Microelectronic temperature sensor and preparation method thereof

A technology of temperature sensor and microelectronics, applied in thermometers, thermometers using electric/magnetic elements directly sensitive to heat, piezoelectric devices/electrostrictive devices, etc., can solve problems such as high cost, complicated process, and low sensitivity , to achieve the effects of low heat loss, improved sensitivity, and short dynamic response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

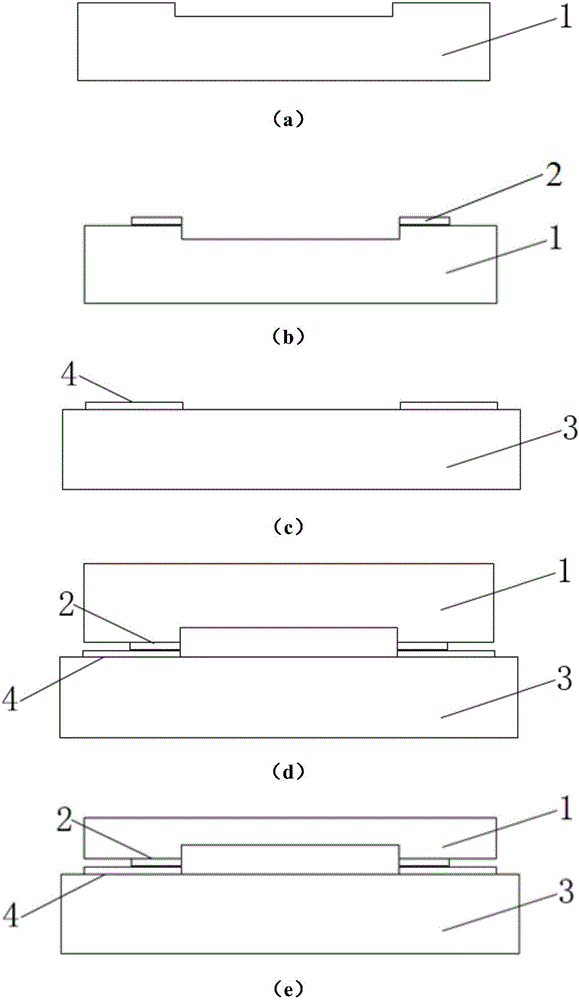

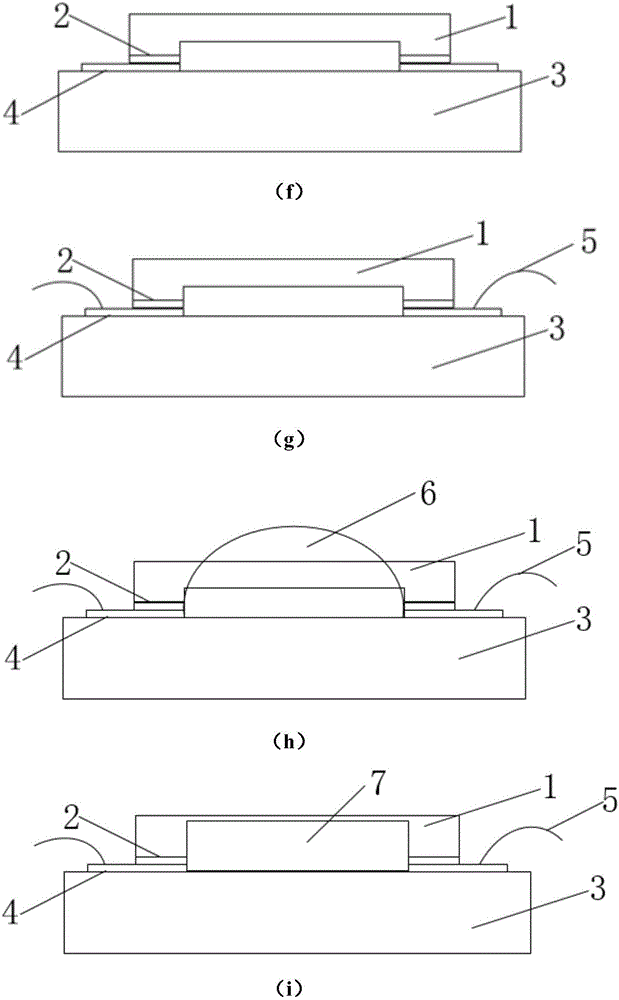

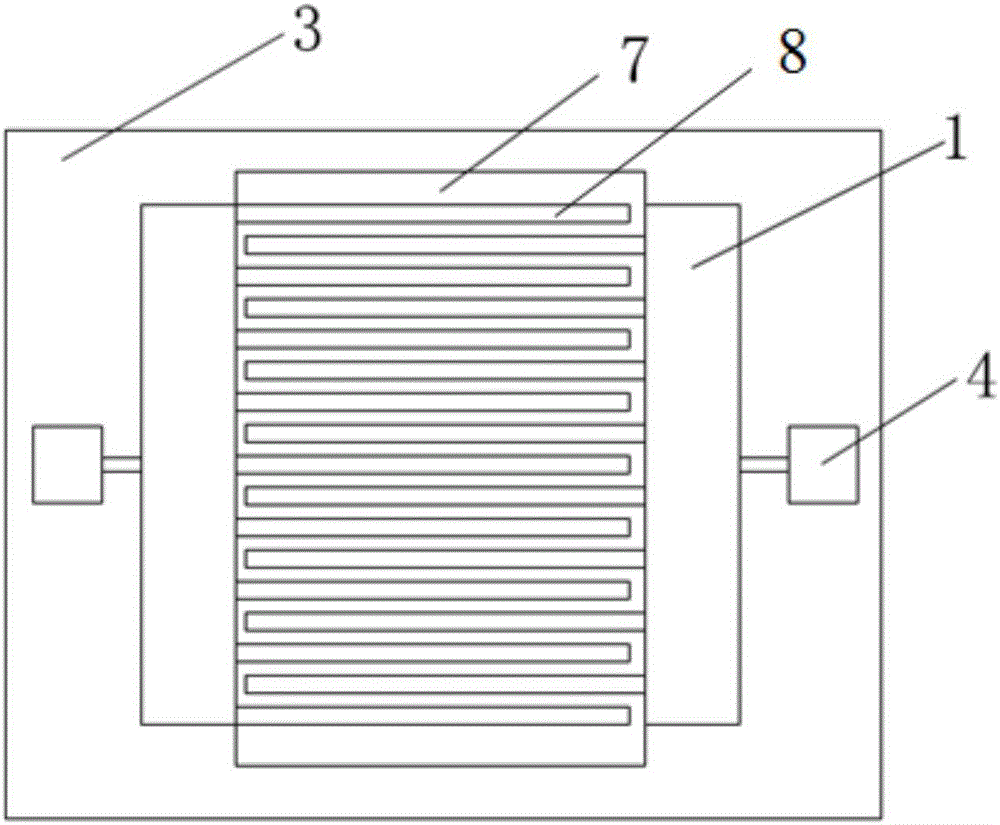

[0019] Such as figure 1 As shown, the microelectronic temperature sensor provided by the invention is prepared through the following steps:

[0020] (a) Etch a shallow trench with a depth of 5 μm on the single crystal silicon substrate 1 by reactive ion etching (RIE);

[0021] (b) Sputter 500Å of Ti on the single crystal silicon substrate 1 as the adhesion material between Au and Si substrate; then sputter 1000Å of Au 2 as the connection material of the low-temperature Au-Au bonding process ;

[0022] (c) On the Pyrex7740 glass substrate 3, 500Å of Ti was firstly sputtered as the adhesion material between Au and the glass substrate, and then 1000Å of Au 4 was sputtered as the connection material of the low-temperature Au-Au bonding process;

[0023] (d) Low-temperature Au-Au bonding is performed on the glass substrate 3 and the single crystal silicon substrate 1, and the bonding process temperature is about 350°C;

[0024] (e) Thinning the monocrystalline silicon substrate 1 t

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap