(Ti-Cu-Ni-Zr)-Sn amorphous composite and preparation method thereof

A technology of ti-cu-ni-zr and amorphous composite materials, which is applied in the field of titanium-based amorphous composite materials and its preparation, can solve problems such as weak glass forming ability, eliminate potential safety hazards, suppress the formation of brittle phases, The effect of broadening the prospects for development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

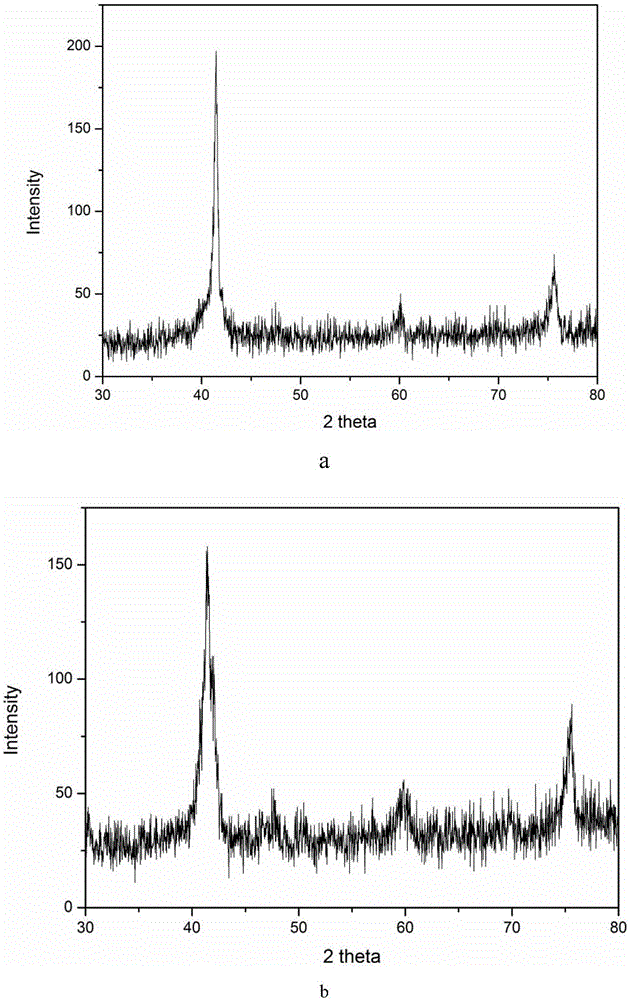

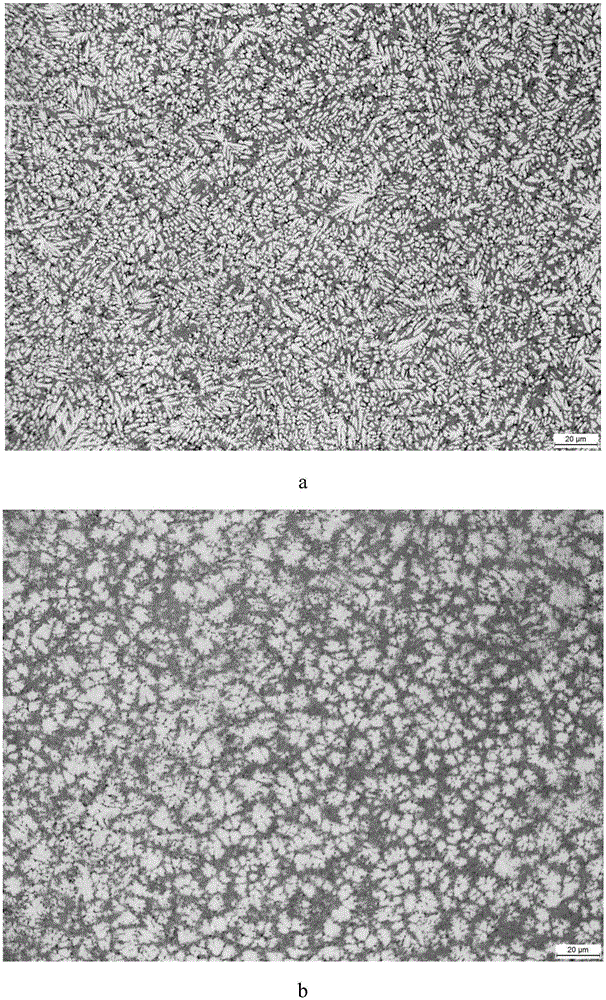

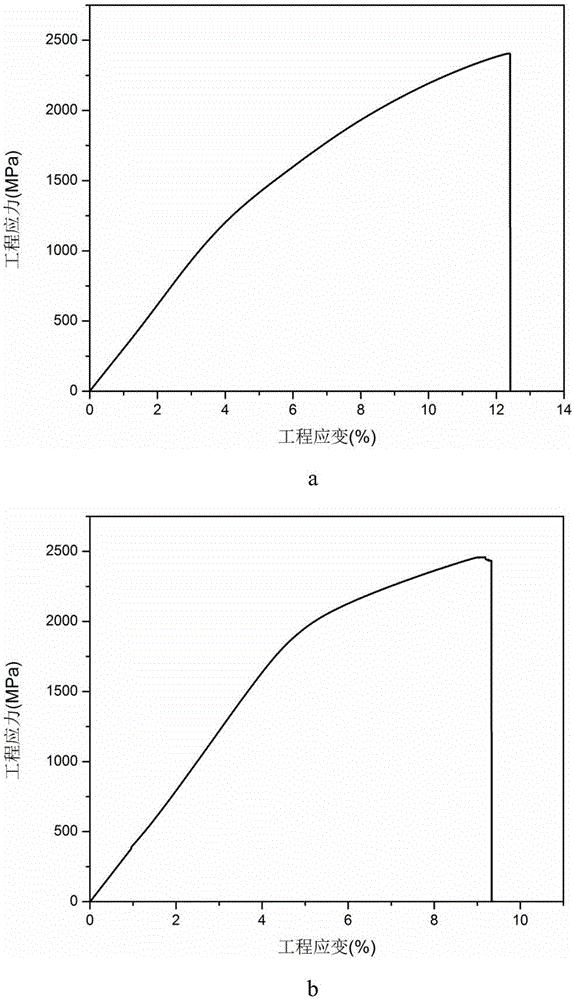

[0024] This embodiment is a (Ti-Cu-Ni-Zr)-Sn based amorphous composite material.

[0025] The (Ti-Cu-Ni-Zr)-Sn series amorphous composite material described in this example is composed of five elements including Ti, Cu, Ni, Zr and Sn, and its atomic percentage is (Ti 45 Cu 39 Ni 11 Zr 5 ) 98 sn 2 , wherein, Ti, Cu, Ni, Zr and Sn are block, and the purity is ≥99.99%.

[0026] The preparation process of the (Ti-Cu-Ni-Zr)-Sn series amorphous composite material proposed in this example is as follows:

[0027] The first step is the surface treatment of raw materials. The weighed Ti, Cu, Ni, Zr and Sn were removed by pickling to remove the surface scale, and then the oil was removed by ultrasonic vibration.

[0028] The second step is to prepare alloy ingots through high vacuum arc melting and suction casting equipment. Using a conventional arc melting method, under the protection of high-purity argon, the surface-treated raw materials were smelted for the first time, with a...

Embodiment 2

[0032] This embodiment is a (Ti-Cu-Ni-Zr)-Sn based amorphous composite material.

[0033] The (Ti-Cu-Ni-Zr)-Sn series amorphous composite material described in this example is composed of five elements including Ti, Cu, Ni, Zr and Sn, and its atomic percentage is (Ti 45 Cu 41 Ni 9 Zr 5 ) 98 sn 2 , wherein, Ti, Cu, Ni, Zr and Sn are block, and the purity is ≥99.99%.

[0034] The preparation process of the (Ti-Cu-Ni-Zr)-Sn series amorphous composite material proposed in this example is as follows:

[0035] The first step is the surface treatment of raw materials. The weighed Ti, Cu, Ni, Zr and Sn were removed by pickling to remove the surface scale, and then the oil was removed by ultrasonic vibration.

[0036] The second step is to prepare alloy ingots through high vacuum arc melting and suction casting equipment. Using a conventional arc melting method, under the protection of high-purity argon, the surface-treated raw materials were smelted for the first time, with a ...

Embodiment 3

[0040] This embodiment is a (Ti-Cu-Ni-Zr)-Sn based amorphous composite material.

[0041] The (Ti-Cu-Ni-Zr)-Sn series amorphous composite material described in this example is composed of five elements including Ti, Cu, Ni, Zr and Sn, and its atomic percentage is (Ti 45 Cu 42.5 Ni 7.5 Zr 5 ) 98 sn 2 , wherein, Ti, Cu, Ni, Zr and Sn are block, and the purity is ≥99.99%.

[0042] The preparation process of this example is as follows:

[0043] The first step is the surface treatment of raw materials. The weighed Ti, Cu, Ni, Zr and Sn were removed by pickling to remove the surface scale, and then the oil was removed by ultrasonic vibration.

[0044]The second step is to prepare alloy ingots through high vacuum arc melting and suction casting equipment. Using a conventional arc melting method, under the protection of high-purity argon, the surface-treated raw materials were smelted for the first time, with a smelting current of 400A and a smelting time of 5 minutes. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap