Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Polyureas/polyurethane adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly polyurethane adhesive, and preparation method and applications thereof

ActiveCN106634778AOrderly rowsGood physical propertiesPolyureas/polyurethane adhesivesPolyurethane adhesiveOperability

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Halogen-free resin composition and cover film prepared from the same

InactiveCN105482442AExcellent resistance to ion migrationGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyPolyester

Owner:GUANGDONG SHENGYI SCI TECH

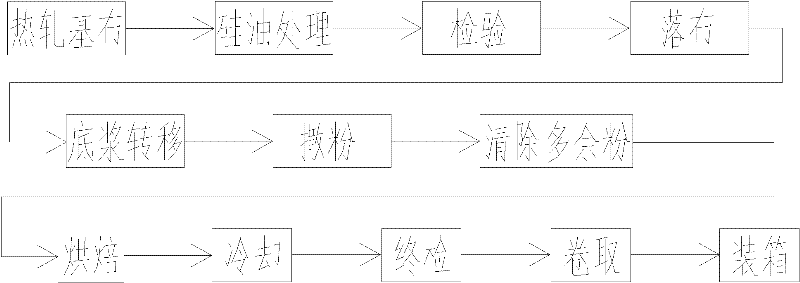

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costPolyureas/polyurethane adhesivesFibre typesInterliningPolyester

Owner:温州鸿马科技有限公司

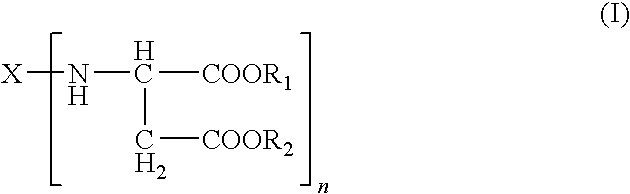

Adhesive systems containing polyisocyanate prepolymers and aspartate-ester curing agents, processes for preparing the same, medical uses therefor and dispensing systems for the same

InactiveUS20090191145A1Broaden applicationSurgical adhesivesPolyureas/polyurethane adhesivesPolyolHydrogen

Owner:BAYER MATERIALSCIENCE AG

Novel acrylate modified waterborne polyurethane adhesive

InactiveCN109266267AShort curing timeImprove adhesionPolyureas/polyurethane adhesivesGraft polymer adhesivesPolyurethane adhesiveEmulsion

The invention provides a novel acrylate modified waterborne polyurethane adhesive. The adhesive is characterized by being prepared by the following steps: taking polyether glycol and polyisocyanate toreact, so as to obtain a waterborne polyurethane pre-polymer; enabling the waterborne polyurethane pre-polymer to react with an acrylic monomer or a methacrylic acid monomer under the action of an emulsifier and an initiator to obtain waterborne polyurethane acrylate, so as to obtain emulsion, wherein the emulsion is the acrylate modified waterborne polyurethane adhesive. The invention further discloses a preparation method and application of the adhesive. Compared with the prior art, the novel acrylate modified waterborne polyurethane adhesive has the advantages of better environment-friendly performance and improved anti-oxidization capability and anti-ageing capability; the adhesive has good bonding performance with adhesive films and paper products.

Owner:CHANGCHUN UNIV OF TECH

Fibreboard from agricultural wastes and a method for manufacturing the same

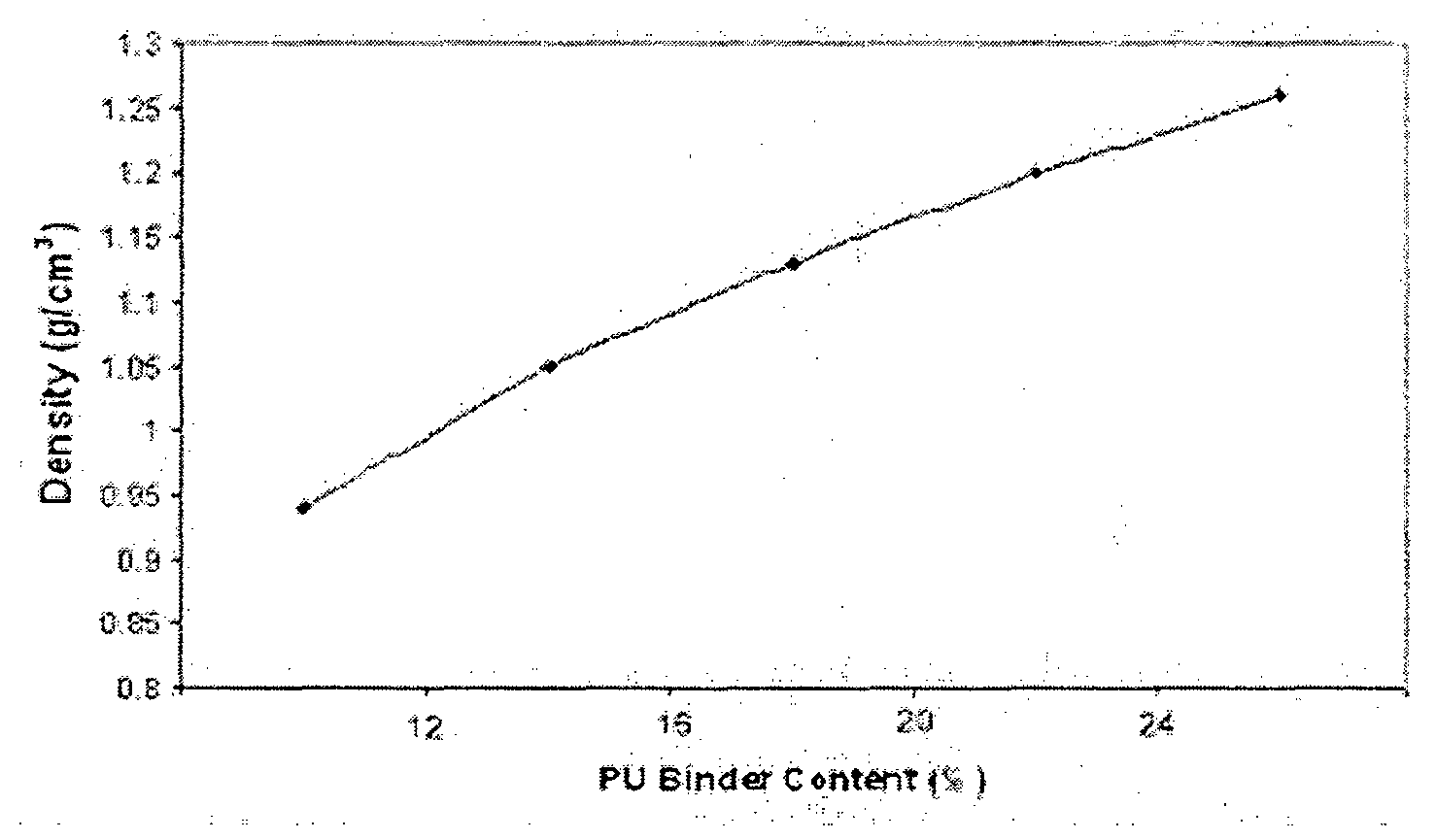

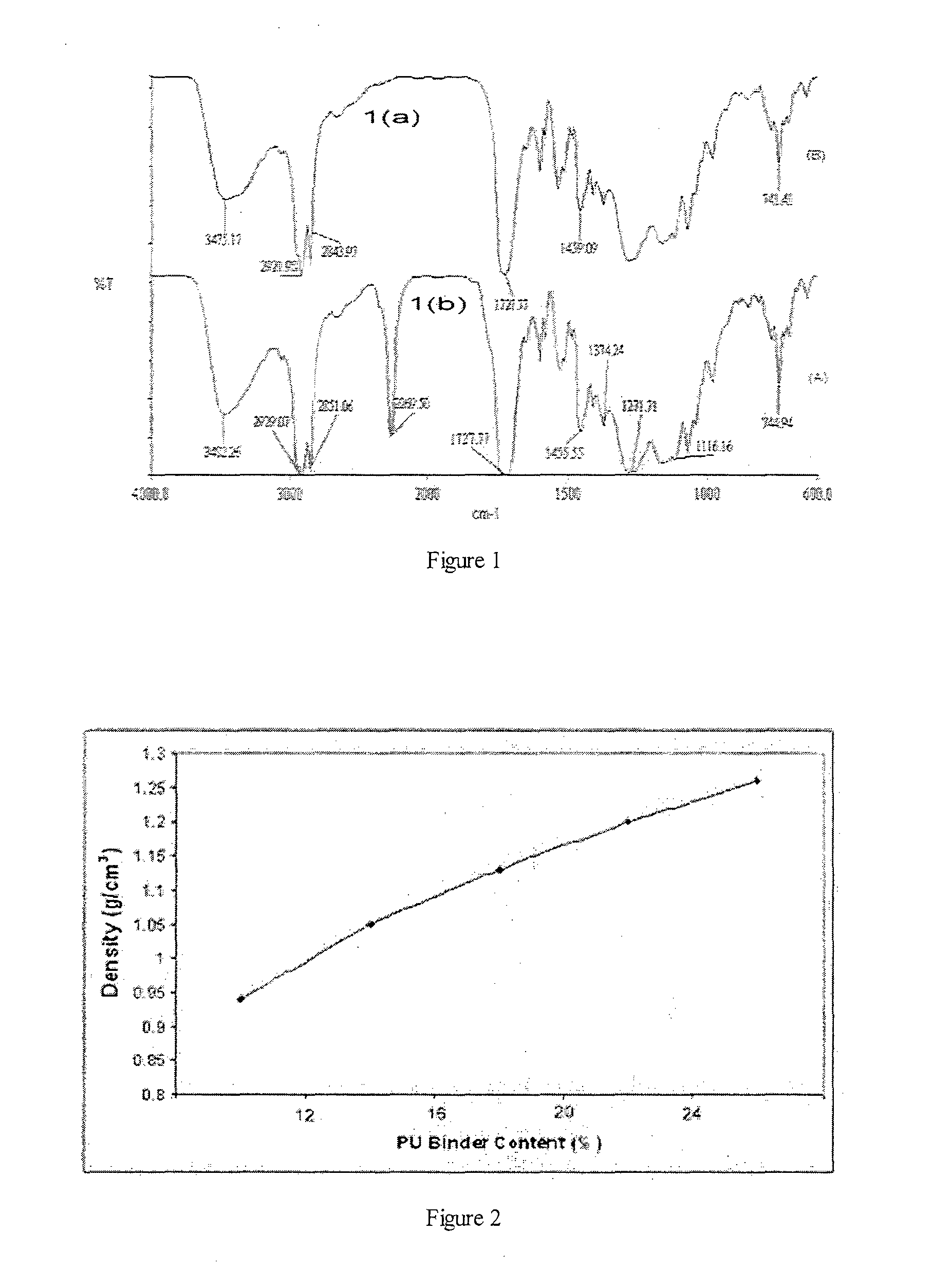

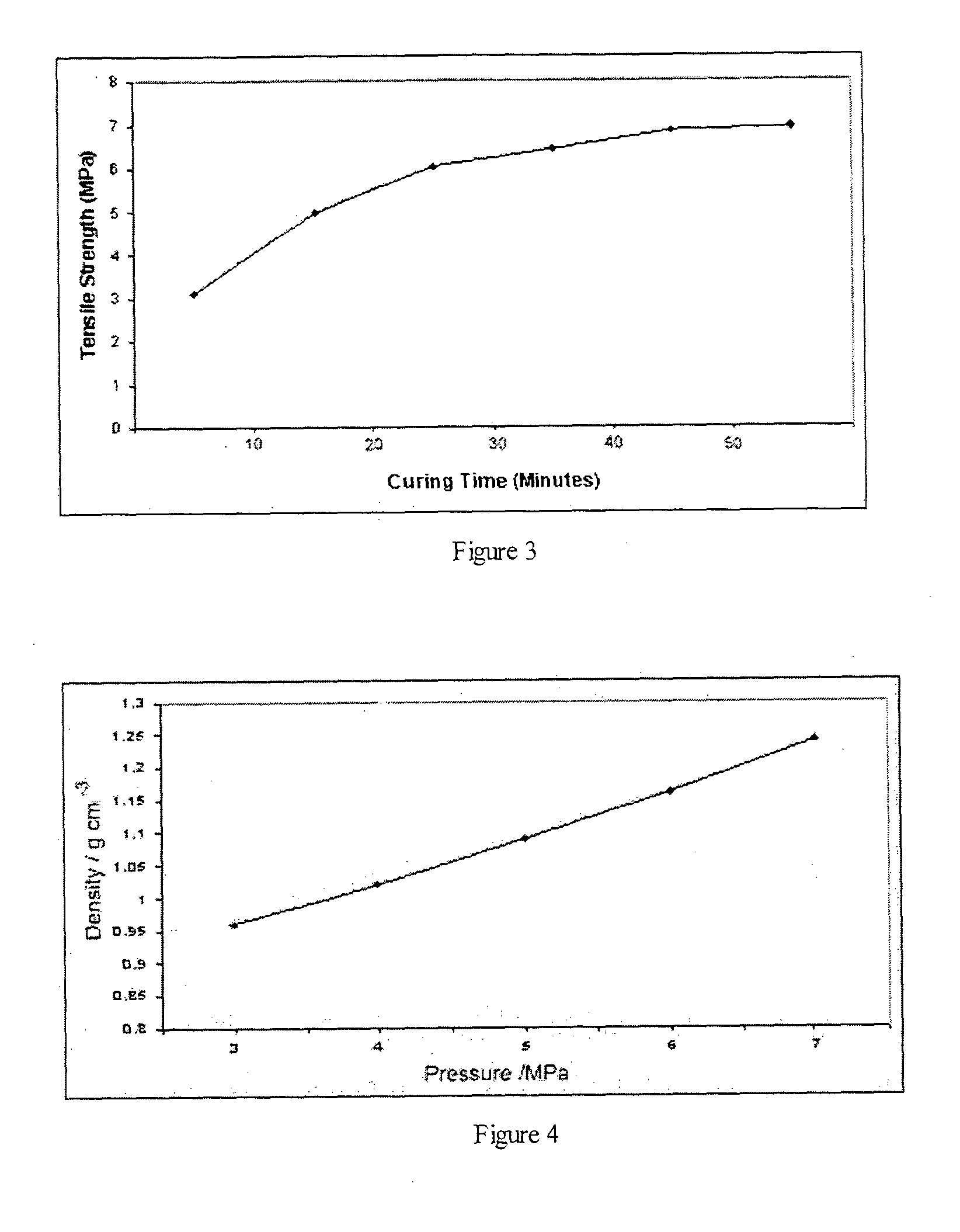

InactiveUS20120296014A1Low costEasy to usePolyureas/polyurethane adhesivesWood working apparatusPolyolPlant fibre

Owner:UNIVERSITI MALAYA +1

Anti-corrosion tube and its manufacturing process

Owner:大庆油田庆新工程材料有限公司

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

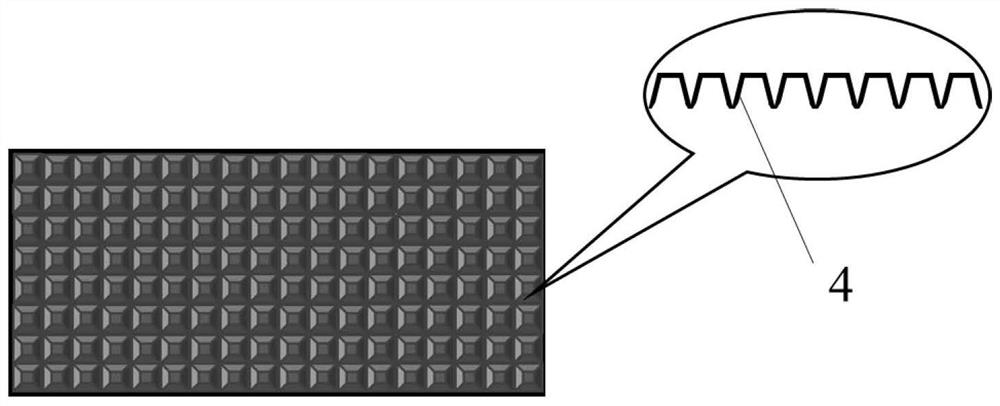

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Solvent-free unfoamed polyurethane structured adhesive and preparation method thereof

InactiveCN106433546ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPolyphenyl isocyanate

Owner:YANTAI DARBOND TECH

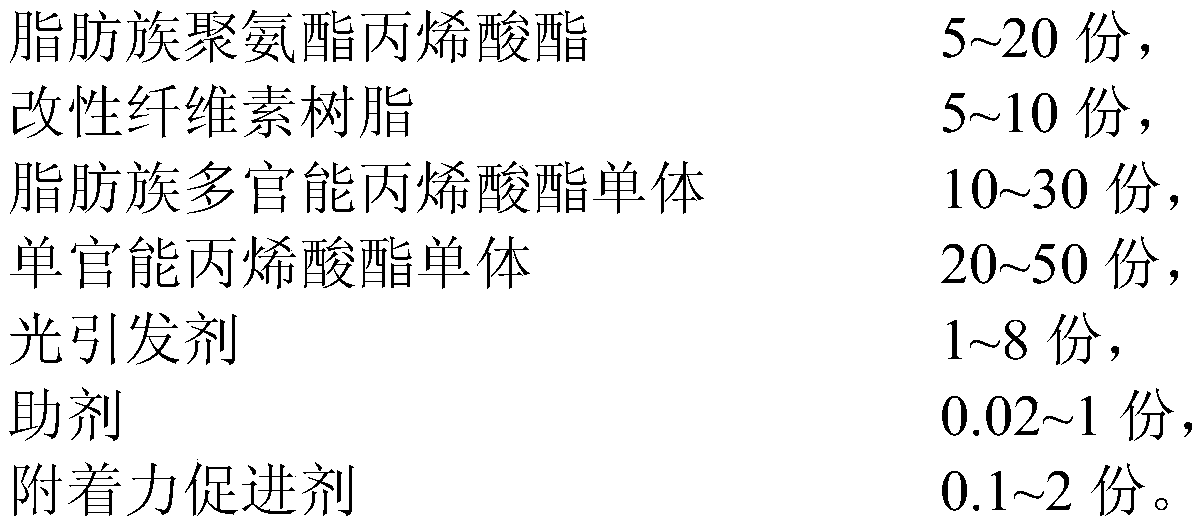

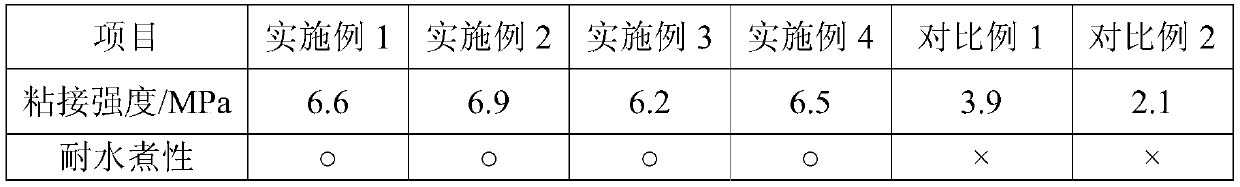

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

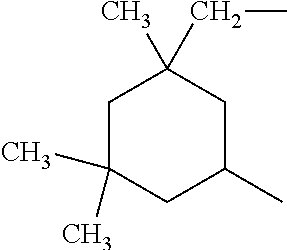

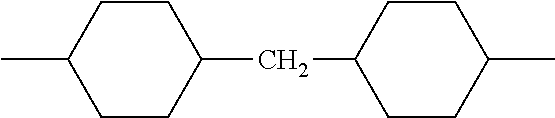

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

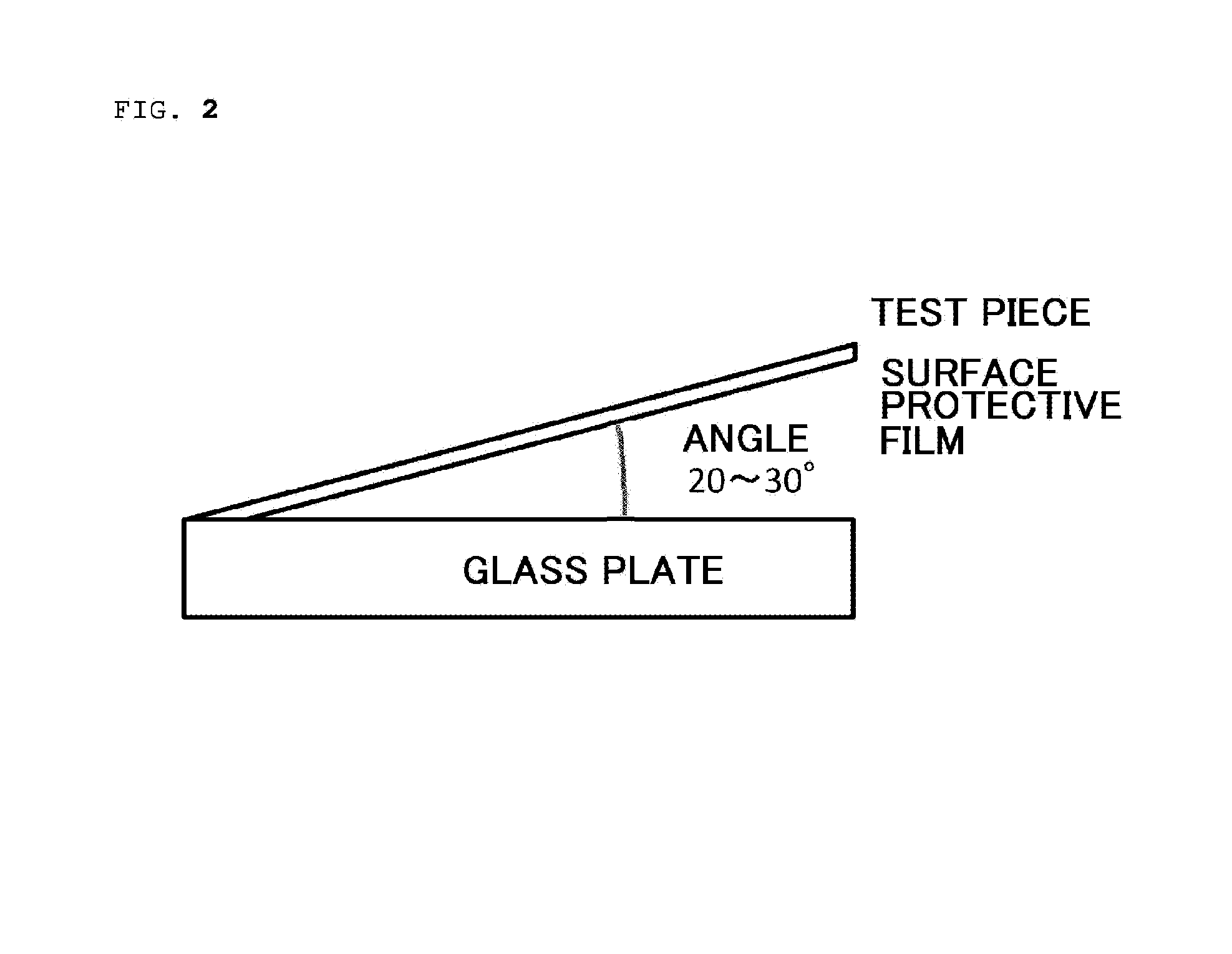

Surface protective film

InactiveUS20140243472A1Film/foil adhesivesPolyureas/polyurethane adhesivesPressure sensitiveChemistry

Owner:NITTO DENKO CORP

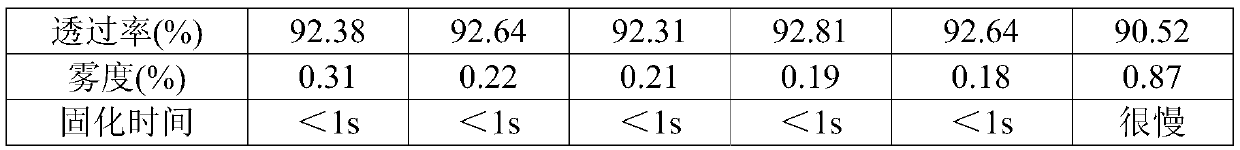

Ultraviolet-curing composition for LED packaging

InactiveCN104031591AImprove bonding performanceGood high and low temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerLed packaging

The invention relates to the technical field of LED packaging, and particularly relates to an ultraviolet-curing composition for LED packaging. The ultraviolet-curing composition comprises the following components: a polyurethane-acrylate-epoxy resin photosensitive prepolymer, epoxy resin acrylate, a light initiator, a flatting agent and an active diluent. According to the ultraviolet-curing composition for LED packaging disclosed by the invention, a certain amount of epoxy resin acrylate is added in the composition, so that the adhesive property of the composition after being cured is effectively improved; the adhesive has the advantages of excellent high and low-temperature resistance, high aging resistance and transparency, good formability, good bonding property, mild curing conditions, and the like.

Owner:江苏华程光电科技有限公司

Quartz rod cutting process

ActiveCN109795041ANo vibrationThere will be no cutting deformationPolyureas/polyurethane adhesivesWax adhesivesWaxHydrofluoric acid

Owner:扬州美和光电科技有限公司

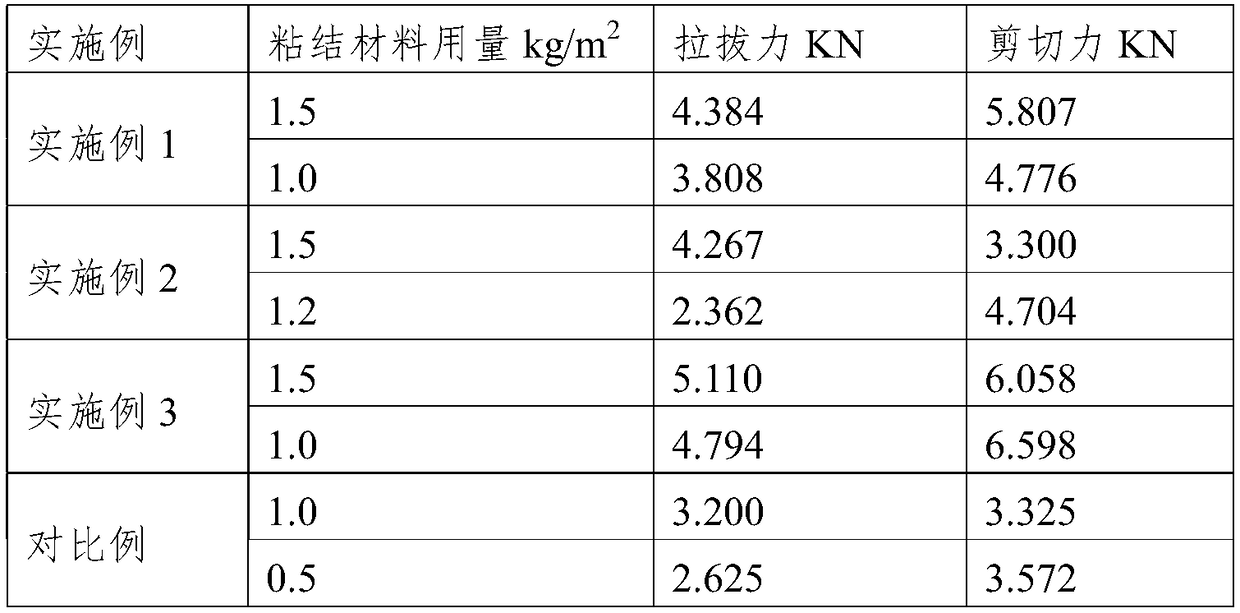

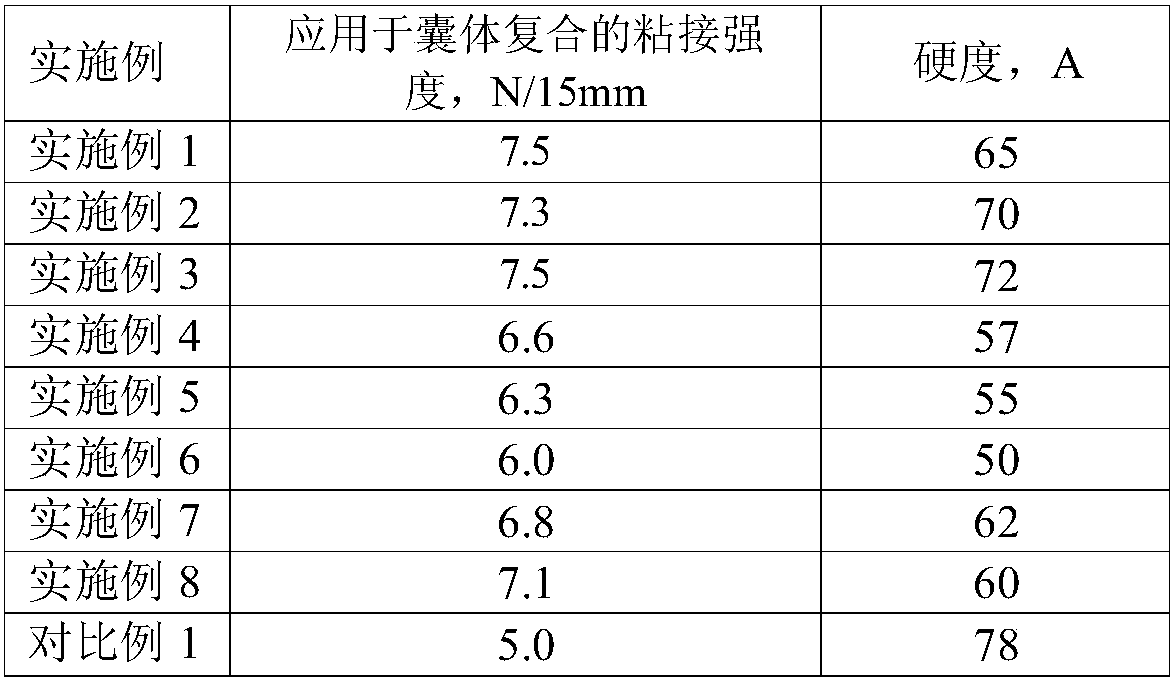

Polyurethane structural adhesive used for bonding automobile spoiler and preparation method and application of polyurethane structural adhesive

ActiveCN108276947AImprove toughnessGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolAdhesive

The invention discloses a polyurethane structural adhesive used for bonding an automobile spoiler and a preparation method and application of the polyurethane structural adhesive used for bonding theautomobile spoiler. The polyurethane structural adhesive comprises raw materials of a first component and a second component in a feed mass ratio of 1: (0.75 to 1.5), wherein the second component comprises polyisocyanate; the first component comprises polyether polyol having the number average molecular weight from 2000 to 4000 and being more than difunctionality, polyether polyol having the number average molecular weight from 300 to 500 and being more than tri-functionality, polyether polyol having the number average molecular weight from 90 to 400 and castor oil in a feed mass ratio of (7 to 33): (0.6 to 5): 1 to (2 to 13); the preparation of the polyurethane structural adhesive used for bonding the automobile spoiler comprises the following steps: respectively mixing various componentsin the first component and the second component through a physical mixing method and then blending to obtain the polyurethane structural adhesive; the application of the polyurethane structural adhesive used for bonding the automobile spoiler is that the first component and the second component of the polyurethane structural adhesive are separately sprayed on the bonding part of the spoiler on anautomobile, and the automobile spoiler is bonded to realize bonding; and by adopting the polyurethane structural adhesive used for bonding the automobile spoiler, all performances in various aspectsat room temperature and high and low temperature are excellent.

Owner:CHINA BUILDING MATERIAL TEST & CERTIFICATION GRP SUZHOU

Method for manufacturing polyurethane flexible foam packing plates

InactiveCN103786231AHigh bonding strengthIncrease elasticityPolyureas/polyurethane adhesivesWood working apparatusPolyurethane adhesiveSingle plate

Owner:孟可星

Reactive permeable tack coat material special for water permeable pavement

InactiveCN108949087ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerRosin

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT +2

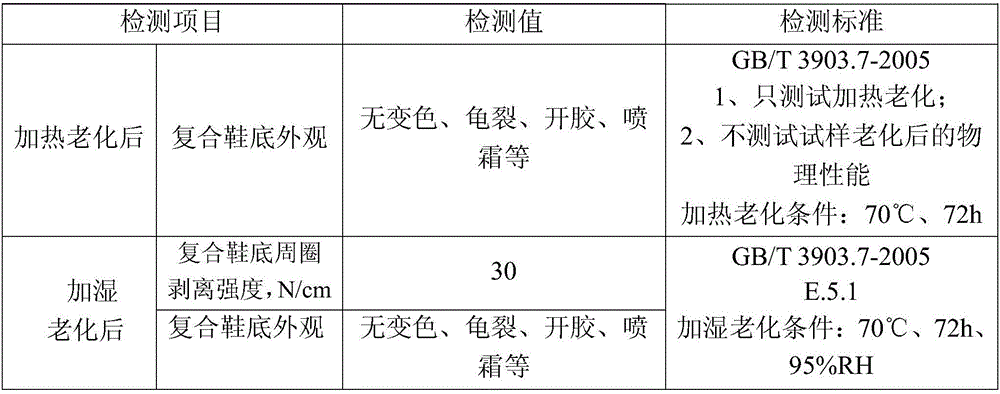

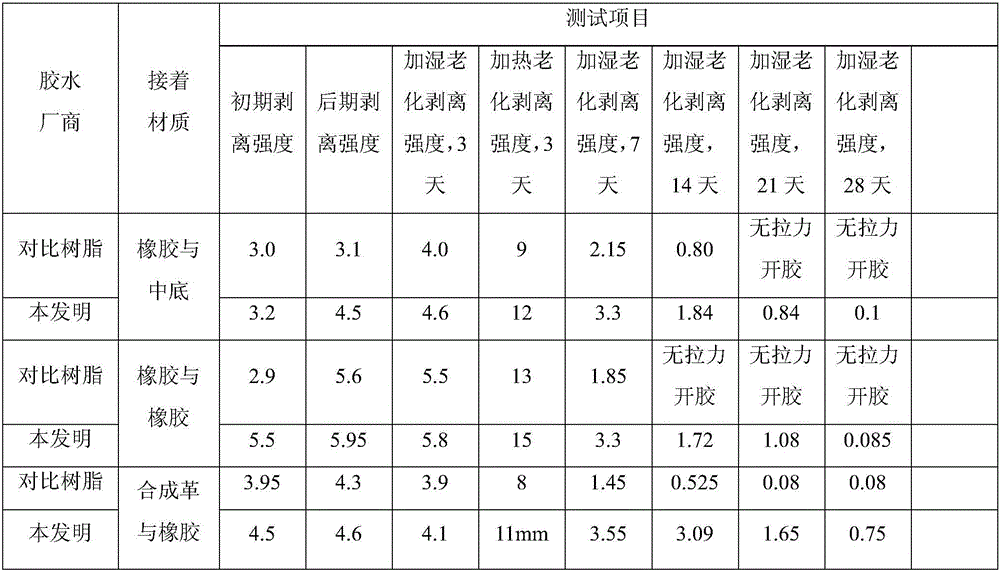

Shoe cellulose powder modified polyurethane adhesive and preparation method thereof

InactiveCN105925229AImprove fastness and hydrolysis resistanceImprove rigidityPolyureas/polyurethane adhesivesSolventIsocyanate compound

The invention discloses a shoe cellulose powder modified polyurethane adhesive and a preparation method thereof. The shoe cellulose powder modified polyurethane adhesive is prepared from the following components in parts by mass: 150 to 200 parts of diphenylmethane diisocyanate, 20 to 50 parts of isophorone diisocyanate, 200 to 400 parts of polyester glycol, 30 to 60 parts of chain extender, 1 to 10 parts of cellulose powder, and 2000 to 4000 parts of solvent. The preparation method has the advantages that under the synergistic action of two types of active isocyanate, by adopting different types of hydroxyl raw materials, the initial viscosity, hydrolysis resistance, wet and heat aging resistance and the like of products are improved; the technology implementing is good, and the environment-friendly and non-pollution effects are realized.

Owner:LI NING CHINA SPORTS GOODS +2

UV-OCA adhesive for TAC film bonding and preparation method thereof

InactiveCN110643319ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhotoinitiatorPolymer chemistry

Owner:无锡阿尔梅新材料有限公司

Adhesive, preparation method thereof and skin

ActiveCN110499134AImprove wettabilityHigh tear strengthLayered productsPolyureas/polyurethane adhesivesEpoxyAdhesive

Owner:SHENZHEN KUANG CHI HIGH END EQUIP TECH DEV LTD +1

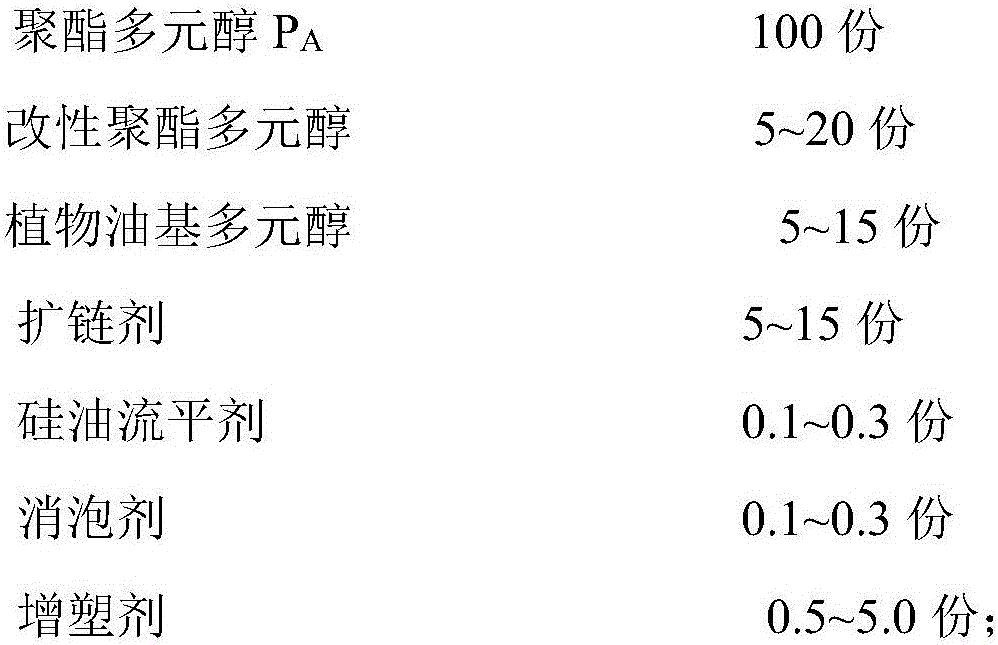

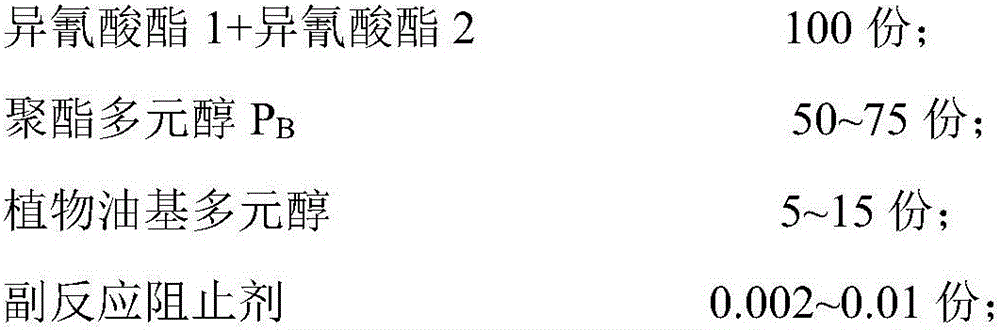

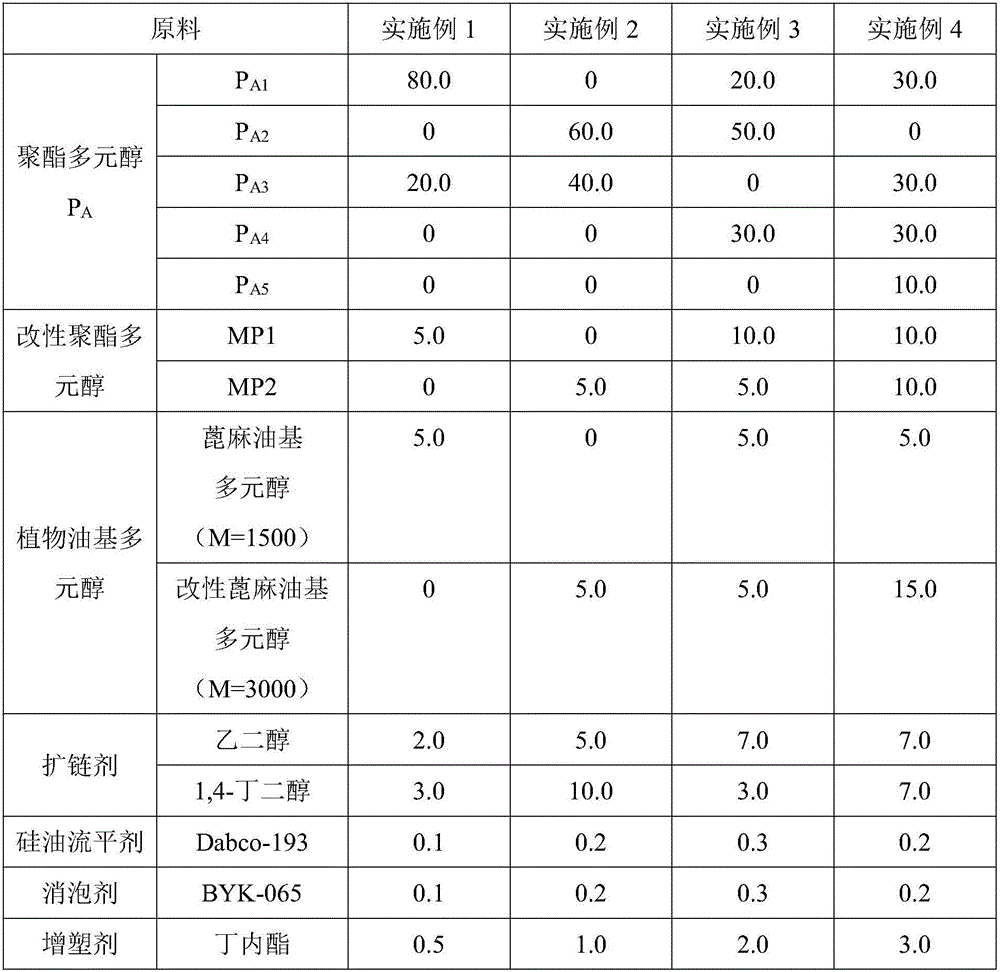

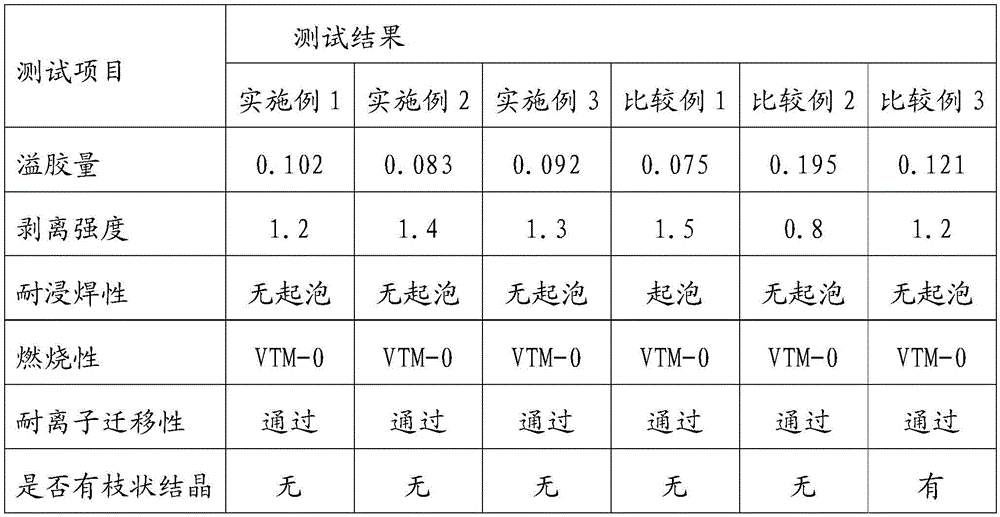

Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

InactiveCN109679562AImprove performanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterMethacrylate

Owner:SHUNDE POLYTECHNIC

Anti-static thermal-insulating adhesive

InactiveCN105733480ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMagnesium silicateAzodicarbonamide

Owner:施向东

Solvent-free type colorized anti-skid road surface adhesive

ActiveCN103923595ALong application periodIncrease stickinessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCross-linkAdhesive

Owner:广东保路威环保材料有限公司

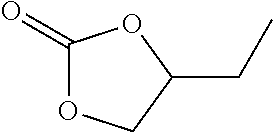

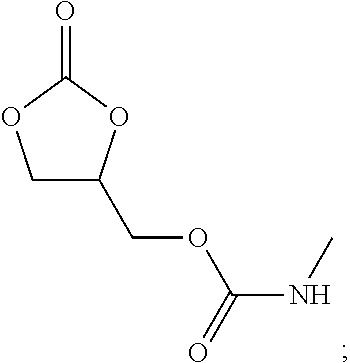

Hardenable synthetic resin comprising considerable proportions of cyclic carbonate groups, as well as/and cyclocarbonate-resin-based fixing systems, the production and use thereof

InactiveUS20160083501A1Increasing bond stressHigh viscosityOrganic chemistryPolyureas/polyurethane adhesivesCarbonateSynthetic resin

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

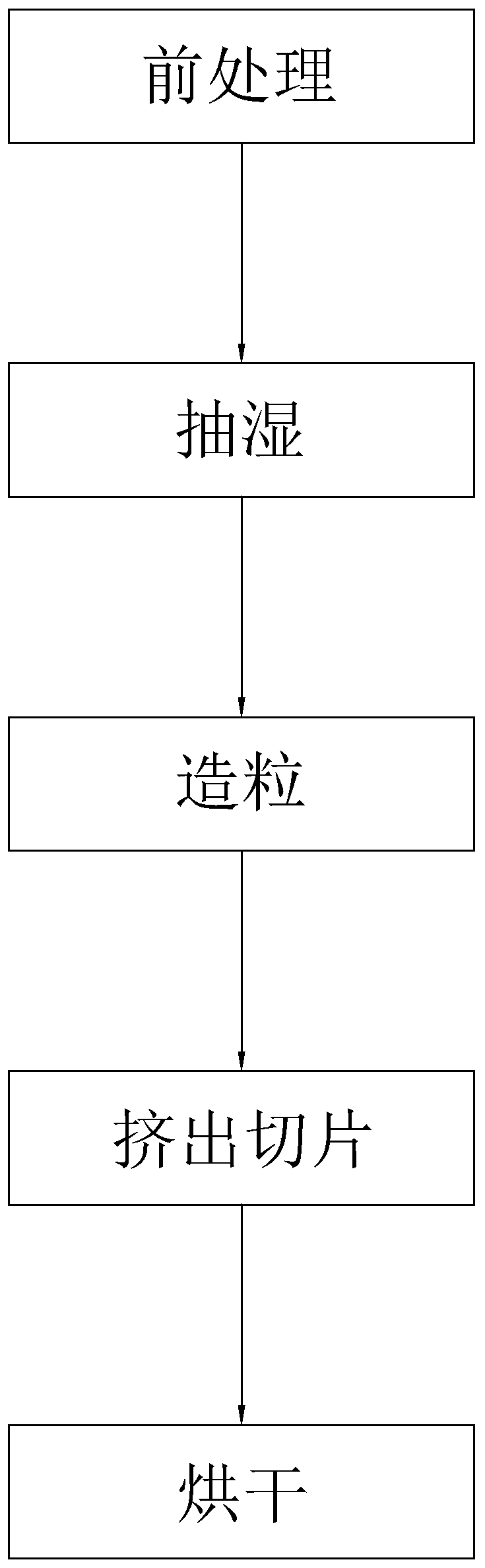

Hot-melt adhesive sheet and production process thereof

ActiveCN110591573APolyureas/polyurethane adhesivesMacromolecular adhesive additivesHot-melt adhesiveThermoplastic polyurethane

Owner:温州力盛新材料有限公司

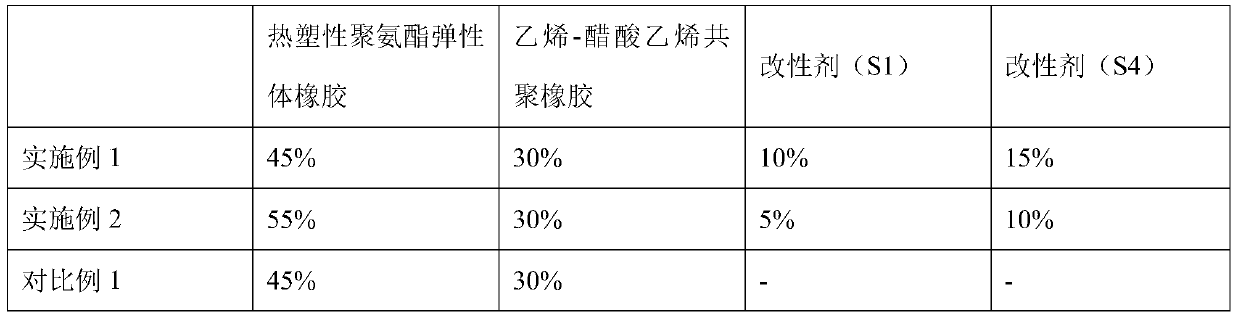

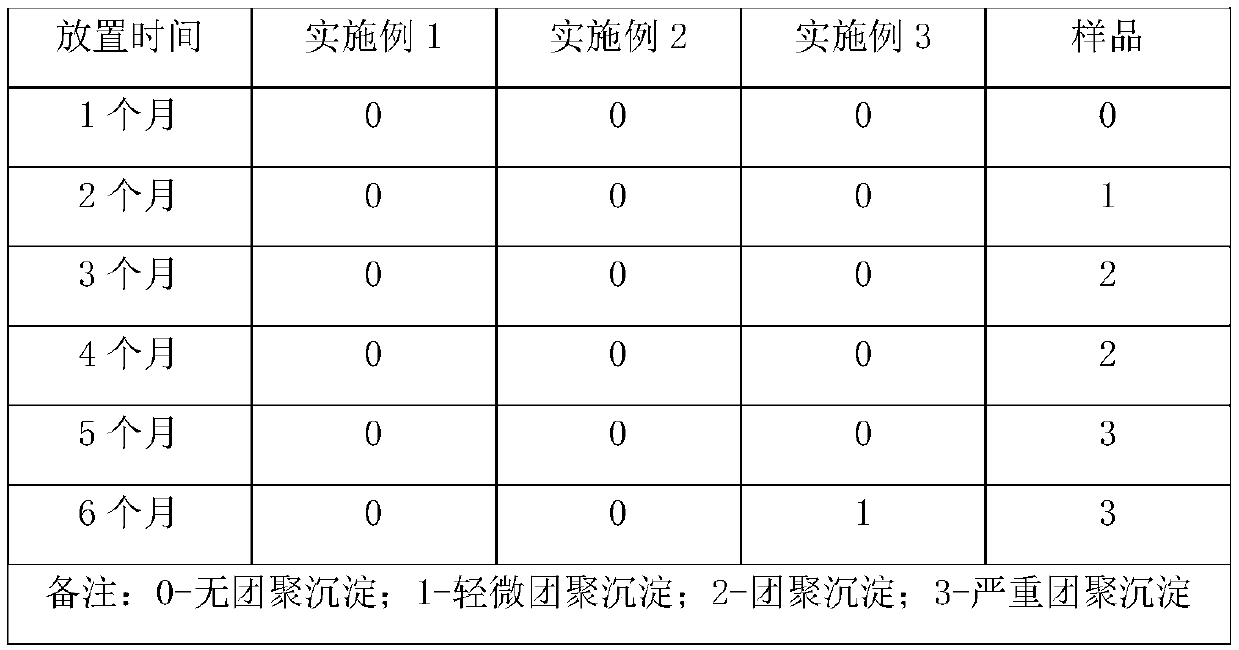

Preparation method of graphene modified polyurethane adhesive

InactiveCN110964474AGood dispersionNot easy to reunitePolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

Owner:SHANDONG WESTBORAN CHEM CO LTD

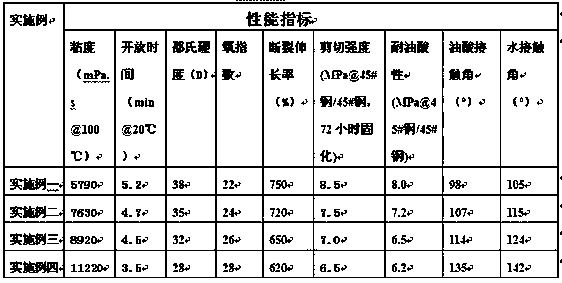

Adhesive dual-component composition based on polyurethane

ActiveUS20190241779A1Increase thermal resistanceNo riskPolyureas/polyurethane adhesivesSynthetic resin layered productsDiaminePrepolymer

Owner:BOSTIK SA

Aqueous urethane resin dispersion, synthetic leather, and method for producing synthetic leather

PendingCN114729181AHigh peel strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceCarbamate

The present invention addresses the problem of providing an aqueous urethane dispersion which does not excessively immerse into a base fabric and which has excellent peel strength and immediate peelability. The present invention provides an aqueous urethane resin dispersion containing a urethane resin (A), water (B), and a crosslinking agent (C), the aqueous urethane resin dispersion being characterized in that the urethane resin (A) has a viscosity in the range of 15000-34000 Pa.s at 50 DEG C, a viscosity in the range of 1000-10000 Pa.s at 100 DEG C, and a viscosity in the range of 100-1300 Pa.s at 150 DEG C. In addition, the present invention provides a synthetic leather having an adhesive layer formed from the aqueous urethane resin dispersion. In addition, the invention provides a manufacturing method of the synthetic leather.

Owner:DIC CORP

3D anti-collision buffer material, preparation method thereof and helmet buffer cushion layer

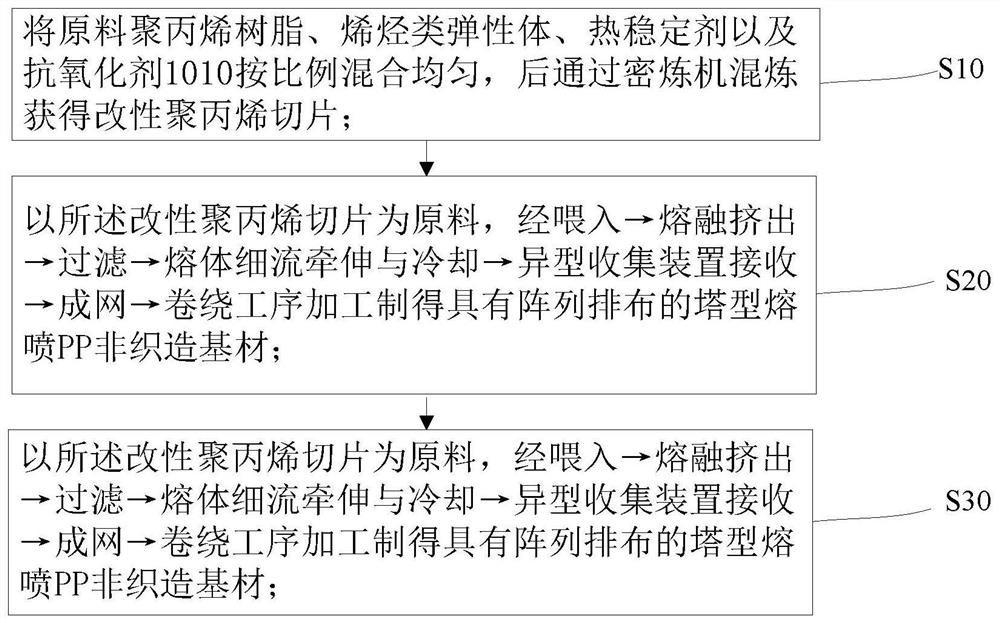

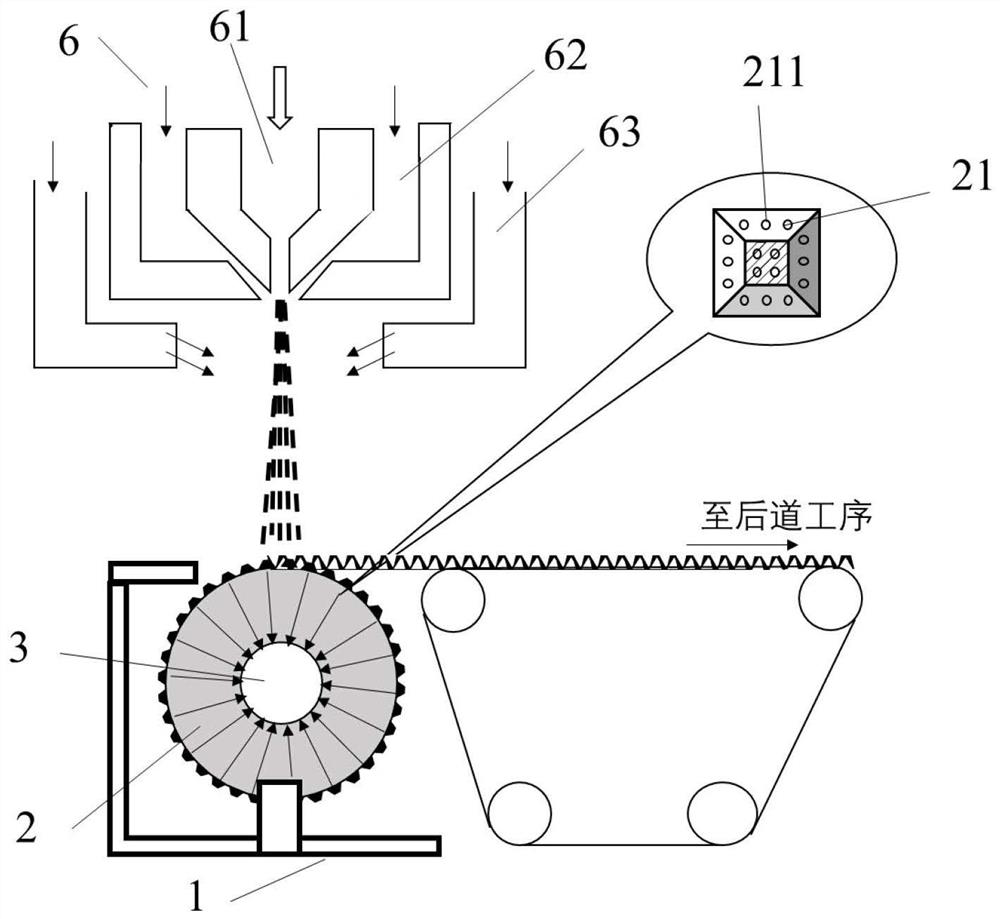

PendingCN112590336ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolypropyleneEngineering

Owner:NANTONG UNIVERSITY

Preparation method of welding glue for vehicle manufacturing

InactiveCN111334229AEasy to useMeet the needs of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyCalcium silicate

Owner:浙江普利斐特汽车科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap