Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Maximum diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exercise Device

InactiveUS20090112137A1Simple and inexpensive to manufactureEasy to useRoller massageTherapy exerciseMaximum diameterEngineering

An exercise device for a person, comprising at least two substantially rigid rails, each rail having an outer surface, and inner surface, and at least one peripheral edge connecting the outer surface to the inner surface. The at least one peripheral edge includes at least one axle slot formed therein. At least one substantially cylindrical axle has two ends and is adapted for rotatably and removably receiving at least one substantially cylindrical roller thereon. Each end of each axle is adapted to be captured within one of the axle slots of one of the rails. Each roller has a peripheral surface and a maximum diameter. Each axle is spaced a distance from an adjacent axle of at least the maximum diameter of the rollers, whereby each roller may rotate freely on the at least one axle. The exercise device is able to support a person lying on his back on the rollers on a flat surface.

Owner:LAMORE GEORGE

Abrasive tools made with a self-avoiding abrasive grain array

InactiveUS20050076577A1Pigmenting treatmentRevolution surface grinding machinesMaximum diameterAbrasive

Abrasive tools contain abrasive grains oriented in an array according to a non-uniform pattern having an exclusionary zone around each abrasive grain, and the exclusionary zone has a minimum dimension that exceeds the maximum diameter of the desired grit size range for the abrasive grain. Methods for designing such a self-avoiding array of abrasive grain and for transferring such an array to an abrasive tool body are described.

Owner:SAINT GOBAIN ABRASIVES INC

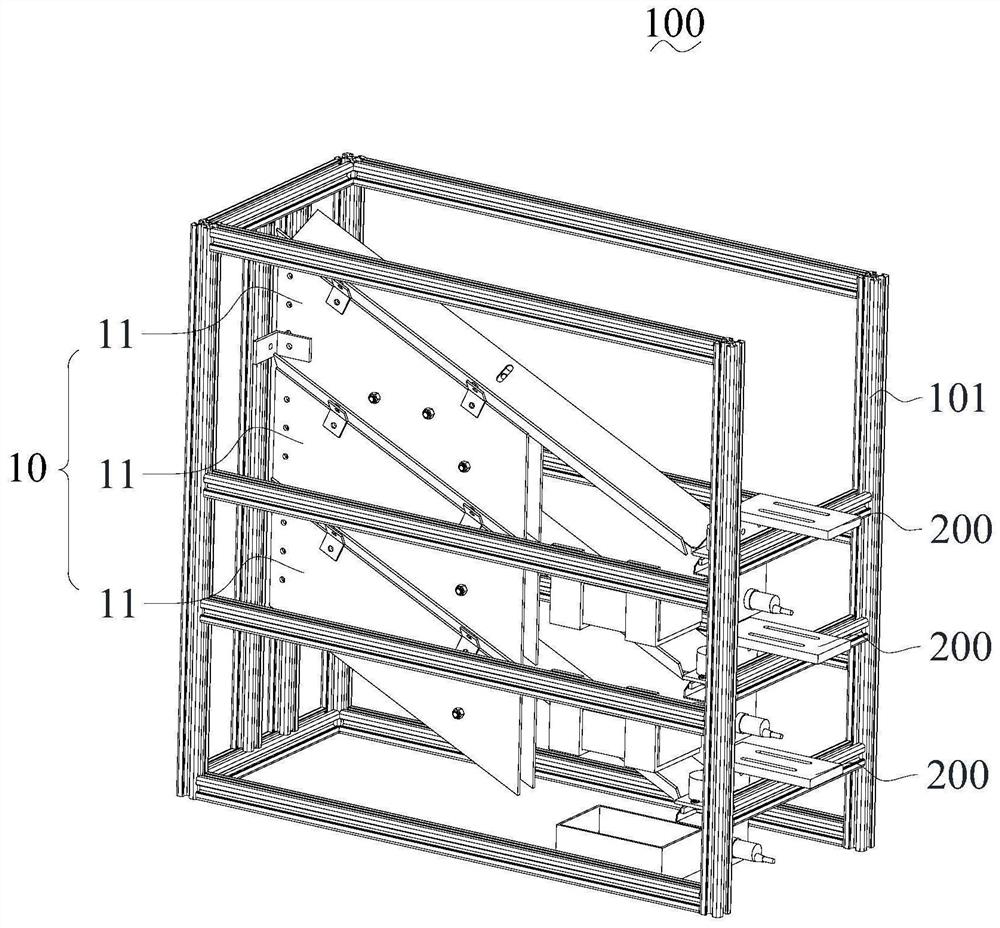

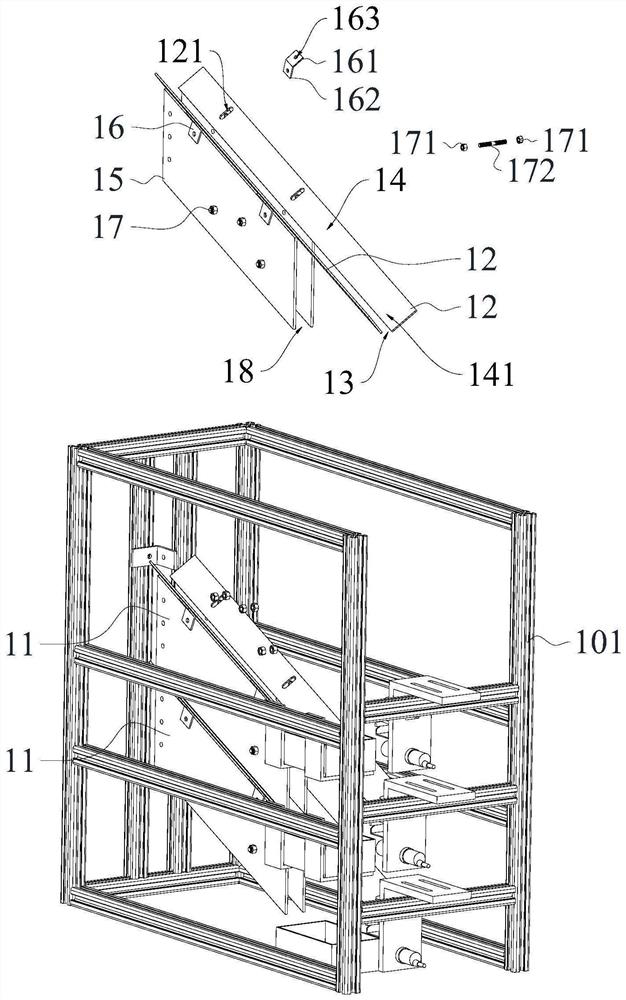

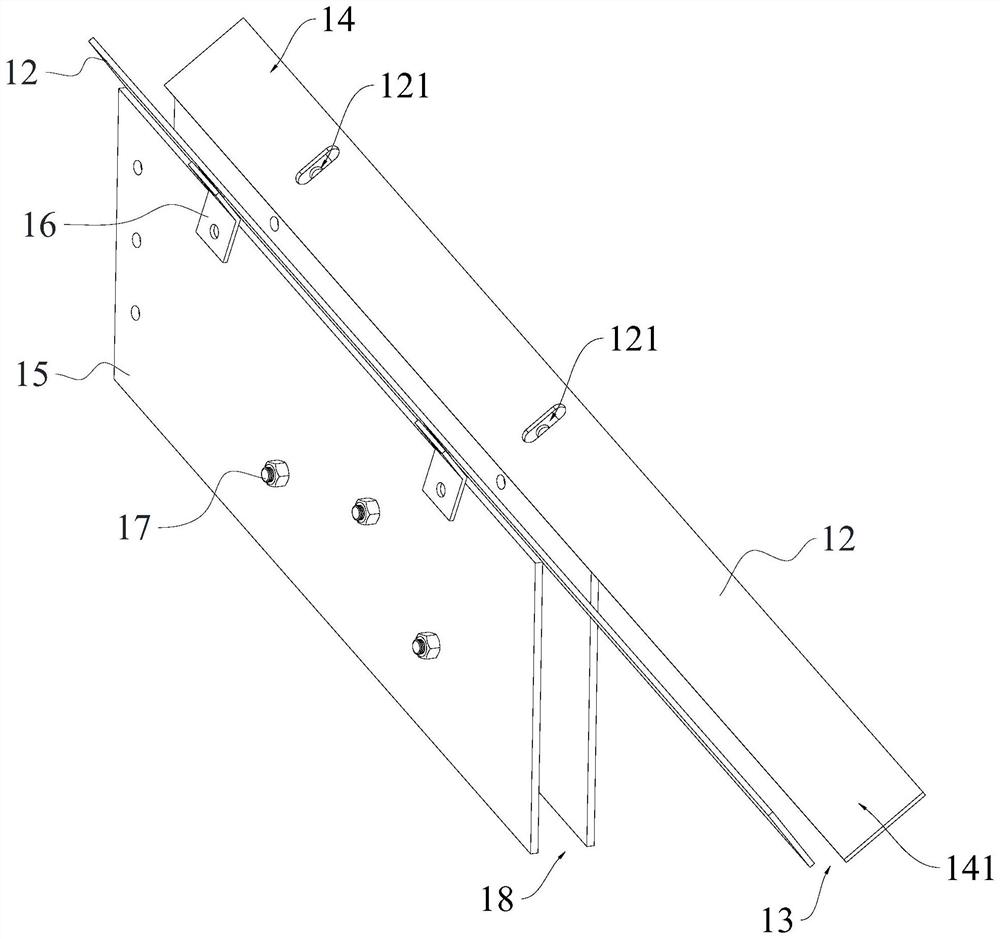

Diameter sorting device and sorting equipment

Owner:SHENZHEN UNIV

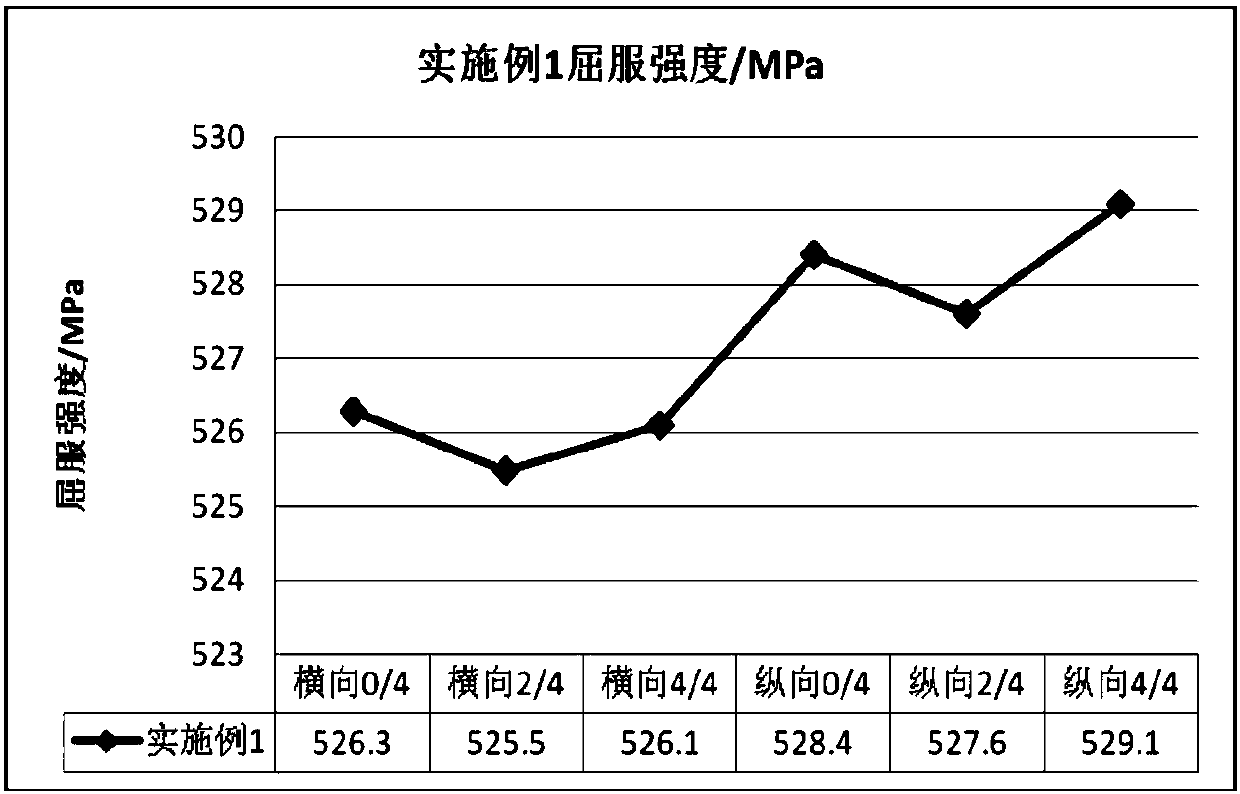

Production method of large-wall-thickness straight-seam submerged-arc-welded pipeline steel plate

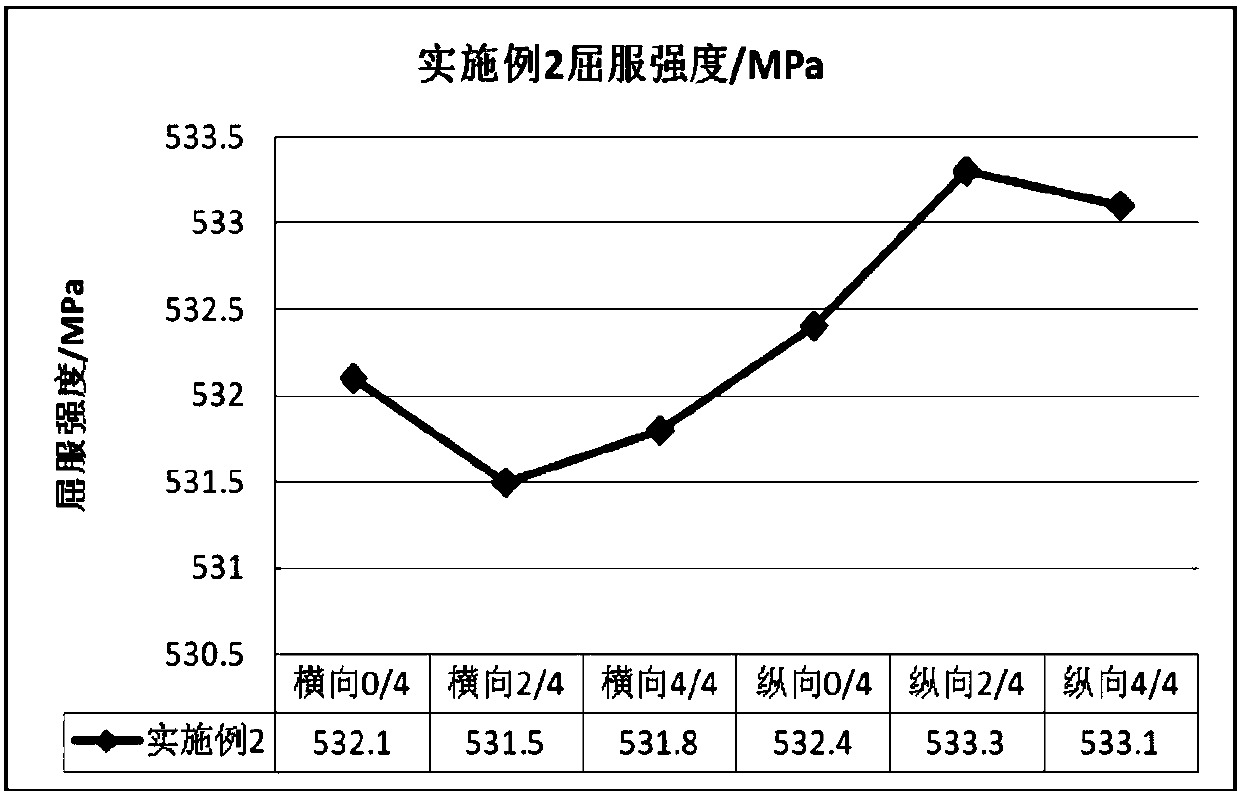

ActiveCN107641768ASmall grain size variabilityUniform mechanical propertiesSheet steelMaximum diameter

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

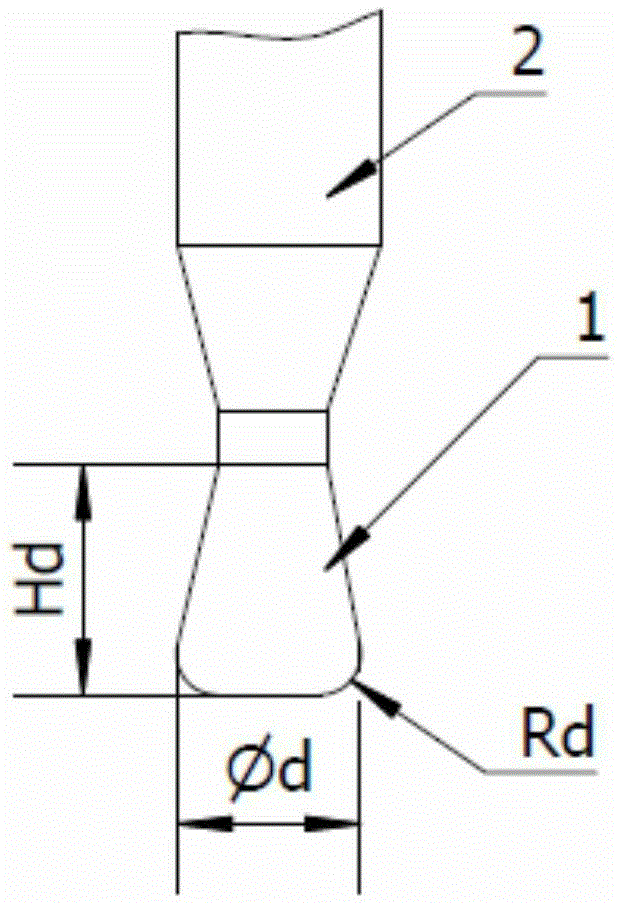

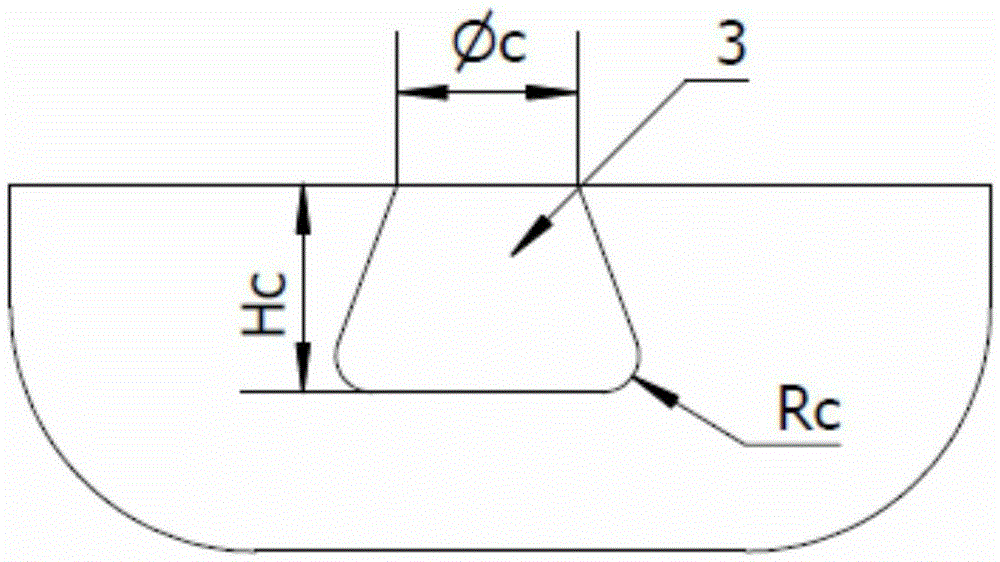

Forming tool for machining inverted-trapezoid sealing ring groove of ceramic component and machining method of forming tool

InactiveCN105382657AEasy to processFast processingBonded abrasive wheelsGrinding machinesHead sizeMaximum diameter

Owner:SHANGHAI COMPANION PRECISION CERAMICS

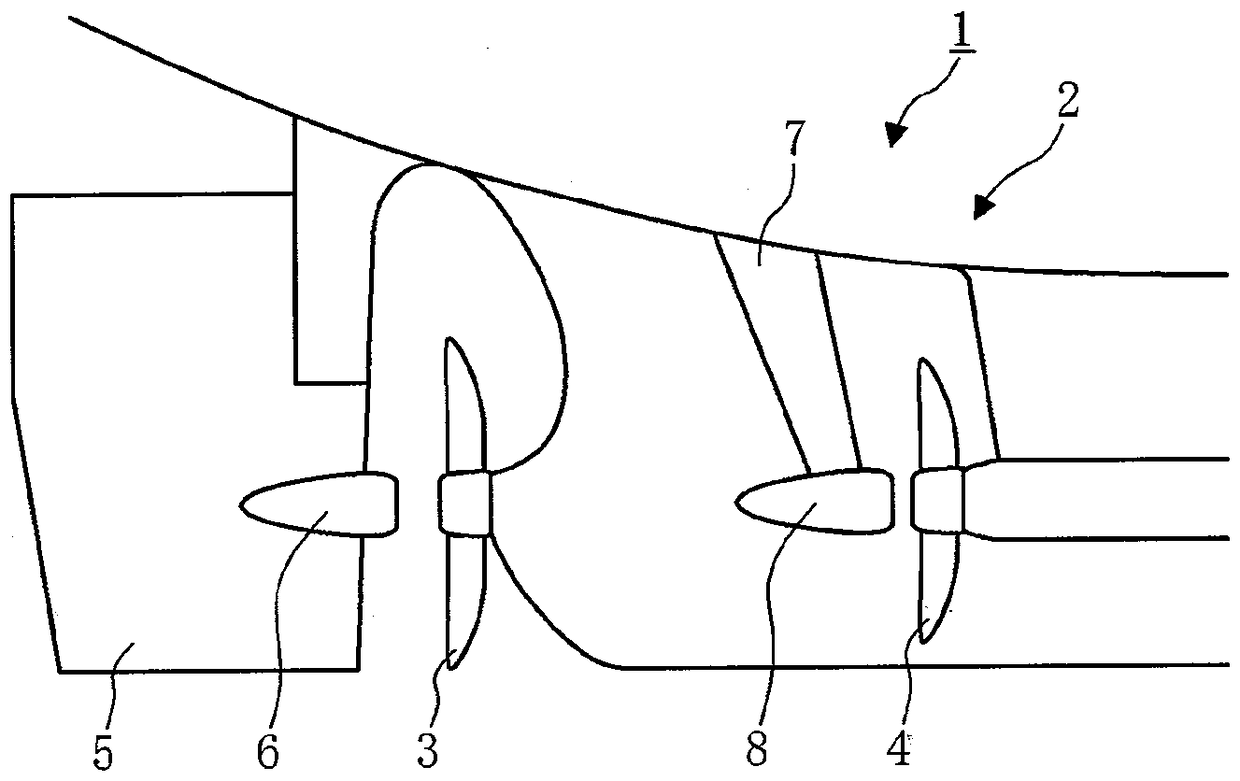

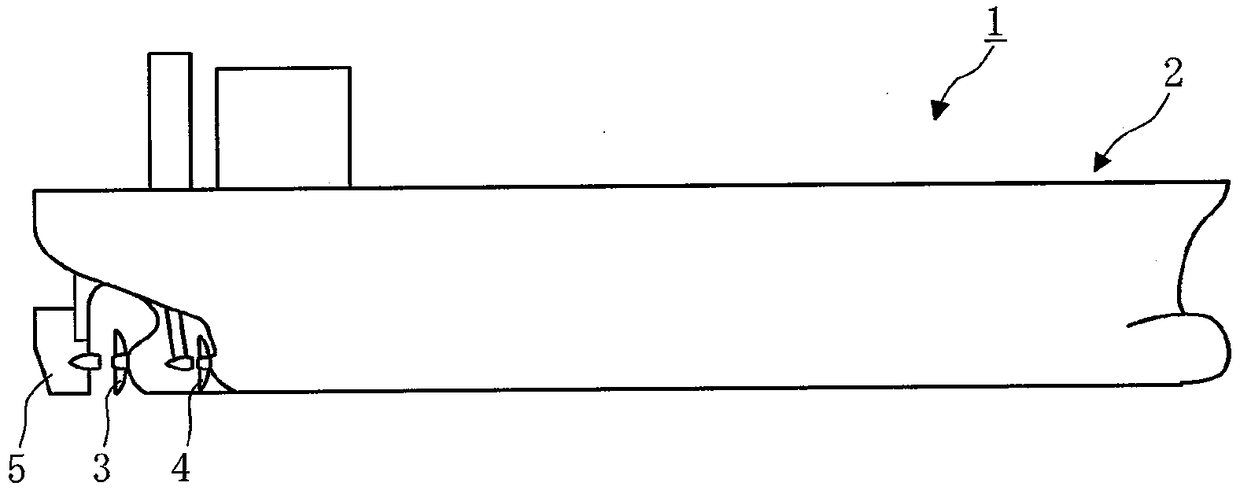

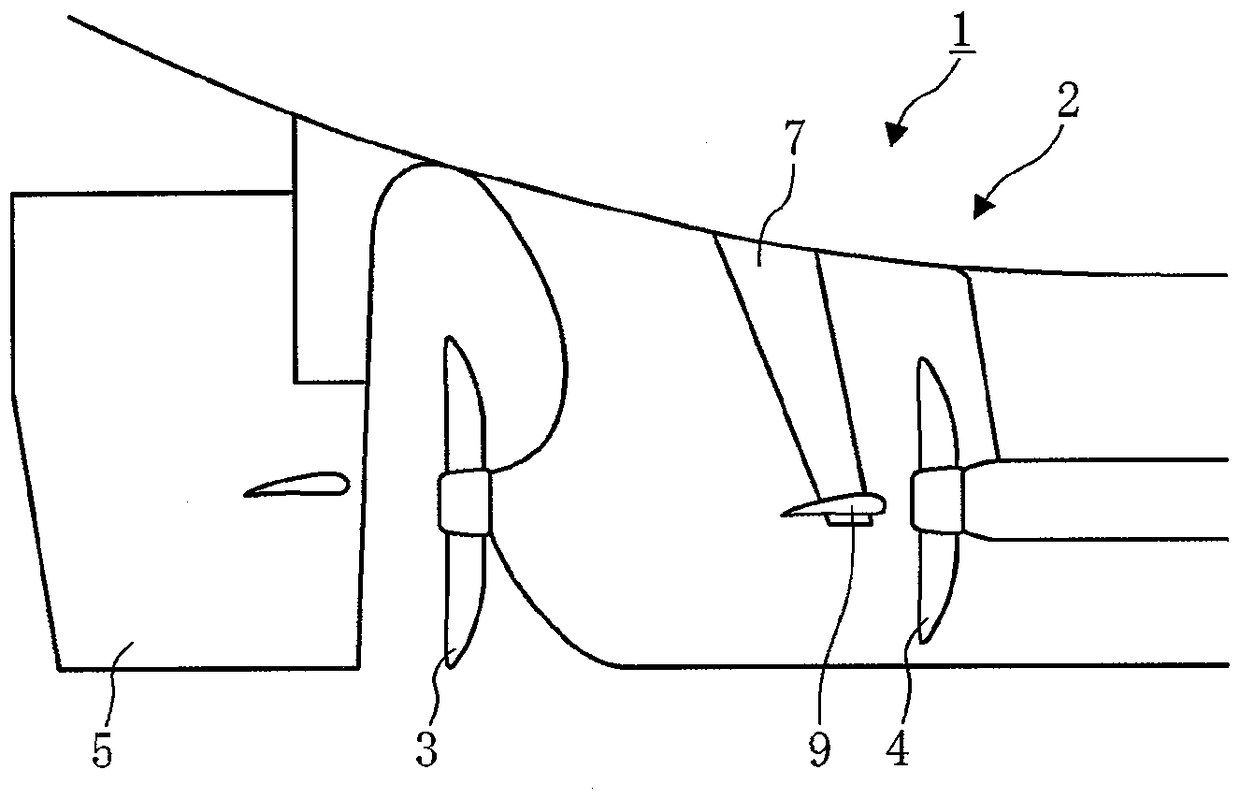

Propulsion device for multi-shaft ship

Owner:JAPAN MARINE UNITED CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap