Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Ultrasonic vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic vibration-assisted (UVA) machining is a process which makes use of a micro-scale high frequency vibration applied to a cutting tool to improve the material removal effectiveness. Its principle is to make the tool-workpiece interaction a microscopically non-monotonic process to facilitate chip separation and to reduce machining forces.

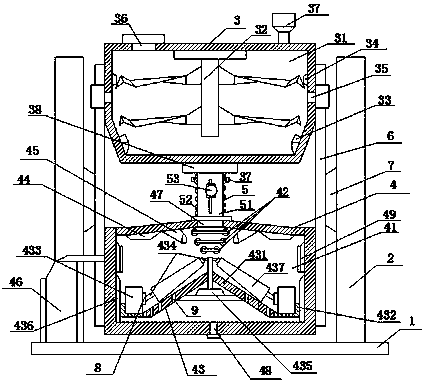

Efficient bone powder preparing system and using method

PendingCN107552202AIncrease productivityImprove product qualityGrain treatmentsProcess specificationUltrasonic vibration

Owner:郑州中技联创环境技术有限公司

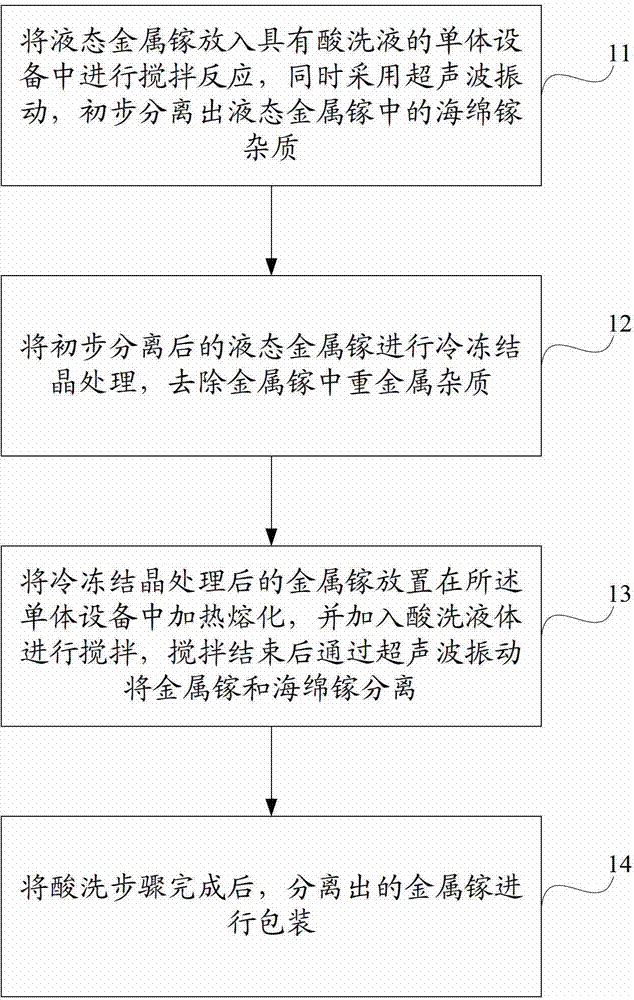

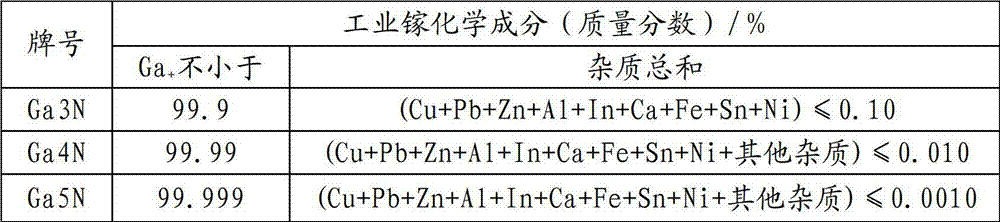

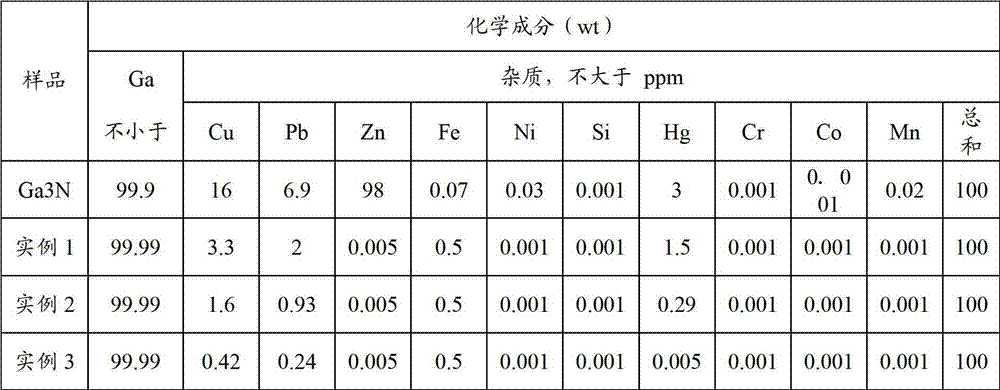

Purification method for gallium

ActiveCN103031450AQuality assuranceTo achieve the purpose of purificationProcess efficiency improvementAutomatic controlPurification methods

Owner:BEIJING JIYA SEMICON MATERIAL

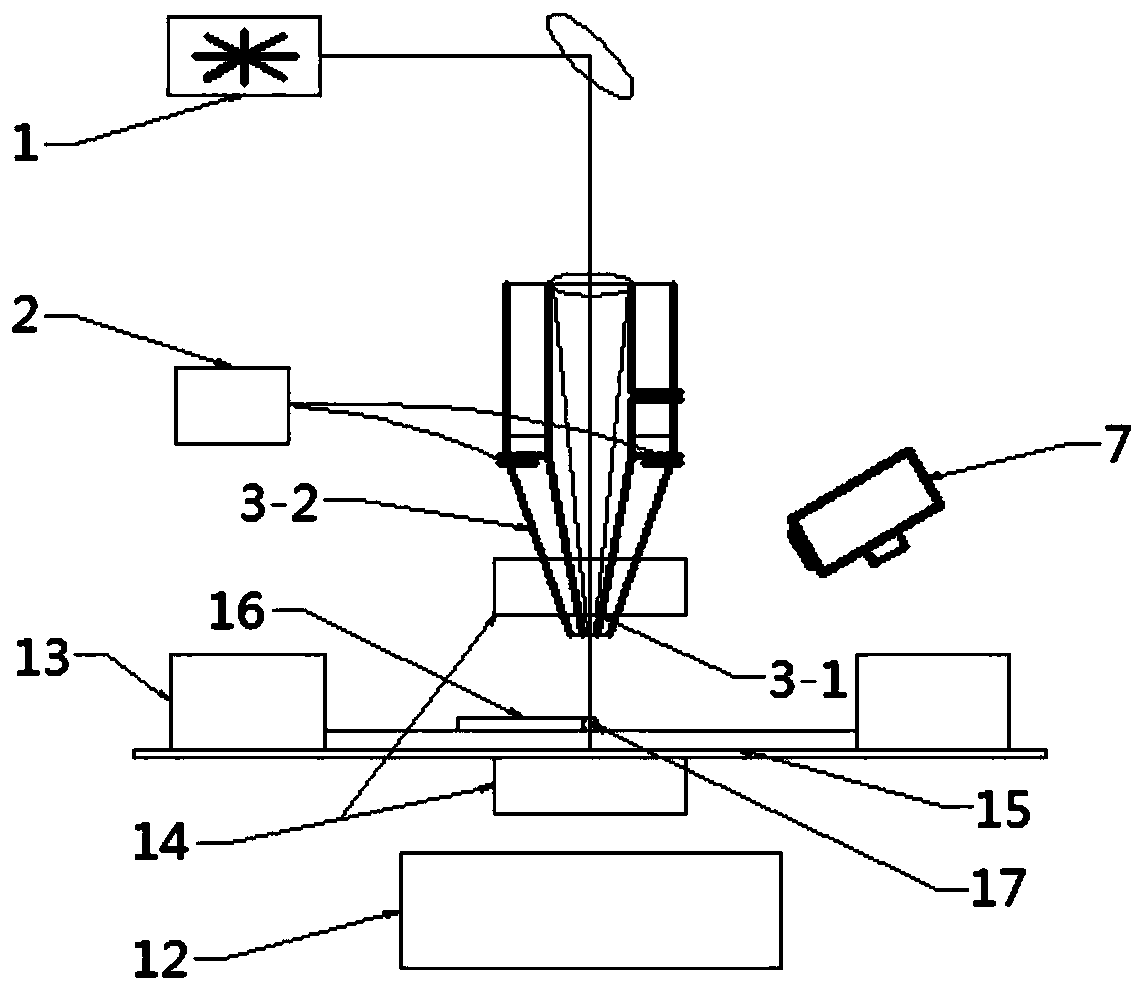

Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

InactiveCN110280904AWide range motion captureComprehensive perspectiveLaser beam welding apparatusUltrasonic assistedLaser Nozzle

Owner:JIANGSU UNIV

Converter unit

ActiveCN105960291AIncrease vibrational energyMechanical vibrations separationNon-electric welding apparatusUltrasonic vibrationEngineering

The invention relates to a converter unit comprising an ultrasonic transmission element having: a transmission surface for transmitting an ultrasonic vibration to a tool that can be attached to the transmission surface, or to a material that is in contact with same, in a longitudinal direction along a longitudinal axis of the ultrasonic transmission element; and at least one ultrasonic transducer for generating an ultrasonic vibration with a propagation direction that is not oriented along the longitudinal direction, wherein the converter unit has an ultrasonic natural frequency. In order to provide a converter unit comprising an ultrasonic transmission element having: a transmission surface for transmitting an ultrasonic vibration to a tool that can be attached to the transmission surface, or to a material that is in contact with same, in a longitudinal direction along a longitudinal axis of the ultrasonic transmission element; and at least one ultrasonic transducer for generating an ultrasonic vibration with a propagation direction that is not oriented along the longitudinal direction, wherein the converter unit has an ultrasonic natural frequency by means of which a high vibration energy can be generated, according to the invention, the ultrasonic transducer is arranged in the propagation direction in a region of + / -lambda / 4 about the longitudinal axis of the ultrasonic transmission element, where lambda is the wavelength of the vibration belonging to the ultrasonic natural frequency.

Owner:HERRMANN ULTRACHALLTECHNIK GMBH & CO KG

Ultrasonic focusing liquid vibration polishing method based on spherical shell piezoelectric transducer

The invention discloses an ultrasonic focusing liquid vibration polishing method based on a spherical shell piezoelectric transducer. The method comprises the steps that a workpiece to be processed isput in an open container, wherein the open container is filled with a polishing solution; the spherical shell piezoelectric transducer which can be moved to change the position in the horizontal or perpendicular direction is placed above the workpiece to be processed, and soaked in the polishing solution all the time, and the concave side points to the surface, to be processed, of the workpiece to be processed; and an ultrasonic power source is started to generate high-frequency electricity so as to excite the spherical shell piezoelectric transducer to generate ultrasonic vibration, the spherical shell piezoelectric transducer is moved according to a preset processing path and the retention time of focused ultrasonic waves on each processing point, ultrasonic vibration is transmitted bythe polishing solution to be focused on the workpiece to be processed, and the surface of the workpiece to be processed is polished. The ultrasonic focusing liquid vibration polishing method based onthe spherical shell piezoelectric transducer can achieve accurate correction of the surface of the workpiece.

Owner:TIANJIN UNIV

Casting device and casting method

InactiveCN105642869AProlong ultrasonic vibration timeImprove Sonication EfficiencyFoundry mouldsFoundry coresDie castingUltrasonic vibration

Owner:QINGDAO TAIWEI MACHINE TOOL

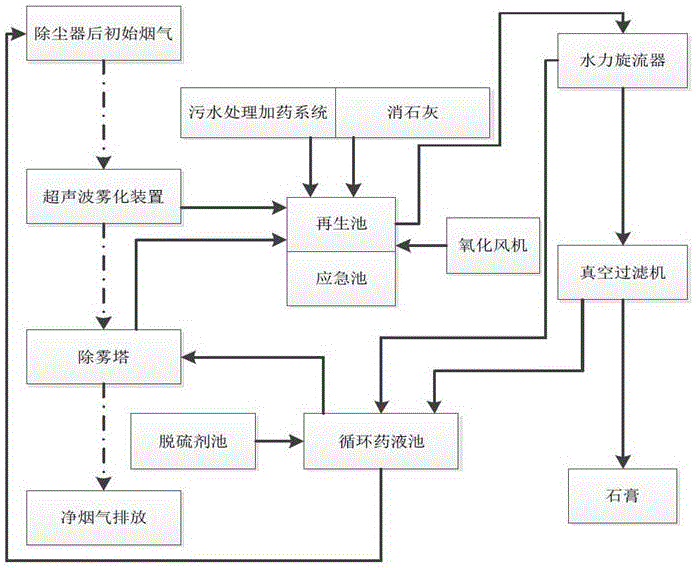

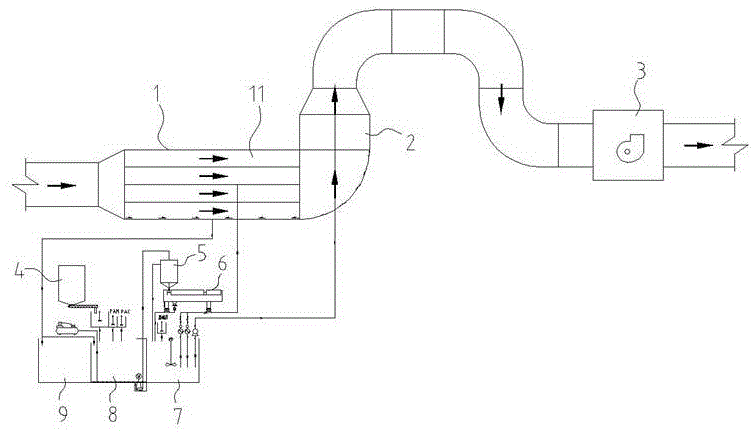

Thermal power plant ultrasonic atomization desulfurization-dust removal-ammonia escape prevention integrated system

InactiveCN107433115ALow concentration of sulfur dioxideReduce dust contentCombination devicesGas treatmentAutomatic controlEngineering

Owner:陈佐会

Method for improving quality of inner wall of laser processing micropore based on dual cavitation effect

ActiveCN114589405AImprove inner wall qualityDecrease produces trendProcess efficiency improvementLaser beam welding apparatusUltrasonic cavitationLaser processing

Owner:SHANDONG UNIV OF TECH

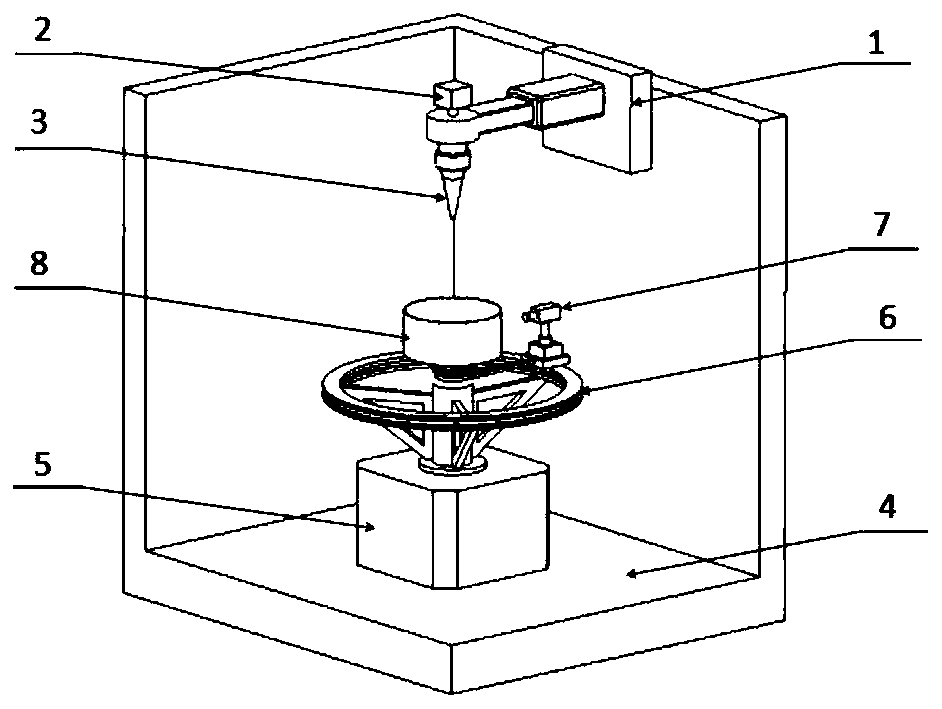

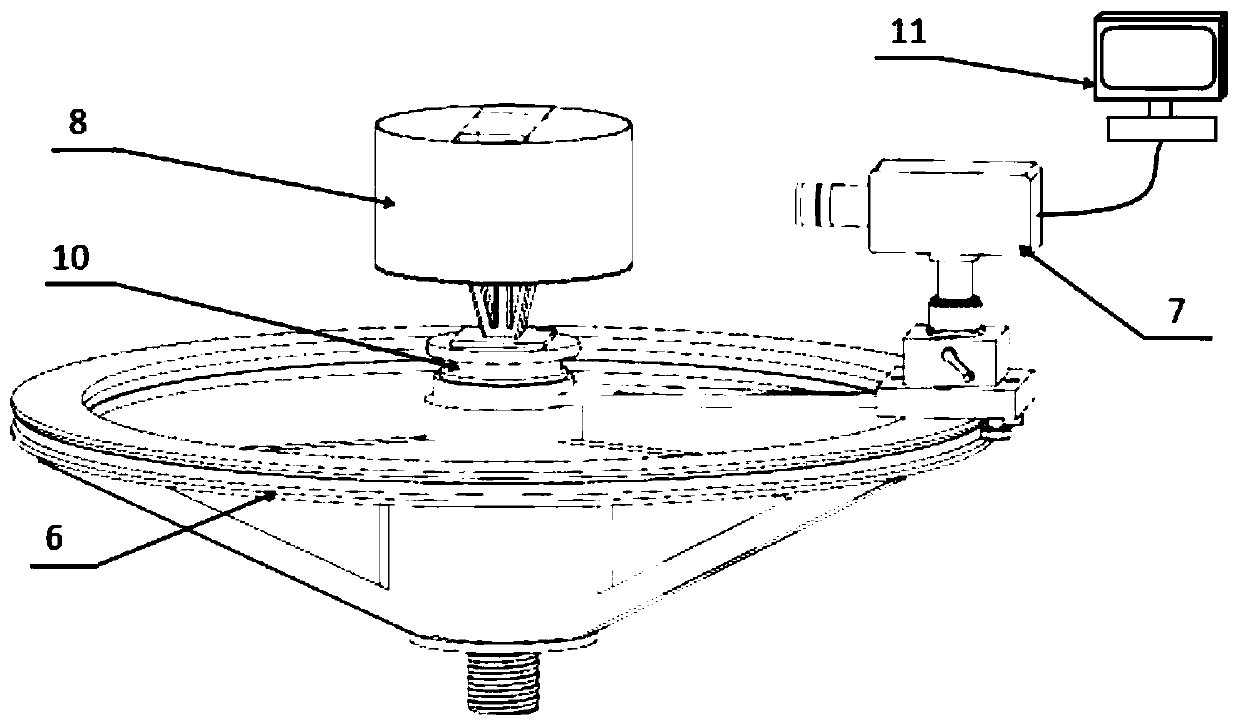

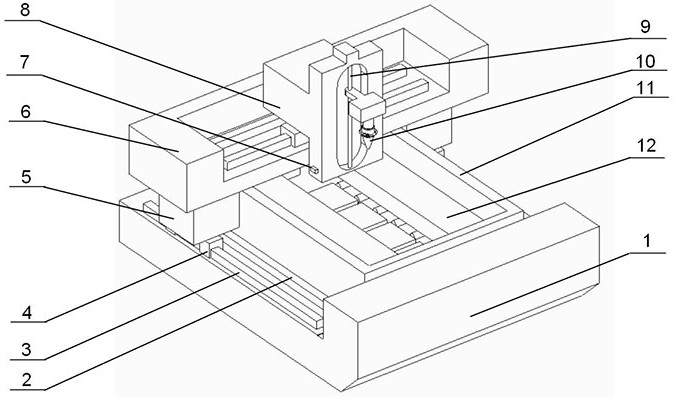

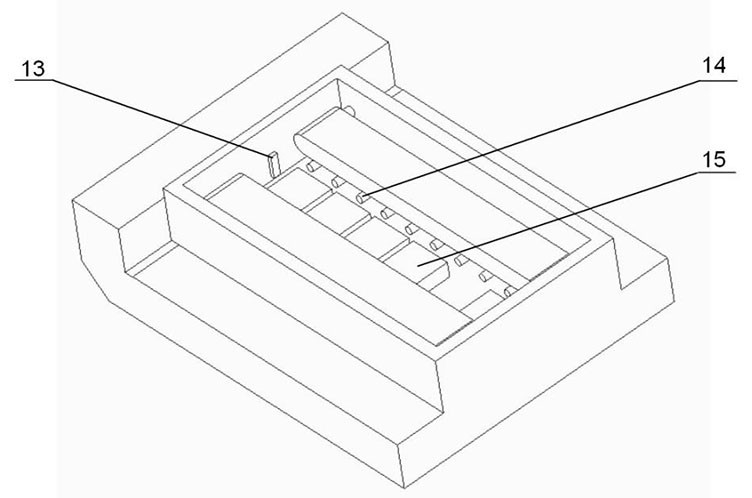

Tooth surface grinding treatment device for involute bevel gear

PendingCN109551060AMotion Precise ControlImprove processing qualityGear teethInvoluteUltrasonic vibration

The invention relates to the field of gear machining and discloses a tooth surface grinding treatment device for an involute bevel gear. The tooth surface grinding treatment device for the involute bevel gear comprises a workbench, an ultrasonic vibration system and a grinding device. The workbench is provided with a limiting column. The periphery of the limiting column is provided with a loadingplate used for bearing the gear and can rotate around the limiting column. The ultrasonic vibration system comprises an ultrasonic generator, an ultrasonic transducer and an amplitude-variable pole. The grinding device comprises a grinding head and a grinding head support. According to the tooth surface grinding treatment device for the involute bevel gear, ultrasonic waves are utilized to drive ato-be-machined gear to swing, so that the grinding head makes full contact with the tooth surface of the gear, and therefore the machining efficiency is improved; the grinding head matched with the to-be-machine gear is utilized to be matched with the periphery of the gear, so that the grinding head can simultaneously grind the tooth surfaces of the gear, the work efficiency is high, and the tooth surfaces of the gear cannot be damaged.

Owner:JIANGXI FG NEW ENERGY TRANSMISSION TECH CO LTD

Method for preparing dried pawpaw by ultrasonic vibration

InactiveCN109497465ASimply goodGreat tasteFood dryingFood ultrasonic treatmentSaline waterUltrasonic vibration

Owner:唐立

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap