Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about "Photomechanical apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

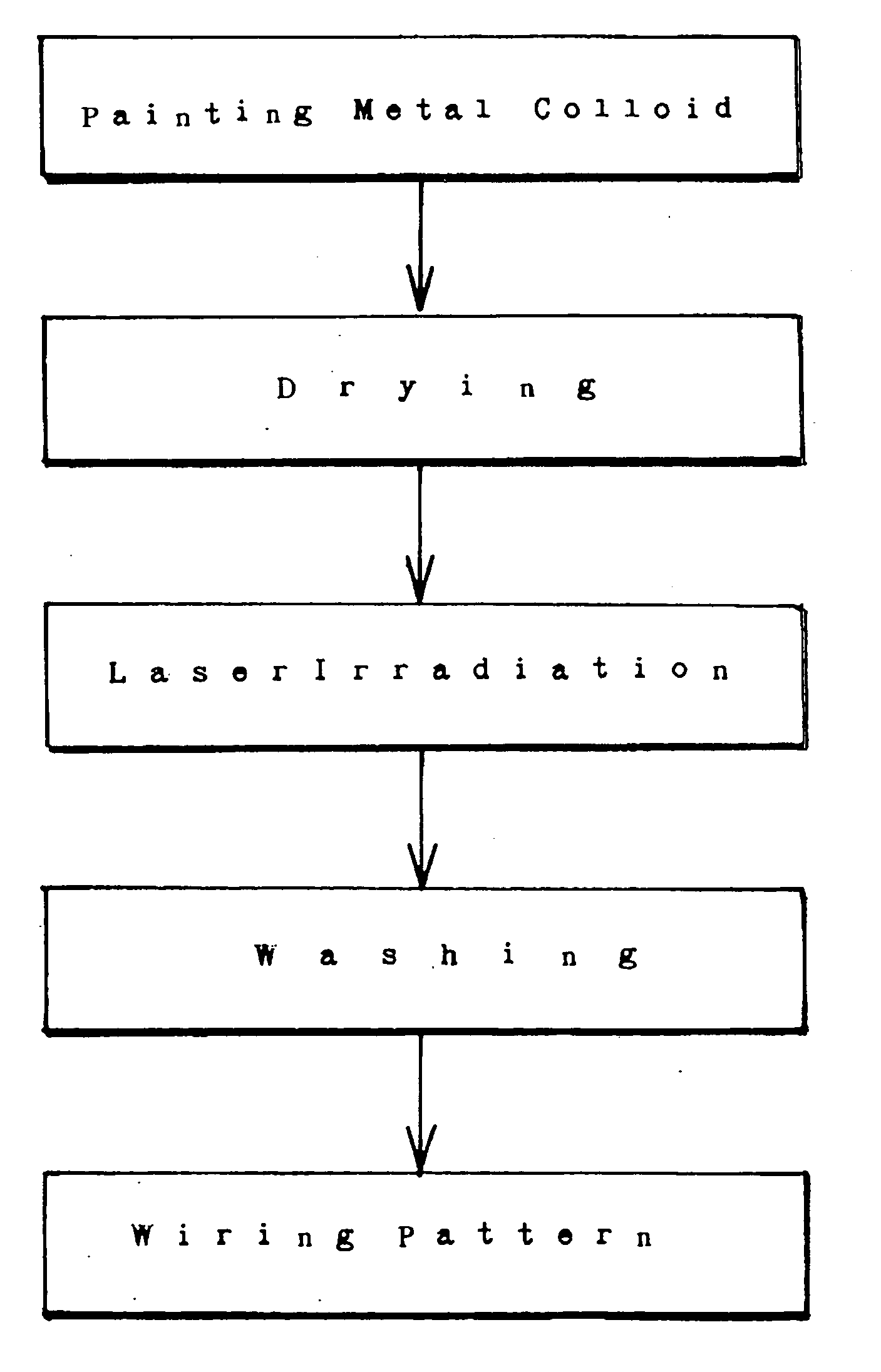

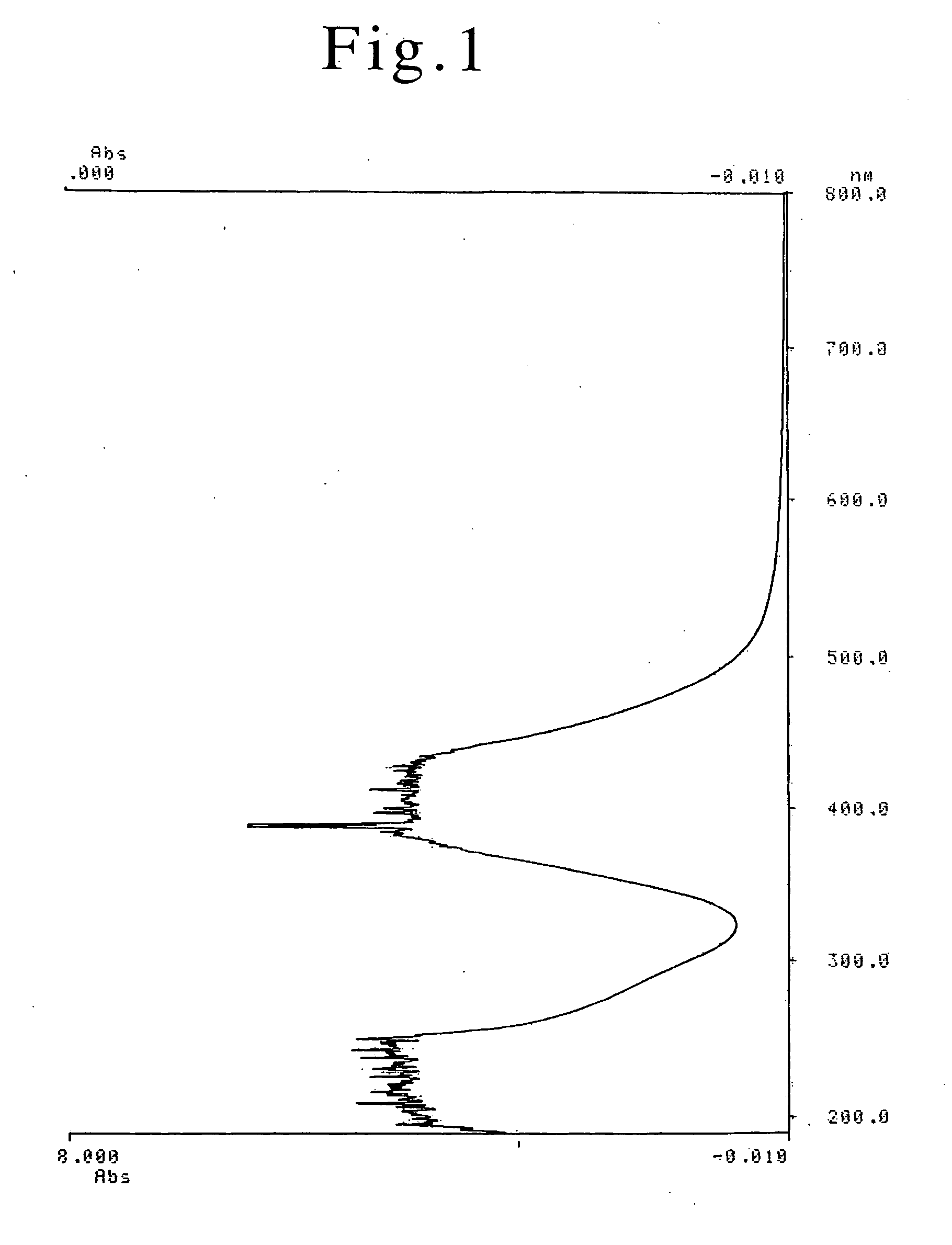

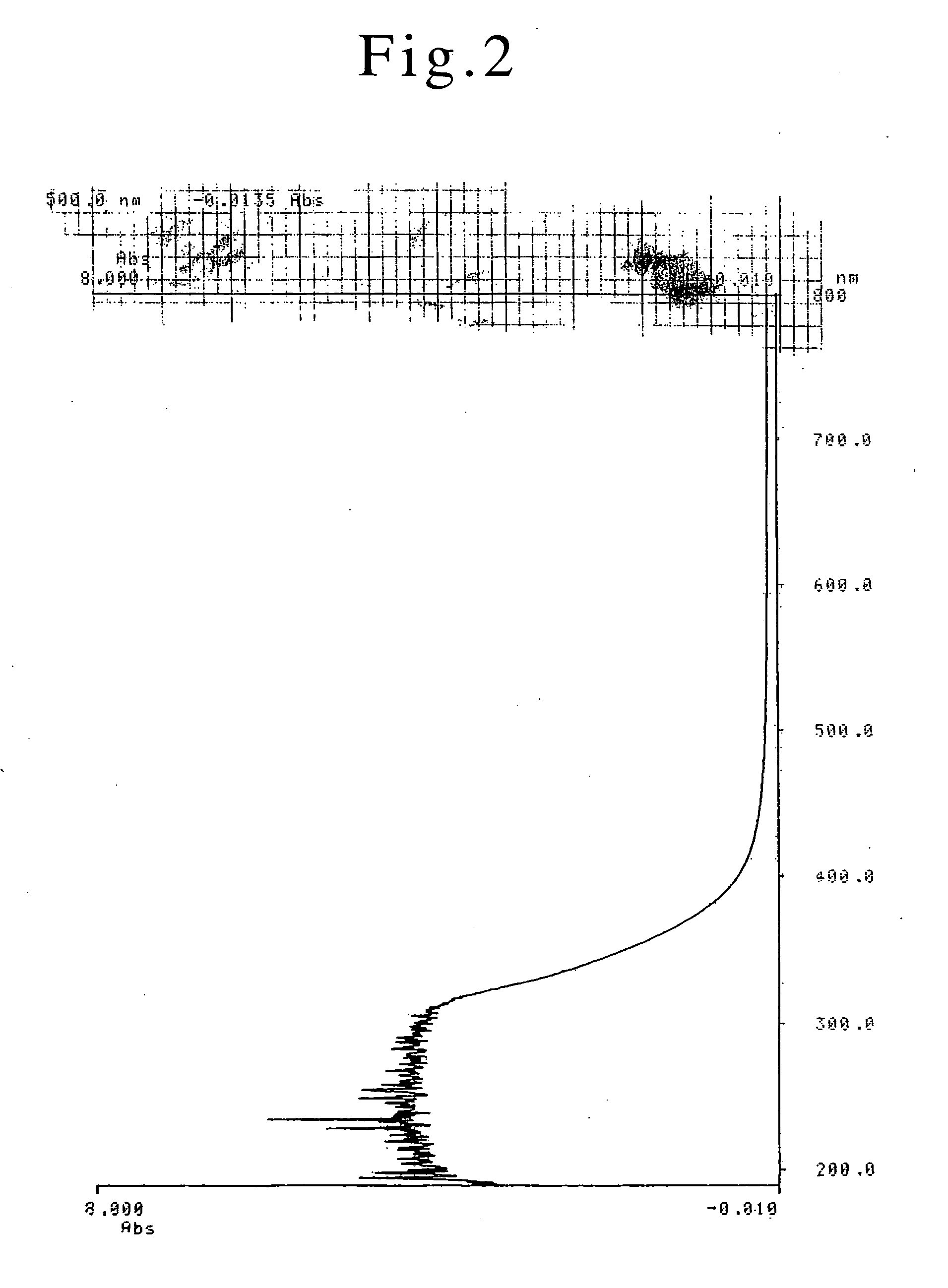

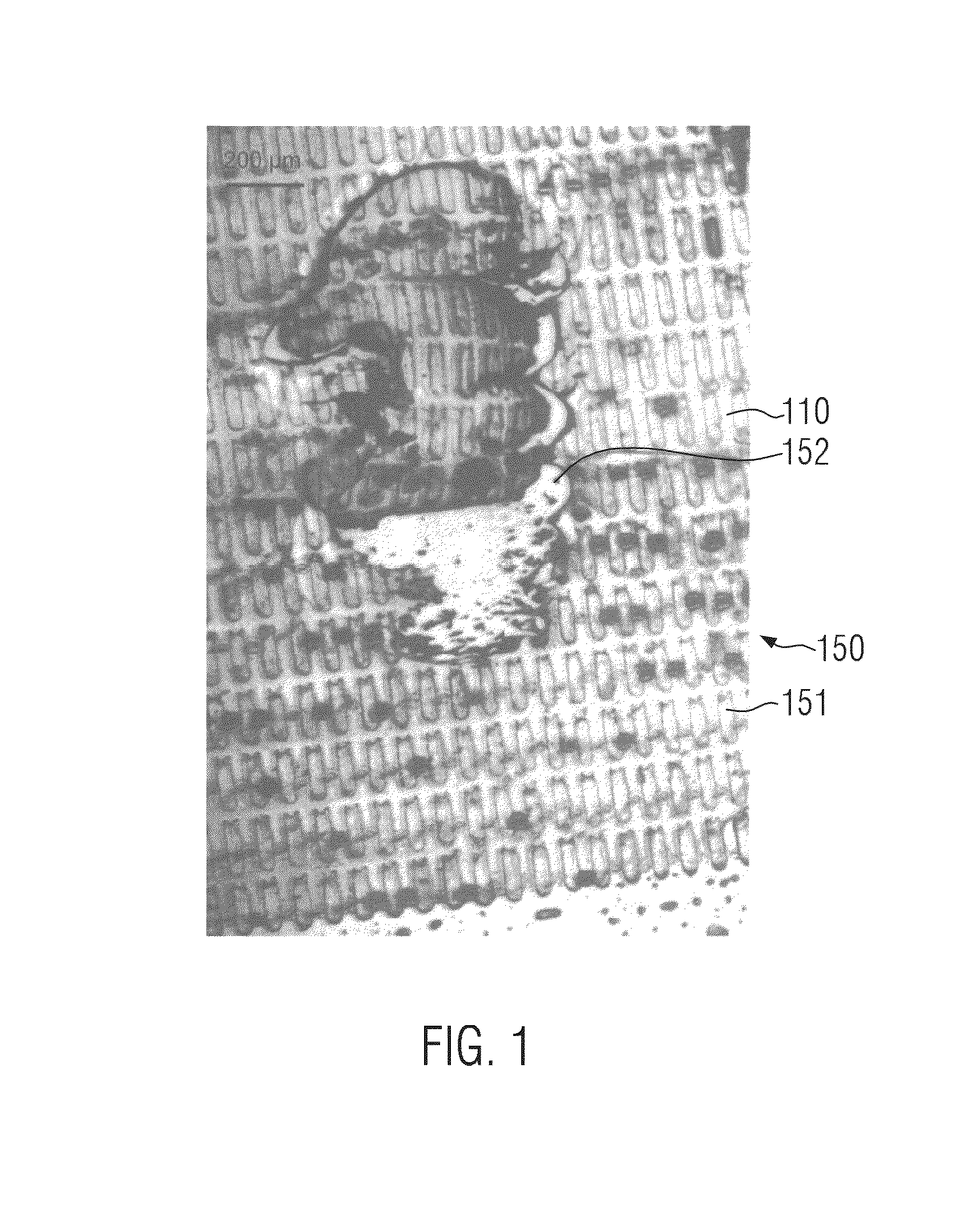

Method of forming a conductive wiring pattern by laser irradiation and a conductive wiring pattern

InactiveUS20060057502A1Poor adhesionEasy to eliminateMaterial nanotechnologyPhotomechanical apparatusResistCompound (substance)

Owner:SUMITOMO ELECTRIC IND LTD

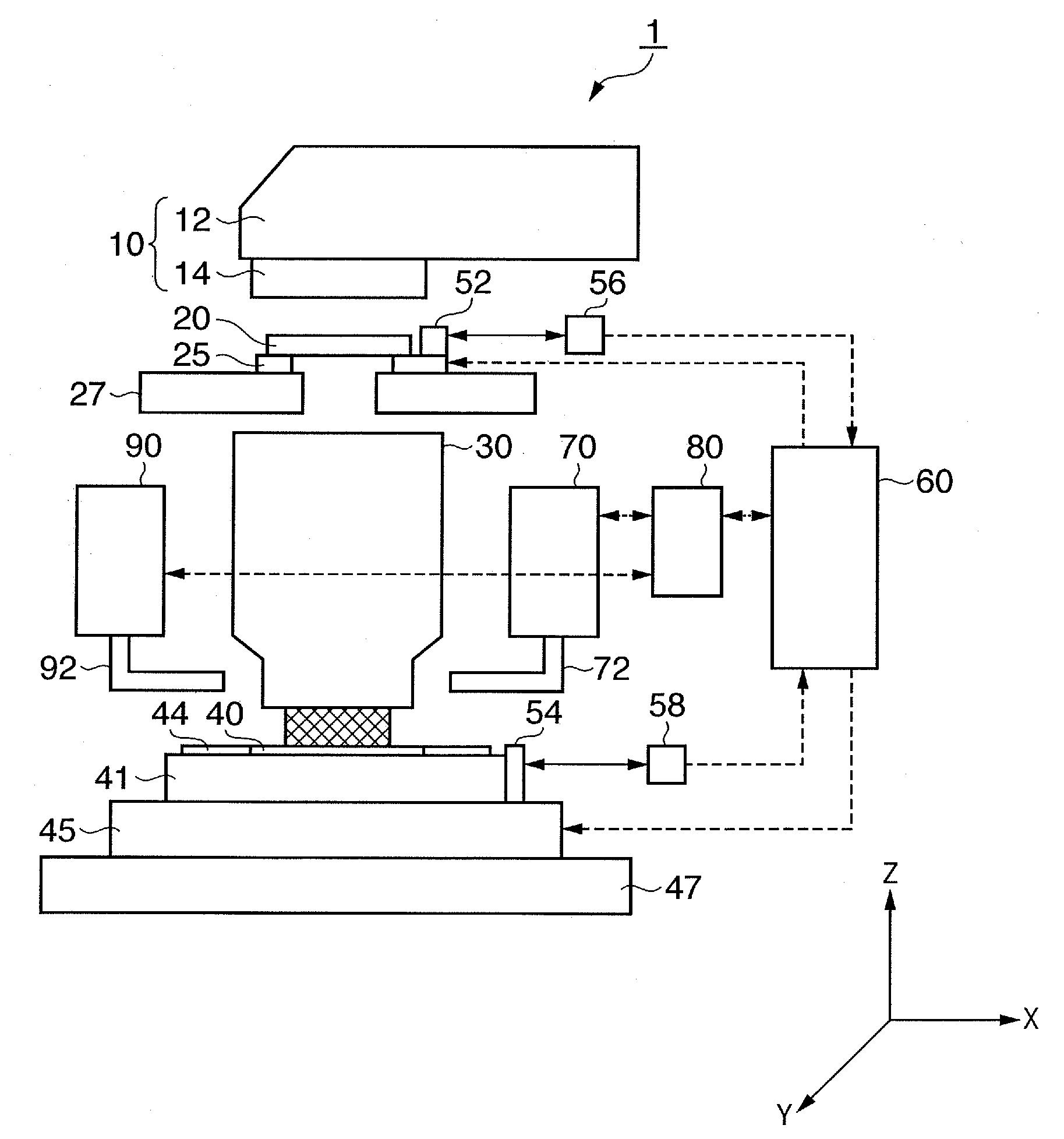

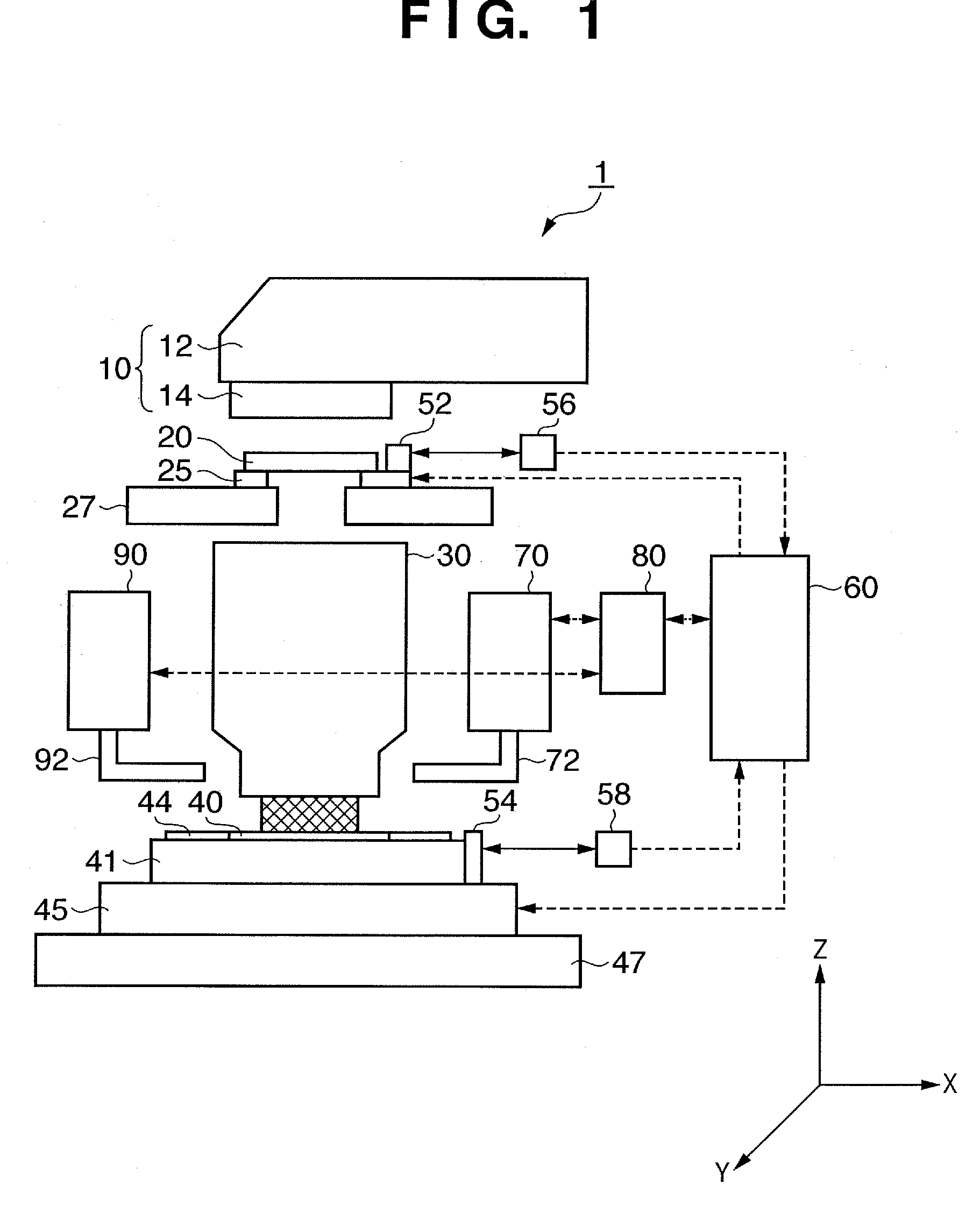

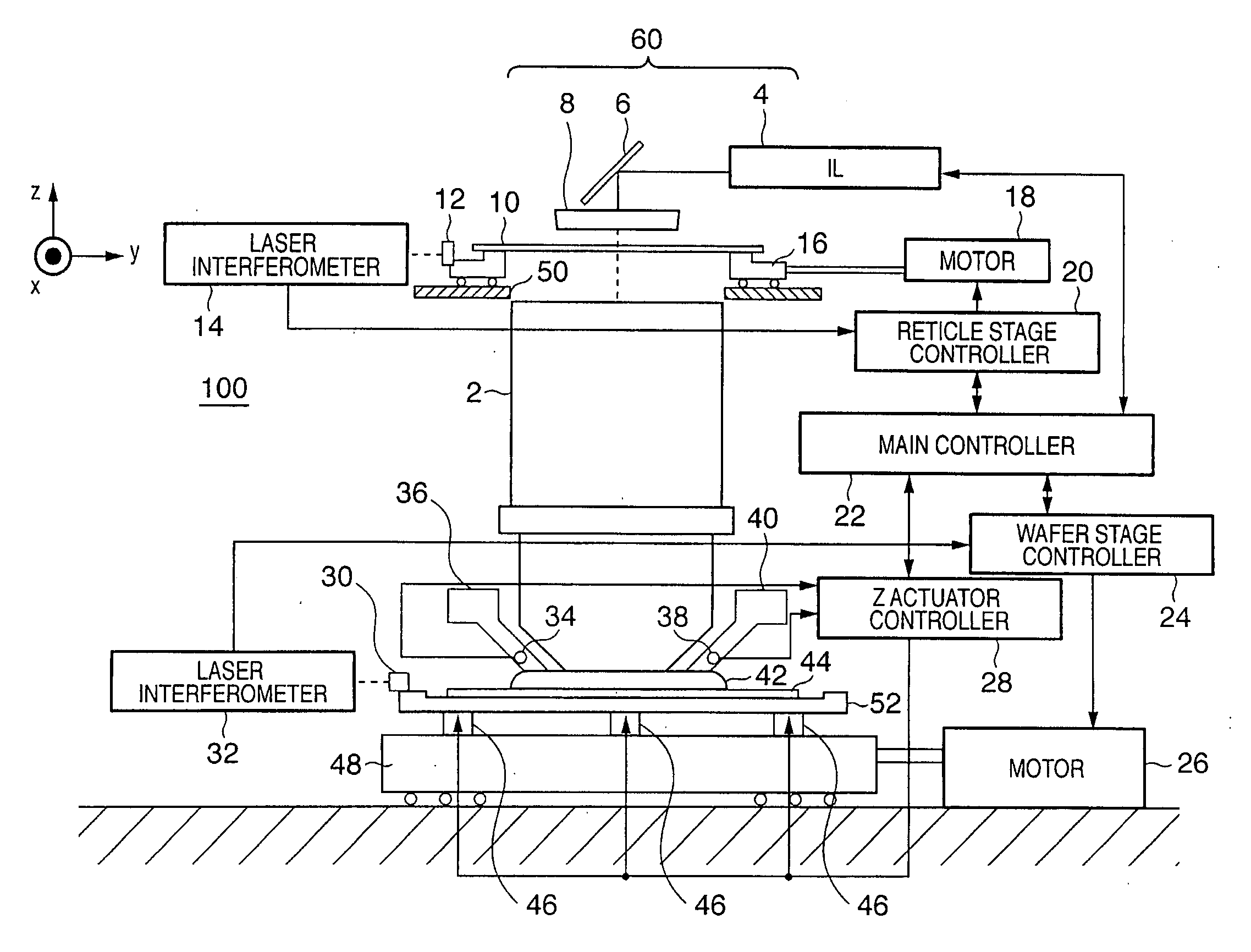

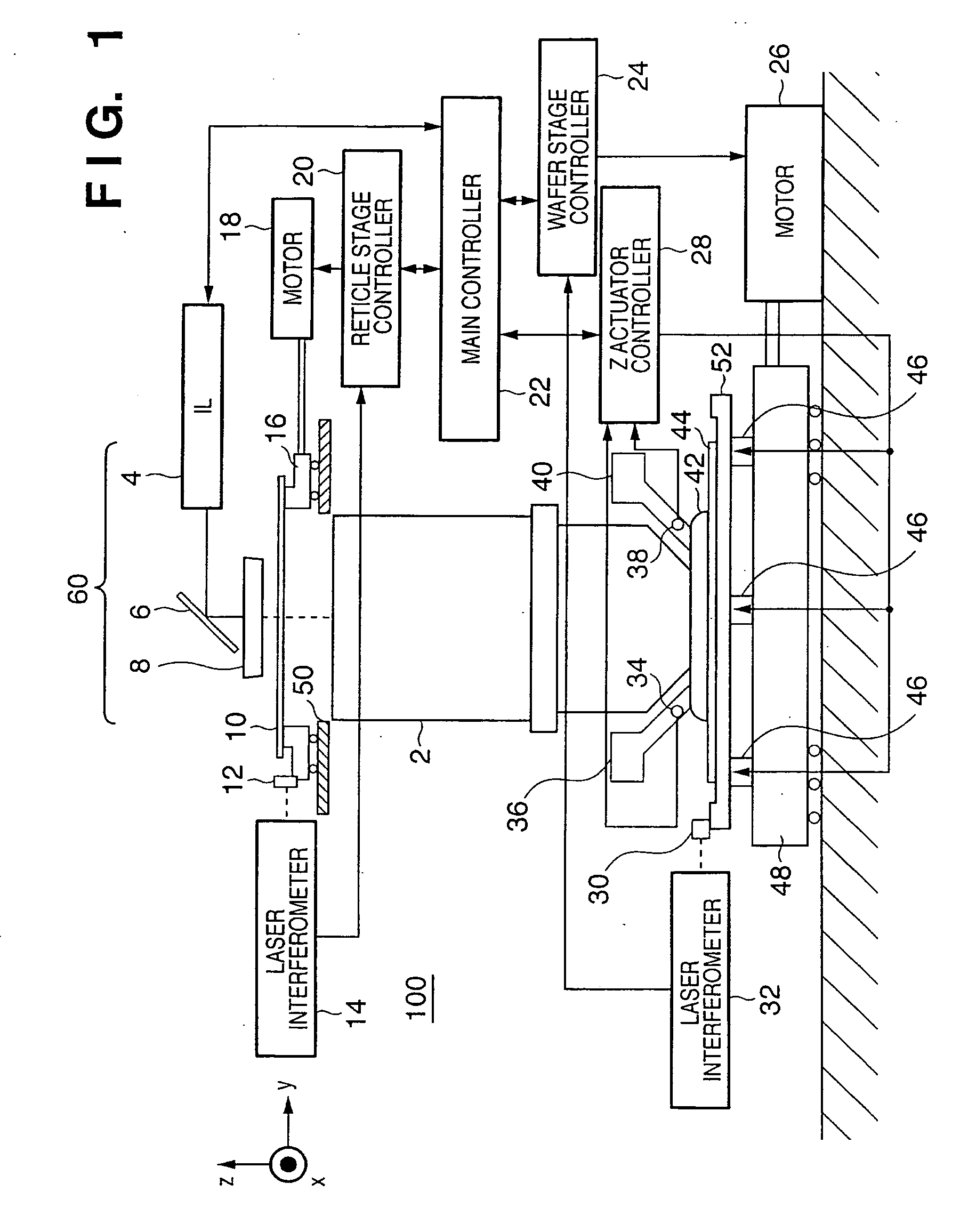

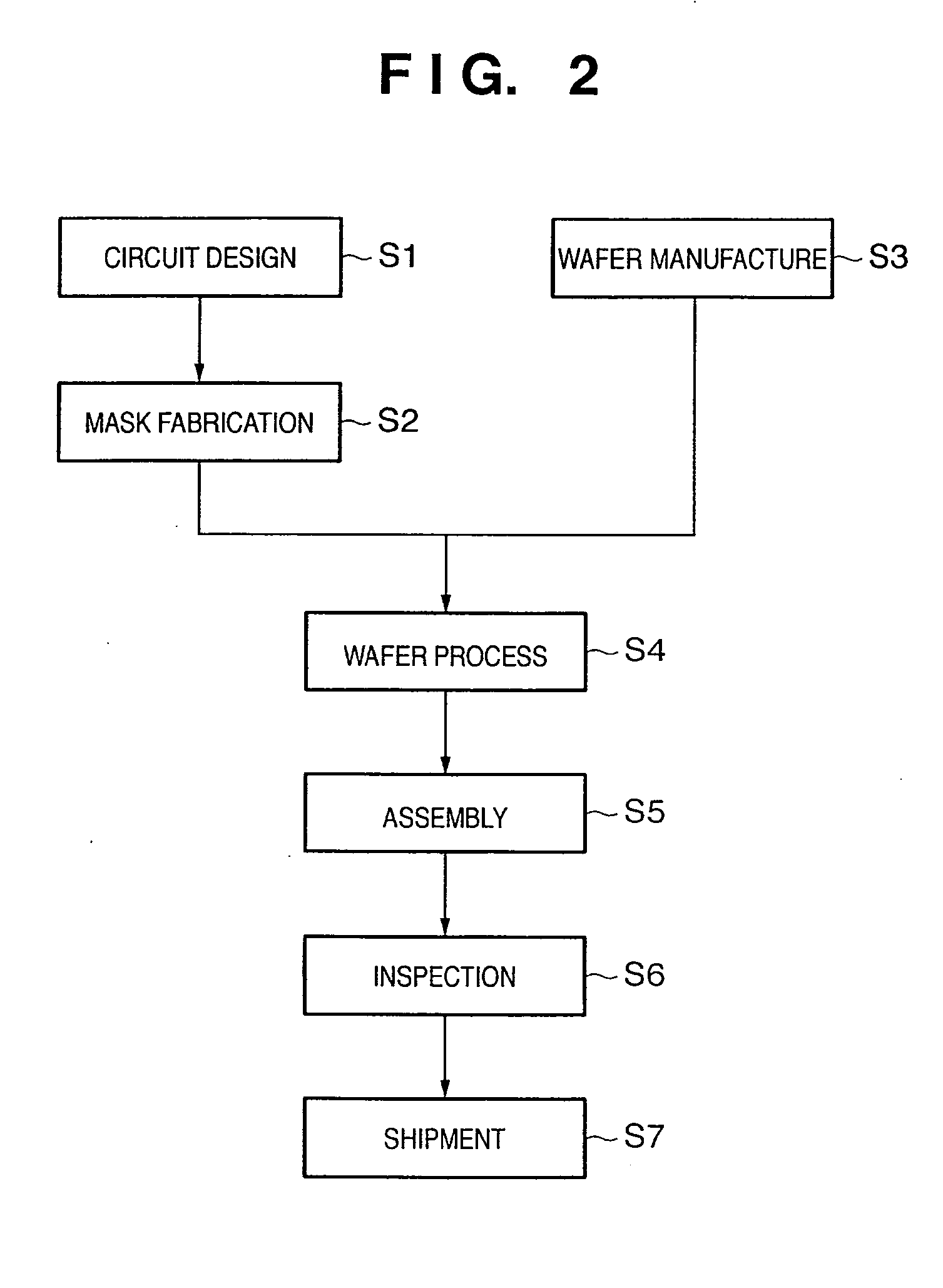

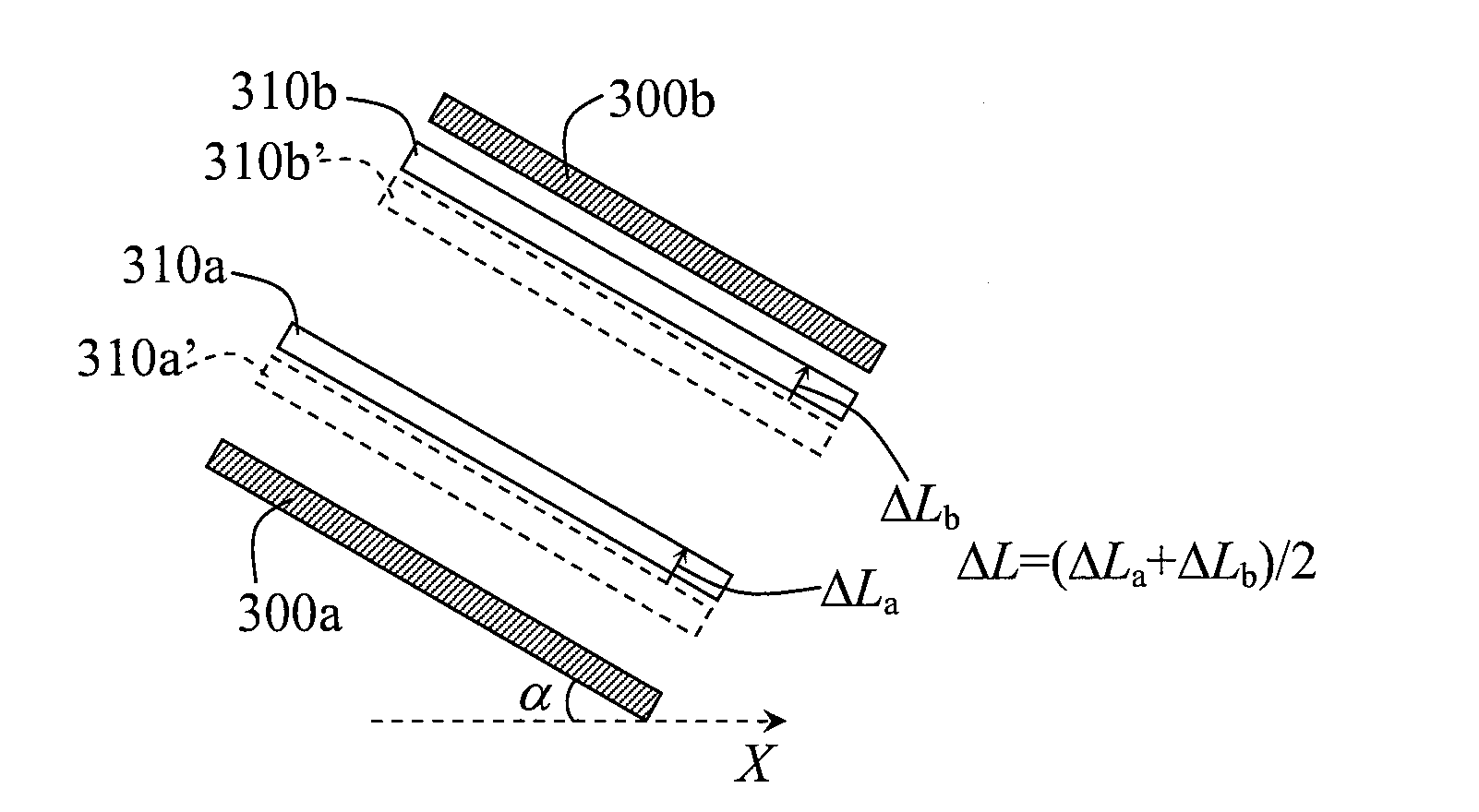

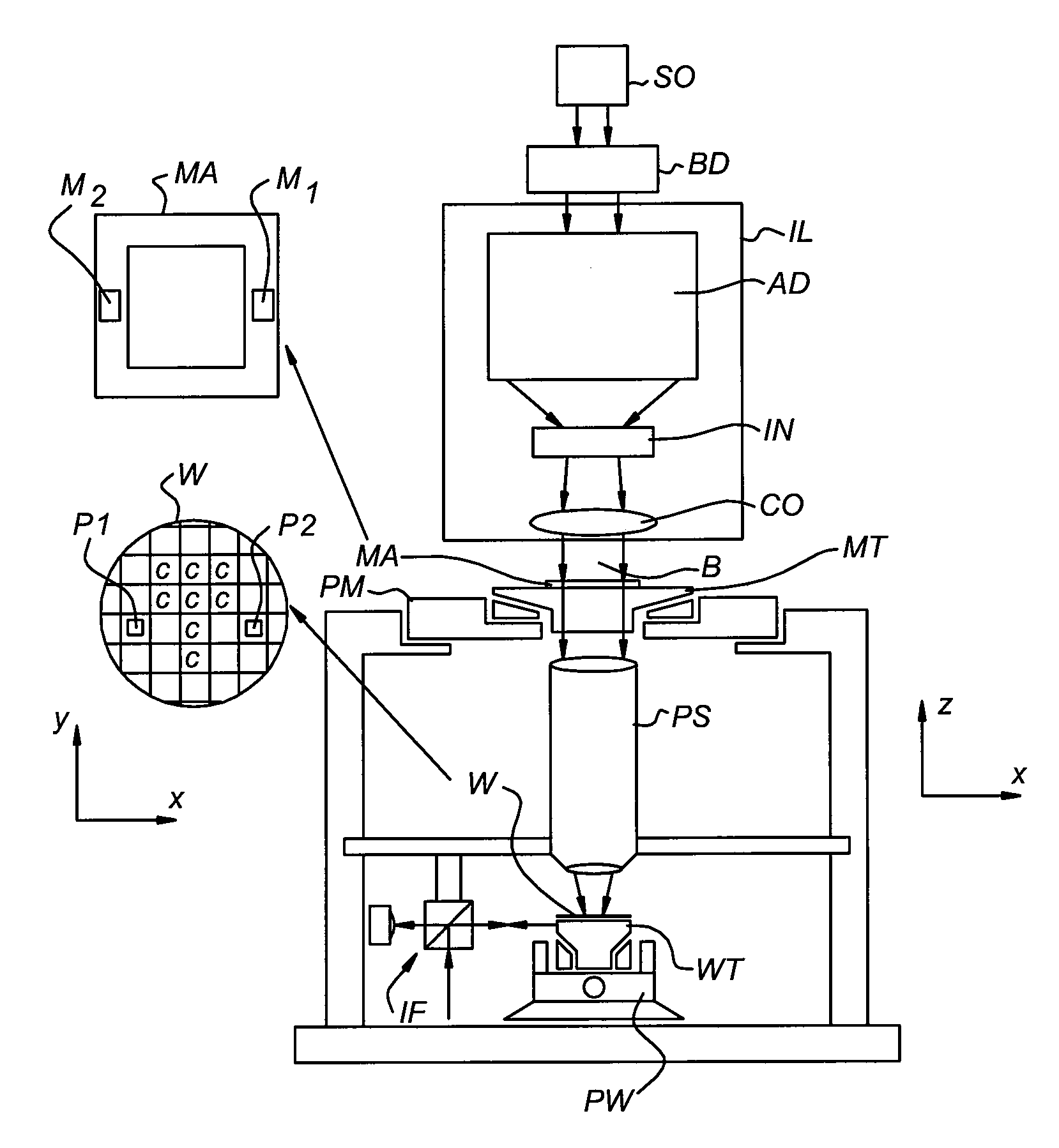

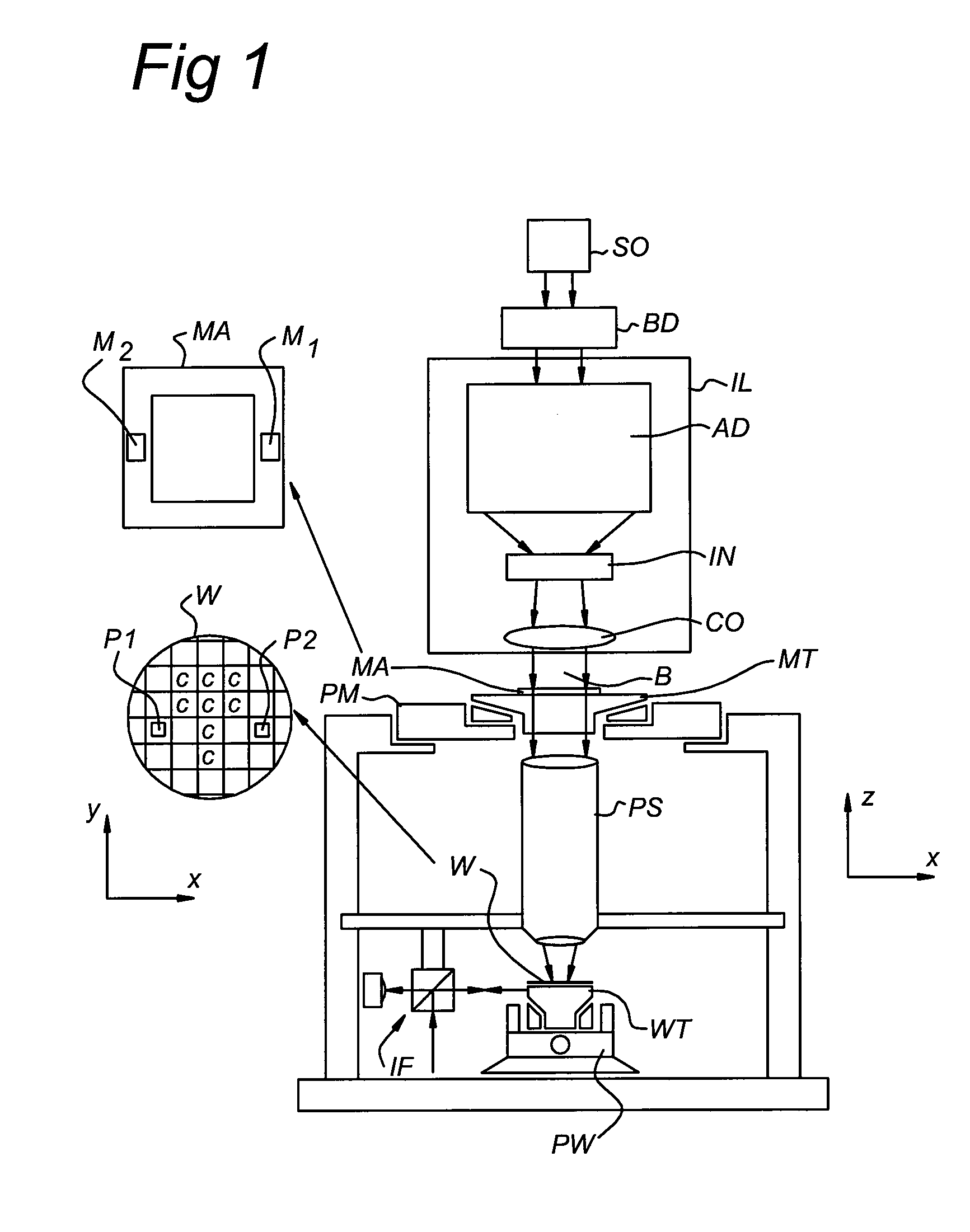

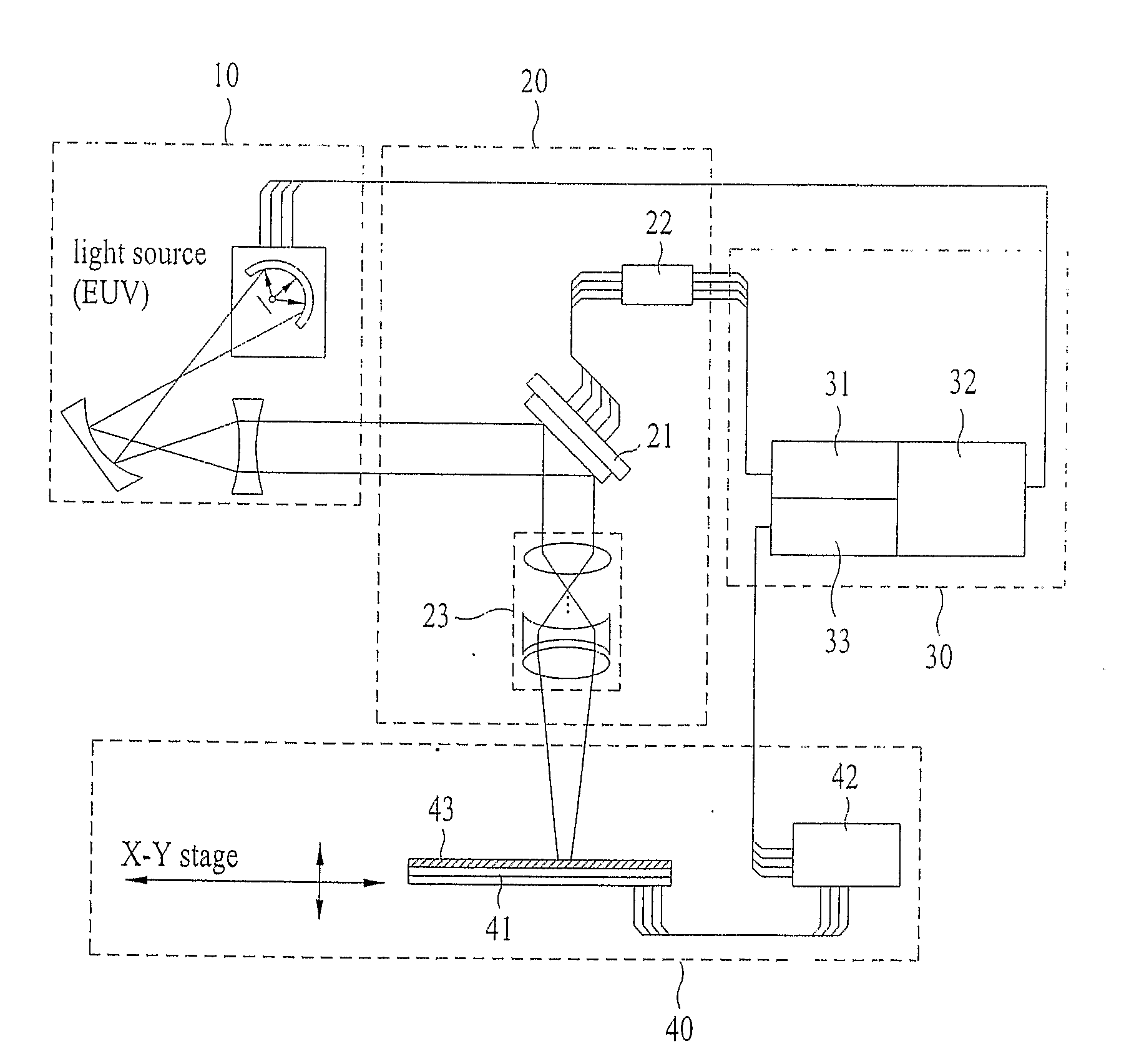

Exposure apparatus

InactiveUS20070229787A1Reduce distortionInfluence of thermal deformationLiquid processingPhotomechanical apparatusEngineeringElectrical and Electronics engineering

Owner:CANON KK

Microcapsule composition

InactiveUS20050164116A1Lower resistanceGood workmanshipPhotosensitive materialsRadiation applicationsPolymer sciencePolystyrene

This invention relates to a composition comprising microcapsules suspended in an aqueous media, said microcapsules comprising a water immiscible material contained within an encapsulating wall of polymeric material, wherein the aqueous media contains a stabilizer comprising an anionic polymer mixture comprising a first sulfonated polystyrene polymer and a second sulfonated polystyrene polymer wherein the ratio of the weight average polymer molecular weight of the first polymer to the second polymer is greater than 2. It further relates to an imaging element comprising said microcapsules.

Owner:EASTMAN KODAK CO

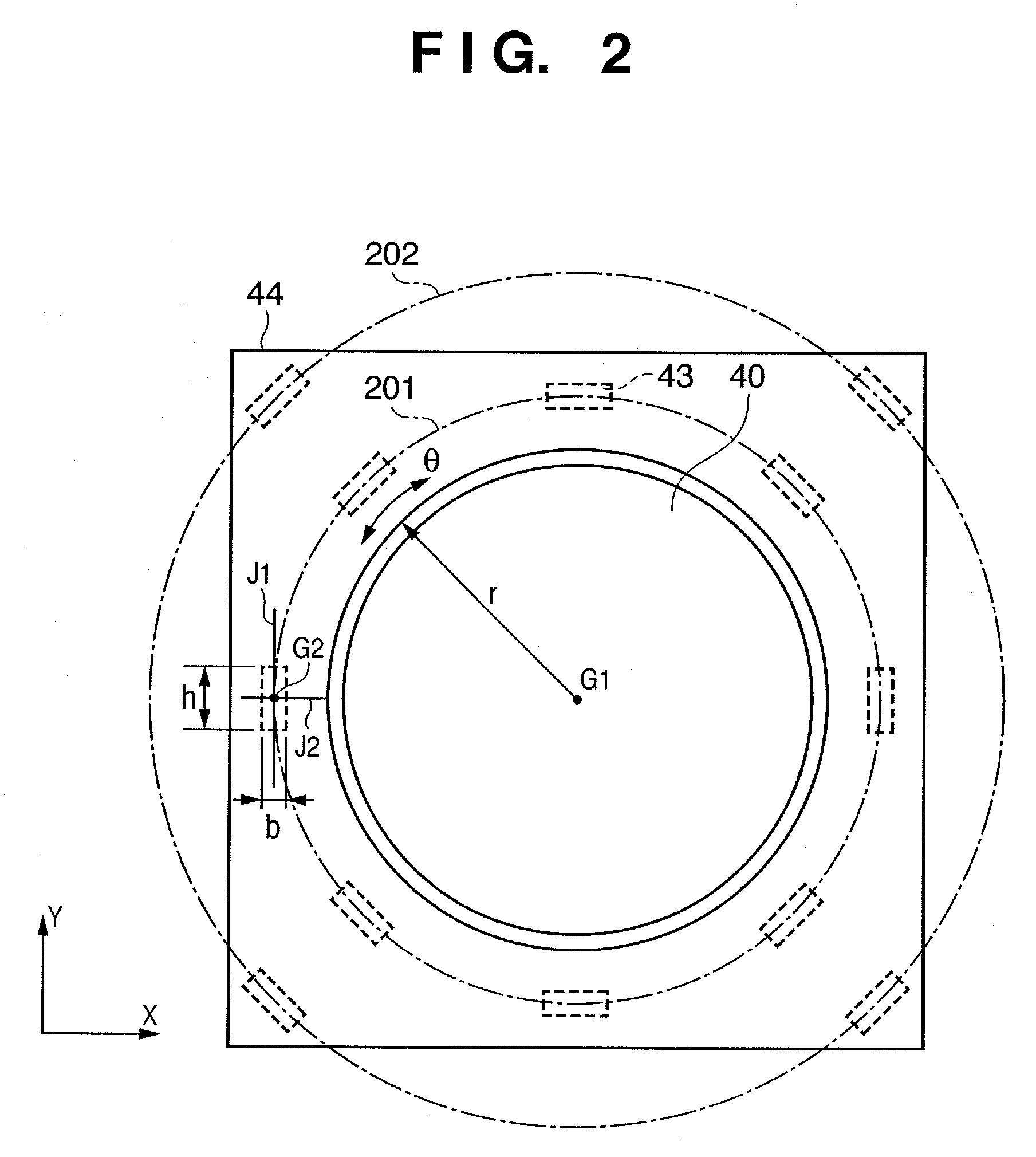

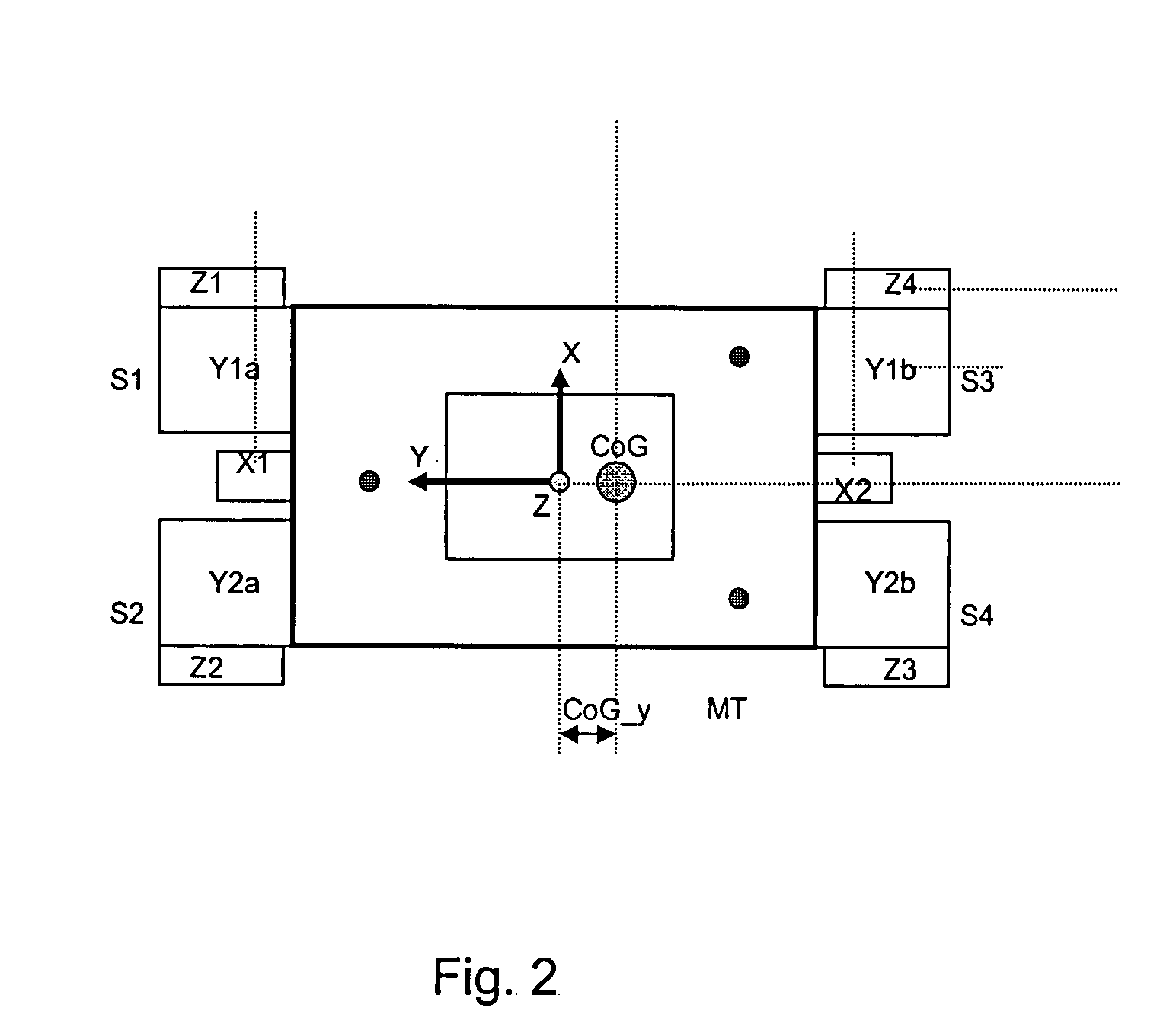

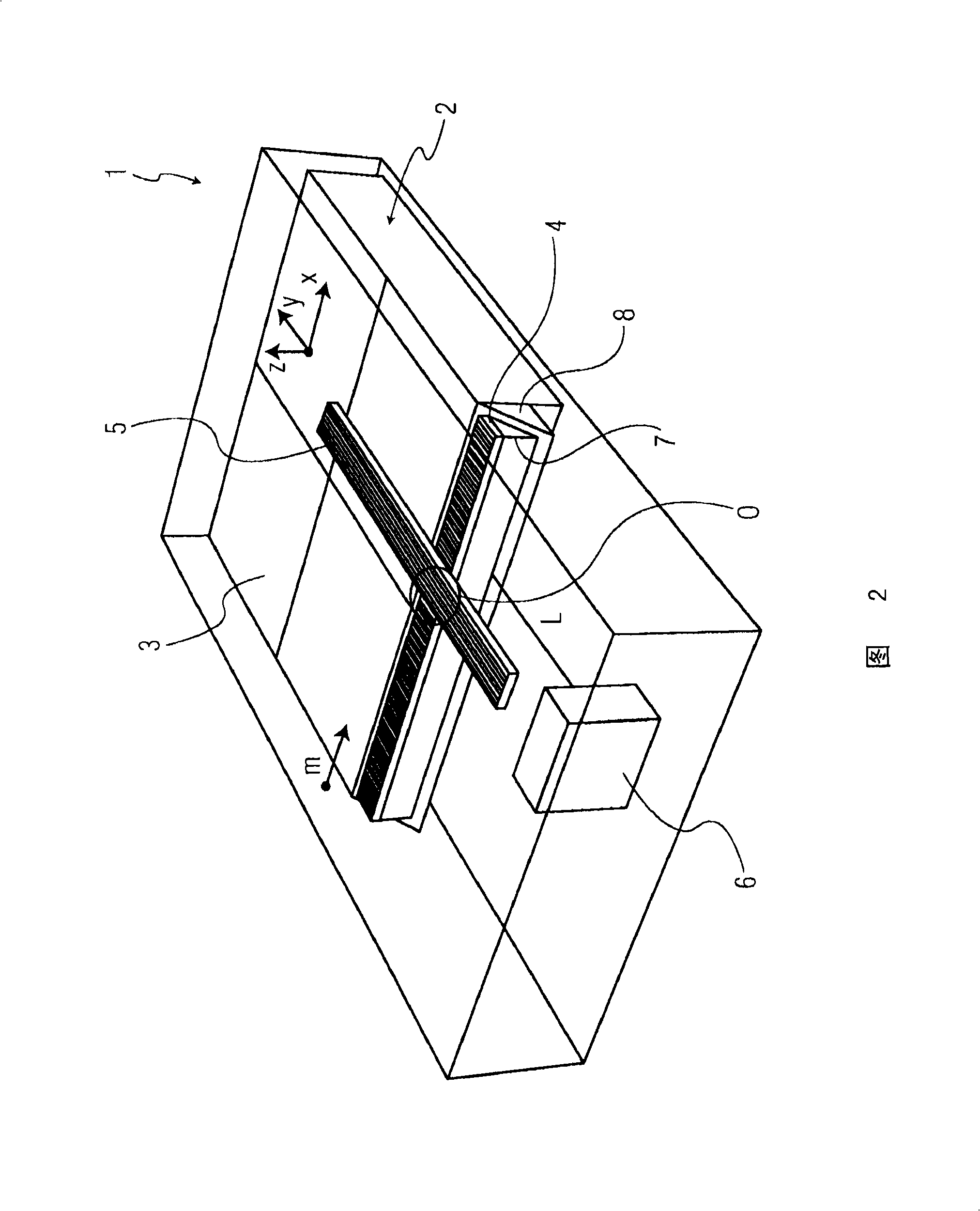

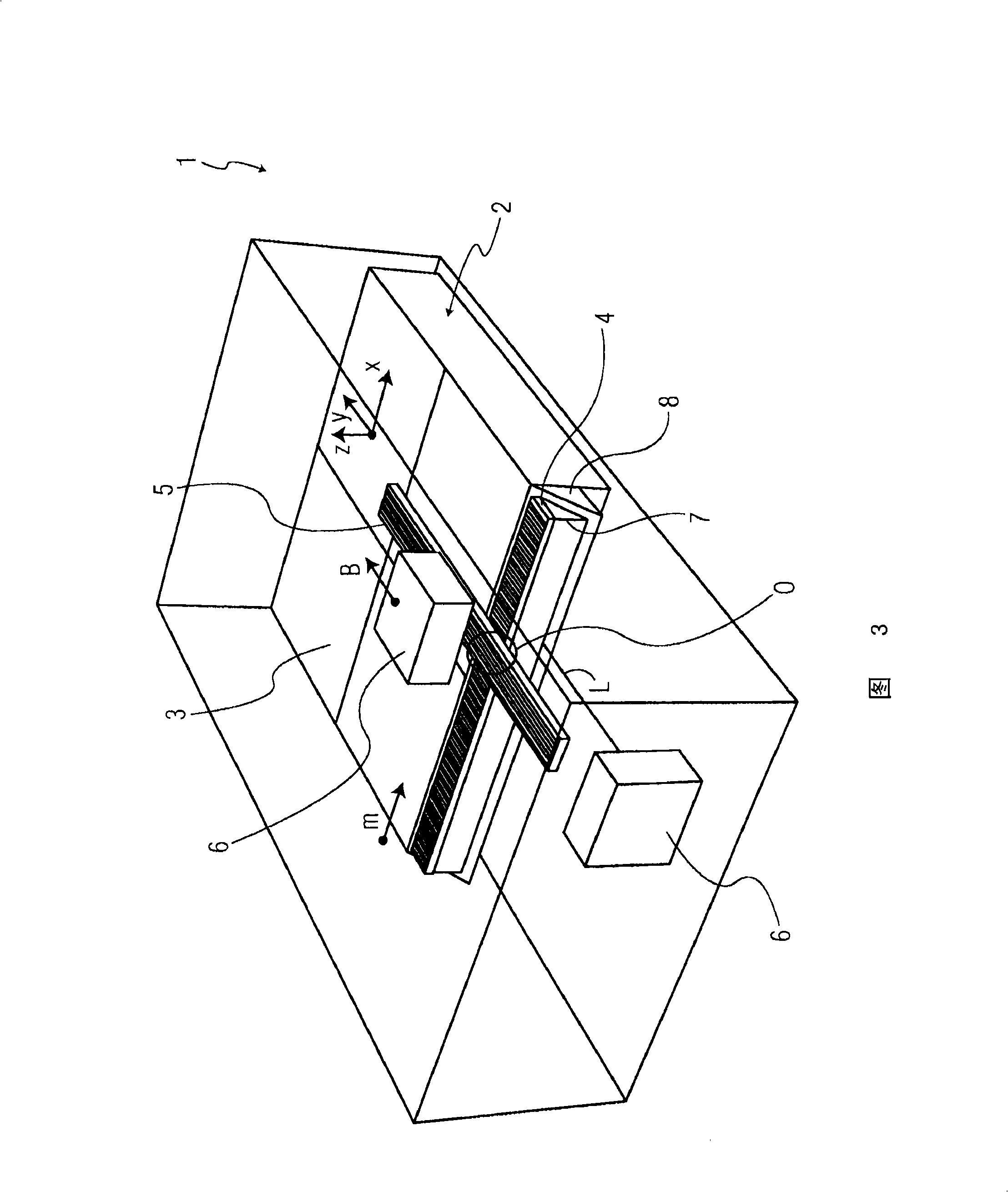

Stage system and lithographic apparatus comprising such stage system

ActiveUS20080212054A1Improve dynamic performancePhotomechanical apparatusPhotographic printingPosition dependentDegrees of freedom

Owner:ASML NETHERLANDS BV

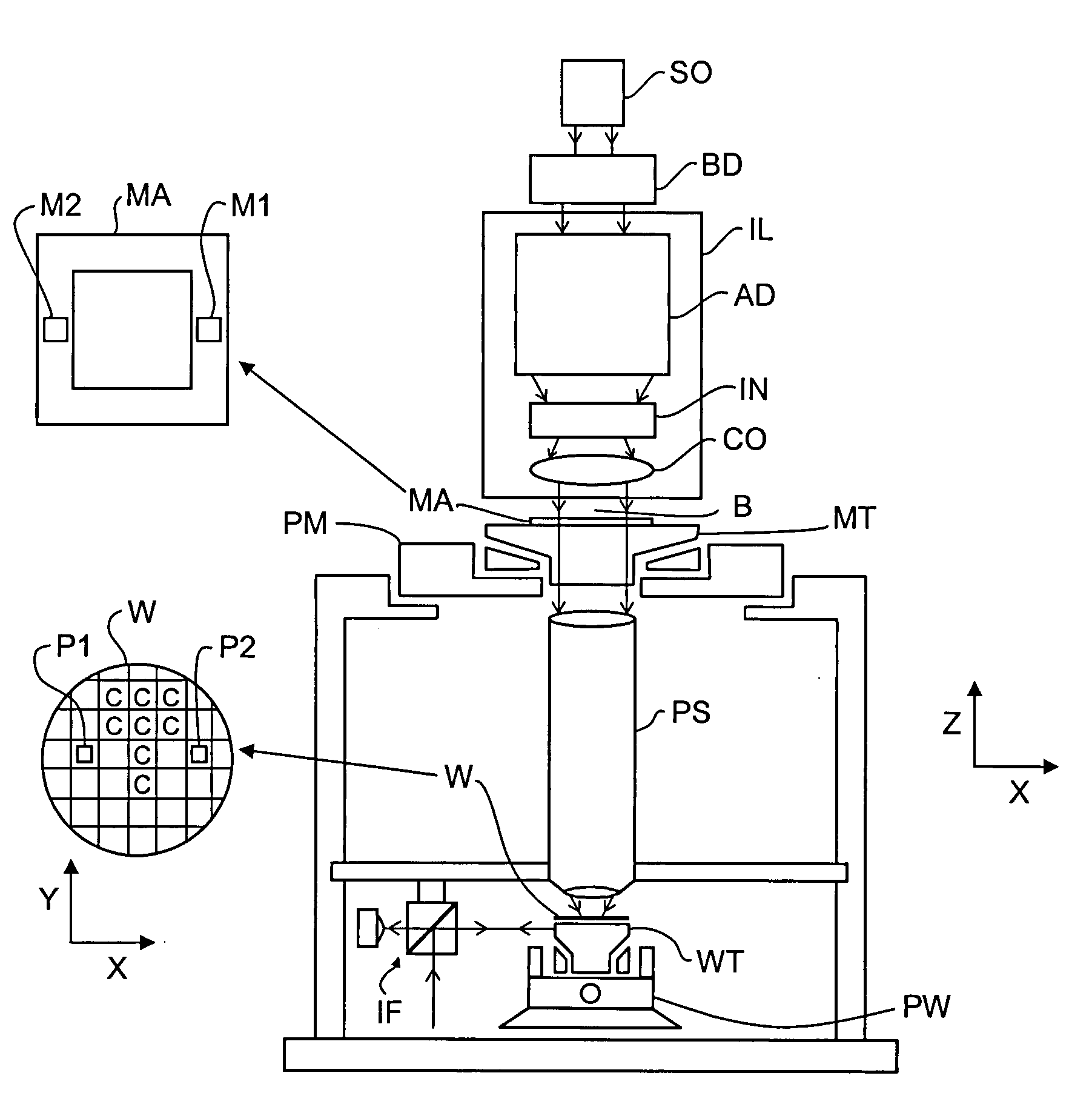

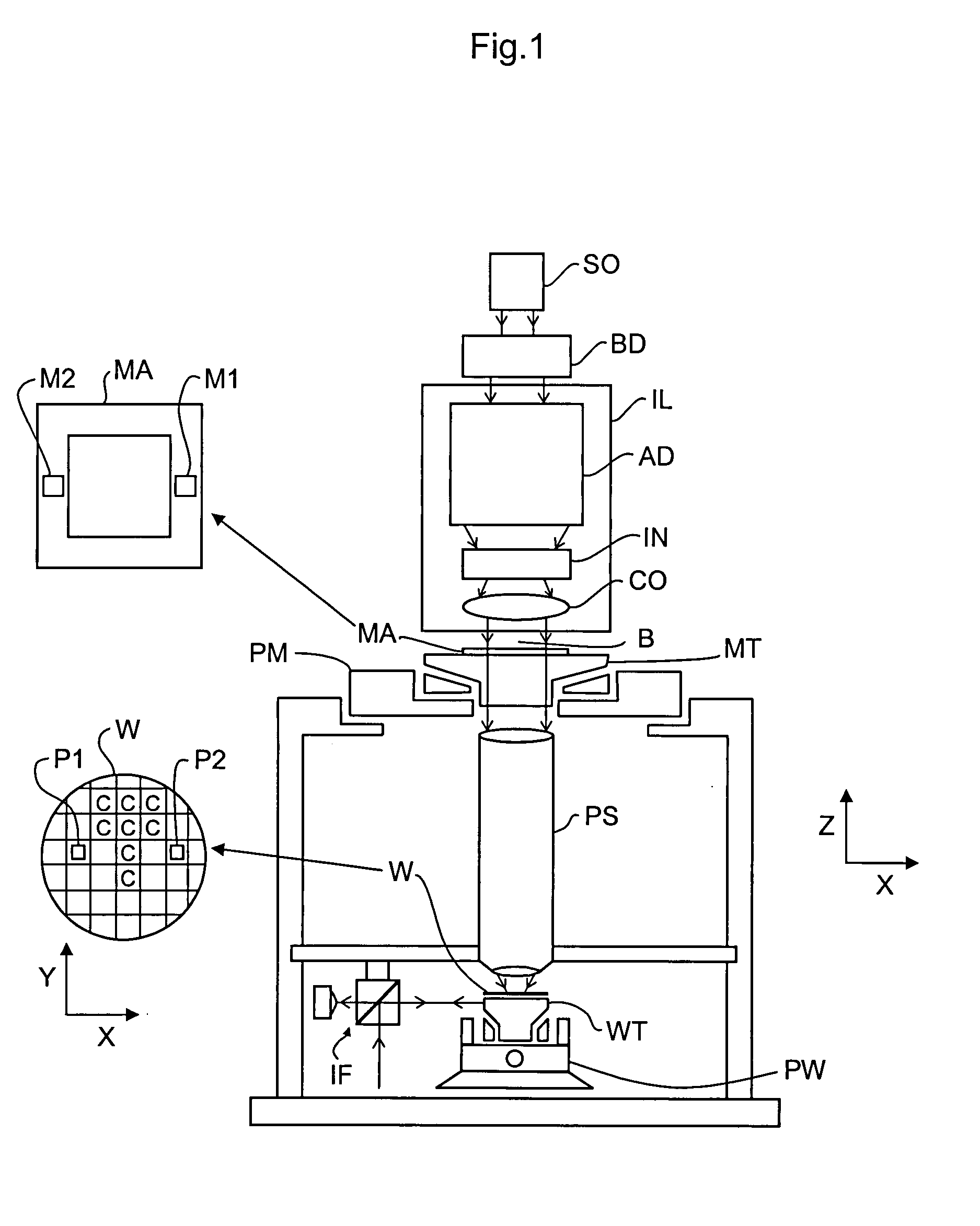

Immersion exposure apparatus, immersion exposure method, and device manufacturing method

InactiveUS20060209280A1Suppress degradation in imaging performanceImprove accuracyCannulasPhotomechanical apparatusTemperature controlBiomedical engineering

Owner:CANON KK

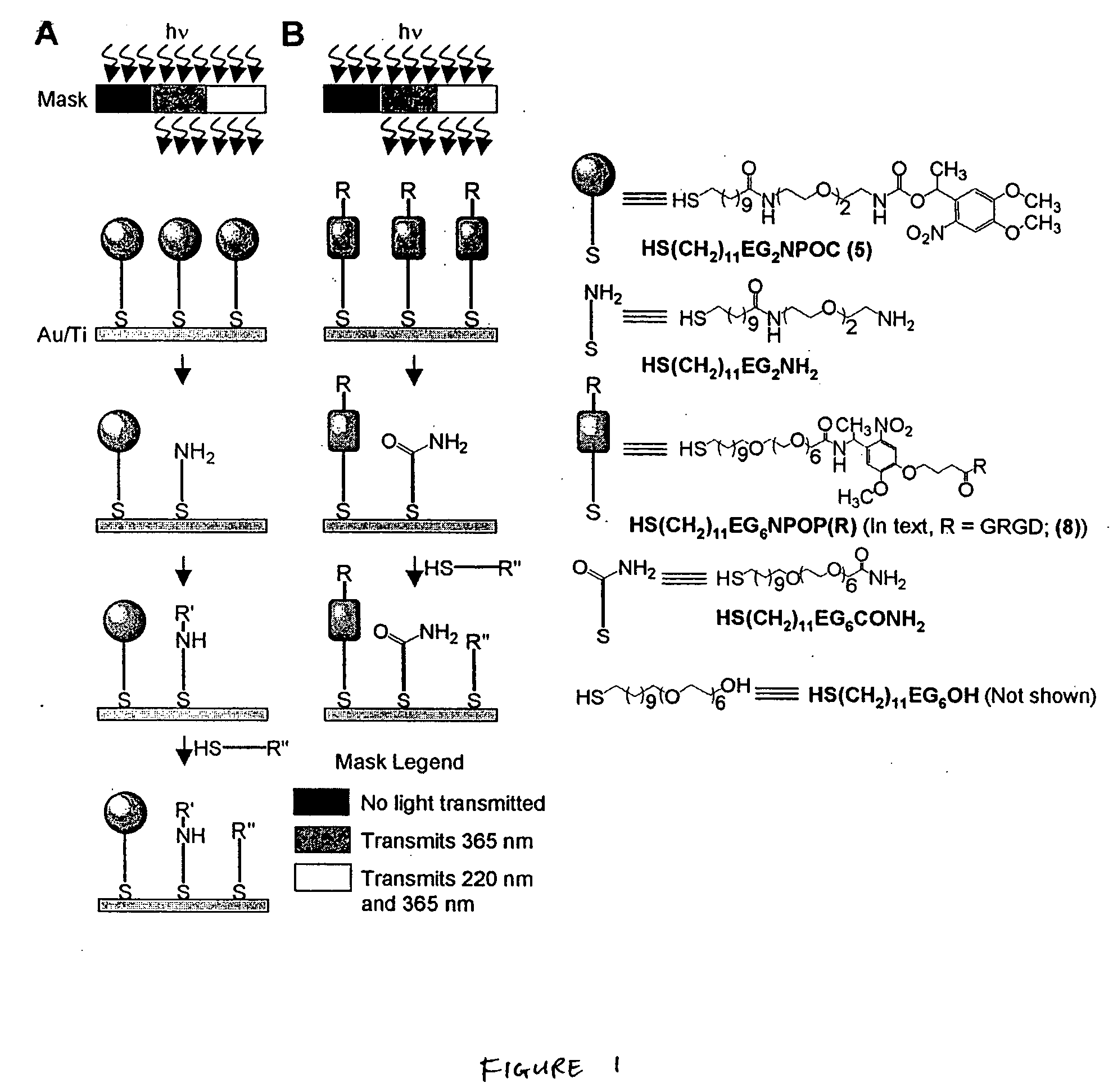

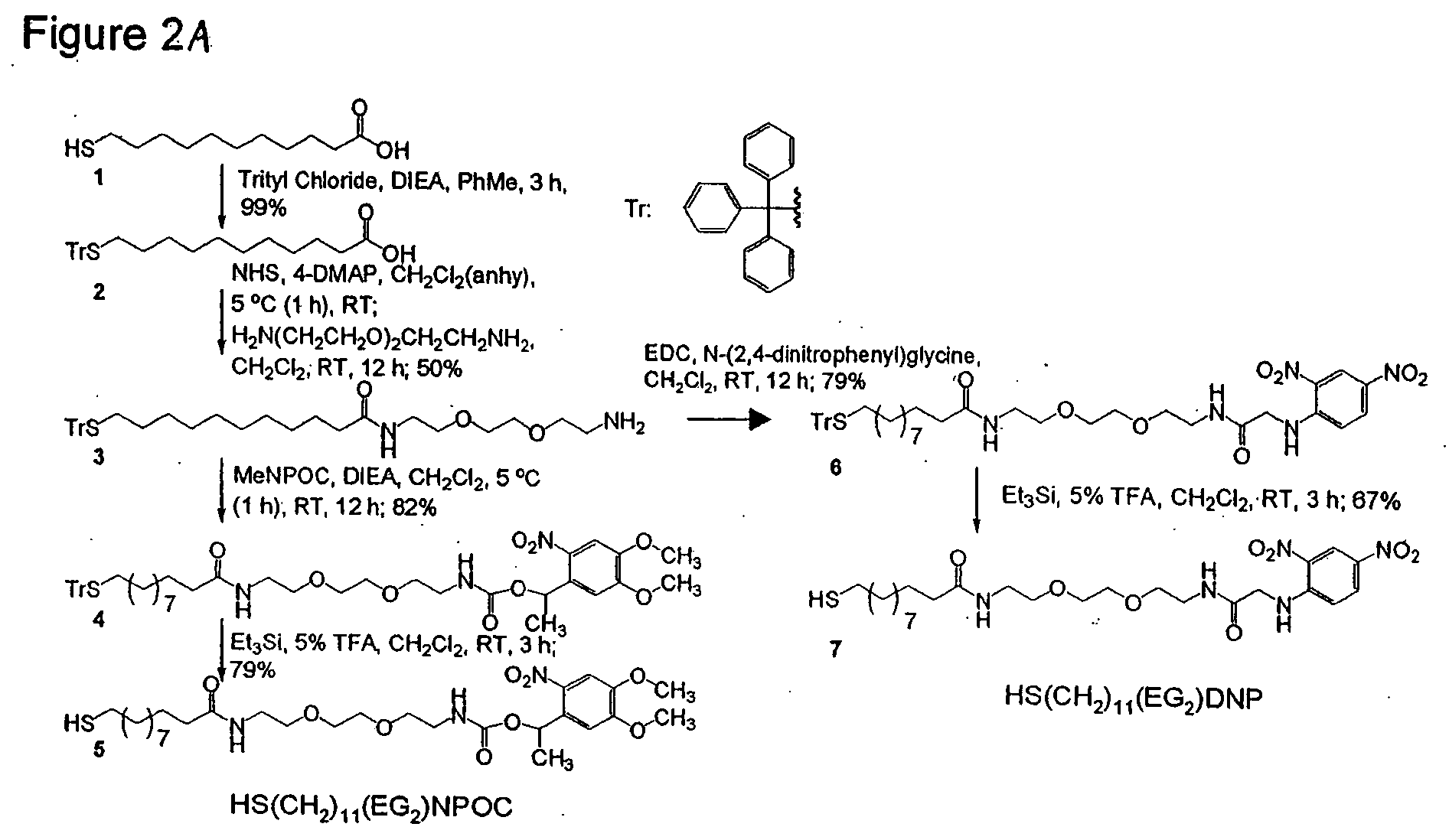

Patterning and alteration of molecules

Owner:RYAN DECLAN +7

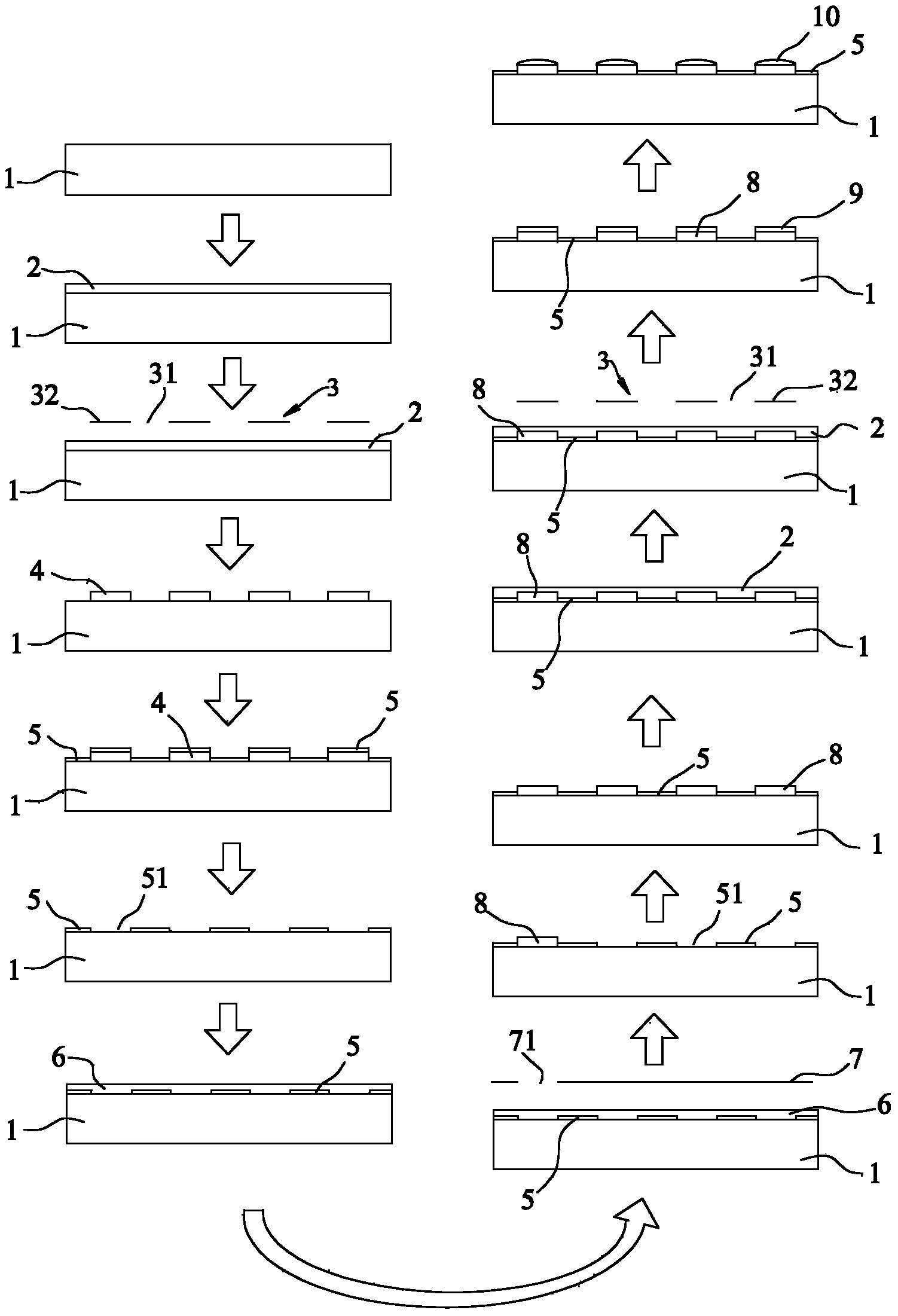

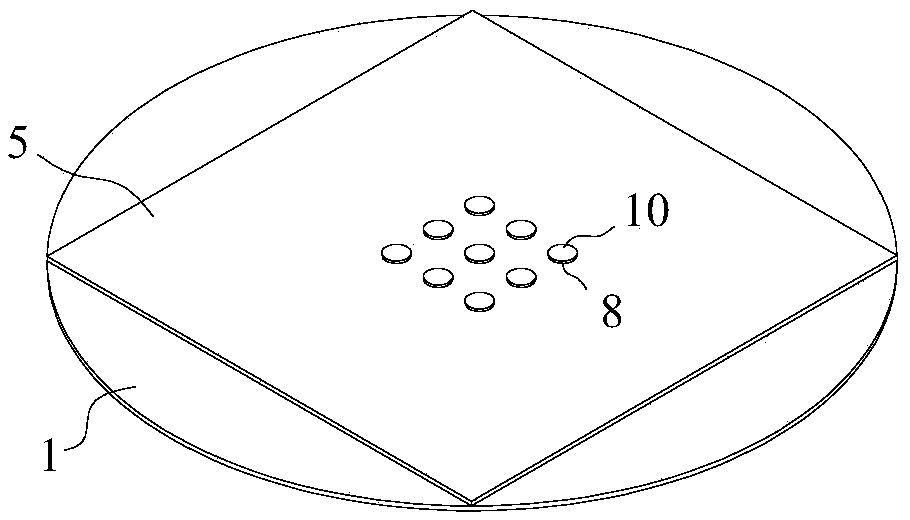

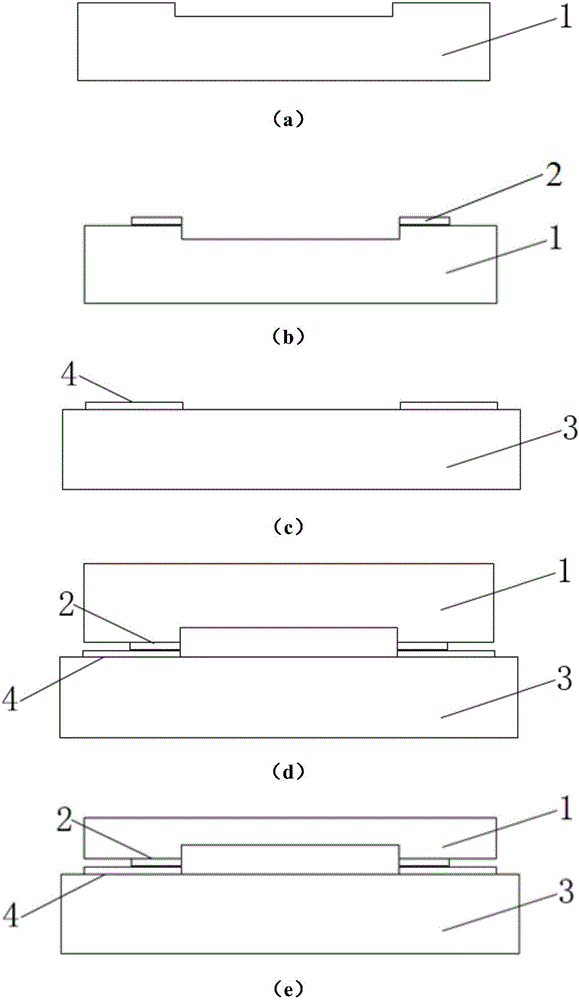

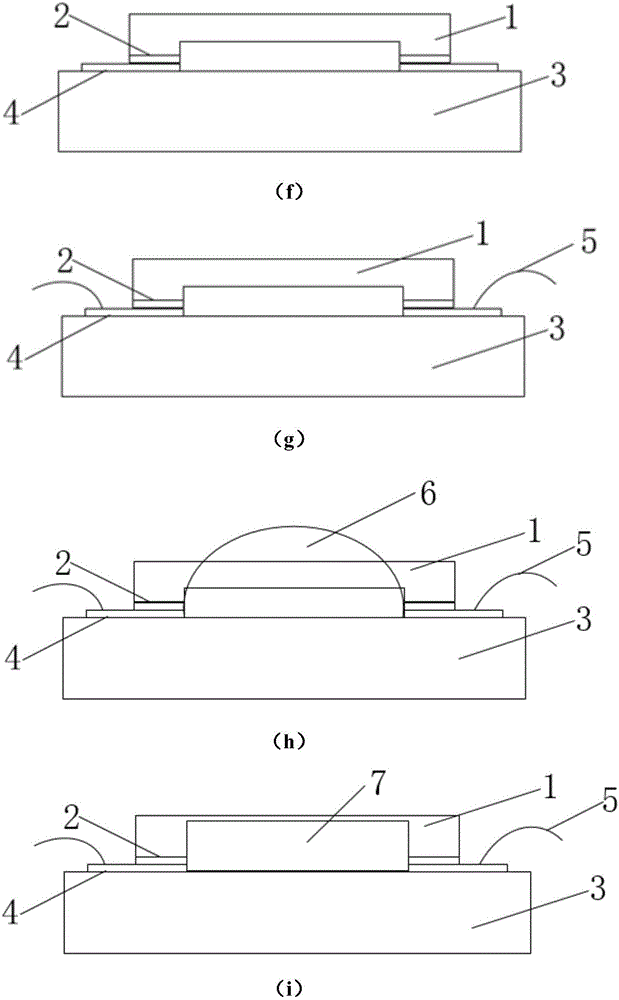

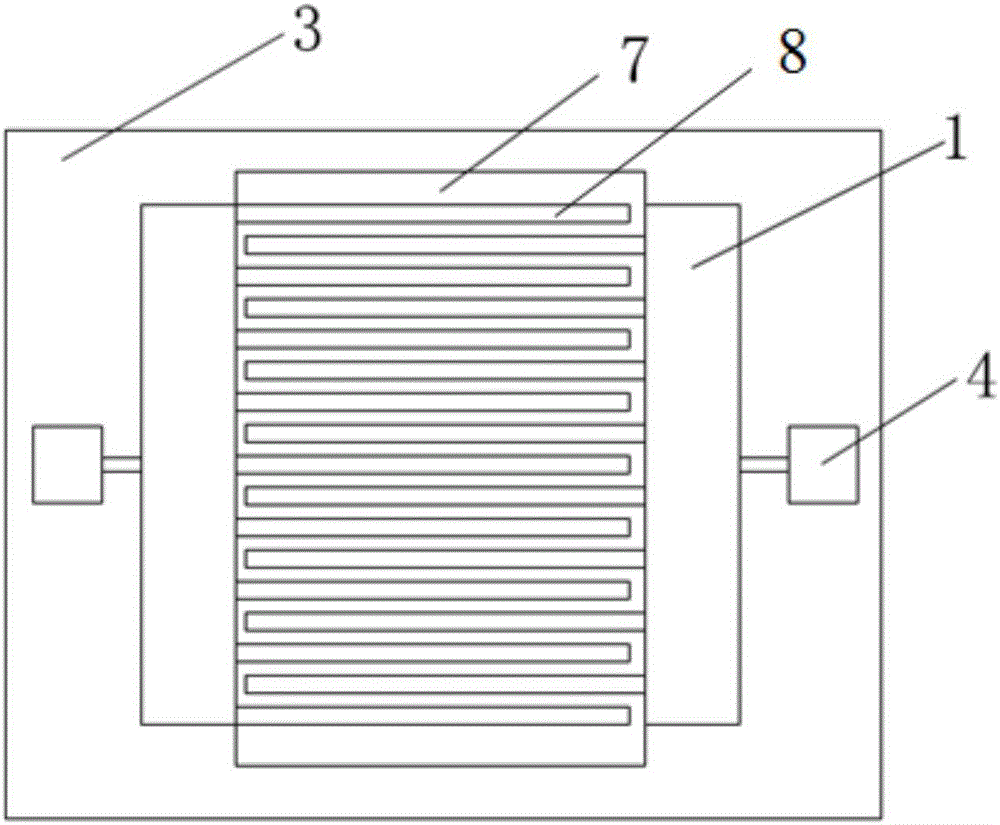

Manufacturing method of multi-channel light filtering micro lens array

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Microelectronic temperature sensor and preparation method thereof

InactiveCN105967136AHigh sensitivityReduce the effect of fringe capacitancePrecision positioning equipmentThermometers using electric/magnetic elementsElectricityElectron temperature

Owner:HOHAI UNIV CHANGZHOU

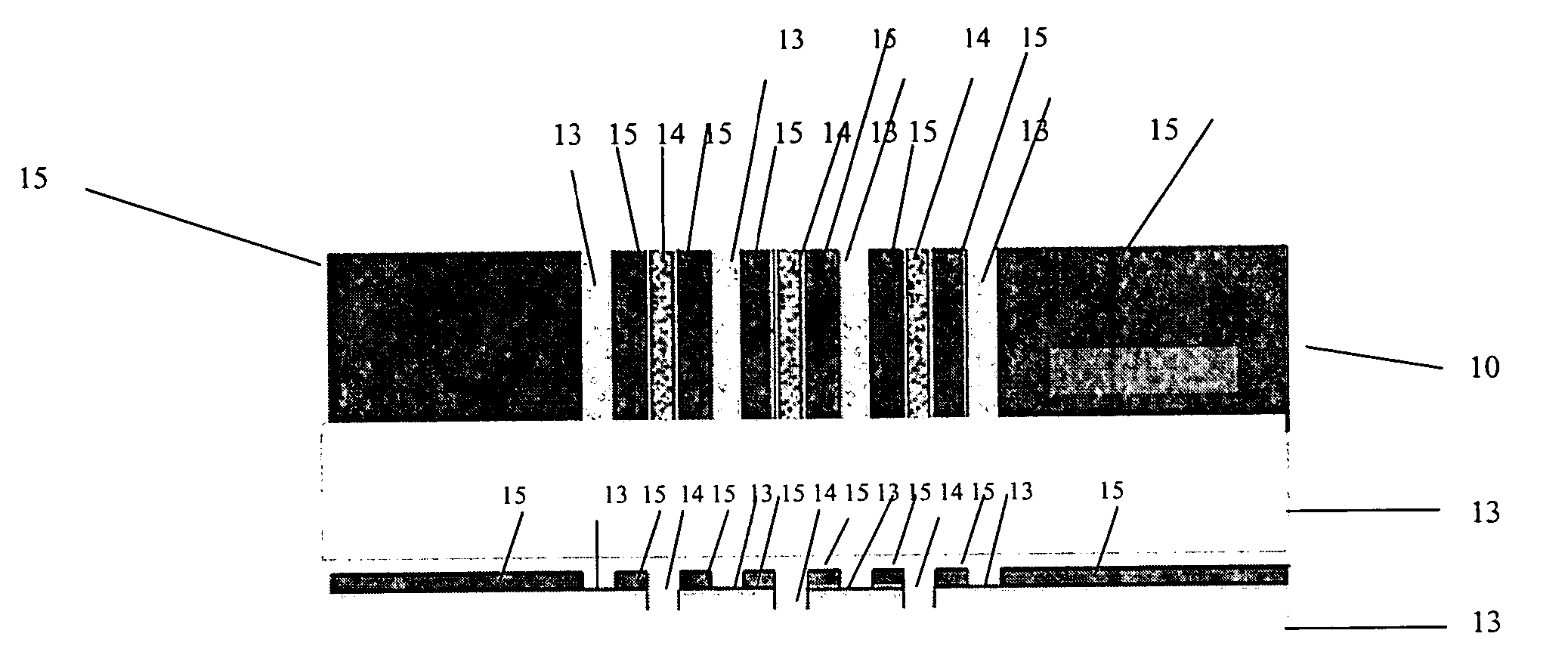

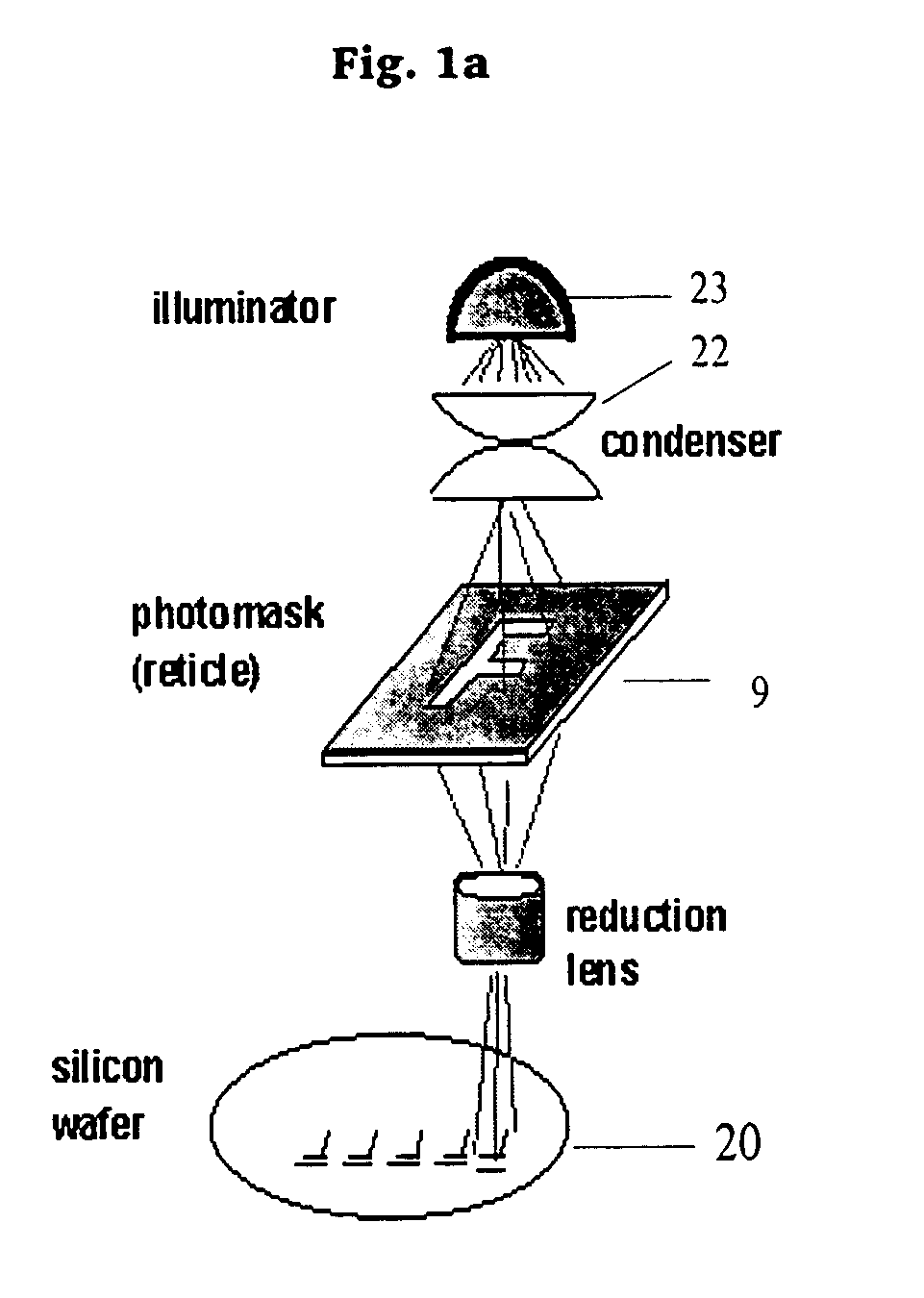

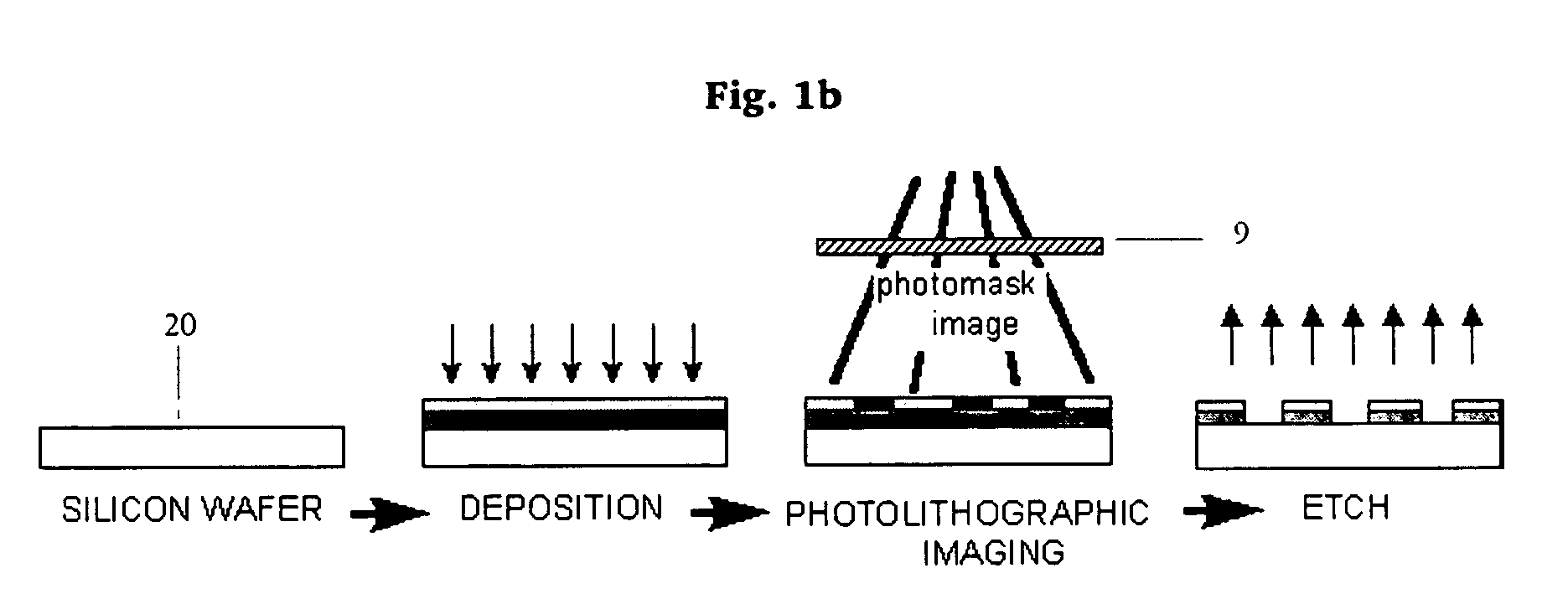

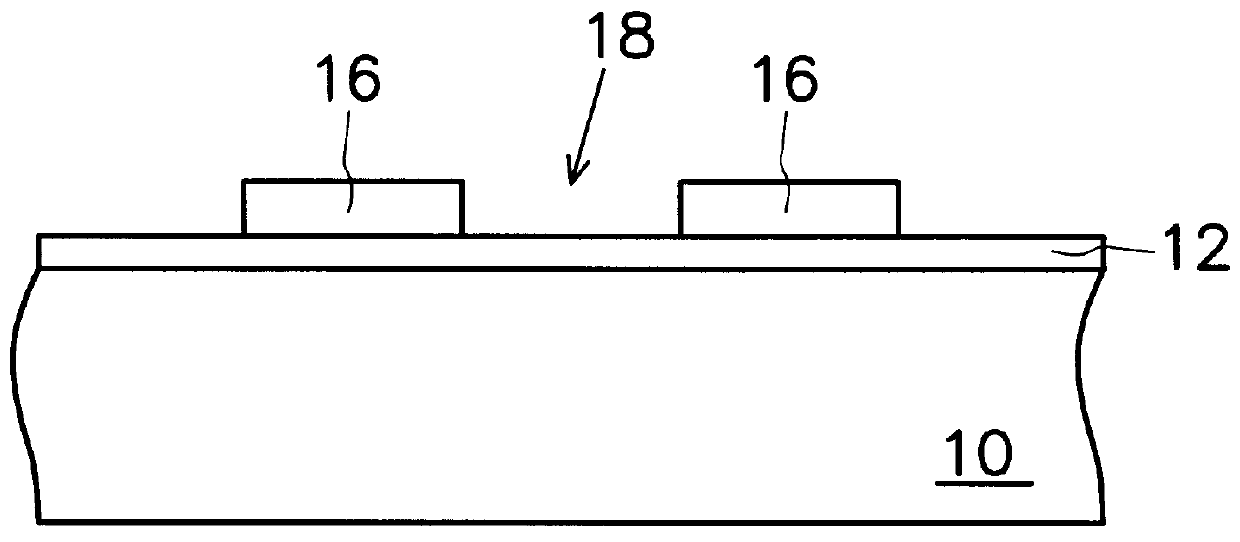

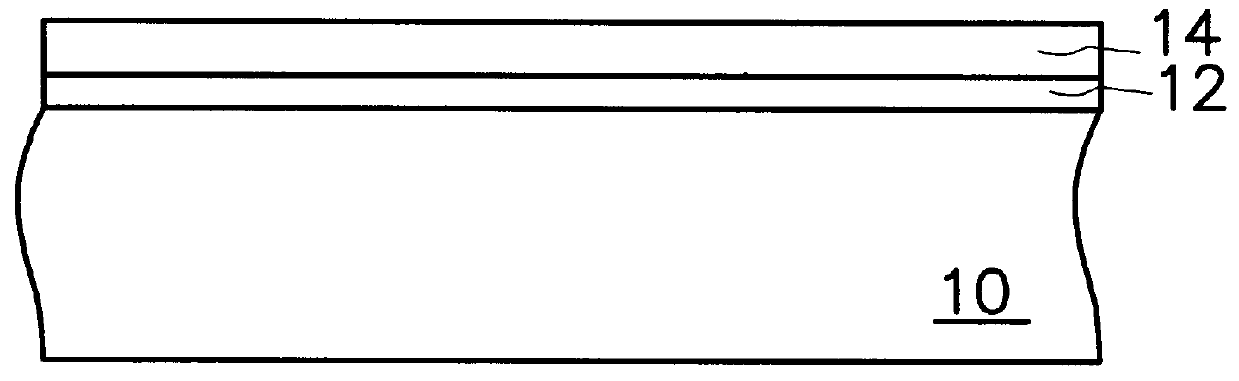

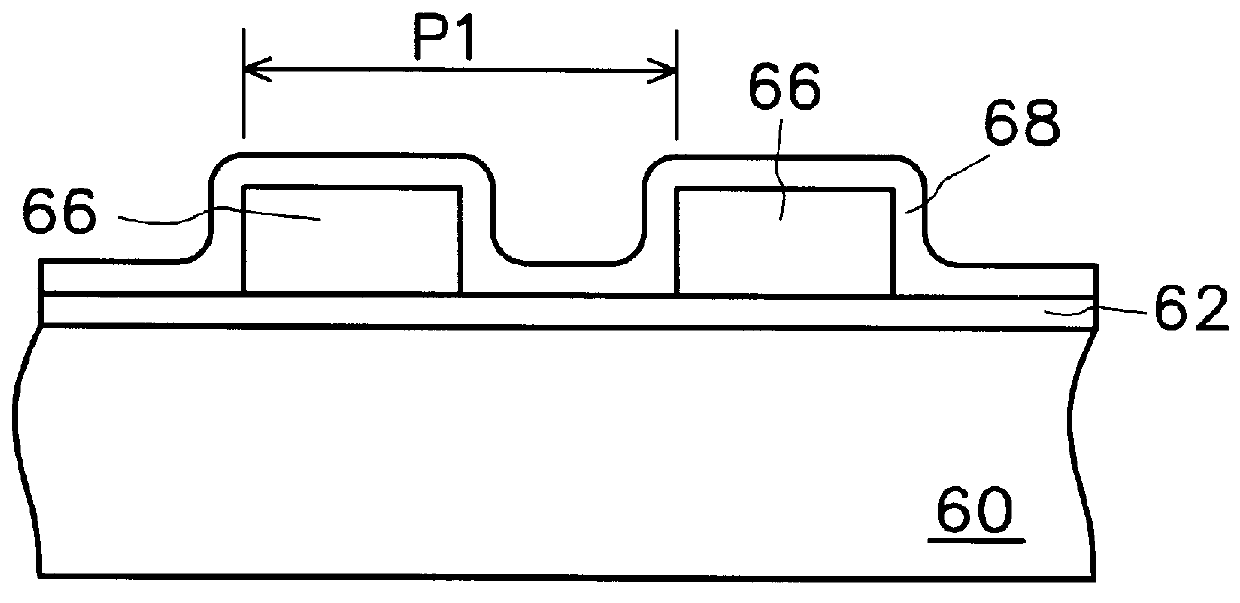

Photomask having an internal substantially transparent etch stop layer

ActiveUS20050053847A1Improve transmittanceImprove adhesionPhotomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistEvaporation

Owner:PHOTRONICS INC

Method for fabricating a photomask

Owner:UNITED MICROELECTRONICS CORP

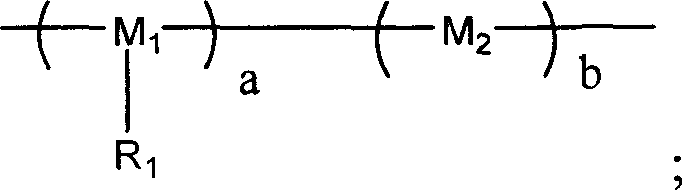

Method for forming phototonus combination, direction distribution membrane and optical compensation membrane

The invention provides a light-sensitive composite which contains a light-sensitive polymer, a light-sensitive monomer and a photo-induced compound. The composite can be used as alignment film or optical compensation film in a liquid crystal display through UV curing. The repetitive units of the light-sensitive polymer are two kinds of olefinic bond, wherein one kind of olefinic bond can polymerize to form the main chain and the other kind of olefinic bond can undergo two-stage UV treatment to form the alignment film. Additionally, the light-sensitive monomer contains more than two olefinic bonds, so that the light susceptibility is improved and the UV exposure is reduced.

Owner:IND TECH RES INST

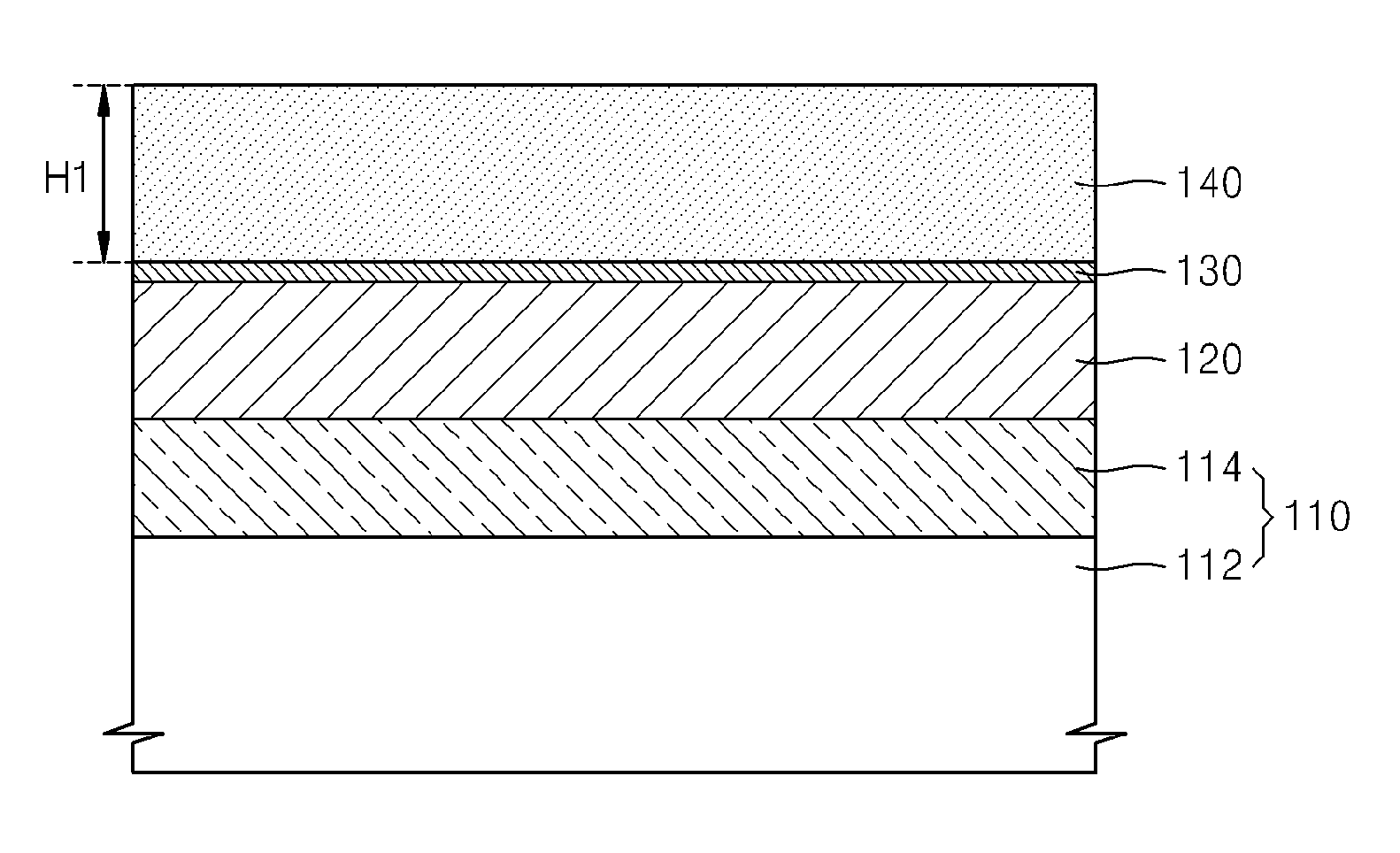

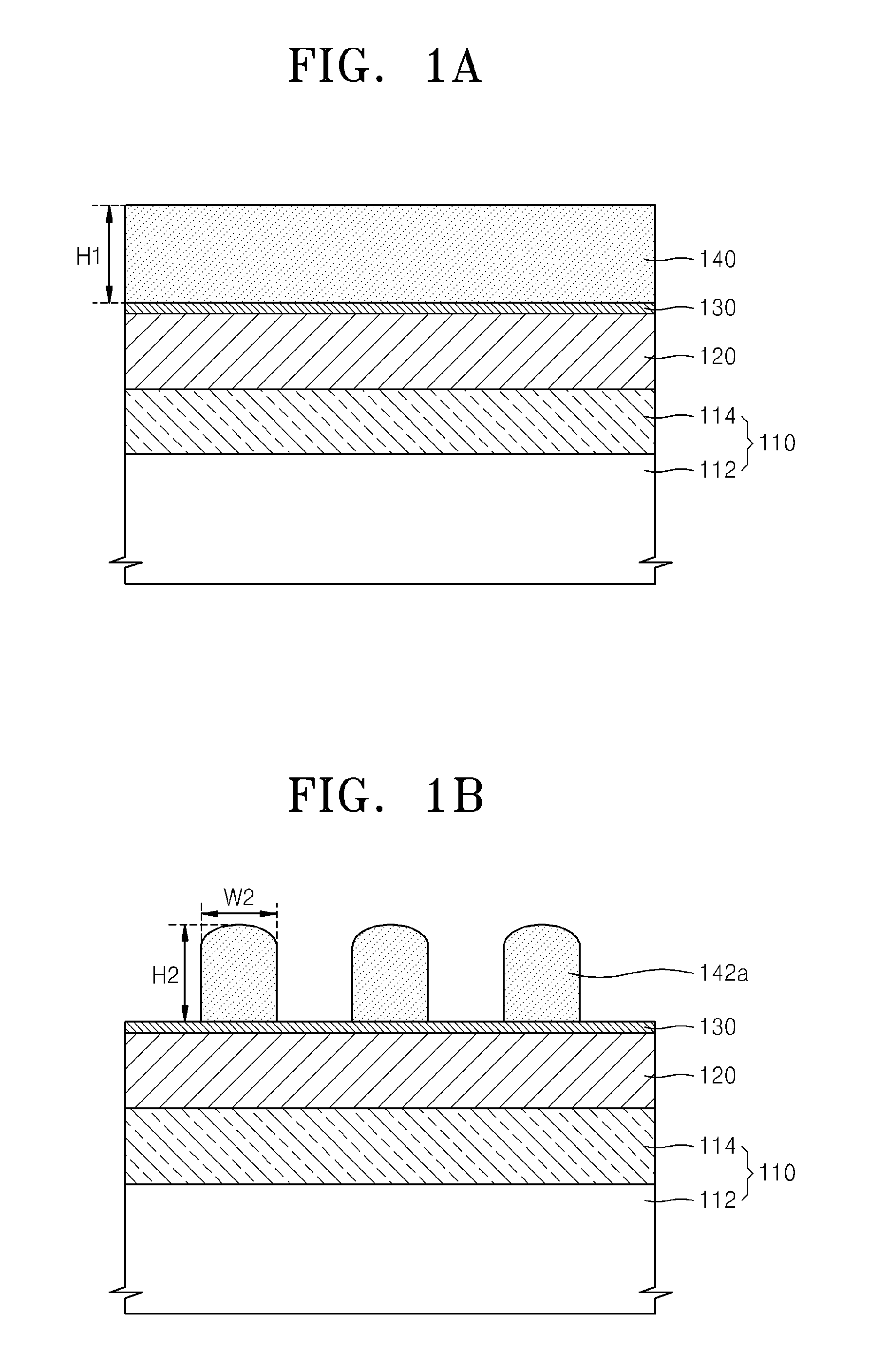

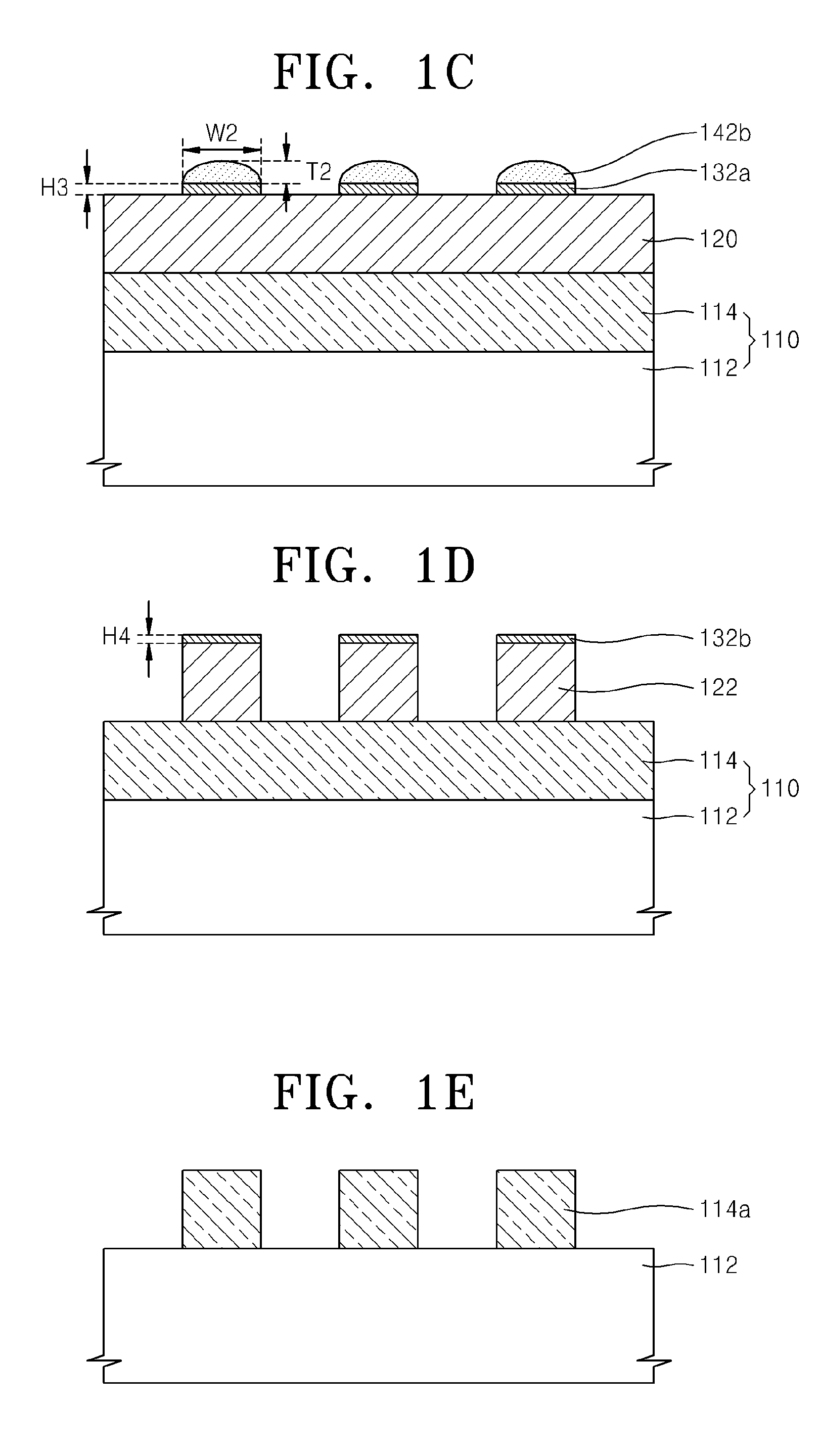

Methods of forming fine patterns and methods of fabricating semiconductor devices

Owner:SAMSUNG ELECTRONICS CO LTD

Overlay mark and application thereof

ActiveUS20130182255A1Correction errorSemiconductor/solid-state device detailsSolid-state devicesSharp angleComputer science

Owner:NAN YA TECH

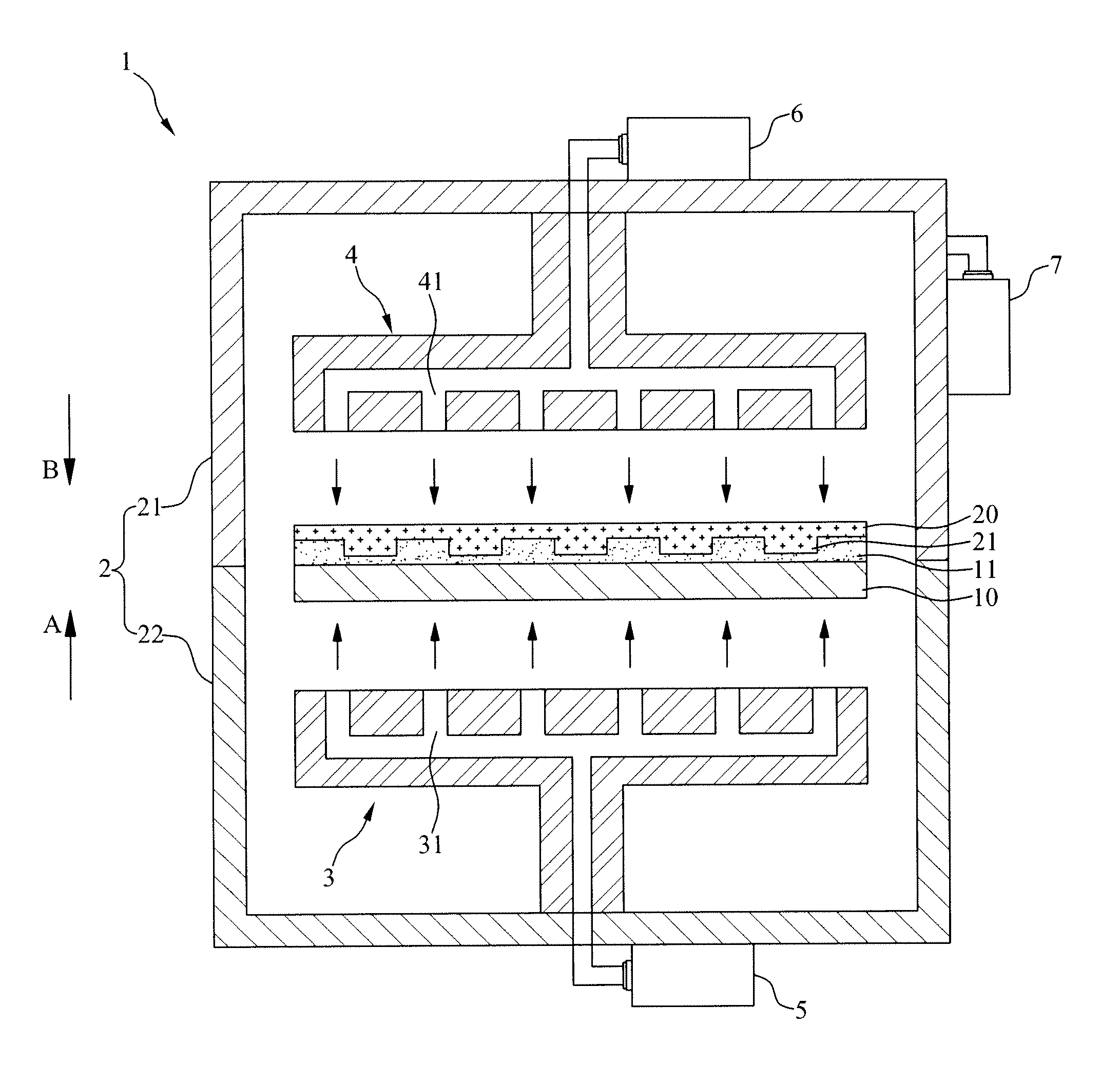

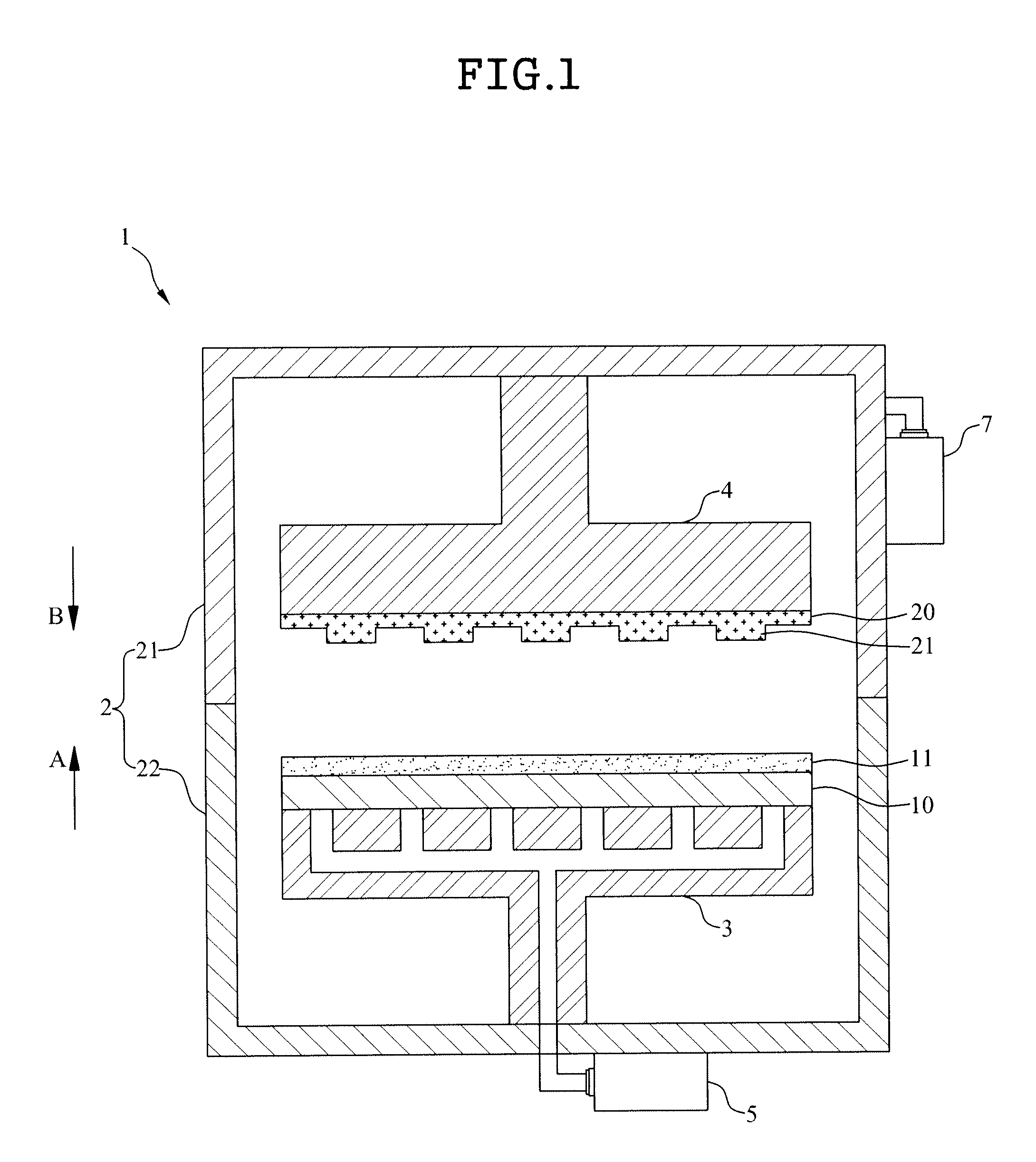

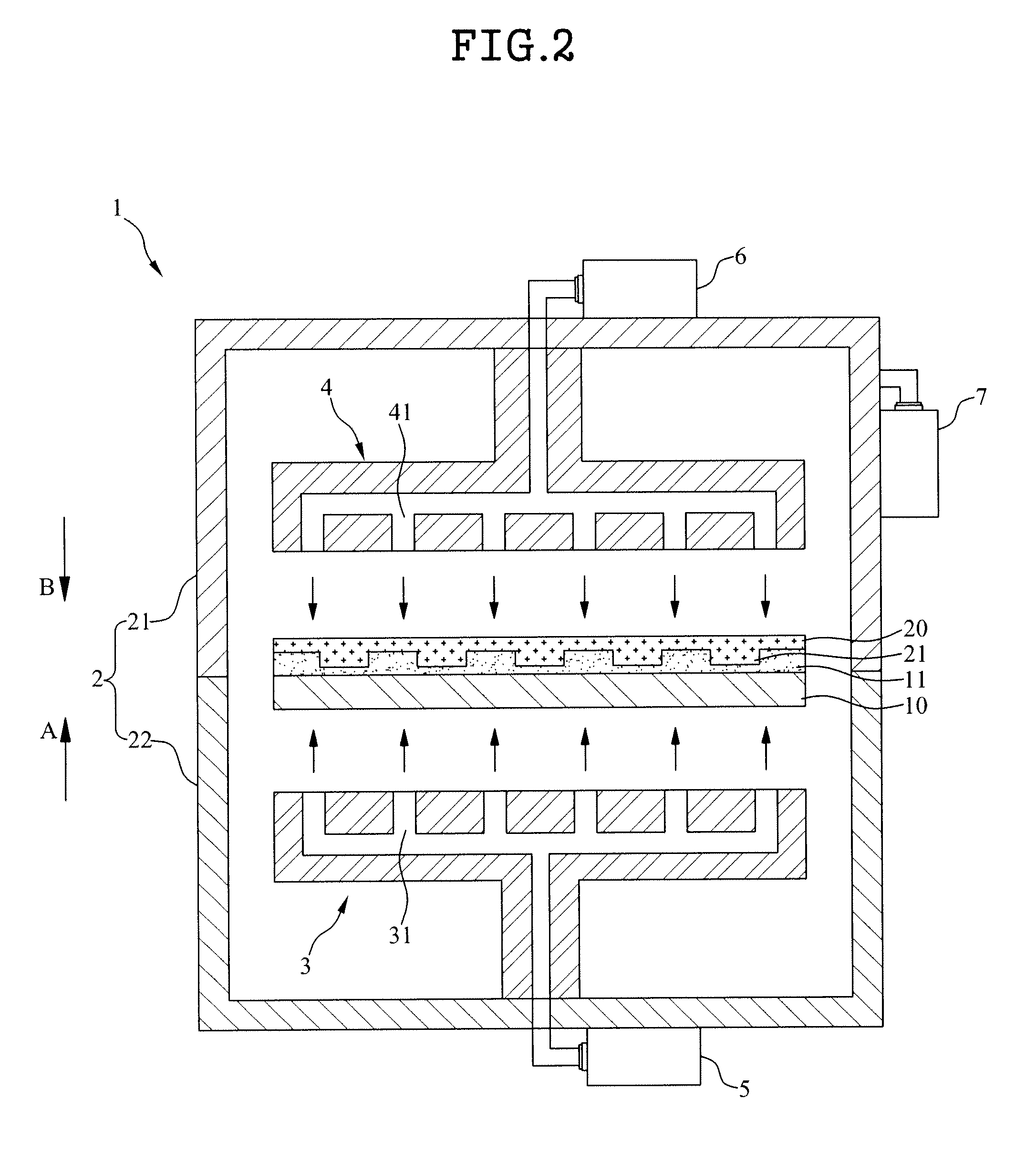

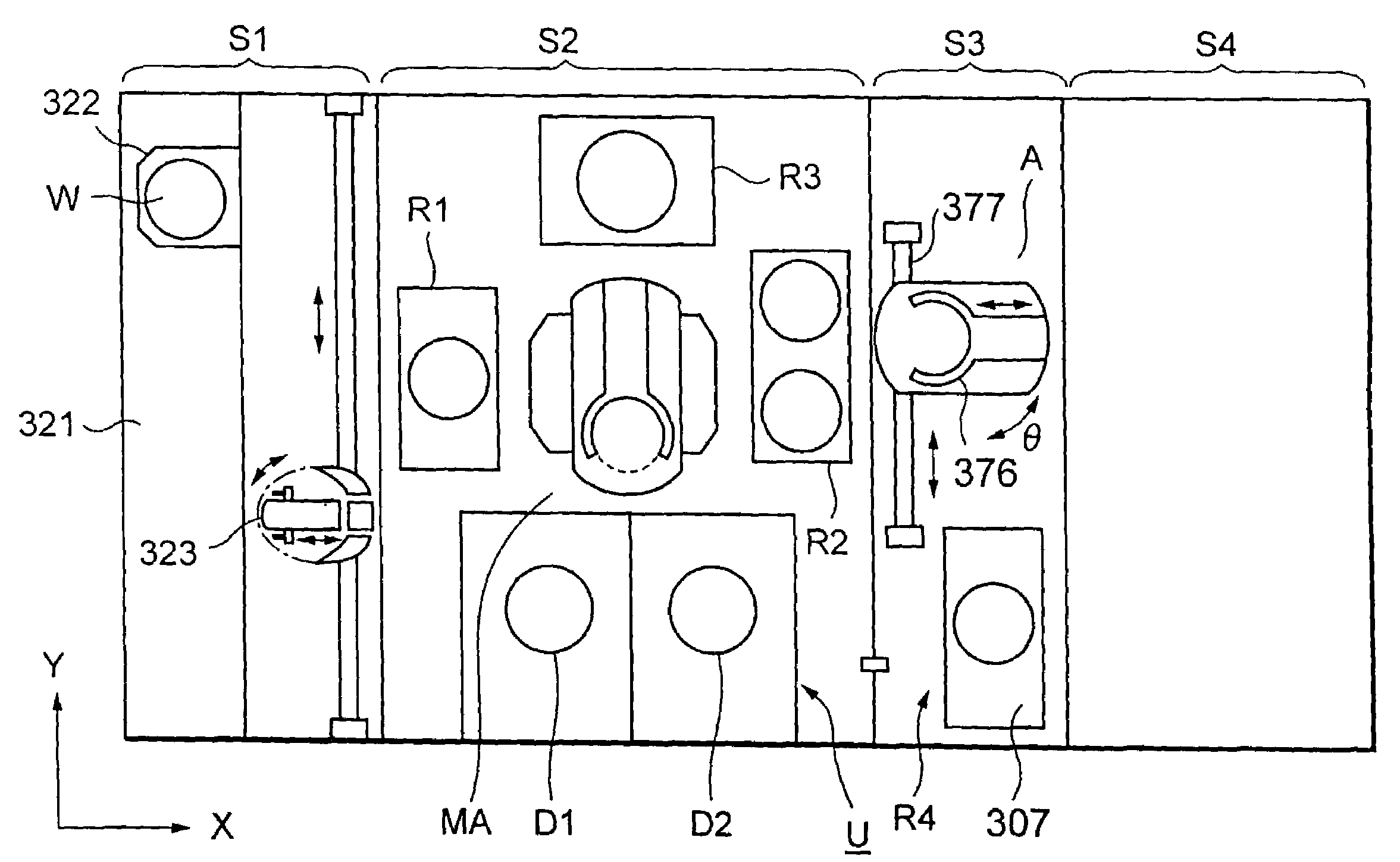

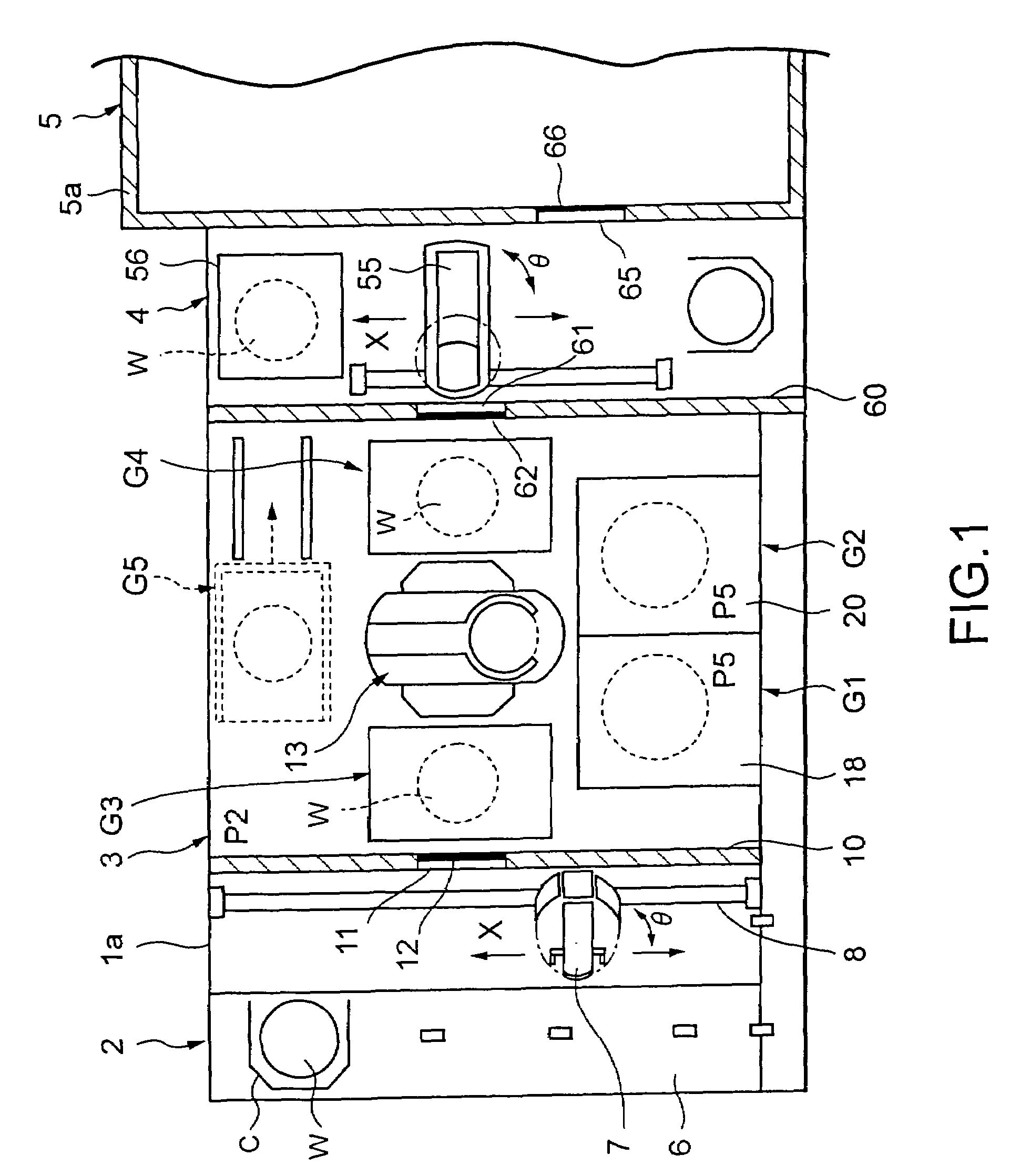

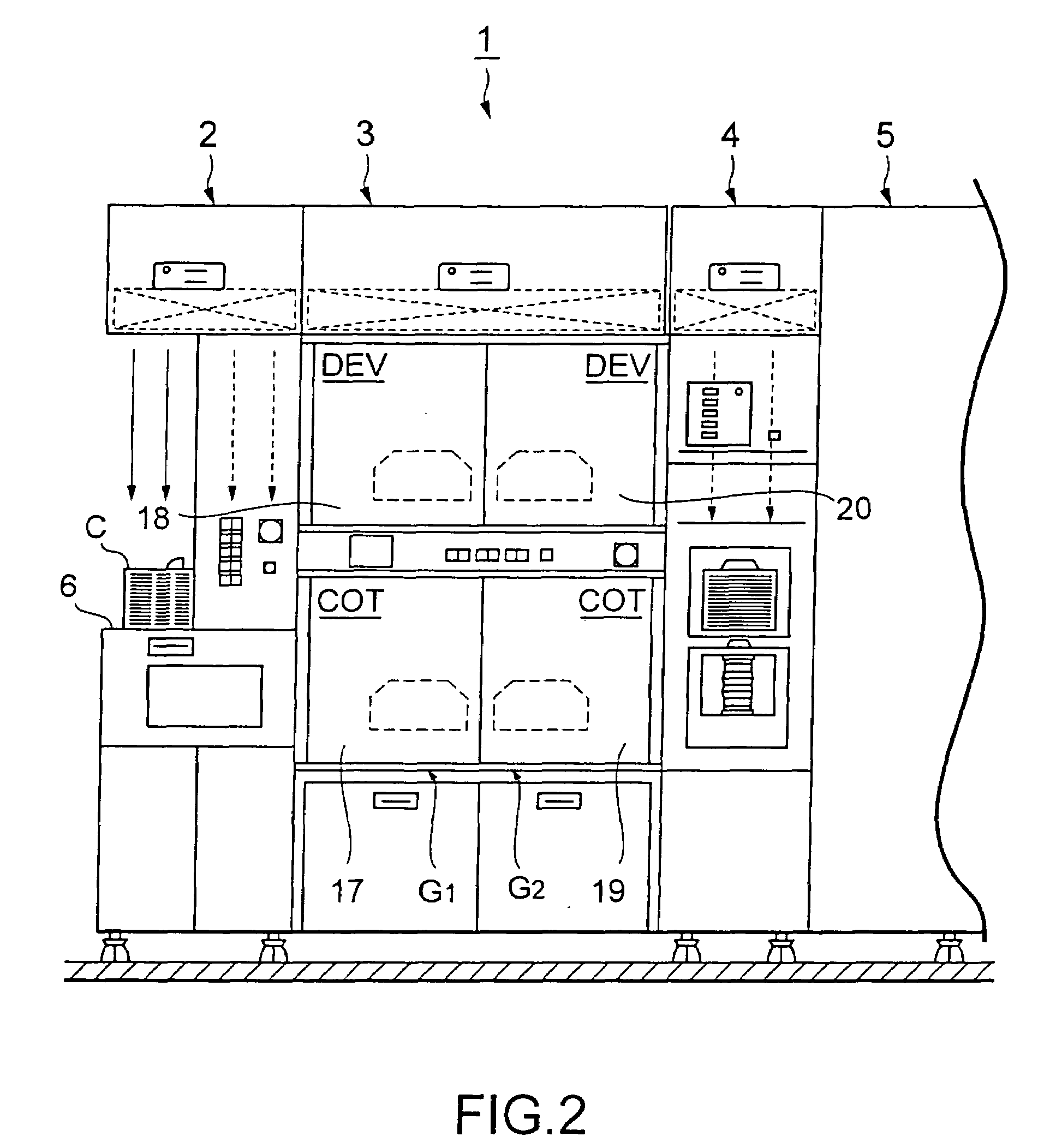

Substrate processing apparatus and substrate processing method

ActiveUS20170213725A1Efficiently formedShort timeSolid-state devicesPretreated surfacesProduct gasEngineering

A substrate processing apparatus comprises: a first solidifier and a second solidifier. The first solidifier solidifies a liquid to be solidified adhering to a front surface of a substrate by supplying a liquid refrigerant to a back surface of the substrate at a first position. The second solidifier solidifies the liquid to be solidified by at least one of a first cooling mechanism and a second cooling mechanism. The first cooling mechanism cools the liquid to be solidified by supplying a gas refrigerant toward the substrate at a second position more distant from a center of rotation of the substrate in a radial direction than the first position. The second cooling mechanism cools the liquid to be solidified by bringing a processing surface into contact with the liquid to be solidified at the second position.

Owner:DAINIPPON SCREEN MTG CO LTD

Imprinting apparatus and imprinting method using the same

InactiveUS20110298159A1Easy to solveTailstocks/centresConfectioneryEngineeringMechanical engineering

Owner:LG DISPLAY CO LTD

Substrate processing apparatus and substrate processing method

InactiveUS7208066B2Avoid levelingLiquid surface applicatorsPhotomechanical apparatusAtmospheric airEngineering

Owner:TOKYO ELECTRON LTD

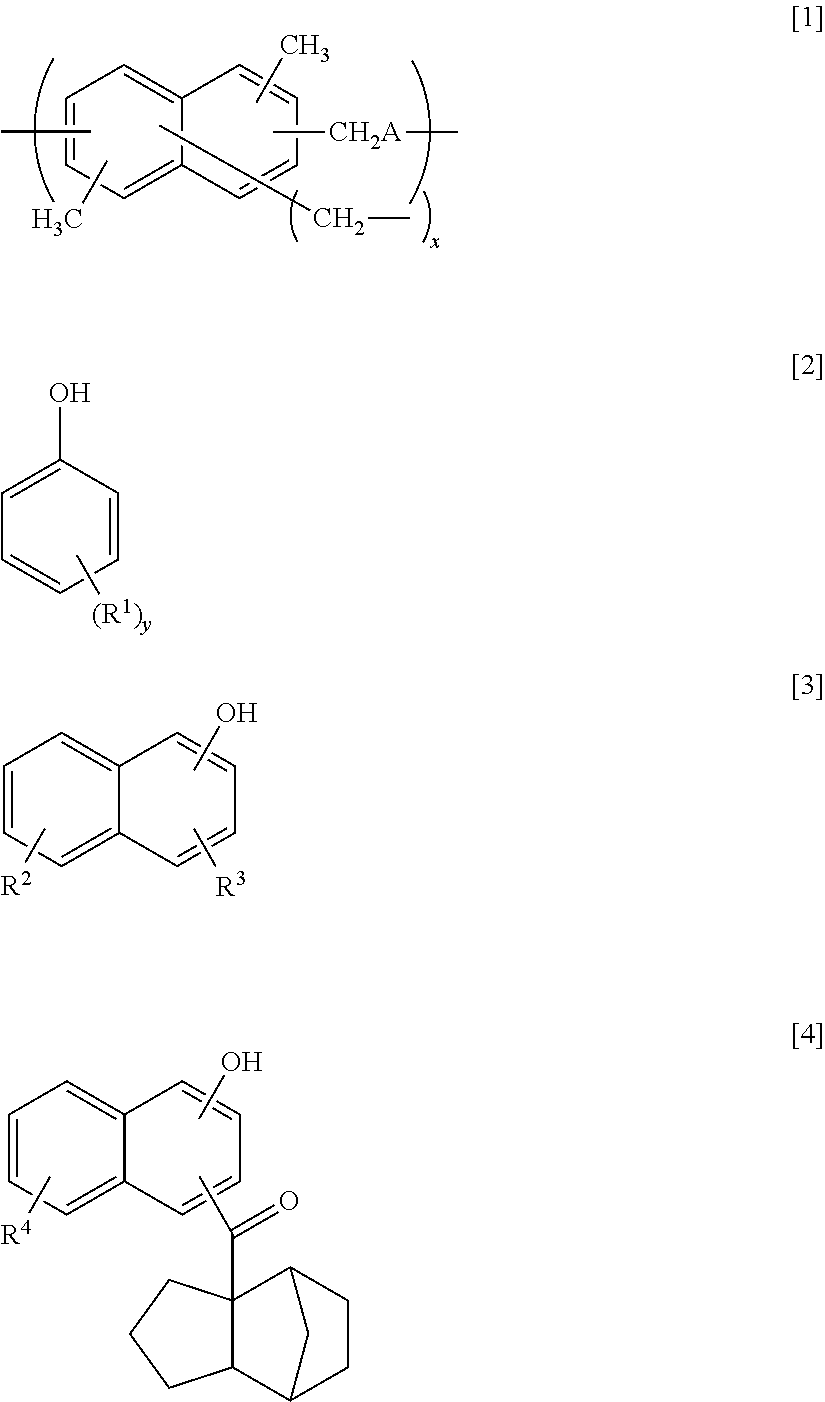

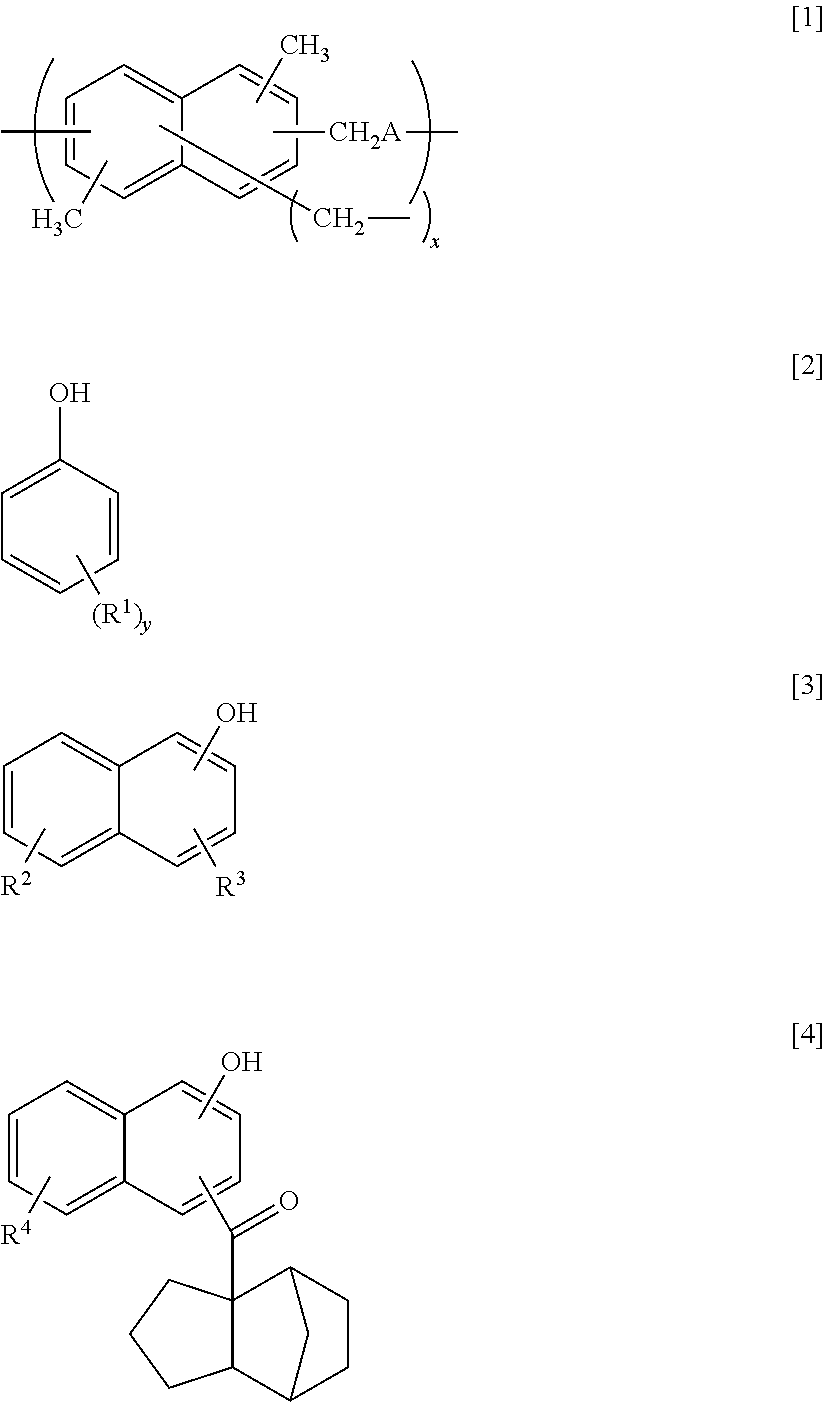

Modified naphthalene formaldehyde resin, tricyclodecane skeleton-containing naphthol compound and ester compound

ActiveUS20110009574A1Improve heat resistancePreparation from carboxylic acid halidesOrganic compound preparationFiberResist

Owner:MITSUBISHI GAS CHEM CO INC

Method for reactive ion beam etching of blazed convex grating

Owner:UNIV OF SHANGHAI FOR SCI & TECH

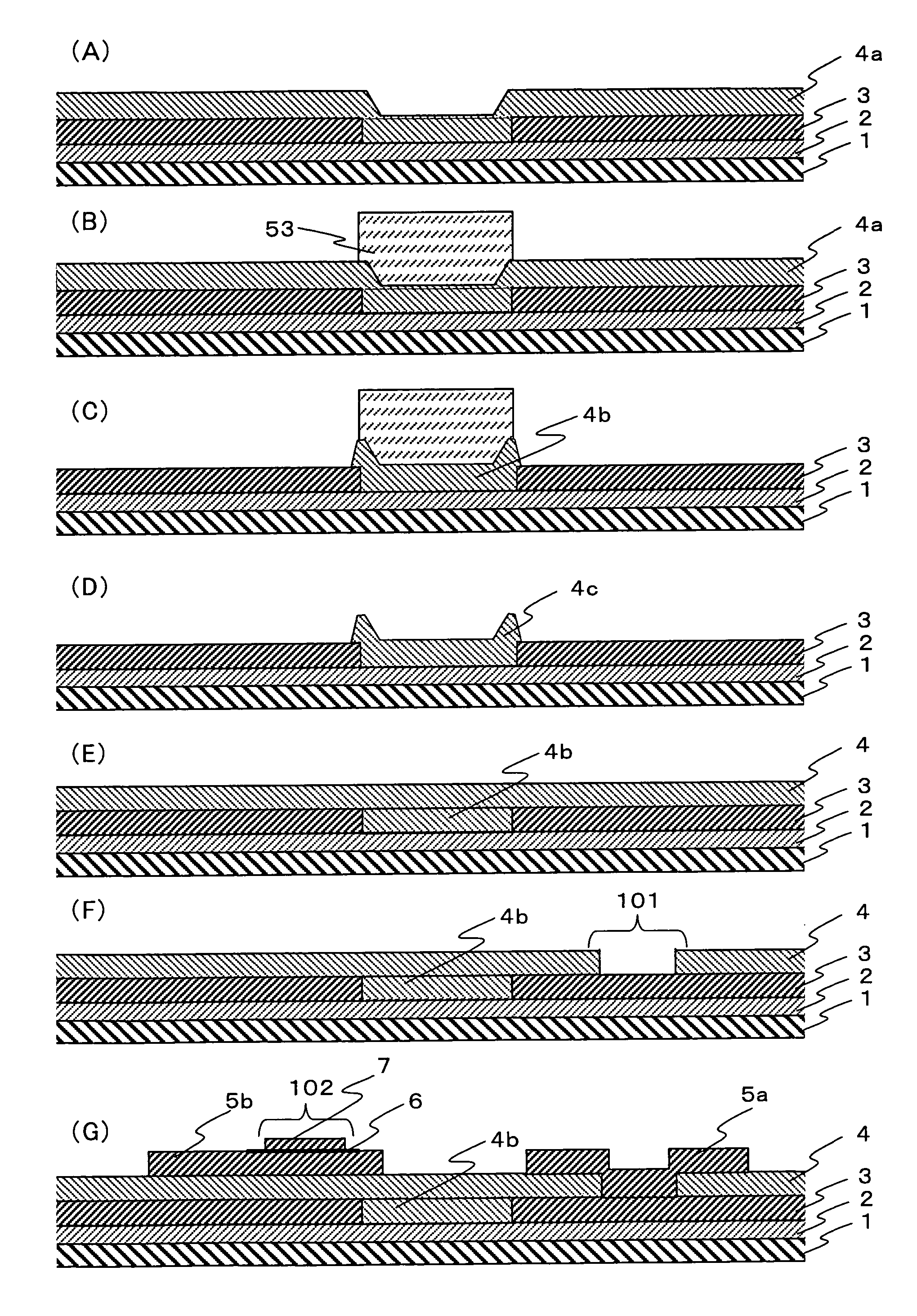

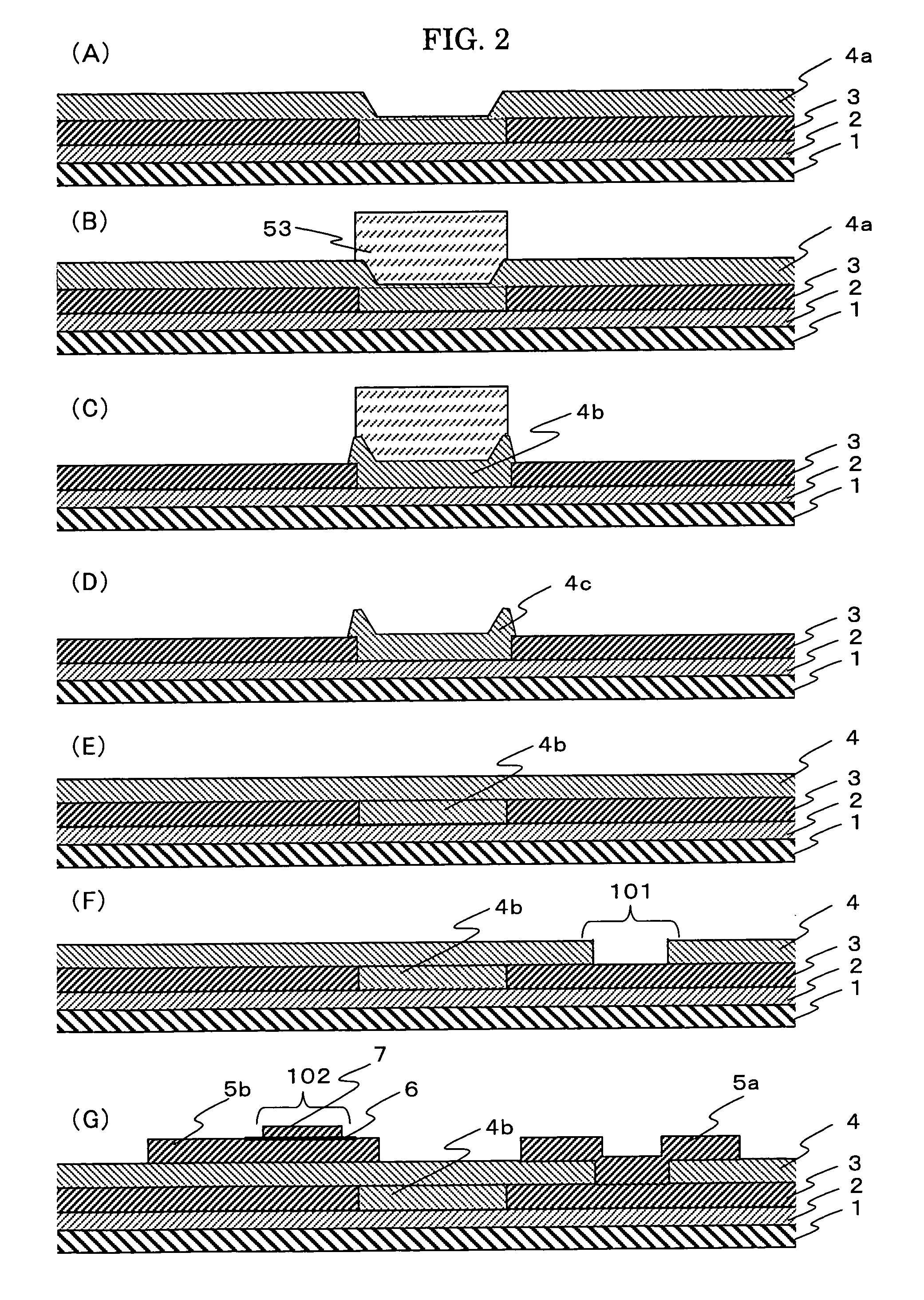

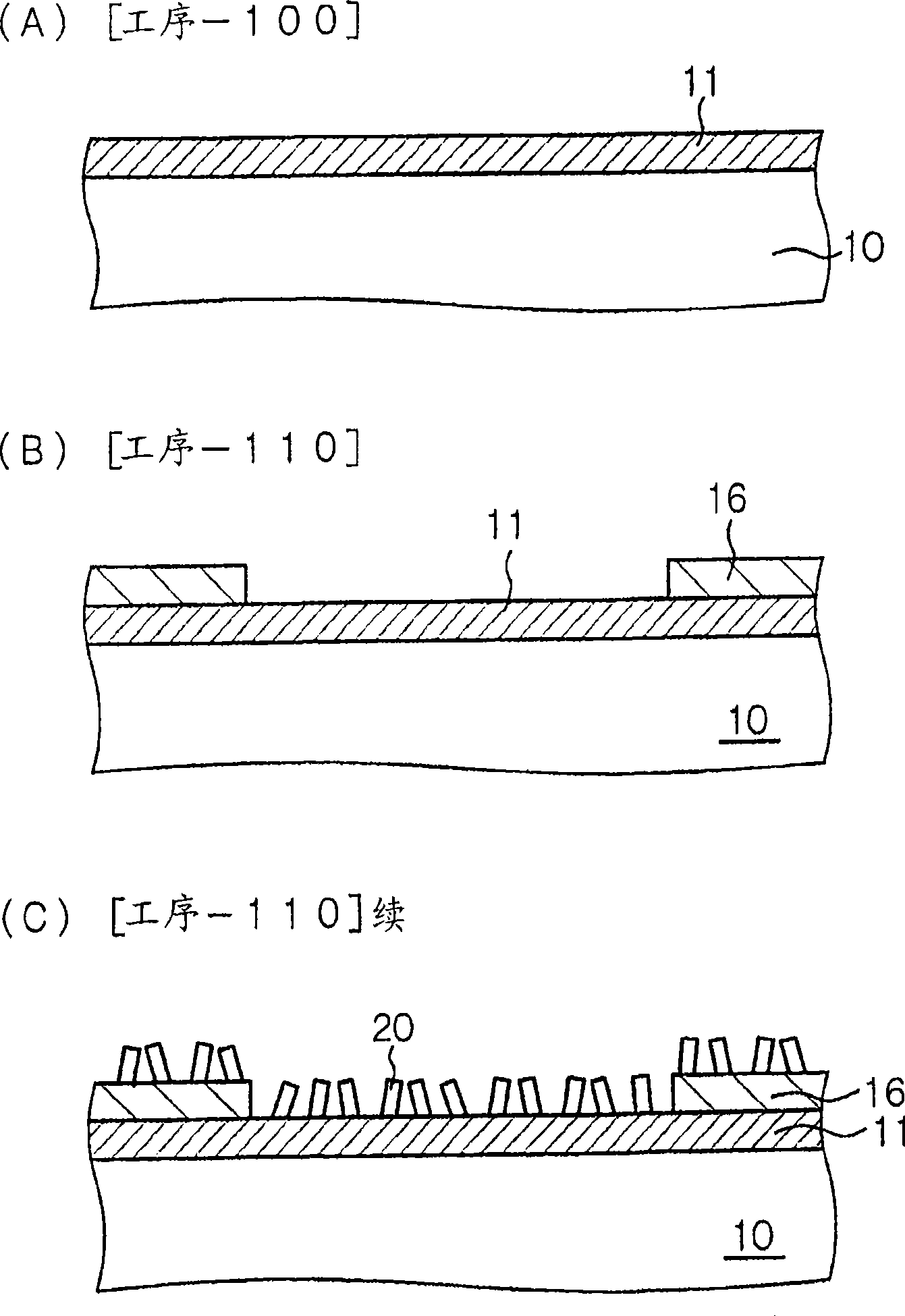

Manufacturing method for electronic device and multiple layer circuits thereof

InactiveUS7081417B2Large process marginRemarkable effectDecorative surface effectsSolid-state devicesInsulation layerMultiple layer

Owner:HITACHI LTD +2

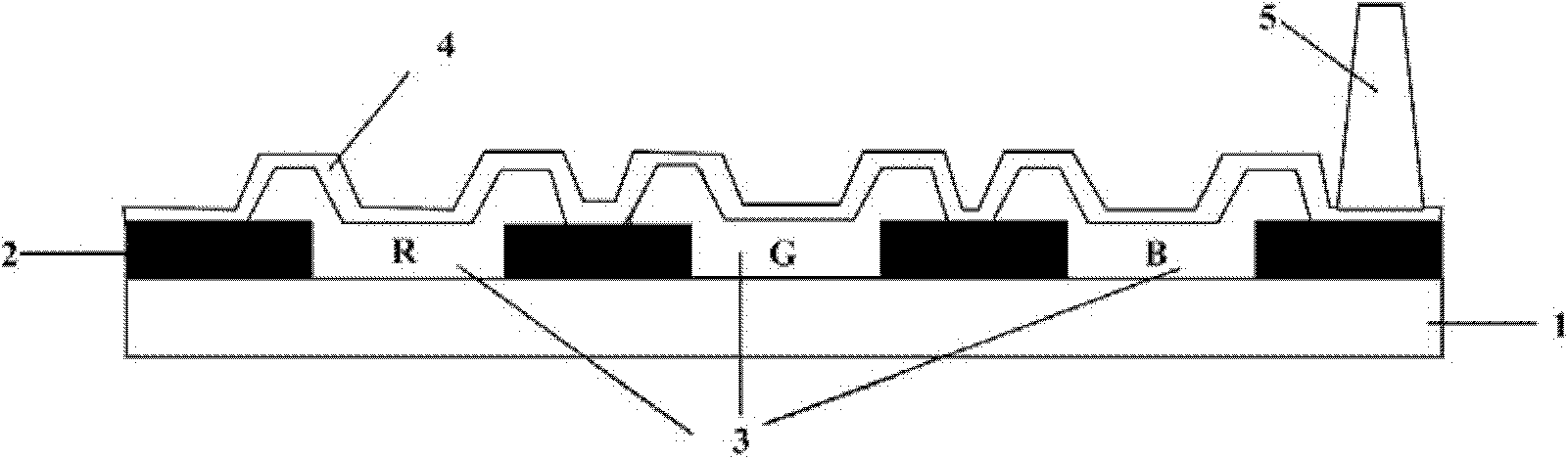

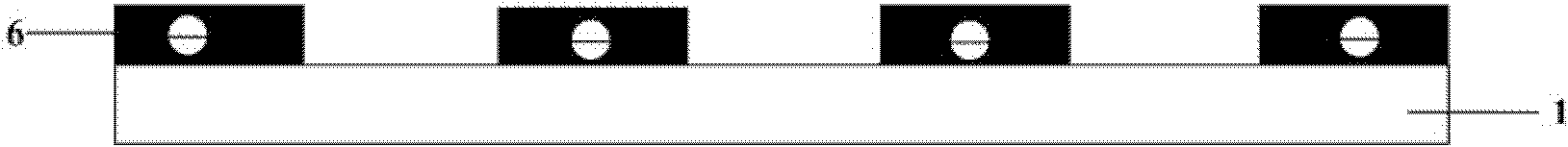

Color filter and manufacturing method thereof

InactiveCN102654592AFit tightlySimple structureOptical filtersPhotomechanical apparatusBlack matrixMaterials science

Owner:BOE TECH GRP CO LTD

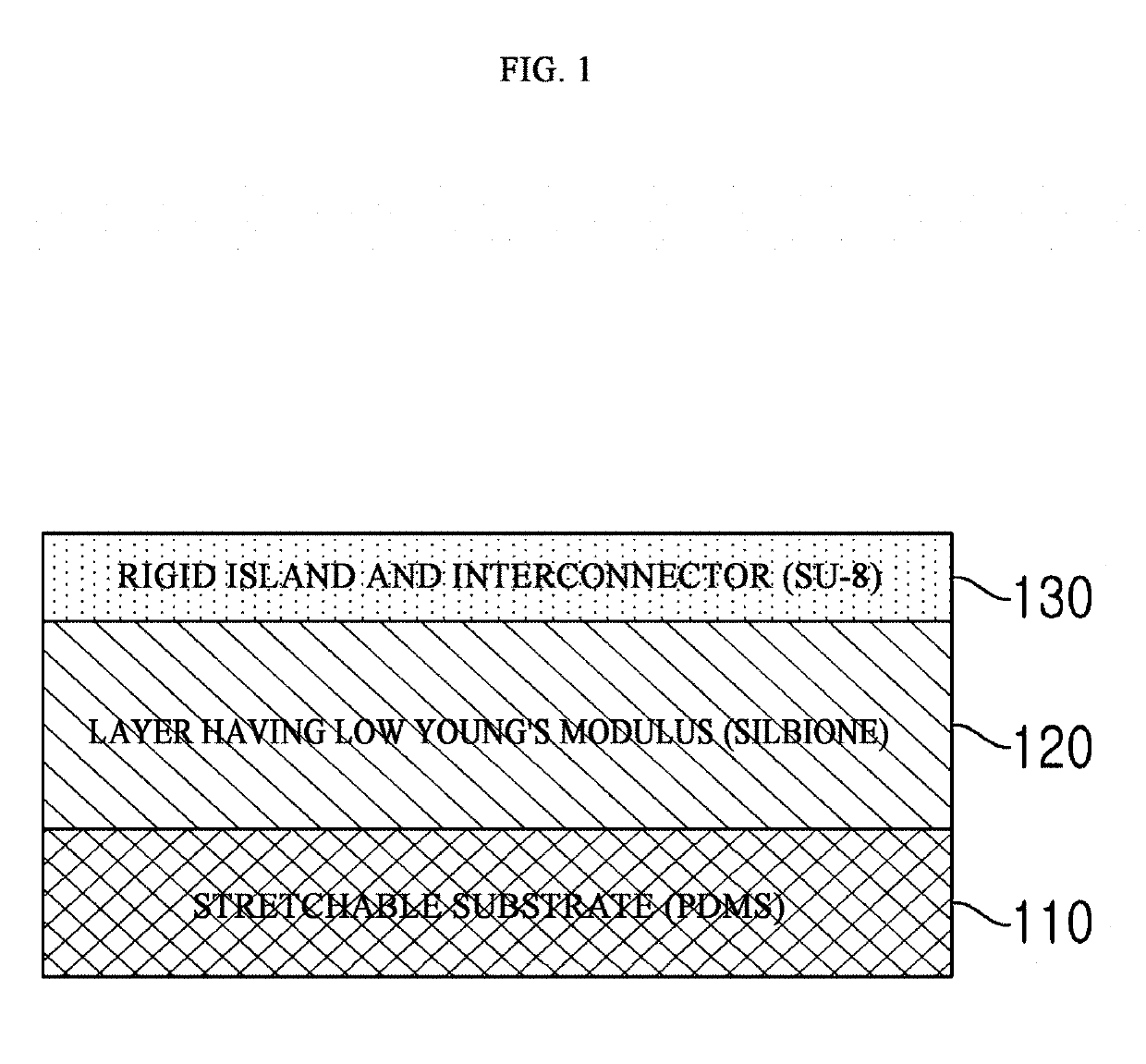

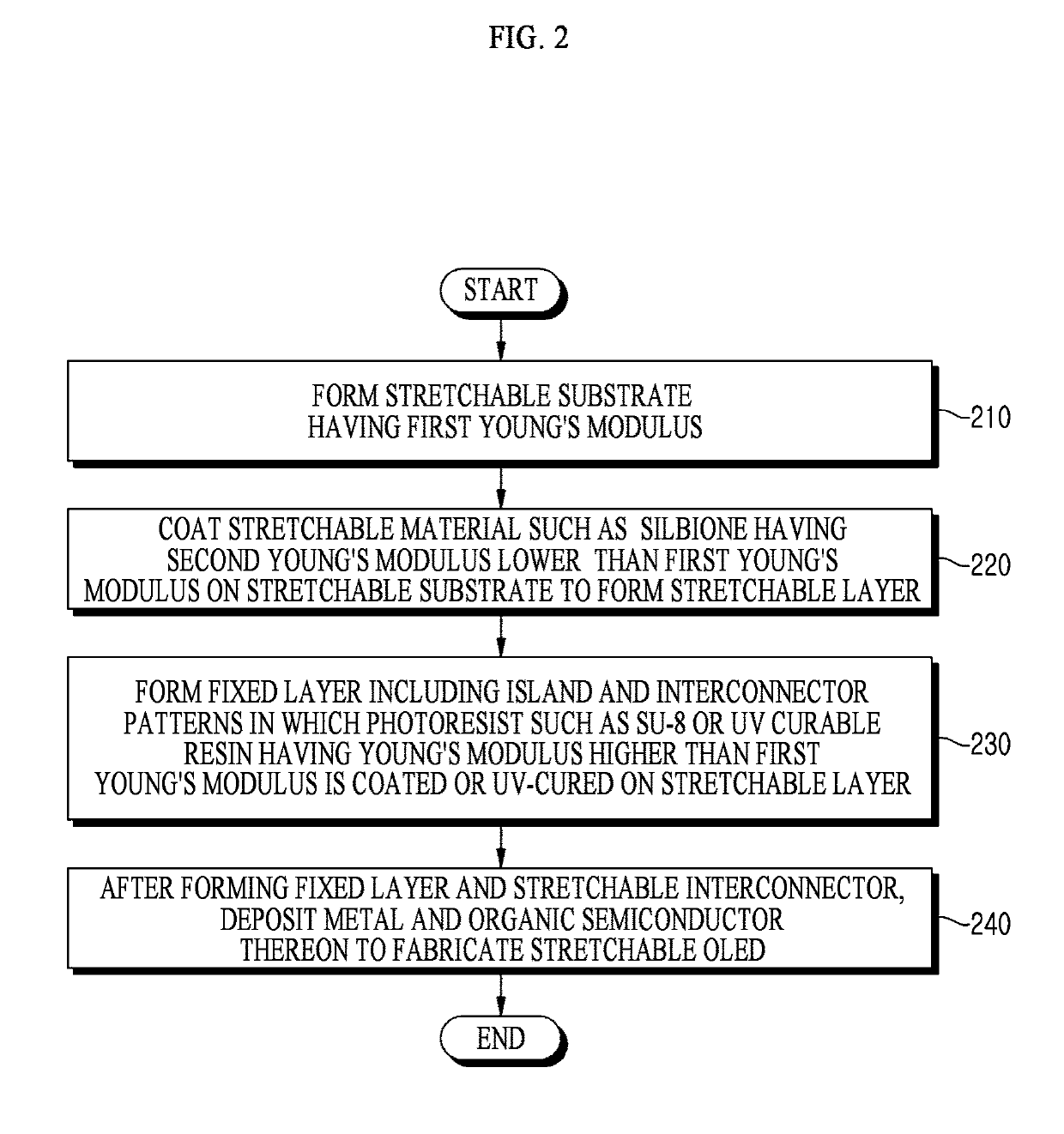

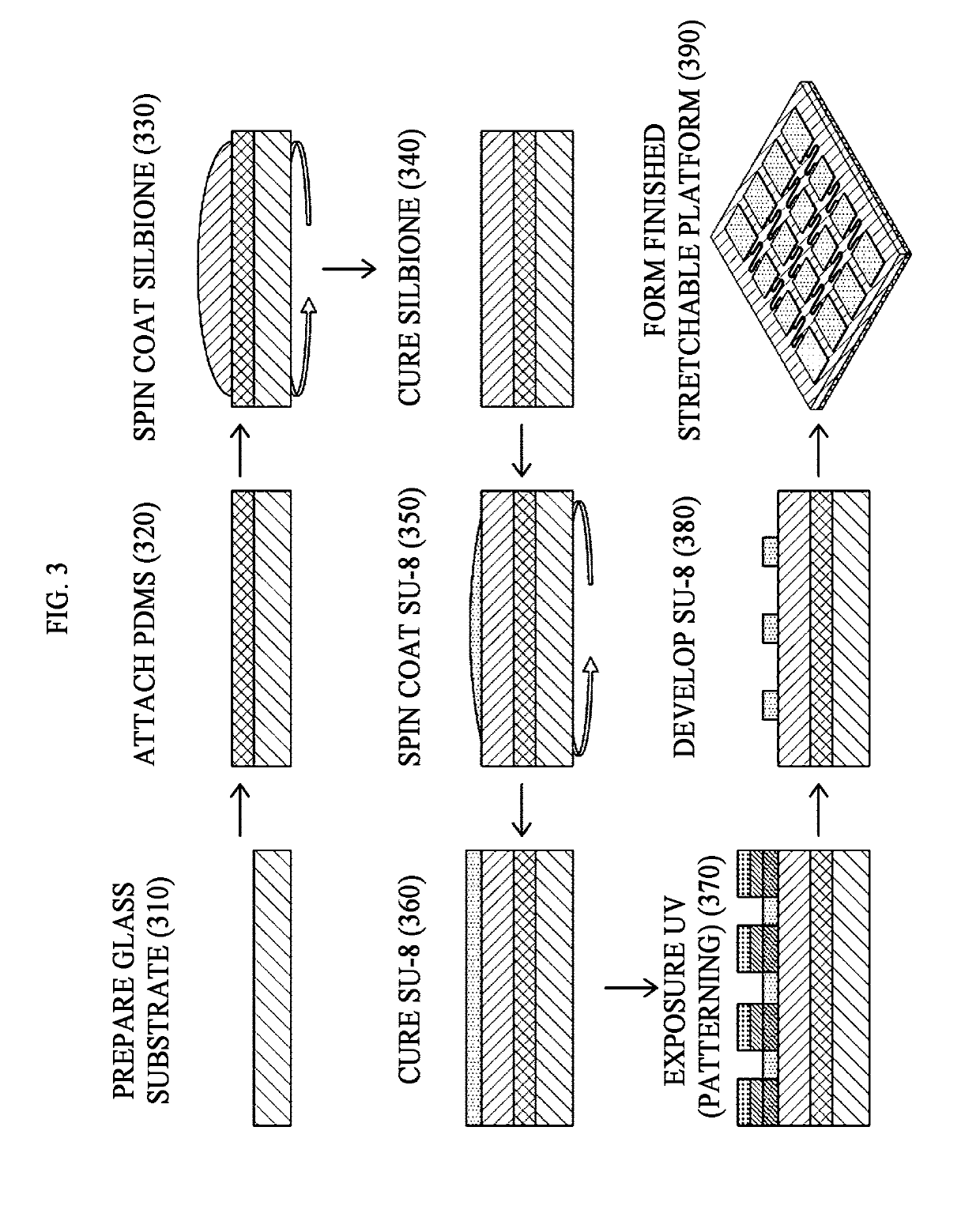

Method of fabricating rigid island pattern on stretchable layer with low young's modulus and stretchable electronic device platform using the same

ActiveUS20190305233A1Simplify the manufacturing processEnsuring stretchabilityCircuit bendability/stretchabilityFinal product manufactureStretchable electronicsResist

Owner:KOREA ADVANCED INST OF SCI & TECH

System for detecting motion of a body

InactiveCN101268337AReduce usageConvenient to accommodatePhotomechanical apparatusConverting sensor output opticallyGratingClassical mechanics

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

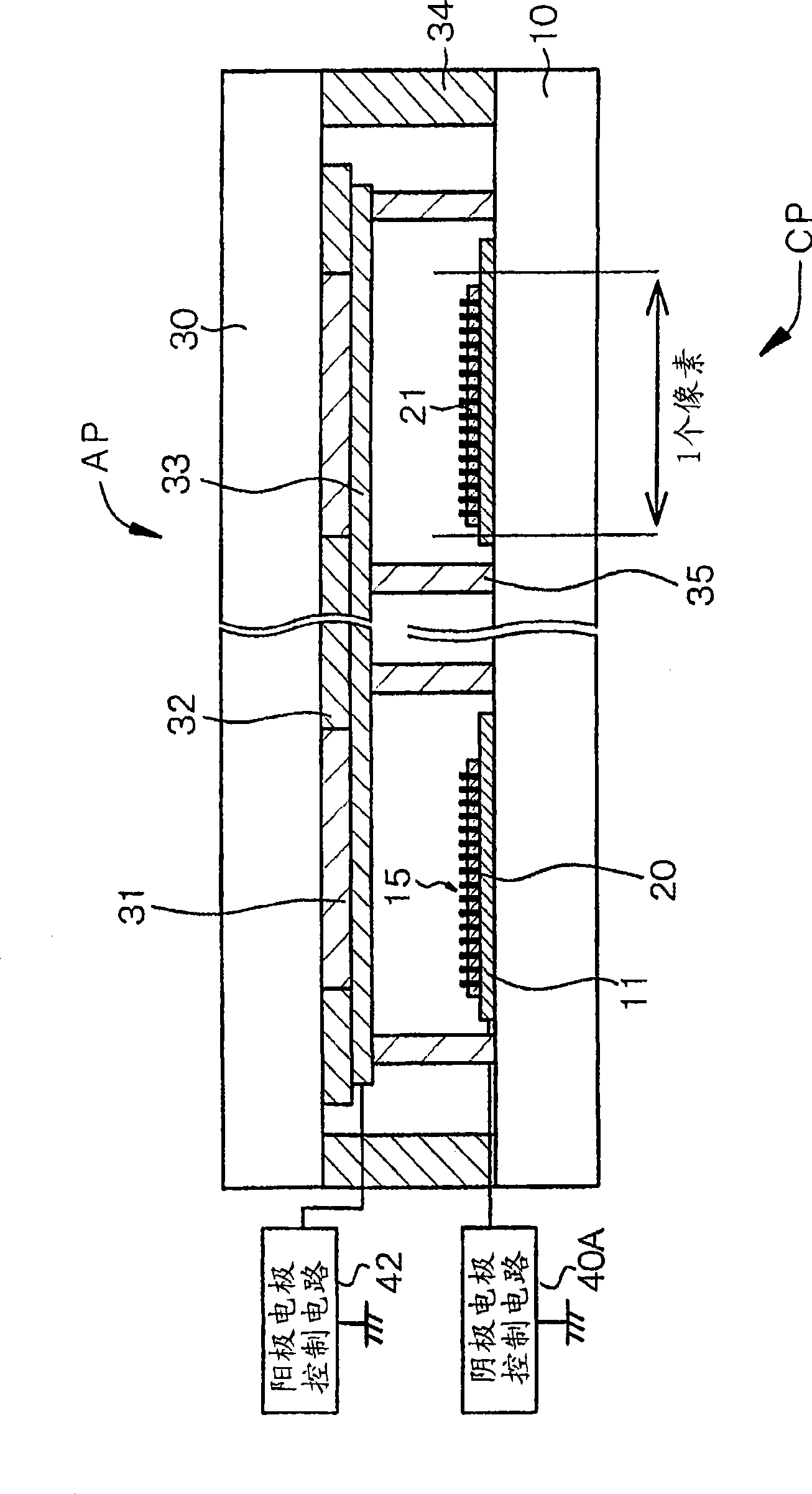

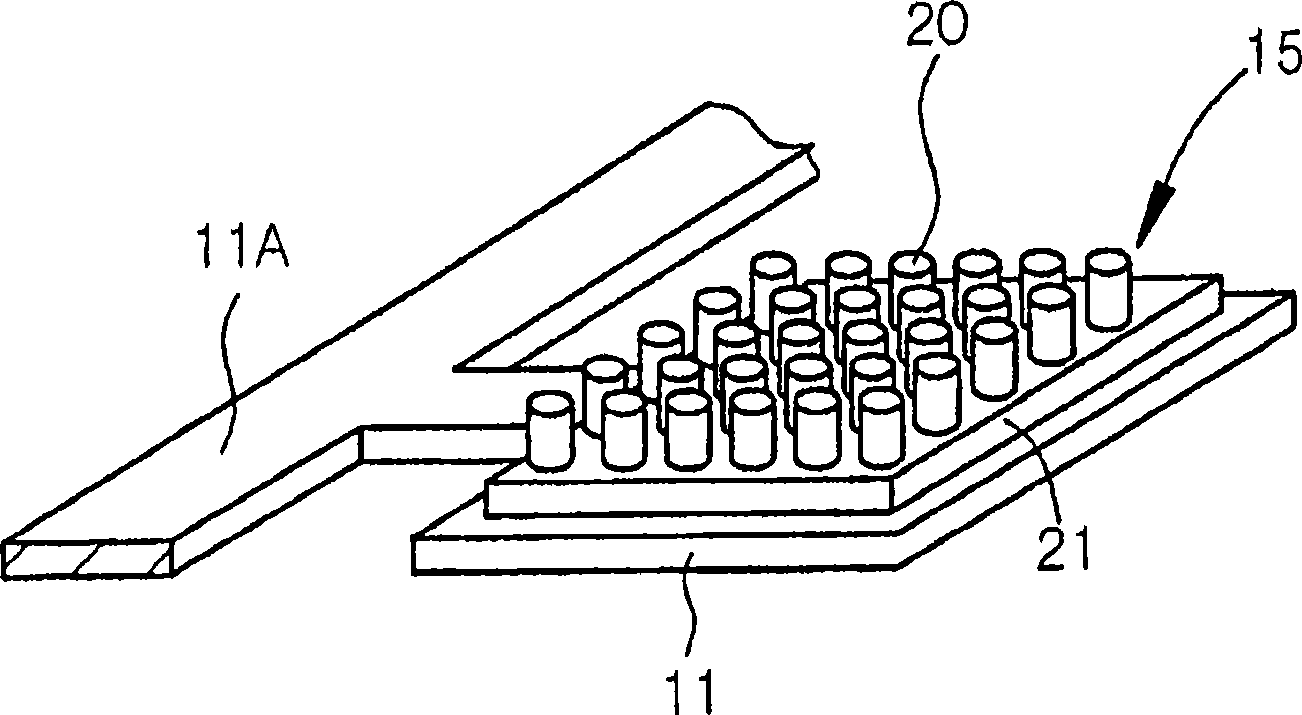

Electron emitter, cold-cathode field electron emitter, and method for manufacturing cold-cathode field electron emission display

Owner:SONY CORP

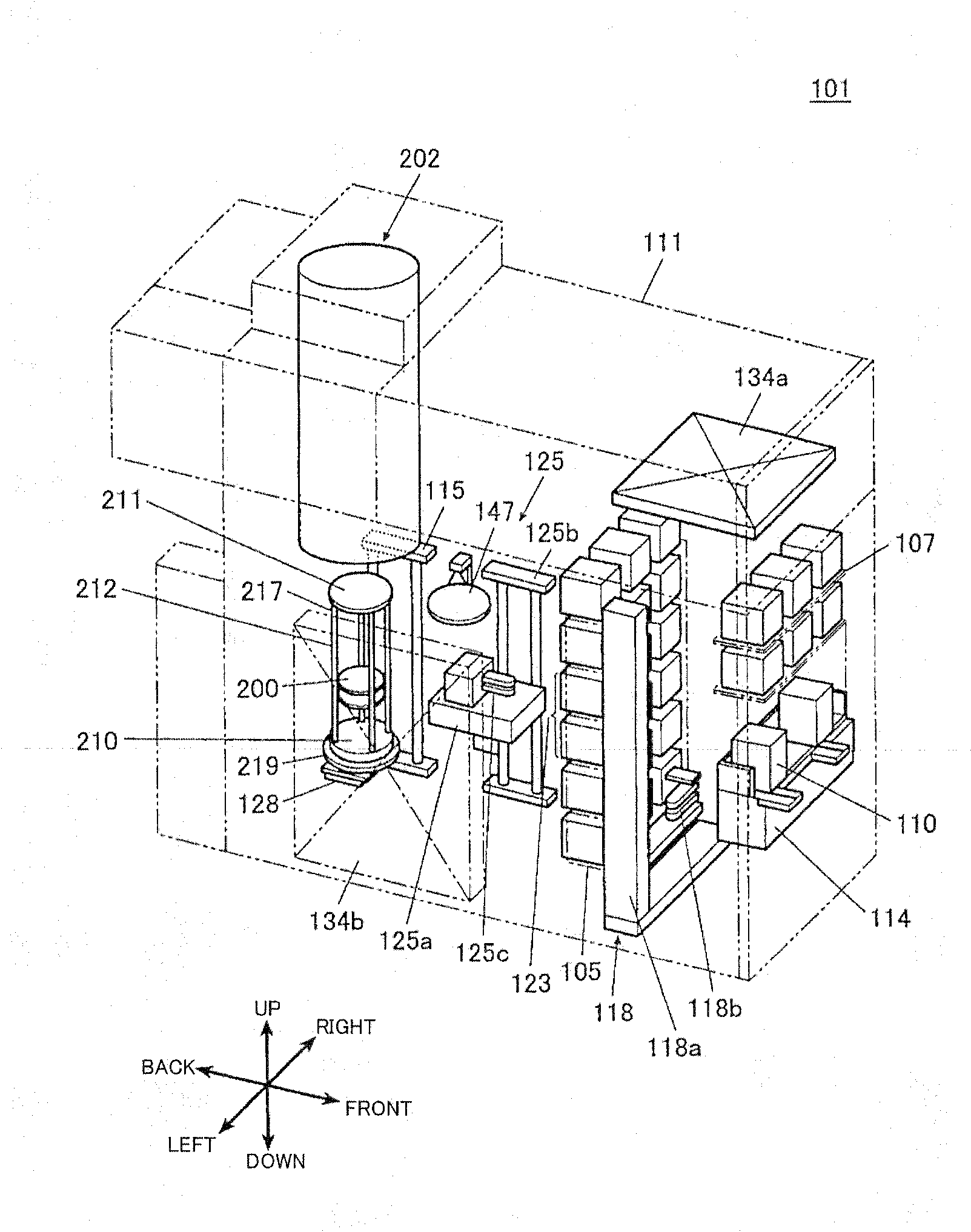

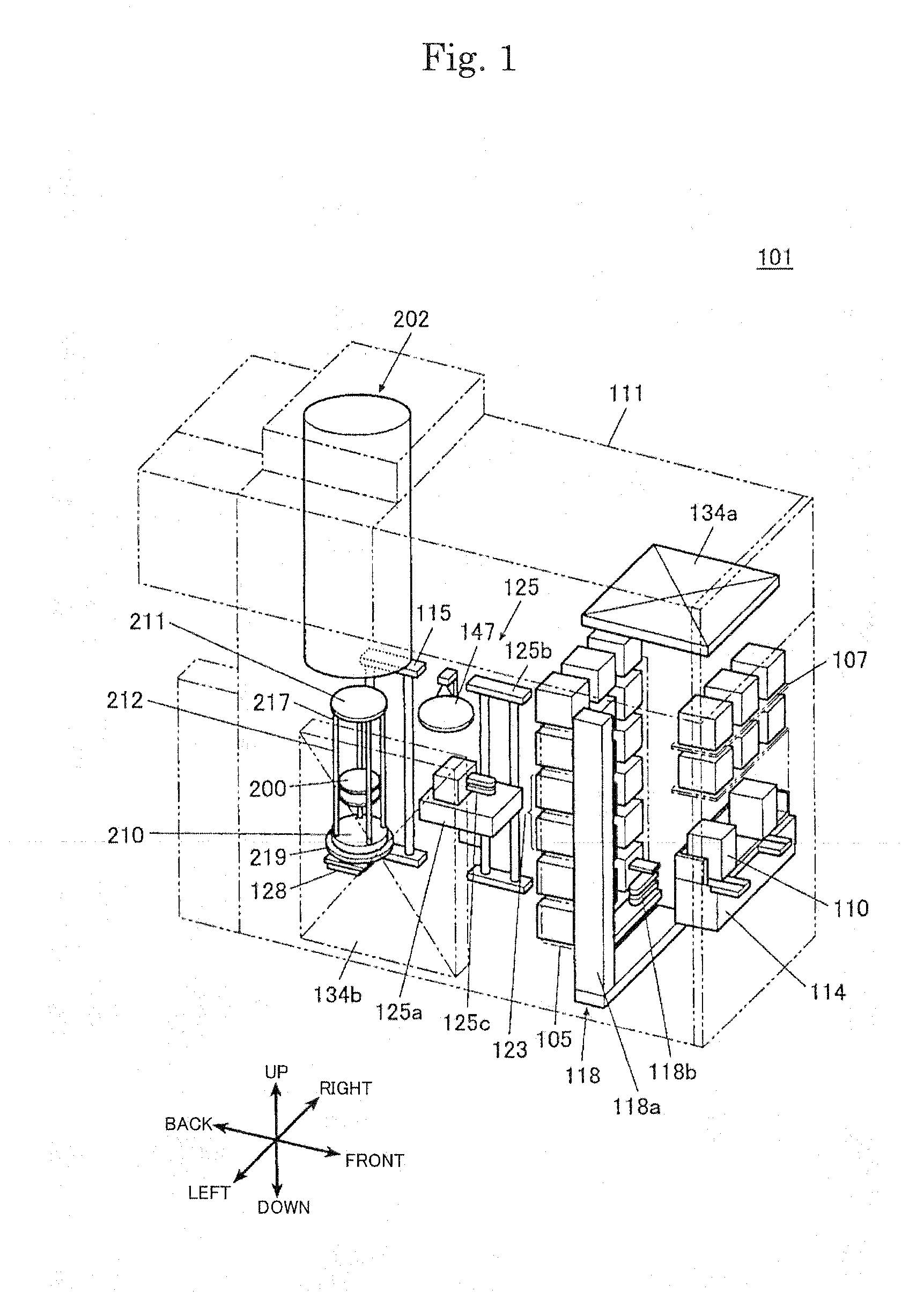

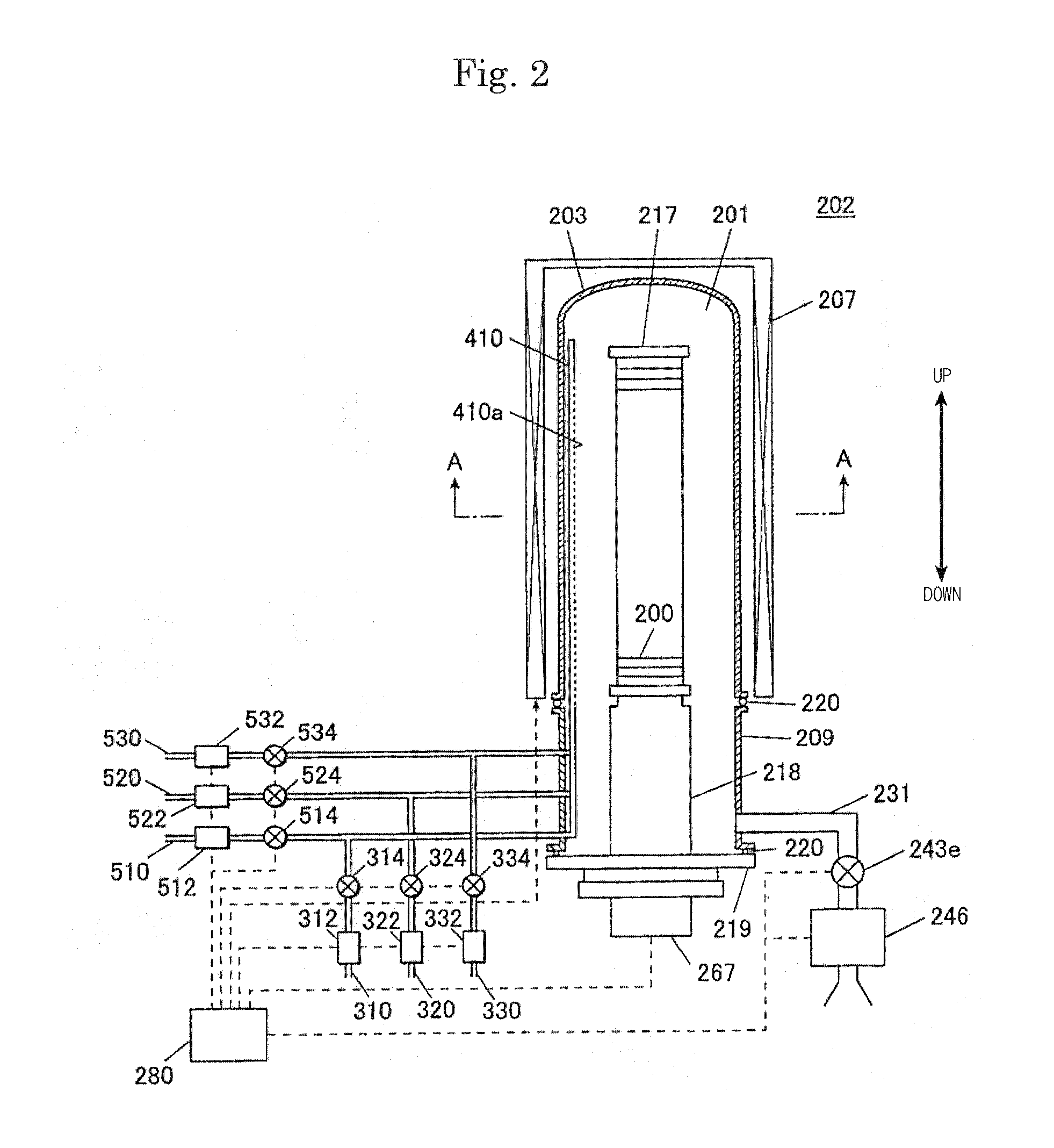

Semiconductor manufacturing apparatus

InactiveUS20090277382A1Maintain stabilityLiquid surface applicatorsPhotomechanical apparatusEngineeringPhotoresist

Owner:KOKUSA ELECTRIC CO LTD

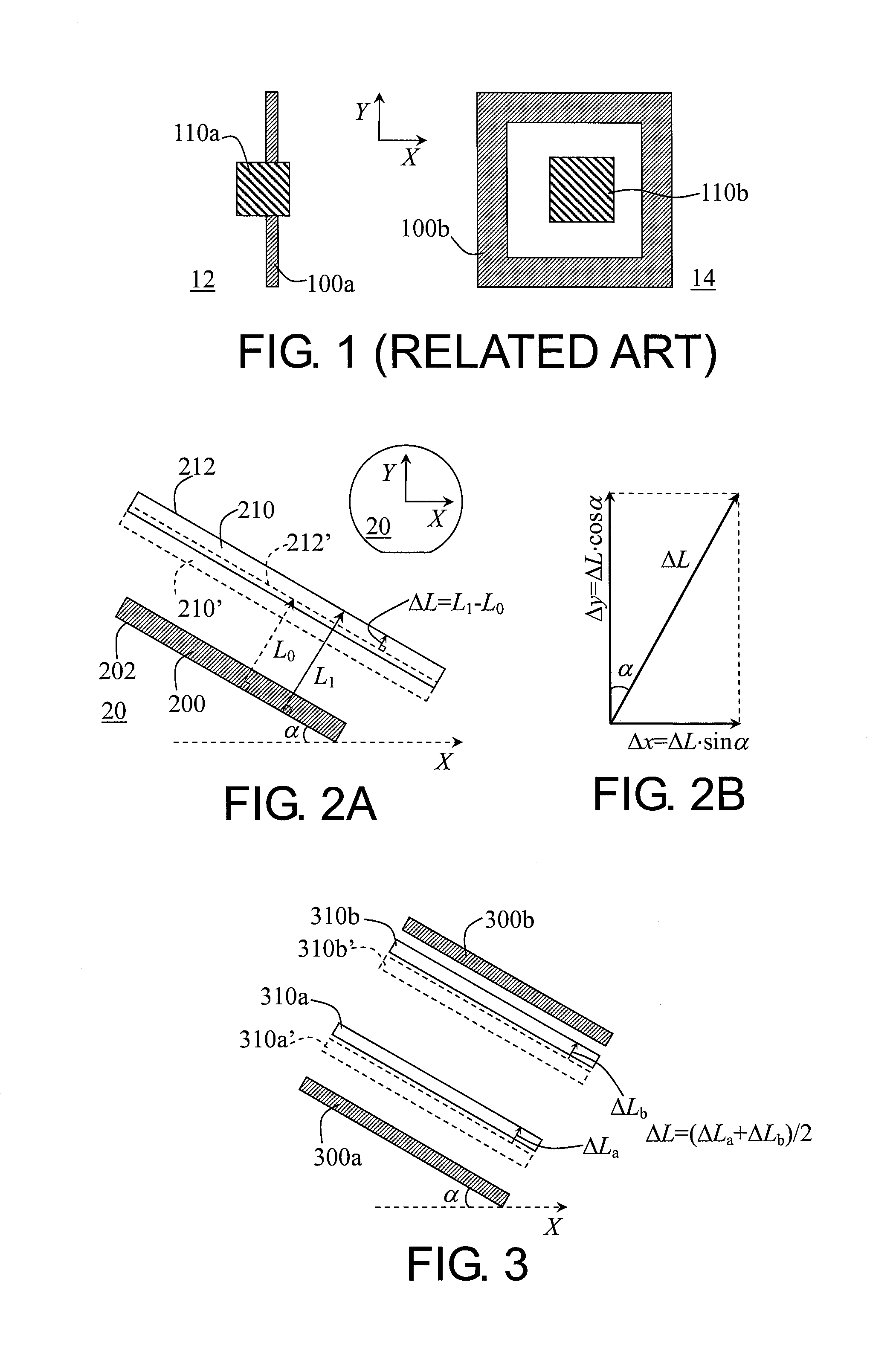

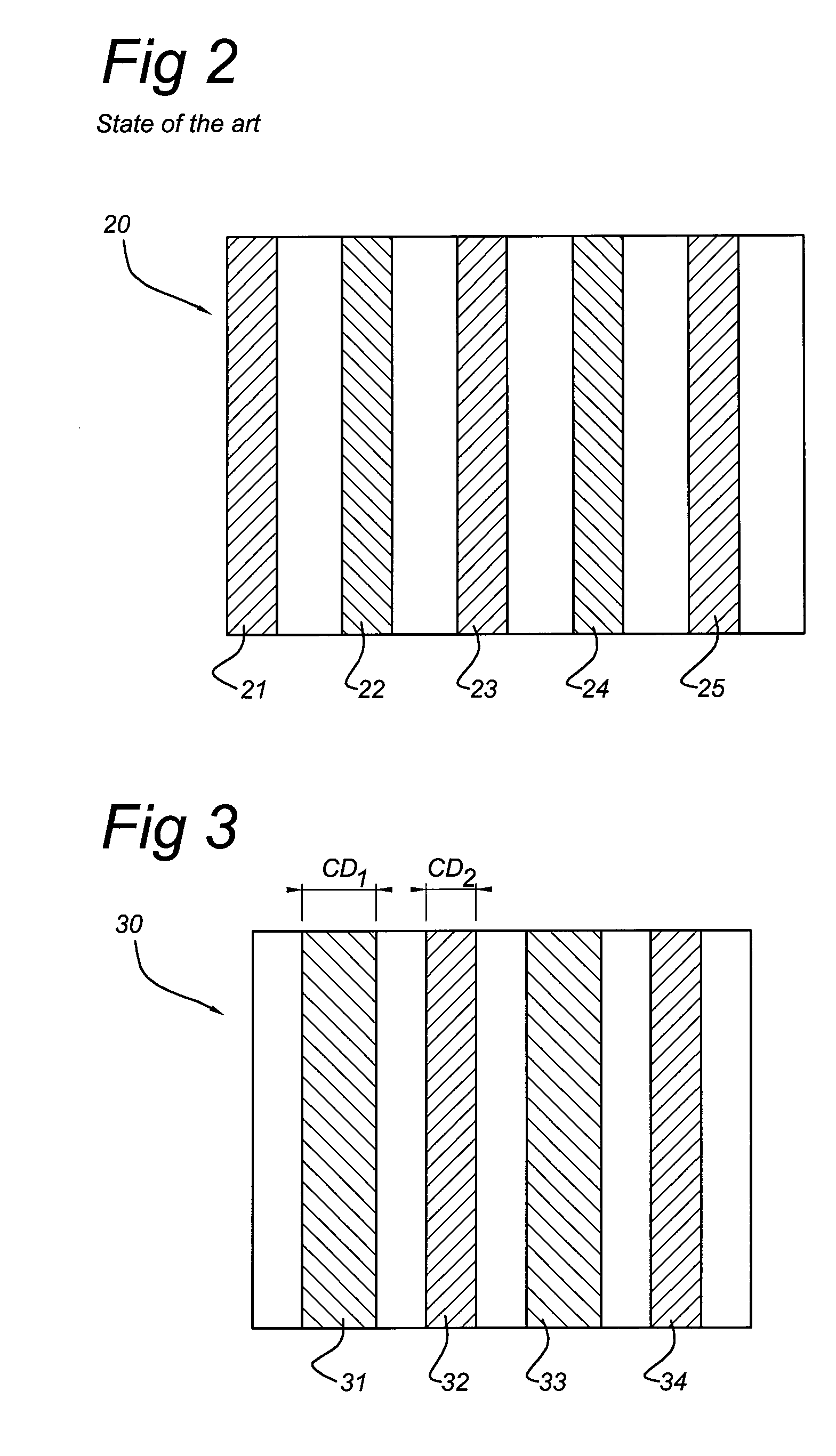

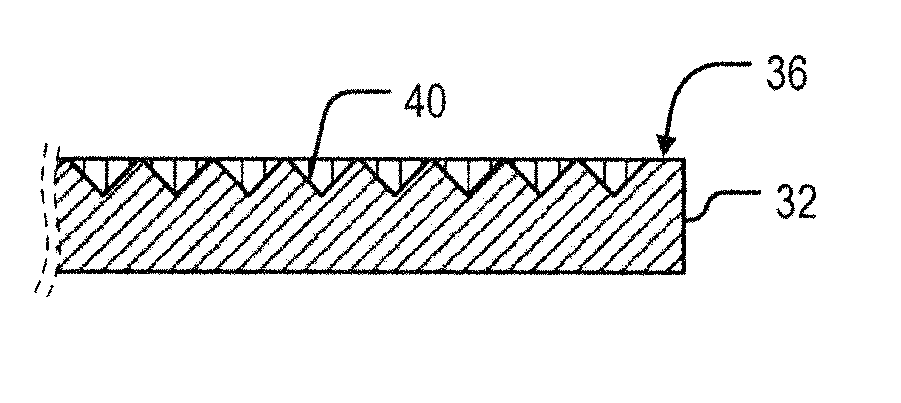

Overlay Measurement on Double Patterning Substrate

InactiveUS20090100391A1Improve reliabilityDetecting faulty computer hardwarePhotomechanical apparatusMeasurement pointPhysics

Owner:ASML NETHERLANDS BV

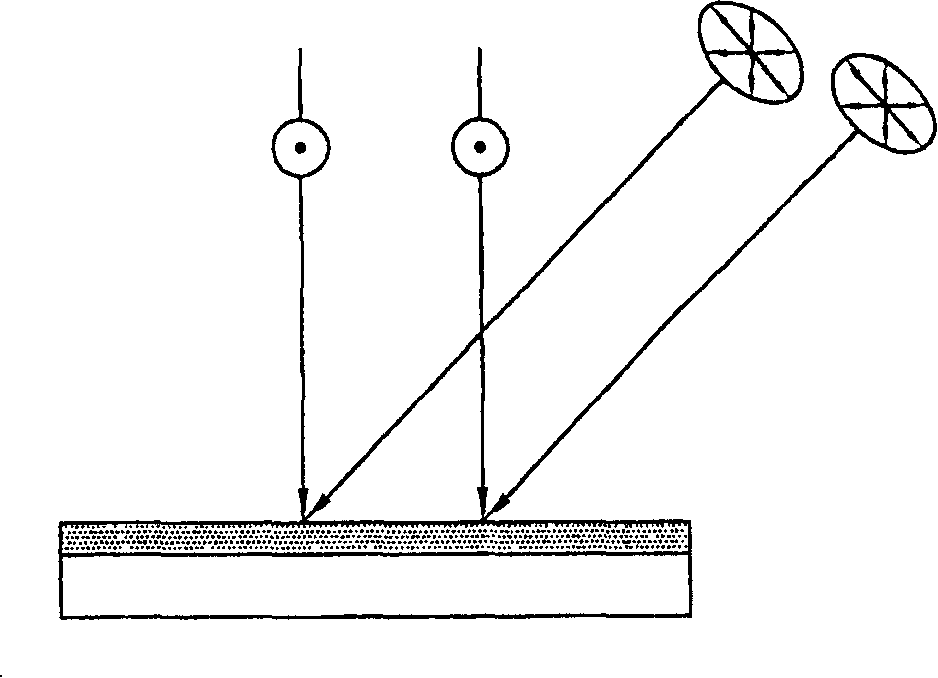

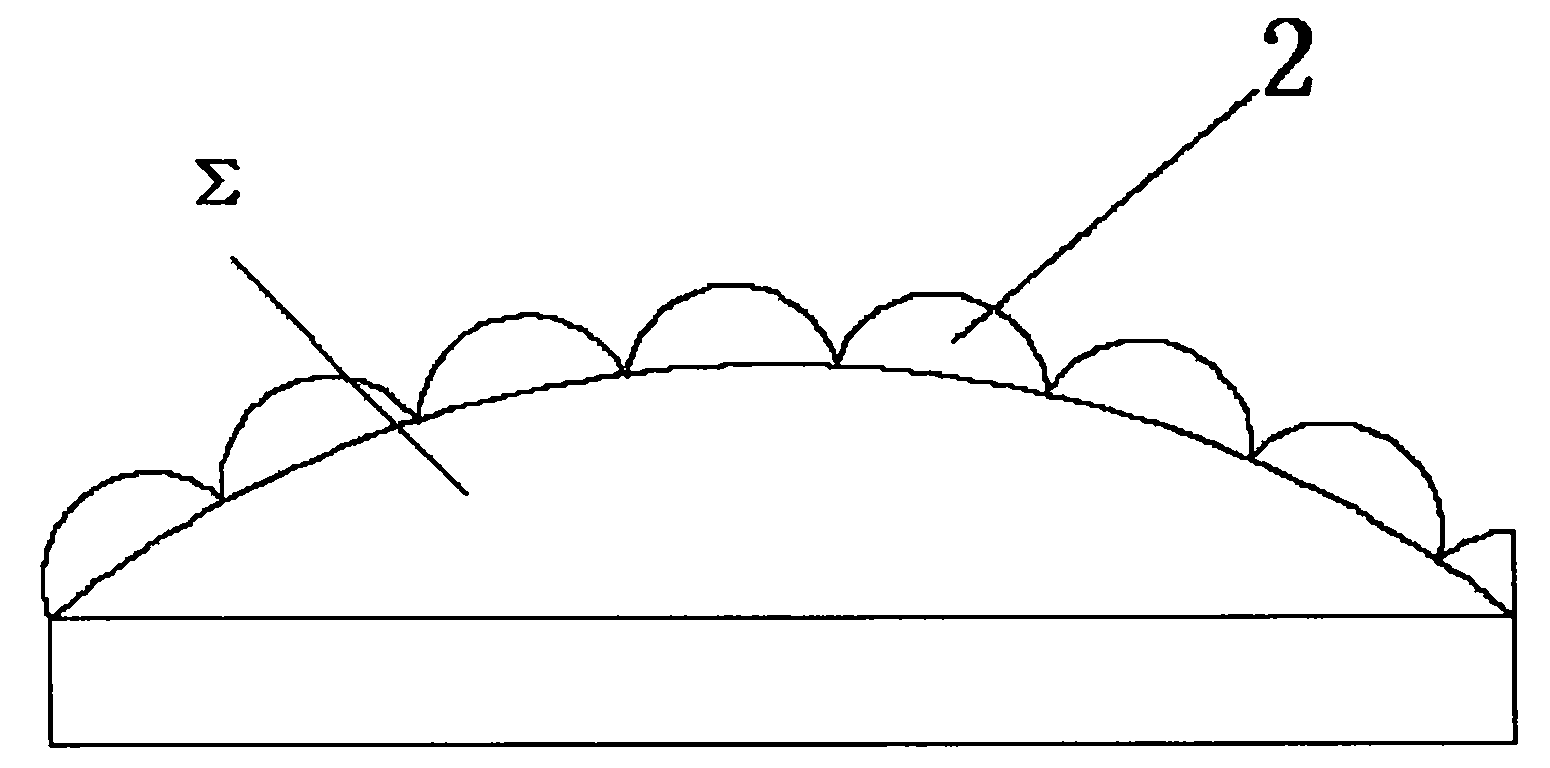

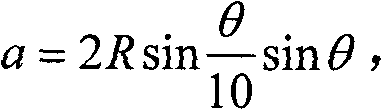

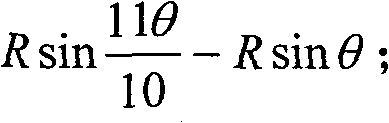

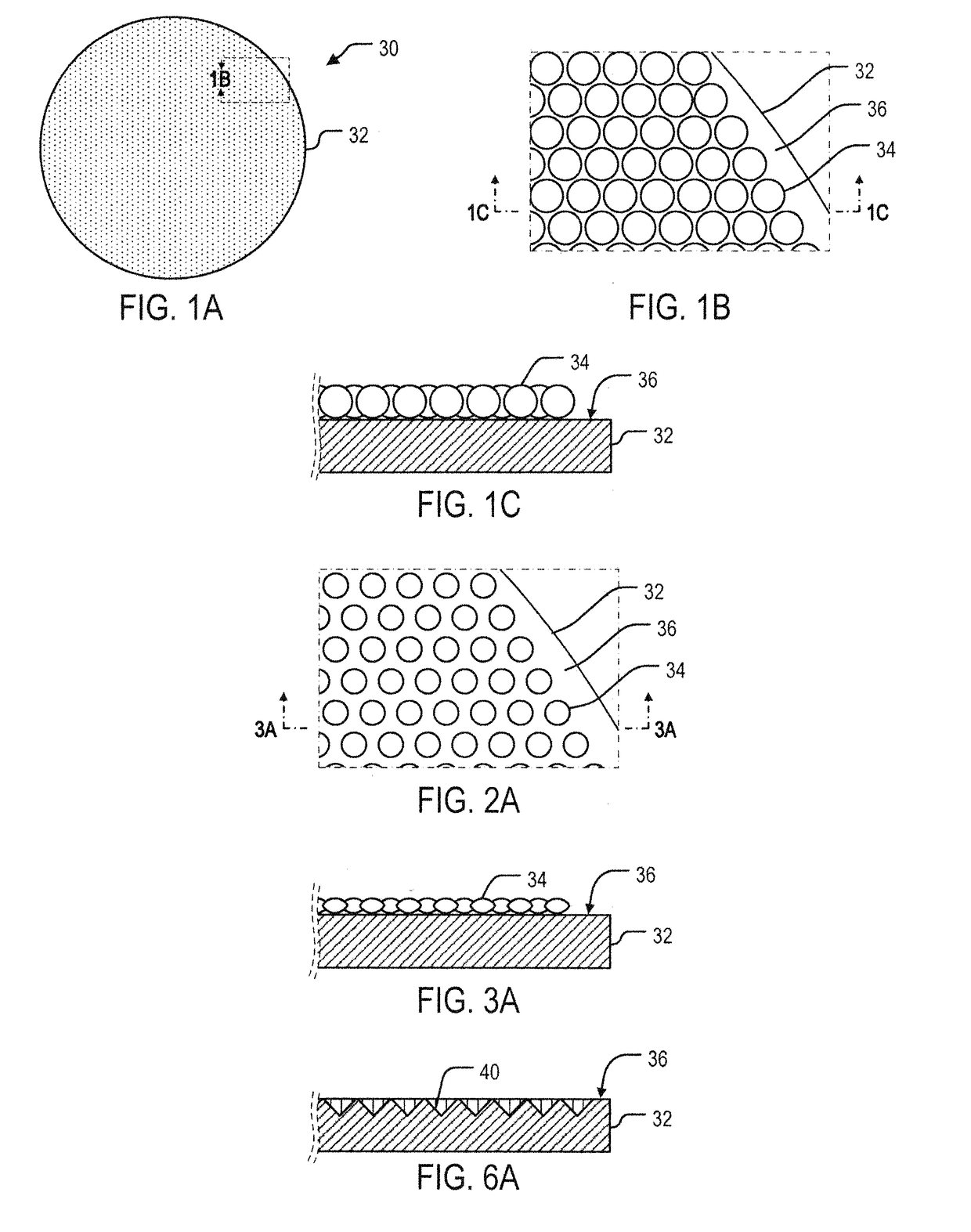

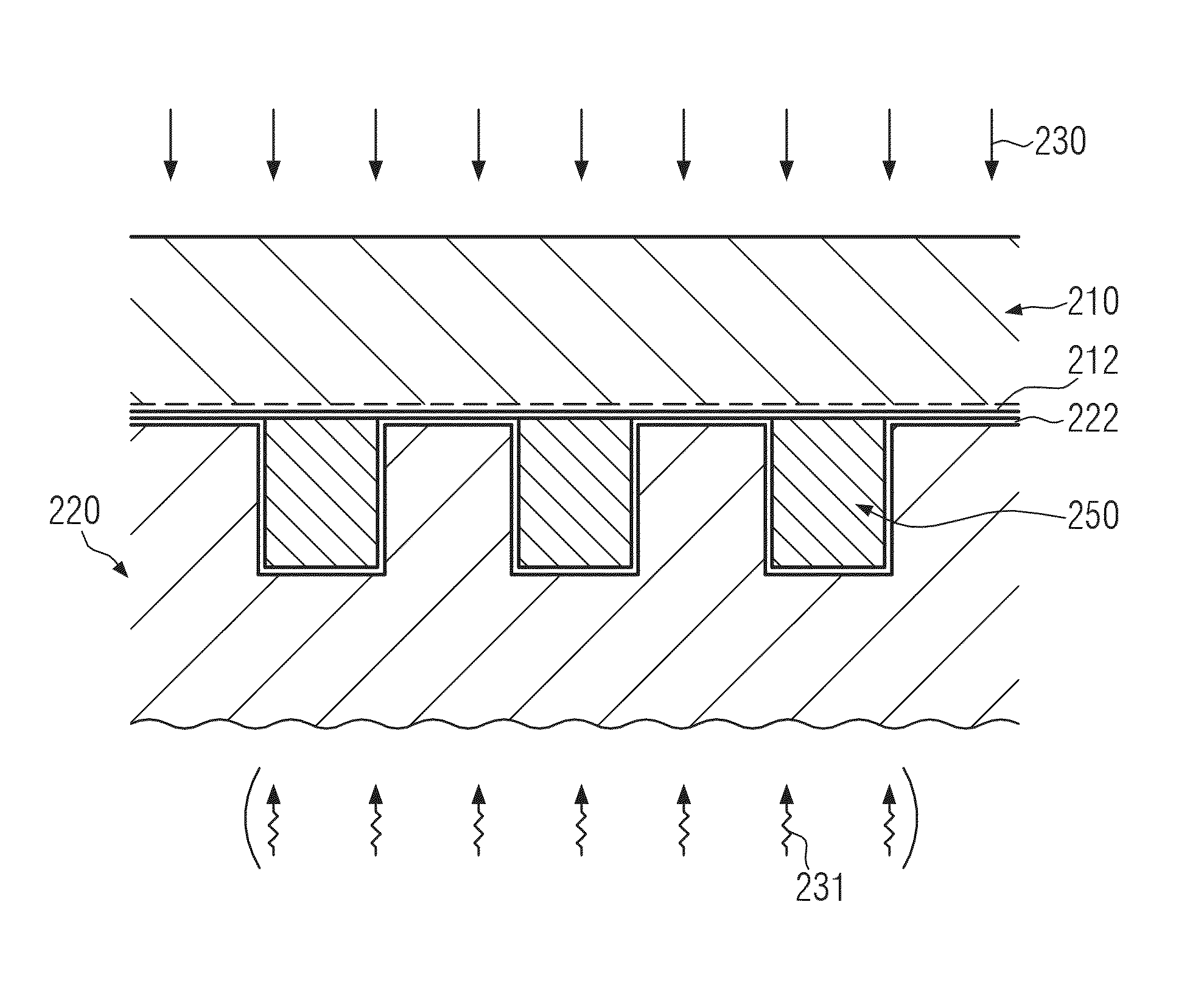

System and method for lithographic surface texturing

InactiveUS20170110330A1Increase distancePhotomechanical apparatusSemiconductor/solid-state device manufacturingMaterials science

Owner:ARIZONA STATE UNIVERSITY

Method for forming gate stack of 3D memory device

ActiveCN110729295AReduce process stepsReduce process complexitySolid-state devicesPhotomechanical apparatusSemiconductor structureIon beam

The invention discloses a method for forming the gate stack of a 3D memory device. The method comprises the following steps that: an insulating stack structure is formed on a semiconductor substrate;a step-shaped mask layer is formed on the insulating laminated structure; a step-shaped insulating laminated structure is formed; and the insulating laminated structure is replaced with a gate laminated structure, and the height of the step-shaped mask layer is set through the material and height of the insulating laminated structure. According to the method of the invention, a gray-scale photoetching method, a nanoimprint lithography method, a gray-scale mask plate photoetching method or an ion beam gas-assisted deposition method is adopted to form a step-shaped mask layer; a semiconductor structure is etched by using dry etching, so that the pattern of the mask layer is transferred into the insulating laminated structure; and therefore, process steps are reduced, and process complexity is reduced.

Owner:SHANGHAI IND U TECH RES INST

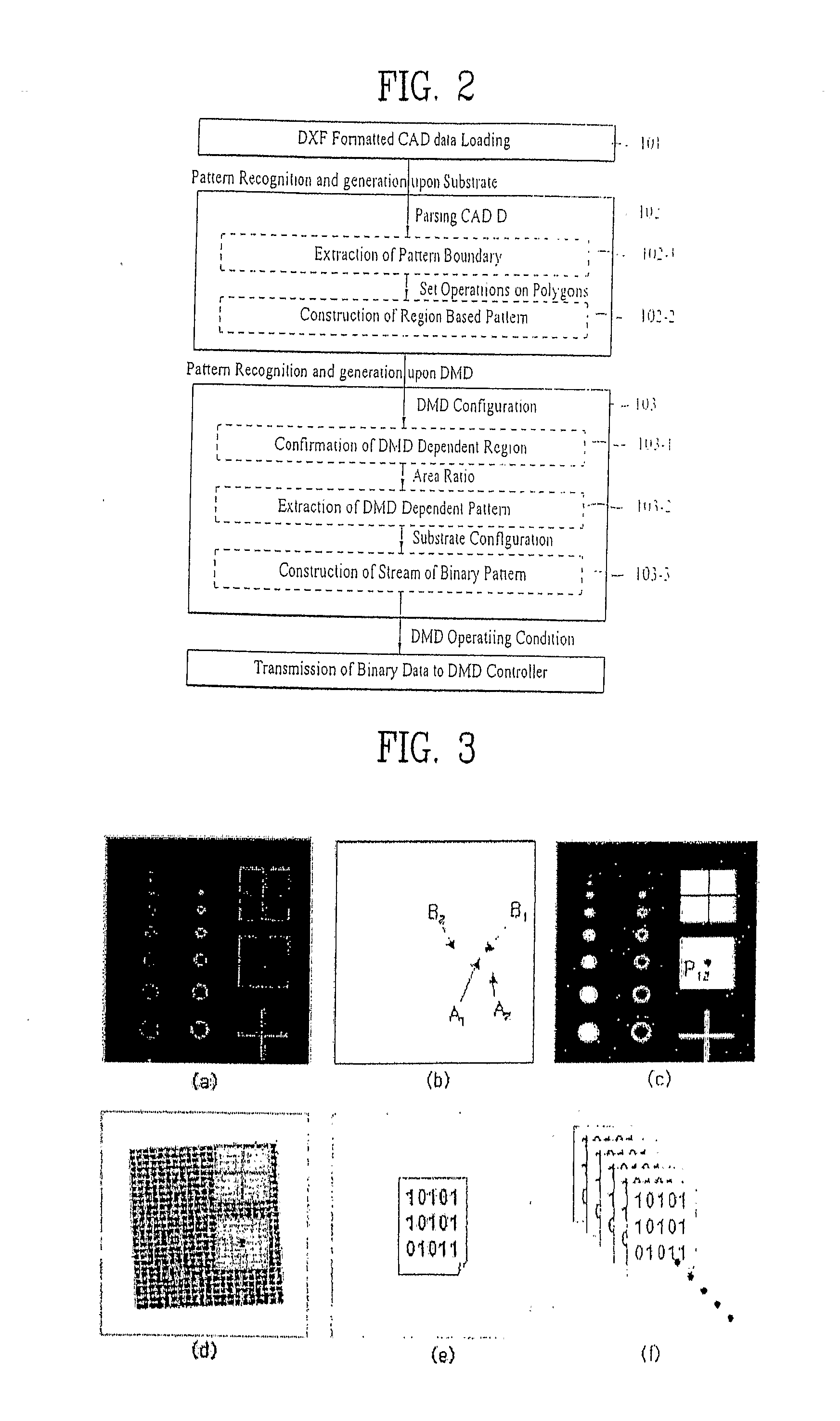

Occupancy Based on Pattern Generation Method For Maskless Lithography

InactiveUS20080313593A1Correctly and precisely and quickly generatedSmall sizePhotomechanical apparatusSpecial data processing applicationsEngineeringPattern generation

Owner:IAMTEN

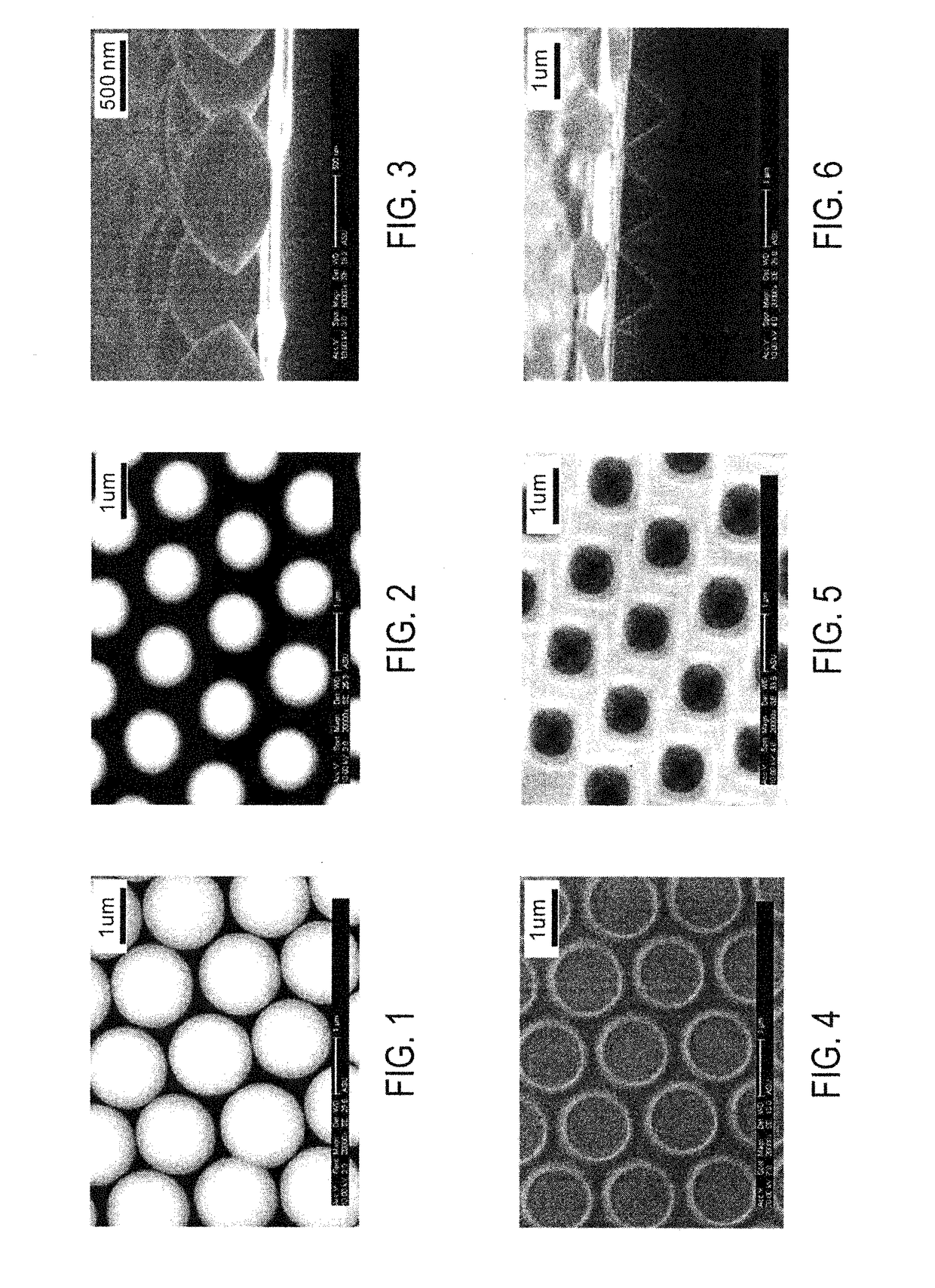

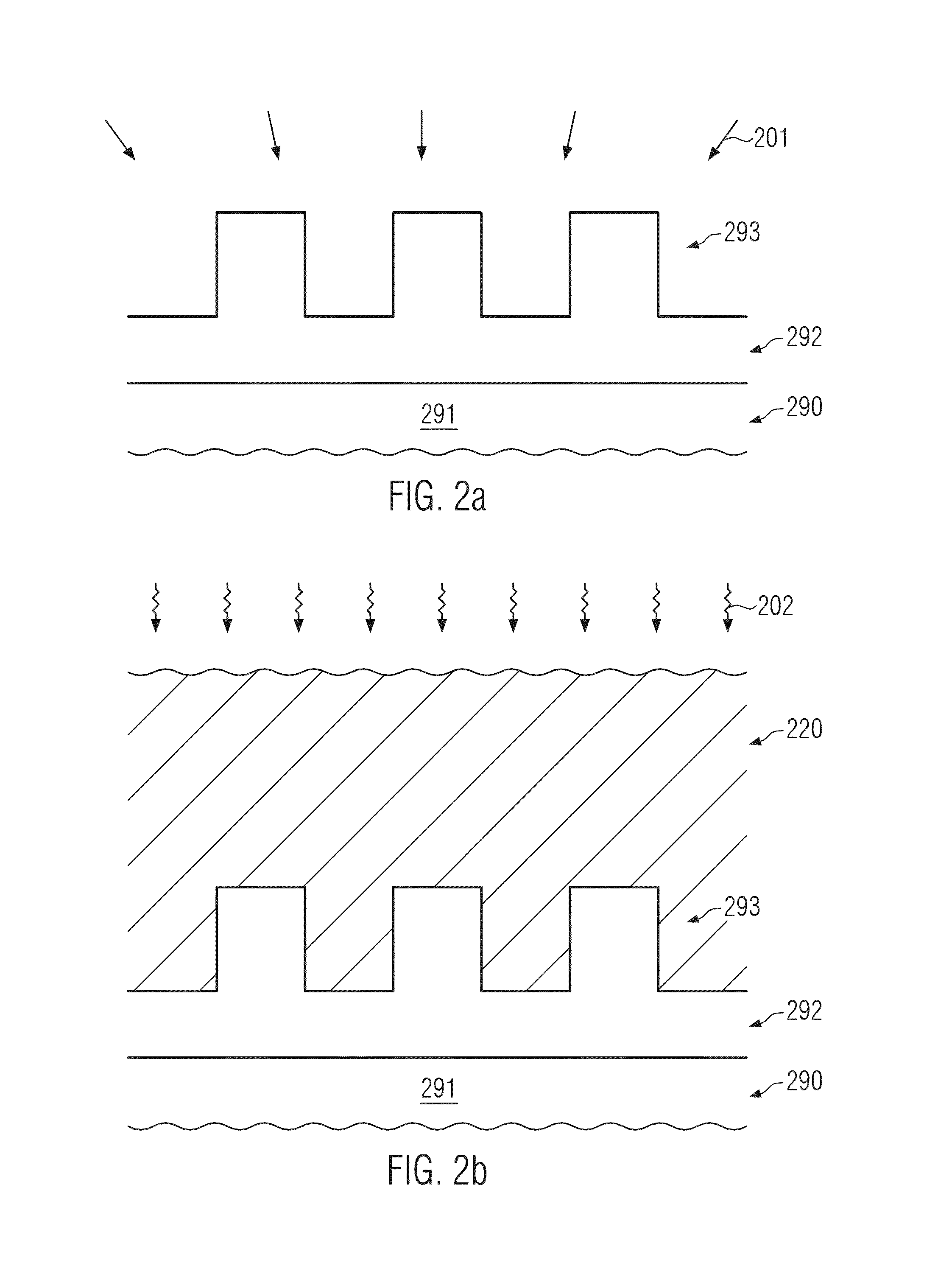

Methods and a mold assembly for fabricating polymer structures by imprint techniques

InactiveUS20140084519A1Highly hydrophobic surfaceReduced surface wettabilityConfectioneryPhotomechanical apparatusLithography processMaterials science

Owner:STMICROELECTRONICS SRL +1

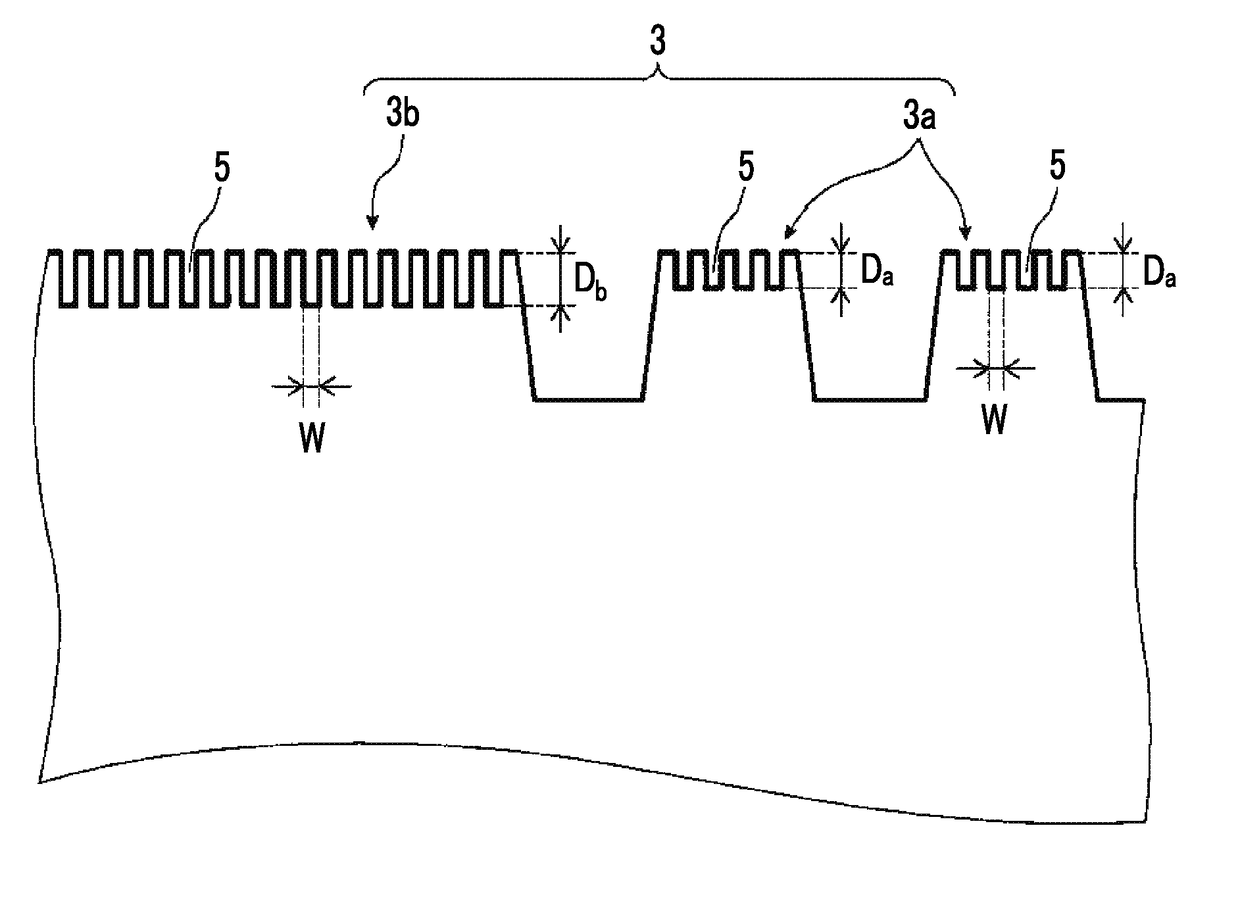

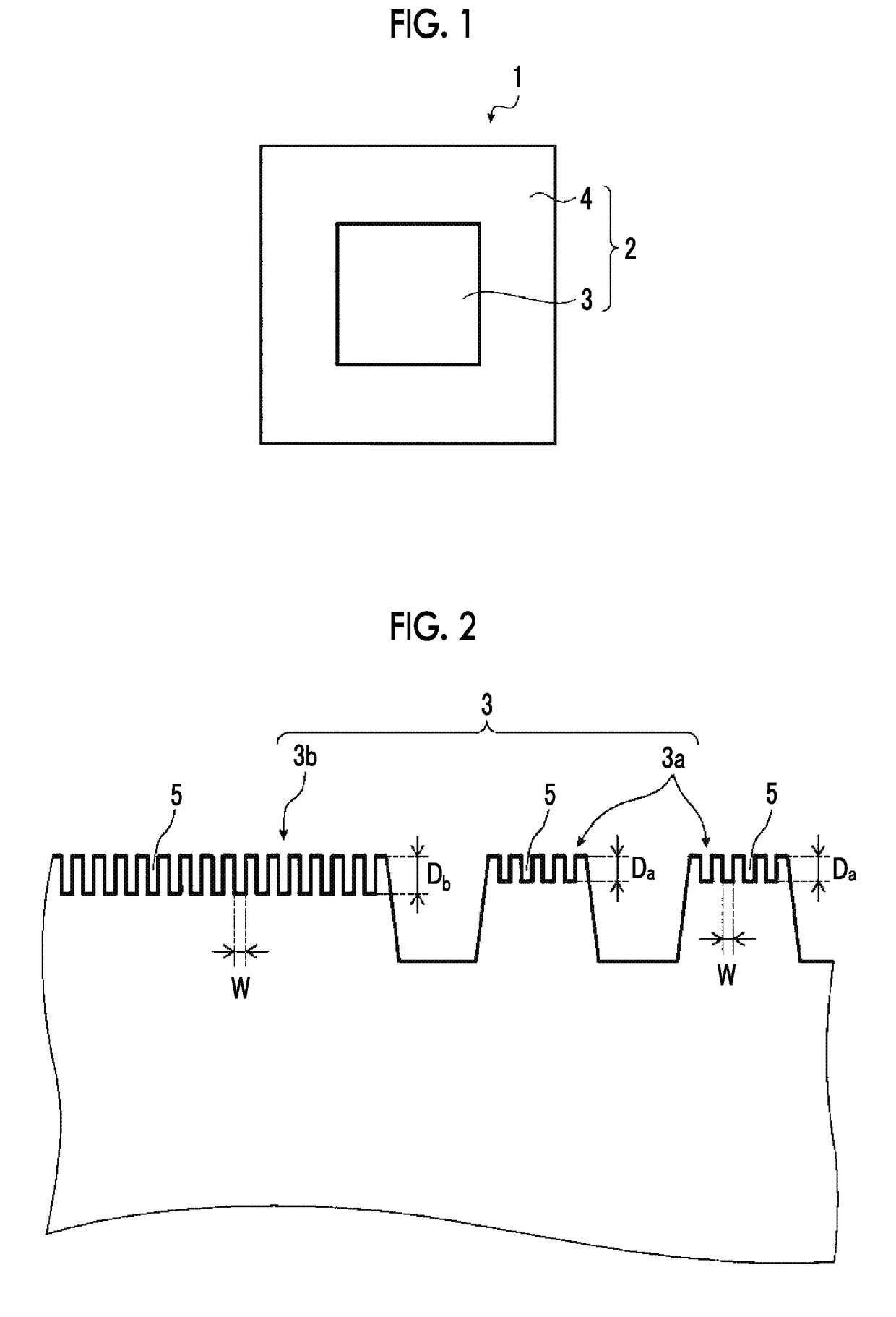

Flexographic printing plate

ActiveUS20180186161A1Excellent ink transferabilityImprove printing qualityPhotomechanical apparatusPlate printingMechanical engineeringArea ratio

Owner:FUJIFILM CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap