Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Silicone oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A silicone oil is any liquid polymerized siloxane with organic side chains. The most important member is polydimethylsiloxane. These polymers are of commercial interest because of their relatively high thermal stability and their lubricating properties.

Synthesis method for terpolymer block silicone oil

ActiveCN103214676ANo demulsification and delaminationNo self-emulsifying propertiesSilicon organic compoundsFibre treatmentDisiloxaneEpoxy

Owner:ZHEJIANG JIEFA TECH

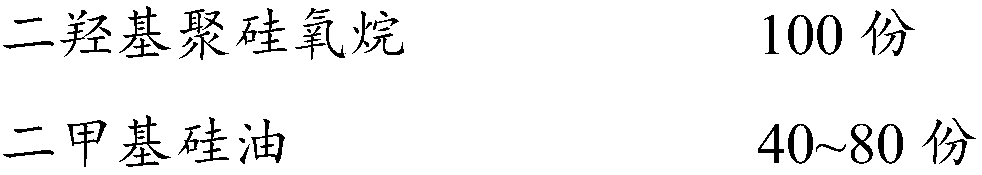

Small pore diameter silicone rubber sponge and preparation method thereof

The invention discloses small pore diameter silicone rubber sponge and a preparation method thereof and relates to the field of processing of high polymer materials. The small pore diameter silicone rubber sponge comprises the following components in parts by weight: a component A: 100 parts of liquid organic silicone rubber; a component B: 3-8 parts of hydrogen-containing silicone oil; a component C: 0.5-10 parts of an emulsifier; a component D: 2-4 parts of a catalyst; a component E: 1-2 parts of an inhibitor; and a component F: 0-35 parts of a silicon resin. An emulsion dispersion mode is adopted, the dispersion phase size is small, and the silicone rubber sponge prepared by the method has the characteristics of bubble dispersion uniformity, small pore diameter and controllable density; and moreover, water serves as a foaming agent, and the sponge has the advantage of environment friendliness. The silicone rubber sponge material prepared by the method can serve as shock absorption, insulating, sound insulation and heat insulation materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

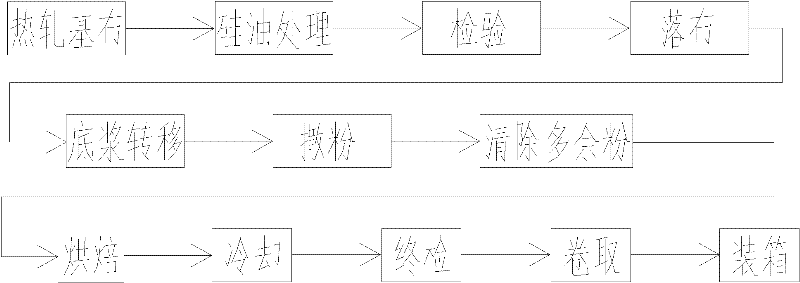

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costPolyureas/polyurethane adhesivesFibre typesInterliningPolyester

Owner:温州鸿马科技有限公司

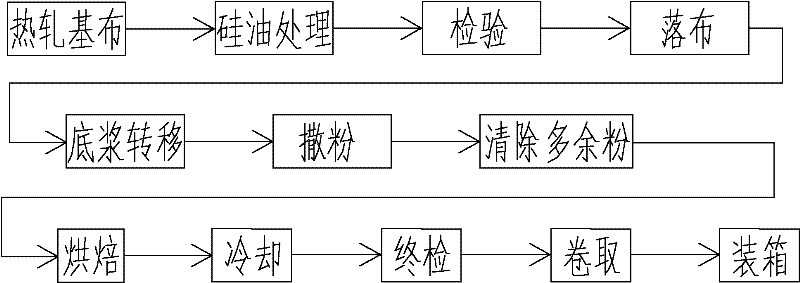

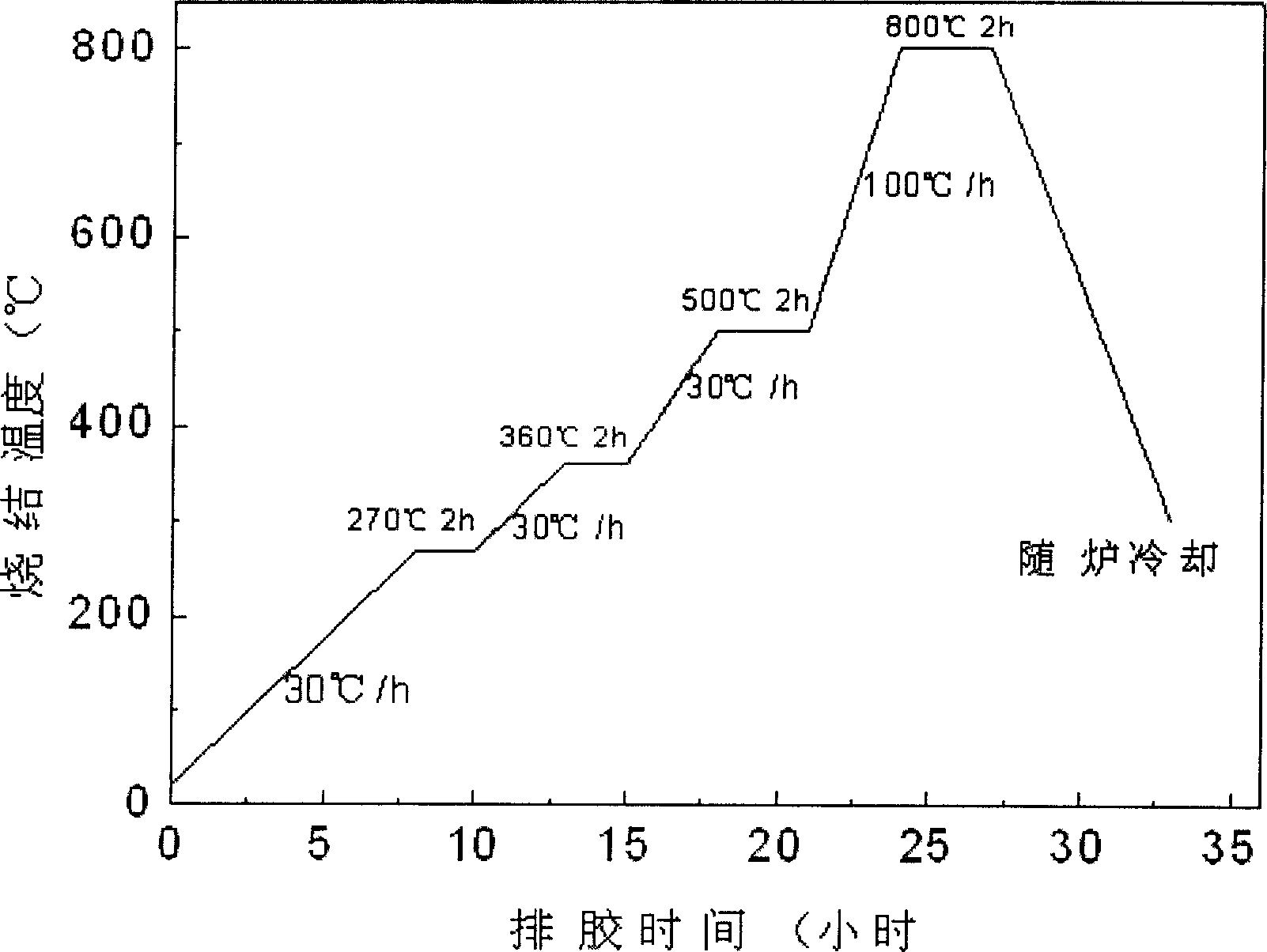

Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

InactiveCN1673178ALower coercive fieldLow resistivityPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateAdhesive

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fabric static electricity remover and preparation method thereof

ActiveCN102587126AStrong emulsificationImprove antistatic performanceFibre treatmentFiberMoisture absorption

Owner:北京绿伞科技股份有限公司

Preparation method of waterborne polyurethane emulsion and waterborne polyurethane emulsion prepared by preparation method

InactiveCN104211902AImprove waterproof performanceGood solvent resistanceHydroxybutyric acidPolymer science

Owner:内蒙古源创绿能节能环保产业创业投资合伙企业(有限合伙)

Composite underwater sound transmission rubber material and preparation method thereof

Owner:TIANJIN RUBBER IND RES INST

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ultrathin heat conductive silicon sheet and preparation method thereof

Owner:SUZHOU TIANMAI THERMAL TECH

Rooting fiber mat for seedling cultivation

ActiveCN103621351AIncrease elasticitySynthetic resin layered productsCultivating equipmentsFiberPotassium

Owner:云南交投生态环境工程有限公司

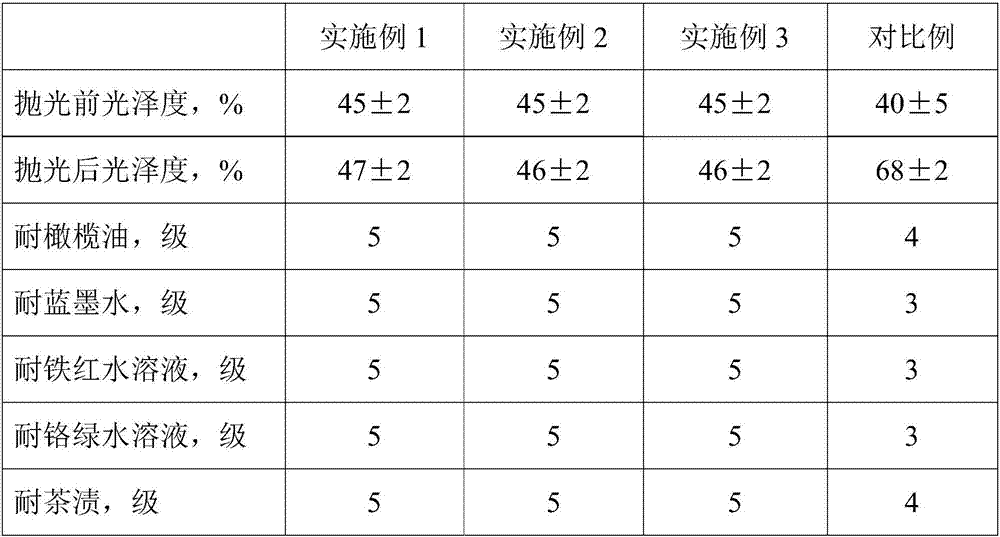

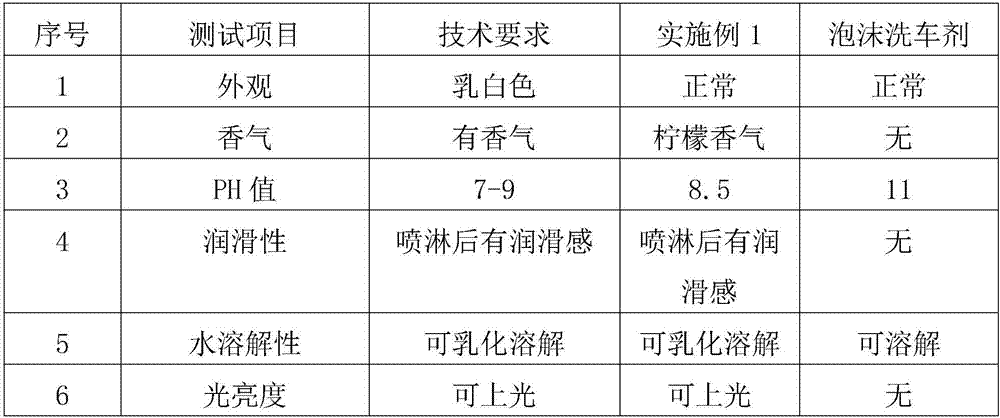

Stone surface polishing coating agent, and preparation method and application thereof

InactiveCN103756572AImprove timelinessStrong antifouling effectPolishing machinesPolishing compositions with abrasivesEpoxyEmulsion

Owner:FOSHAN LINK WAY CHEM

SiALONC ceramic with hydrogen silicone oil and Al powder and production thereof

Owner:HARBIN INST OF TECH

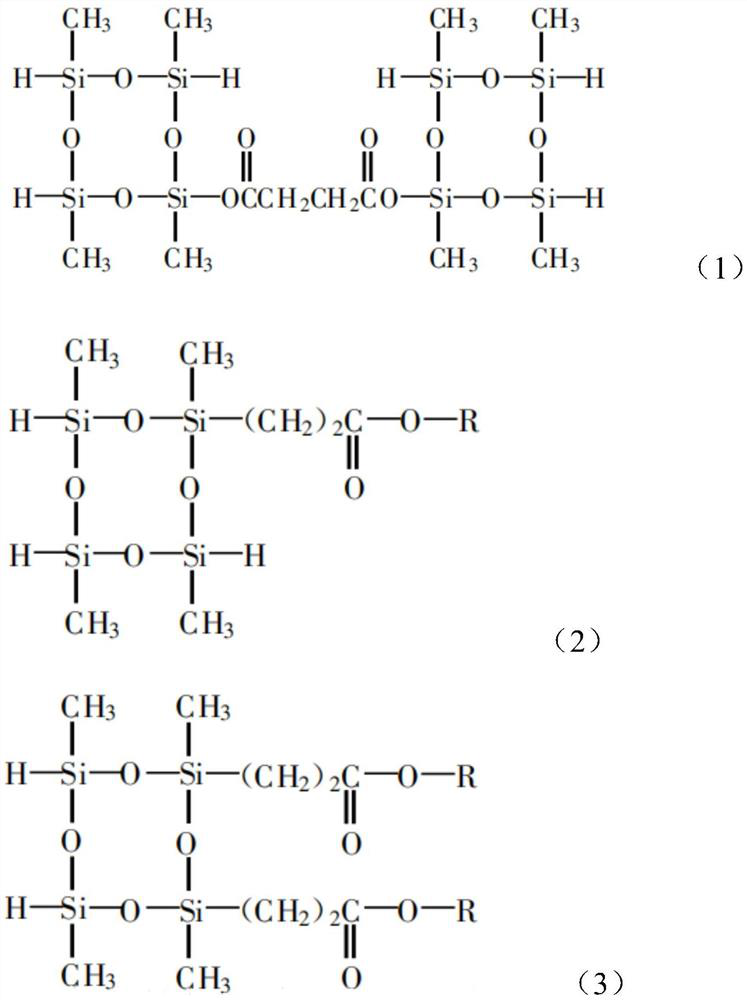

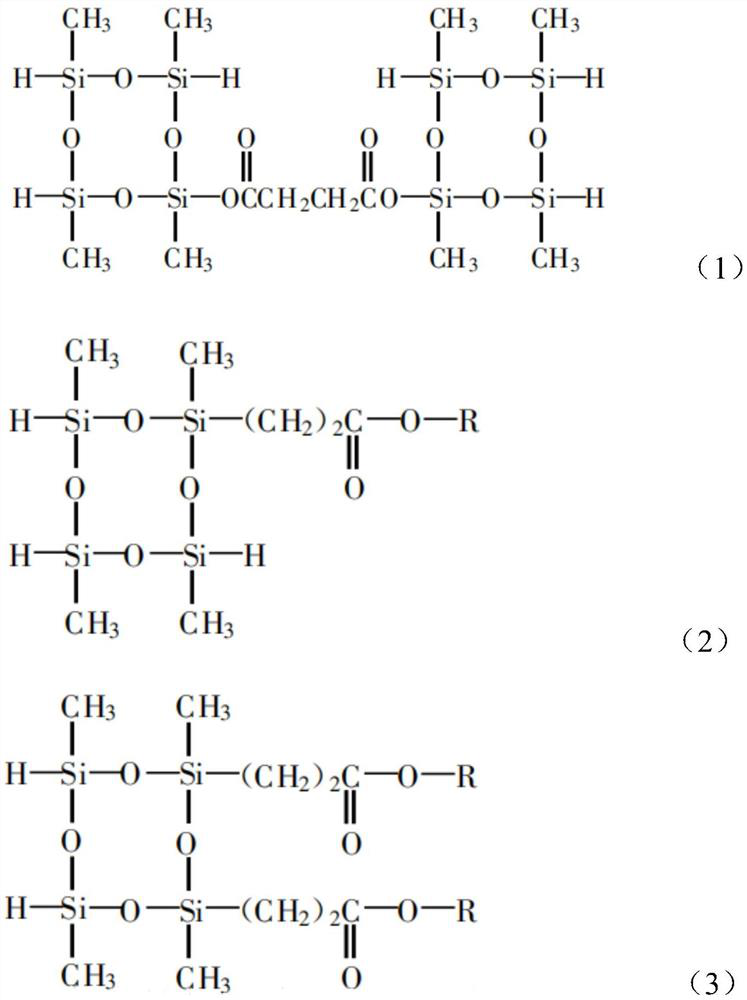

High-hardness matte ceramic antifouling agent, and preparation method thereof

ActiveCN107400461AHas hydrophobic antifouling and antibacterial effectDoes not add glossAntifouling/underwater paintsPaints with biocidesCross-linkHydrogen

Owner:黄艳红

Heat-resistant modified asphalt

Owner:WUJIANG HUAWEI SPECIAL OIL

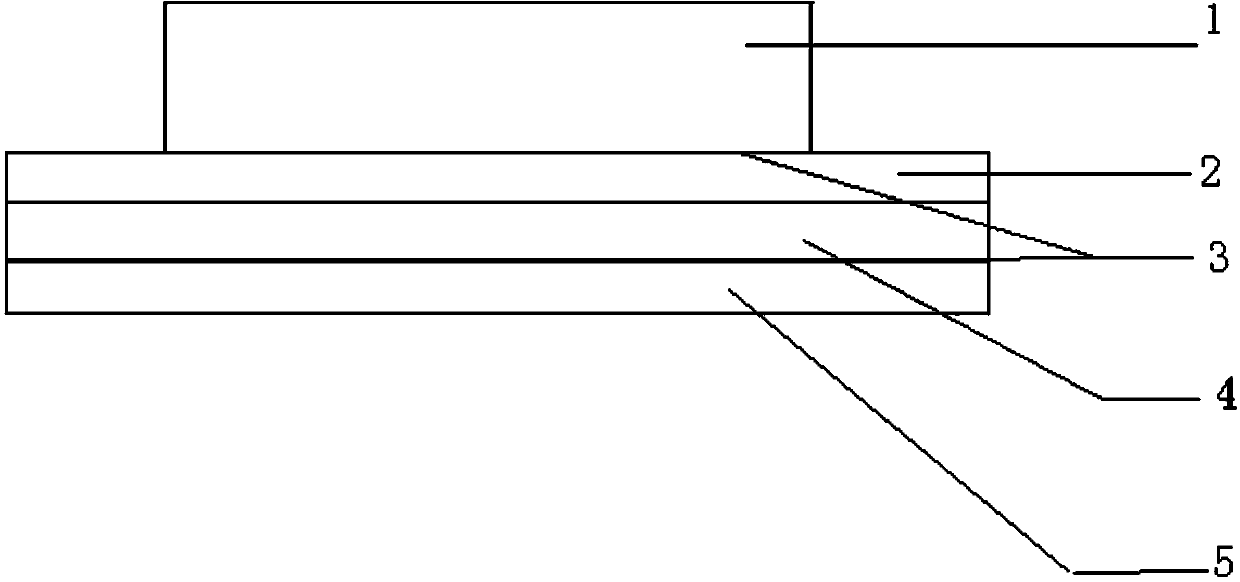

Silicone oil damper with leakage blocking and opening sealing bolt for oil filling hole

The invention relates to a silicone oil damper, and specifically relates to a silicone oil damper with a leakage blocking and opening sealing bolt for an oil filling hole. The silicone oil damper with the leakage blocking and opening sealing bolt for the oil filling hole comprises a housing, an inertial block, a cover plate, a radiating plate and a bearing belt; the radiating plate and the bearing belt are fixedly connected to the housing; the inertial block is mounted in the housing; silicone oil is filled in a clearance between the inertial block and the housing; the inertial block, the bearing block and the silicone oil are sealed in the housing; the leakage blocking and opening sealing bolt for the oil filling hole is arranged between the housing and the inertial block. According to the silicone oil damper with the leakage blocking and opening sealing bolt for the oil filling hole, the opening sealing bolt with a novel design is adopted and directly screwed, thus the bolt which protrudes from the housing and is to be milled through a mill is avoided, and the purpose of quickly and conveniently sealing the oil filling hole; in addition, the phenomenon of oil leakage can be avoided; compared with the traditional milling sealing technology, the silicone oil damper has the advantages of being fast and convenient; the used opening sealing bolt is simple in structure, small in size and convenient to use; the oil filling hole of the vibration absorber can effectively blocked; in addition, the silicone oil damper can stably and reliably work.

Owner:JIANGSU HONGFENG AOKAI ELECTROMECHANICAL

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Novel powder metallurgical gear

InactiveCN106041095AUniform densityLarge elongationTransportation and packagingMetal-working apparatusCarbon fibersALUMINUM STEARATES

Owner:黄宇

Bismaleimide resin/silicone rubber ablation-resistant thermal insulation composite material and preparation method thereof

Owner:湖北三江航天江北机械工程有限公司

Non-stick coating layer and coating process thereof

InactiveCN111171682ASmall coefficient of static frictionLower coefficient of dynamic frictionPretreated surfacesSpecial surfacesPolymer sciencePapermaking

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:CHENGRUN (JIAXING) NEW MATERIAL TECH CO LTD

Ultraviolet-proof anhydrous automobile-washing agent and preparation method thereof

InactiveCN106929200AEfficient removalExcellent decontaminationInorganic/elemental detergent compounding agentsCationic surface-active compoundsUltravioletSalicylic acid

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

Organic silicon electronic potting adhesive for PCB circuit board with stable dielectric insulation performance

InactiveCN106634810AHigh tensile strengthHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesDielectricAdhesive

The invention discloses an organic silicon electronic potting adhesive for a PCB circuit board with stable dielectric insulation performance. The organic silicon electronic potting adhesive is prepared from the following raw materials in parts by weight: 40 to 50 parts of vinyl-terminated silicone oil-1, 50 to 60 parts of vinyl-terminated silicone oil-2, 0.38 to 0.5 part of 12% of a platinum catalyst, 0.02 to 0.04 part of acetenyl cyclohexanol, 25 to 30 parts of vinyl silicon resin, 14.8 to 16.8 parts of 1-allyloxy-2,3-epoxypropane, 23 to 25 parts of 1,3,5,7-tetramethyl cyclotetrasiloxane, 2.7 to 3.6 parts of a silane coupling agent A171, an appropriate amount of silicon-containing silicon oil, 2.6 to 3 parts of mica powder, 1.8 to 3 parts of porcelain powder, 0.2 to 0.3 part of dimethyl silicone polymer, 4.6 to 5 parts of carboxylated latex, 1.1 to 1.6 parts of polyvinyl alcohol and an appropriate amount of deionized water. The potting adhesive disclosed by the invention has high heat conduction, dielectric insulation, impact resistance and adhesive performance, is high in fluidity, and is extremely suitable for potting electronic products.

Owner:TONGLING ONBOLE PCB CO LTD

Turmeric scalp follicle cleaning liquid and production method thereof

InactiveCN108785210ASimple recipeEasy to prepareCosmetic preparationsHair cosmeticsMint extractHair follicle

The invention discloses turmeric scalp follicle cleaning liquid and a production method thereof. The turmeric scalp follicle cleaning liquid comprises the following components in percent by mass: 10%of a fenugreek seed extract, 5% of a mint extract, 5% of a ginger root extract, 0.5% of tea polyphenol, 5% of ethanol, 2% of propylene glycol, 0.1% of an essence and the balance of deionized water. The turmeric scalp follicle cleaning liquid is simple in formula, simple in production method and convenient to use; through natural extracts such as the fenugreek seed extract, the mint extract, the ginger root extract and the tea polyphenol, the turmeric scalp follicle cleaning liquid cleans and conditions the surface of scalp and is safe and environment-friendly; meanwhile, through small molecules such as the ethanol and the propylene glycol, the turmeric scalp follicle cleaning liquid deeply penetrates into follicles to clean the follicles deeply, so that silicone oil, left on the scalp, inliquid shampoo and unwashed grease are removed, the cleanliness of the follicles is improved, the bacterial growth caused by blockage is reduced, and the health of the scalp is promoted.

Owner:CHENGDU ZHUOLANYA BUSINESS INFORMATION CONSULTING CO LTD

Two-component organic silicon composition for mold top packaging and preparation method thereof

Owner:广东皓明有机硅材料有限公司

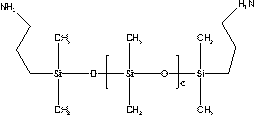

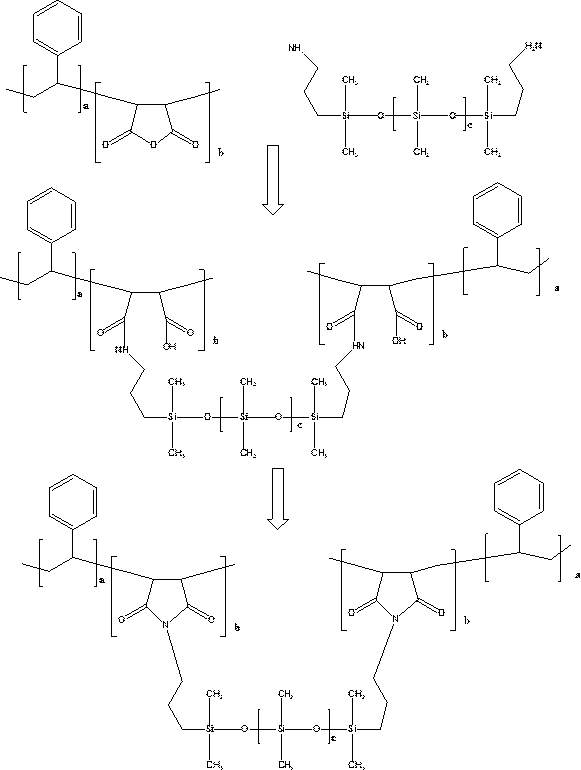

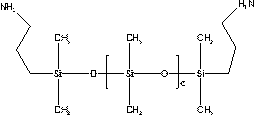

Synthesis of end amino silicone oil modified stryenemaleic anhydride copolymer

InactiveCN109337085AFlexible structure adjustmentControl Molecular Weight DistributionElastomerPolyolefin

Owner:YANTAI DARBOND TECH

Wear-resistant flame-retardant TPU material and preparation method thereof

The invention relates to the technical field of TPU materials, and particularly discloses a wear-resistant flame-retardant TPU material and a preparation method thereof. The TPU material is prepared from the following raw materials in parts by weight: 60 to 100 parts of polyurethane, 15 to 30 parts of epoxy resin, 3 to 10 parts of di-o-chlorodiphenylamine methane, 20 to 50 parts of polyethylene, 10 to 28 parts of modified calcium sulfate dihydrate whisker, 10 to 28 parts of composite flame retardant and 2 to 6 parts of silicone oil. The preparation method comprises the following steps: uniformly mixing the silicone oil and the modified calcium sulfate dihydrate whisker to obtain a mixture A; uniformly mixing polyurethane, epoxy resin, di-o-chlorodiphenylamine methane and polyethylene to obtain a mixture B; then adding the composite flame retardant into the mixture B, and uniformly stirring to obtain a mixture C; finally, uniformly mixing the mixture A and the mixture C to prepare the wear-resistant and flame-retardant TPU material. The wear-resistant flame-retardant TPU material disclosed by the invention has the advantages of high wear resistance and high flame retardance.

Owner:RONGWEIDA OPTOELECTRONICS (DONGGUAN) CO LTD

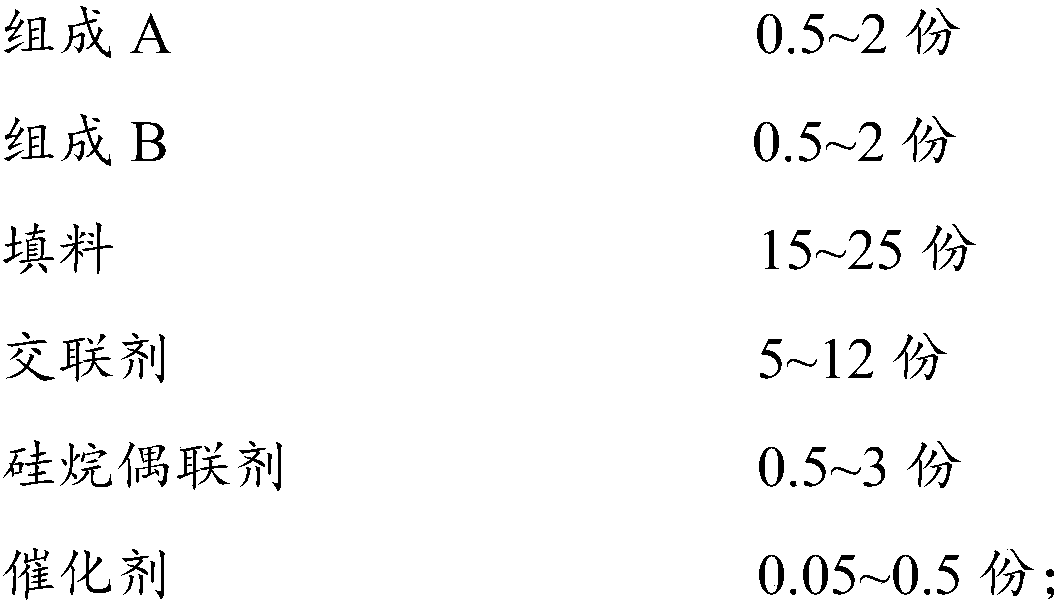

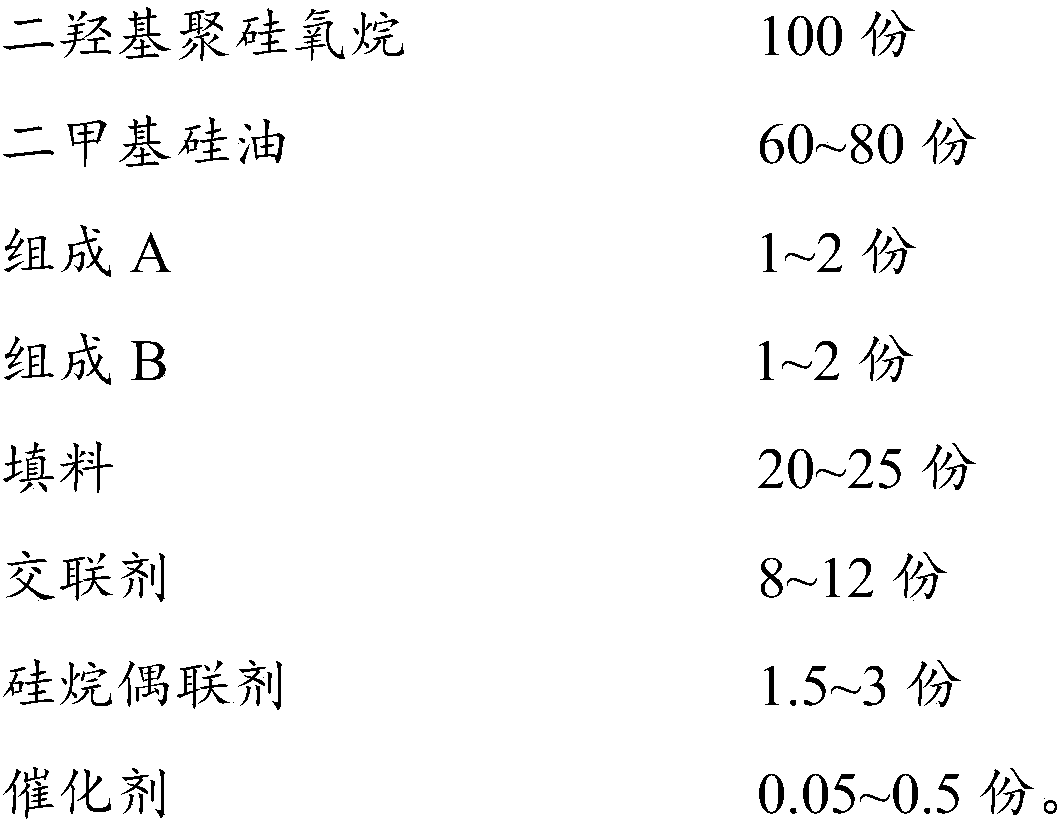

Ketonic oxime type silicone sealant and preparation method thereof

InactiveCN108192561AExcellent and long-lasting anti-mold effectAvoid yellowingNon-macromolecular adhesive additivesCross-linkThiazole

Owner:GUANGZHOU BAIYUN CHEM IND

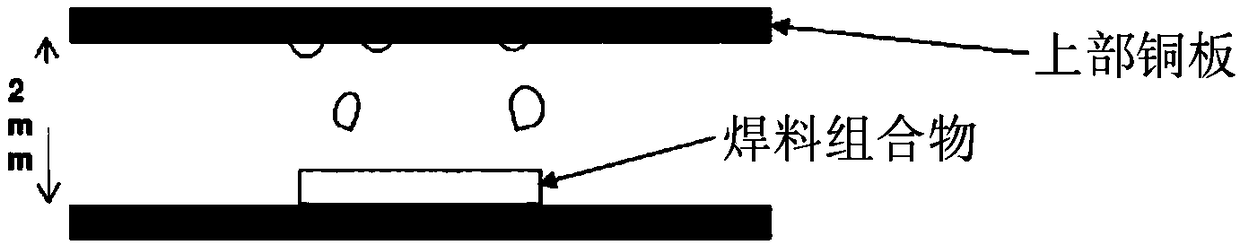

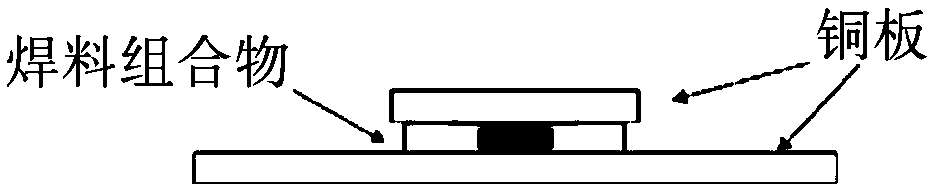

Solder composition

PendingCN109414787ASuppression of scatteringWelding/cutting media/materialsWelding/soldering/cutting articlesSilicone oilSilicon

Owner:KOKI

Borehole reinforcement shielding agent and preparation method thereof

The invention relates to a borehole reinforcement shielding agent and a preparation method thereof, and belongs to the technical field of chemical engineering. The shielding agent comprises, by weight, 40-68 parts of organic silicon resin, 10-22 parts of acrylate polymers, 6-22 parts of epoxy resin, 0.5-1.0 part of nano-blocking agents, 10-18 parts of reactive silicon oil, 0.1-0.5 part of catalysts, 0.5-1 part of emulsifying agents and 80-100 parts of deionized water. The preparation method includes the steps: sequentially adding organic silicon resin, the acrylate polymers, the epoxy resin, the reactive silicon oil and the deionized water into a reaction kettle, uniformly stirring mixture, and adjusting a pH (potential of hydrogen) value to reach 7-9; adding the emulsifying agents, stirring mixture for 2 hours, adding the nano-blocking agents, stirring mixture for 3 hours, and heating the mixture to reach the temperature of 80-90 DEG C; adding the catalysts, performing reaction for 5hours at the temperature of 100-120 DEG C, cooling mixture to reach the temperature of 50-60 DEG C, keeping the temperature for 2 hours, and performing cooling and discharging. The method is simple inprocess and low in cost, the prepared borehole reinforcement shielding agent is stable in performance and good in quality, the compressive strength and the sealing capability of sand rock and mud rock cores can be enhanced, and stability is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap