Alkaloid compound with antibacterial activity in tobaccos as well as preparation method and use of alkaloid compound

A technology of alkaloids and compounds, which is applied in the field of tobacco chemistry, can solve the problems that the ingredients have not been identified, and achieve the effects of easy artificial synthesis, easy separation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

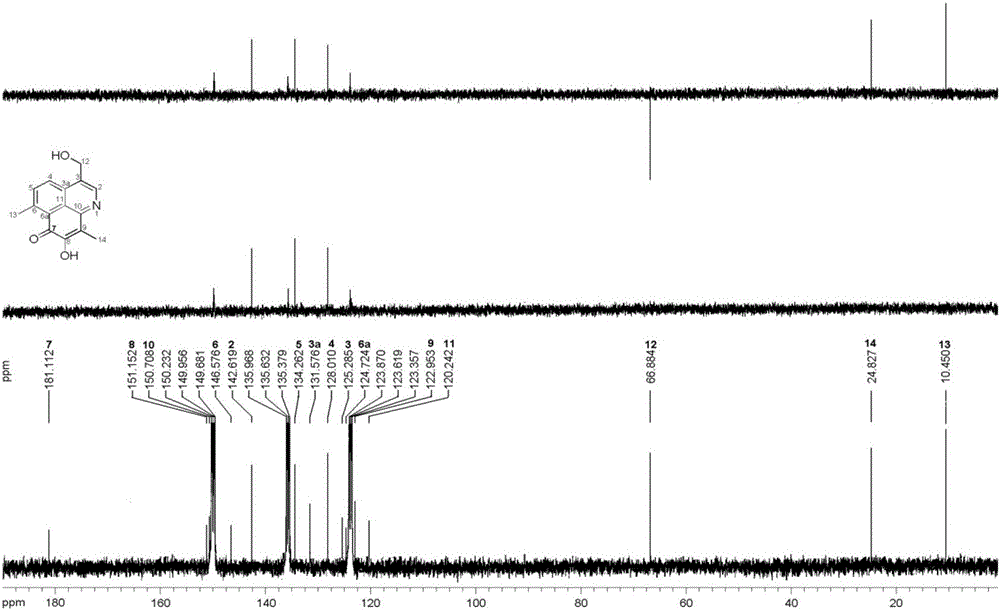

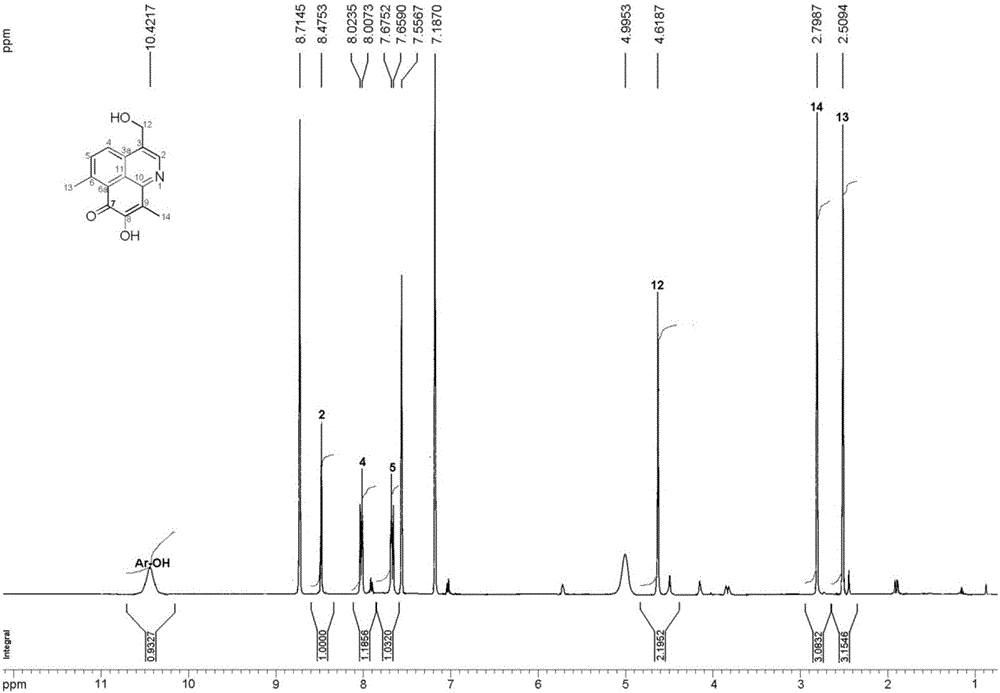

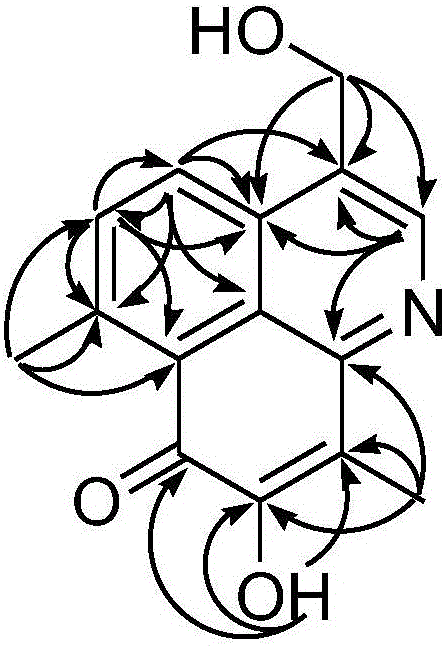

Image

Examples

Embodiment 1

[0027] Preparation of alkaloid compound C 15 h 13 NO 3 , including extracting extract, silica gel column chromatography, and high-pressure liquid chromatography separation, specifically adopting the following steps:

[0028] 1. Extraction of extract: take tobacco leaves and pulverize them, use high-concentration methanol (w%: 95%) or high-concentration ethanol (w%: 95%) or high-concentration acetone (w%: 70%) as extraction solvent, extraction solvent: Tobacco (weight ratio)=3:5, soaked for 54h, extracted 4 times, combined extracts, filtered and concentrated into extract.

[0029]2. Silica gel column chromatography: dissolve the extract with 2.5 times the weight ratio of pure methanol or pure ethanol or pure acetone, mix the sample with 1.2 times the weight ratio of 80-100 mesh silica gel, and use 3 times the weight ratio of 250 mesh silica gel Dry packing for silica gel column chromatography; chloroform in volume ratios (1:0, 20:1, 9:1, 8:2, 7:3, 6:4, 1:1 and 1:2) - Gradient

Embodiment 2

[0034] The tobacco samples were from Yuxi, Yunnan, and the variety was Yuxi K326. Sampling 2.0 kg of tobacco was pulverized and extracted 5 times with 95% methanol for 24 hours each time. The extracts were combined, filtered, and concentrated under reduced pressure to form an extract to obtain 105 g of extract. After dissolving the extract with 2.0 times the amount of pure methanol by weight, mix the sample with 120g of 100-mesh silica gel, pack 0.6kg of 160-mesh silica gel into a column for silica gel column chromatography, and use a volume ratio of 1:0, 20:1, 9:1, 8:2, 7:3, 6:4, 1:1, 1:2 chloroform-acetone gradient elution, TLC monitoring and merging the same parts to obtain 8 parts, wherein the volume ratio is 8: The chloroform-acetone elution part of 2 was separated by Agilent 1100 semi-preparative high-performance liquid chromatography, with 52% methanol as mobile phase, ZorbaxSB-C18 (21.2×250mm, 5 μm) preparative column as stationary phase, flow rate was 20ml / min, the d

Embodiment 3

[0036] The tobacco sample comes from Dali, Yunnan, and the variety is Yunyan 200. The tobacco sample is 3.5kg and chopped, and extracted 4 times with 95% ethanol, each extraction is 48h, the extracts are combined, filtered, and concentrated under reduced pressure to obtain an extract. 250g. The extract is dissolved in pure methanol with a weight ratio of 2.0 times, and then mixed with 250 g of 80 mesh thick silica gel, and 1.2 kg of 200 mesh silica gel is packed for silica gel column chromatography, and the volume ratio is 1:0, 20:1, 9:1, 8:2, 7:3, 6:4, 1:1, 1:2 chloroform-acetone gradient elution, TLC monitoring and merging the same parts to obtain 8 parts, wherein the volume ratio is 8: The chloroform-acetone elution part of 2 was separated by Agilent 1100 semi-preparative high-performance liquid chromatography, with 52% methanol as mobile phase, ZorbaxSB-C18 (21.2×250mm, 5 μm) preparative column as stationary phase, flow rate was 20ml / min, the detection wavelength of the u

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap