High-hardness matte ceramic antifouling agent, and preparation method thereof

An antifouling, high hardness technology, applied in antifouling/underwater coatings, paints containing biocides, coatings, etc. Glossiness and other issues to achieve the effect of increasing glossiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

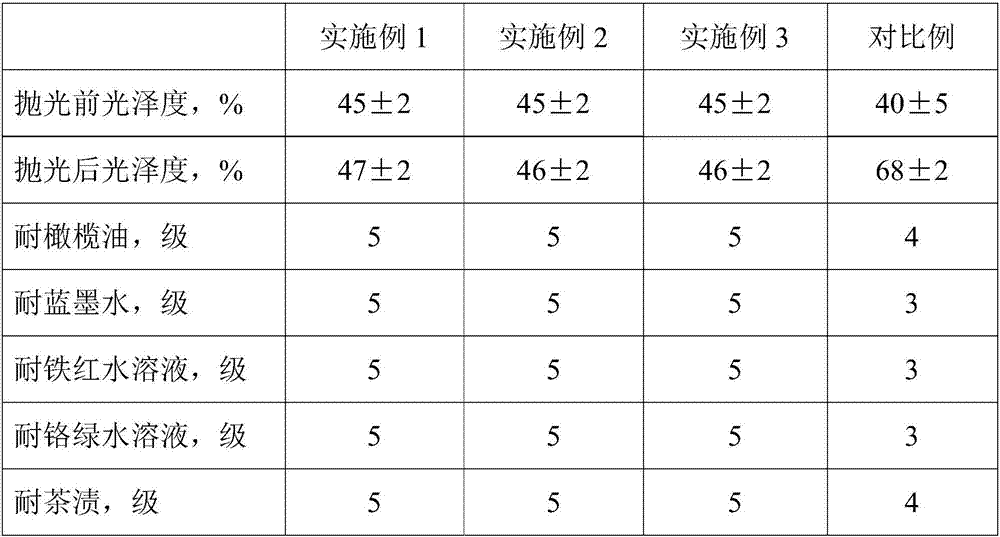

Examples

Embodiment 1

[0024] An active MQ silicone resin modified nano-silica matt ceramic antifouling agent, its preparation method is as follows:

[0025] a), hydrolysis: In the reaction kettle, add 5.0 parts of deionized water, 3.0 parts of glacial acetic acid, and 100.0 parts of ethanol in order by weight, stir and control the temperature at 35-40 ° C, dropwise add hexamethyldisiloxane, 100.0 parts of a mixture of tetramethyldivinyldisiloxane and tetramethyldisiloxane and 50.0 parts of a mixture of tetramethoxysilane, ethyl orthosilicate and tetraisopropoxysilane, within 1.5 to 2 hours The internal dropwise addition was completed; then, after stirring and reacting at room temperature for 12 hours, 100.0 parts of a mixed solvent (petroleum ether / ethyl acetate=8 / 2) was added for extraction, and the water layer was removed to obtain MQ silicone resin prepolymer;

[0026] b) Cross-linking: heat up the above-mentioned MQ silicone resin prepolymer to 100°C, add 20.0 parts of high hydrogen-containing

Embodiment 2

[0029] An active MQ silicone resin modified nano-silica matt ceramic antifouling agent, its preparation method is as follows:

[0030] a) Hydrolysis: In the reaction kettle, add 3.0 parts of deionized water, 3.0 parts of glacial acetic acid, and 100.0 parts of ethanol in order by weight, stir and control the temperature at 35-40°C, and add tetramethyldivinyl disilazine dropwise 100.0 parts of a mixture of oxane and tetramethyldisiloxane and 40.0 parts of a mixture of tetraisopropoxysilane and tetrabutoxysilane were added dropwise within 1.5 hours; then the reaction was stirred at room temperature for 12 hours, and 100.0 parts of Part of dibutyl ether solvent is extracted, removes water layer, obtains MQ silicone resin prepolymer;

[0031] b) Cross-linking: heat up the above-mentioned MQ silicone resin prepolymer to 90°C, add 15.0 parts of high hydrogen-containing silicone oil, and continue the reaction for 3.5-4 hours to obtain active MQ silicone resin;

[0032] c), modified gra

Embodiment 3

[0034] An active MQ silicone resin modified nano-silica matt ceramic antifouling agent, its preparation method is as follows:

[0035] a) Hydrolysis: In the reaction kettle, add 5.0 parts of deionized water, 3.0 parts of glacial acetic acid, and 100.0 parts of ethanol in order by weight, stir and control the temperature at 35-40 ° C, and drop tetramethyldivinyl disilazine Oxane, tetramethyldisiloxane, 1,1,3,3-tetramethyl-1,3 diphenyldisiloxane and 1,3-diethyl-1,1,3,3- 100.0 parts of a mixture of tetramethyldisiloxane and 40.0 parts of a mixture of tetraisopropoxysilane, tetrabutoxysilane and tetrabutoxyethoxysilane were added dropwise within 2 hours; then stirred at room temperature After reacting for 12 hours, add 100.0 parts of mixed solvent (dibutyl ether / butyl acetate=8 / 2) for extraction, remove the water layer, and obtain MQ silicone resin prepolymer;

[0036] b) Cross-linking: heat up the above-mentioned MQ silicone resin prepolymer to 70-75°C, add 25.0 parts of high h

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap