Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Fluorite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorite (also called fluorspar) is the mineral form of calcium fluoride, CaF₂. It belongs to the halide minerals. It crystallizes in isometric cubic habit, although octahedral and more complex isometric forms are not uncommon.

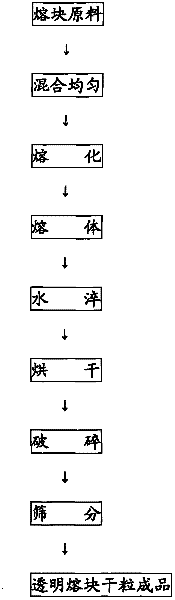

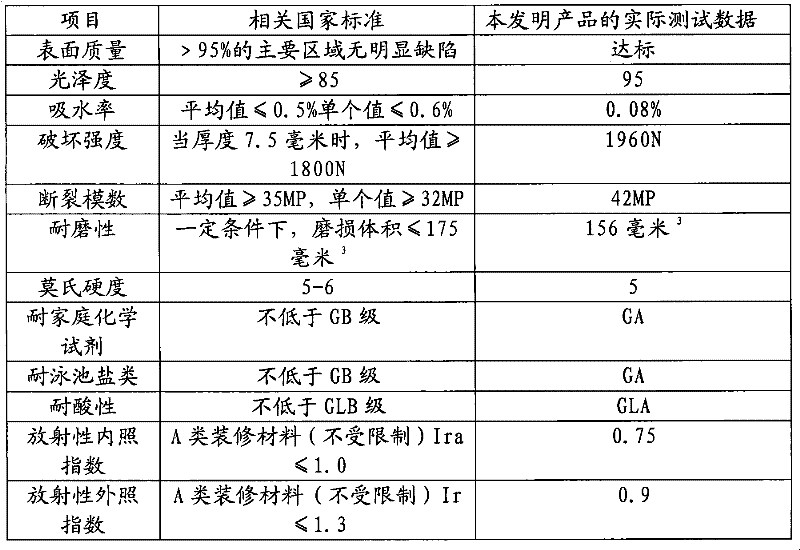

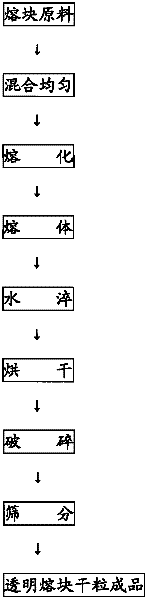

Method for producing transparent clinker capable of being compounded with colored glaze ceramic blank

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

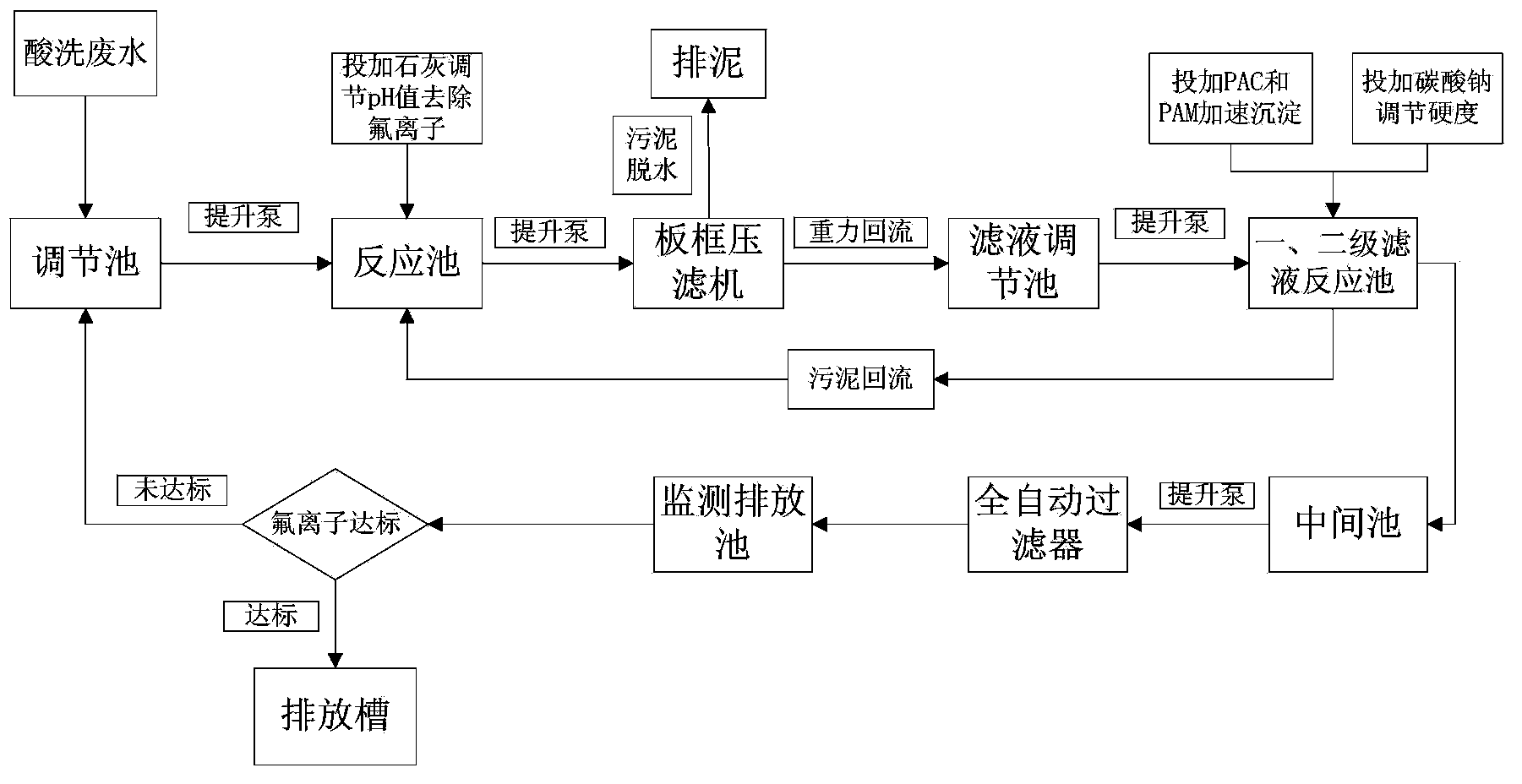

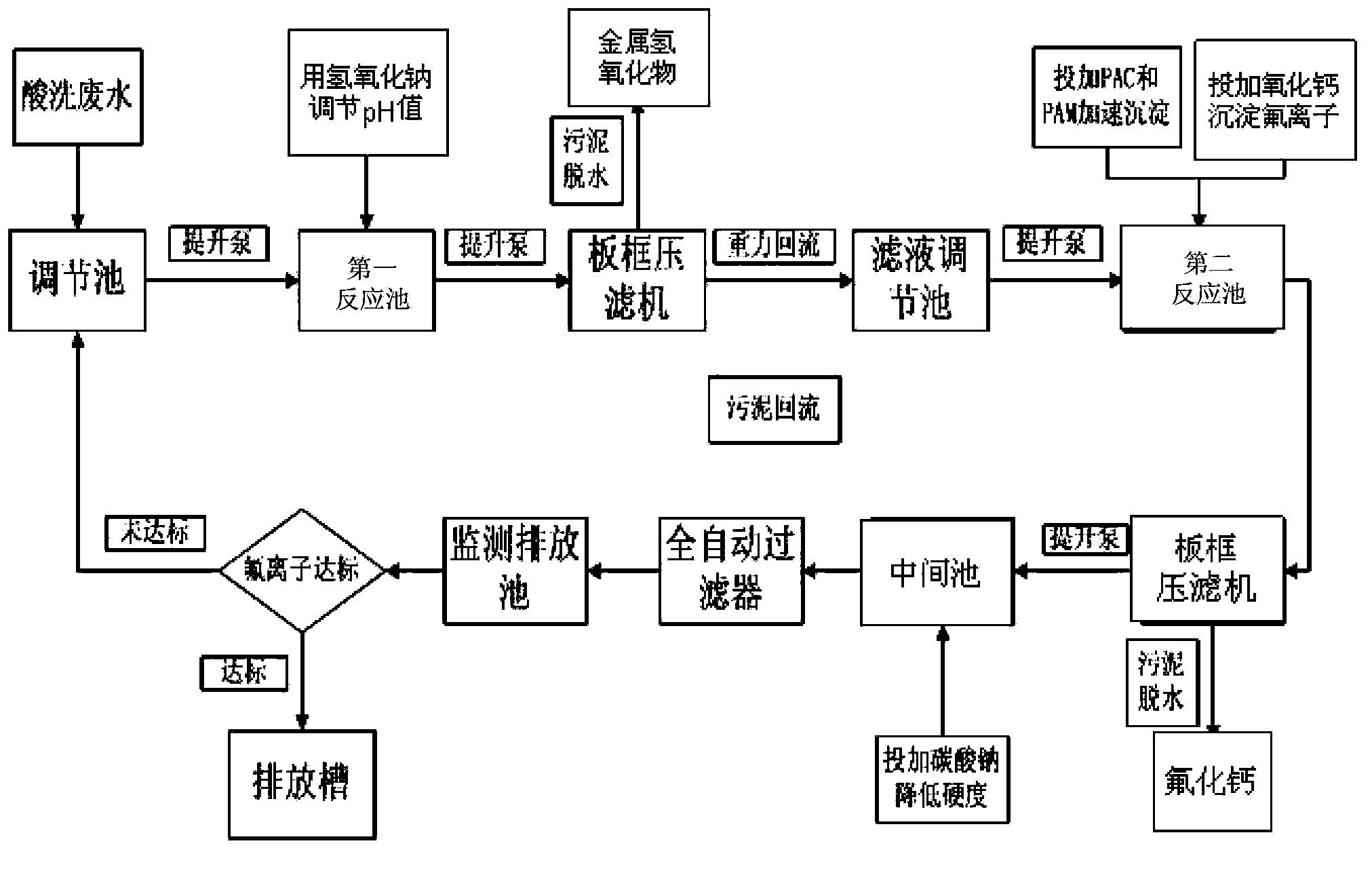

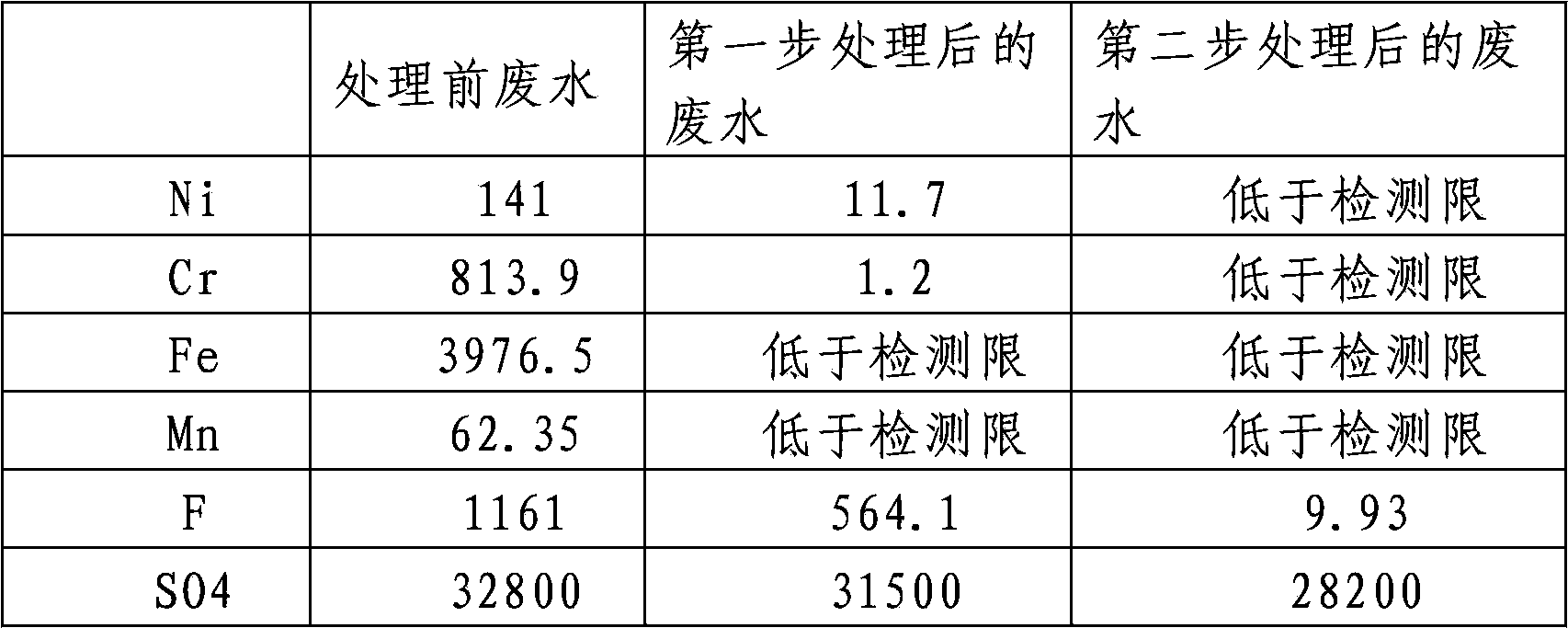

Double-alkali neutralization treatment method of heavy metal-containing acidic wastewater

Owner:宝钢特钢长材有限公司

Processing method of abrasion resistant welding wire

InactiveCN105772993APrevent oxidationImprove protectionWelding/cutting media/materialsSoldering mediaArc stabilityIron powder

The invention relates to flux-cored wires, in particular to a processing method of an abrasion resistant welding wire. The processing method comprises the steps of drying microcrystalline graphite powder, aluminium powder, fluorite powder, magnesite powder, potassium carbonate powder, ferrosilicon powder, ferromanganese alloy powder and iron powder, and screening; adding the powder into a mixer for mixing; putting a cleaned and dried steel belt on a roller die, adding the mixed powder on the steel belt, and carrying out mold molding; drawing the molded welding wire to decrease the diameter; and winding the drawn wire layer by layer, and packaging the wound wire. According to the processing method, core wire powder is dried, so that the prepared abrasion resistant welding wire is not liable to have the defects of pores, press pits, even cracks, and the like, during the welding process; and during the preparation process of the abrasion resistant welding wire, the contents of carbon and aluminium are increased, so that the deoxidizing and nitrogen fixing capacities are improved, the electrical arc stability is improved, and the carbon oxidation is inhibited, and the gas overflow splashing is reduced.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199AIncrease the solidification rateImprove vertical welding operabilityWelding/cutting media/materialsSoldering mediaElectrolysisSS - Stainless steel

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Composite desulfurizer of iron and steel and its preparing process

Owner:TAIYUAN UNIV OF TECH

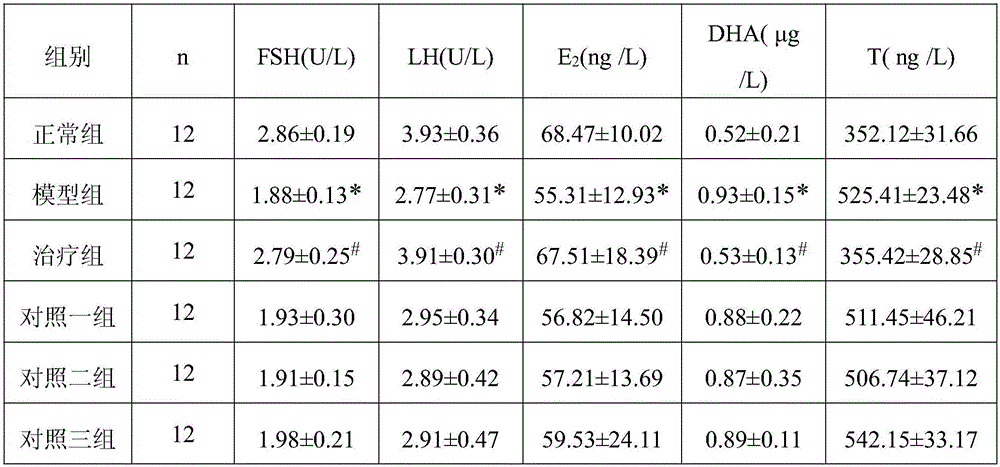

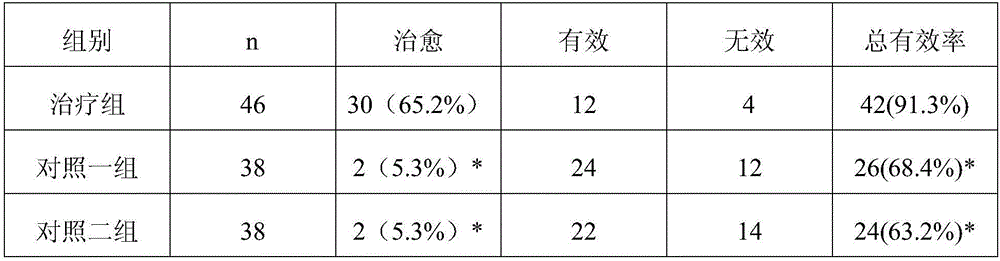

Traditional Chinese medicine composition for treating infertility and application of traditional Chinese medicine composition

ActiveCN105943758AEasy to acceptNo side effectsSexual disorderAlkali/alkaline-earth metal chloride active ingredientsCurative effectInfertility

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

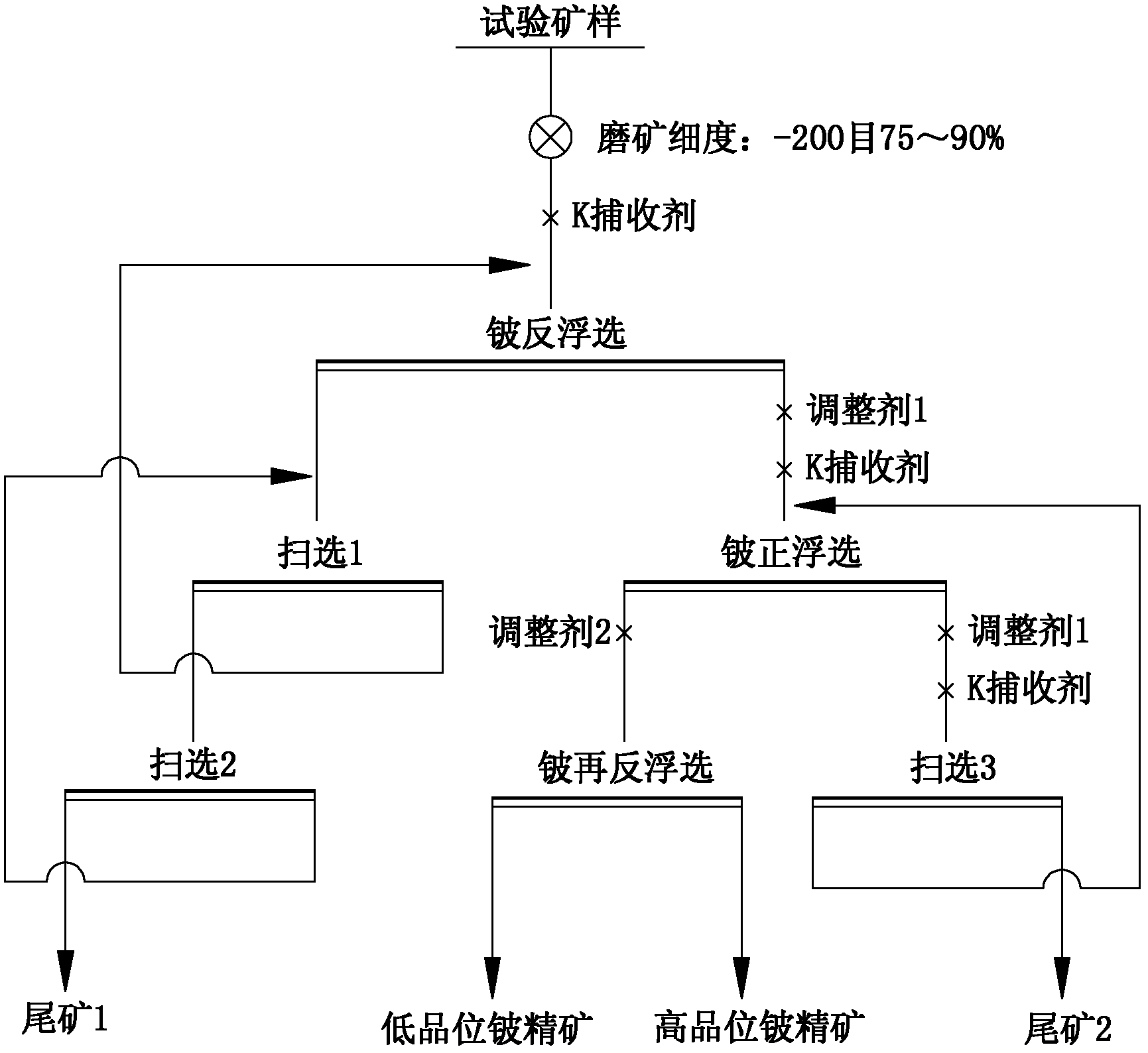

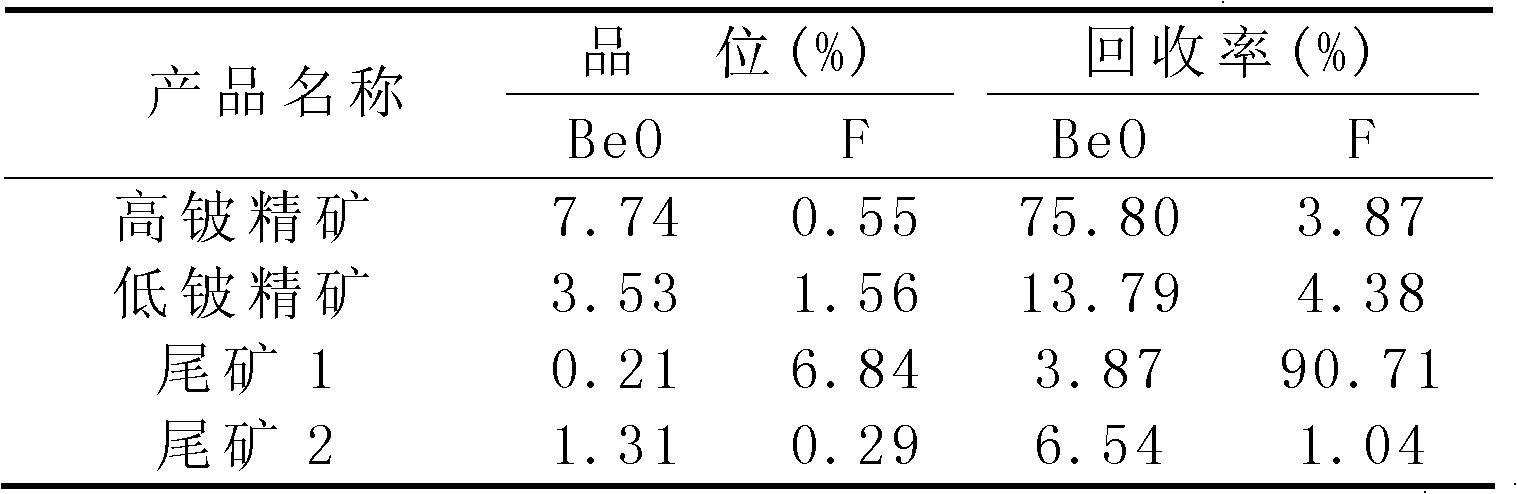

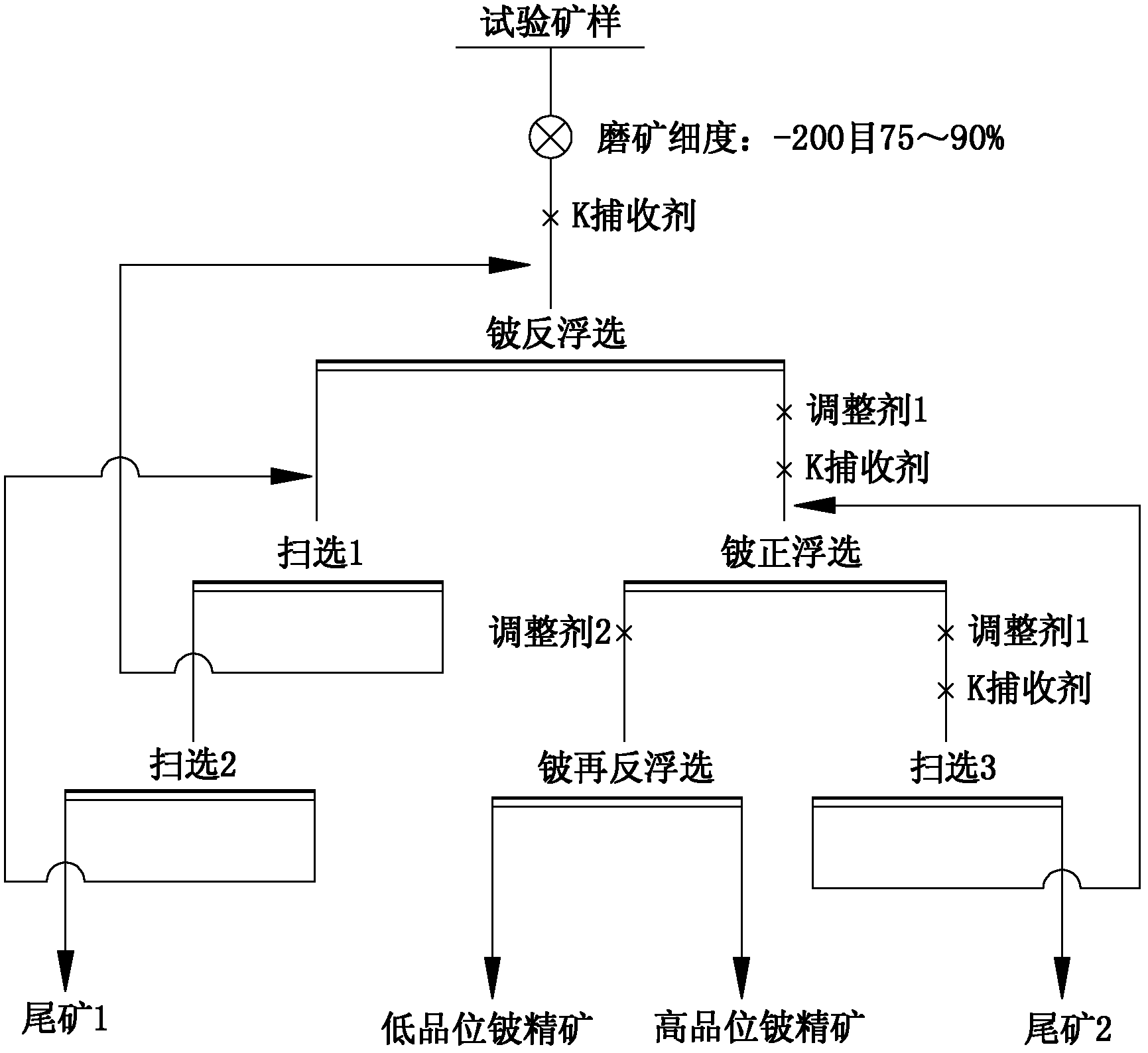

High-efficiency floatation method for beryllium ore

InactiveCN102600989AFully follow the characteristics of floatabilityFollow the floatability featureFlotationResource utilizationWater quality

Owner:HUNAN RES INST FOR NONFERROUS METALS

Low-aluminum and low-silicon welding wire steel low-sulfur-control smelting method

ActiveCN111979374AReduce sulfur contentPrevent slagSteelmakingSlag (welding)

Owner:NANJING IRON & STEEL CO LTD

Alkali-free glass fiber yarn

Owner:安徽省绩溪县华宇防火滤料有限公司

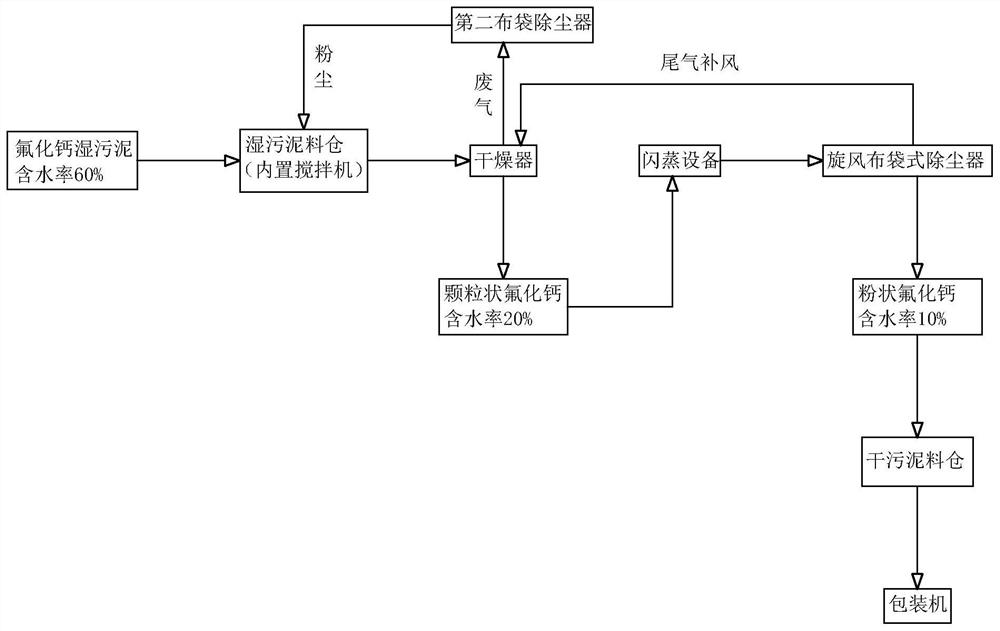

Method for recovering powdery calcium fluoride products from calcium fluoride sludge resources

PendingCN112850768ACompliant with usage standardsAvoid pollutionCalcium/strontium/barium fluoridesSludgeEngineering

Owner:丁学锋 +1

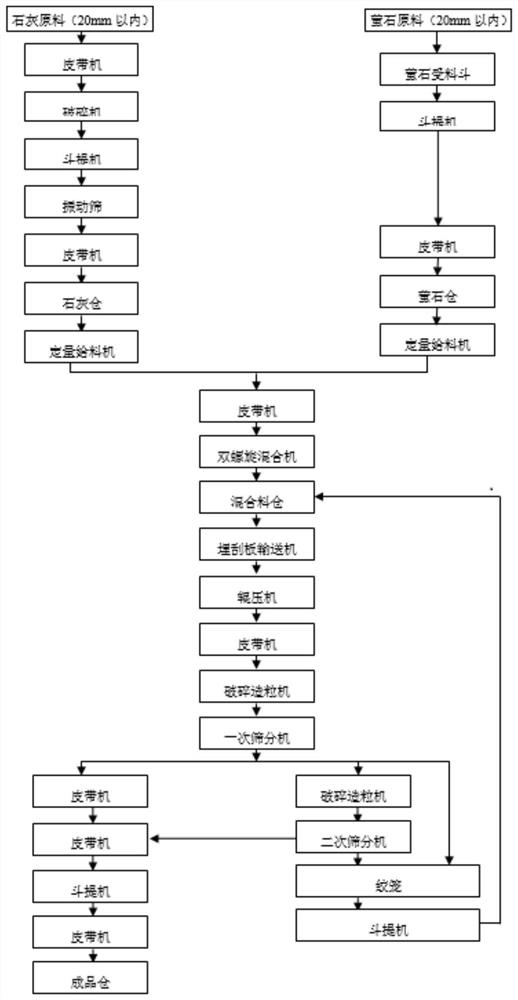

Cyclic granulation method of KR desulfurizing agent

InactiveCN111659519AGranulation by pressingProcess efficiency improvementChemical engineeringFluorite

Owner:SHAGANG GROUP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap