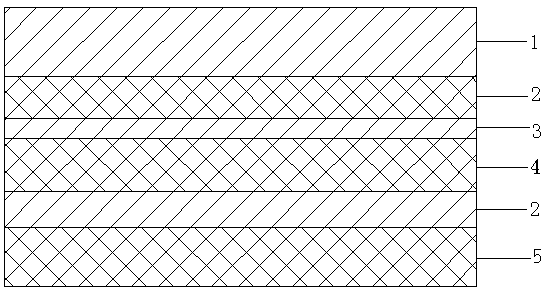

Coldly-stamped formed composite hard plate and production process

A technology of composite hard sheet and production process, applied in synthetic resin layered products, lamination, layered products, etc., can solve the problems of unclean cleaning of oil stains on the surface of aluminum materials, reduced material adhesion, material delamination, etc. Achieve the effect of reducing fracturing and delamination, improving yield, and enhancing composite fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] The primer (English: Primer) used on the aluminum substrate according to the present invention is a two-component chemical raw material composed of blocked polyisocyanate curing polyester-epoxy block copolymer, and the formula of the primer (English: Primer) is 26.82 parts of 1,2 propylene glycol and 73.072 parts of isophthalic acid were reacted under the catalysis of dibutyltin oxide at 240-260°C to an acid value of 112 (number average molecular weight 1000); it was dissolved in 51.5 parts of Solvesso100 to obtain a solution, and then Add 71.669 parts of Epikote828 epoxy resin and 0.1 part of benzyldimethylamine to the solution, control the reaction at 150°C until the acid value is 3mgKOH / g, the product hydroxyl value is 108.5mgKOH / g, and the molecular weight is 6000; use 1:1 ethylene glycol ether Solevesso 100

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap