Fiber paste coating machine

A technology of coating machine and fiber paste, applied in the direction of fiber mechanical structure, etc., can solve the problems of waste of fiber paste, increase of production cost, dirty machine frame, etc., and achieve the effect of reducing waste and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be further described in detail below in conjunction with the drawings:

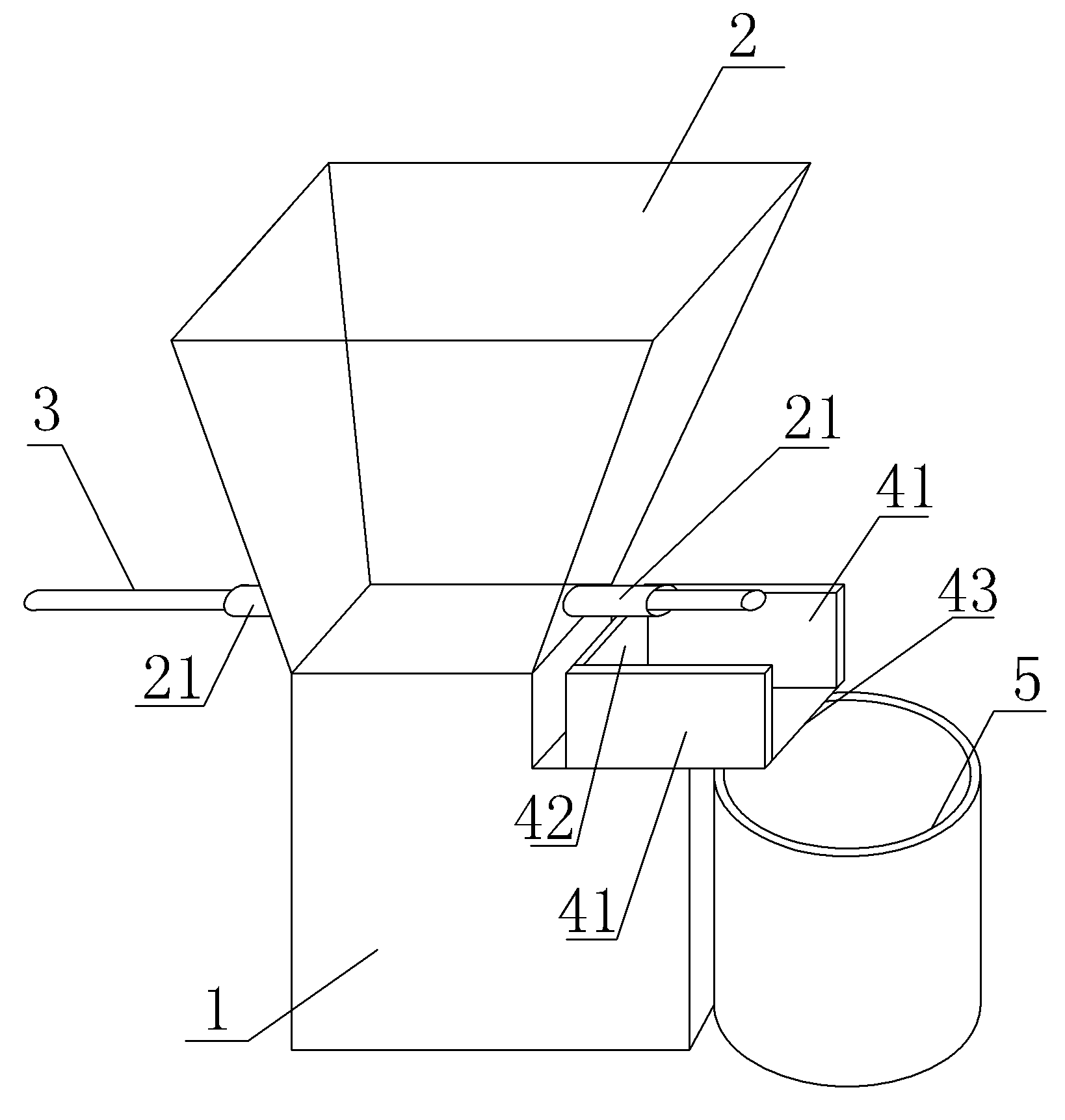

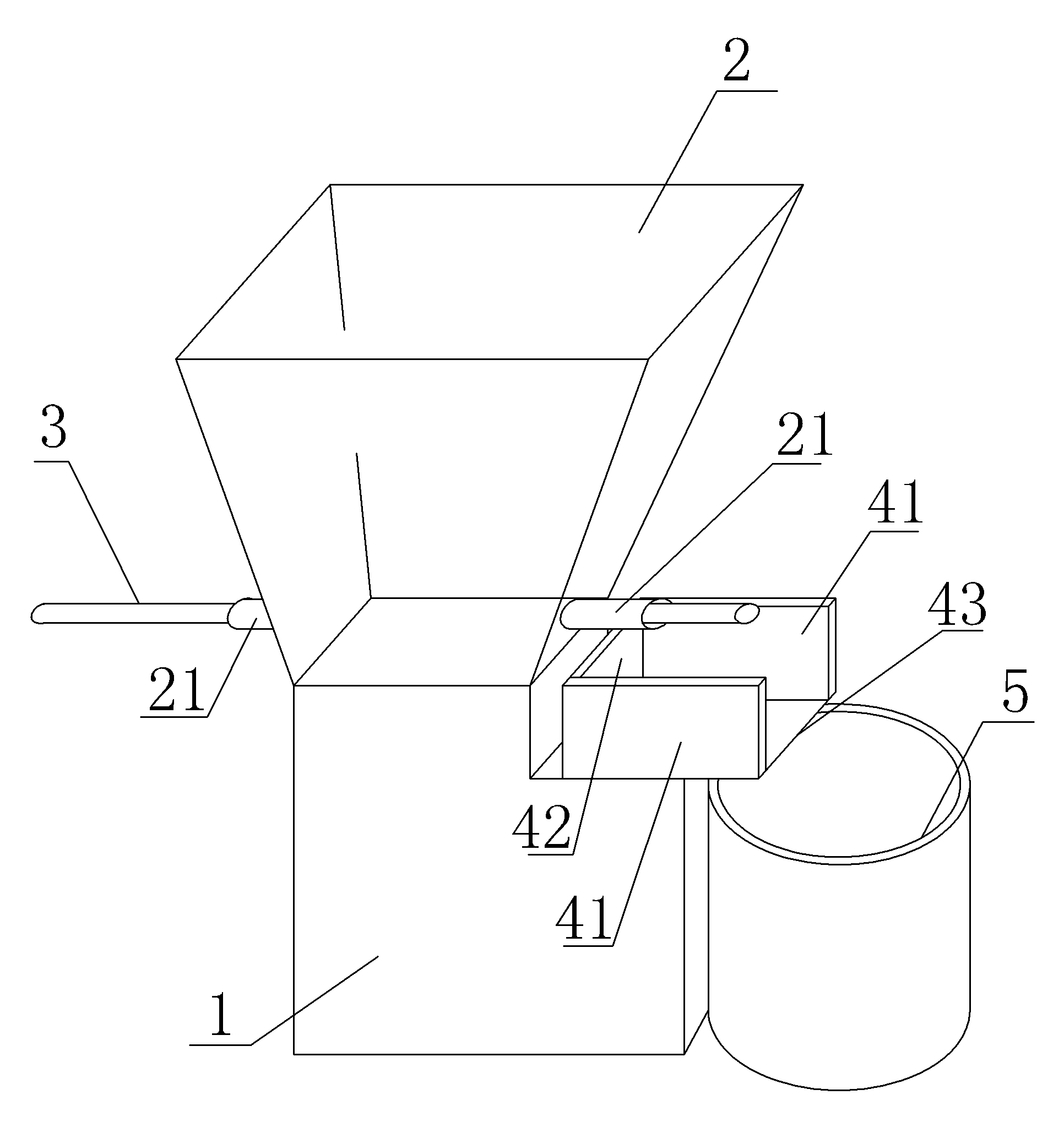

[0015] Such as figure 1 As shown, the fiber paste coating machine is used to coat fiber paste on the cable core 3, and it includes a frame 1, an inverted cone-shaped coating box fixed on the frame 1 to contain the fiber paste 2, and is used for recycling. Recycling tray 4 and recycling bin 5 for fiber paste.

[0016] In this embodiment, the bottom of the side wall of the coating box 2 is provided with a pair of opposite holes, and the two holes are respectively provided with a horizontally arranged cable inlet 21 and a cable outlet 22. The cable core 3 is threaded in each pair of opposite cable inlet pipe 21 and cable outlet pipe 22, and passes through the coating box 2 through a pulling device (not shown in the figure). The inner diameter of the cable inlet tube 21 is the same as the outer diameter of the cable core 3, so that the fiber paste can be prevented from leaking from

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap