Single-side welding machine used for electrostatic dust collector moving electrode plate

An electrostatic precipitator and single-side welding technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of inability to meet modern mass production, difficult to guarantee product quality, and high labor intensity of workers, and achieve improvement Improvement of labor productivity, production efficiency, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the present invention clearer, the device will be described in detail below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

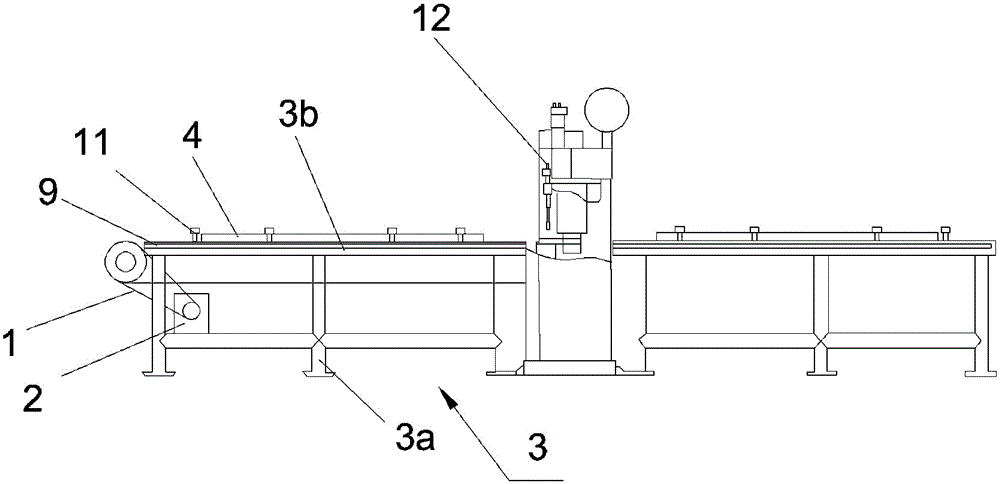

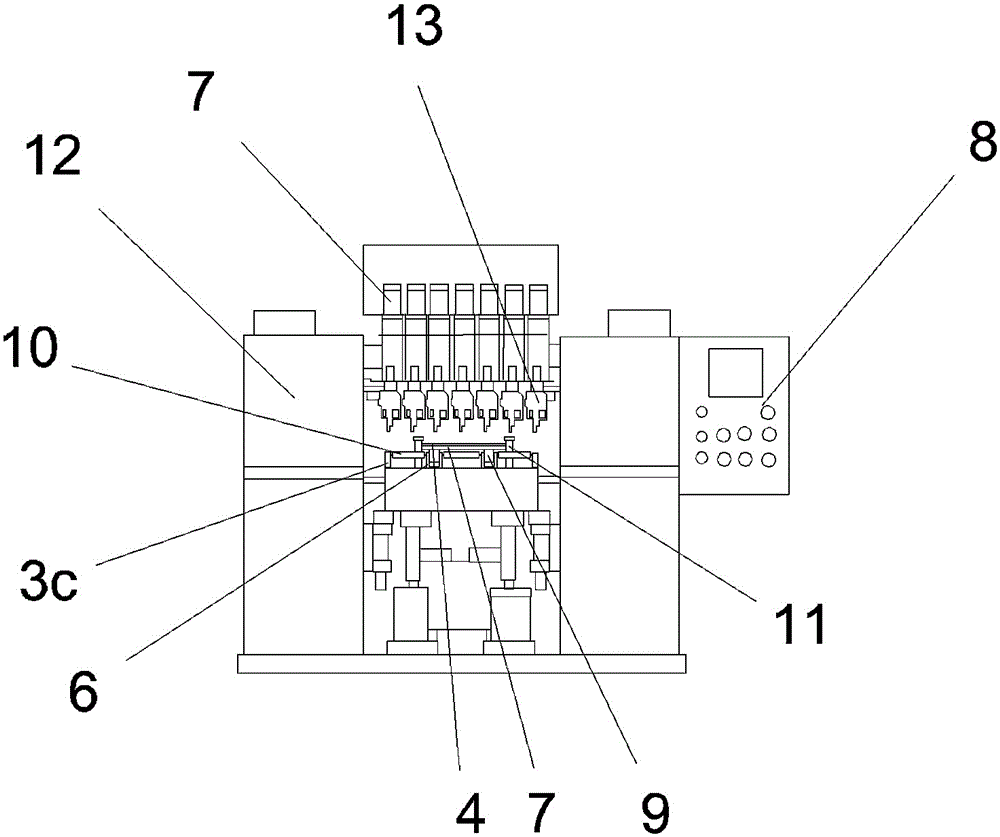

[0016] Such as figure 1 and figure 2 As shown, a single-sided welding machine for electrostatic precipitator mobile plate provided by the present invention includes a frame 3, the frame 3 includes a leg 3a, a platform 3b is welded on the leg 3a, and in the A side plate 3c is arranged symmetrically on both sides of the platform 3b, and two parallel U-shaped plates 6 are arranged in the middle of the platform 3b.

[0017] A motor 2 is fixedly connected under one side of the frame 3, and the motor 2 is selected from a Siemens servo motor, equipped with a Japanese Mitsubishi PLC controller to control parameters such as the moving speed of the pole plate and the spacing of the welding points during

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap