Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

28 results about "Welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This is a list of welding processes, separated into their respective categories.The associated N reference numbers (second column) are specified in ISO 4063 (in the European Union published as EN ISO 4063). Numbers in parentheses are obsolete and were removed from the current (1998) version of ISO 4063. The AWS reference codes of the American Welding Society are commonly used in North America.

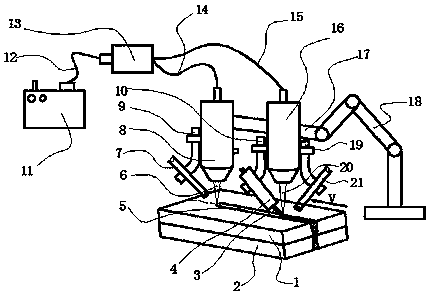

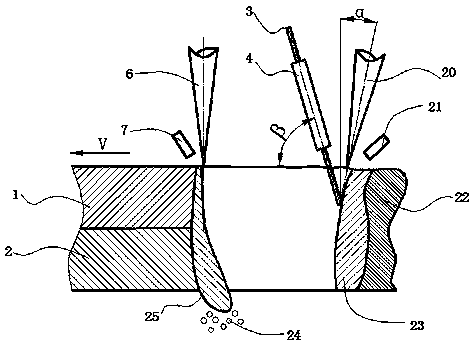

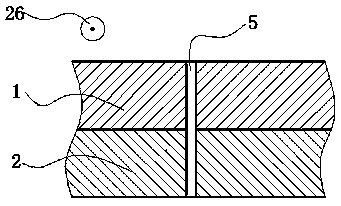

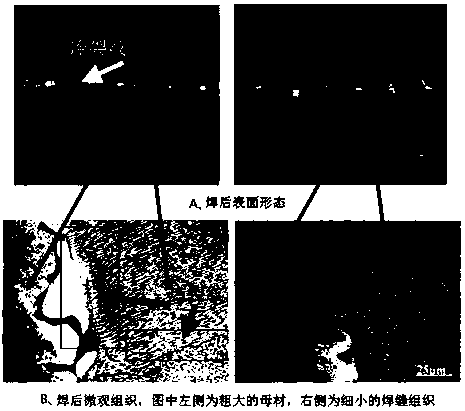

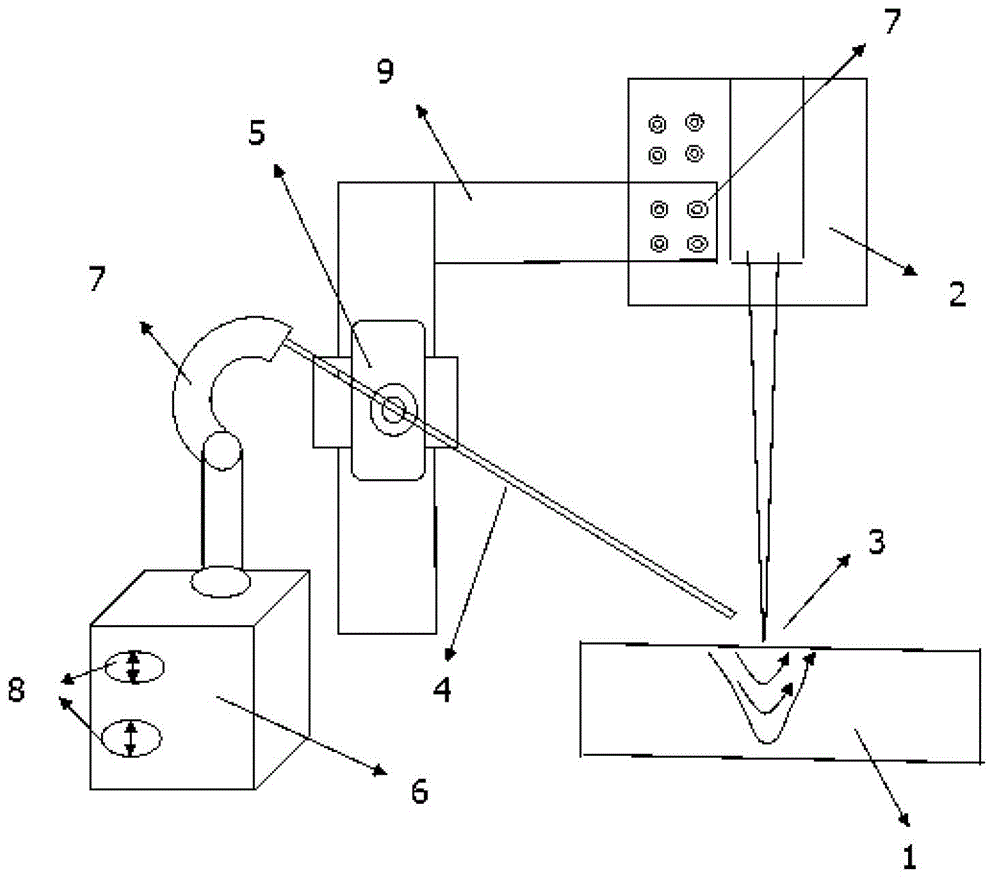

Car steel-aluminum splicing joint welding method and system

InactiveCN107971650AImprove connection strengthIncrease binding areaWelding/soldering/cutting articlesWelding apparatusLaser cuttingEngineering

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

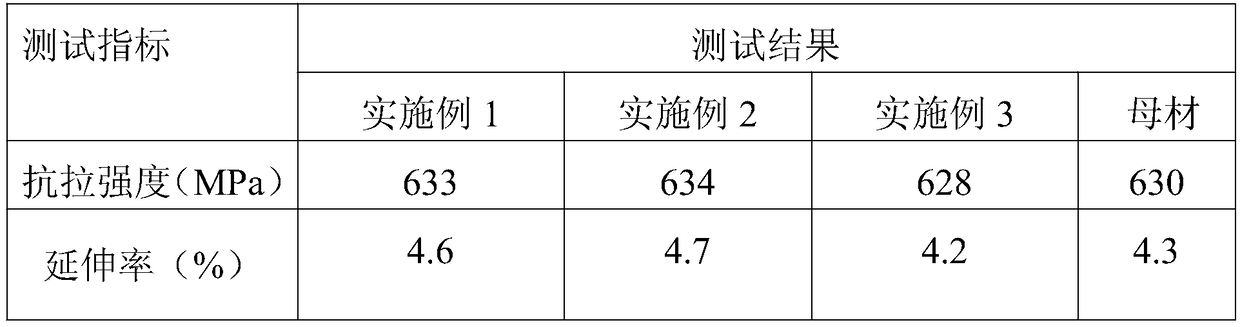

Laser welding method of CoCrCuFeNi high-entropy alloy

ActiveCN108747006AHigh strengthImprove plasticityLaser beam welding apparatusCrazingHigh entropy alloys

Owner:GUIZHOU INST OF TECH

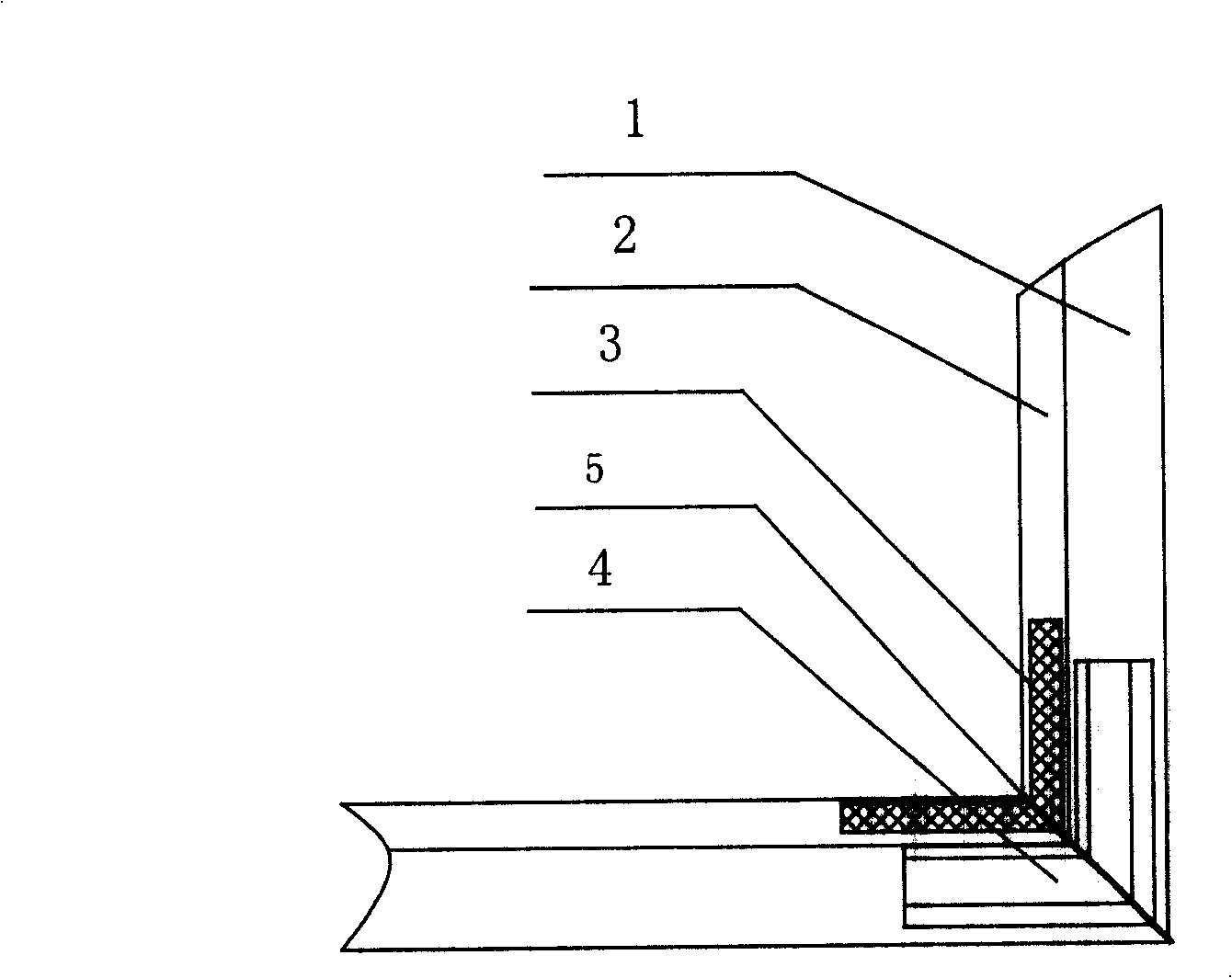

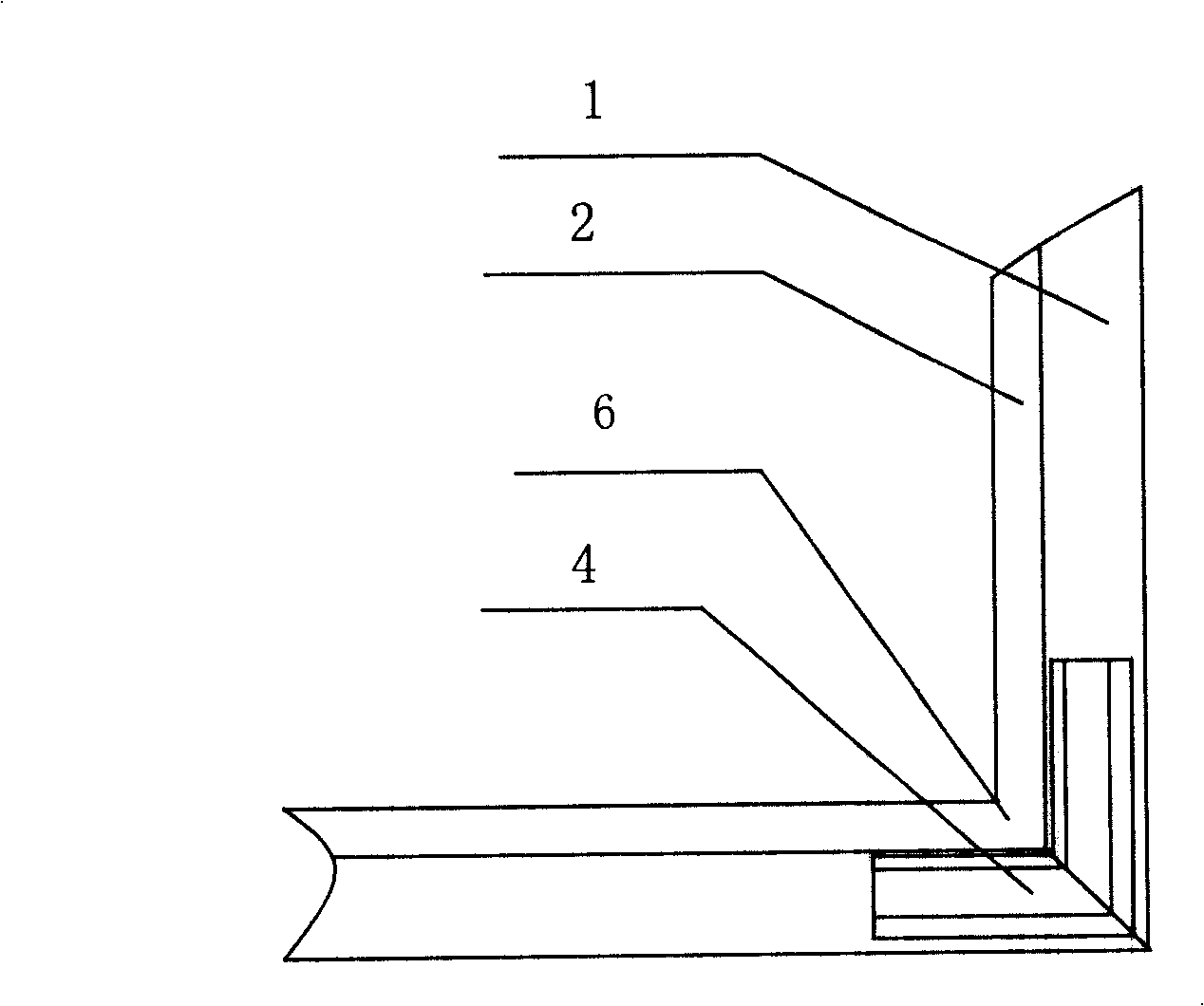

Welding process for aluminum plastics door and window

InactiveCN101244628AEliminate worriesIncrease productivityMilling cuttersMilling equipment detailsMilling cutterPlastic materials

Owner:CHANGZHI HUIFENG ELECTROMECHANICAL INDAL TRADE

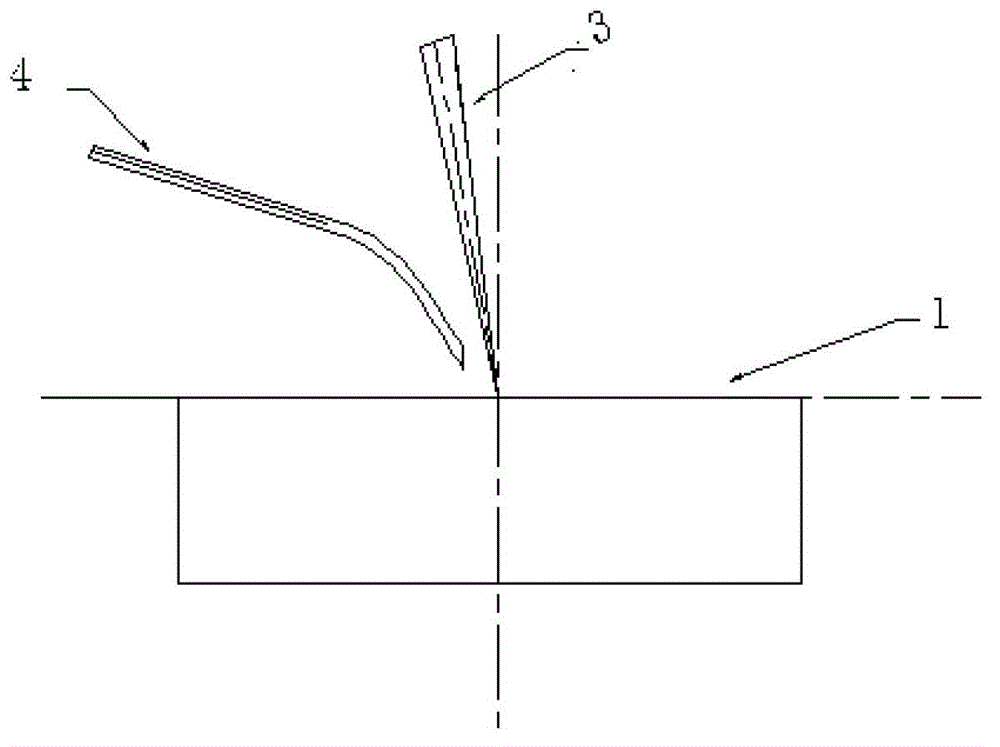

Method and device for controlling laser welding seam holes

InactiveCN102941412AGuaranteed patencyAvoid formingLaser beam welding apparatusThick plateEngineering

Owner:HUAZHONG UNIV OF SCI & TECH

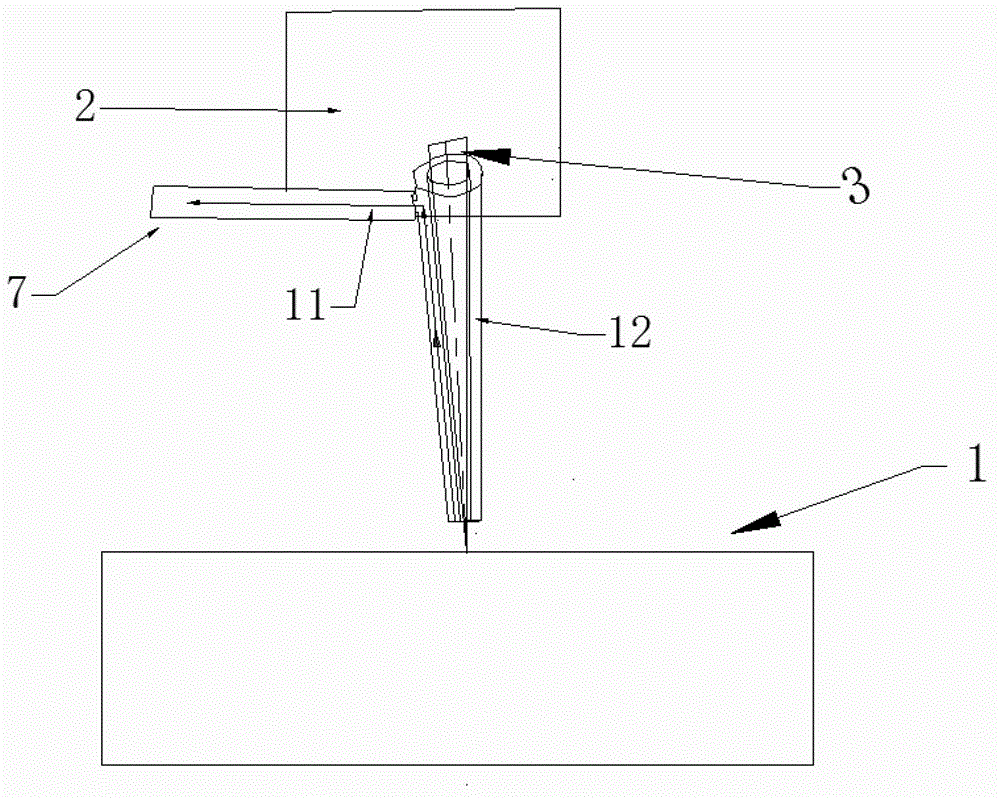

Laser welding apparatus and method of laser welding

ActiveCN102196879AAvoid meltingInhibitionWelding/cutting auxillary devicesAuxillary welding devicesThick wallLaser beams

Owner:MITSUBISHI SHIPBUILDING CO LTD

Processing method of abrasion resistant welding wire

InactiveCN105772993APrevent oxidationImprove protectionWelding/cutting media/materialsSoldering mediaArc stabilityIron powder

The invention relates to flux-cored wires, in particular to a processing method of an abrasion resistant welding wire. The processing method comprises the steps of drying microcrystalline graphite powder, aluminium powder, fluorite powder, magnesite powder, potassium carbonate powder, ferrosilicon powder, ferromanganese alloy powder and iron powder, and screening; adding the powder into a mixer for mixing; putting a cleaned and dried steel belt on a roller die, adding the mixed powder on the steel belt, and carrying out mold molding; drawing the molded welding wire to decrease the diameter; and winding the drawn wire layer by layer, and packaging the wound wire. According to the processing method, core wire powder is dried, so that the prepared abrasion resistant welding wire is not liable to have the defects of pores, press pits, even cracks, and the like, during the welding process; and during the preparation process of the abrasion resistant welding wire, the contents of carbon and aluminium are increased, so that the deoxidizing and nitrogen fixing capacities are improved, the electrical arc stability is improved, and the carbon oxidation is inhibited, and the gas overflow splashing is reduced.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

Stainless steel welding rod improving vertical welding process performance

ActiveCN112975199AIncrease the solidification rateImprove vertical welding operabilityWelding/cutting media/materialsSoldering mediaElectrolysisSS - Stainless steel

The invention provides a stainless steel welding rod improving vertical welding process performance. The stainless steel welding rod comprises a stainless steel core wire and a coating wrapping the surface of the stainless steel core wire, the coating is prepared from the following raw materials, in parts by weight, 30-40 parts of rutile, 3-8 parts of zircon quartz, 5-10 parts of feldspar, 10-18 parts of marble, 2-6 parts of fluorite, 2-8 parts of dolomite, 1-5 parts of magnesia, 1-5 parts of aluminum oxide, 5-10 parts of electrolytic manganese metal, 5-10 parts of chromium metal, 3-6 parts of ferrotitanium, 2-7 parts of iron powder, 1-2 parts of sodium alginate and 1-2 parts of microcrystalline cellulose. According to the stainless steel welding rod improving the vertical welding process performance, the excellent flat welding process performance of an acid coating stainless steel welding rod is reserved, meanwhile, by designing the coating of the welding rod, the welding rod melting rate is reduced, the slag forming number in unit time is reduced, the slag solidification rate is improved, vertical welding slag is stably solidified and does not flow downwards, and the vertical welding operability of the stainless steel welding rod is improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

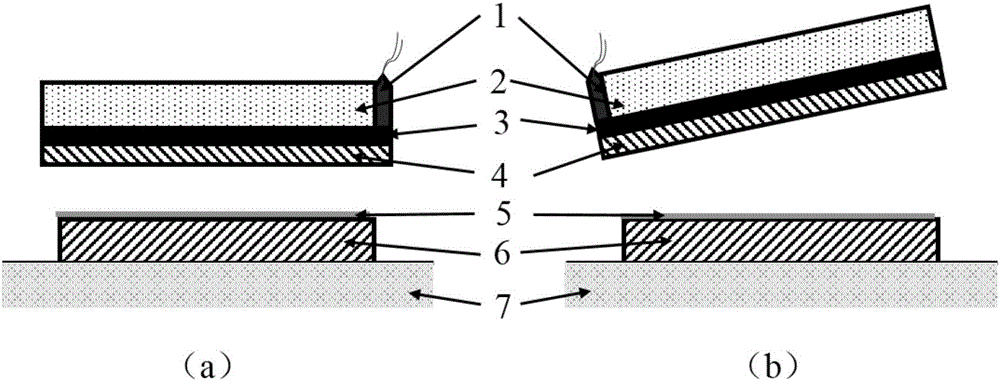

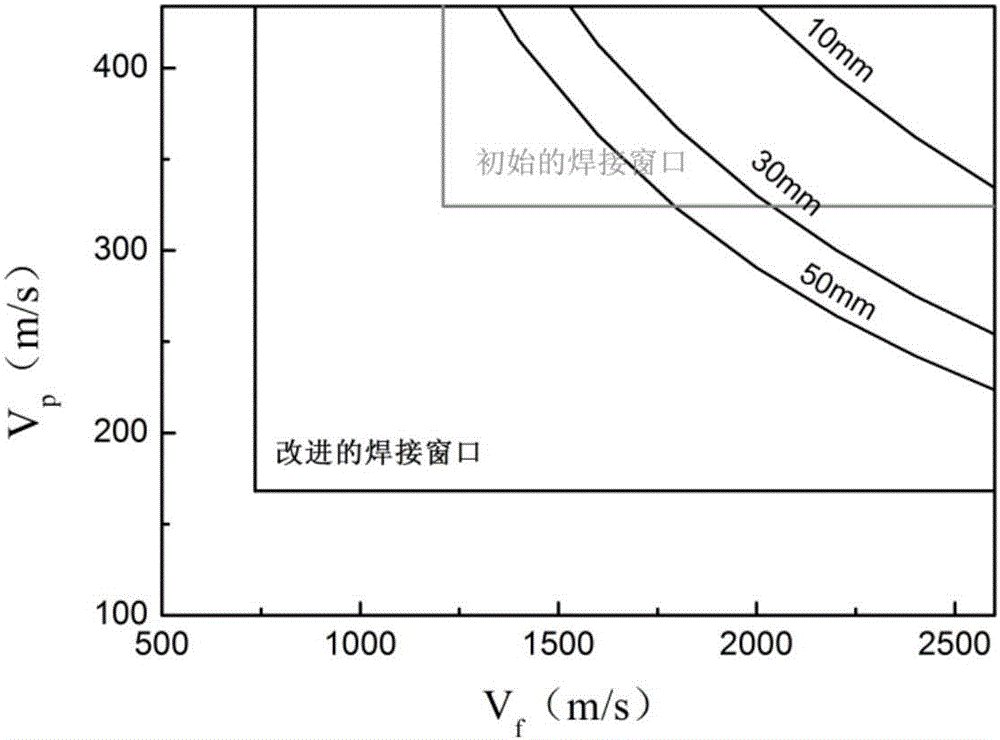

Method capable of improving explosive welding weldability of large-thickness high-strength alloy

Owner:XI AN JIAOTONG UNIV

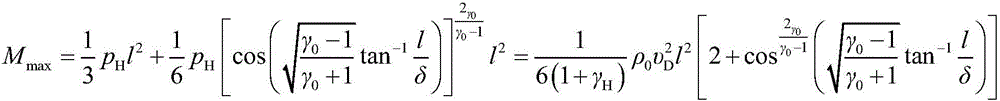

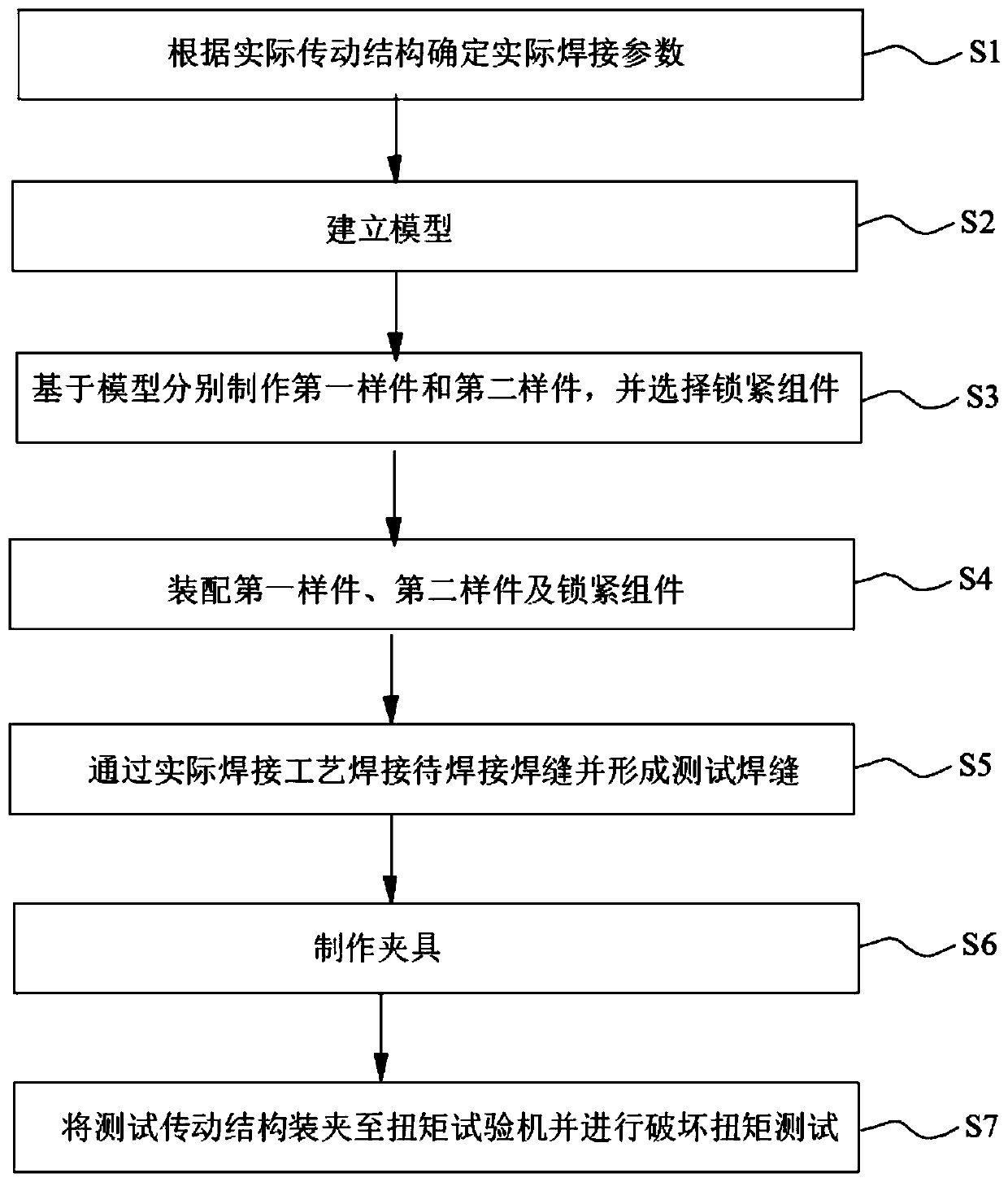

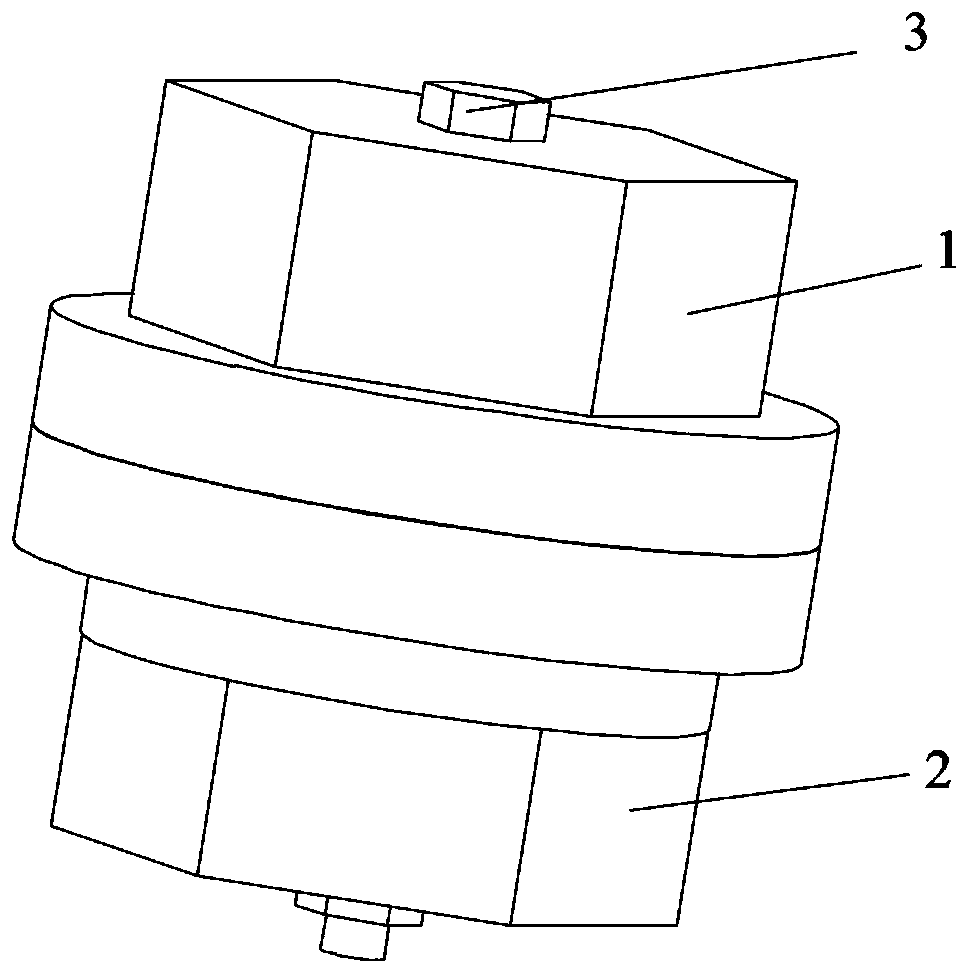

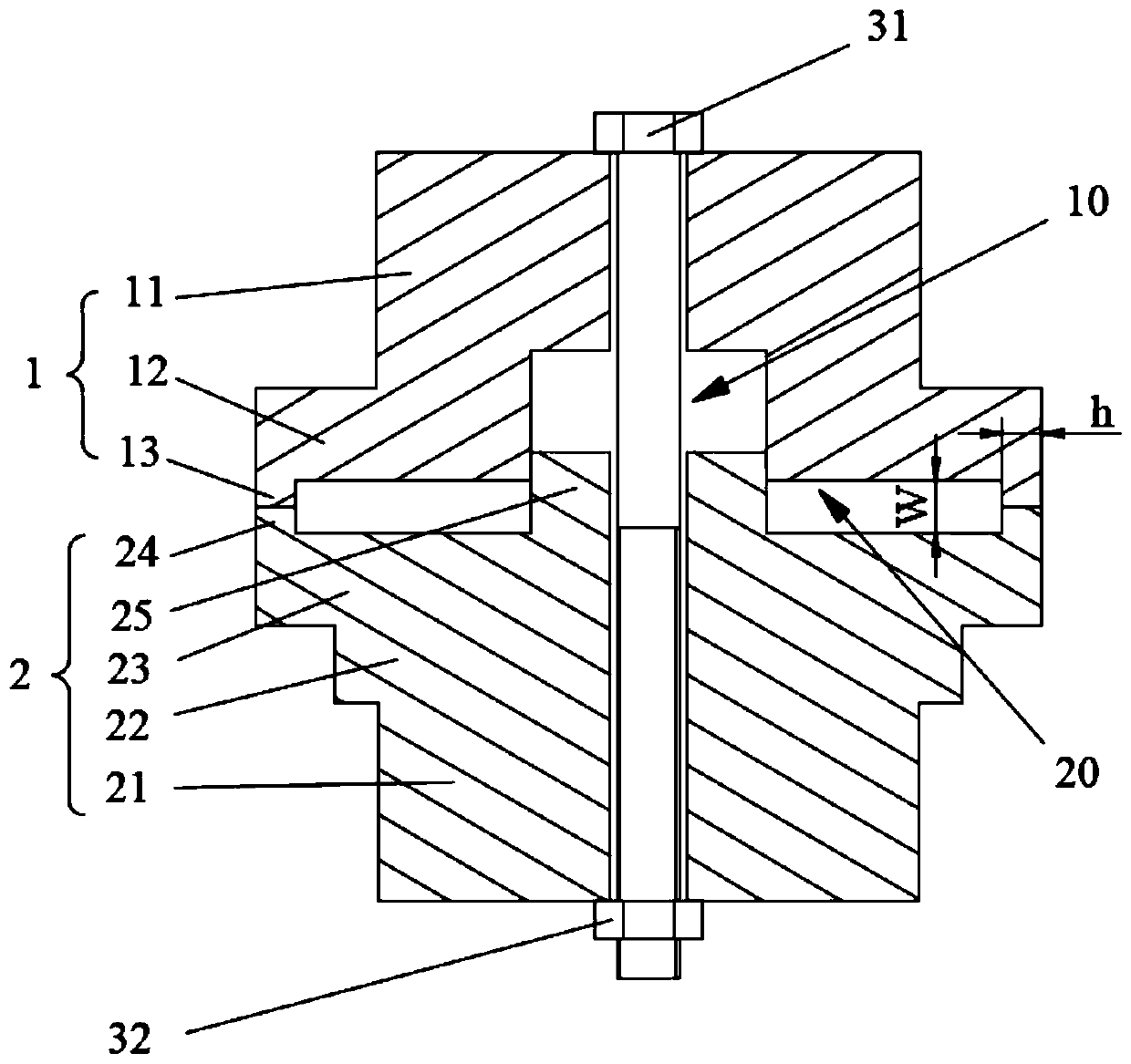

Circular radial butt weld damage torque testing method

ActiveCN111413213AAccurate assessment of maximum load torqueReduce manufacturing costMachine part testingPreparing sample for investigationButt weldingStructural engineering

Owner:CHINA FIRST AUTOMOBILE

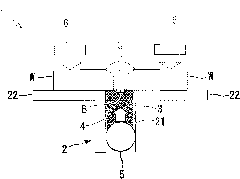

Single-side welding machine used for electrostatic dust collector moving electrode plate

InactiveCN105014214AMeet needsGuaranteed stabilityResistance welding apparatusEngineeringSpot welding

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

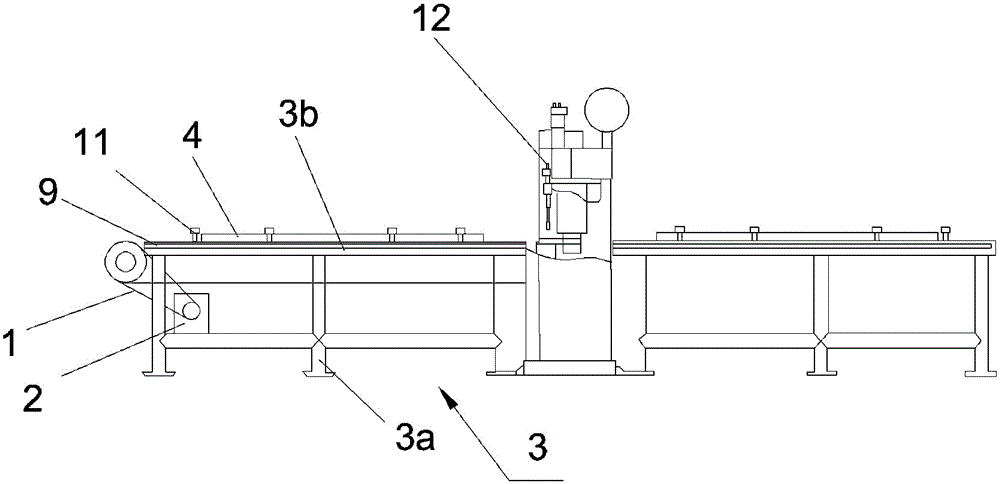

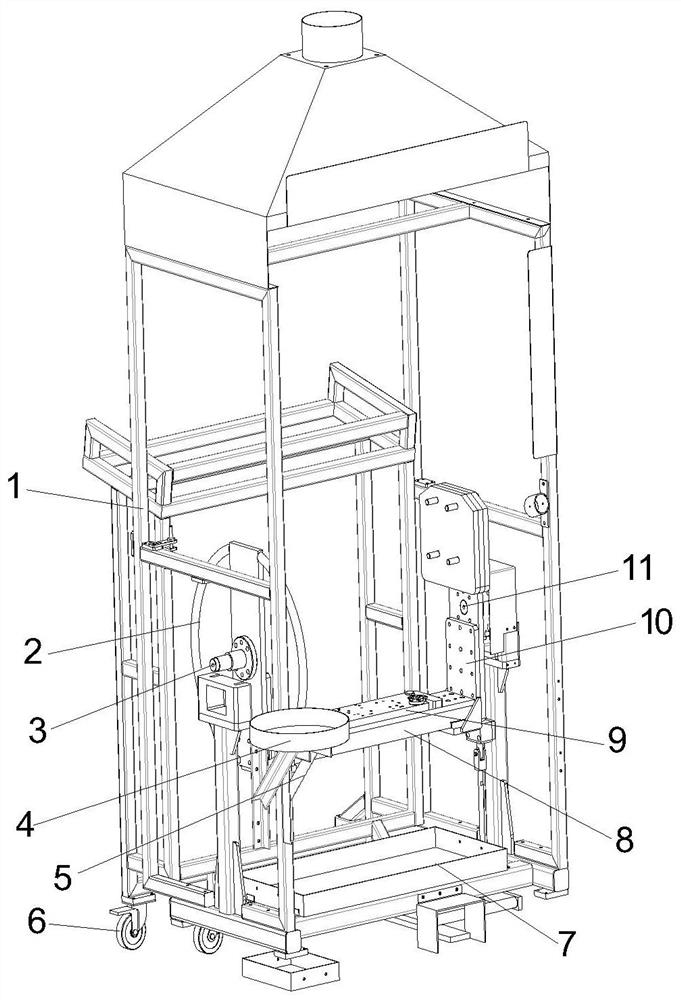

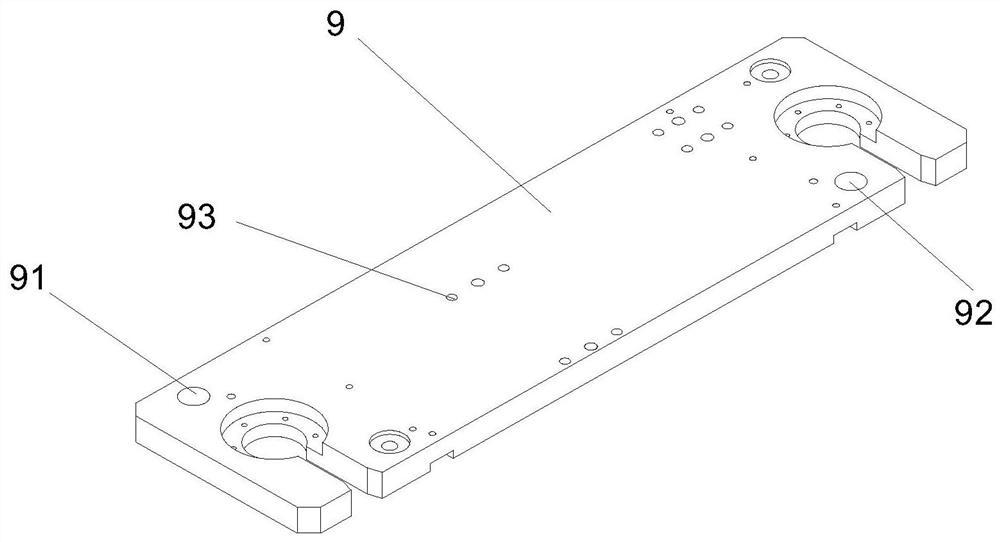

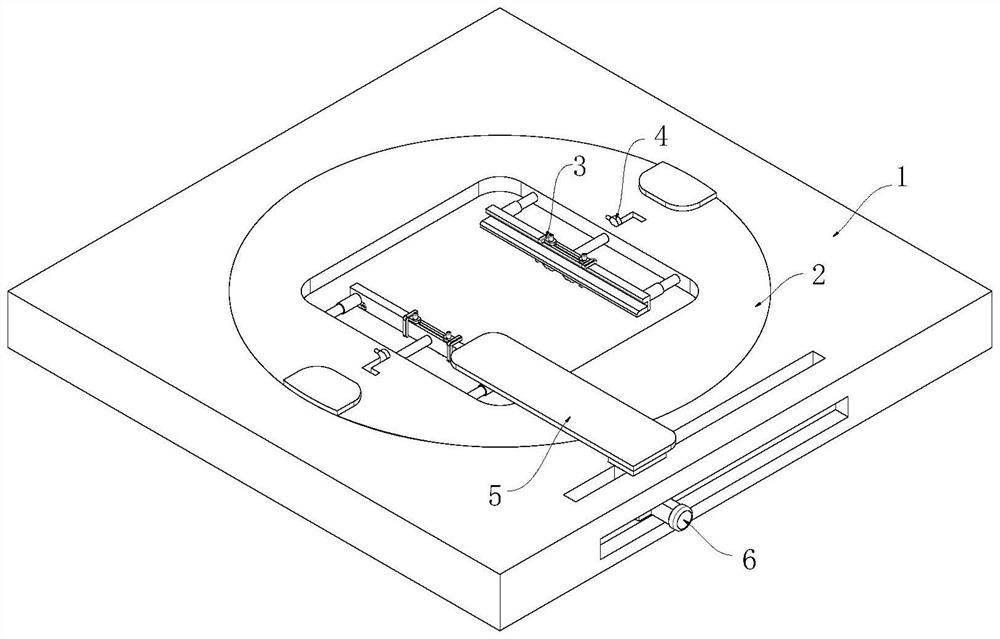

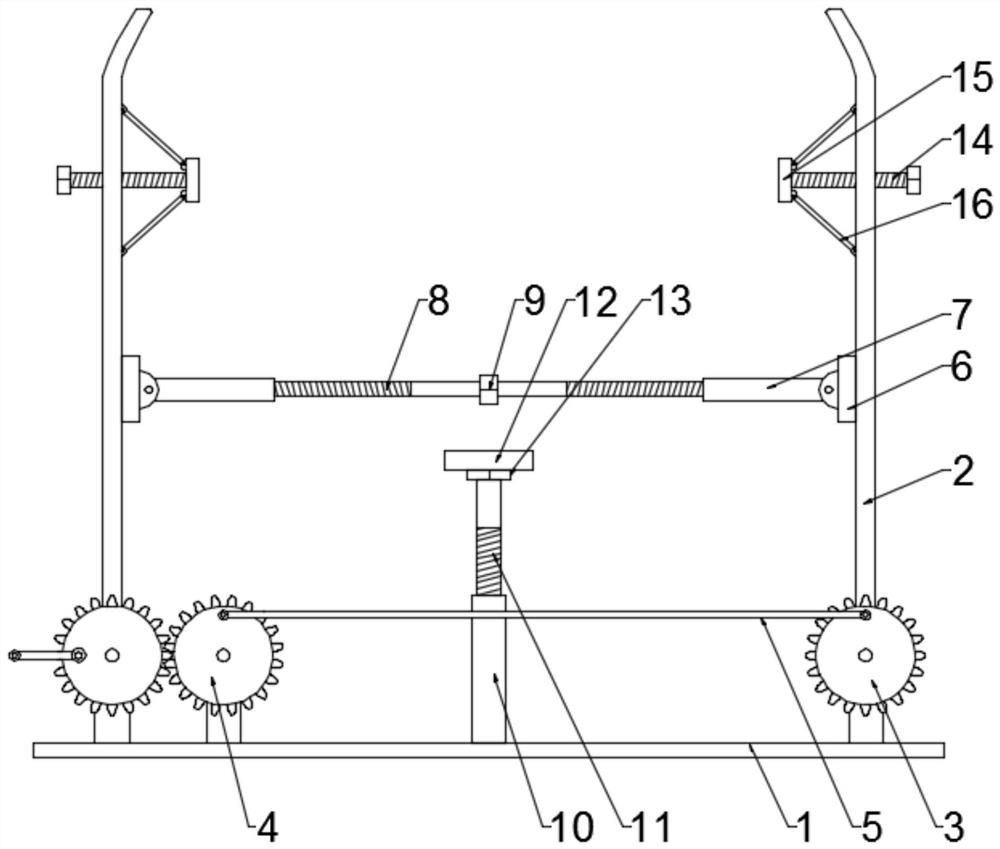

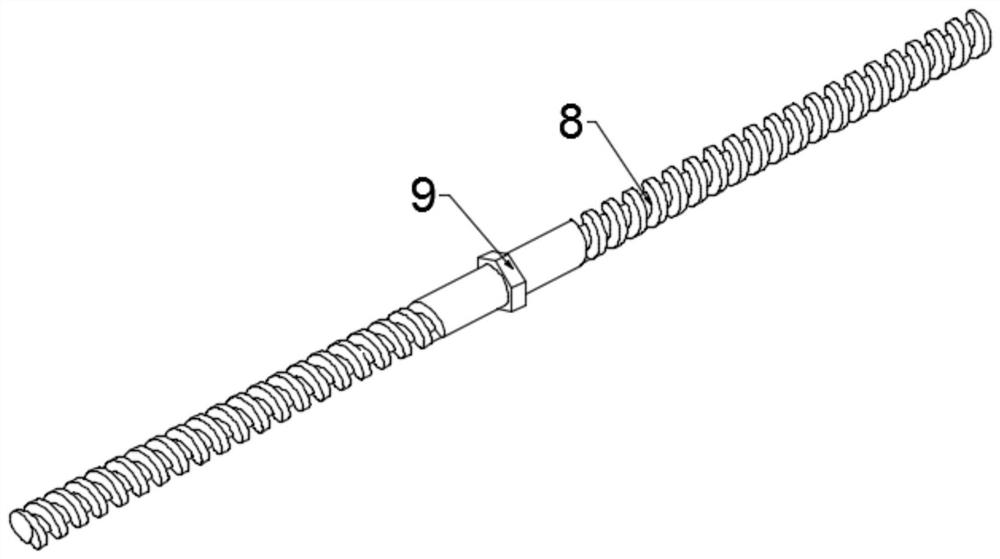

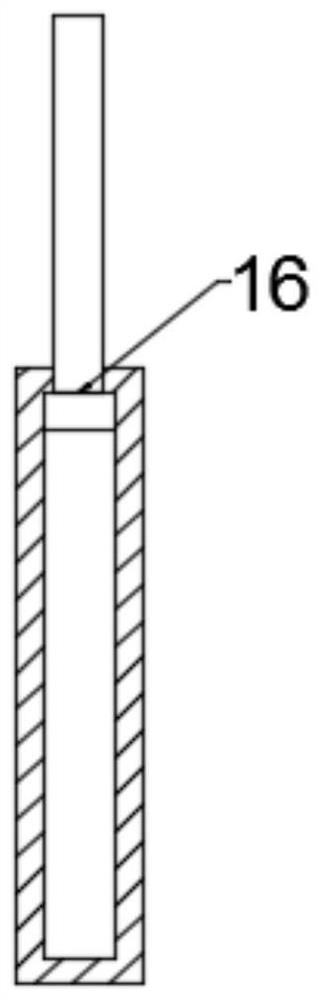

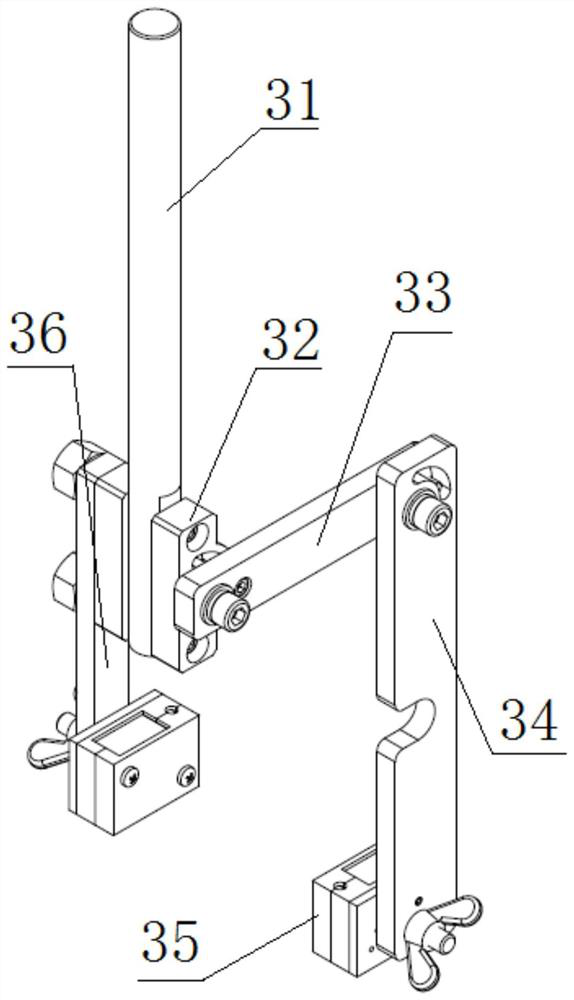

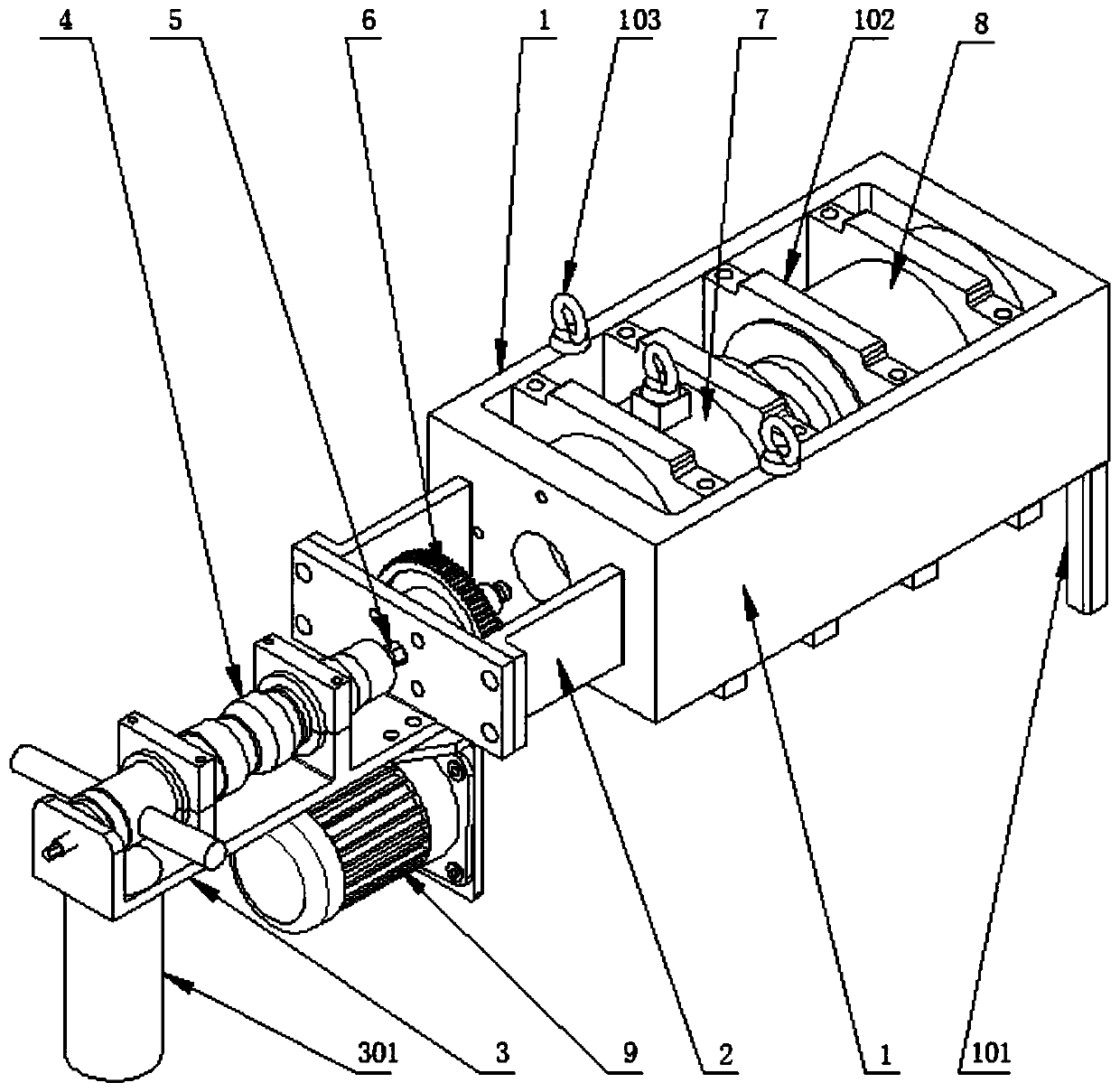

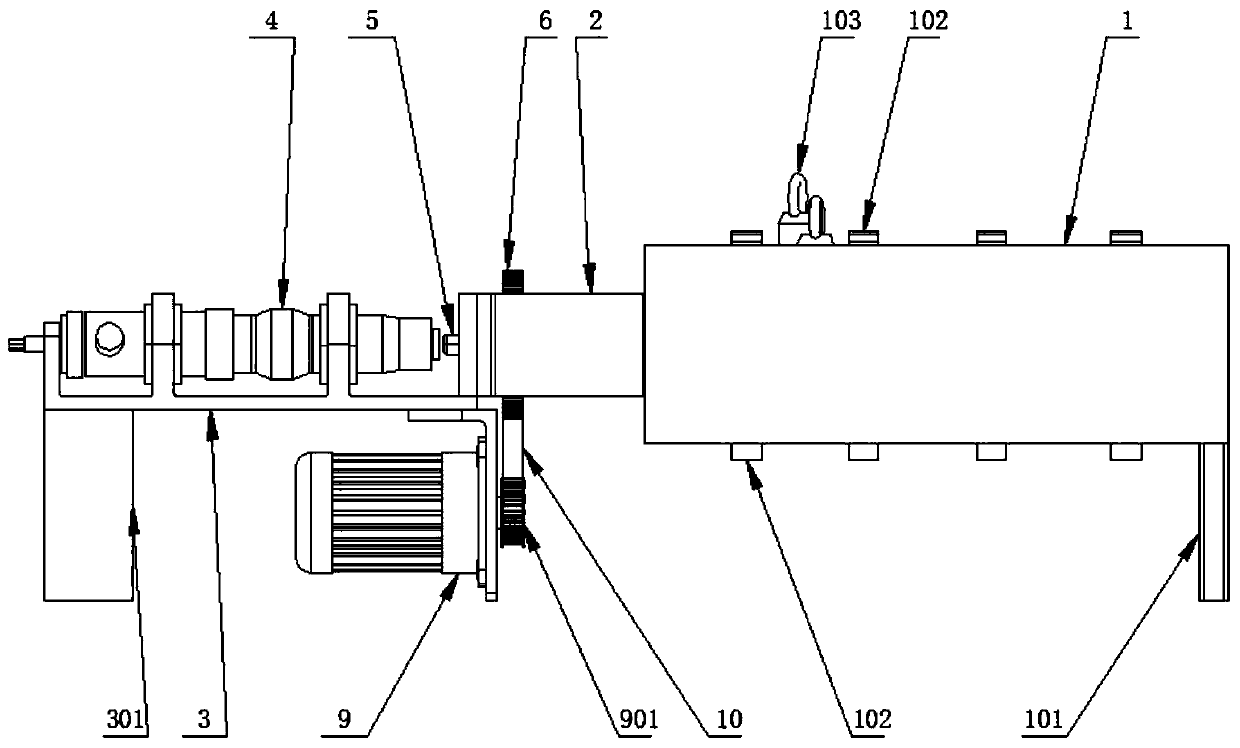

Automatic positioning equipment for drill rods

ActiveCN112317980AExtended service lifeGuaranteed connection strengthWelding/cutting auxillary devicesAuxillary welding devicesElectric machinePositioning equipment

The invention provides automatic positioning equipment for drill rods, and relates to the technical field of a workpiece positioning device. In order to solve the technical problems of low machining efficiency and poor positioning accuracy in the welding process of the drill rods and drill bits in the prior art, the technical scheme of the invention is as follows: the automatic positioning equipment comprises a rotating platform, stations and a collection device, wherein the rotating platform is provided with a rotating motor; the rotating motor drives the rotating platform to rotate so as toachieve the circumferential autorotation function of the rotating platform; at least two stations are set in the circumferential direction of the rotating platform, each station comprises a clamp mechanism and a rotating mechanism, the clamp mechanisms fasten drill rods to be welded, and the rotating mechanisms drive the clamp mechanisms to rotate; and the correction device comprises an angle sensor, a controller, a driving mechanism and a telescopic mechanism, the controller is respectively and electrically connected with the angle sensor and the driving mechanism, the telescopic mechanism drives the driving mechanism to be in matched connection with the rotating mechanism, and the driving mechanism drives the rotating mechanism to rotate.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

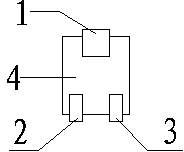

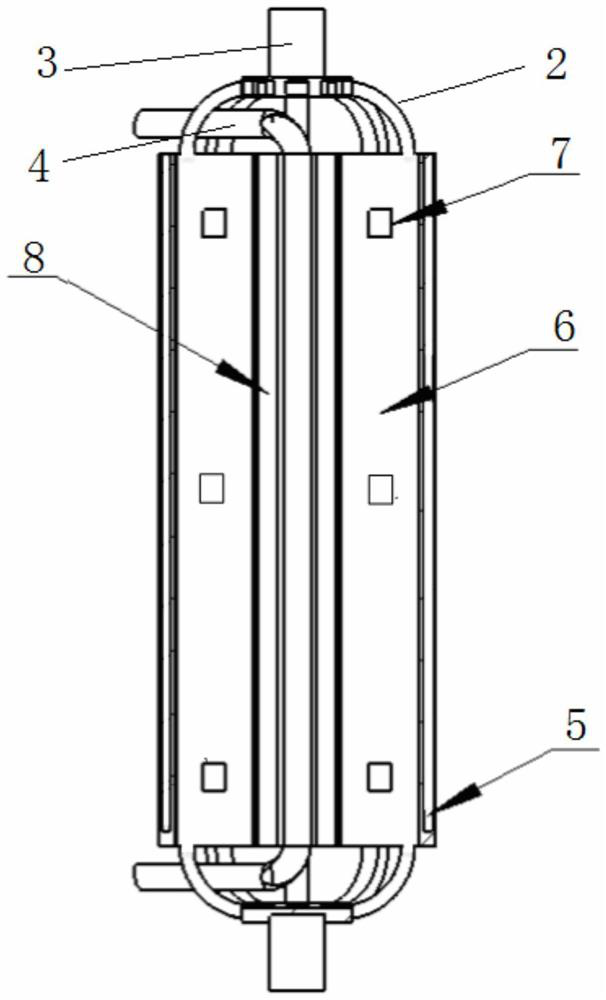

Ultrasonic welding device

PendingCN108247193AOvercoming usage defectsSimple designNon-electric welding apparatusUltrasonic weldingEngineering

The invention relates to the technical field of welding, in particular to an ultrasonic welding device. The ultrasonic welding device mainly comprises a driving mechanism, a head portion and an energyexchange component and is characterized in that a supporting frame is arranged in the head portion and connected with a power output end of the driving mechanism, and the energy exchange component isarranged in front of the head portion and fixedly connected with the supporting frame. By structural optimization and improvement, a welding head is capable of flexibly adapting to incoming materialdirections in a welding process, adaptability is achieved no matter materials come from a longitudinal direction or a transverse direction and from the bottom of the head portion or left and right sides of the head portion, defects in use of traditional welding equipment are well overcome, and more supply choices are provided in an ultrasonic welding process. Especially in application to integration of automatic equipment, a wide application range is realized, production efficiency is greatly improved, a design structure of the automatic equipment is simplified, and design cost of the automatic equipment is reduced.

Owner:KEPU ULTRASONIC ELECTRONICS TECHCAL

Heat exchanger pipe and pipe plate welding process

InactiveCN110883441AAchieve isolationGuaranteed to be fullWelding/cutting auxillary devicesAuxillary welding devicesEngineeringNitrogen gas

The invention discloses a heat exchanger pipe and pipe plate welding process. The heat exchanger pipe and pipe plate welding process comprises the following steps that the surfaces of the marked positions of a heat exchanger pipe and a pipe plate are polished through a special polisher, and an oxidation layer or a grease layer on the surfaces is removed through polishing; the polished heat exchanger pipe and pipe plate are fixedly mounted on a multi-freedom-degree clamp, the polishing position of the heat exchanger pipe corresponds to the polishing position of the pipe plate, and the pipe plate and the heat exchanger pipe are oppositely arranged in parallel; the to-be-welded position and the position nearby the to-be-welded position are heated through a flame spray gun, and the temperatureof the to-be-welded position is increased to 200 DEG C to -230 DEG C; and a nitrogen isolation device is moved to the position below the welding position of the heat exchanger pipe and the pipe plate, the welding position is filled with nitrogen, and oxygen is isolated. The invention relates to the technical field of heat exchanger pipes. By means of the heat exchanger pipe and pipe plate weldingprocess, the purposes of pretreating the welding position and improving the welding precision and quality are achieved.

Owner:NANJING YANGZI PETROCHEMICAL MAINTENANCE & INSTALLATION CO LT

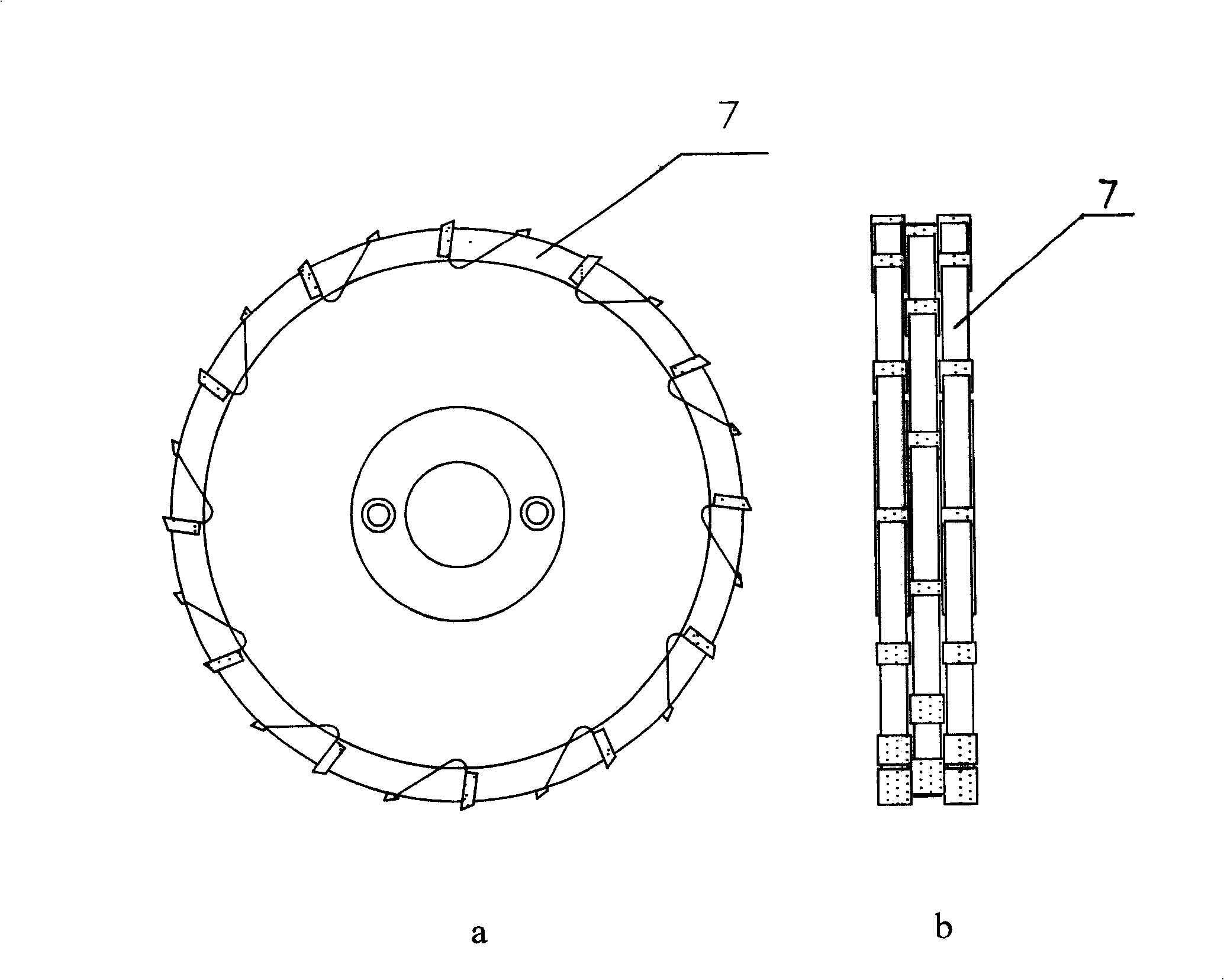

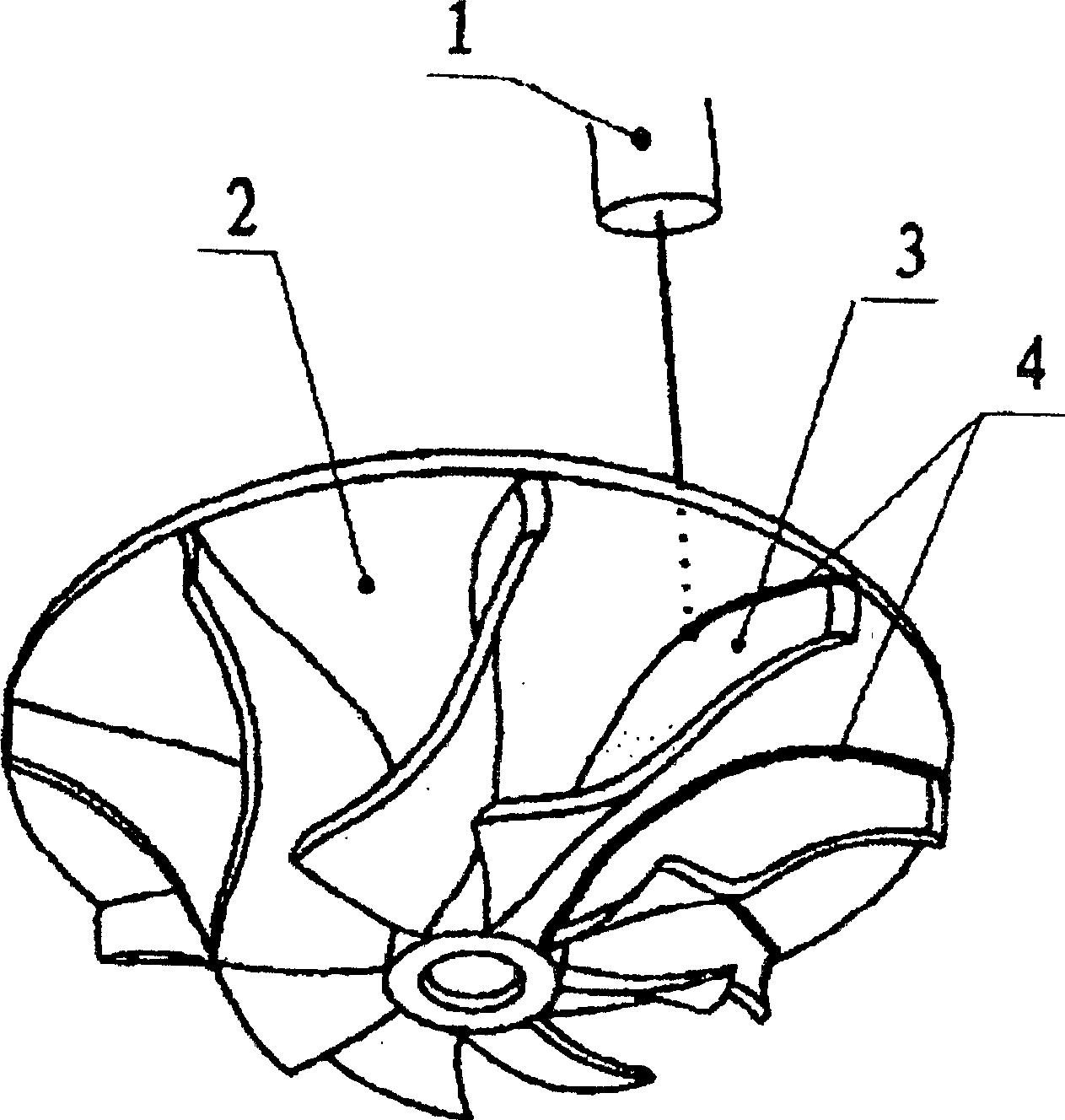

Continuously welded vane

Owner:毛义庆

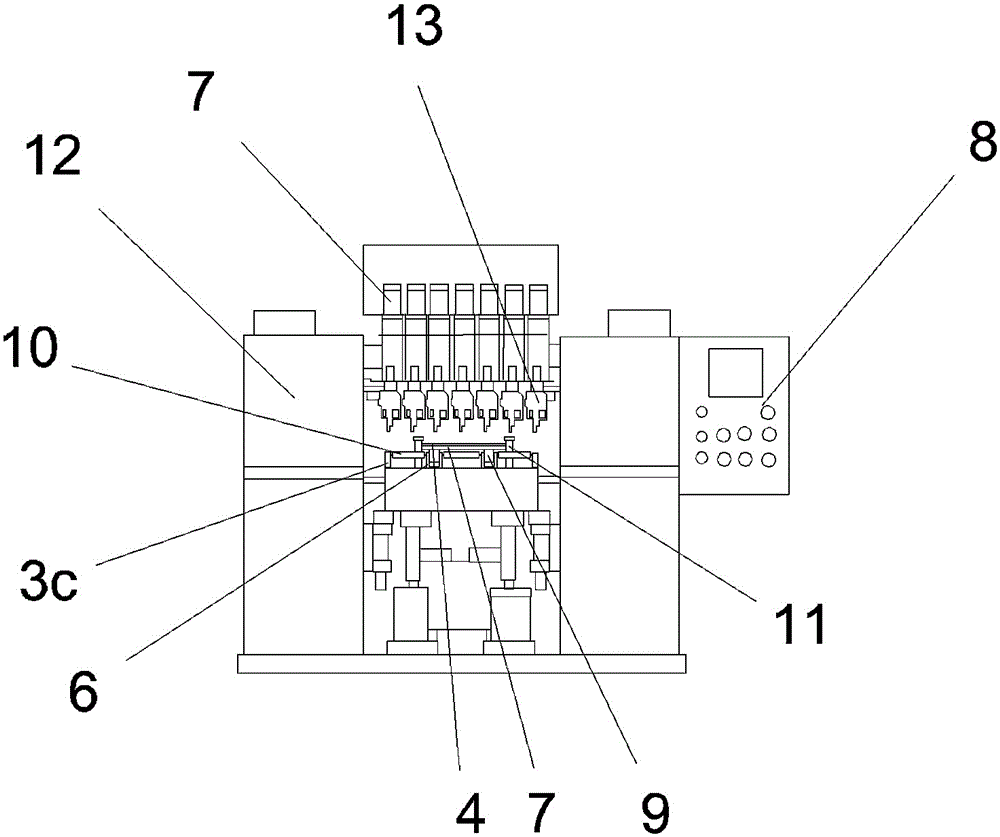

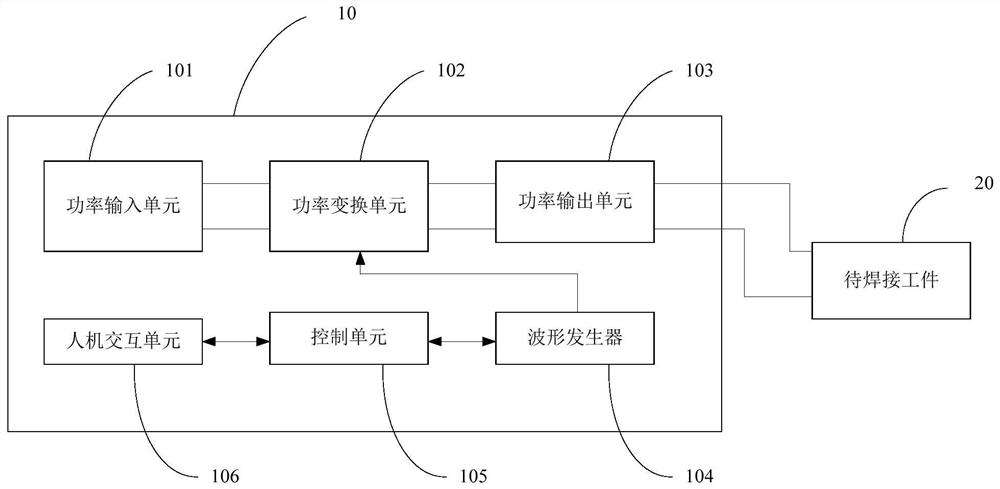

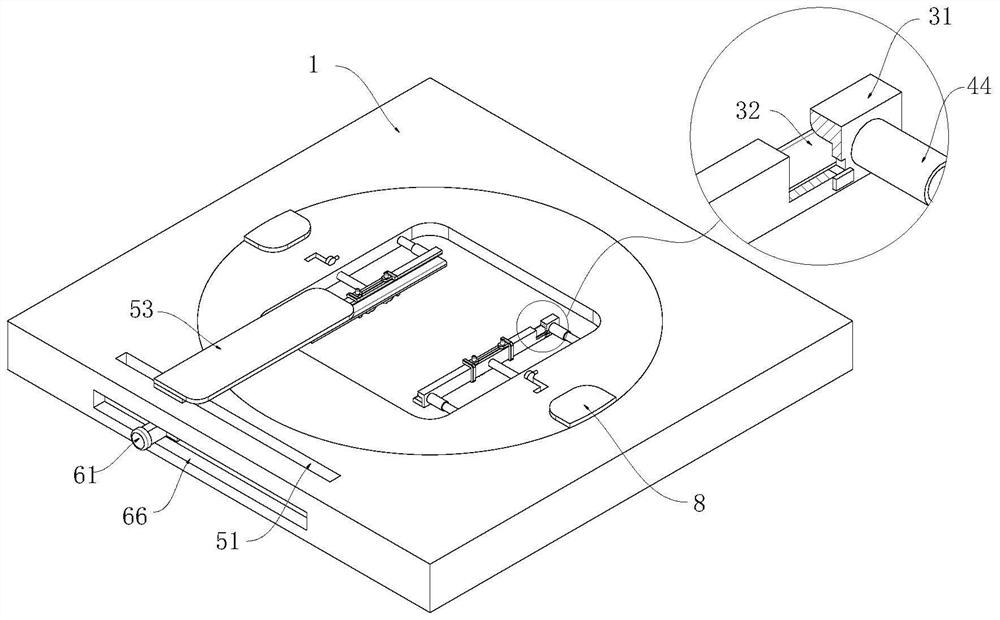

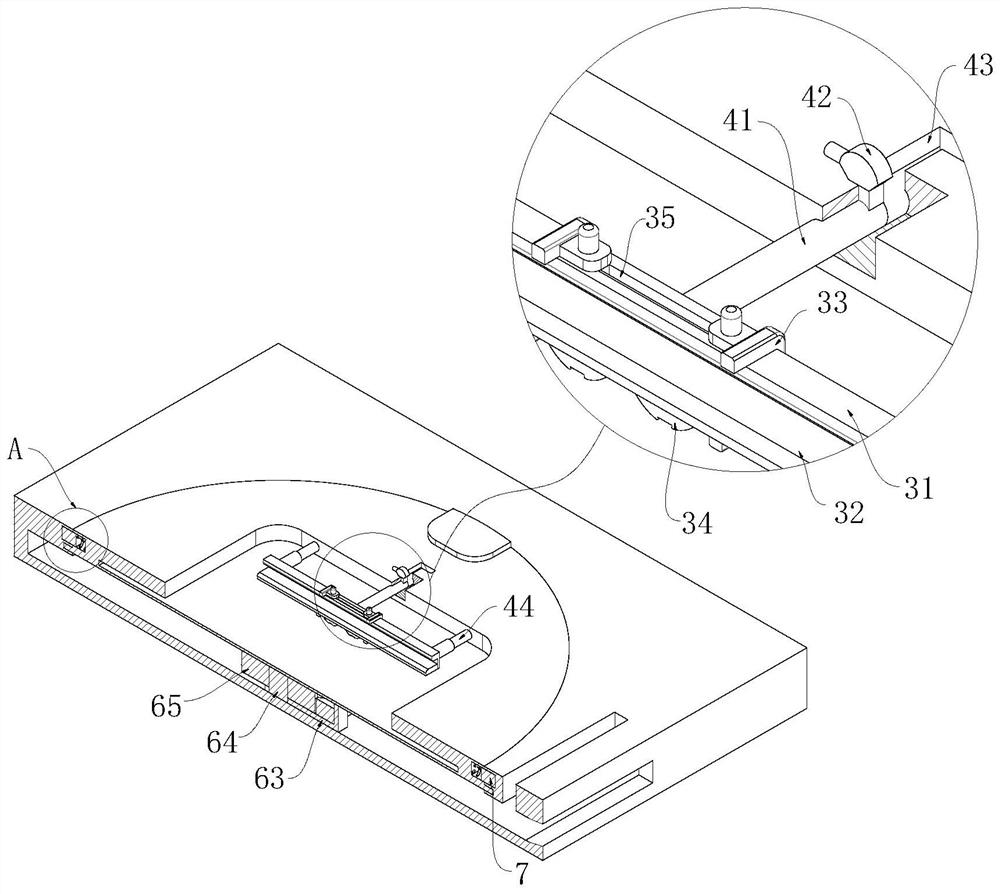

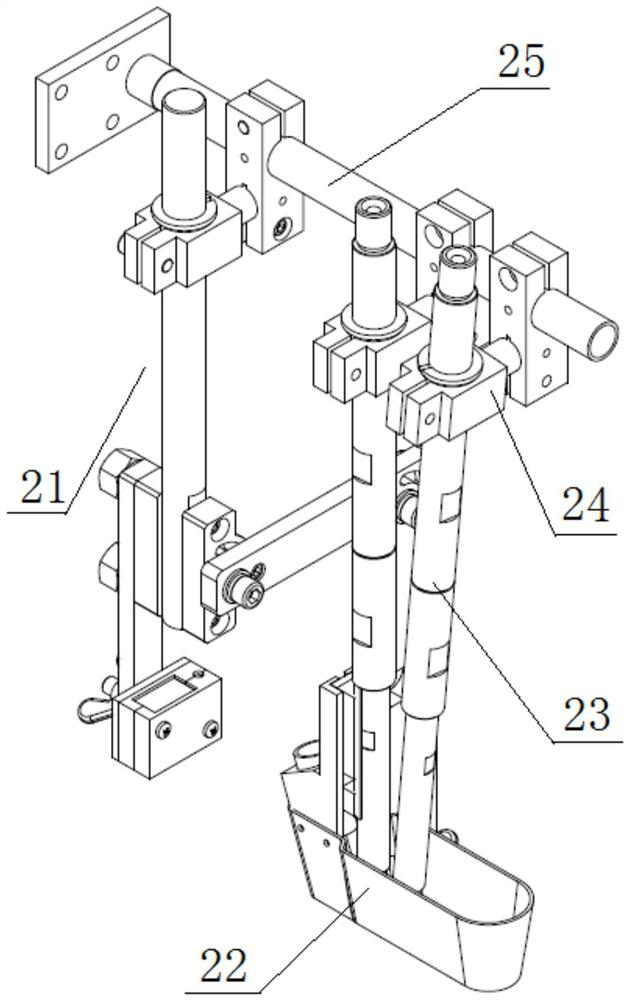

Laser welding equipment and method for drying towel rack

ActiveCN114515904AIncrease profitQuality improvementLaser beam welding apparatusDisplay deviceEngineering

A laser welding device for drying a towel rack is used for welding a transverse rod and a vertical rod of the towel rack and comprises a three-dimensional adjusting platform, a laser welding machine, a laser welding device and a control device. The laser welding machine is arranged on the three-dimensional adjusting platform, generates high-energy laser irradiating the welding position of the towel rack and is used for welding the transverse rod and the vertical rod; and the visual tracking system obtains video information of the welding position and is used for tracking the welding position and displaying the welding process on a computer display. According to the structural characteristics of the towel rack, a welding track can be obtained according to a model, and then a laser welding mode easy to control by a program is adopted, so that welding flux plastic and quality are improved; and a jacking mechanism and a positioning mechanism are arranged according to structural characteristics, so that continuous laser welding is realized. In terms of comprehensive benefits, the welding cost can be reduced by 70% compared with the original cost, full coverage of similar products is met through laser tracking, and the cost is greatly saved.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

High-current bypass diode for concentrating photovoltaic system

InactiveCN103633171ALow costReduce processing costsSolid-state devicesPhotovoltaic energy generationSolar powerMaterials science

Owner:成都聚合科技有限公司

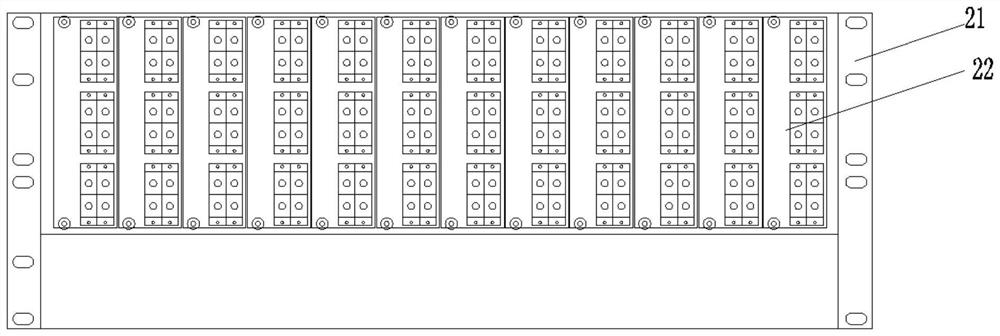

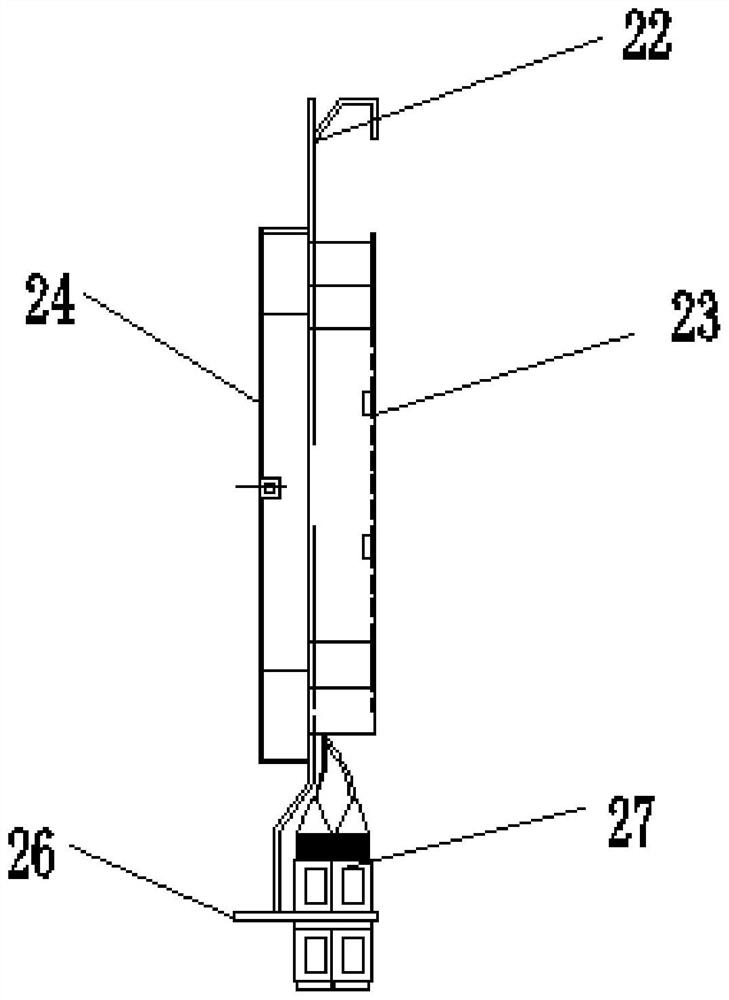

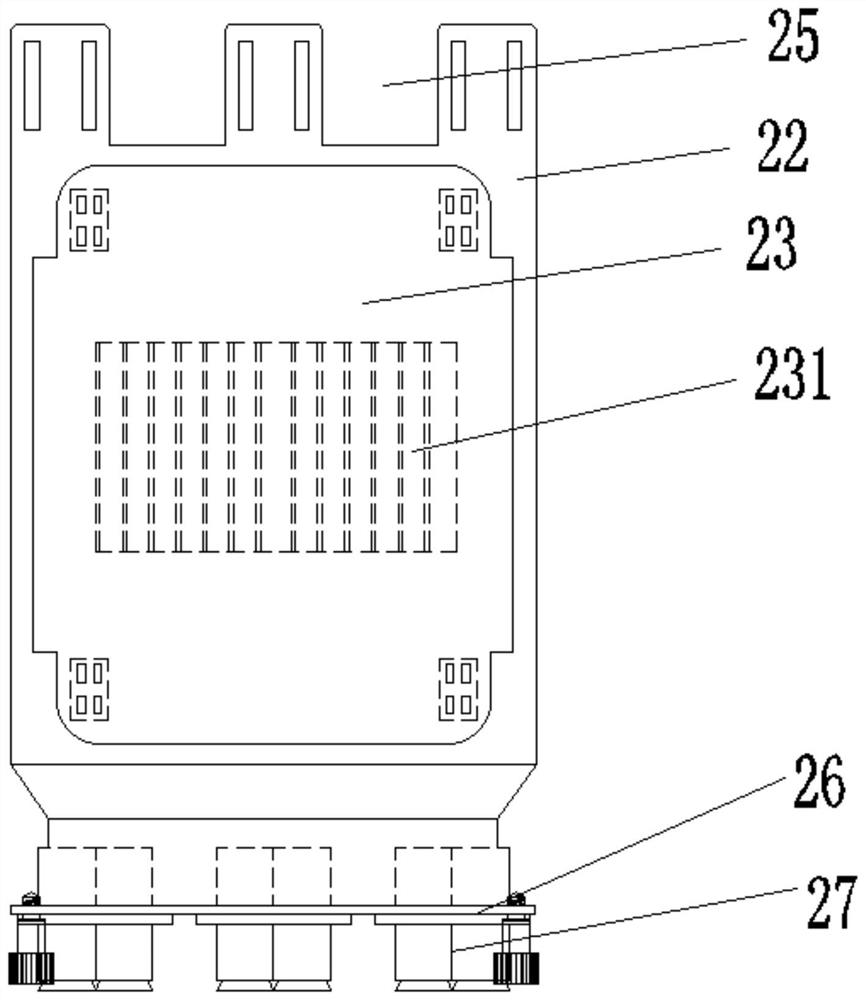

Insertion sheet type melting and distribution separation type optical fiber distribution module and distribution frame

PendingCN114296192AClear wiringConvenient modular operation habitsCoupling light guidesFibre mechanical structuresDistribution frameFiber

Owner:JIANGSU HENGTONG PHOTOELECTRIC

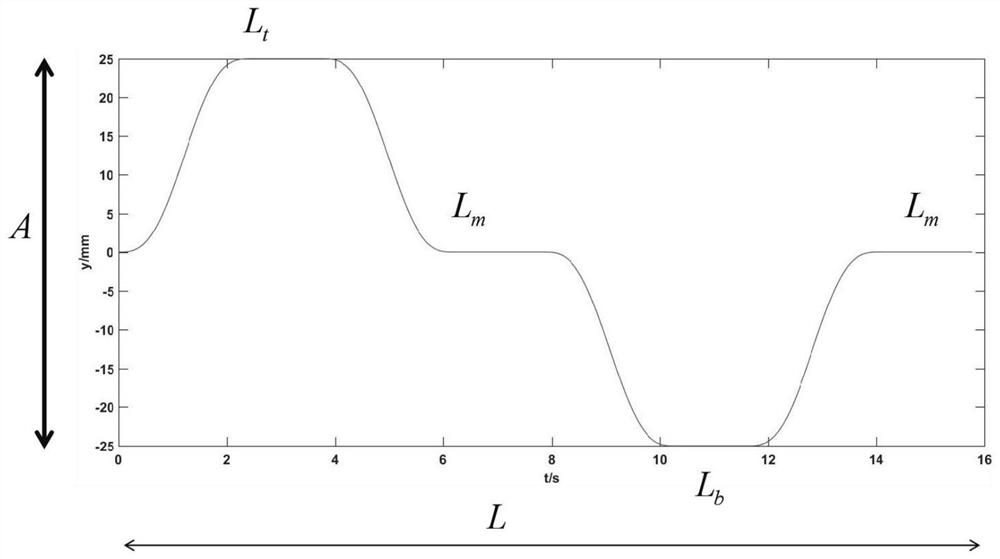

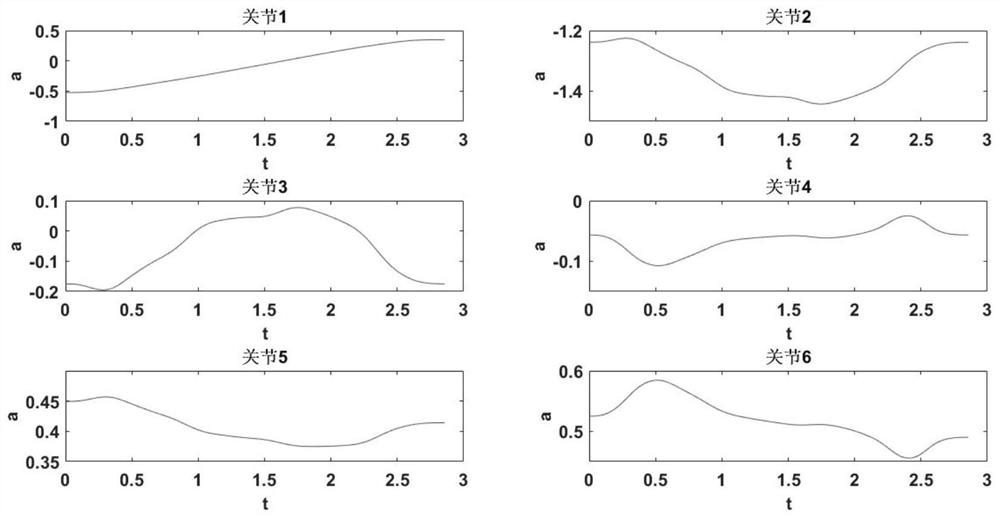

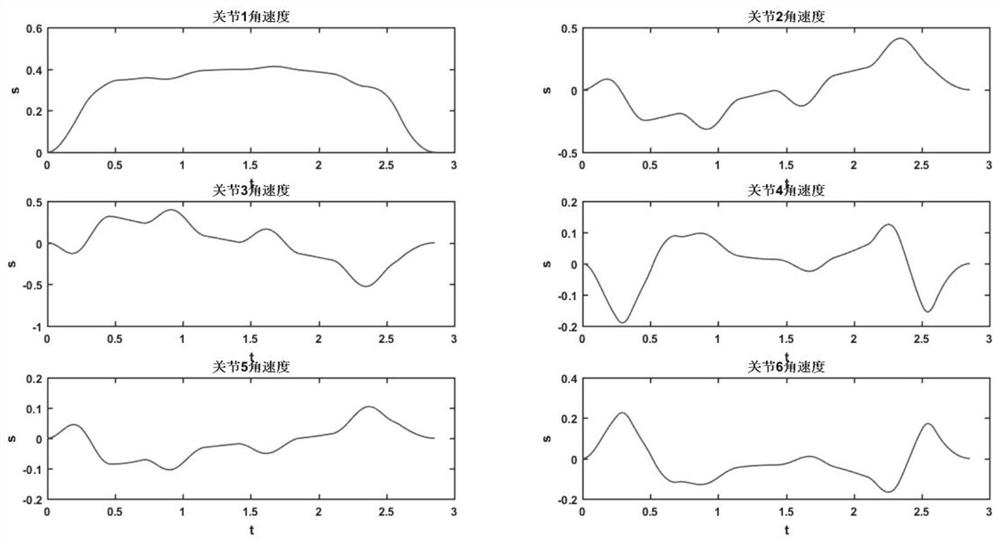

Novel swing welding track planning method for welding robot

PendingCN113305852AContinuous speedAcceleration continuousProgramme-controlled manipulatorWelding/cutting auxillary devicesWeld seamTrajectory planning

Owner:WUXI XINJIE ELECTRICAL

Manual welding tool

PendingCN112621081AMeet the needs of the rotation angleImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

Owner:东风佛吉亚排气控制技术有限公司

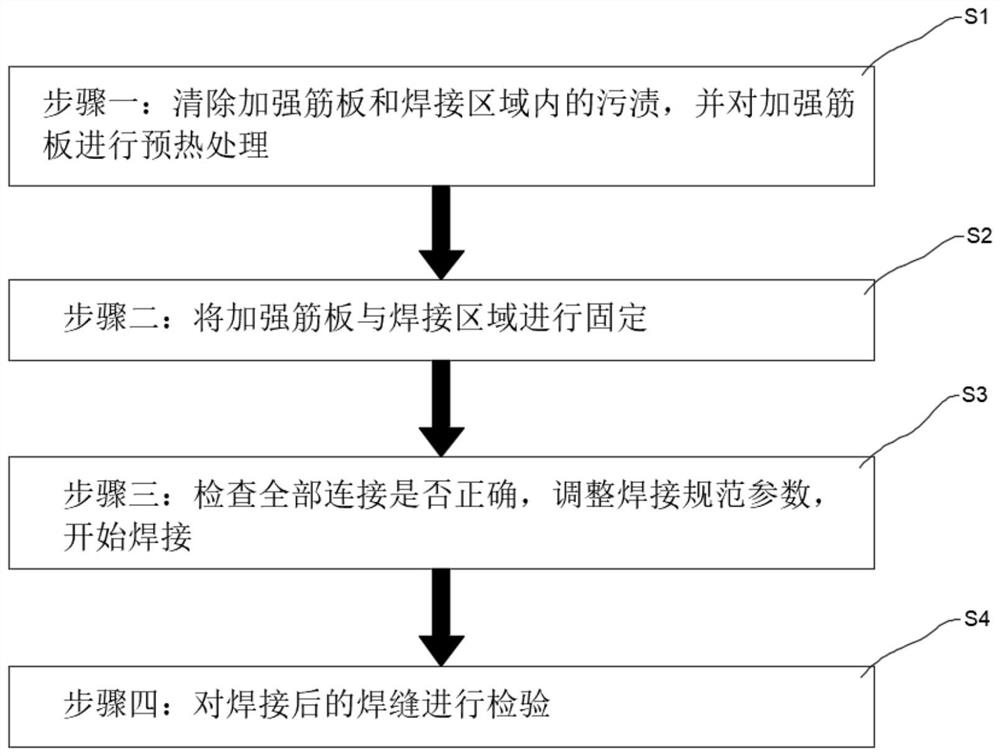

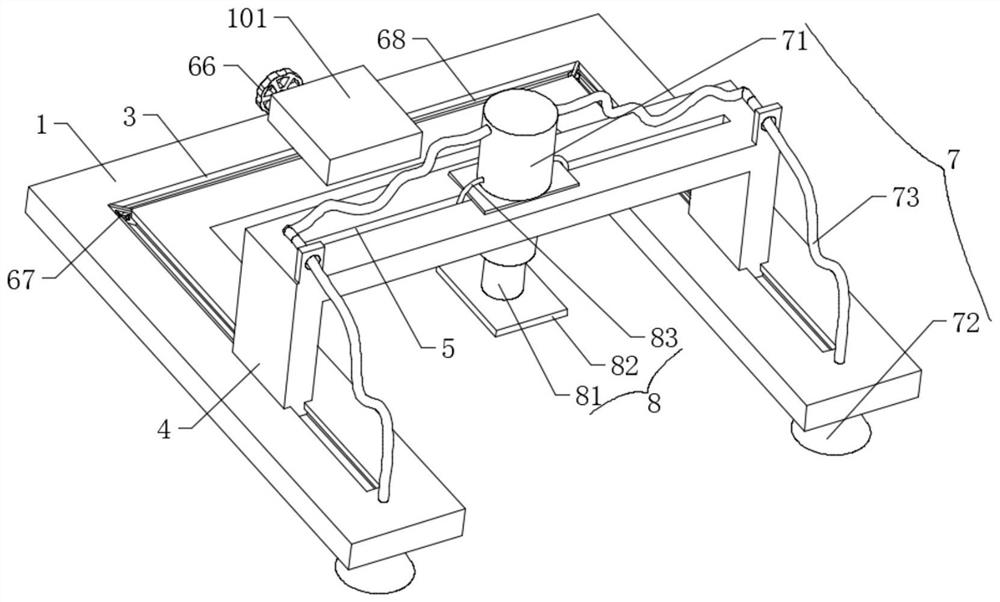

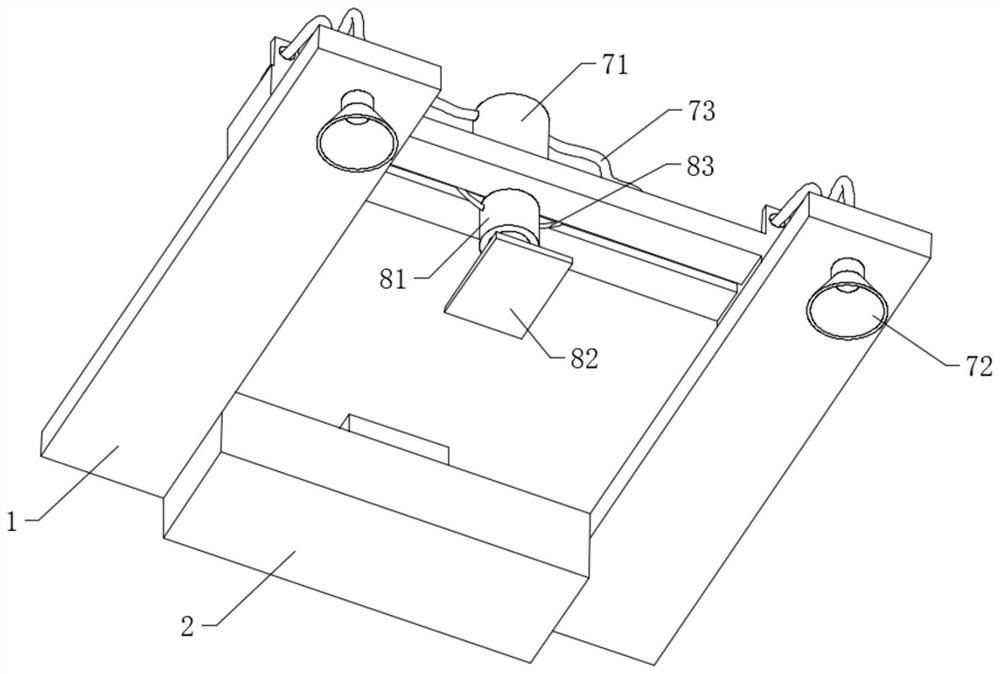

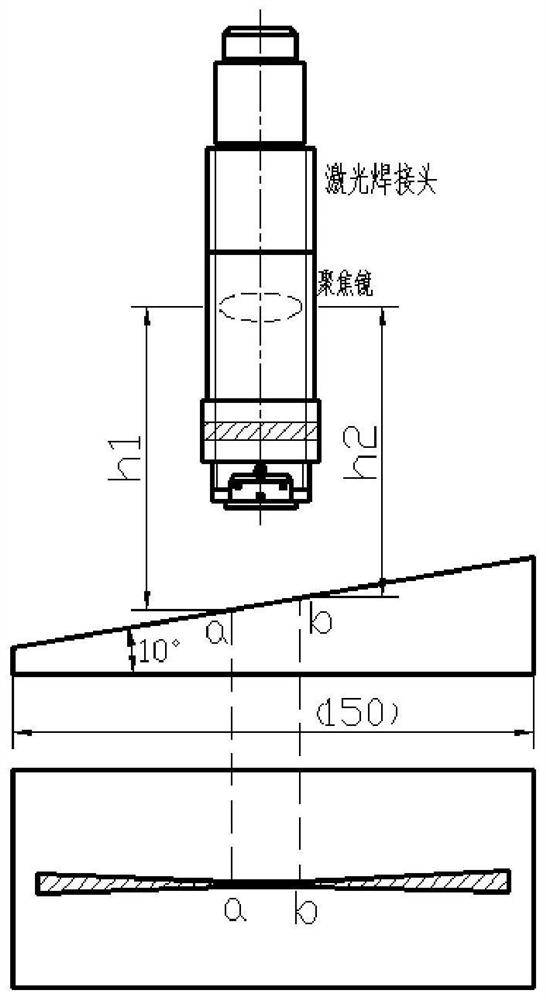

Reinforcing rib plate welding process and welding equipment thereof

ActiveCN114226914AImprove stabilityGuaranteed accuracyWelding/cutting auxillary devicesAuxillary welding devicesSuction forceButt joint

Owner:河北邯峰发电有限责任公司

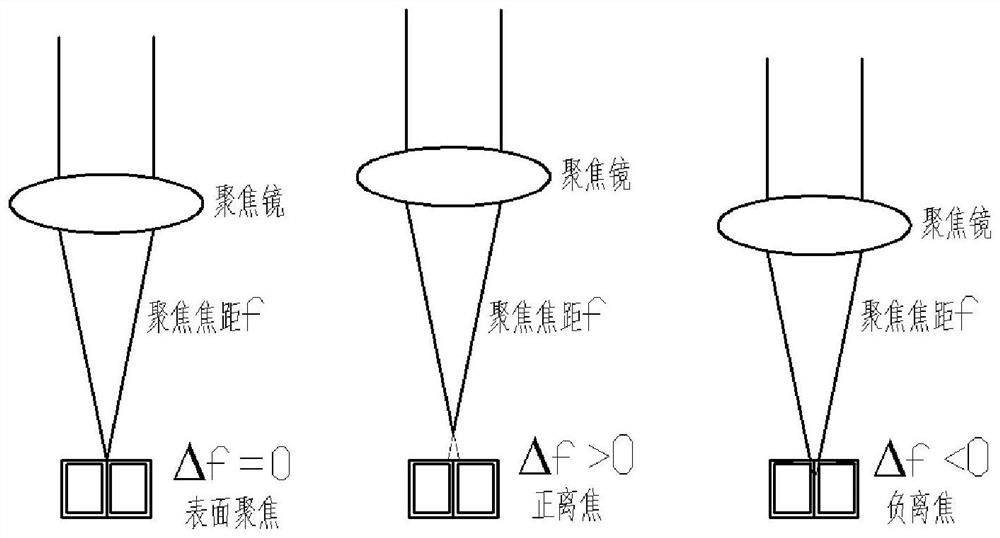

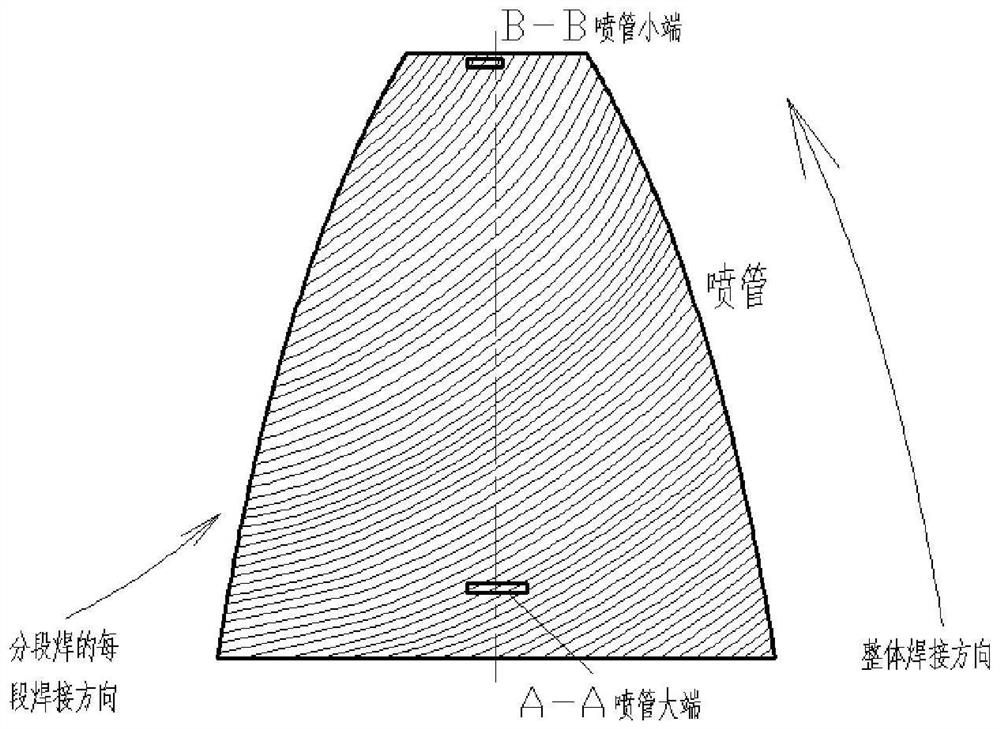

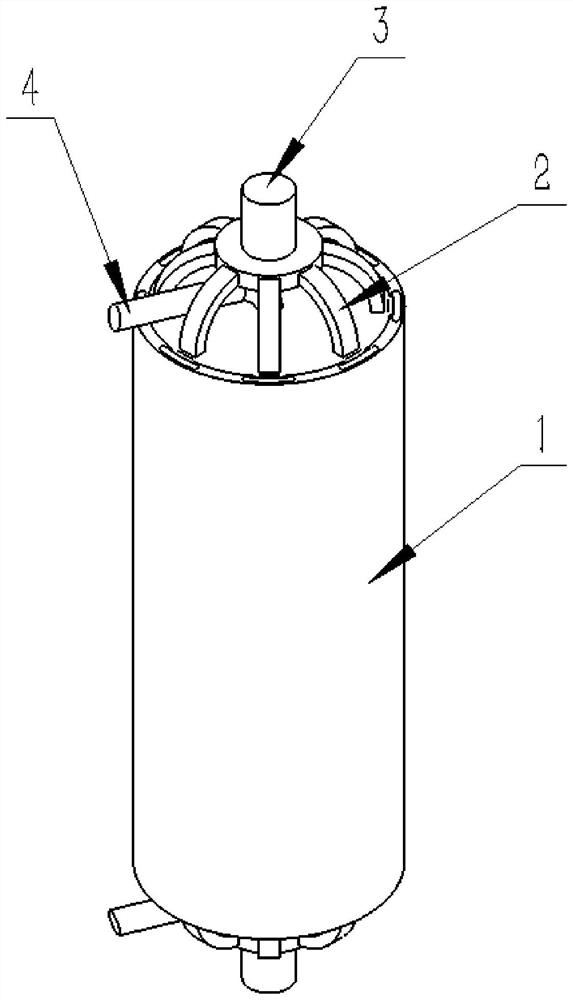

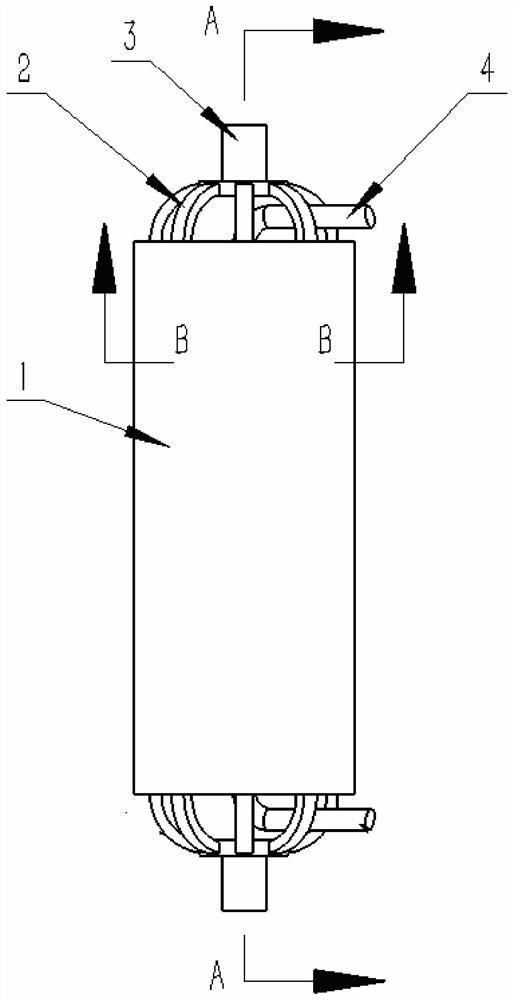

Laser welding method for spiral tube bundle type spray pipe

PendingCN114043086AGood melt width consistencyMeet the requirements of design indicatorsLaser beam welding apparatusEngineeringWeld seam

Owner:CAPITAL AEROSPACE MACHINERY

Cold source device for welding

PendingCN113305475AAchieve coolingRapid coolingWelding/cutting auxillary devicesAuxillary welding devicesShielding gasEngineering

Owner:XIANGTAN UNIV

Positioning device for welding flexible circuit board

PendingCN114273844AEasy to replaceEasy to holdWelding/cutting auxillary devicesAuxillary welding devicesFlexible circuitsEngineering

Owner:深圳市景发顺科技有限公司

Conductive heating type drying bin

InactiveCN113513892AExtend the lifespanIncrease resistanceDrying machines with non-progressive movementsDrying solid materialsThin metalThick wall

The invention provides a conductive heating type drying bin which comprises a drying bin body and a metal pipe. The drying bin is a double-cone drying bin or a single-cone drying bin or a roller drying bin. Two ends of the metal pipe are inserted into the upper and lower corresponding hot melting holes of the drying bin body, and the a head of the metal pipe and the bosses of the hot melting holes are fixedly welded into a whole. The bosses of the hot melting holes have certain widths and thicknesses, and the bin body of the thin metal plate with the hot melting holes has low requirements on the welding process. Under the supporting effect of a hot melting hole taper sleeve thick wall layer, the metal pipe has high resistance and high torsion resistance, the welding position between the metal pipe and the bosses of the hot melting holes cannot be damaged under the shaking stress effect of the metal pipe, and the service life of the conductive heating type drying bin is prolonged.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Adjustable opening limiting tool for pickling tank machining

PendingCN113319506AEasy to weldEnsure symmetryWelding/cutting auxillary devicesAuxillary welding devicesMachiningMaterials science

Owner:ANHUI HONGYUAN IRON TOWER

Intelligent gantry welding machine and gun aligning and positioning method thereof

ActiveCN113814540APositioning reachedReduce positioningElectrode holder supportersWelding accessoriesEngineeringErbium lasers

Owner:CHENGDU HUAYUAN WELDING & CUTTING EQUIP

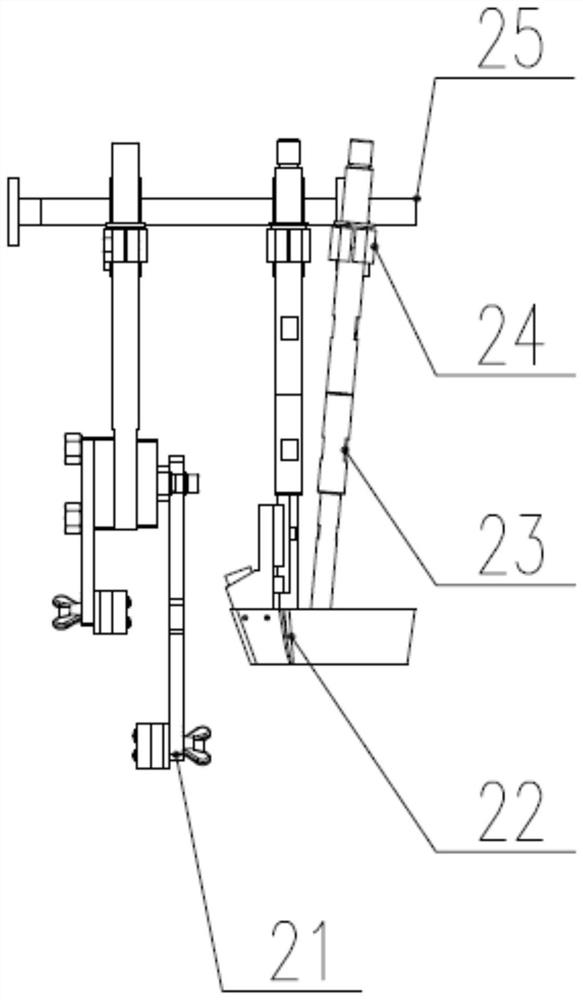

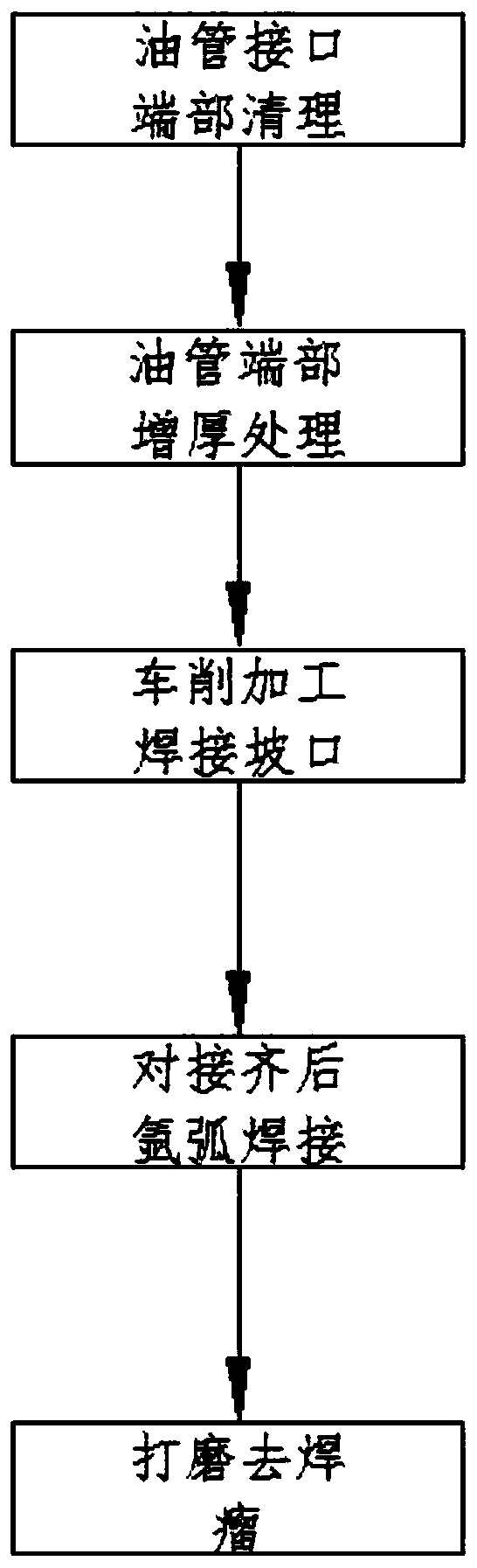

Coiled tubing pipe-to-pipe butt joint process and raw material thickening equipment thereof

PendingCN110961869ASolve burning edgeSolve the phenomenon of grinding thinningMetal-working apparatusButt jointCoiled tubing

Owner:XINDA KECHUANG TANGSHAN PETROLEUM EQUIP CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap