Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal stability also describes, as defined by Schmidt (1928), the stability of a water body and its resistance to mixing. This is the amount of work needed to transform the water. (e.g. a lake) to a uniform water density. The Schmidt stability 'S' is commonly measured in Joule per square meter or g*cm/cm. Compare Stratification. "thermal stability can also be defined as the no change at micro-structural level."

Laser diode combiner modules

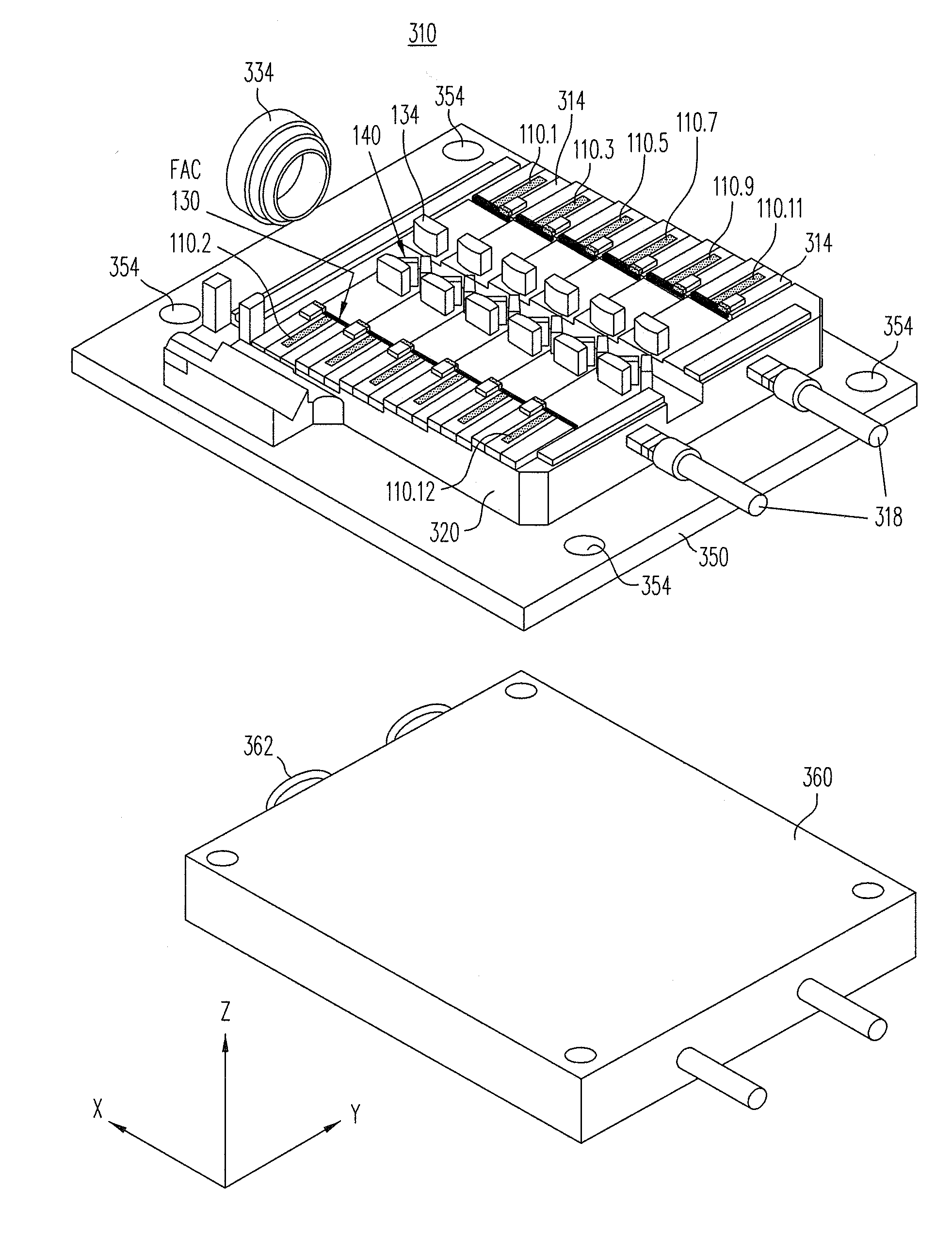

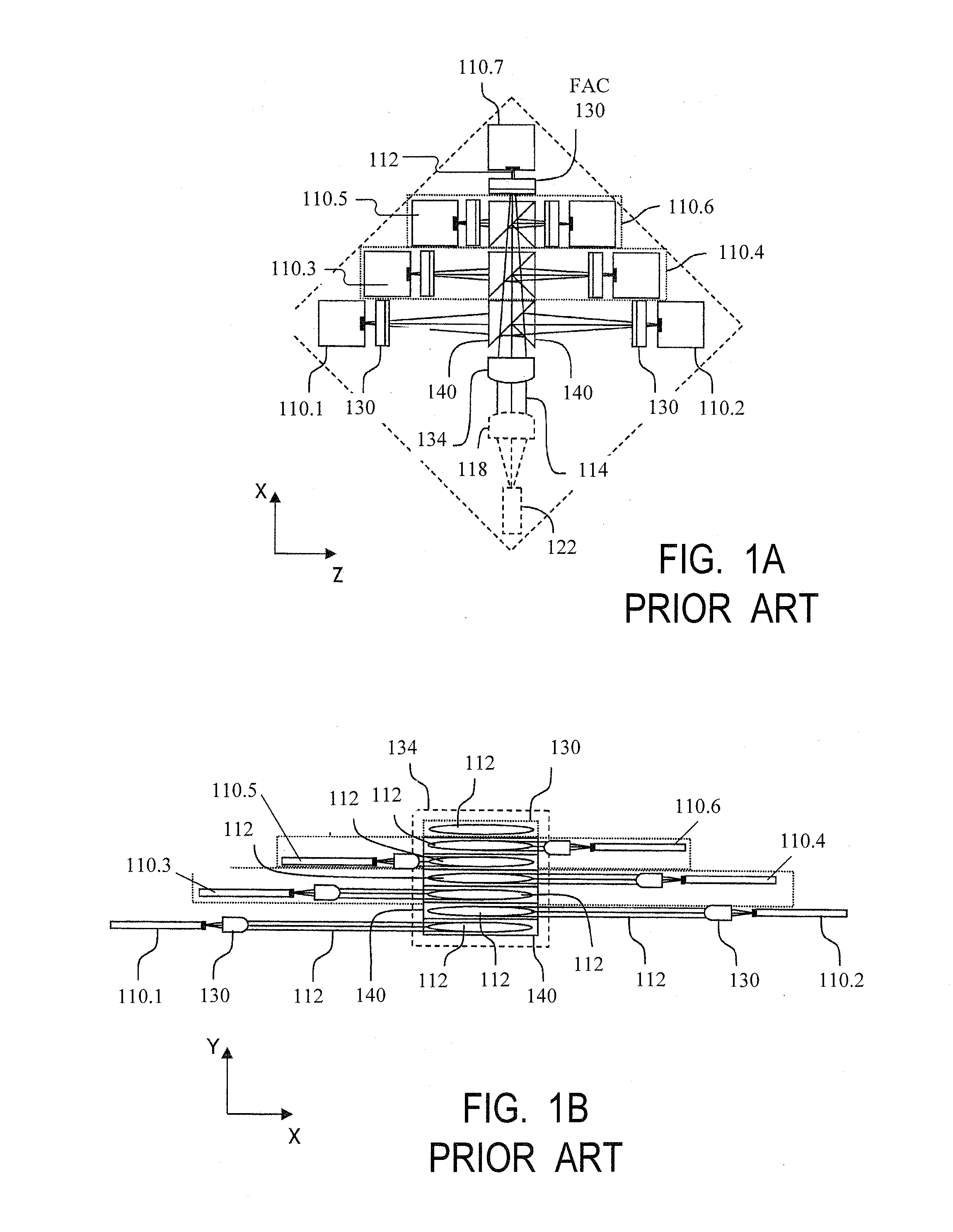

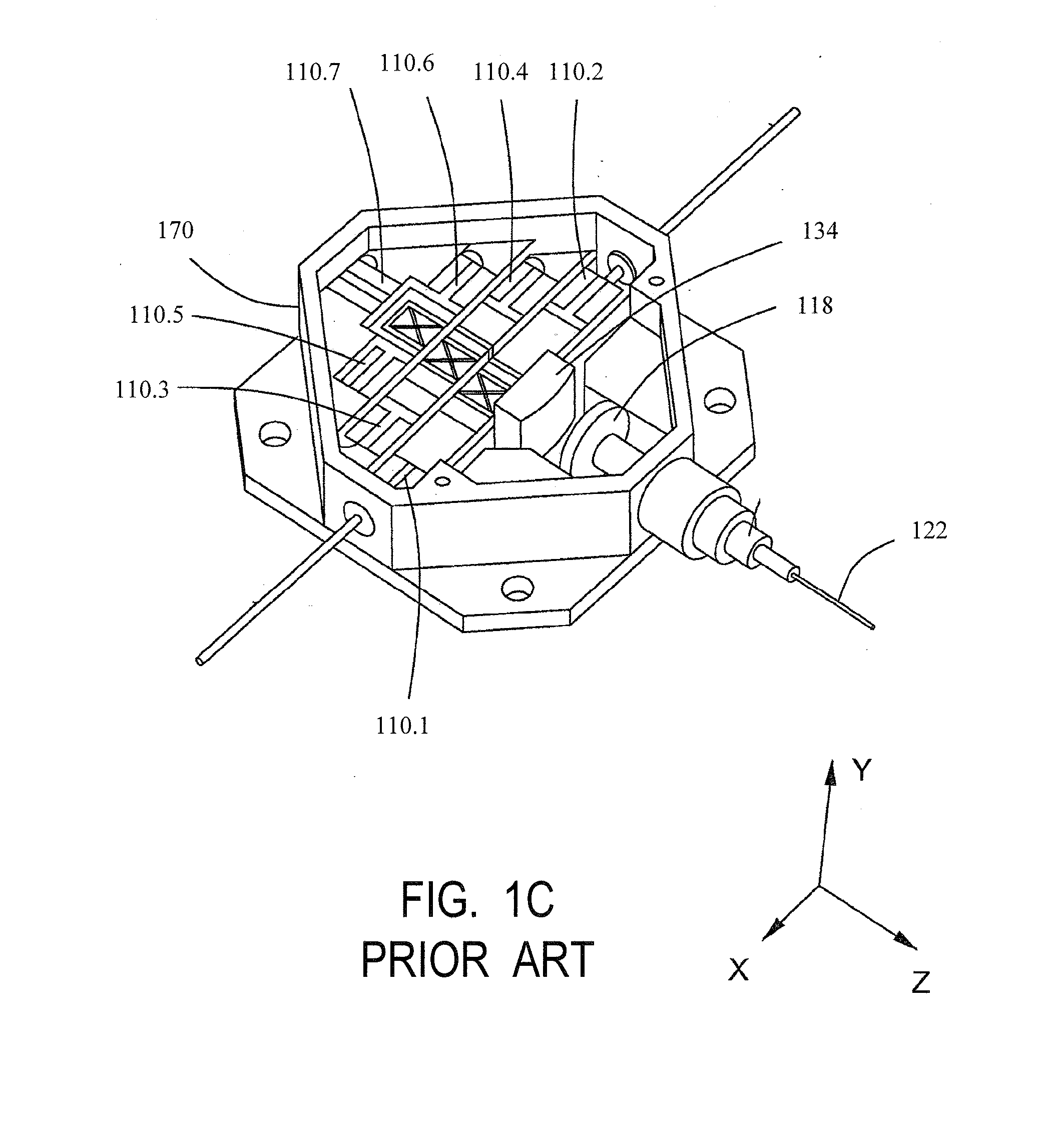

InactiveUS20120081893A1Reduce the heating effectImprove thermal stabilityNon-electric lightingPoint-like light sourceLight beamThermal stability

Owner:FAYBISHENKO VICTOR

Cutting elements, methods for manufacturing such cutting elements, and tools incorporating such cutting elements

The present disclosure relates to cutting elements incorporating polycrystalline diamond bodies used for subterranean drilling applications, and more particularly, to polycrystalline diamond bodies having a high diamond content which are configured to provide improved properties of thermal stability and wear resistance, while maintaining a desired degree of impact resistance, when compared to prior polycrystalline diamond bodies, hi various embodiments disclosed herein, a cutting element with high diamond content includes a modified PCD structure and / or a modified interface (between the PCD body and a substrate), to provide superior performance.

Owner:SMITH INT INC

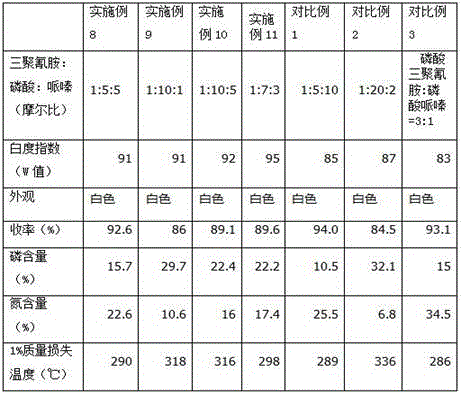

Phosphor-silicon-containing aggregated flame retardant and preparation method thereof

ActiveCN107266685AOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolymer science

Owner:宁波塑之华塑化有限公司

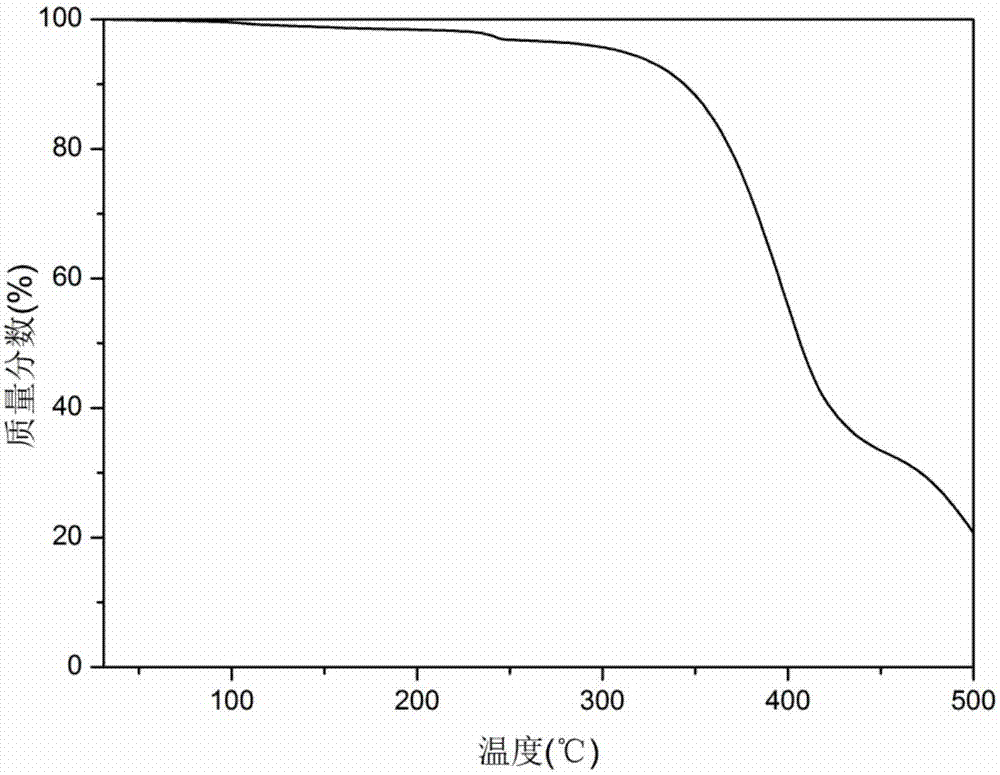

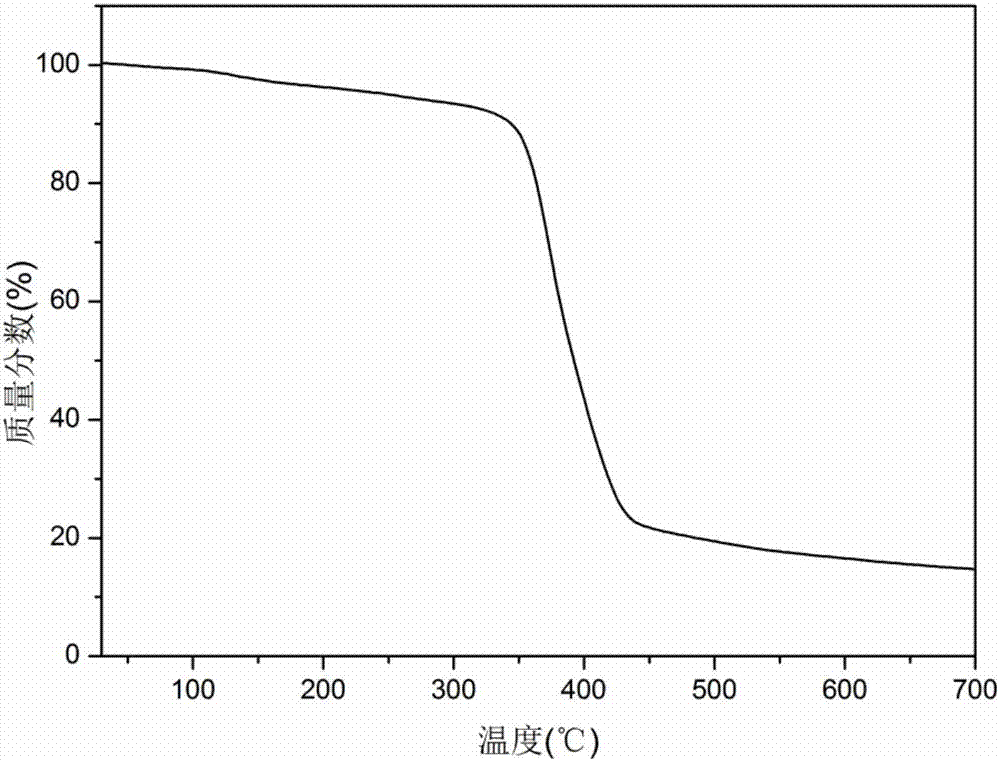

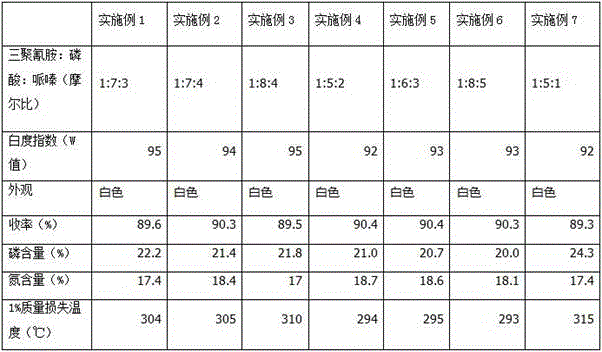

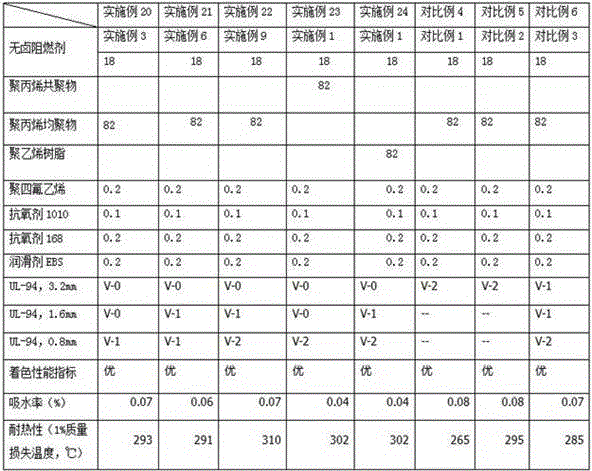

Halogen-free flame retardant and preparation method thereof and flame-retardant polyolefin composition composed of same

ActiveCN105837855AImprove thermal stabilityThe content of functional components is flexible and adjustableOrganic chemistryPolymer sciencePolyolefin

Owner:KINGFA SCI & TECH CO LTD

High-temperature iron-based zeolite molecular sieve honeycomb type denitration catalyst and preparation method thereof

ActiveCN107519926AEvenly dispersedSimple preparation processMolecular sieve catalystsDispersed particle separationFerrous saltsStearic acid

Owner:VALIANT CO LTD

Naphthalimide-selenophene-based organic n-type semiconductor polymer material, preparation method and application thereof

ActiveCN108864415AImprove mobilityImprove thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingElectronChemistry

The invention discloses a naphthalimide-selenophene-based organic n-type semiconductor polymer material, a preparation method and application thereof, in particular to an n-type organic conjugated polymer semiconductor material based on long-chain naphthalimide as an electron pulling unit and selenophene and biselenophene and terselenophene as derivatives as an electron feeding unit and a preparation method thereof, and application of the polymer as a cathode interface modification layer material in a perovskite solar cell. The naphthalimide and selenophene derivative based n-type conjugated polymer semiconductor disclosed by the invention has the advantages of solution processing, high electron mobility, excellent thermal stability, appropriate energy level and the like, and is an ideal perovskite solar cell cathode interface modification material.

Owner:NANJING UNIV OF POSTS & TELECOMM

Photo-cured acrylate-layered double hydroxide nano composite material and preparation method thereof

InactiveCN101555304AImprove efficiencyFast curingPigment treatment with non-polymer organic compoundsIon exchangeUltraviolet lights

Owner:广州市番禺广信丝印材料有限公司 +1

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

Basic metal nitrate, process for producing the same and gas generating agent composition

InactiveUS20070119530A1Enhanced interactionDecrease in decomposition temperatureNitrogen-metal/silicon/boron binary compoundsExplosivesGuanidine derivativesSlag

Owner:ZHOU XINGXI +5

Camera and double-ring glass component thereof

InactiveCN102148925AImprove seismic performanceImprove performanceTelevision system detailsColor television detailsCore componentShock resistance

The invention discloses a camera and a double-ring glass component thereof. The camera comprises a front cylinder component, a rear cylinder component and a machine core component. The front cylinder component comprises a front cylinder and the double-ring glass component; the front cylinder has a cylindrical structure with two open ends; one end of the front cylinder is closed by the double-ring glass component, and the other end of the front cylinder is connected with the rear cylinder component; the double-ring glass component comprises a light-transmitting ring, a light-transmitting sheet and a ray isolation ring; and the light-transmitting ring is sleeved outside the ray isolation ring, while the light-transmitting sheet is arranged inside the ray isolation ring, and the light-transmitting ring is made of acrylics. When the camera of the double-ring glass component based on the technical scheme adopted by the invention is adopted, because the light-transmitting ring is made of acrylics, the impact resistance of the acrylic light-transmitting ring is 200 times that of a glass light-transmitting ring, so the light-transmitting ring is not broken by shock, and the shock resistance of the camera can be improved; moreover, the thermal stability is better than that of the glass light-transmitting ring, so the glass light-transmitting ring is not ruptured by thermal shock, and the performance of the camera can be greatly improved.

Owner:SHENZHEN FSAN INTELLIGENT TECH

Novel high-chromium ferritic heat resistant steel and thermo-mechanical treatment process

InactiveCN102994888AImprove high temperature performanceIncrease service temperatureRoom temperatureThermal stability

Owner:TIANJIN UNIV

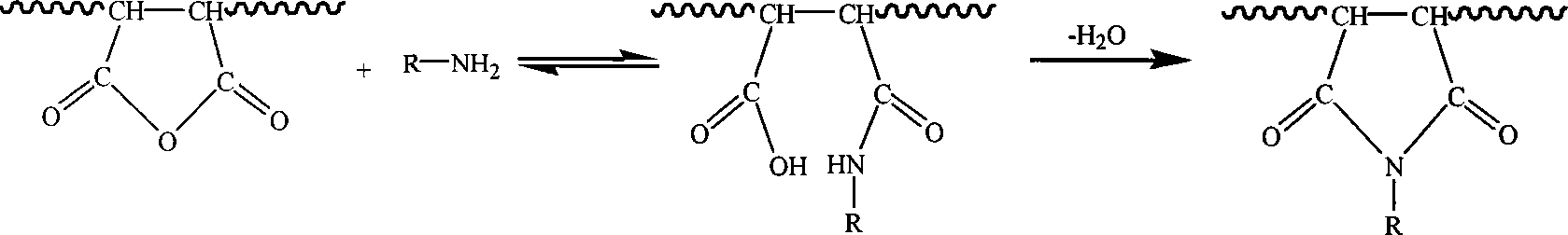

Fused aza-heterocyclic aromatic hydrocarbon porous framework of two-dimensional lamellar structure, and preparation method and application thereof

ActiveCN105949443APromote complexationEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCycloadditionNitrogen

The invention specifically relates to a fused aza-heterocyclic aromatic hydrocarbon porous framework of a two-dimensional lamellar structure, and a preparation method and application thereof, belonging to the technical field of functional materials. According to the invention, aza-heteropolycyclic aromatic hydrocarbon is synthesized on the basiss of cyclization of a diamino group and a diketo group for formation of phenazine and is used as a monomer; and then aza-heteropolycyclic aromatic hydrocarbon is subjected to the Scholl reaction under the catalysis of a Lewis acid salt so as to allow aza-heteropolycyclic aromatic hydrocarbon to undergo homopolymerization at high temperature and low pressure, so a conjugated polymer material of a microporous structure and with two-dimensional lamellar layers for complex catalysis of metal is produced. The two-dimensional material has the characteristics of a high specific surface area, a full conjugate plane structure, heat stability, resistance to acid and alkali, excellent catalytic activity, high recovery rate, etc. The method provided by the invention is simple to operate and controllable in process; and the prepared material can be used for catalyzing a cycloaddition reaction of CO2 with epoxypropane compounds so as to immobilize CO2 and has good application prospects.

Owner:FUDAN UNIV

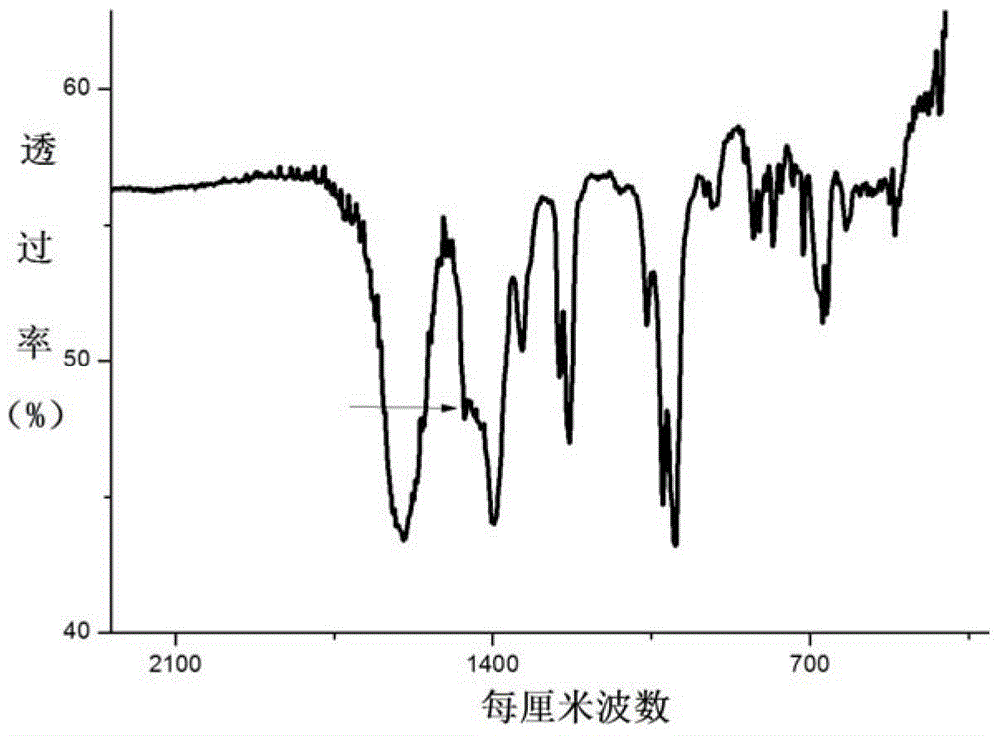

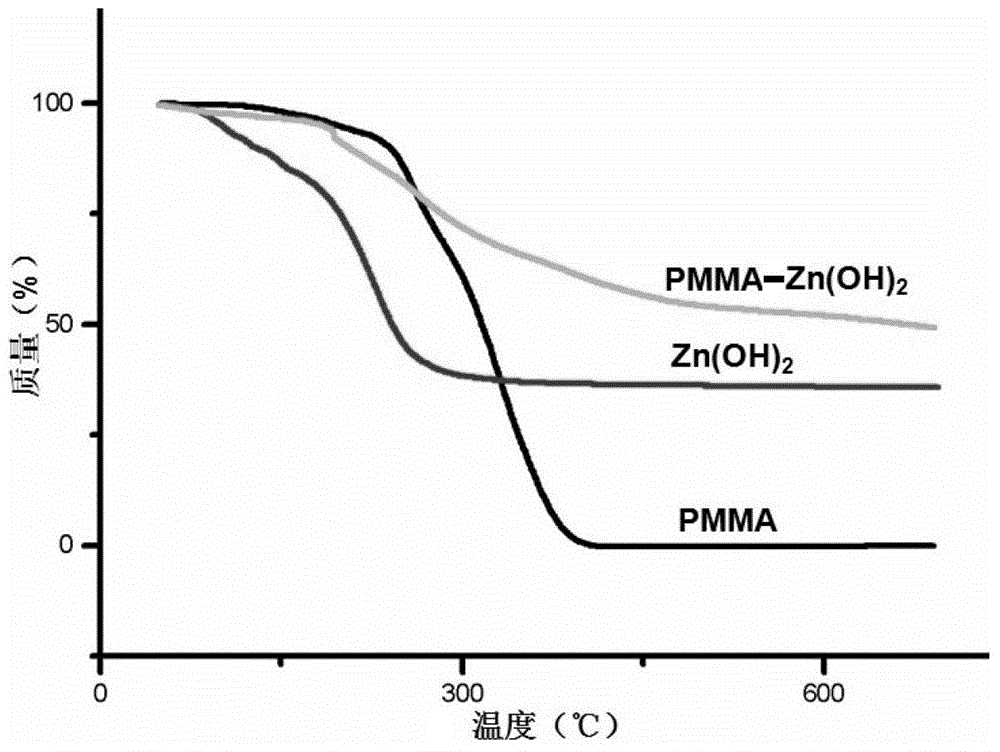

Polymethyl methacrylate-zinc hydroxide nanocomposite and preparation method thereof

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Novel magnesium oxysulfate cement-based fireproof coating and preparation and application methods thereof

Owner:UNIV OF SCI & TECH LIAONING

Fluorine-carbon surfactant and method of producing the same

InactiveCN101279217AReduce surface tensionReduce manufacturing costTransportation and packagingMixingAdditive ingredientHigh surface

Owner:上海亚孚化工科技有限公司

Dispersion strengthening copper base composite material for high-strength and high-conductivity spot-welding electrode and preparation method thereof

Owner:HENAN UNIV OF SCI & TECH

Preparation method of organic tin-free chlorine ether resin

Owner:HANGZHOU ELECTROCHEM GROUP

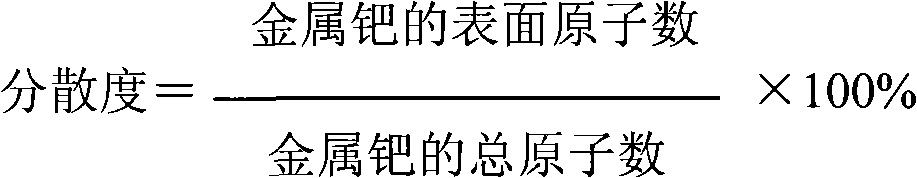

Process for preparing Pd/carbon catalyst

ActiveCN101347727AGood dispersionHigh microcrystalline contentMetal/metal-oxides/metal-hydroxide catalystsCarboxylic compound separation/purificationActivated carbonBenzaldehyde

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing heat resisting type vinyl aromatic monomer polymer

Owner:ZHEJIANG UNIV

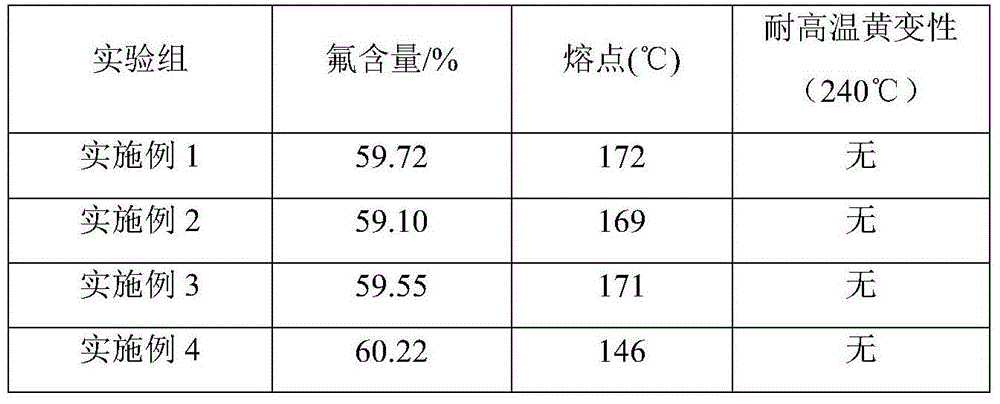

Preparation method of polyvinylidene fluoride resin

ActiveCN104558306AIncrease responsivenessShorten the polymerization reaction timeParaffin waxOrganic solvent

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Heat-resisting and high-breathability composite modified water glass sand used for pump valve casting and manufacturing method of heat-resisting and high-breathability composite modified water glass sand

InactiveCN105436394AExcellent normal temperature wet strengthImprove thixotropyFoundry mouldsFoundry coresSodium BentoniteRoom temperature

Owner:TONGLING JINGWEI FLUID SCI & TECH

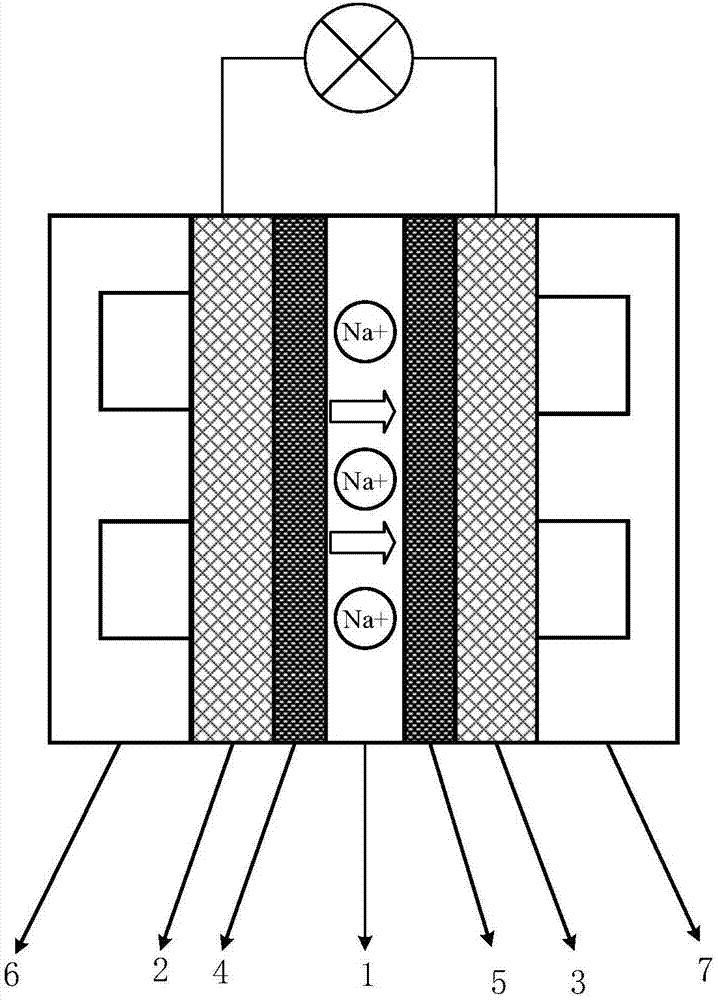

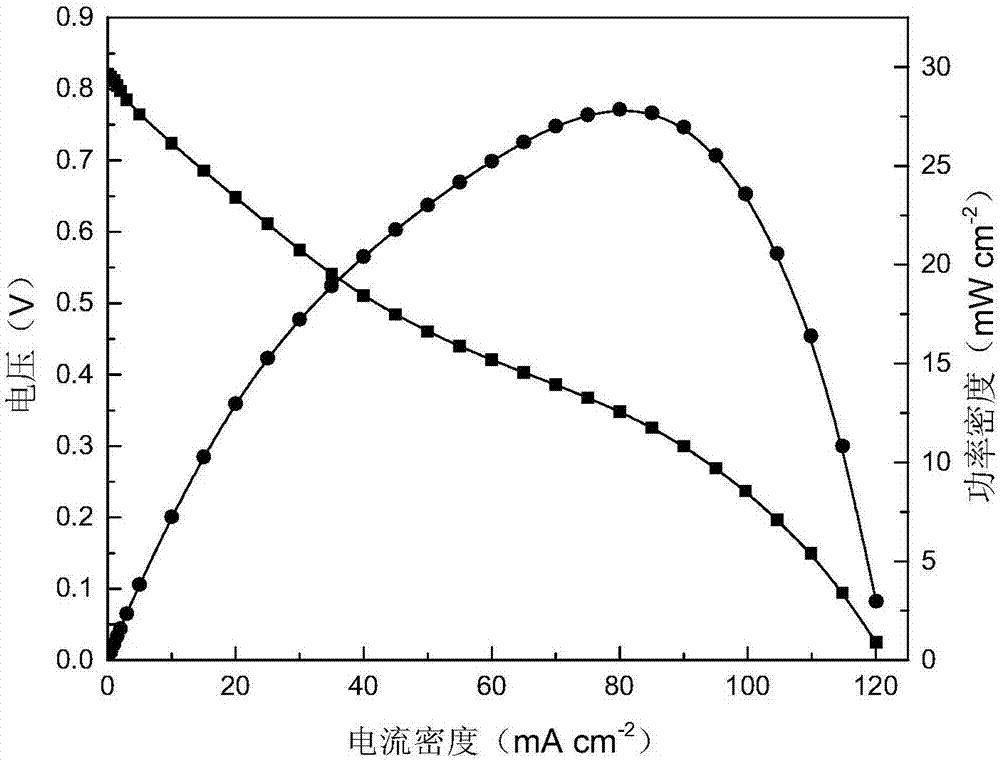

High temperature direct formate fuel cell with electricity and alkali salt co-production

ActiveCN106972176AOvercome stabilityLower internal resistanceCell electrodesFinal product manufactureFormateNon platinum

Owner:XI AN JIAOTONG UNIV

Electrostatic spraying slushing oil

InactiveCN104611109AImprove adhesionImprove thermal stabilityLubricant compositionPolyesterPhosphate

The invention discloses electrostatic spraying slushing oil. The electrostatic spraying slushing oil is composed of the following raw materials in parts by weight: 0.4-1 part of p-nitrophenyl phosphate sodium, 60-70 parts of #25 transformer oil, 1-2 parts of polyisobutene, 3-5 parts of microcrystalline wax, 2-3 parts of hosho oil, 2-4 parts of phthalate polyester, 4-6 parts of petroleum sodium sulfonate, 2-3 parts of fumed silica, 1-3 parts of triethanolamine oleic soap, 1-2 parts of diphenyl silandiol, 0.5-1 part of monopotassium phosphate, 0.4-1 part of inositol hexaphosphoric acid, 0.3-0.5 part of zinc acetylacetonate, 2-3 parts of oleic acid and 3-5 parts of wear resistant machine oil. A molecular directional adsorption film can be formed on the surface of the metal by adding the wear resistant machine oil into the slushing oil, so that the friction can be reduced; the modified terpene resin has a good cohesive property and strong thermal stability so that the compatibility between the materials can be promoted and the adhesive force of the film can be enhanced; the zinc dihydrogen phosphate is used as a common metal surfactant which has a good rust removal preservative effect; the rare earth lanthanum ion and the OH<-> generated on the surface of the metal material during the oxygen absorption corrosion process can generate an insoluble complex which can slow down the corrosion of the electrode reaction and has a good slow-release effect.

Owner:ANHUI KING AUTO ELECTRONICS TECH CO LTD

ABS color master batch

Owner:天津毅兴彩科技有限公司

Thermochromic composite material for intelligent window

PendingCN113773599AImprove thermal stabilityLower phase transition temperatureLight protection screensTenebresent compositionsAqueous solubilityThermal stability

Owner:FUJIAN AGRI & FORESTRY UNIV

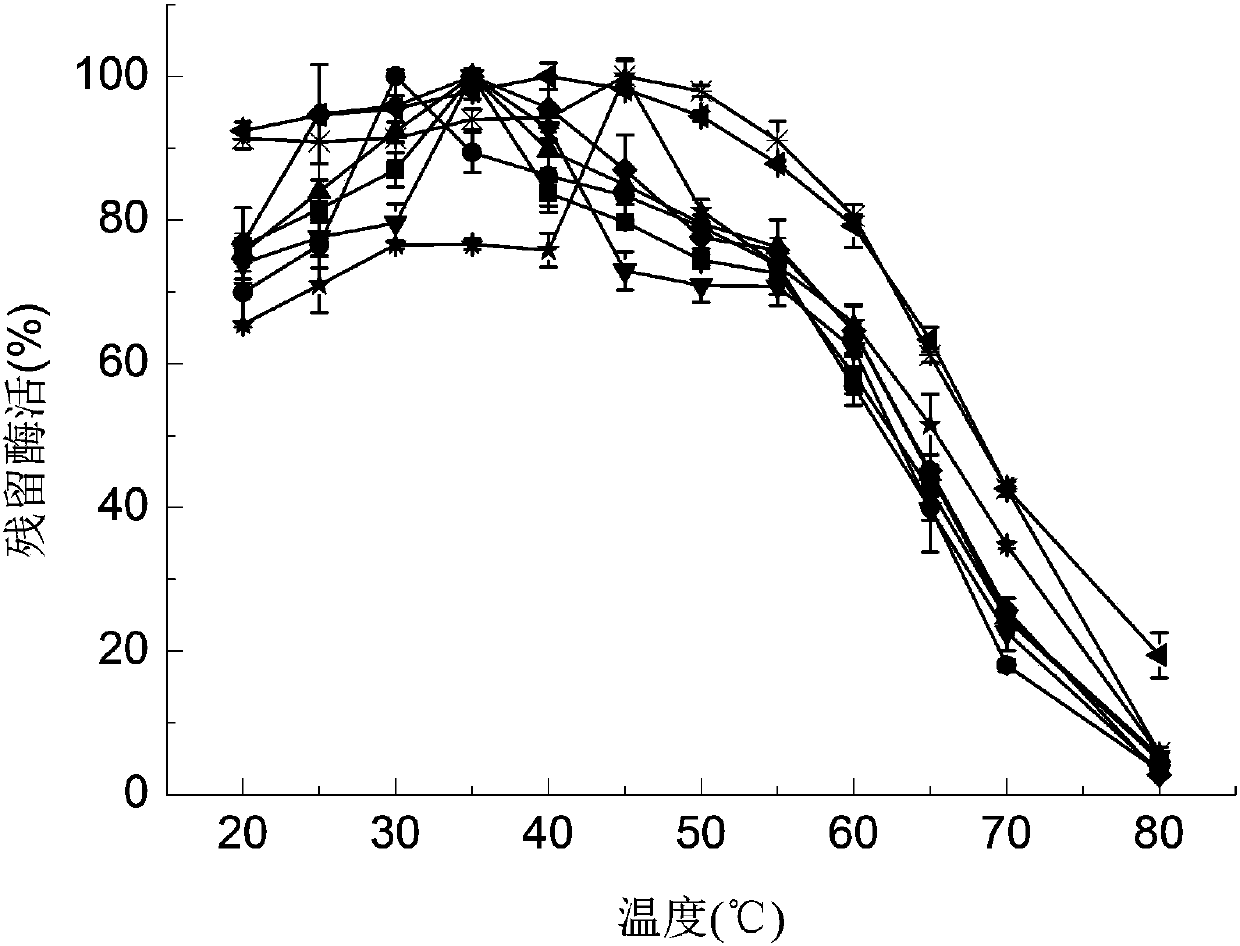

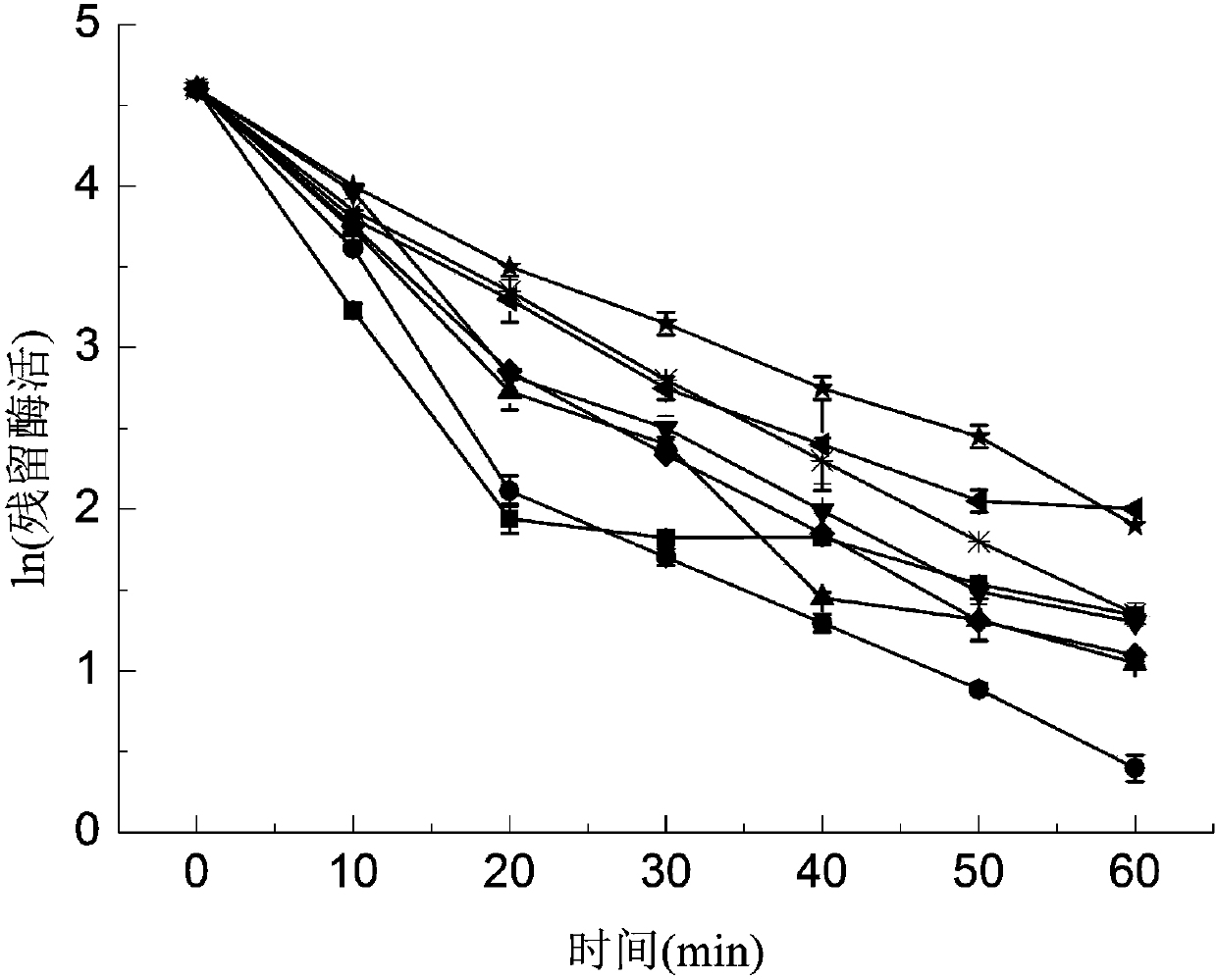

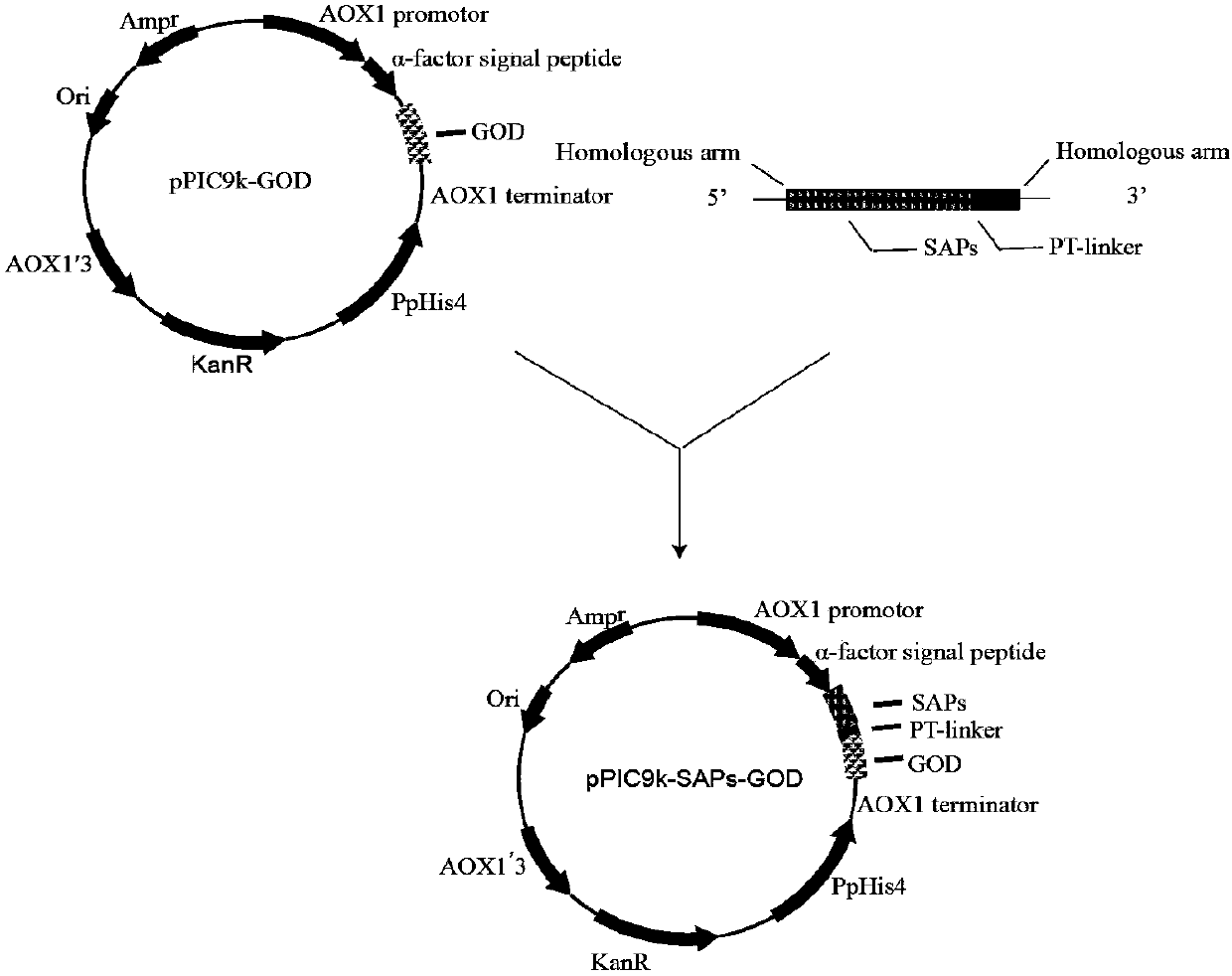

Method for improving thermal stability of glucose oxidase

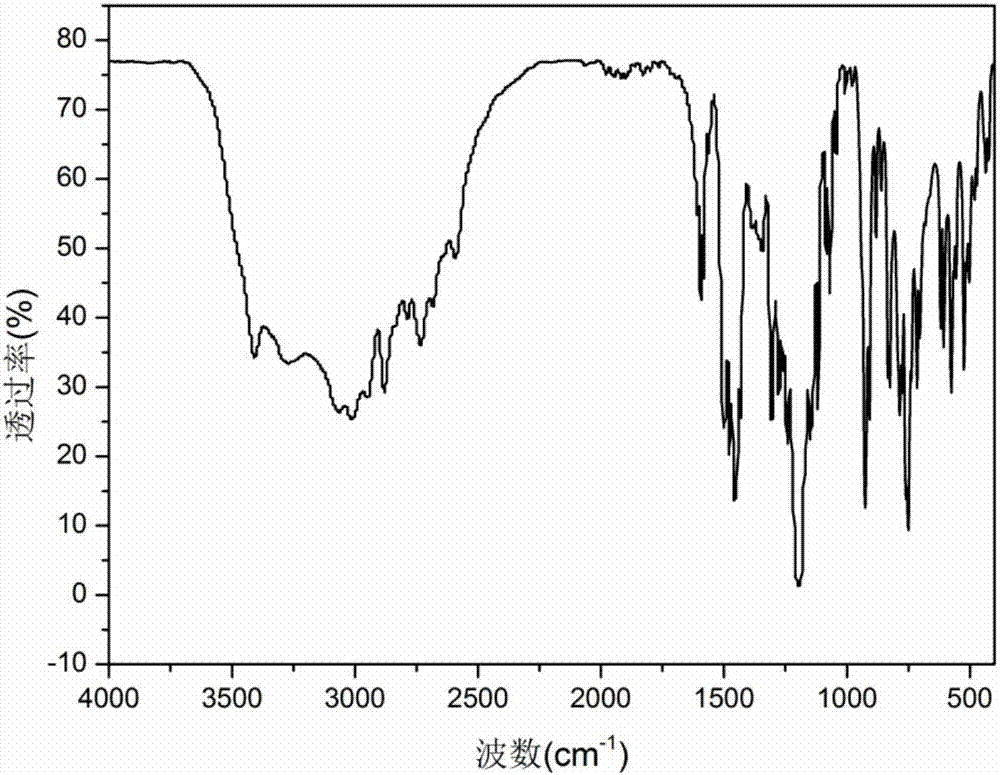

InactiveCN108048442AImprove thermal stabilityEnzyme stabilisationOxidoreductasesThermal stabilityAspergillus niger

Owner:JIANGNAN UNIV

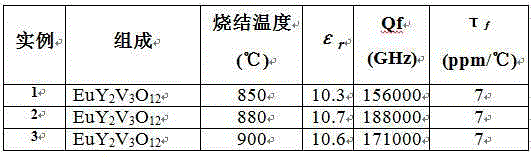

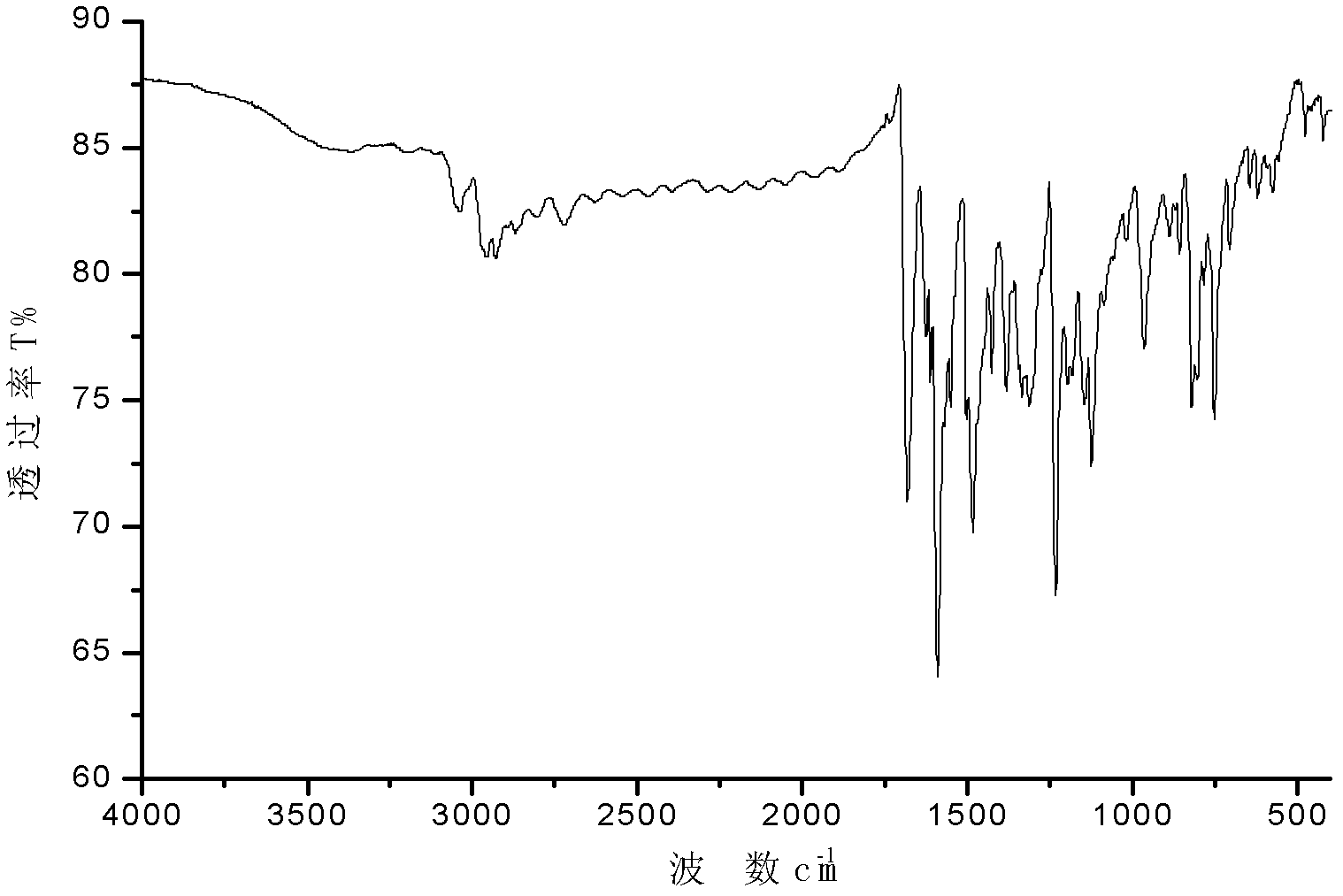

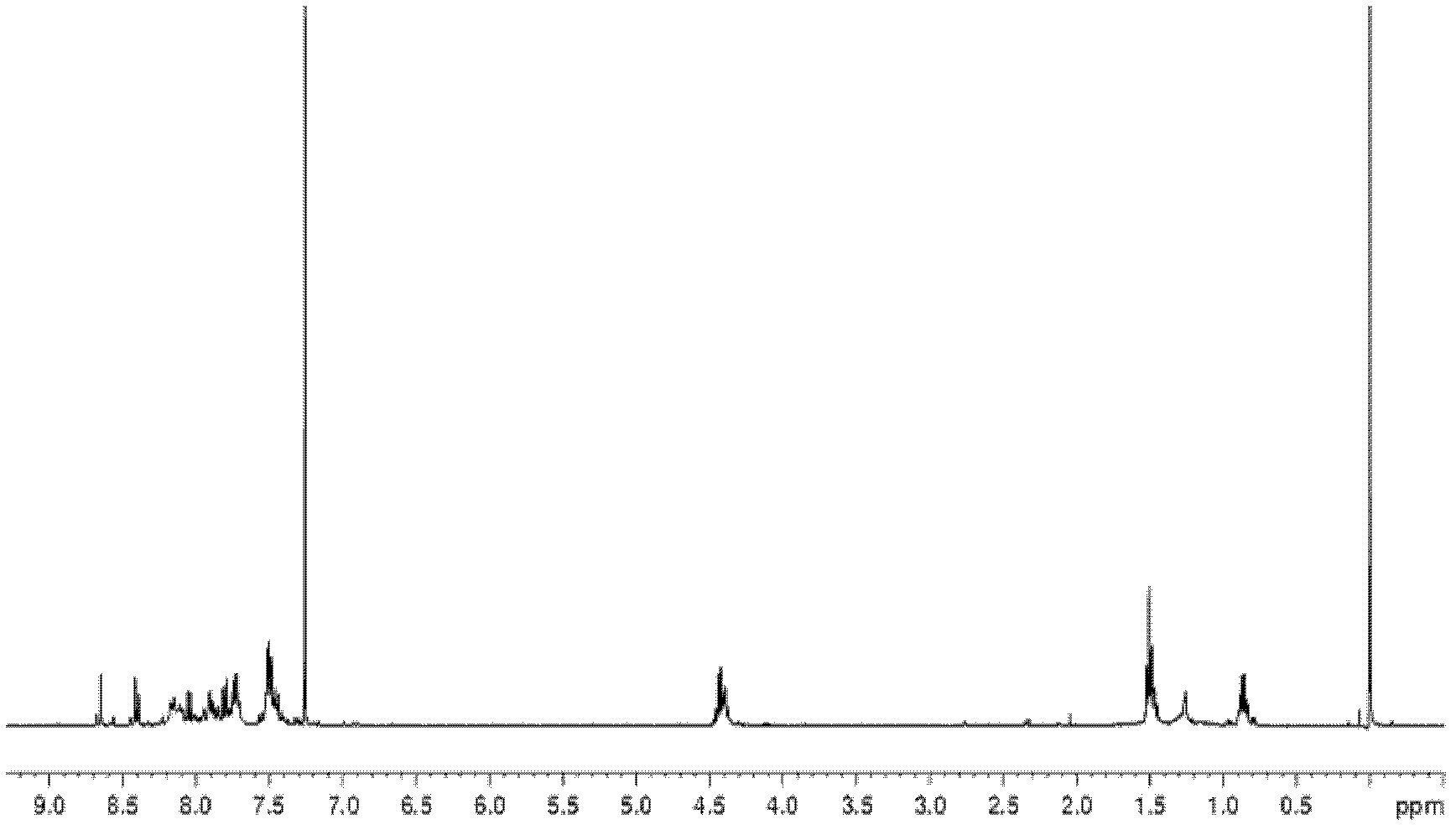

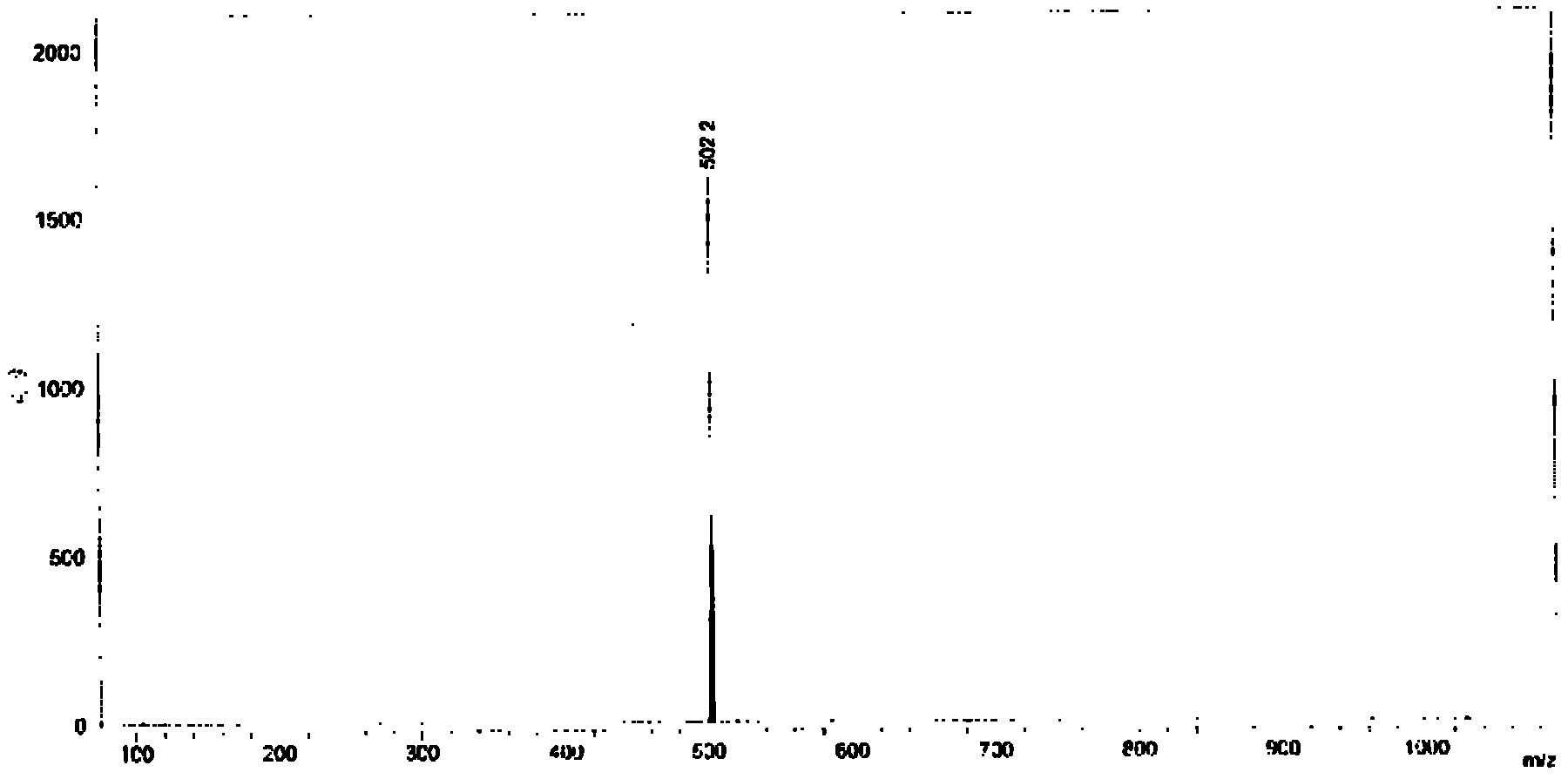

Ultra-low dielectric constant microwave dielectric ceramic EuY2V3O12 with low loss and high thermal stability

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Accumulator case material for new energy automobiles

Owner:HUANGSHAN ANDAER PLASTIC IND

Agricultural insecticide emulsion

InactiveCN1478398ALow toxicityBroad insecticidal spectrumBiocideAnimal repellantsCypermethrinEmulsion

An agricultural insecticide emulsion contains one of cypermethrin, efficient cypermethrin and efficient cyhalothrin, trichlorfon, emulsifier, assistant and solvent. Its advantages are broad spectrum, high effect, high stability, low poison, and low cost.

Owner:陈华玲

N-alkyl group-3, 6-di-(2-quinoline) vinyl) carbazole and preparation method thereof

InactiveCN102633781AEasy to manufactureEfficient use ofOrganic chemistryLuminescent compositionsSolubilityTwo-photon absorption

Owner:HEILONGJIANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap