Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Improve mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsGas phaseAging resistance

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:JIAXING JUNHONG OPTICAL CO LTD

Efficient molding core production method for water glass sand blowing hardening

InactiveCN105665646ASolve the overblowing problemReduce the amount addedFoundry mouldsFoundry coresAmorphous siliconProduct gas

The invention discloses a high-efficiency core-making method for blowing and hardening water glass sand. The original sand, water glass for casting and non-crystalline silicon oxide are mixed by a sand mixer to obtain a core sand mixture, and then the mold-making The core sand mixture is filled into the mold by a core shooter or manually, and the CO blowing is used to 2 CO 2 The gas is blown into the cavity of the mold for blowing hardening, the blowing pressure is 0.1-0.4Mpa, the blowing time is 5-200s, and CO blowing 2 After the gas is finished, replace the compressed air, blow the compressed air into the mold cavity, the blowing pressure is 0.1-0.4Mpa, blow the compressed air for 10-200s, and the mold is ejected after the blowing is completed. The present invention can solve the problem of water glass sand blowing CO 2 The overblowing problem of the method can be solved, and the added amount of water glass can be reduced by more than 50%, and the mechanical properties of the manufactured core can be significantly improved at the same time.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Lldpe Pressure Pipe

InactiveUS20070273066A1Low densityImprove mechanical propertiesElectric/magnetic/electromagnetic heatingLow-density polyethyleneEngineering

The present invention relates to a multimodal linear low density polyethylene composition for the preparation of a pressure pipe. The invention further relates to a pressure pipe, comprising said composition, a process for the manufacturing of a pipe made of the composition and to a process for the recycling of pipe material consisting of the composition according to the invention. Furthermore the invention relates to the use of the pressure pipe as an irrigation pipe, especially a drip irrigation pipe.

Owner:BOREALIS TECH OY

Heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof

The invention provides a preparation method for heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane and functionalized derivates thereof. The preparation method comprises the steps as follows: adding tridecafluorooctylpropyl trimethoxy silane into an organic solvent, adding de-ionized water and NaOH, heating, stirring, reacting under reflux condition, washing by a washing solvent, and drying to obtain trisilanol sodium salt of heptatridecafluorooctylpropyl polyhedral oligomeric silsesquioxane; and adding trisilanol sodium salt into an organic reagent, dropwise adding hydrochloric acid, triethylamine and a silane coupling agent, stirring a mixture at normal temperature for reaction, removing generated deposit, carrying out rotary evaporation, removing the solvent, obtaining white crystals, dissolving the crystals in methanol, filtering for collecting insoluble parts, and carrying out vacuum drying to obtain a T8-type monofunctional tridecafluorooctylpropyl POSS (polyhedral oligomeric silsesquioxane) monomer. The preparation method can obtain long branch chain type active fluorine-containing POSS, is simple and easy in process, low in cost, high in yield and higher in product purity, and is suitable for large-scale industrial production.

Owner:HOHAI UNIV

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

Preparation method of anesthesia stem and plastic composite material

The present invention discloses preparation process of composite material of hemp stalk and plastic. The composite material is prepared through mixing hemp stalk powder and mineral powder to obtain composite hemp stalk powder, extruding and pelletizing to obtain composite hemp stalk pellet, mixing with plastic, and pelletizing or extruding into product. The composite material is environment friendly, reusable and low in cost.

Owner:LINGCAI BAICHUAN (XINXING) TECH CO LTD

High-strength ultralow-density transparent silicon dioxide aerogel as well as preparation method and application thereof

ActiveCN112158852AImprove intrinsic mechanical strengthImprove mechanical propertiesSilicon compoundsDeep space explorationHYDROSOL

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Asphalt pavement structure suitable for Tibet plateau area and construction method thereof

InactiveCN106868972AImprove road performanceImprove bending deformationIn situ pavingsSurface layerRoad surface

The invention relates to an asphalt pavement structure suitable for the Tibet plateau area and a construction method thereof. The asphalt pavement structure suitable for the Tibet plateau area sequentially comprises a cushion layer, a semi-rigid base layer, a penetrable layer, an SBR emulsified asphalt lower sealing layer, a lower surface layer, a bonding layer and an upper surface layer from bottom to top. The construction method of the asphalt pavement structure suitable for the Tibet plateau area comprises the following steps of (1) tamping and leveling a roadbed, (2) laying the cushion layer on the roadbed, (3) laying a cement stabilized sand gravel layer on the cushion layer, (4) flatly laying a low-shrinkage super-early-strength cement stabilized macadam layer, (5) laying the penetrable layer, (6) laying the SBR emulsified asphalt lower sealing layer, (7) laying the lower surface layer, (8) laying the bonding layer, and (9) laying the upper surface layer.

Owner:QINGHAI ACAD OF TRANSPORTATION SCI +1

Pitaya peel-based edible packaging film and preparation method thereof

ActiveCN105419370AFull edible medicinal valueAvoid pollutionWrappersFlexible coversCellulosePolymer science

The invention provides a preparation method for a pitaya peel-based edible packaging film. The preparation method is characterized by comprising the following steps: (1) washing and stripping and slicing pitaya peels; (2) performing blanching treatment; (3) adding water and pulping to obtain pitaya peel pulp, wherein the mass ratio of matter obtained in the step (2) to the water is (15 to 45):100; (4) adding a thickening agent and a plasticizer into the pitaya peel pulp, wherein the mass ratio of the thickening agent to the pitaya peel pulp is (0 to 0.4):100, and the mass ratio of the plasticizer to the pitaya peel pulp is (0 to 0.3):100; the thickening agent is sodium alginate or sodium carboxymethylcellulose, and the plasticizer is glycerinum or sorbitol; (5) performing homogenization treatment at a treatment rate of 15000 to 20000 r / min for 5 to 8min; then, performing degassing treatment and standing to obtain shaped pulp; (6) casting and drying, and then performing film uncovering to obtain the pitaya peel-based edible packaging film. The invention also provides the packaging film prepared by the preparation method.

Owner:SICHUAN AGRI UNIV

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hydrogenated styrene-conjugated diene copolymer as well as preparation method and application thereof in self-adhesive films

InactiveCN108219090AGood physical propertiesEasy to processFilm/foil adhesives without carriersPolymer scienceUltimate tensile strength

The invention discloses a hydrogenated styrene-conjugated diene copolymer as well as a preparation method and application thereof in self-adhesive films. The hydrogenated styrene-conjugated diene copolymer has the following expression: S1-EB1-S2-EB2, wherein S1 and S2 are styrene blocks; EB1 is a hydrogenated butadiene block; and EB2 is a hydrogenated conjugated diene block. The hydrogenated styrene-conjugated diene copolymer has good processing properties and can be used for preparing the self-adhesive films together with other poly stylene polymers; and the prepared self-adhesive films are less affected by temperature, humidity and other external conditions, have good stability, have adhesive strength capable of being controlled within a wide range, and are suitable for application requirements of various materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mixture of PPC (polyenyl phosphophatidyl choline), PHBV (Polyhydroxybutyrate Valerate), PLA (Poly lactic Acid), PBS (Polybutadiene Styrene), PBAT (polybutylene adipate terephthalate) and PCL (polycaprolactone) and preparation method thereof

The invention relates to a mixture of PPC (polyenyl phosphophatidyl choline), PHBV (Polyhydroxybutyrate Valerate), PLA (Poly lactic Acid), PBS (Polybutadiene Styrene), PBAT (polybutylene adipate terephthalate) and PCL (polycaprolactone) and a preparation method thereof. The mixture comprises the PPC, the PHBV, the PLA, the PBS, the PBAT, the PCL, an end-capping agent, a lubricating agent and modified light calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PHBV, the PLA, the PBS, the PBAT, the PCL, the end-capping agent, the lubricating agent and the modified light calcium carbonate in a high-speed stirrer at a temperature not more than 35 DEG C; and extruding and granulating cold mixing materials by using a screw extruder at a temperature not more than 200 DEG C. The invention has the advantages that the method has simple process and common equipment and is very suitable for industrialized production; in addition, raw materials used in the method are simple and easy to obtain and buy in the market, and the mixture processed by the method is greatly enhanced in tacky agglomeration temperature compared with pure PPC and superior to the pure PPC in mechanical property and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

Block aerogel composite material and preparation method thereof

Owner:GRADUATE SCHOOL OF THE CHINESE ACAD OF SCI GSCAS

Dealcoholized silicone rubber sealant

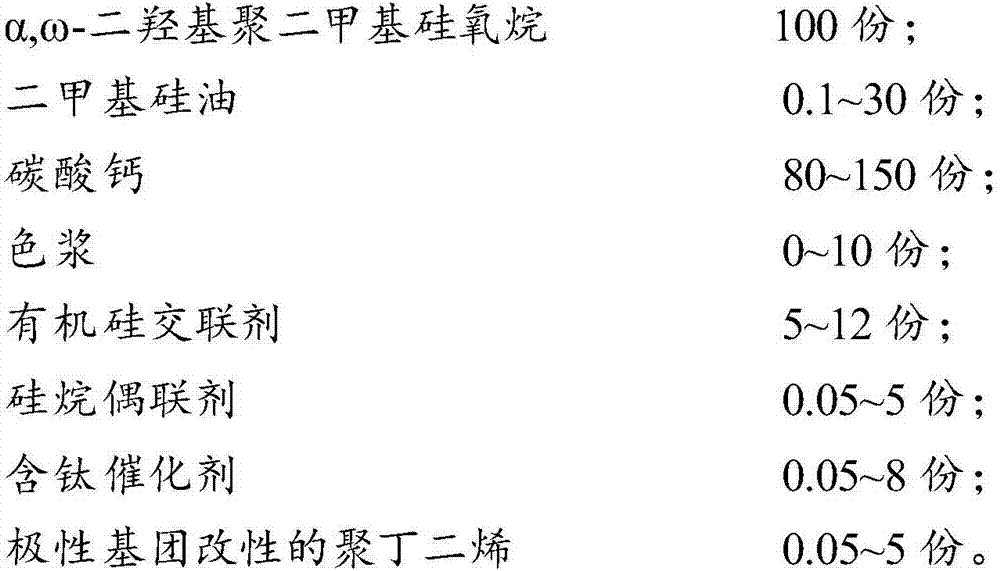

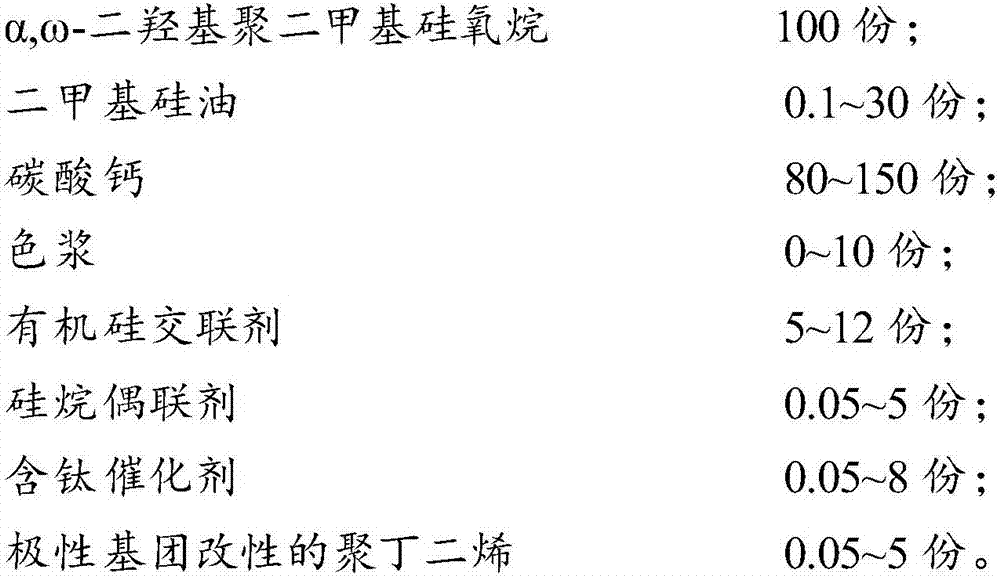

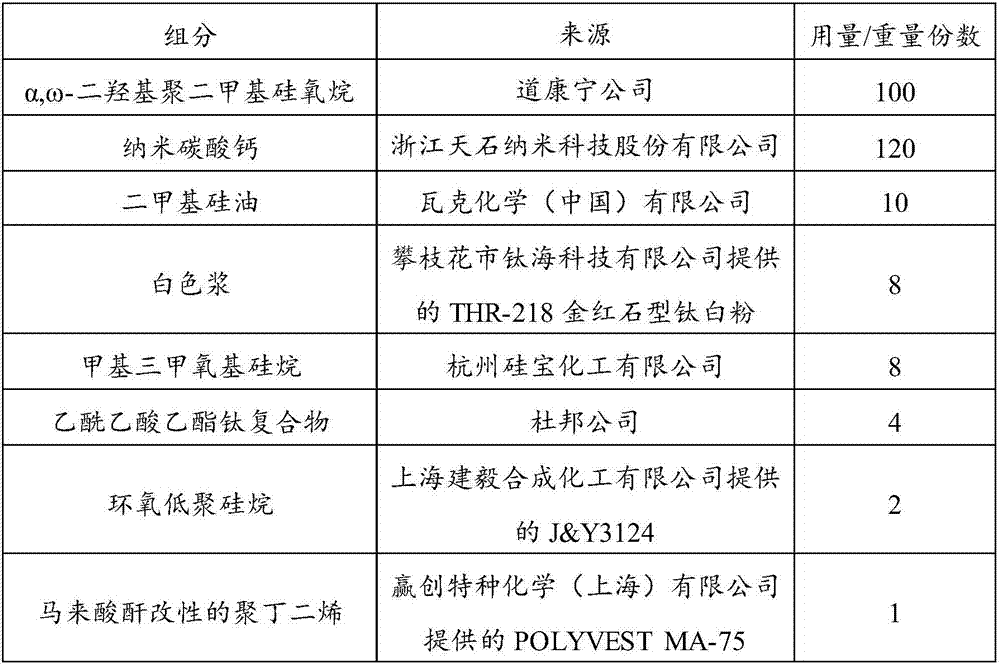

ActiveCN106957631AGood flexibilityGood mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilicone sealantMoisture

The invention provides a dealcoholized silicone rubber sealant, which is prepared from the following components in parts by weight: 100 parts of alpha, omega-dyhydroxyl polydimethylsiloxane, 0.1 to 30 parts of simethicone, 80 to 150 parts of calcium carbonate, 0 to 10 parts of mill base, 5 to 12 parts of silicone cross-linking agent, 0.05 to 5 parts of silane coupling agent, 0.05 to 8 parts of titanium-containing catalyst, and 0.05 to 5 parts of polar group modified polybutadiene. According to the dealcoholized silicone rubber sealant provided by the invention, the polar group modified polybutadiene is adopted, and a polar group is contained, so that the moisture introduction in air is increased, and the initial curing speed and the initial strength of the sealant are improved. According to the dealcoholized silicone rubber sealant provided by the invention, through reasonably controlling the components in the sealant and adjusting the content of each component, so that the sealant has the advantages of fast initial curing speed, high shearing strength, and excellent cohesiveness under the combined action of the components.

Owner:HANGZHOU ZHIJIANG SILICONE CHEM +1

Attapulgite aerogel as well as preparation method and application thereof

PendingCN111392740AImprove mechanical propertiesImproved thermal stability and flame retardancyAerosol preparationColloidal chemistry detailsAerogelAqueous solution

Owner:SHANGHAI JIAO TONG UNIV

Permeation consolidation type solvent-free epoxy anticorrosive coating, and preparation method and application thereof

ActiveCN105238217AImprove wetting abilityImprove bonding abilityAnti-corrosive paintsEpoxy resin coatingsSolventSurface corrosion

The invention belongs to the technical field of anticorrosive coatings, and discloses a permeation consolidation type solvent-free epoxy anticorrosive coating, and a preparation method and an application thereof. The anticorrosive coating consists of a component A and a component B. The component A consists of the following components in parts by weight: 18-89 parts of epoxy resin, 5-50 parts of enhanced type reactive solvents, 5-60 parts of permeation type reactive solvents, 0-5 parts of interfacial modifiers and 0-3 parts of permeation enhancers. The component B consists of the following components in parts by weight: 5-95 parts of functional curing agents, 0-30 parts of curing regulators, 0-50 parts of double-function regulators, 0-40 parts of curing accelerators and 0-5 parts of condensation catalysts. The coating is low in viscosity and excellent in permeability, and has an excellent mechanical property after being cured. In addition, the permeation consolidation type solvent-free epoxy anticorrosive coating disclosed by the present invention has good wettability and viscocity with concrete, and strength of the concrete can be improved, water on the surface of the concrete can be removed, and surface corrosion factors of the concrete are reduced.

Owner:SOUTH CHINA UNIV OF TECH

Polyamide toughening agent as well as preparation method and use thereof

InactiveCN104177825AImprove impact resistanceImprove low temperature impact resistanceElastomerPolyolefin

The invention provides a polyamide toughening agent as well as a preparation method and use thereof. The polyamide toughening agent is mainly prepared from the following raw materials in parts by weight: 50-95 parts of an ethylene-octene copolymer elastomer, 0.5-2.5 parts of a grafting monomer, 5-50 parts of polyolefin, 0.05-0.5 part of an initiator and 5-20 parts of polyamide. The toughening agent provided by the invention is simple in preparation method, have good mechanical property and low-temperature impact toughness when being used for toughening the polyamide, and can be widely applied to modification of polyamide materials in the fields of inner and outer decorative parts of automobiles, electric tools, rail bases, transformers, oil tubes and the like.

Owner:DONGGUAN CALVIN PLASTIC & TECH

Method for enhancing anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application

The invention provides a method for enhancing the anti-freeze and tensile properties of cellulose ion hydrogel, anti-freeze stretchable cellulose ion hydrogel and application, relating to the technical field of ion hydrogel. The method for enhancing the anti-freeze and tensile properties of the cellulose ion hydrogel comprises steps as follows: enabling the cellulose ion hydrogel to be immersed into a chlorinated metal salt solution, and dipping for 10-40min to obtain the anti-freeze stretchable cellulose ion hydrogel. Current cellulose ion hydrogel has the technical problems that the tensileproperty is poor and tensile and wire properties can lose at low temperature as well. According to the method, by enabling the cellulose ion hydrogel to be immersed in the chlorinated metal salt solution, metal ions and chloride ions in chlorinated metal salt enter the cellulose ion hydrogel, so that the anti-freeze property of the cellulose ion hydrogel is effectively improved, and the prepared anti-freeze stretchable cellulose ion hydrogel still has good mechanical property and chemical property at the low temperature.

Owner:SOUTH CHINA UNIV OF TECH

Epoxy resin composition and prepreg and printed circuit board made therefrom

ActiveCN102260402AImprove heat resistanceGood chemical resistanceCircuit susbtrate materialsMetal layered productsEpoxyManganese oxide

The invention relates to an epoxy resin composition which comprises (a) epoxy resin; (b) a hardening agent; and (c) manganese oxide used as inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

Fiber composite warm-keeping flocculus and preparation method thereof

ActiveCN112981712AImprove mechanical propertiesImprove stabilityNon-woven fabricsElectrospinningElectrostatic adsorption

Owner:DONGHUA UNIV

Wire arc additive manufacturing method of Al-Mg-Si alloy

Owner:NORTHEASTERN UNIV

Edge treating a cut edge of a glass piece

InactiveUS20150218045A1Improve mechanical propertiesDifficult to restoreGlass tempering apparatusEngineeringHeat spreader

Owner:CORNING INC

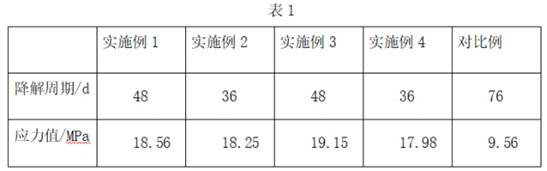

Full-biodegradable material with controllable period

Owner:SHENZHEN MPD HITECH CO LTD

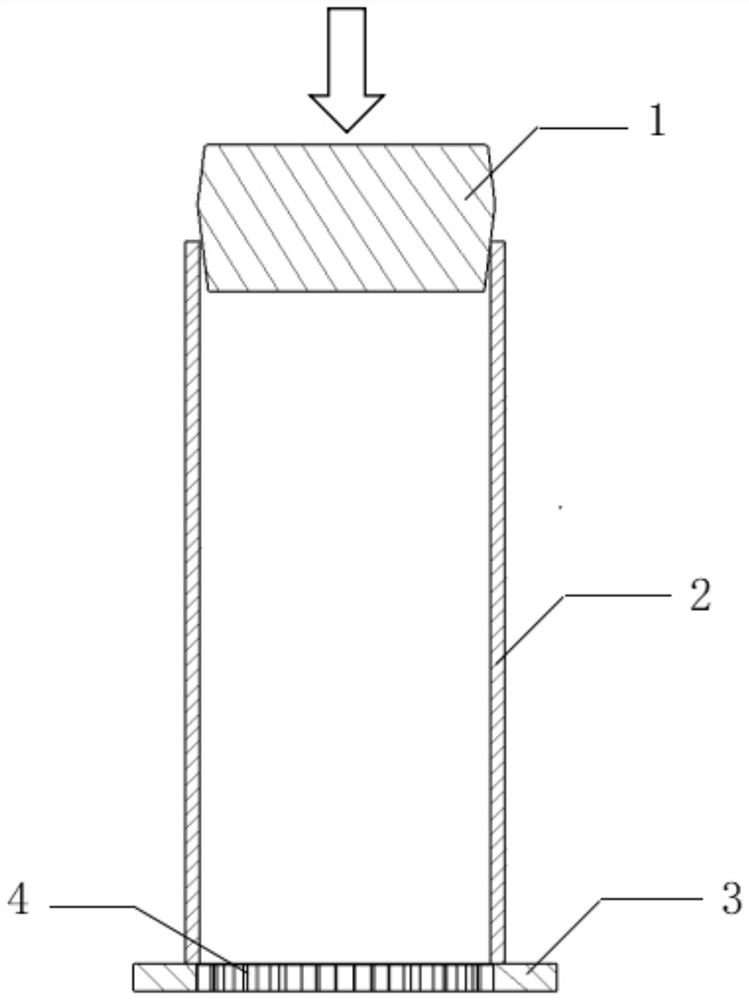

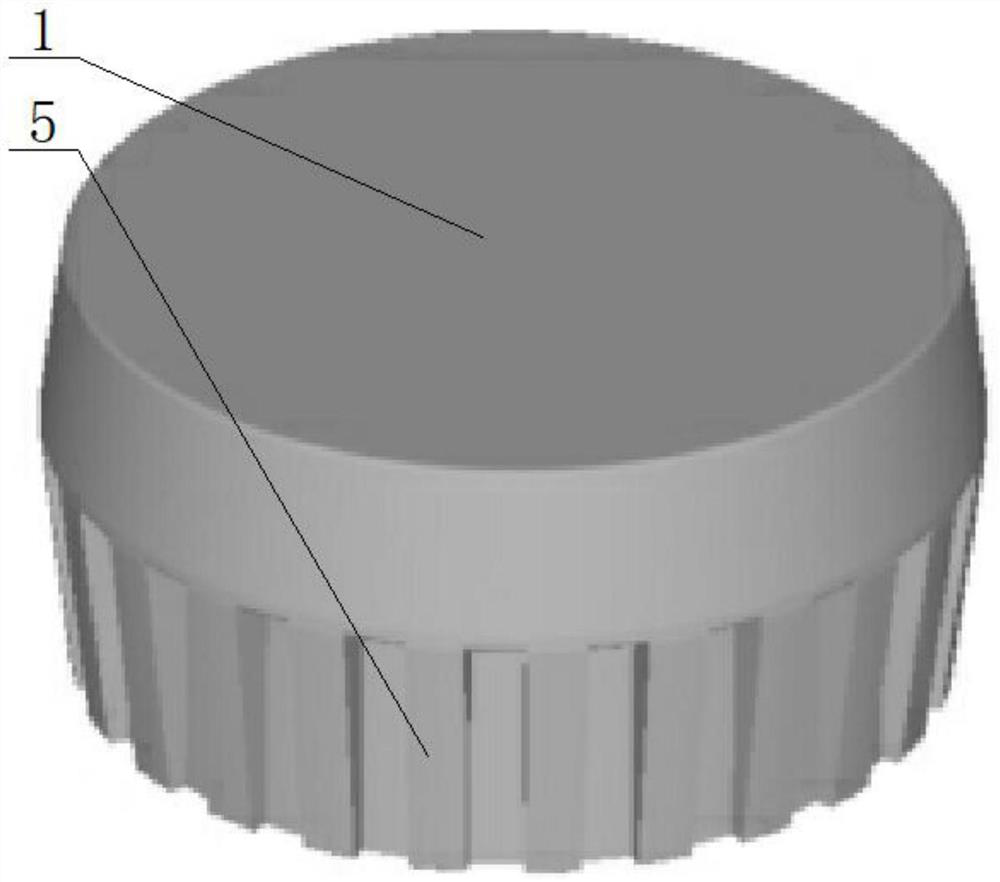

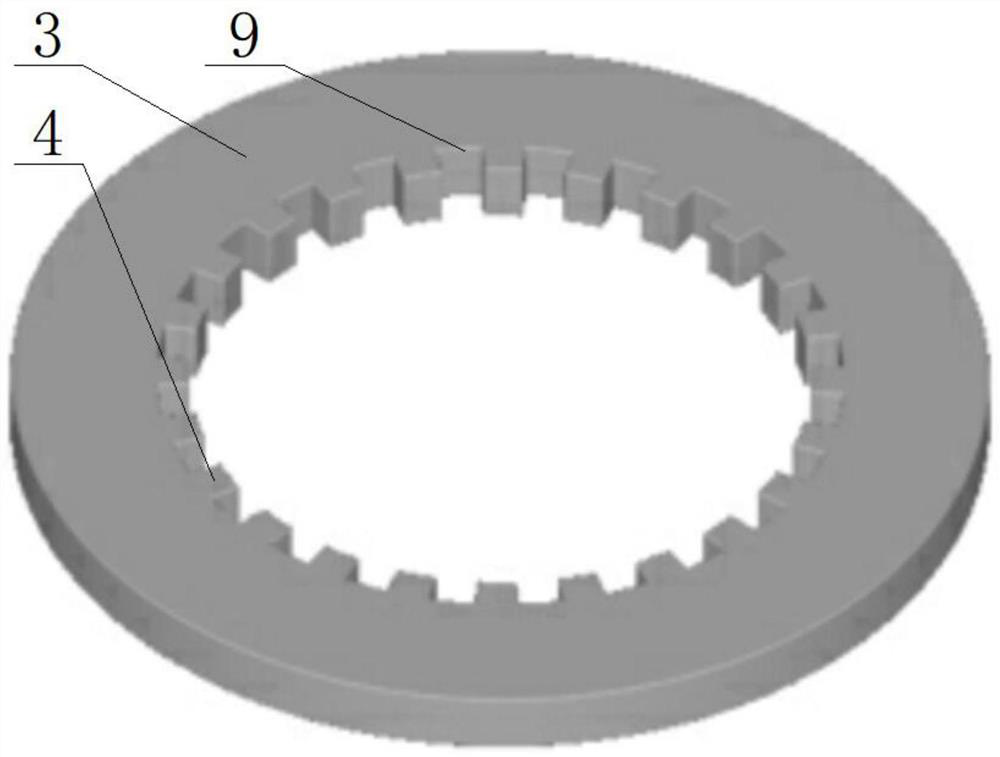

Method for eliminating residual stress of aluminum alloy aviation forge cylinder

ActiveCN111763895AGood residual stress reliefUniform deformationFurnace typesProcess efficiency improvementStructural engineeringManufacturing engineering

The invention discloses a method for eliminating residual stress of an aluminum alloy aviation forge cylinder. The method comprises the following steps that step 1, solution treatment and quenching heat treatment are carried out on the forged and formed forge cylinder, and in the quenching process, a circumferential supporting frame is arranged at the interior of the forge cylinder to prevent therelatively-large deformation of the long forge cylinder; step 2, according to the diameter, the wall thickness and the material performance of a quenched forge piece, the deformation amount of cold bulging is determined, and a corresponding cold bulging punch and lower cutting board are designed according to the calculated deformation amount of cold bulging; and step 3, the cold bulging punch is placed in the forge cylinder, the cold bulging punch is pressed downwards at the pressing speed of 2 mm / s till the cold bulging punch reaches the bottom end of the forge cylinder, the forge cylinder isturned over up and down, and the cold bulging punch is pressed to reach the bottom end of the forge cylinder again at the same pressing speed. According to the method, a good residual stress eliminating effect can be achieved, all parts of the forge piece uniformly deform, and the surface quality is high.

Owner:SHANDONG NANSHAN ALUMINUM +1

Preparation method of refining agent for melting aluminum alloy section doped with plant ash

Owner:邹学千

Production method of prepressing combination vertical reinforced concrete shield lining segment

ActiveCN110978257AAvoid a large footprintImprove mechanical propertiesDischarging arrangementFeeding arrangmentsArchitectural engineeringCivil engineering

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Dissimilar material brazing method of porous intermediate layer structure brazing seam

ActiveCN104475898AReduce residual stressImprove mechanical propertiesSoldering apparatusMetallic materialsCeramic matrix composite

Owner:HARBIN INST OF TECH

Modified graphene reinforced magnesium matrix metal material and preparation method thereof

The invention discloses a modified graphene reinforced magnesium matrix metal material and a preparation method thereof. The modified graphene reinforced magnesium matrix metal material comprises the following components in percentages by mass: 0.02-0.5wt% of modified graphene, 5.9-11.2wt% of copper, 1.2-4.6wt% of silicon dioxide, 1.4-5.6wt% of aluminum oxide, 1.3-7.8wt% of carbon nanotubes, 4.5-7.9wt% of nickel, 1.3-3.8wt% of titanium dioxide, 1.3-4.6wt% of lanthanum oxide and the balance of magnesium. The mechanical property of the modified graphene reinforced magnesium matrix metal material can still be good at the temperature of minus 20 DEG C; and the performance parameters such as the tensile strength and the elongation of the magnesium matrix metal material are increased, and are higher than the performance parameters of commercial alloy by 7-11%.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

Method for preparing biological-based plastics by using wood fibers as raw material

The invention discloses a method for preparing biological-based plastics by using wood fibers as a raw material. The method comprises the steps: crushing wood fiber biomasses, then carrying out ball milling to obtain a powder material; dissolving a modifying reagent by using a solvent, adding the powder material for performing a modification reaction; and after the modification reaction is ended, washing and drying the product to obtain the biological-based plastics. The method has the main advantages that 1, the raw material is wide in source and low in cost; 2, cellulose, hemicellulose and lignin in the wood fiber biomasses are compressively utilized, and a conventional single modification mode in which the cellulose is modified and utilized by separation, extraction and modification is changed; 3, a conventional pretreatment mode adopting a chemical method is changed through ball milling and pretreatment, and a large quantity of highly-corrosive reagents and solvents are prevented from being used; 4, the modification process is simple and easy to operate, a normal-temperature or low-temperature reaction is achieved, the reaction time is short, the industrial application prospect is wide; 5, the prepared product can be prepared into a plastics product through forming processes of extrusion molding, extruding and the like, and the plastic product is good in mechanical property.

Owner:NANJING FORESTRY UNIV

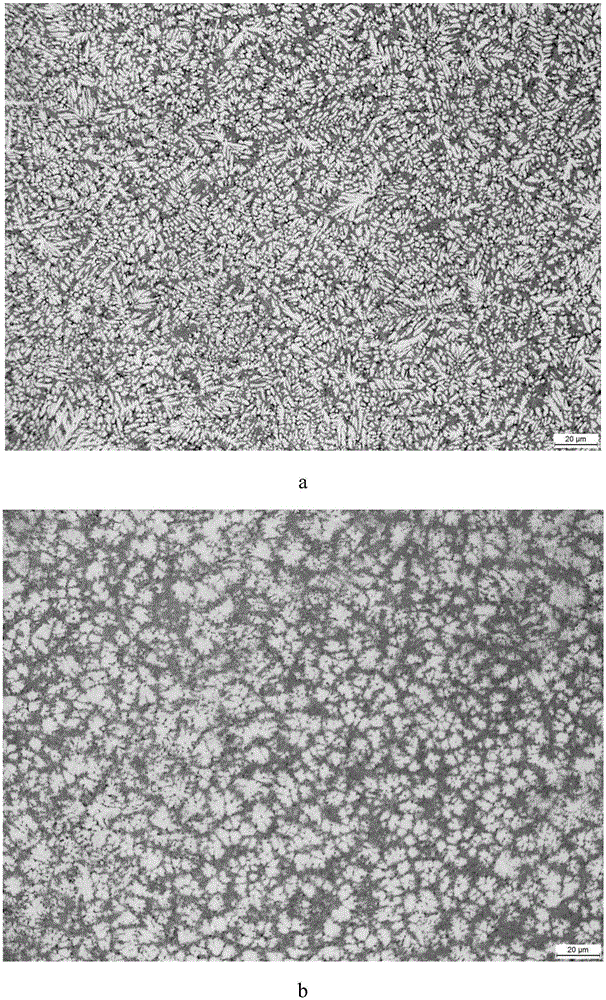

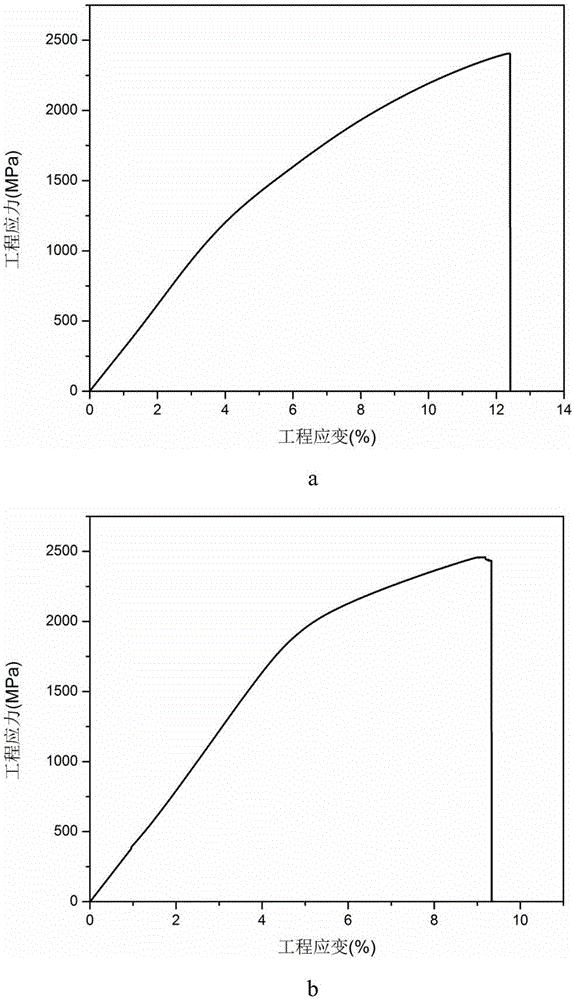

(Ti-Cu-Ni-Zr)-Sn amorphous composite and preparation method thereof

The invention relates to a (Ti-Cu-Ni-Zr)-Sn amorphous composite and a preparation method of the (Ti-Cu-Ni-Zr)-Sn amorphous composite. The (Ti-Cu-Ni-Zr)-Sn amorphous composite comprises Ti, Cu, Ni, Zr and Sn, and an atomic percent of the composite is as follows: (Ti[45]Cu[39-42.5]Ni[7.5-11]Zr[5])[98]Sn[2]. The Ti-based amorphous composite with high rupture strength and certain plasticity is obtained by selecting an alloy system free from a toxic element Be, reasonably adjusting an element proportion and adding a little element Sn. The prepared alloy comprises an amorphous phase and a beta-Ti dendritic crystal reinforcing phase, so that the alloy shows superhigh mechanical property matching, the yield strength sigma[y] is greater than or equal to 1310MPa, the compressive strength sigma[bc] is greater than or equal to 2460MPa, and the plastic strain epsilon[p] before rupture is greater than or equal to 9.3%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap