Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Evaporation is a type of vaporization that occurs on the surface of a liquid as it changes into the gas phase. The surrounding gas must not be saturated with the evaporating substance. When the molecules of the liquid collide, they transfer energy to each other based on how they collide with each other. When a molecule near the surface absorbs enough energy to overcome the vapor pressure, it will escape and enter the surrounding air as a gas. When evaporation occurs, the energy removed from the vaporized liquid will reduce the temperature of the liquid, resulting in evaporative cooling.

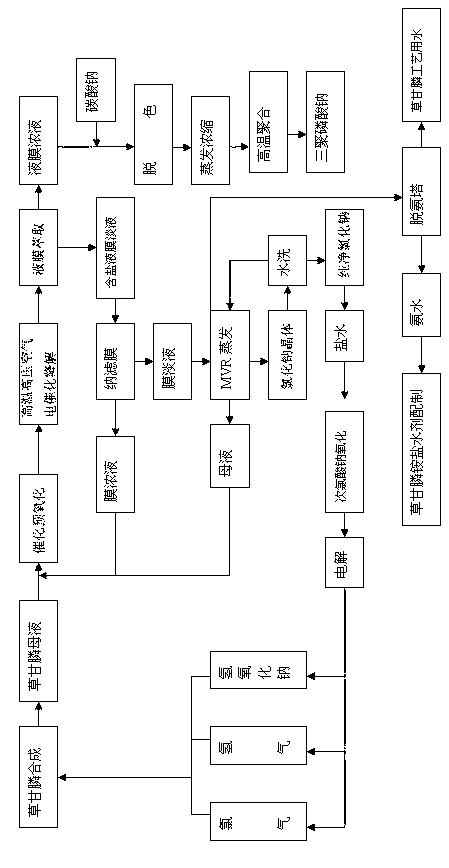

Cyclic production method of glyphosate

ActiveCN103012474AAvoid influenceReduce pollutionBiocideGroup 5/15 element organic compoundsEvaporationHigh pressure

Owner:HANGZHOU JINFADA CHEM IND

Mineral recovery processes

InactiveUS6077441AQuality improvementEffective sedimentationSeparation devicesDifferential sedimentationPhosphateEvaporation

Owner:CIBA SPECIALTY CHEM WATER TRATMENTS

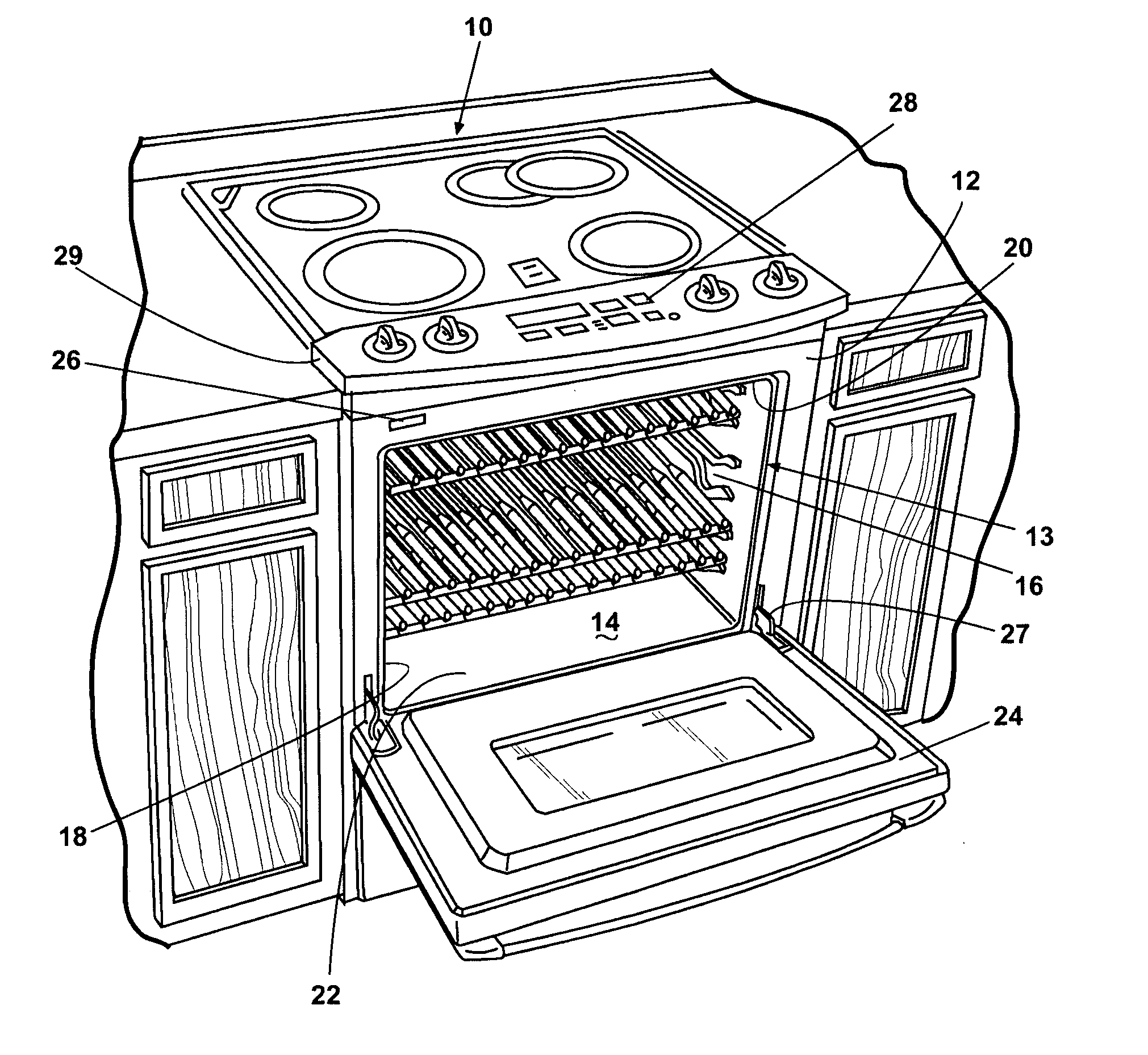

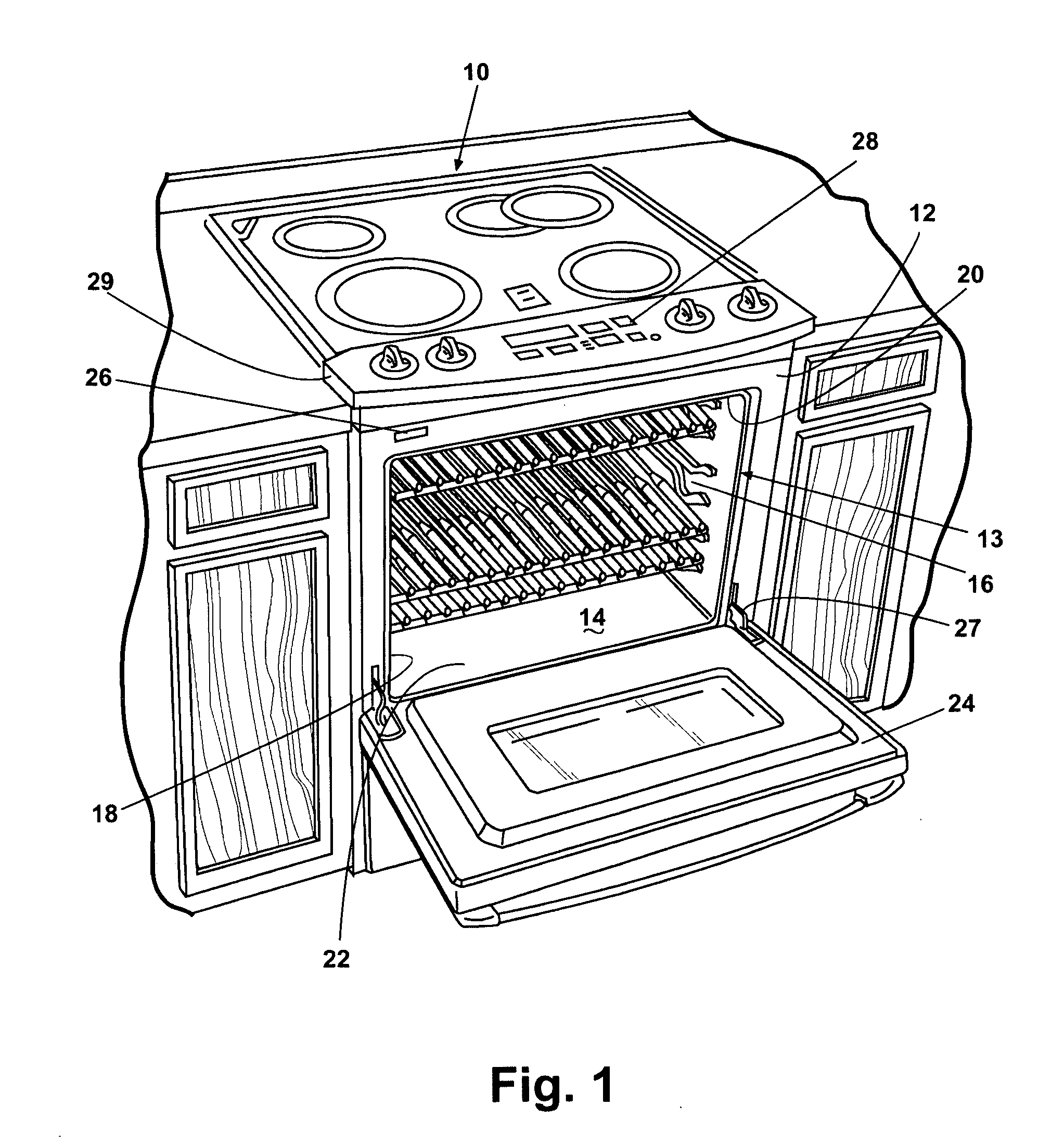

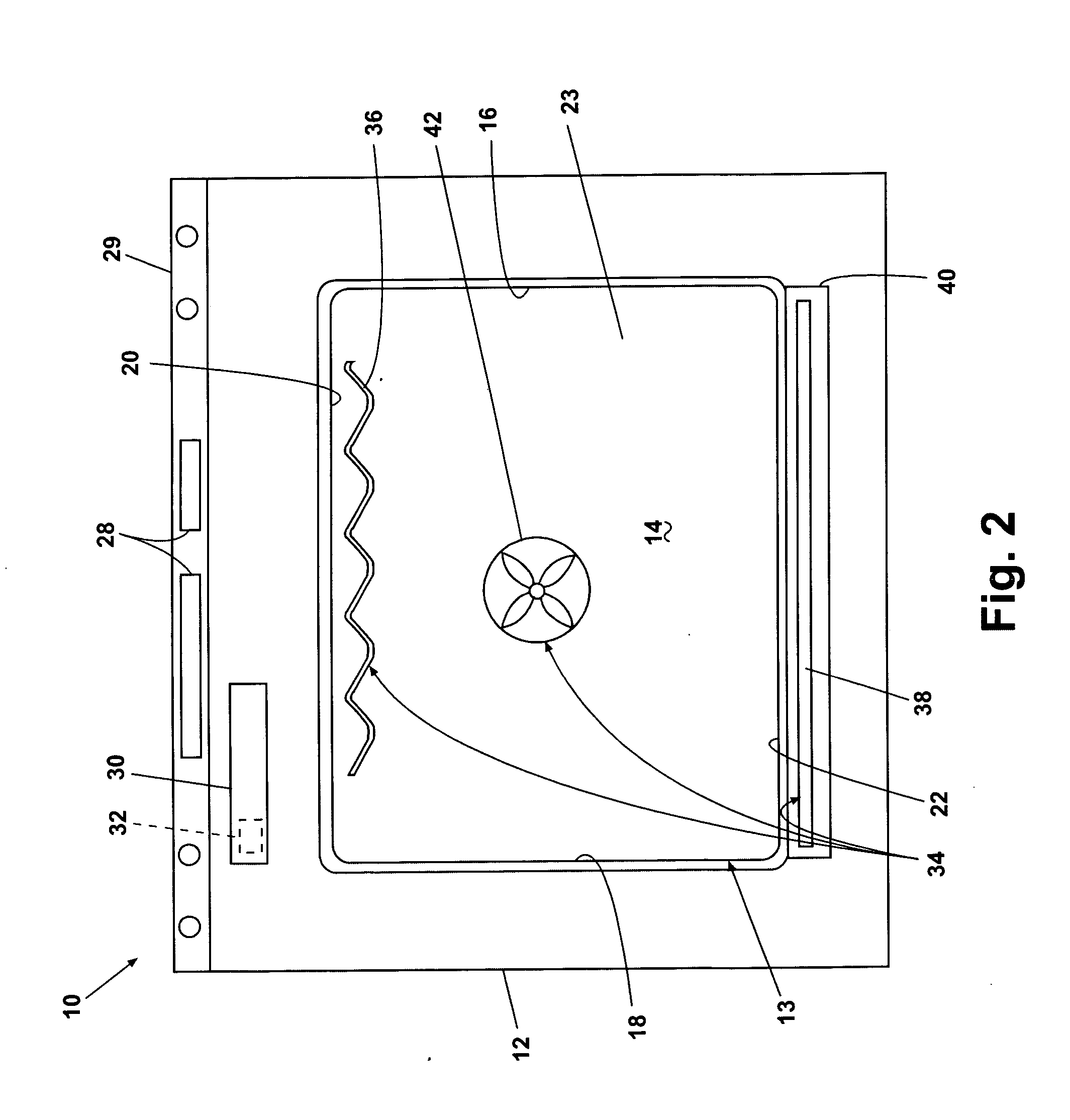

Oven with a system for generating steam

Owner:WHIRLPOOL CORP

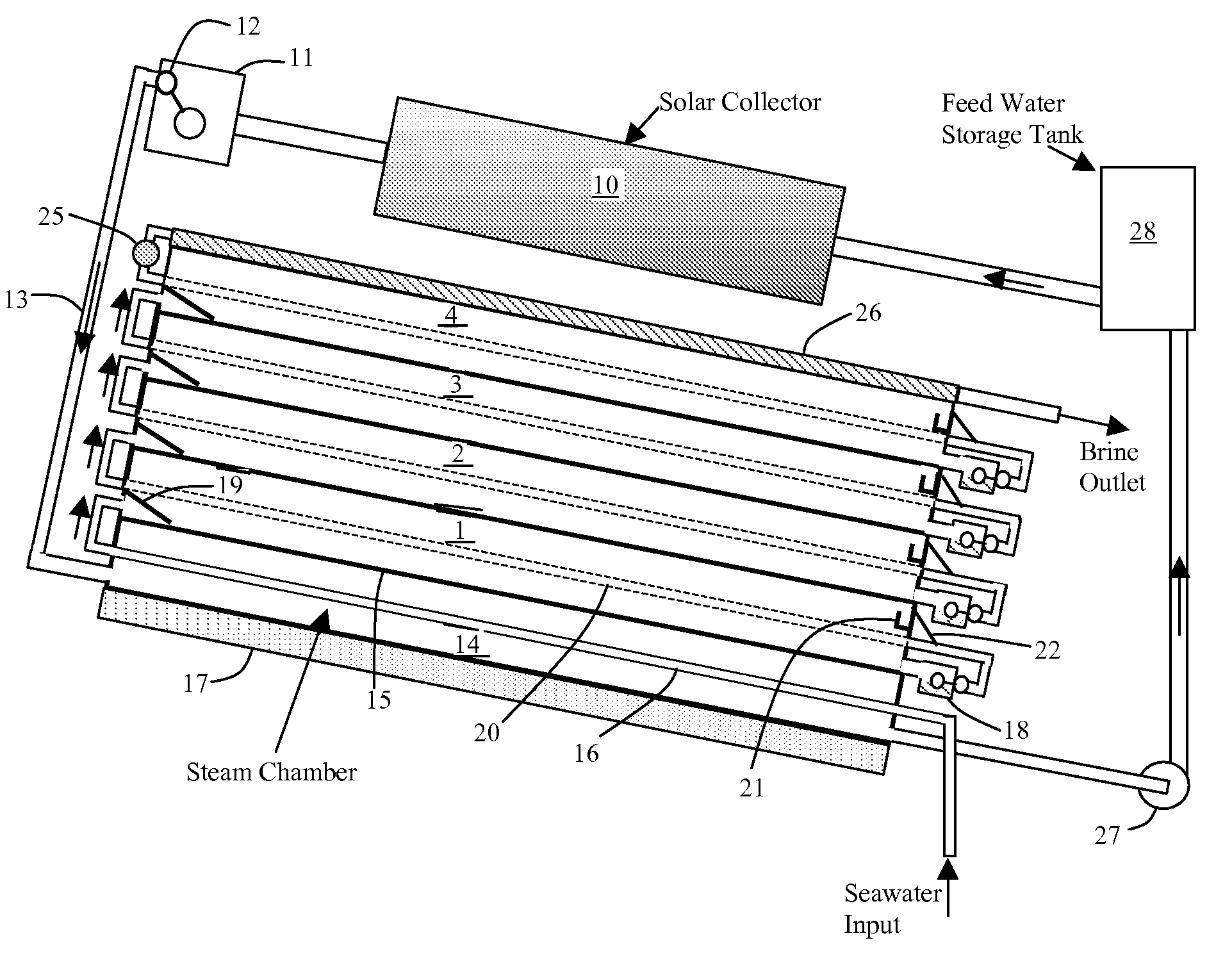

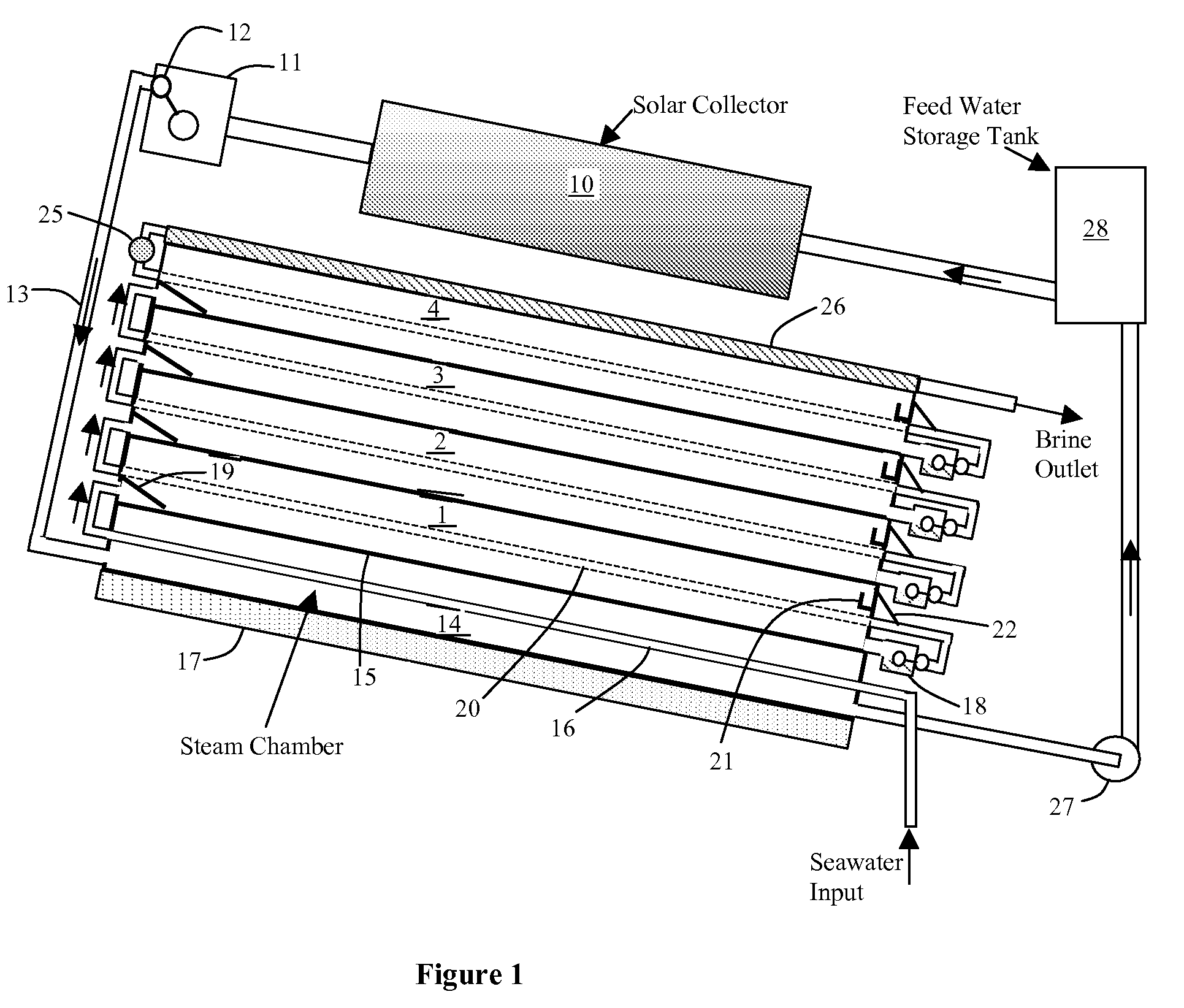

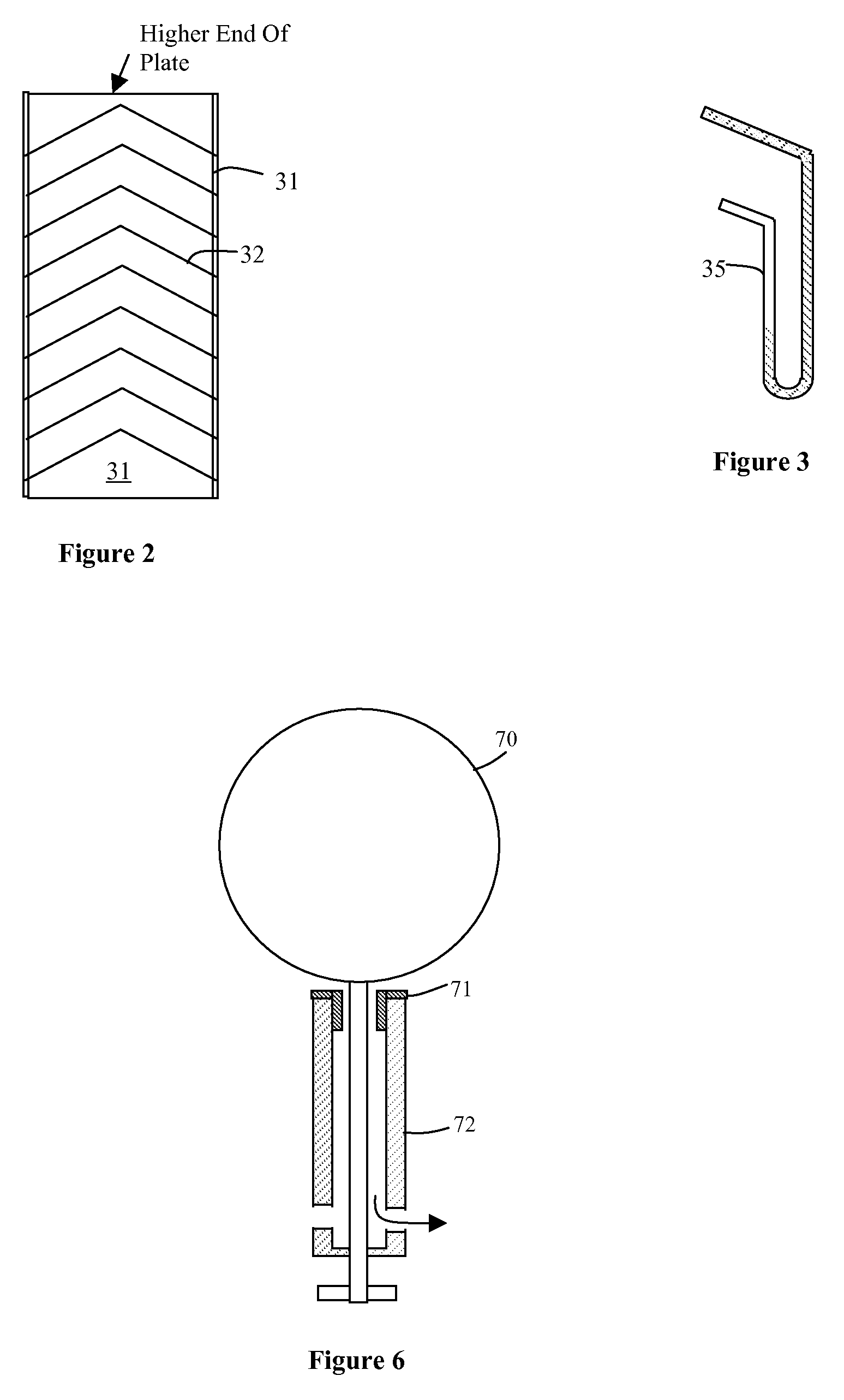

Solar-powered desalination system

InactiveUS20070193870A1Easy to useExcessive numberGeneral water supply conservationMultiple-effect/fractional condensationSaline waterParallel plate

Owner:PRUEITT MELVIN L

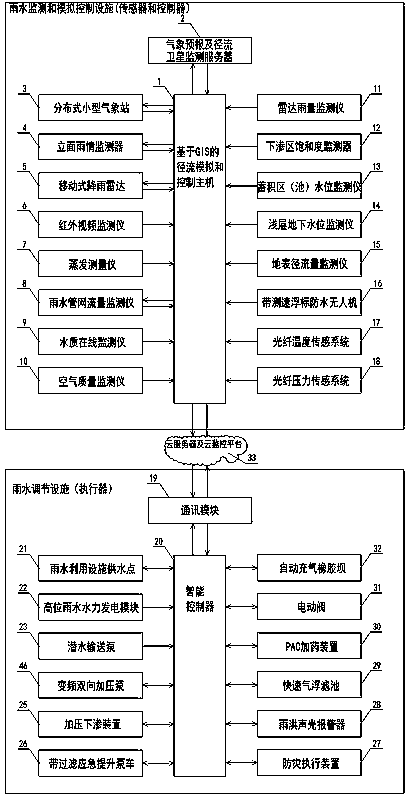

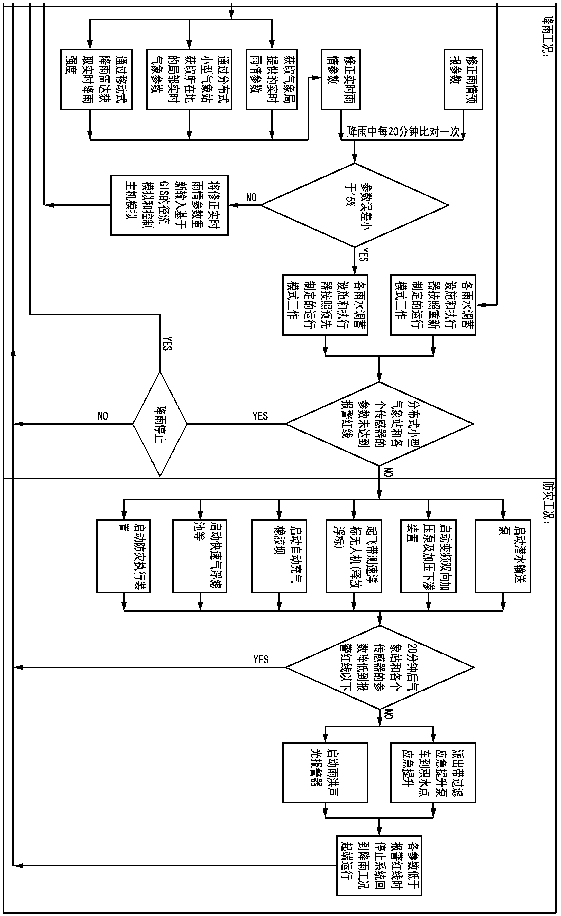

Intelligent rainwater system based on runoff simulation and multi-sensor monitoring, and operation method

PendingCN109164509ACompensating for lagging solid-state rainfall monitoringMaster water absorption capacityIndication of weather conditions using multiple variablesICT adaptationMeasuring instrumentRadar rainfall

Owner:CHINA RAILWAY CONSTR GROUP

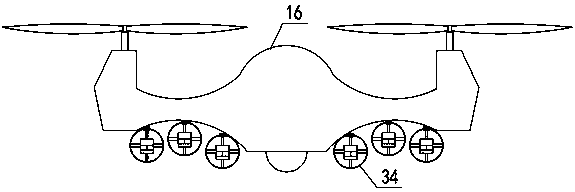

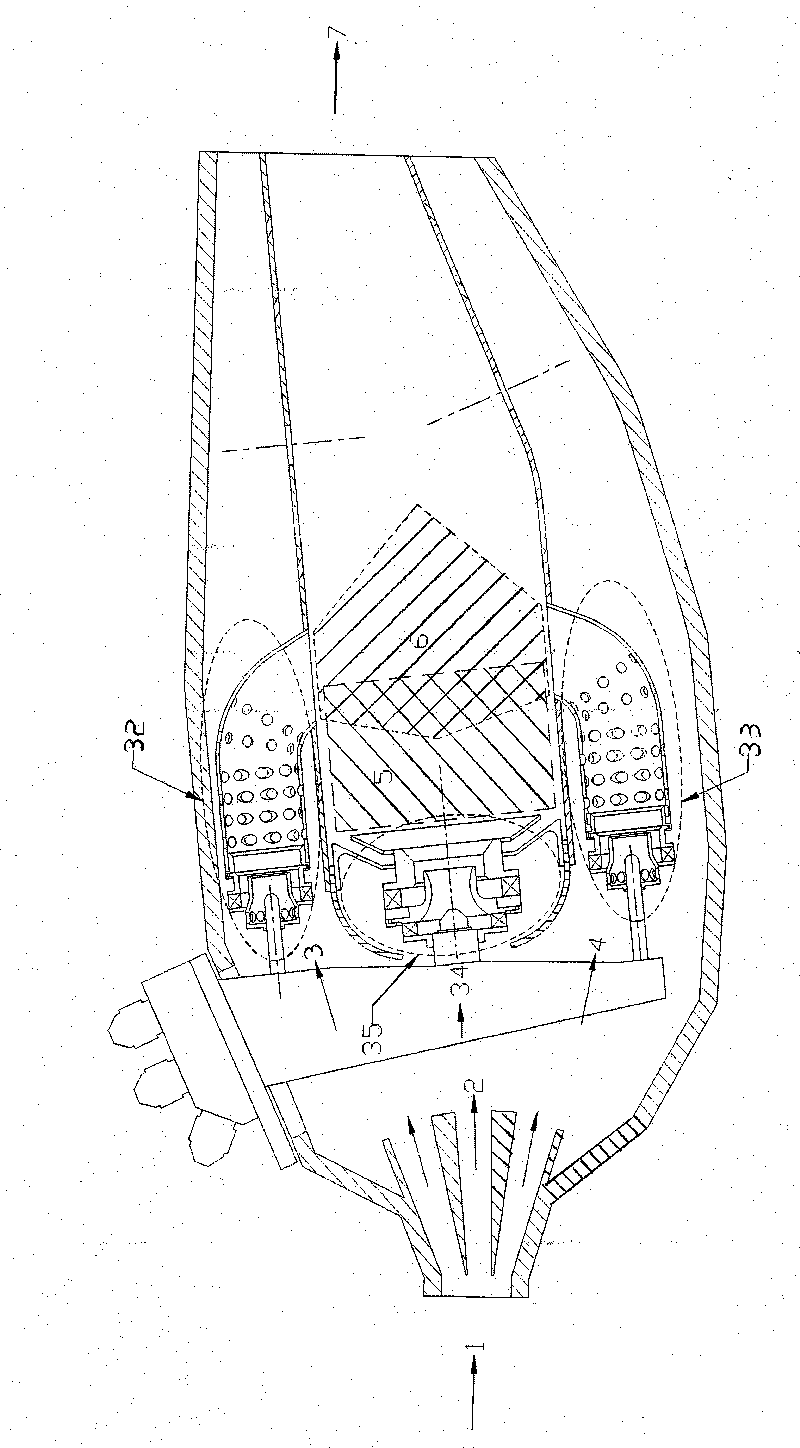

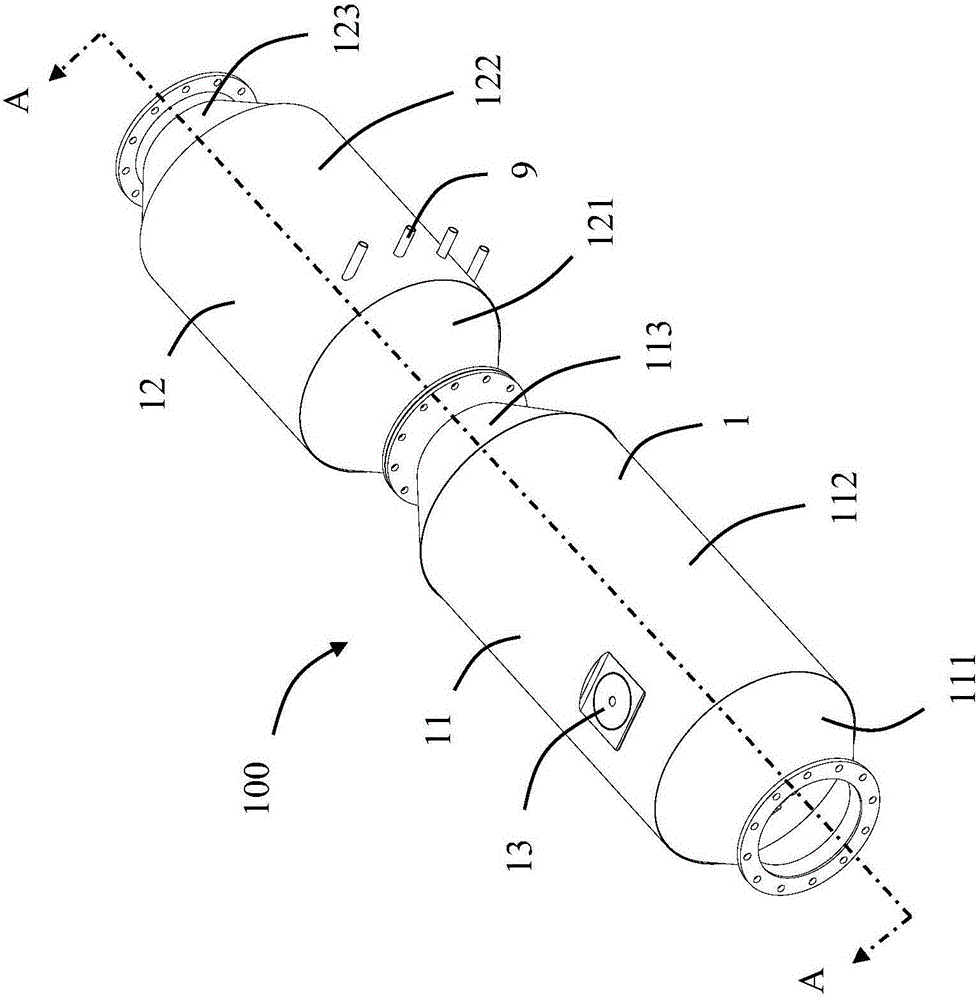

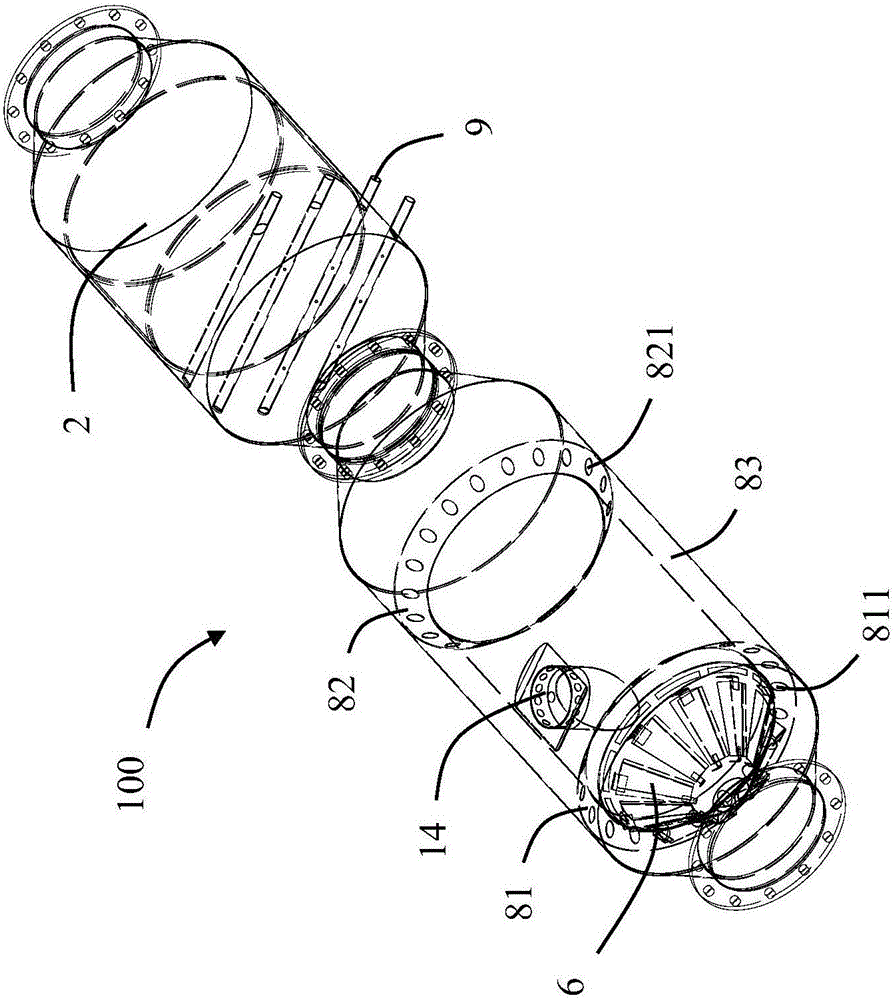

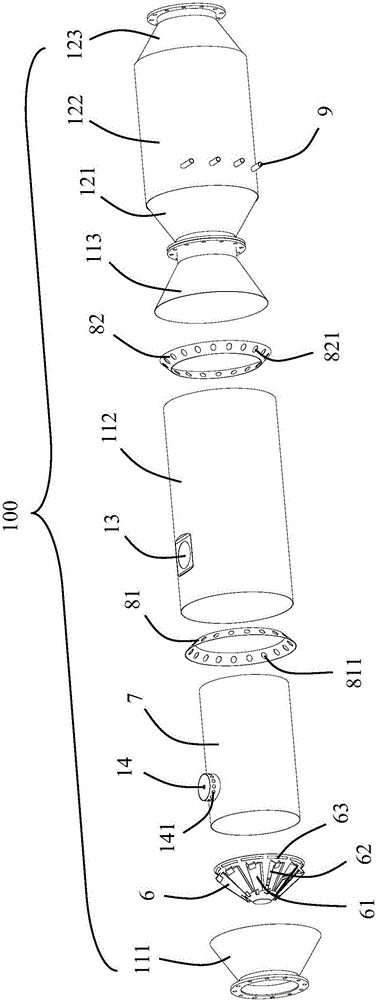

Counter-flow flame combustion chamber

Owner:BEIHANG UNIV

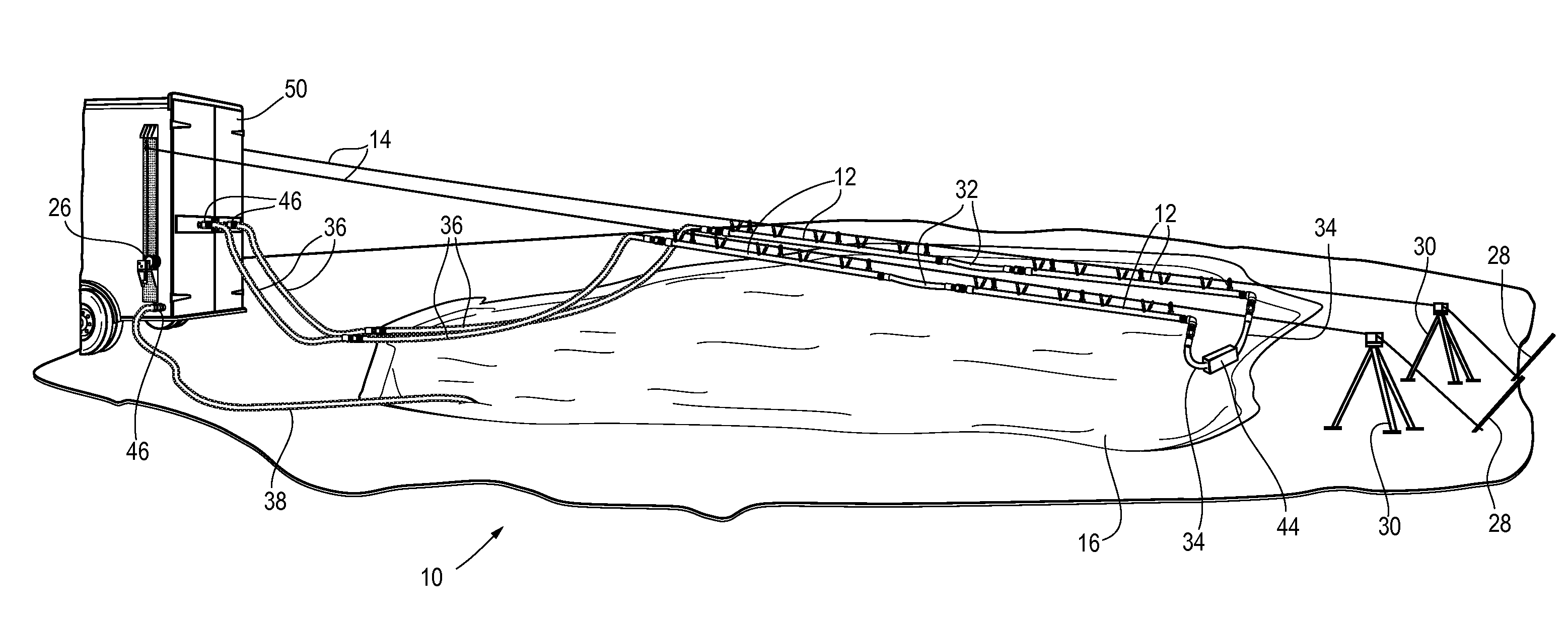

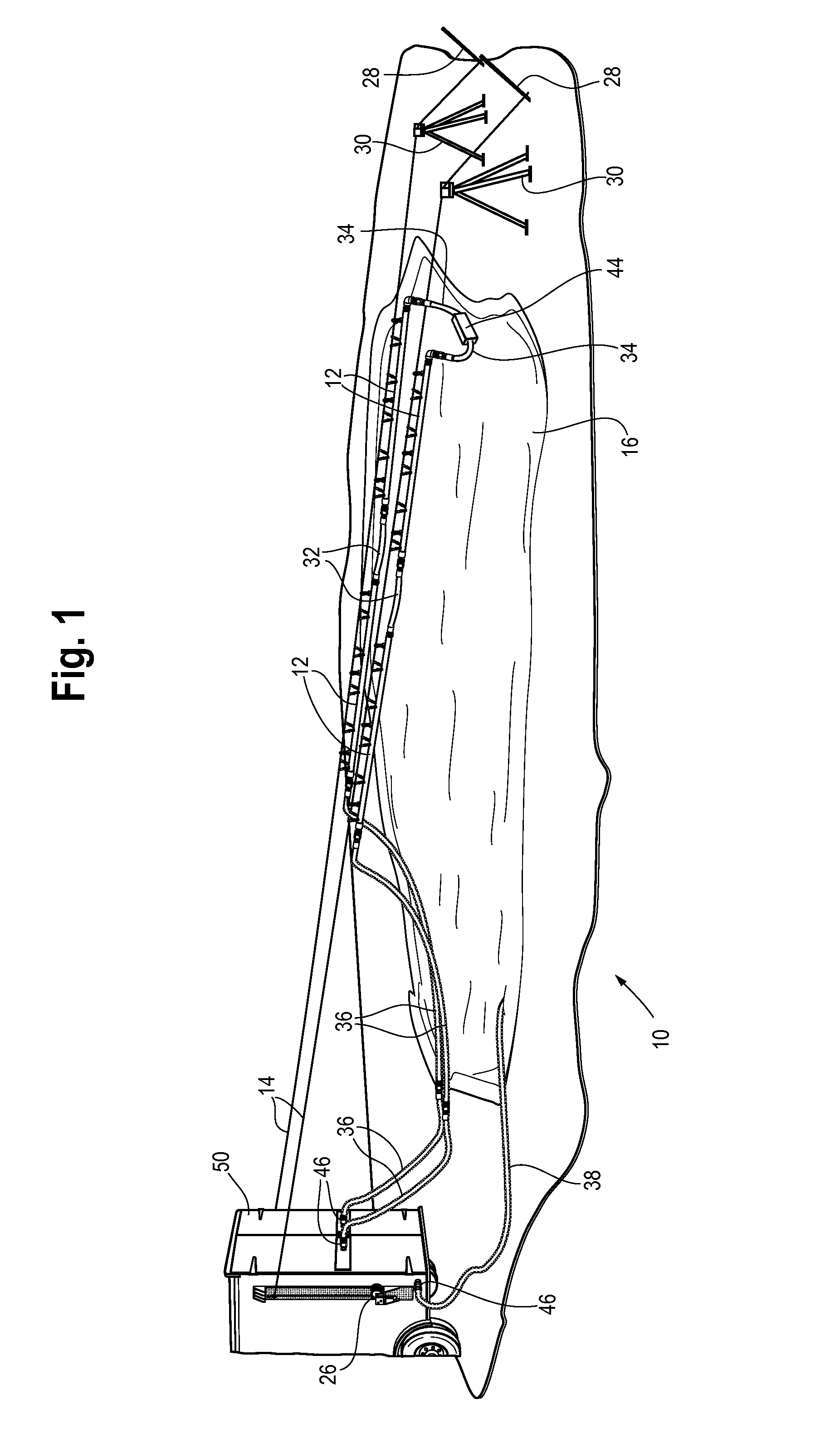

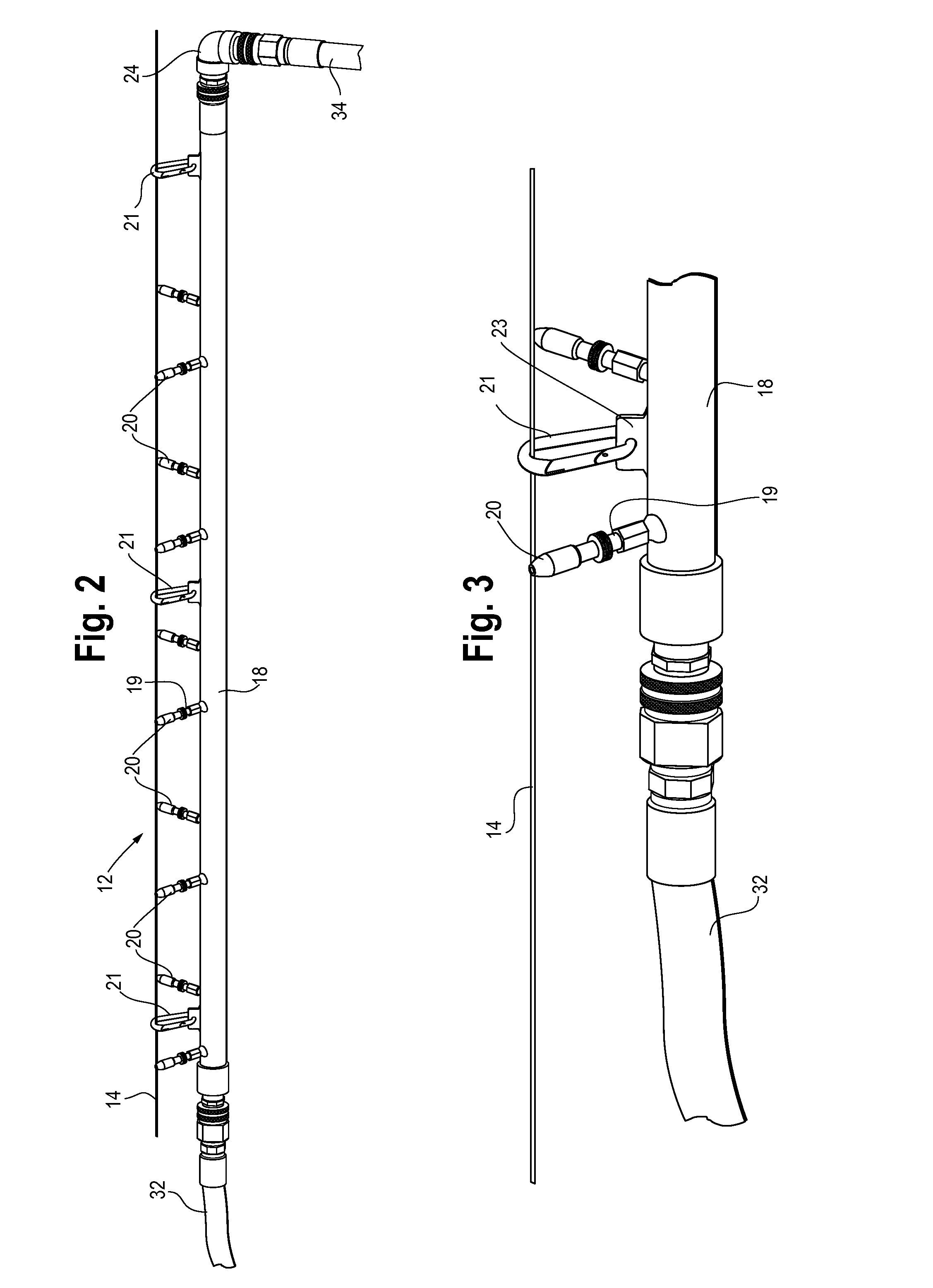

Water evaporation system using nozzles attached to a suspended cable

Owner:EVAPORITE SYST

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

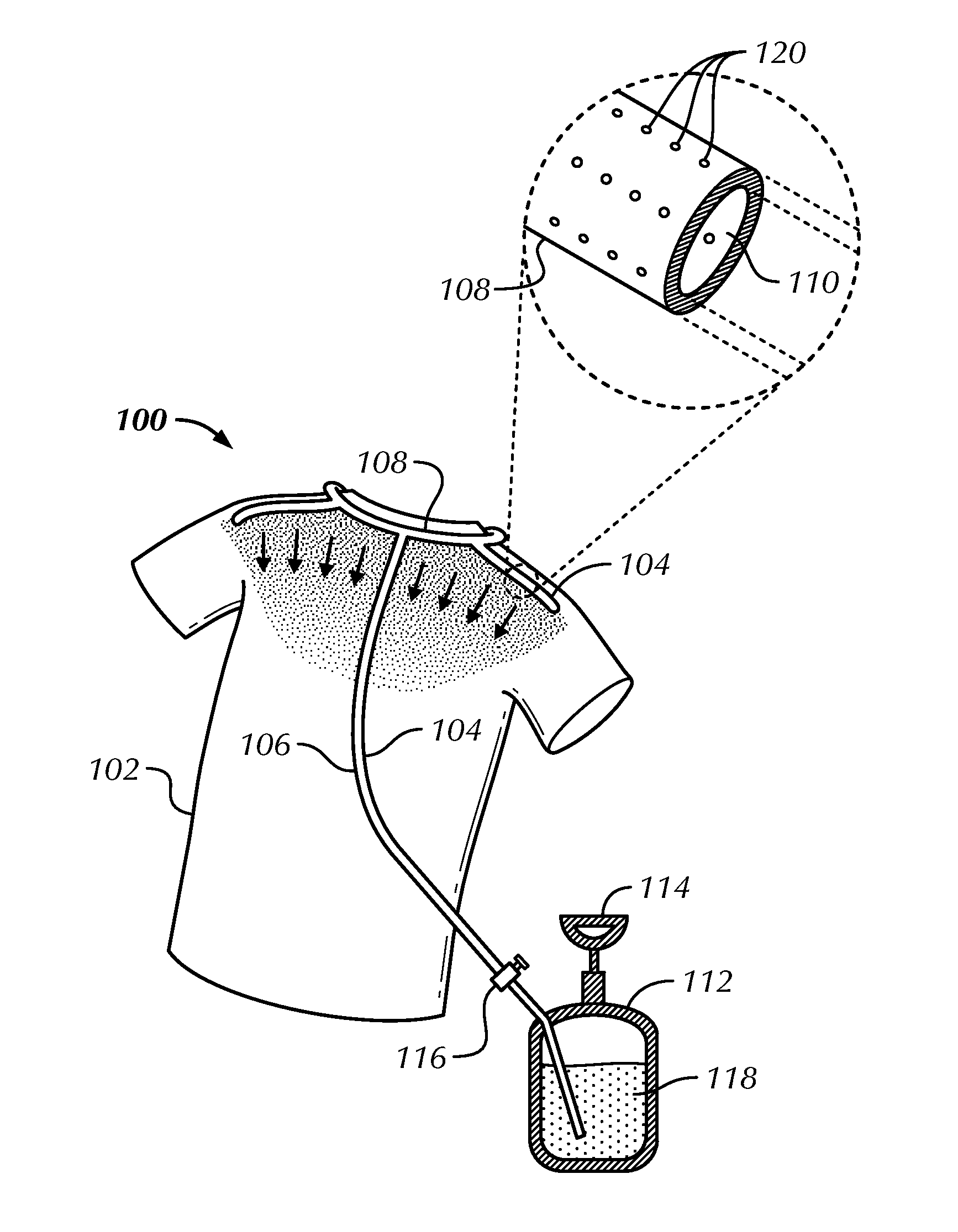

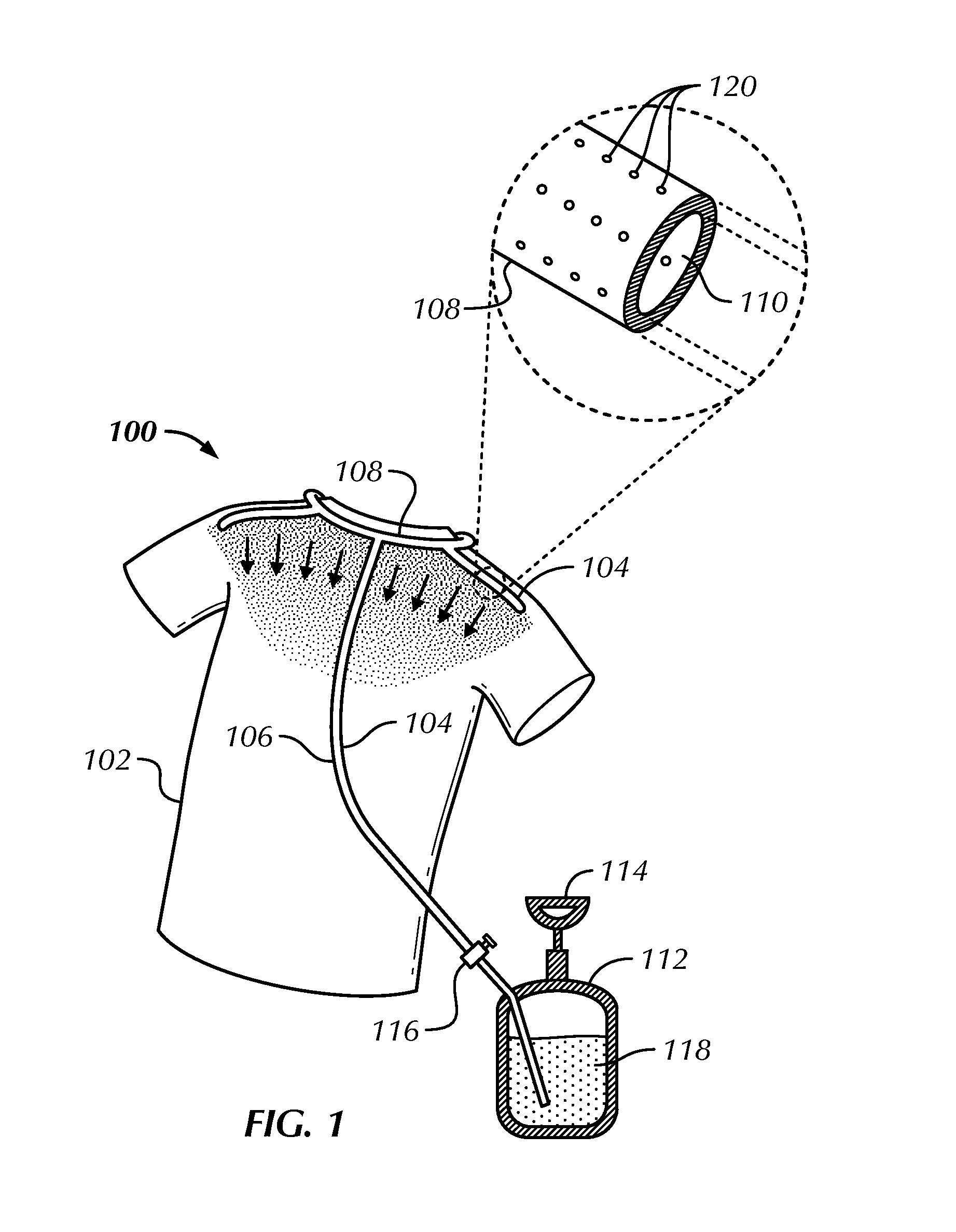

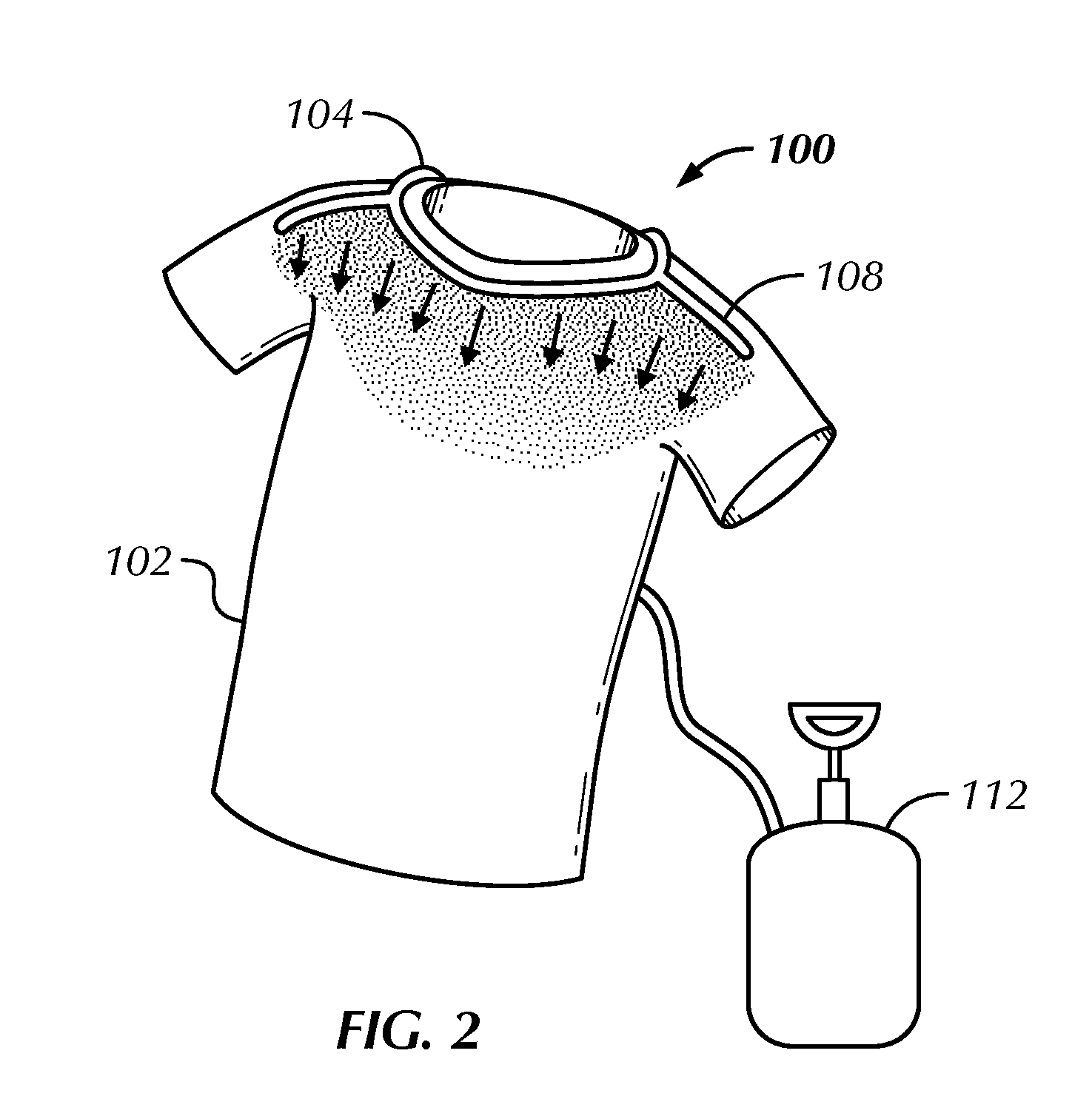

Evaporative cooling clothing system for reducing body temperature of a wearer of the clothing system

InactiveUS20140305148A1Lower body temperatureLighting and heating apparatusCooling fluid circulationEvaporationEngineering

Owner:PAULL LESLIE OWEN

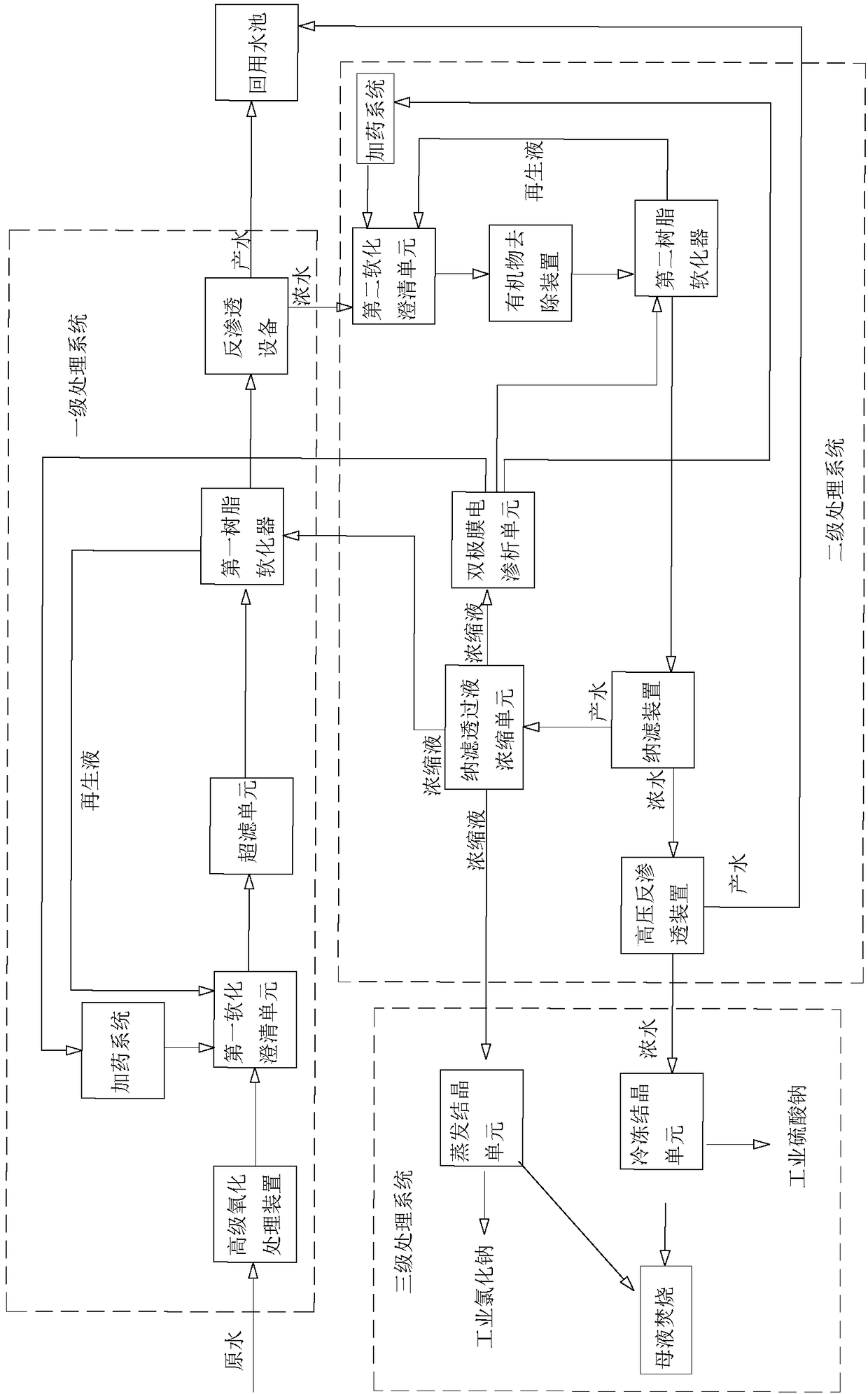

Treatment method for recycling high-hardness and high-salinity waste water

InactiveCN108275817ATake advantage ofRealize internal consumptionWater/sewage treatment by irradiationGeneral water supply conservationChemical treatmentTreatment effect

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

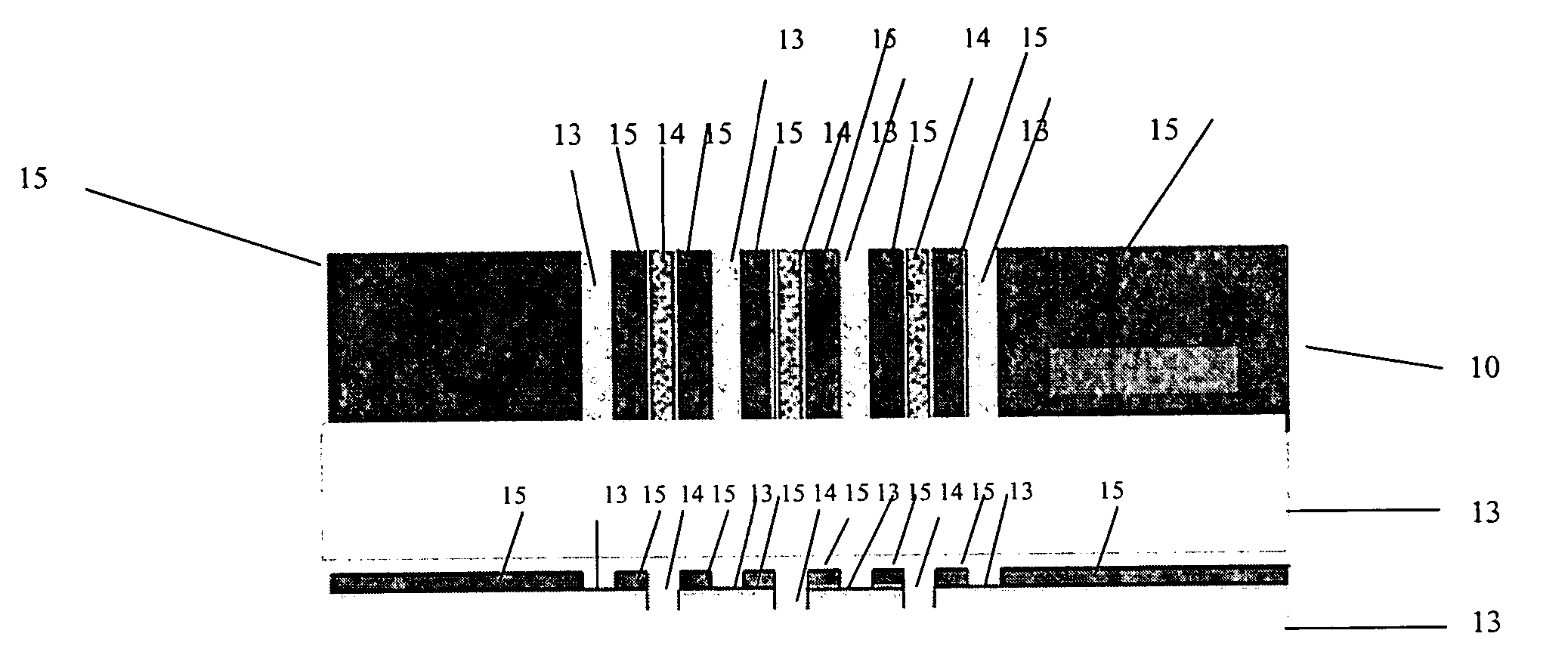

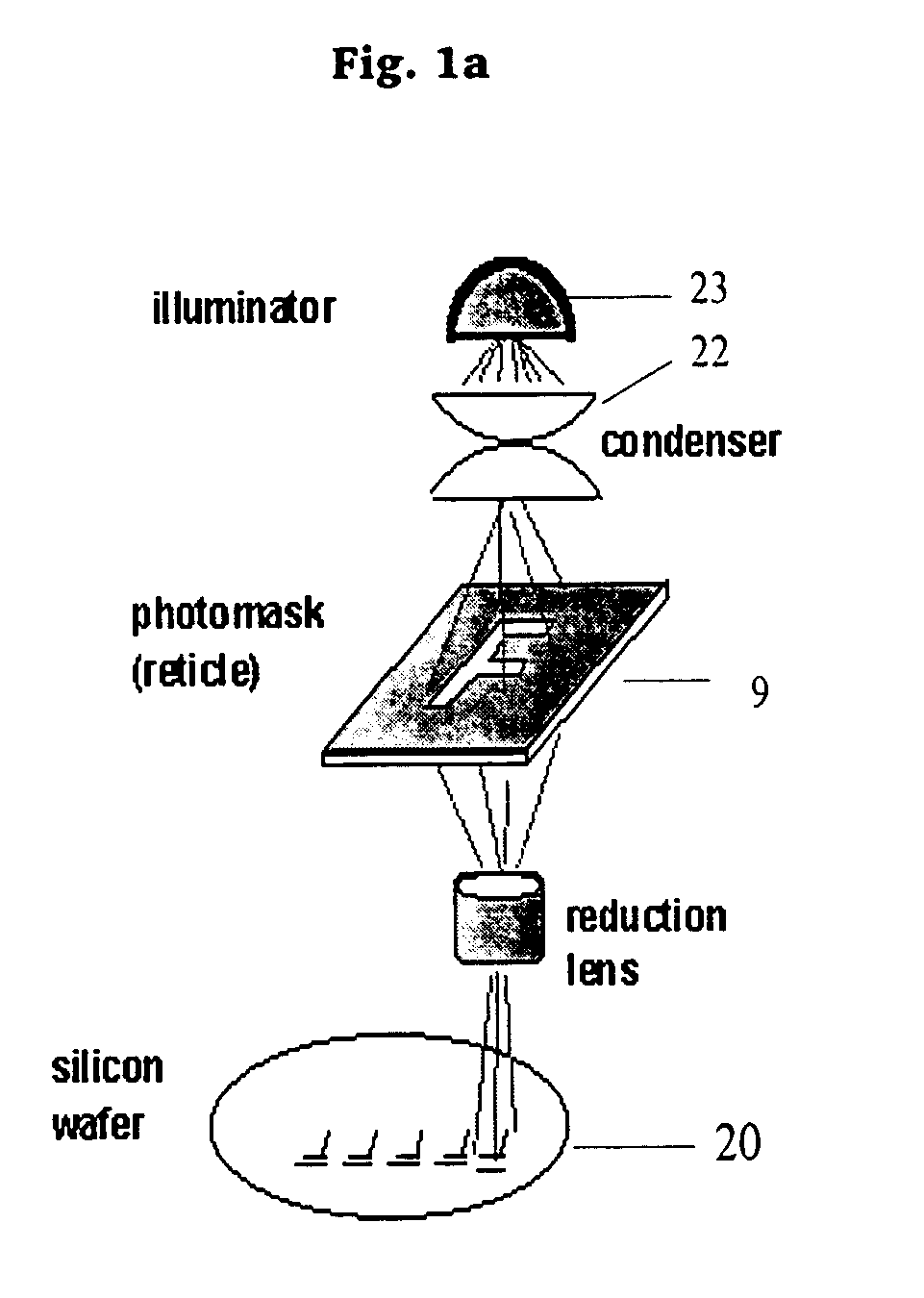

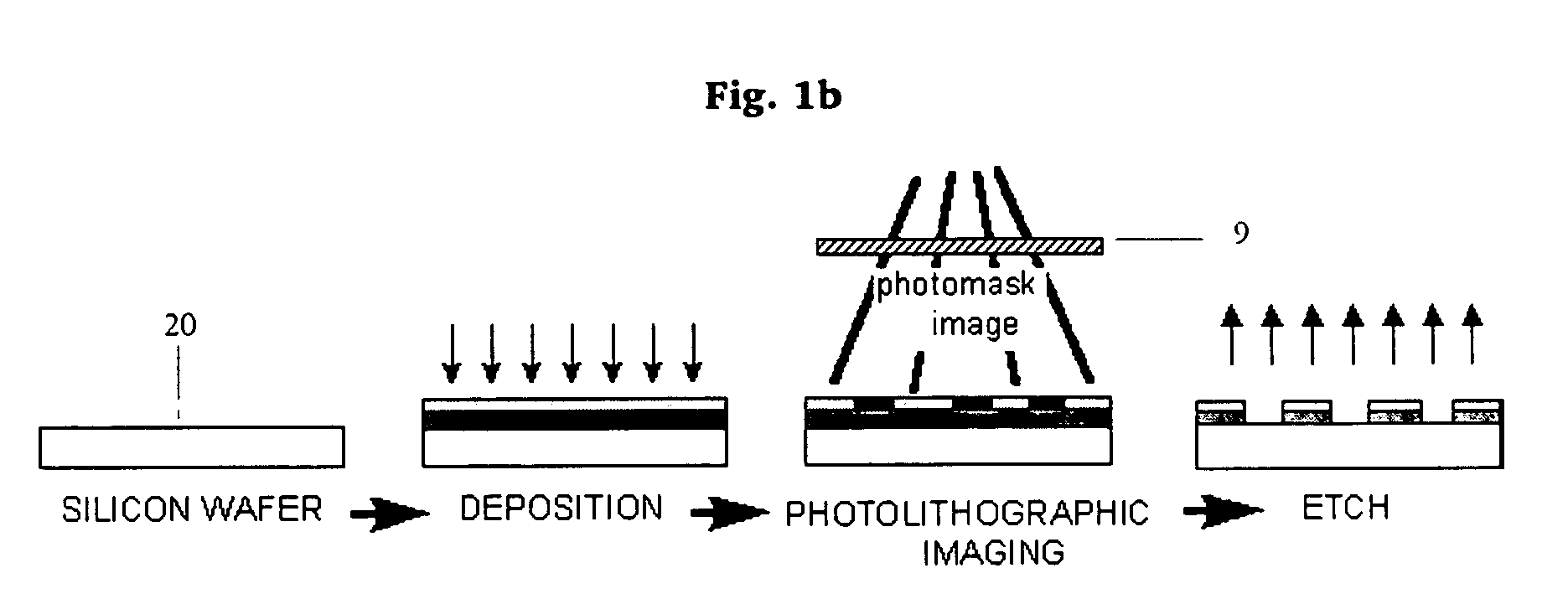

Photomask having an internal substantially transparent etch stop layer

ActiveUS20050053847A1Improve transmittanceImprove adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistEvaporation

Owner:PHOTRONICS INC

Exhaust gas treatment device

ActiveCN105804840AIncrease evaporation areaExtended stayExhaust apparatusSilencing apparatusEvaporationEngineering

Owner:TENNECO SUZHOU EMISSION SYST

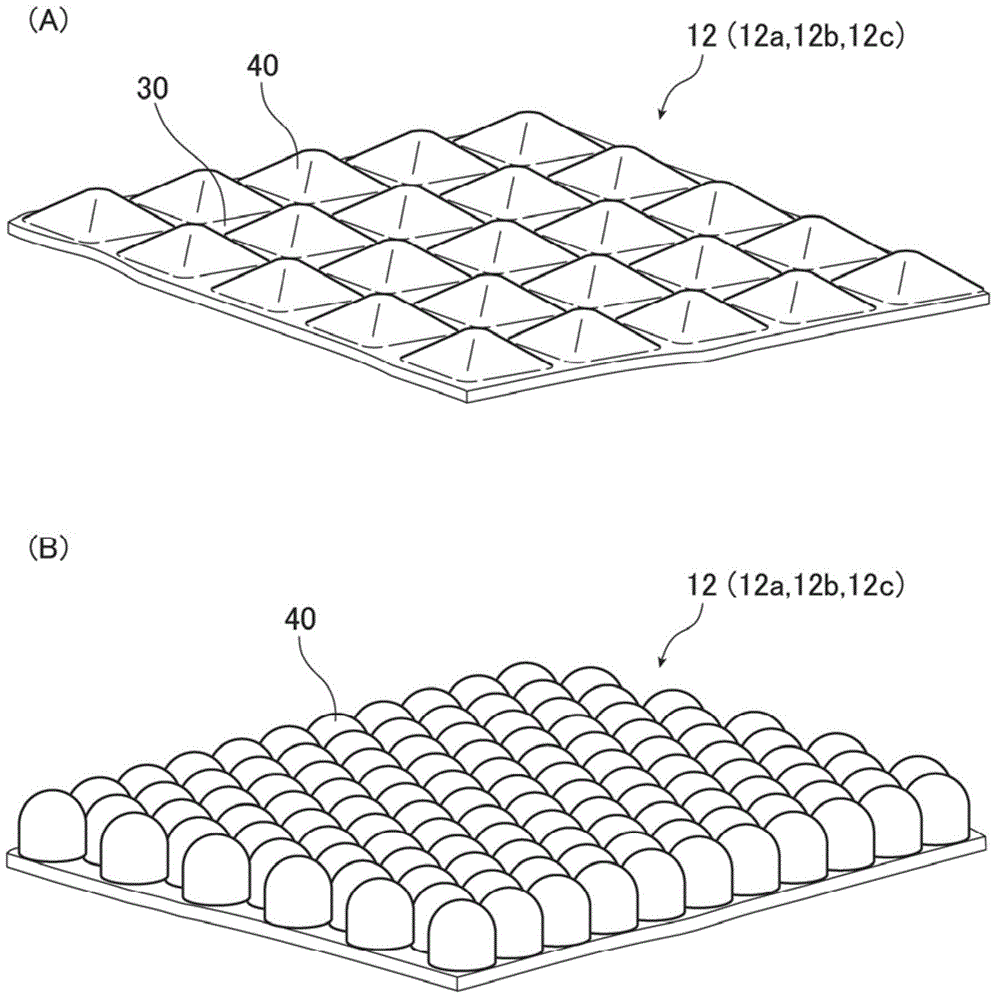

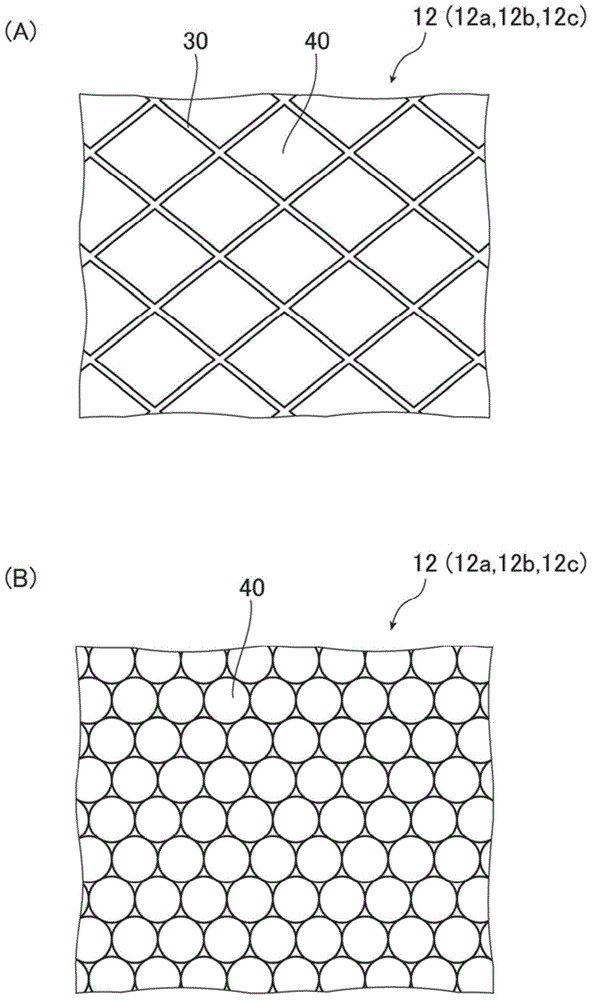

Adhesion-prevention Plate Used For Vacuum Film-forming Device And Applications Thereof

InactiveCN104032259AExcellent anti-peeling effectAnodisationVacuum evaporation coatingConvex structureEvaporation

Owner:FUJIFILM CORP

Preparation method of waterborne polyurethane emulsion and waterborne polyurethane emulsion prepared by preparation method

InactiveCN104211902AImprove waterproof performanceGood solvent resistanceHydroxybutyric acidPolymer science

Owner:内蒙古源创绿能节能环保产业创业投资合伙企业(有限合伙)

Automatic liquid nitrogen filling refrigeration device of high-temperature superconducting magnet

InactiveCN107068323AReduce gapReduce lossesSuperconducting magnets/coilsNitrogenHigh temperature superconducting

The invention relates to an automatic liquid nitrogen filling refrigeration device of a high-temperature superconducting magnet. The refrigeration device comprises a magnet cooling dewar flask, a nitrogen evaporation pipeline, a liquid nitrogen pipeline, a liquid nitrogen communication vessel and an outside liquid nitrogen vessel, wherein the magnet cooling dewar flask comprises an inner liner and an outer liner; a vacuum interlayer is formed between the inner liner and the outer liner; the outer liner is connected with an upper end cover of the magnet cooling dewar flask by flange bolts; a permanent magnet is arranged above the upper end cover; cold conducting discs are respectively arranged on the two outer sides of the top of the inner liner; the high-temperature superconducting magnet generating a suspension force with the permanent magnet is arranged above the cold conducting discs; the nitrogen evaporation pipeline penetrates through the tops of the outer liner and the inner liner; the liquid nitrogen pipeline penetrates through the bottoms of the outer liner and the inner liner; the nitrogen evaporation pipeline is connected with one port at the top of the liquid nitrogen communication vessel by a first hose; a port at the bottom of the liquid nitrogen communication vessel is connected with the liquid nitrogen pipeline by a second hose; and another port at the top of the liquid nitrogen communication vessel is connected with a port of the outside liquid nitrogen vessel by a third hose.

Owner:SICHUAN FEICHUANGNENGDA TECH CO LTD

Dynamic operation characteristic modeling method for waste heat boiler

InactiveCN109977560AImprove versatilityQuick buildDesign optimisation/simulationSpecial data processing applicationsDynamic modelsEvaporation

The invention provides a dynamic operation characteristic modeling method for a waste heat boiler. The method is characterized in that the components such as an evaporation heating surface, a steam pocket, a coal economizer, a superheater and a reheater of the waste heat boiler are divided into three modules such as a phase change heating surface, a non-phase change heating surface and a steam pocket, modeling is conducted on each module from the heat exchange angle, the heat storage angle and the flowing angle, a dynamic model of the waste heat boiler is established through a sequential module method, so that the dynamic operation characteristic of the waste heat boiler is obtained. According to the method, the waste heat boilers with different arrangements and different capacities can beconveniently and rapidly modeled, the dynamic operation characteristics of the waste heat boilers are obtained, the understanding of the characteristics of the waste heat boilers is facilitated, andthe operation adjustment of the waste heat boilers can be guided.

Owner:JIANGSU FRONTIER ELECTRIC TECH +2

Preparation method for micron-size carbonyl iron and nickel alloy powder

ActiveCN105965033AReduce carbon and oxygen impurity contentEven distribution of iron and nickelEvaporationHigh pressure

Owner:JIANGYOU HEBAO NANO MATERIAL CO LTD

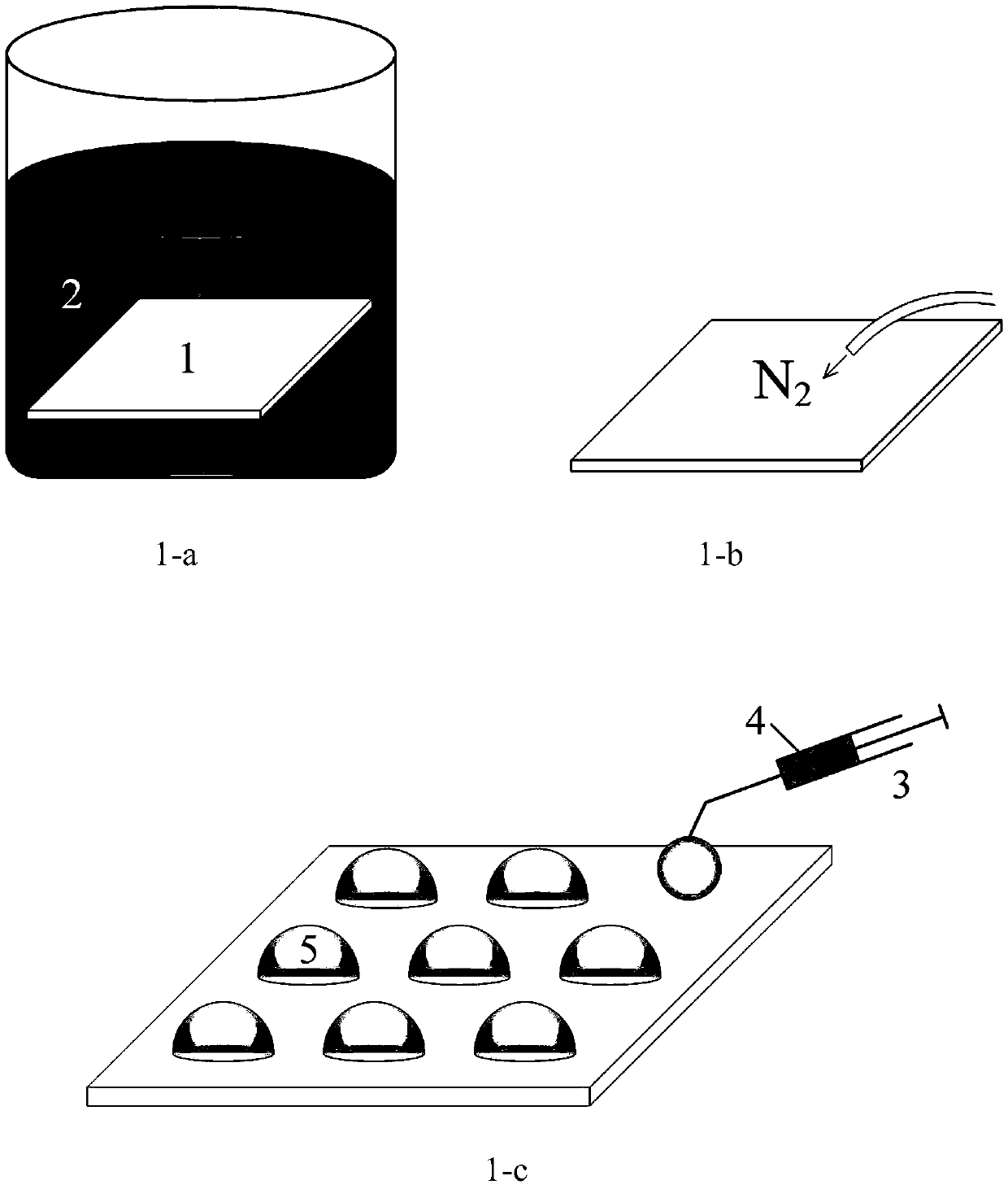

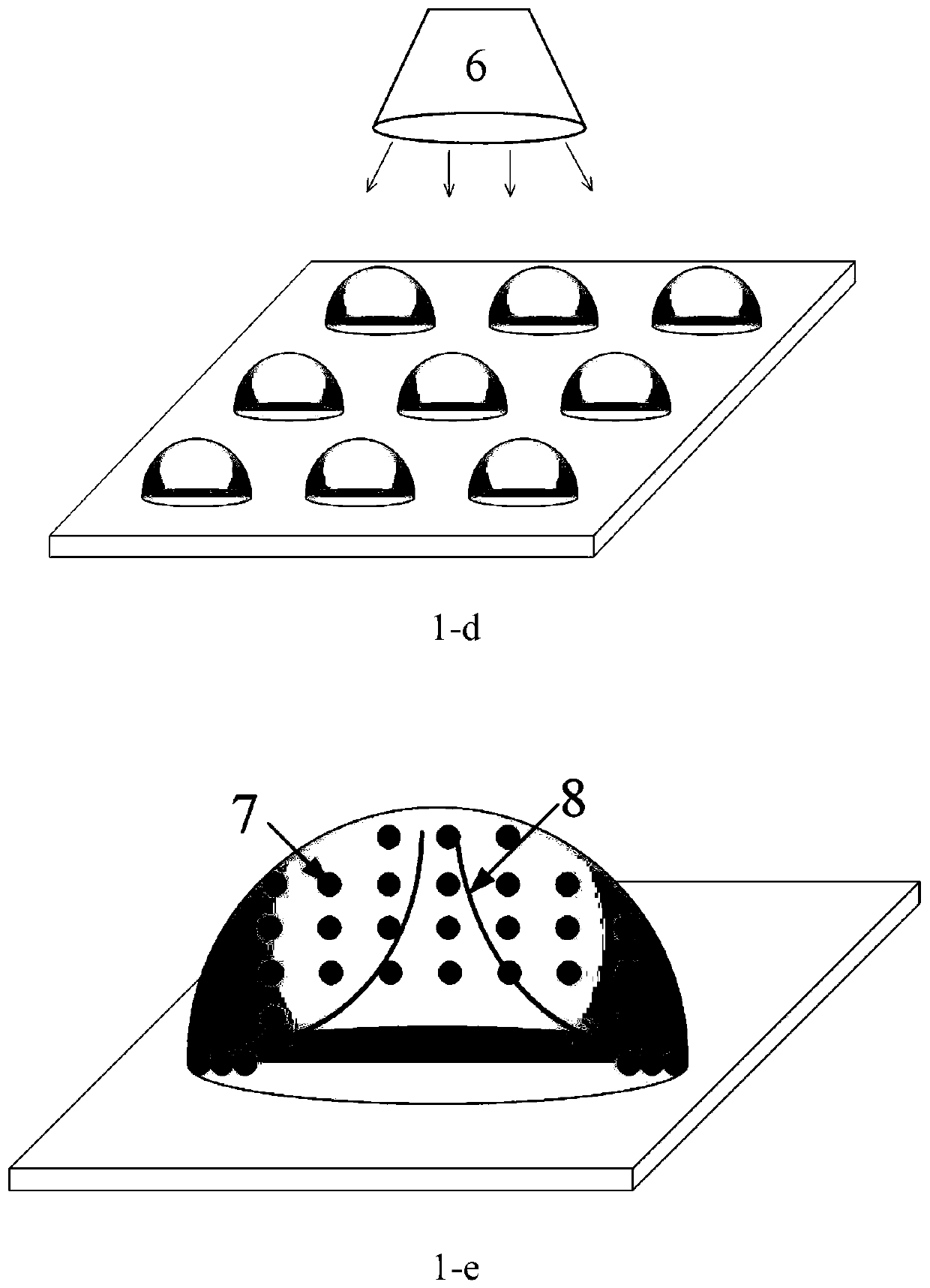

Photothermal evaporation surface, and preparation method and application thereof

ActiveCN109879344AReduce spacingIncrease interface areaSeawater treatmentGeneral water supply conservationPhotothermal conversionEvaporation

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

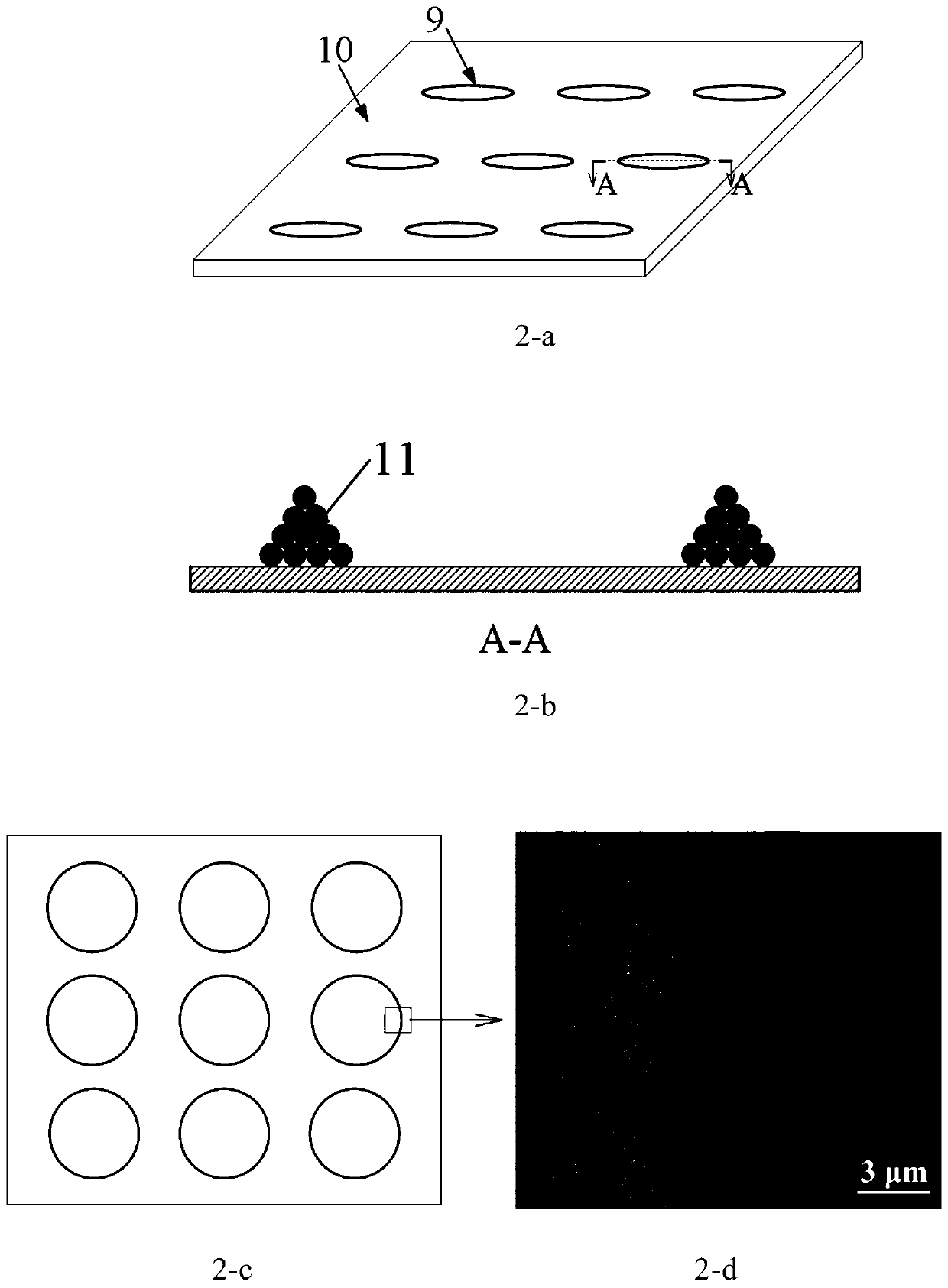

System and technology for continuously recycling waste ternary lithium-ion battery

PendingCN107946687AReduce manufacturing costAchieving continuous operationWaste accumulators reclaimingBattery recyclingManganeseEvaporation

Owner:TIANQI LITHIUM CORP

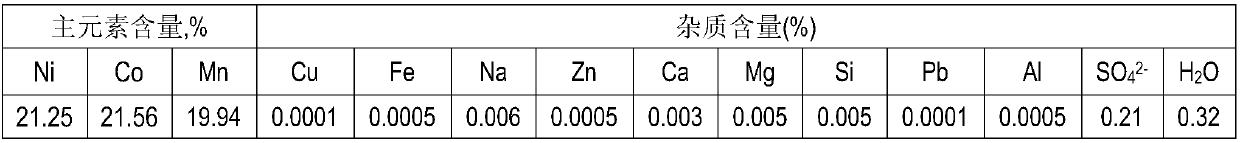

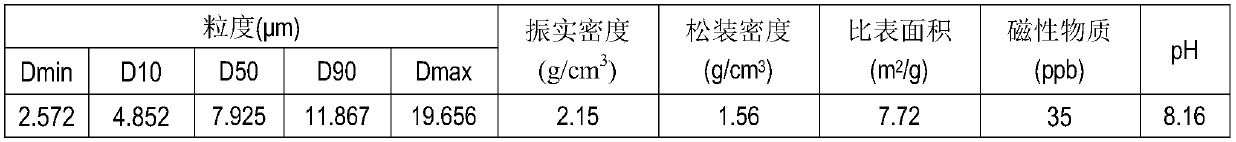

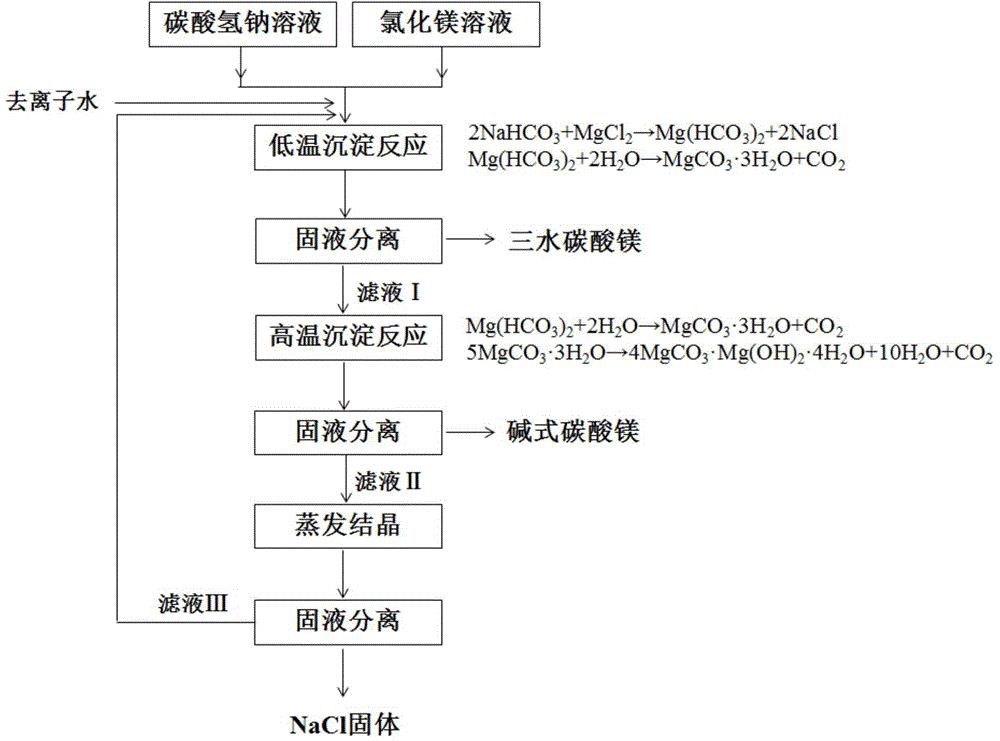

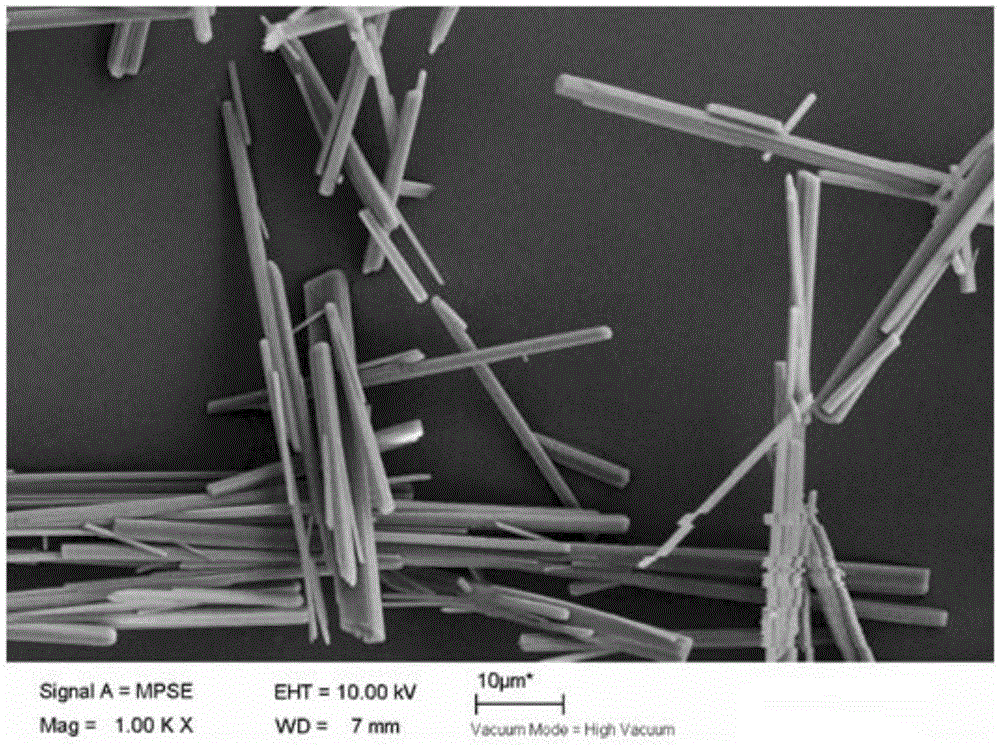

Method for preparing nesquehonite whiskers and nano flaky basic magnesium carbonate

InactiveCN104828847AGood dispersionHigh purityMagnesium carbonatesNanotechnologyDispersitySodium bicarbonate

Owner:COSL CHEM TIANJIN

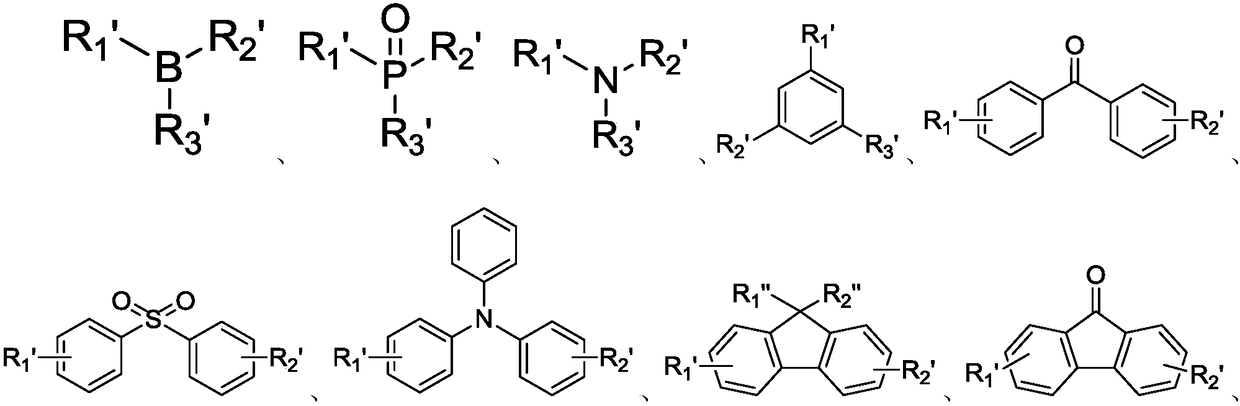

Organic light emitting device, fabrication method thereof and display device

ActiveCN108281557AImprove stabilityImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEnergy transferOrganic light emitting device

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

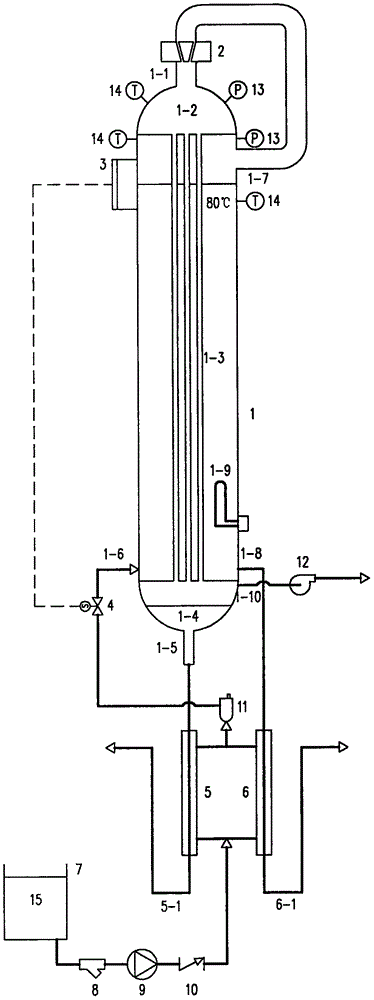

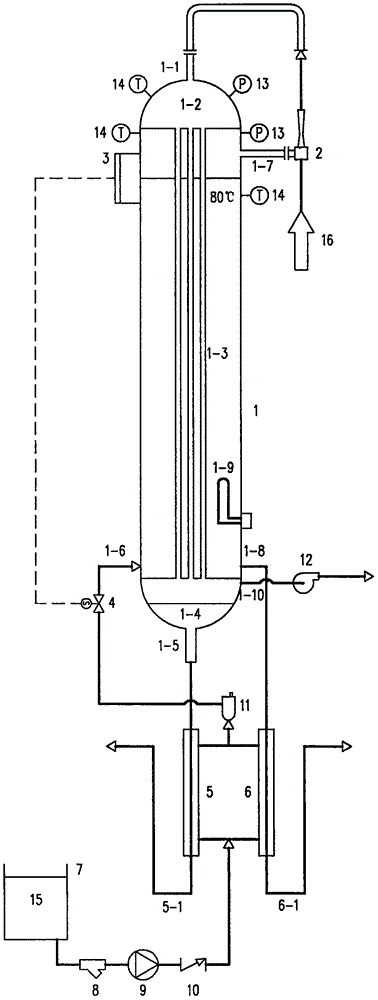

Siphon circulation, contraflow heat regeneration and vapor compression distillation device

InactiveCN105920863ASave investmentSave power consumptionEvaporation with vapour compressionSeawater treatmentSiphonWater vapor

Owner:侴乔力 +1

Desulfurization wastewater zero discharging system and method based on waste heat reuse under low-load working condition

PendingCN107973475AIncrease temperatureSolve the problem of incomplete evaporationGas treatmentLighting and heating apparatusFlue gasEvaporation

Owner:DATANG ENVIRONMENT IND GRP

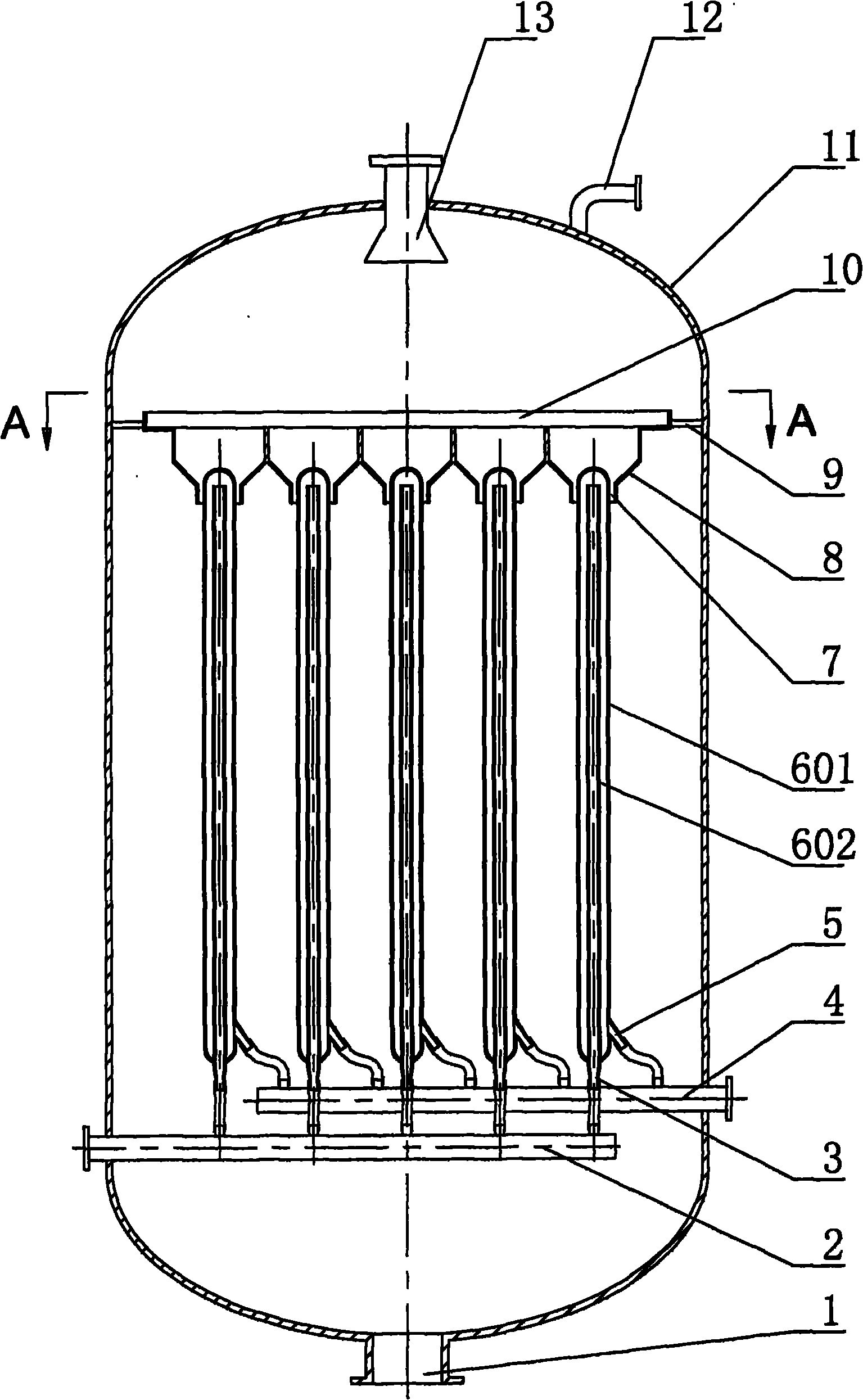

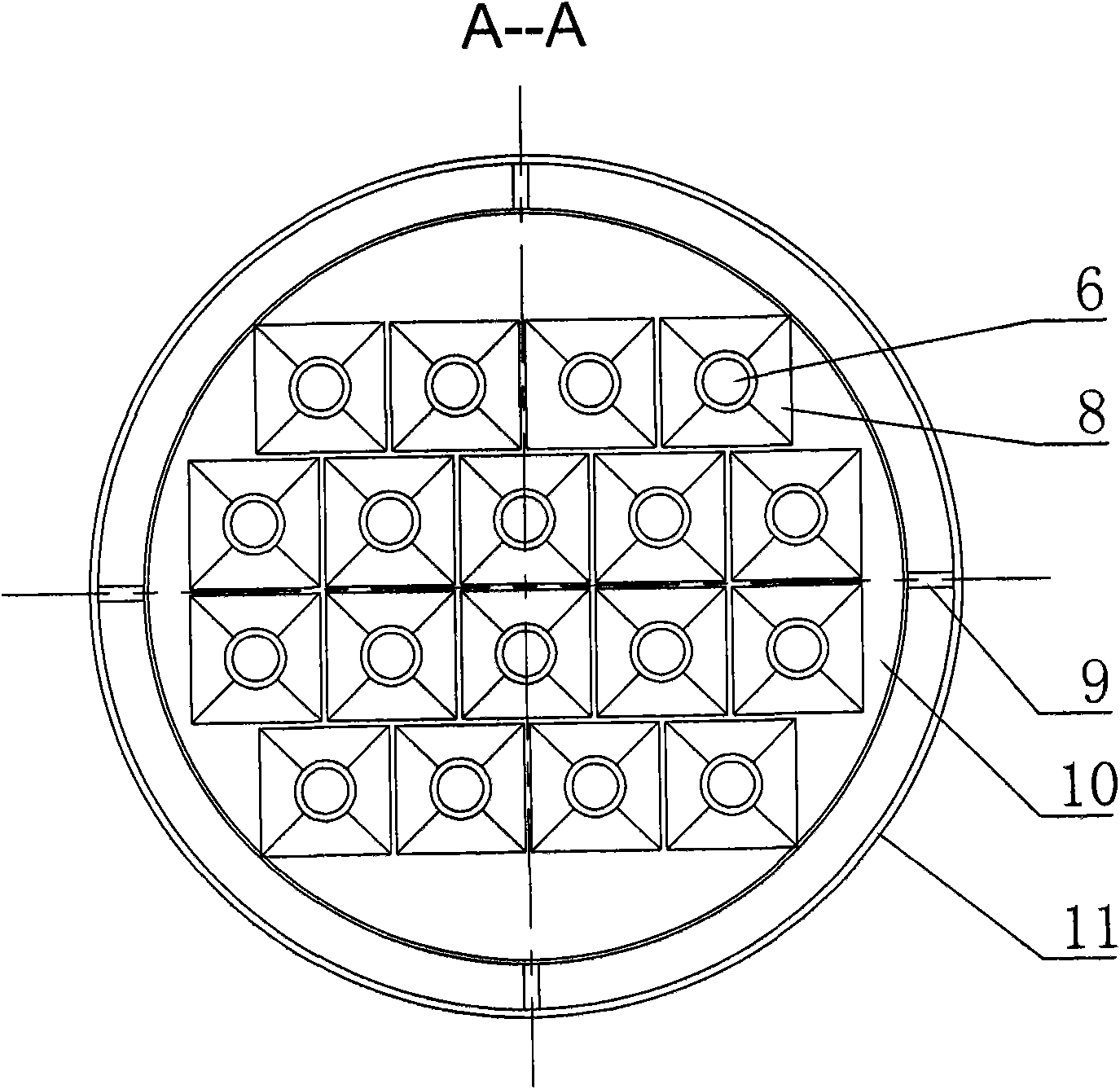

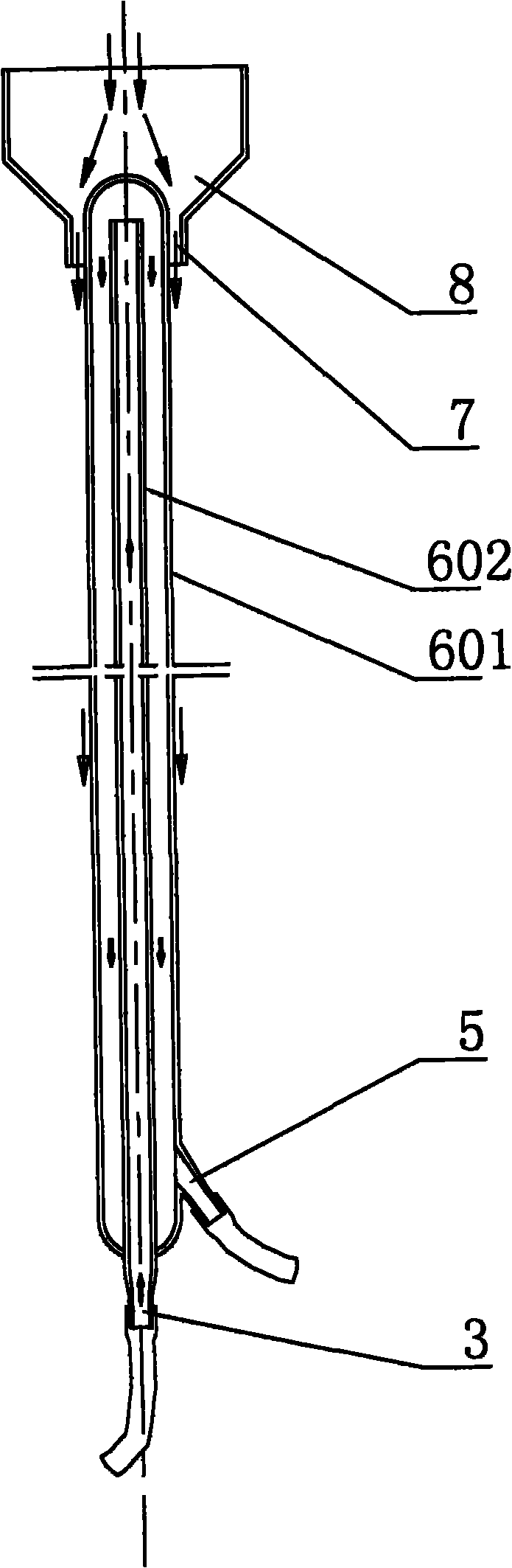

Tubular film evaporator

ActiveCN101785930ANo cloggingGood film formingEvaporators with vertical tubesPolyesterVacuum pumping

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Method for treating dinitro-diazophenol (DDNP) primary explosive production wastewater

ActiveCN102003715AHandling safety and environmental protectionZero emissionGeneral water supply conservationEnergy based wastewater treatmentHigh concentrationSolid fuel

Owner:山东圣世达化工有限责任公司

Heat pipe type concentrator-type photovoltaic/thermal integration-based combined heat and power generation apparatus

InactiveCN106160650AReduce the temperatureEfficient use ofPhotovoltaicsPhotovoltaic energy generationCogenerationEvaporation

Owner:NANJING JIAYE NEW ENERGY

Depleted body heterojunction quantum dot solar cell and manufacturing method thereof

InactiveCN102593206AImprove conversion efficiencySimple processFinal product manufacturePhotovoltaic energy generationHeterojunctionSemiconductor materials

A depleted body heterojunction quantum dot solar cell is formed by successively superposing FTO, TiO2, TiO2, a PbS quantum dot and Au, wherein the FTO is served as a substrate anode; the TiO2 is served as a barrier layer; the TiO2 is served as a n-type layer; the PbS quantum dot is served as a p-type layer and the Au is served as an electrode layer; the TiO2 and the PbS quantum dot form an active layer. The manufacturing method comprises the following steps: successively spinning and coating a barrier layer TiO2 film, an active layer TiO2 film, the PbS quantum dot and a MPA methanol solution on a cleaned and dried substrate; then carrying out vacuum thermal evaporation so as to plate a gold electrode. The invention has the following advantages that: in the active layer of the solar cell, a n-type semiconducting material and the p-type quantum dot are crosswise mixed so as to form a plurality of heterojunctions; the quantum dot is used on the body heterojunction solar cell so that a structure advantage of the body heterojunction structure is used and an unique nature of the quantum dot can be used too, and conversion efficiency of the solar cell can be improved; the manufacturing method of the solar cell has a simple process, is easy to be performed and is beneficial to be popularized and applied in a large scale.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Cooling circulating system, natural gas liquefaction device, operation method and improvement method of cooling circulating system

The invention provides a cooling circulating system (61). The cooling circulating system (61) is equipped with a refrigerant compressor (1) for compressing a refrigerant, a condenser (10) for cooling and condensing the refrigerant which is compressed by the refrigerant compressor (1), a reservoir (11) for accommodating the refrigerant which is condensed by the condenser (10), dilation mechanism (18) for dilating the refrigerant from the reservoir (11), an evaporation mechanism (19) for cooling an object to be cooled by heat exchange with the refrigerant which is dilated by the dilation mechanism (18) and vaporizing the refrigerant which is provided by the refrigerant compressor (1), and an auxiliary cooling mechanism (62) which is equipped with a line (47) for an auxiliary refrigerant to flow in and run through the reservoir (11) and cools the refrigerant in the reservoir (11) by the heat exchange with the refrigerant which flow in the line (47) before the refrigerant compressor (1) is started. Therefore, the power for starting the refrigerant compressor can be reduced, and the refrigerant compressor can be stably started by a drive source with a small torque.

Owner:HITACHI LTD

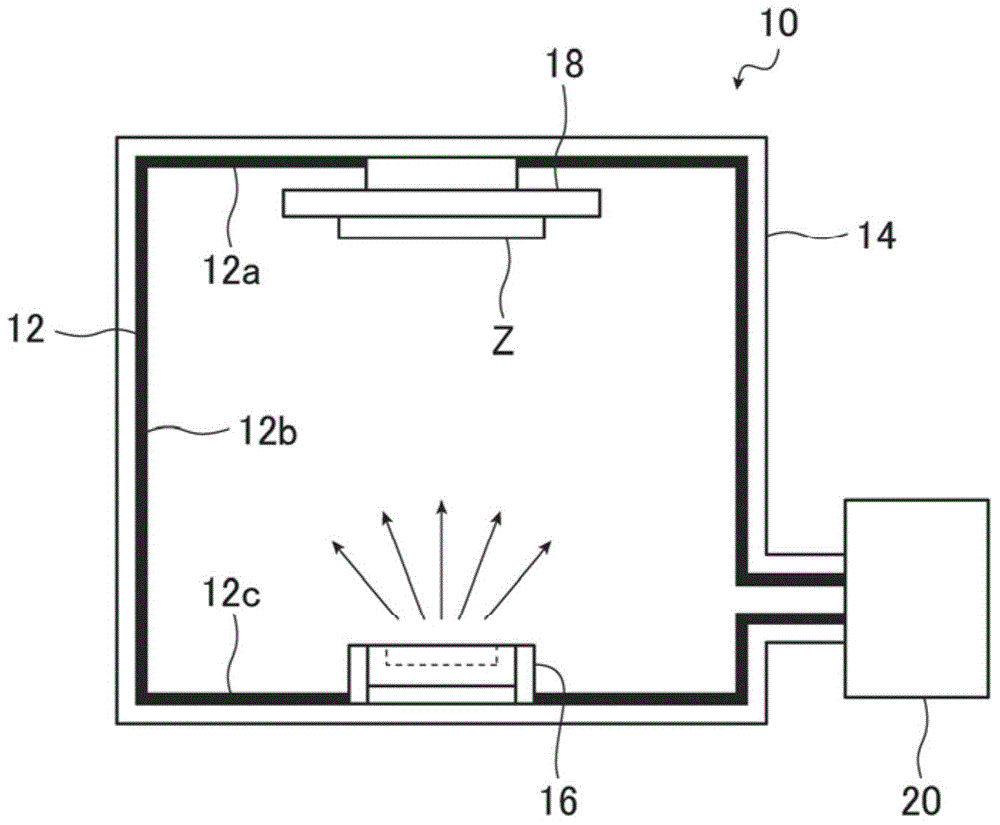

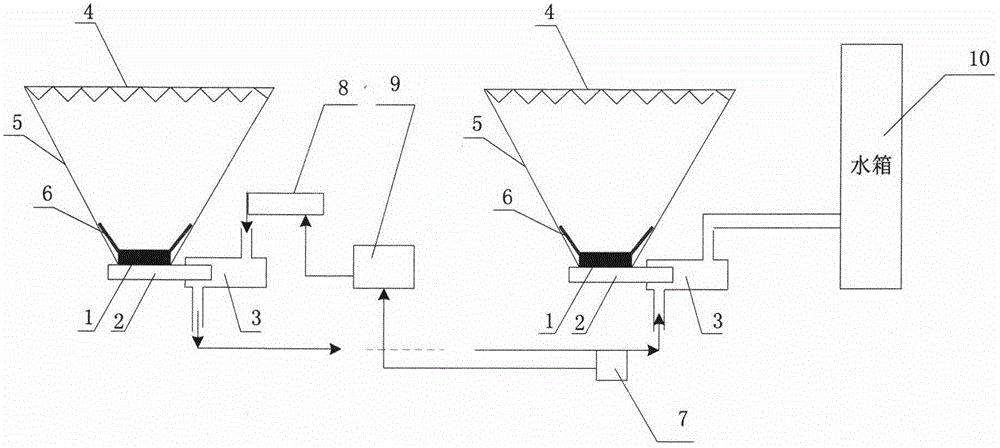

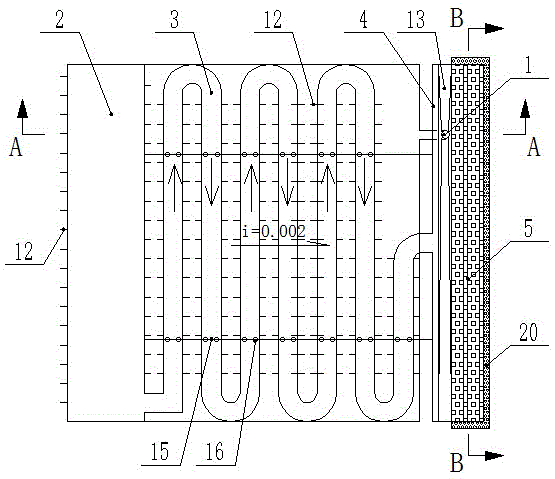

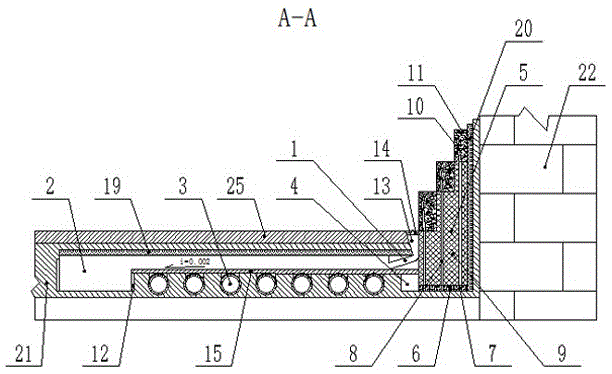

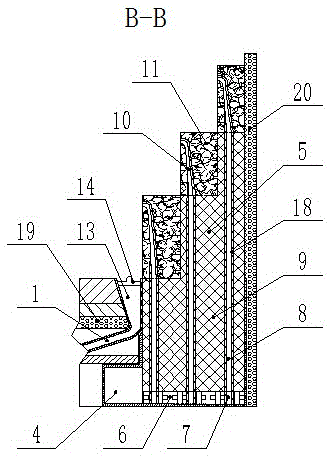

Invisible humidifier of floor heating system

InactiveCN105650793AIncrease surface areaRegulate humidityLighting and heating apparatusAir humidification systemsElectricityWarm water

Owner:ZHONGBEI UNIV

Double-trench close planting water and fertilizer integrated Chinese yam cultivation method

InactiveCN107624320AIncrease profitReduce evaporationFertilising methodsRoot crop cultivationWater savingEvaporation

Owner:宁夏佳禾恒农业开发有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap