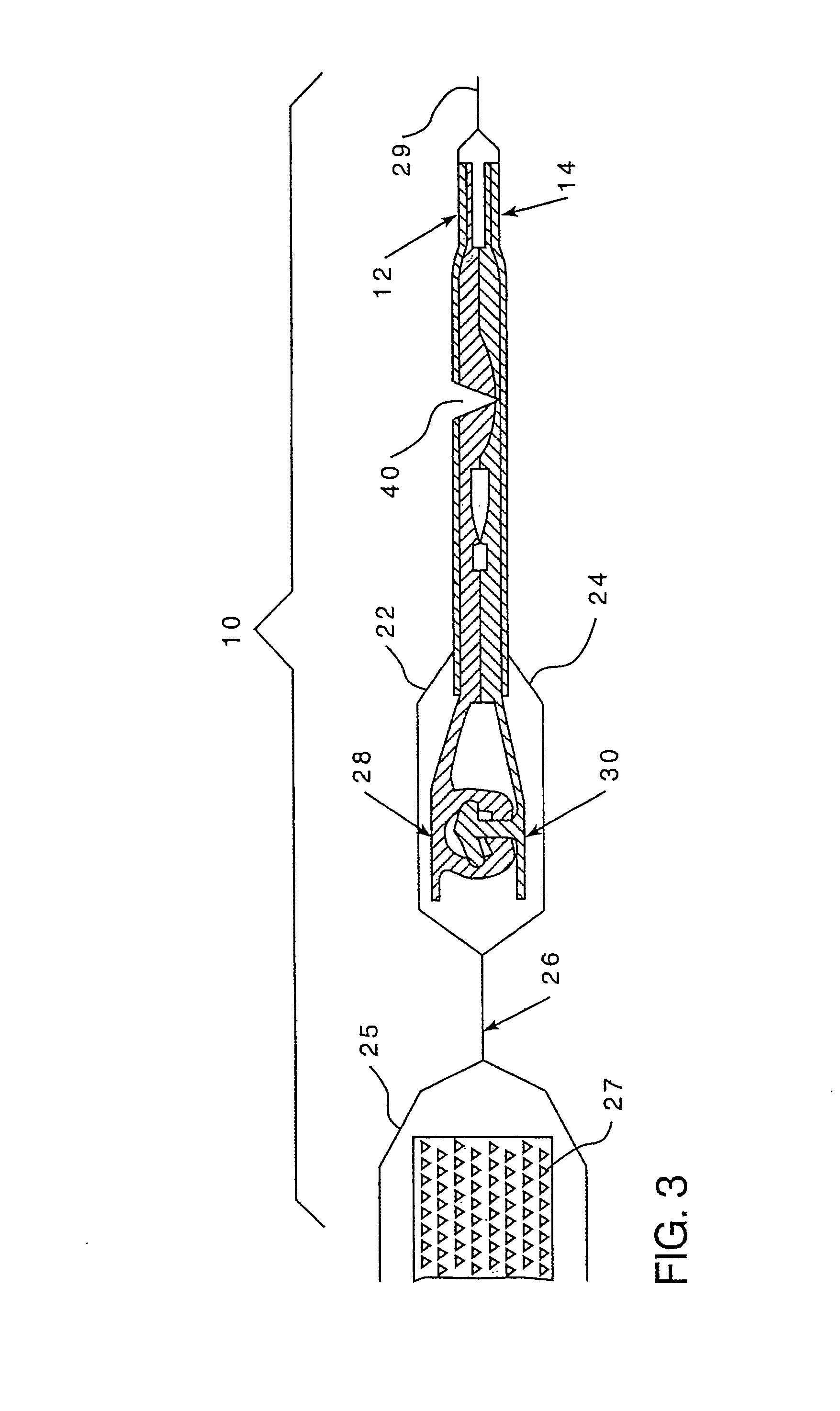

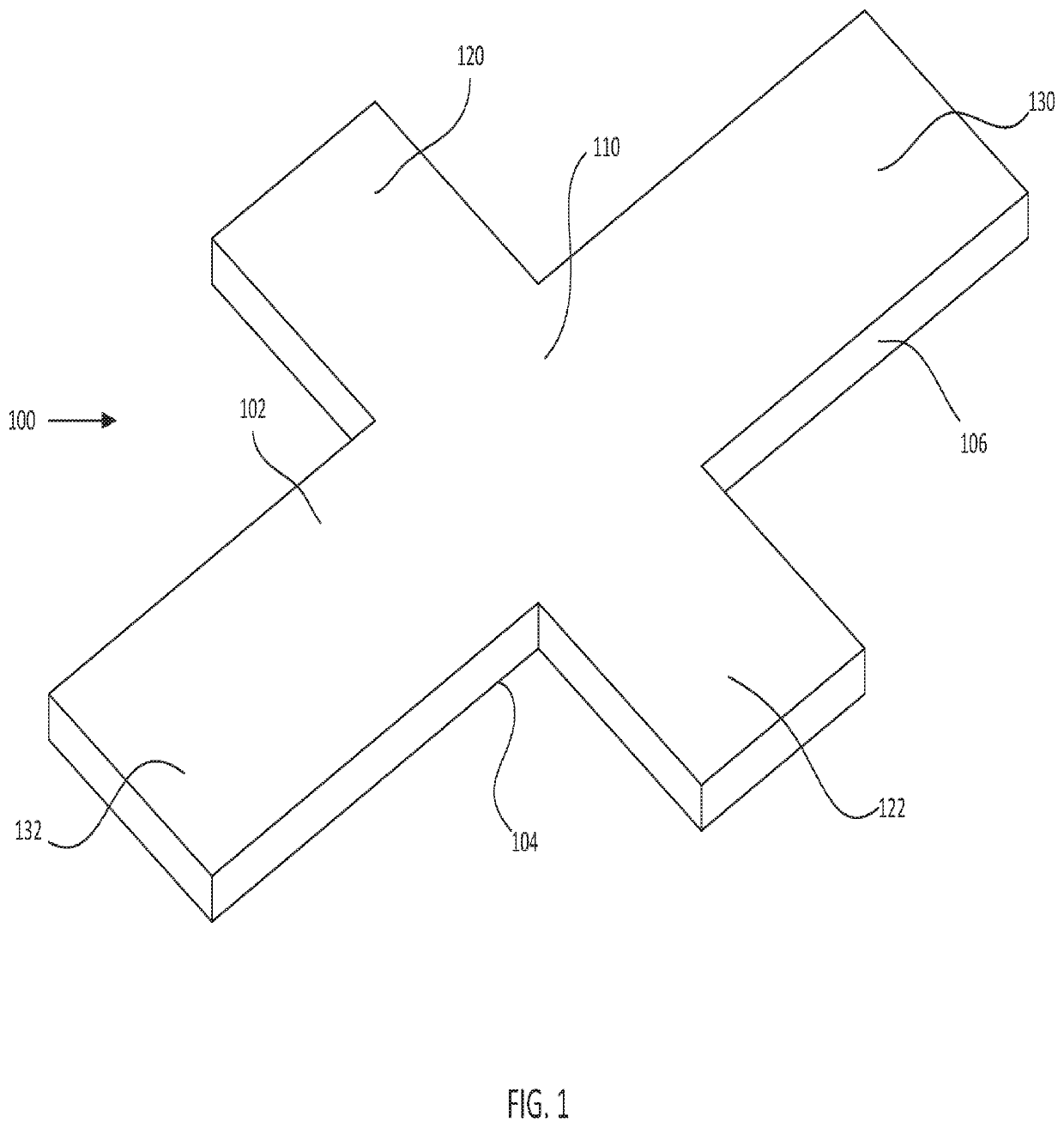

System, Method, and Apparatus for an Insulating Packaging Product

Owner:LYONS KEVIN LEE

Food packaging film

InactiveCN102975949AEasy to acceptDoes not affect the tasteWrappersFlexible coversNutritive valuesWAS PROTEIN

The invention discloses food packaging film. The food packaging film comprises animal protein and vegetable protein. The food packaging film has the advantages of achieving easiness for environmental protection and having no effect on the own taste of food. The main raw material of the food packaging film is protein, and the protein is harmless to human bodies and has certain nutritive value, and thus the food packaging film can be accepted by users easily.

Owner:DALIAN JUNLE PRINTING & PACKING CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap