Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Microcrystalline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

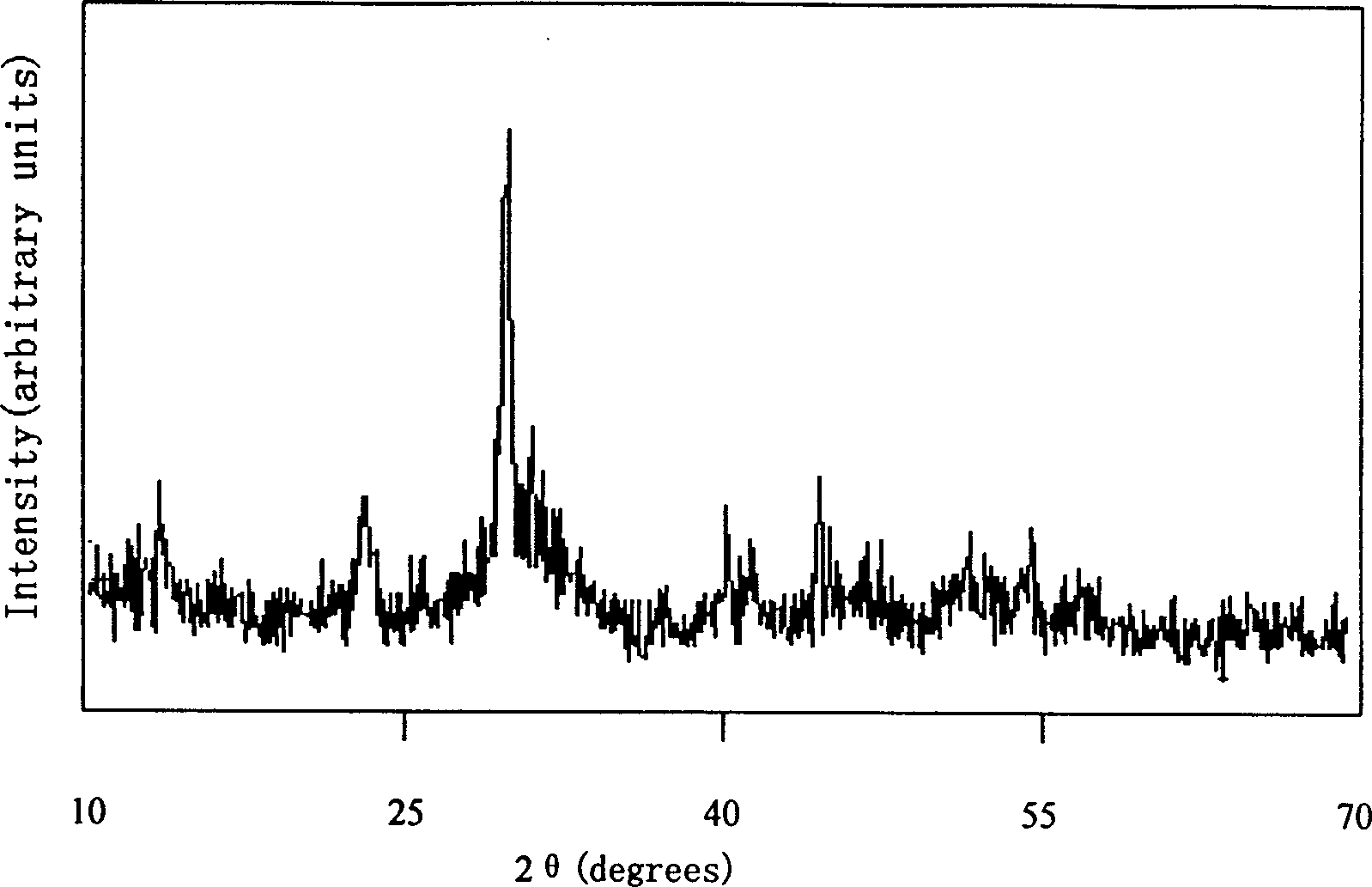

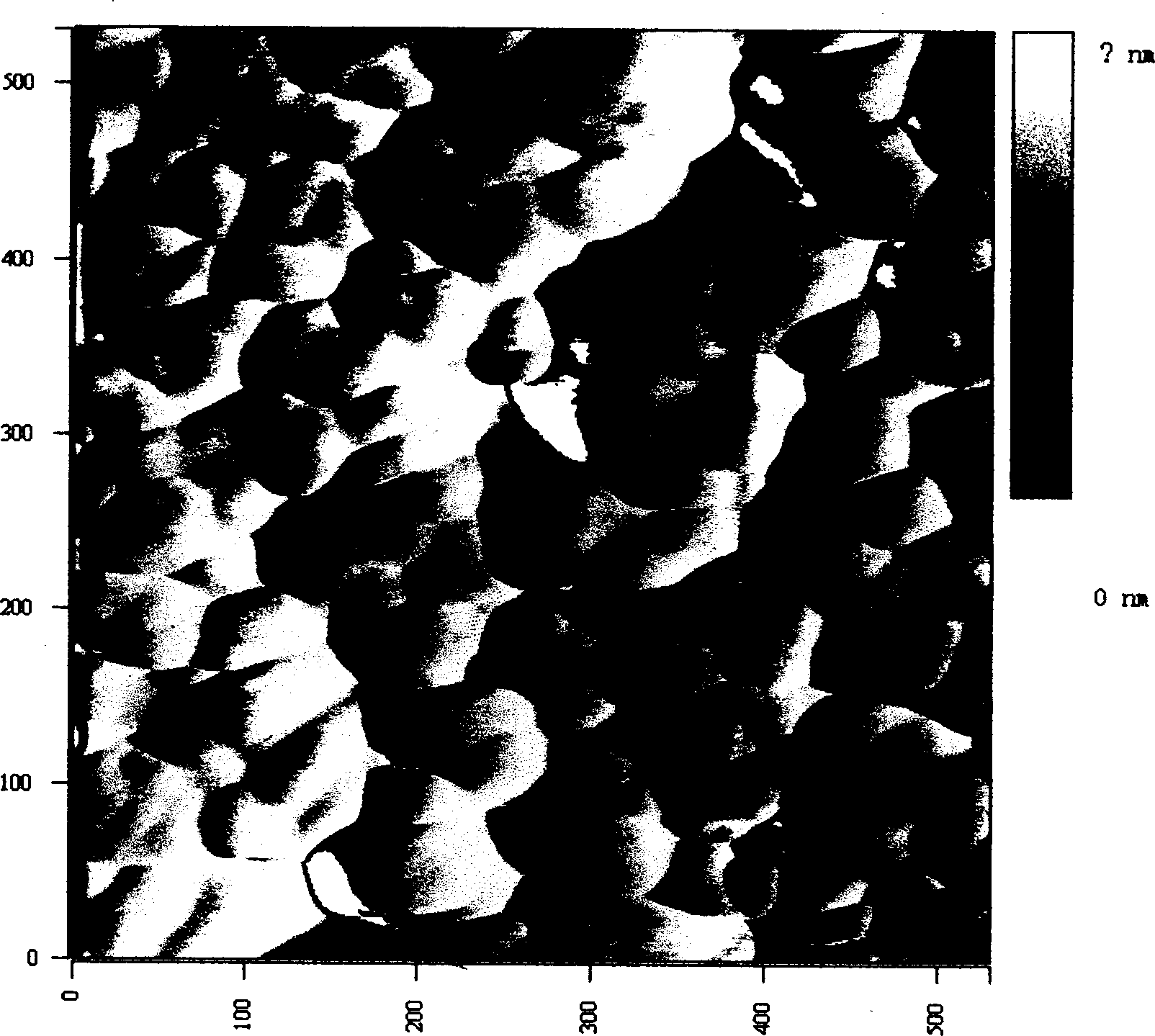

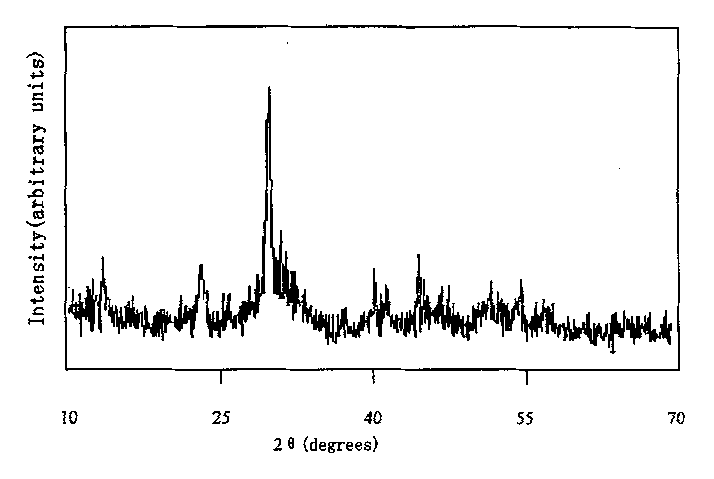

A microcrystalline material is a crystallized substance or rock that contains small crystals visible only through microscopic examination.

Nano-grade lanthanum titanium compound oxide, its preparation method and application

InactiveCN1394680AReduce viscosityReduce the temperatureCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOligomerLactide

Owner:CHONGQING UNIV

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199AIncrease the solidification rateImprove vertical welding operabilityWelding/cutting media/materialsSoldering mediaElectrolysisSS - Stainless steel

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

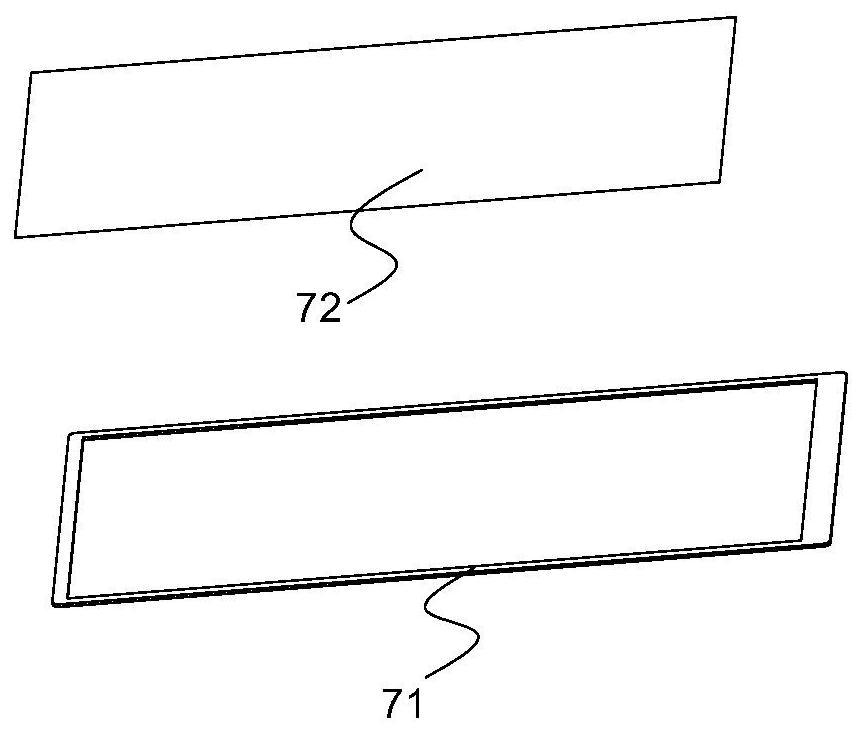

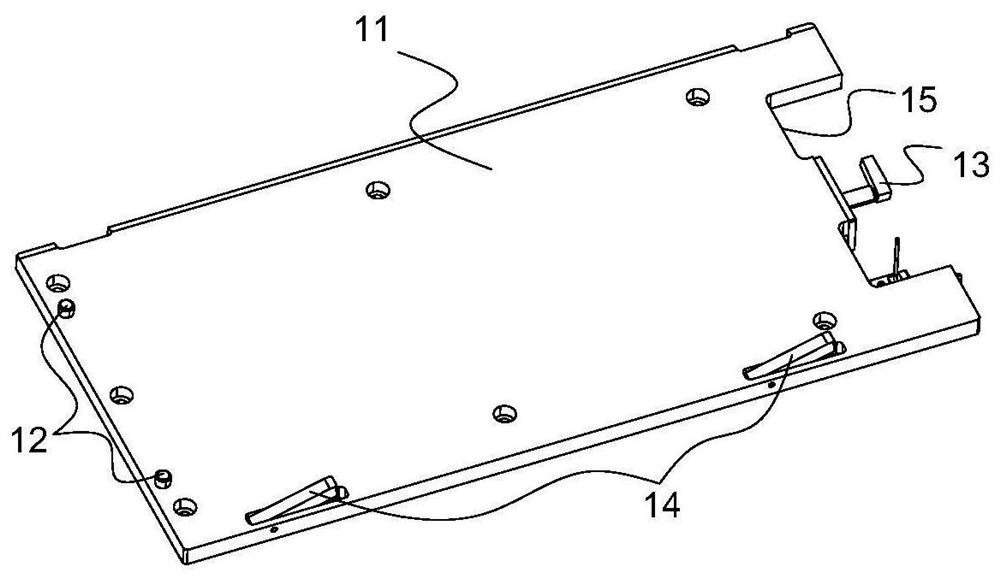

Wear-resistant composite microcrystalline sheet material

Owner:HENAN JINGXIANG ABRASION PROOF MATERIAL

Preparation method of silicon carbide microcrystalline homogenized in dimension and shaped in polyhedron form

ActiveCN103643294AUniform nucleationUniform growth orientationPolycrystalline material growthFrom frozen solutionsCrucibleCrystal growth

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

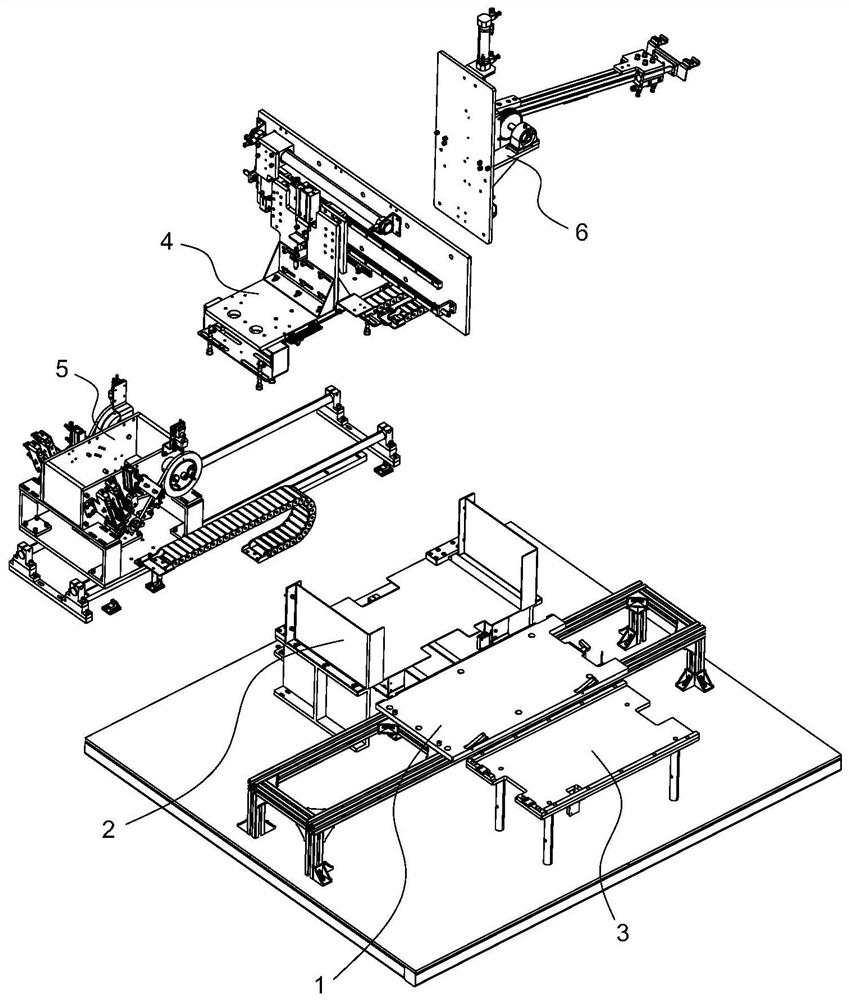

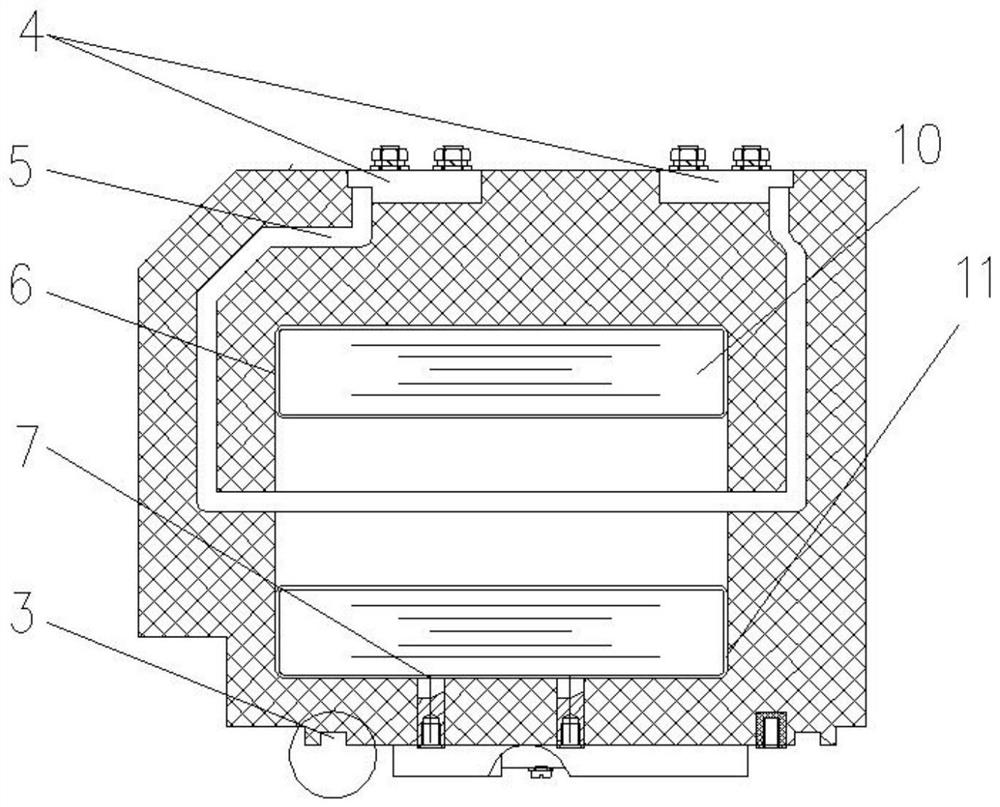

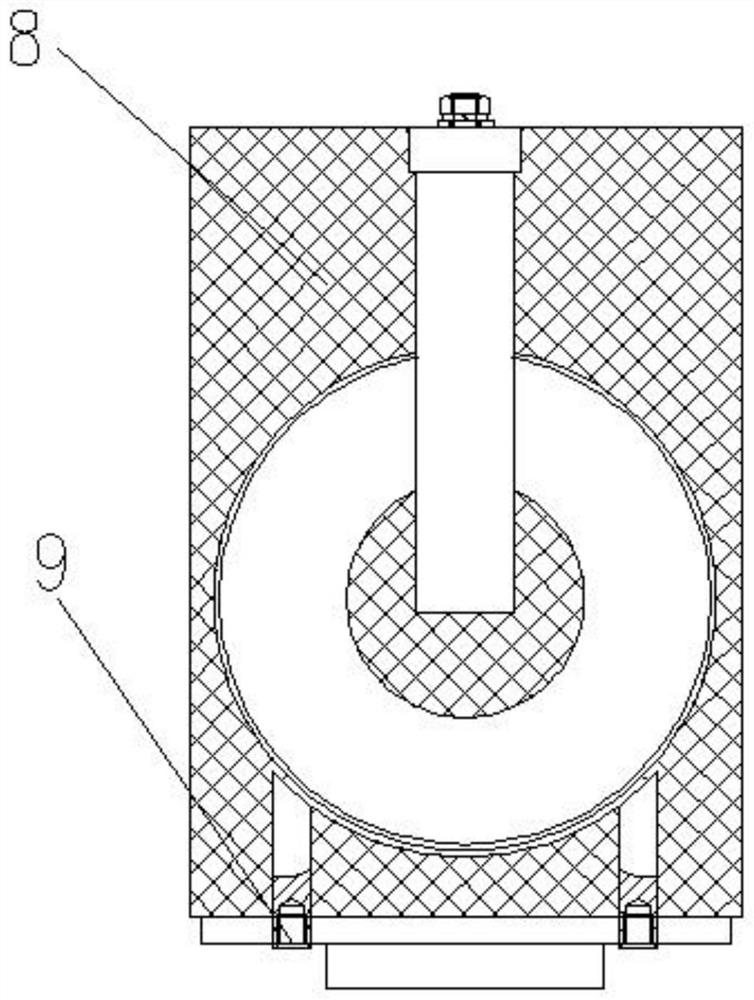

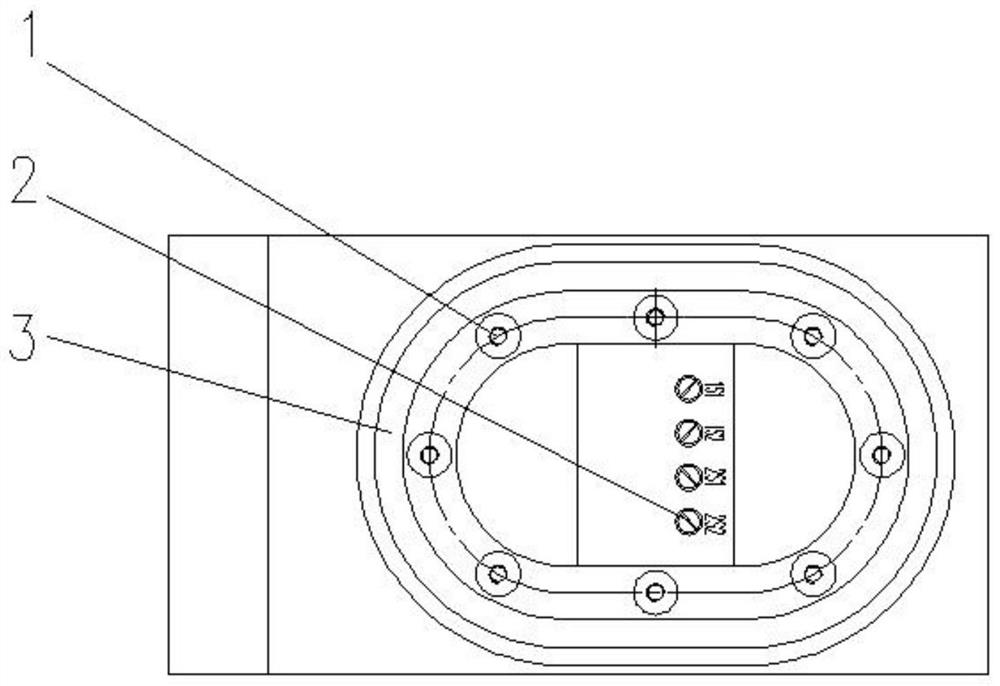

Rubberizing mechanism and rubberizing device for assembling and producing microcrystalline far-infrared heater

InactiveCN112601300AImprove adhesionPrevent crushingOhmic-resistance heatingArticle feedersAdhesive beltEngineering

Owner:徐永辉

Current transformer for CGIS

PendingCN112397287AGuaranteed measurement accuracy requirementsConvenient wiring operationTransformersTransformers/inductances casingsInstrument transformerHigh voltage

Owner:湖北大二互科技股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap