Dry salt salting machine

A dry salt and rack technology, applied in the field of dry salt pickling machines, can solve the problems of labor and time consumption, low degree of mechanization, breeding of spoilage bacteria, etc., to improve quality and flavor, shorten pickling time, and accelerate moisture leaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

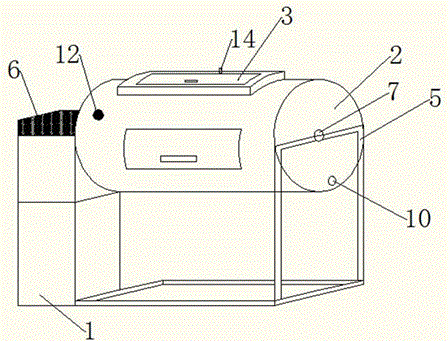

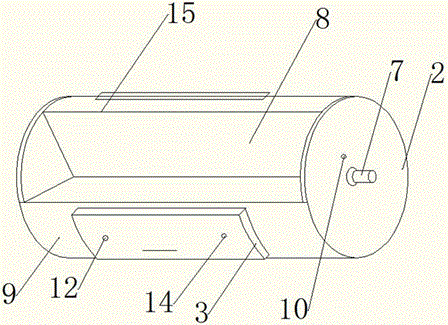

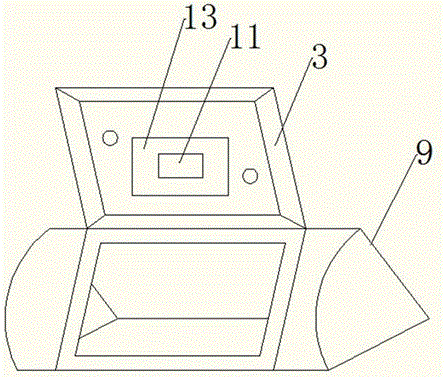

[0020] Seen from accompanying drawing, the present invention provides a kind of dry salt pickling machine, comprises frame 1, pickling frame 2, pickling lattice 9, and described frame 1 is provided with deceleration motor 6 and rotating seat 5, and described The central position of pickling frame 2 is provided with rotating shaft 7, and described rotating shaft 7 is installed on the rotating base 5, and described reduction motor 6 links rotating shaft 7; 9 mutually matched pickling frame 8; the pickling frame is divided by the interlayer block 15; the pickling frame 8 and the pickling grid 9 split structure; the pickling grid 9 is fixed on the On the pickling frame 8; the sealing box cover 3 is arranged on the said pickling box 9, and an extruding device is arranged in the said sealing box cover 3; a pressure gauge 12 is arranged on the said sealing box cover; A vibrator 11 is arranged in the grid 9 .

[0021] The present invention is further improved, the said sealing box cover

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap