Forming tool for machining inverted-trapezoid sealing ring groove of ceramic component and machining method of forming tool

A technology for ceramic parts and forming tools, applied in the field of ceramic processing, can solve the problem of inability to process inverted trapezoidal sealing ring grooves, and achieve the effects of stable size, fast processing and correct groove shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

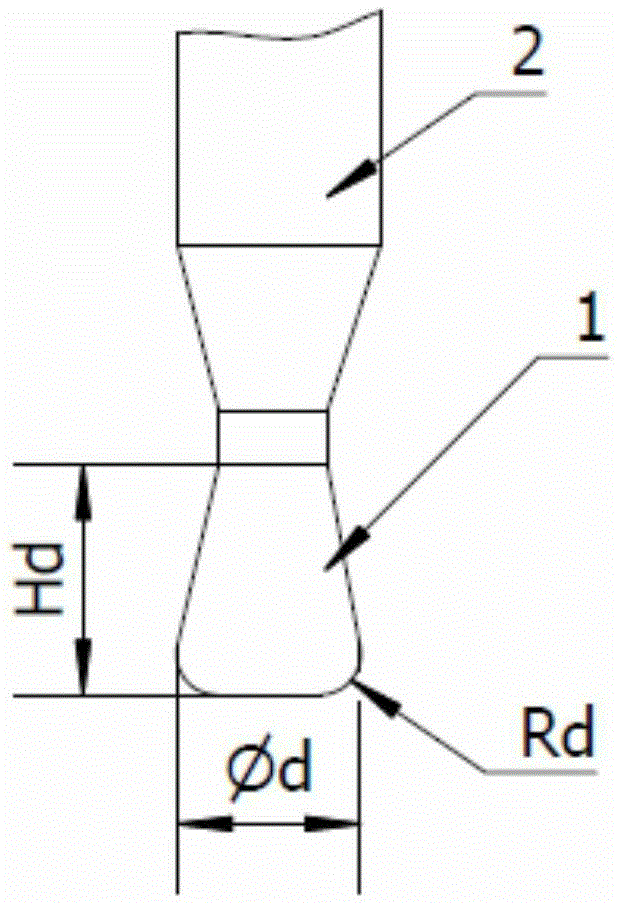

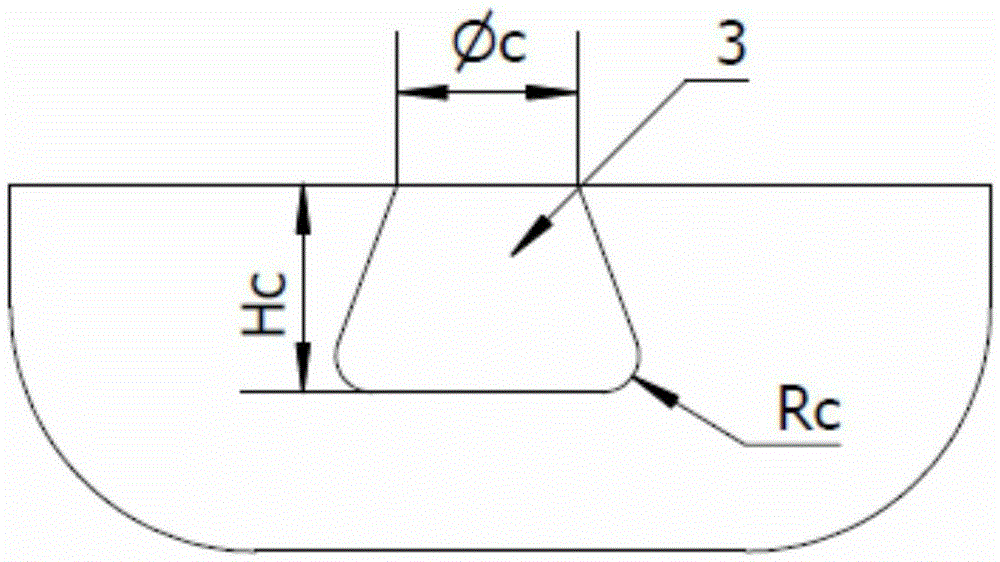

[0022] like Figures 1 to 2 As shown, an inverted trapezoidal sealing ring groove forming tool for processing ceramic parts includes a tool head 1 and a tool handle 2, wherein the tool head 1 is an inverted trapezoid, and the short side of the trapezoid is connected to the tool handle 2, the The maximum diameter Фd of the tool head 1 is smaller than the minimum notch width Фc of the inverted trapezoidal sealing ring groove 3 to be processed, and the long side fillet Rd of the tool head 1 is the same as the rounded corner Rc of the inverted trapezoidal sealing ring groove 3 to be processed. Correspondingly, the length Hd of the tool head 1 corresponds to the depth Hc of the groove of the inverted trapezoidal sealing ring to be machined.

[0023] The tool handle 2 is a cylindrical body with one end in the shape of a truncated cone, and the truncated end of the tool handle 2 is connected with the short side of the tool head. The tool head 1 is connected to the drilling machine thro

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap