Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about "Cell component details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

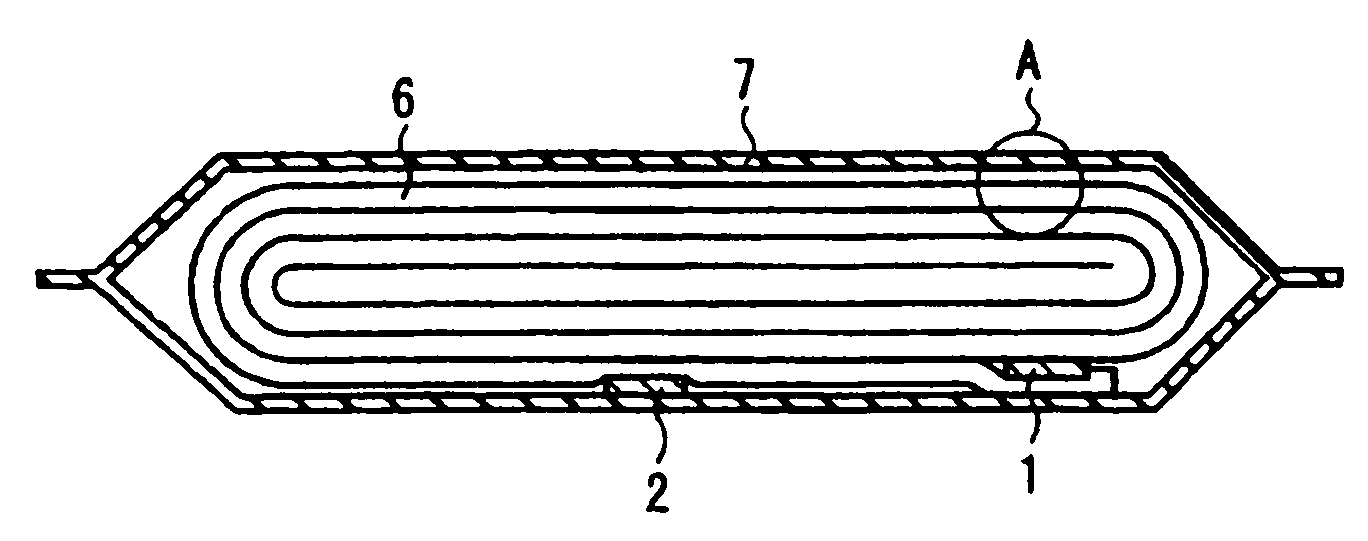

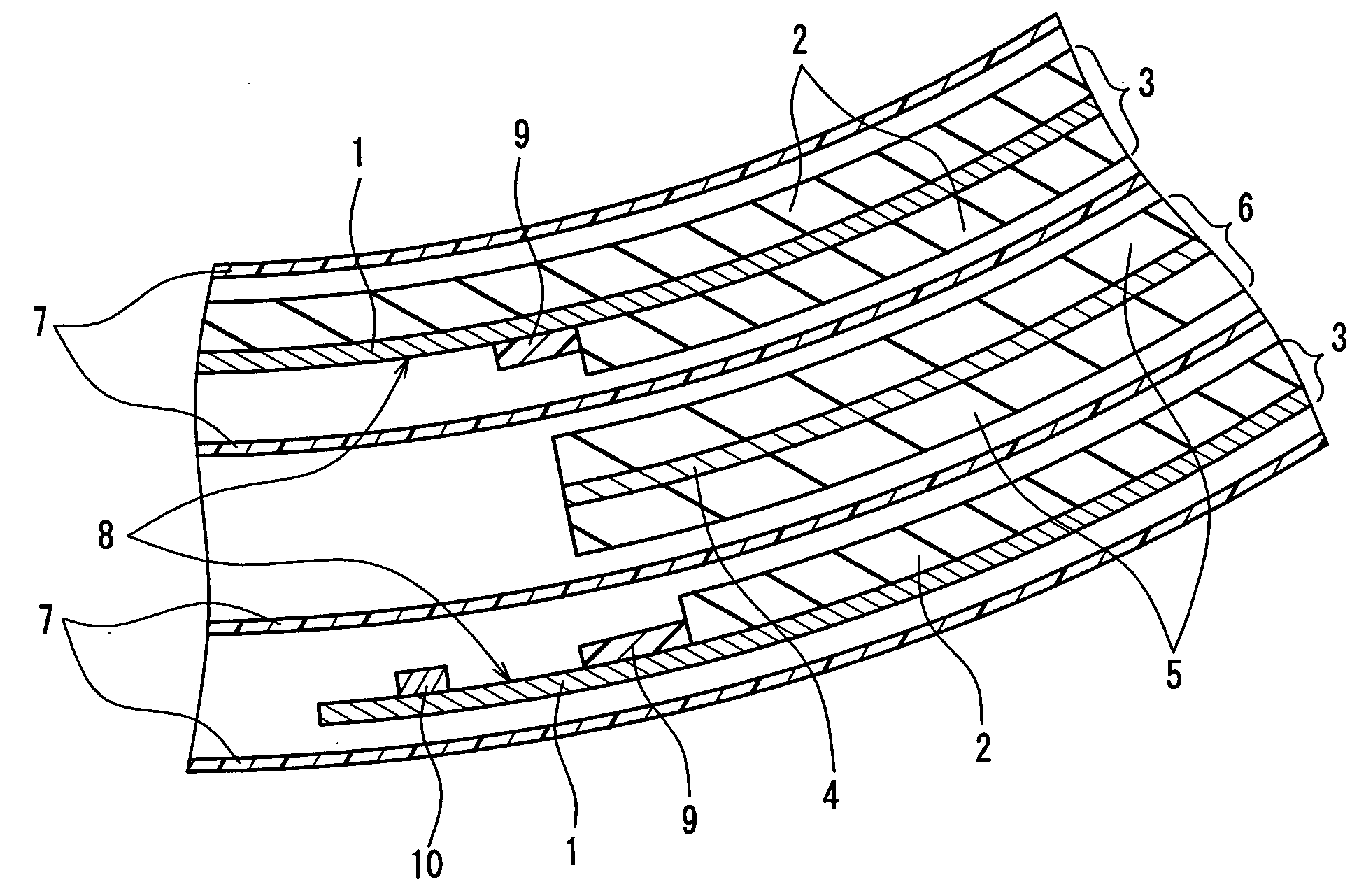

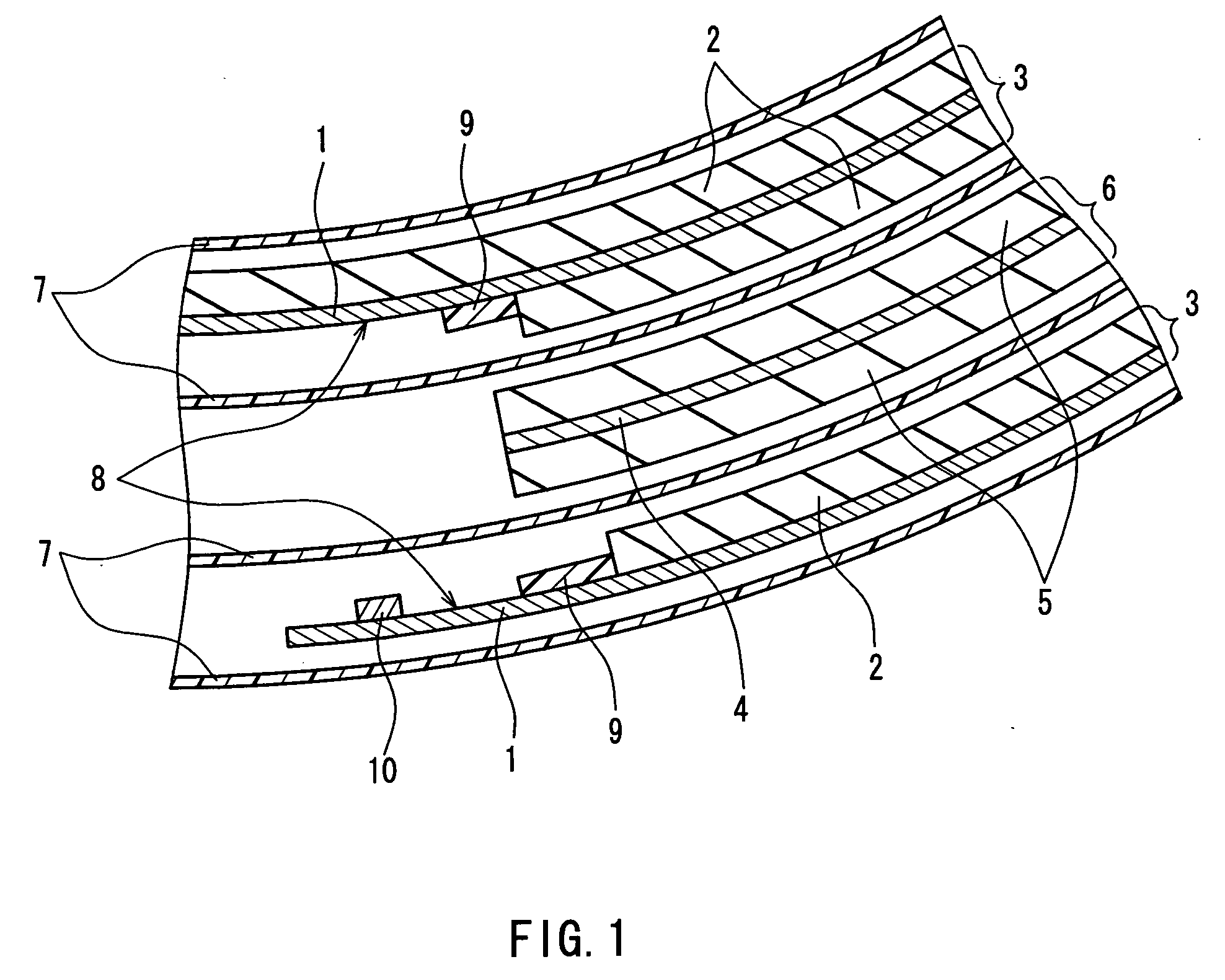

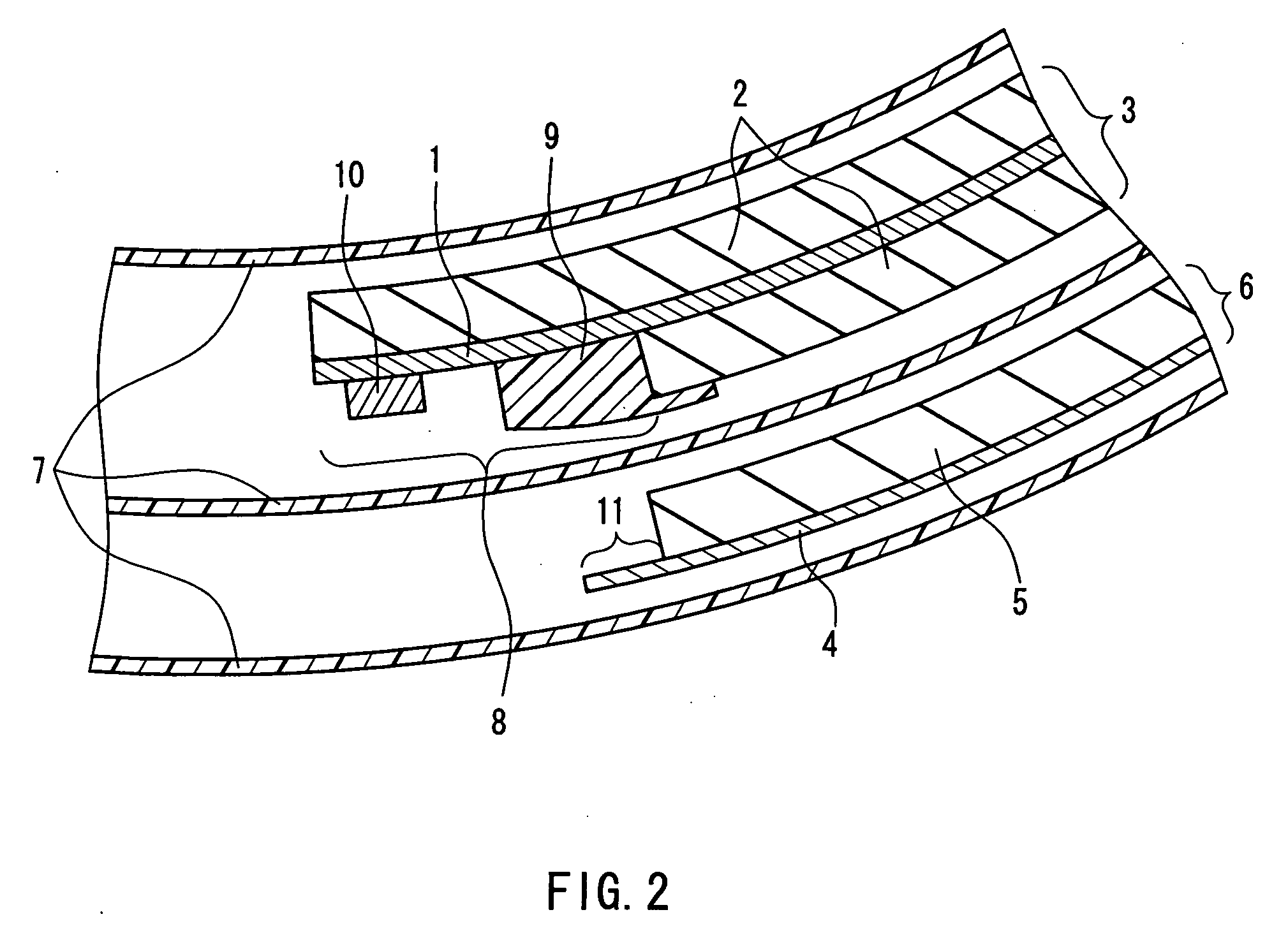

Battery module with improved cell barrier between unit cells

ActiveUS20070037051A1Improved unit cell cooling performanceEasy to makePrimary cell to battery groupingFinal product manufactureBiomedical engineering

Owner:SAMSUNG SDI CO LTD

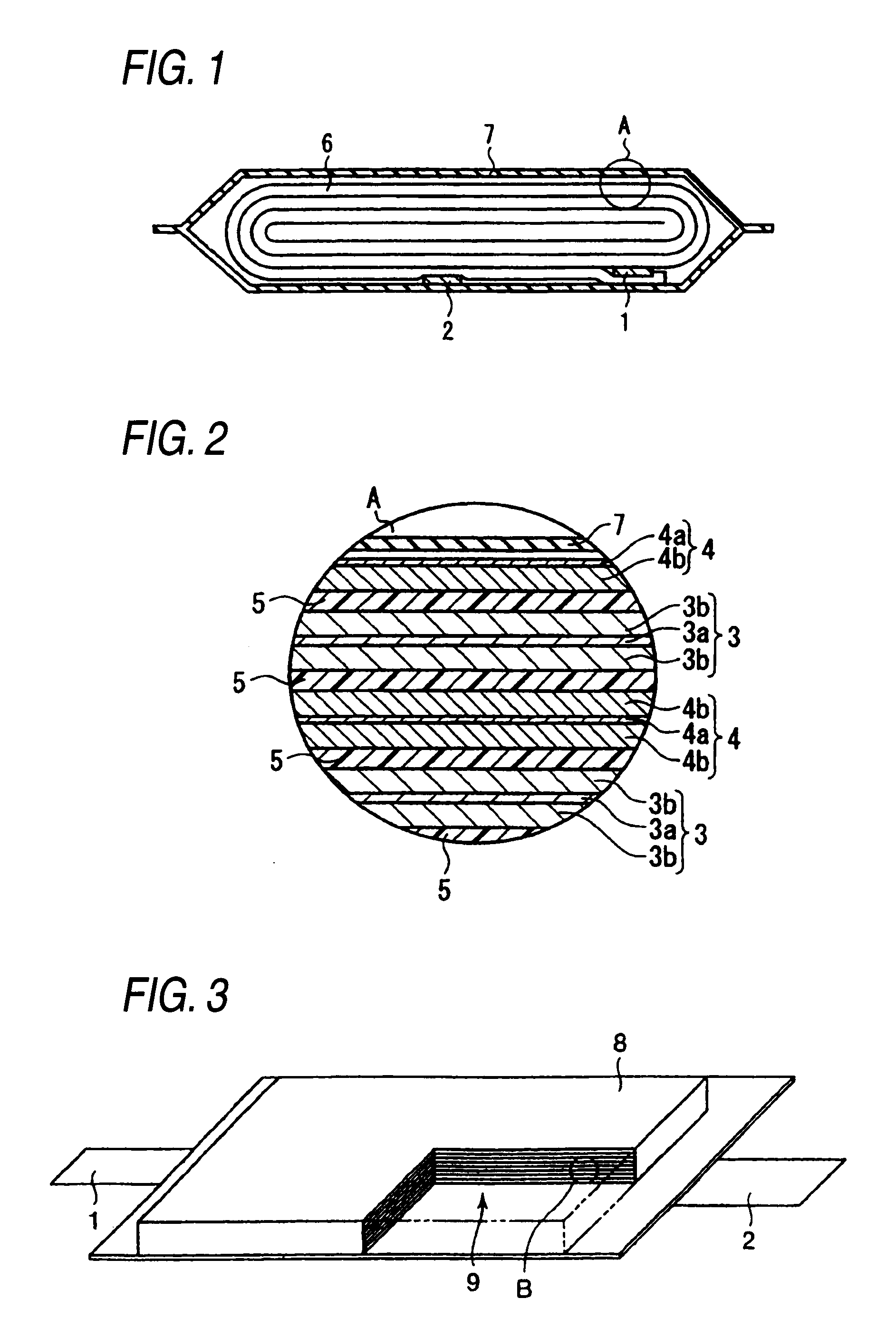

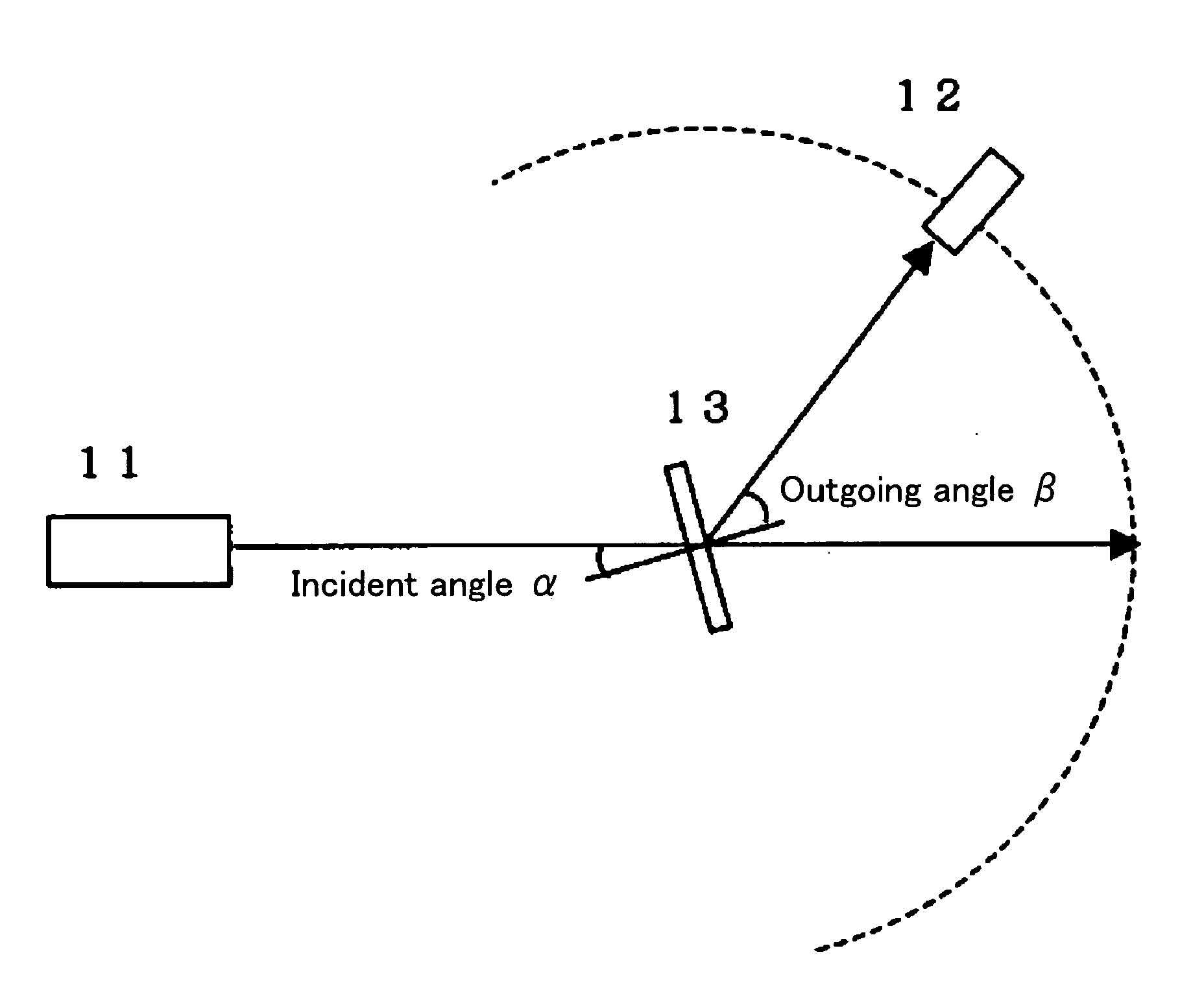

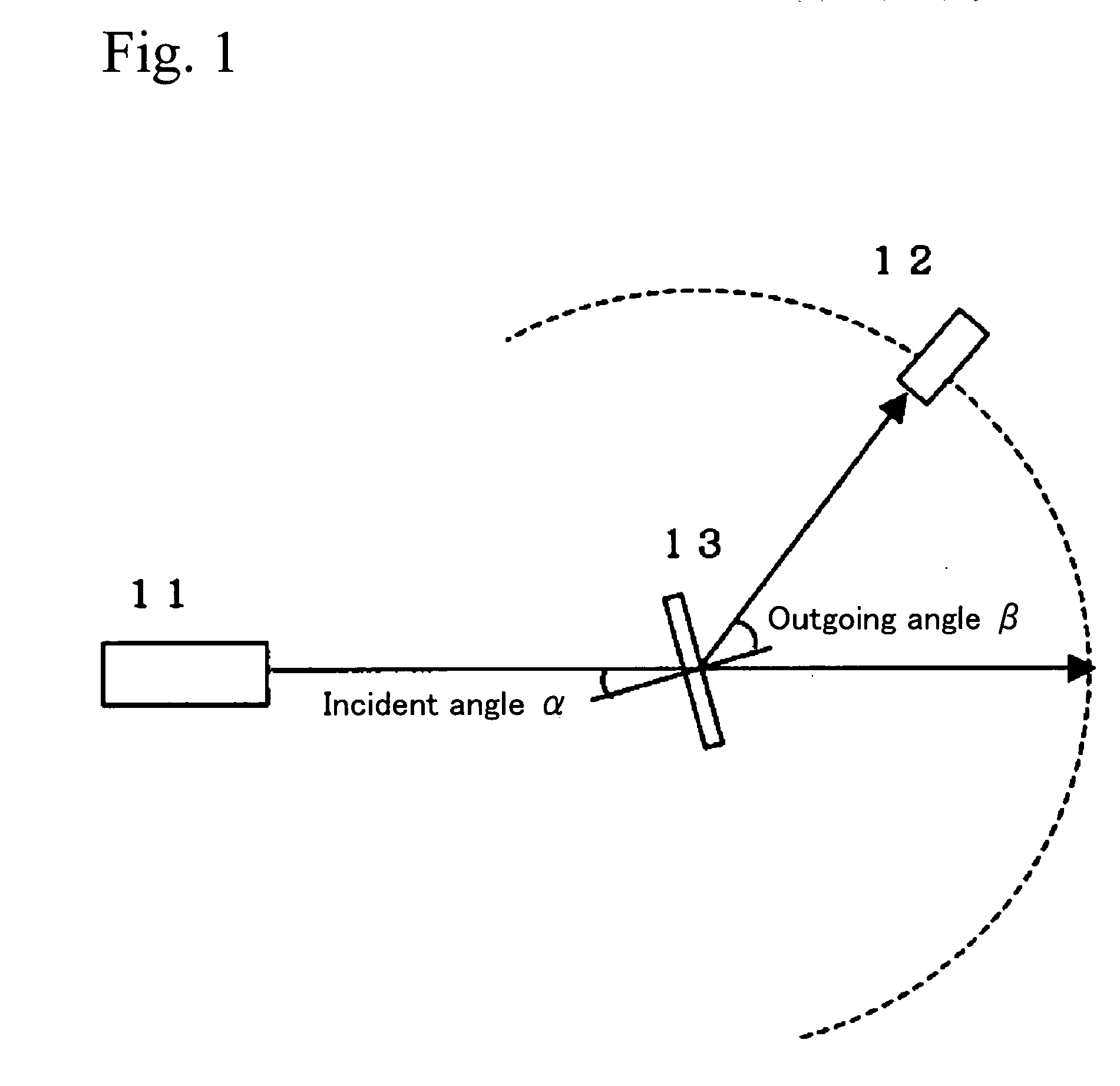

Nonaqueous-electrolyte battery

ActiveUS20090061303A1Improve securitySatisfactory battery characteristicCell electrodesCell component detailsSimple Organic CompoundsLithium

Owner:KK TOSHIBA

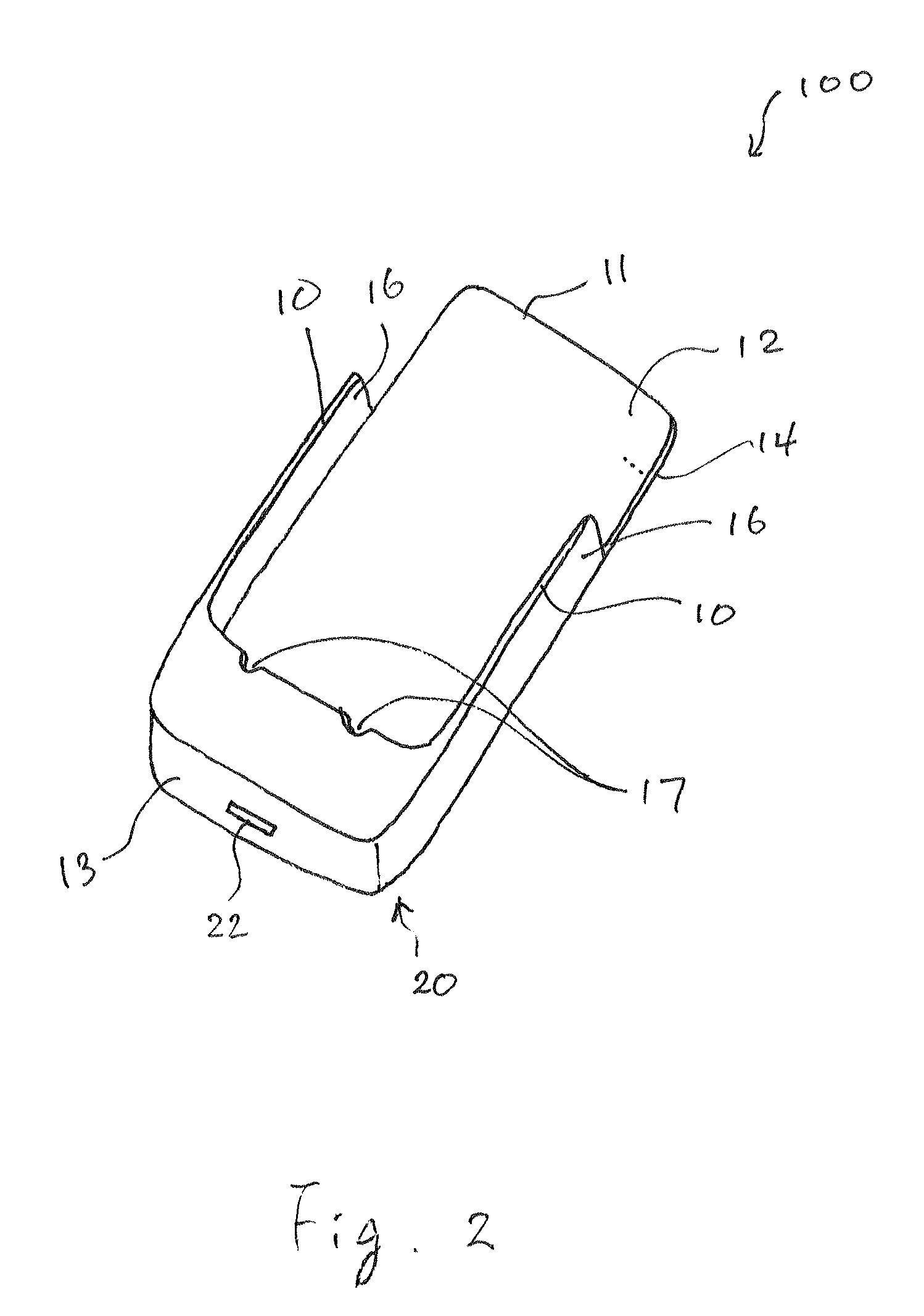

Case battery

InactiveUS20090108800A1Extended use timeBatteries circuit arrangementsDigital data processing detailsElectricityEngineering

Owner:WOUD STEVEN

Non-aqueous electrolyte battery and method for producing the same

InactiveUS20060216609A1Process safetyAvoid it happening againMaterial thermal conductivityFinal product manufactureEngineeringNon aqueous electrolytes

Owner:HITACHI MAXELL ENERGY LTD

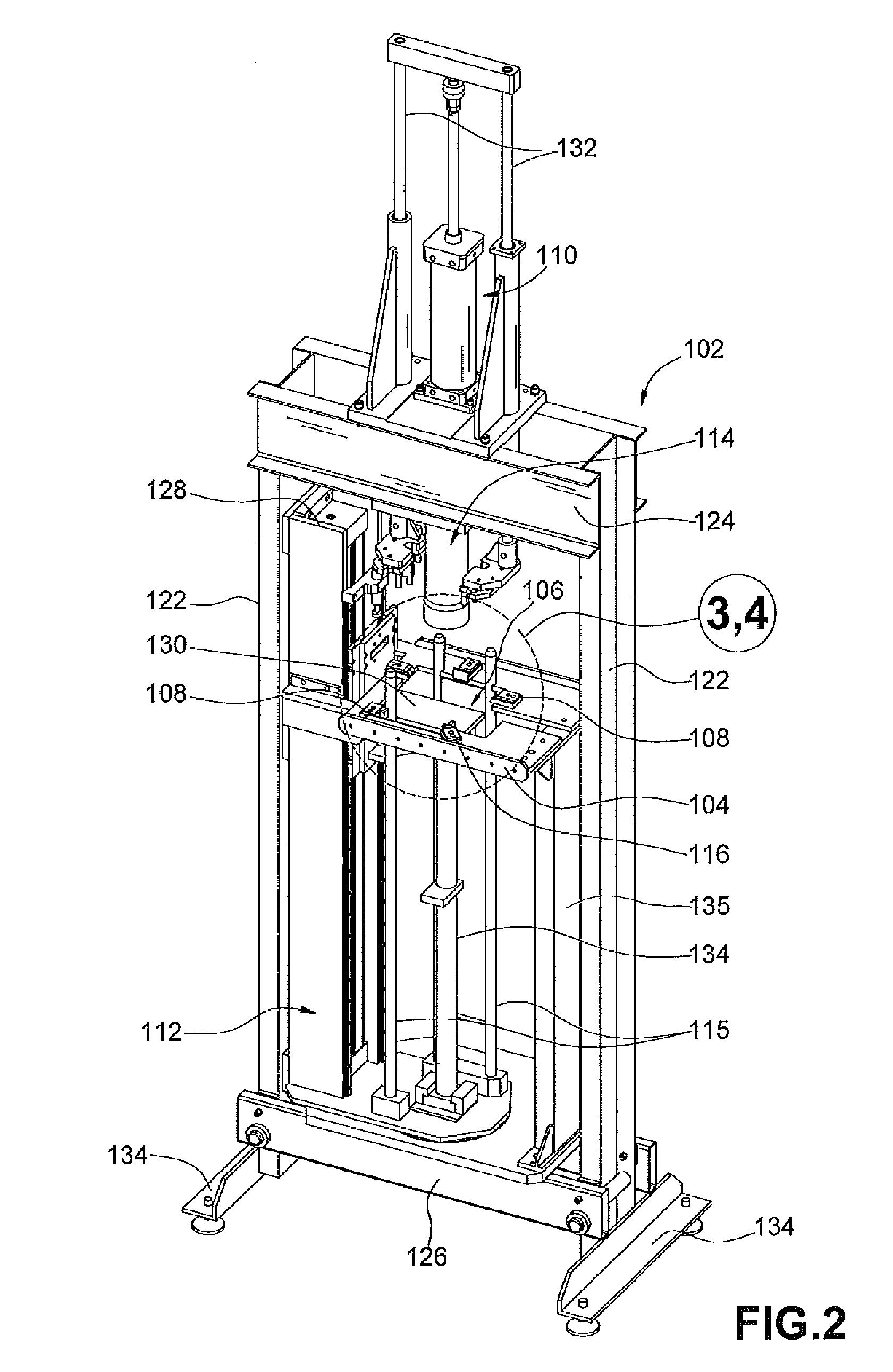

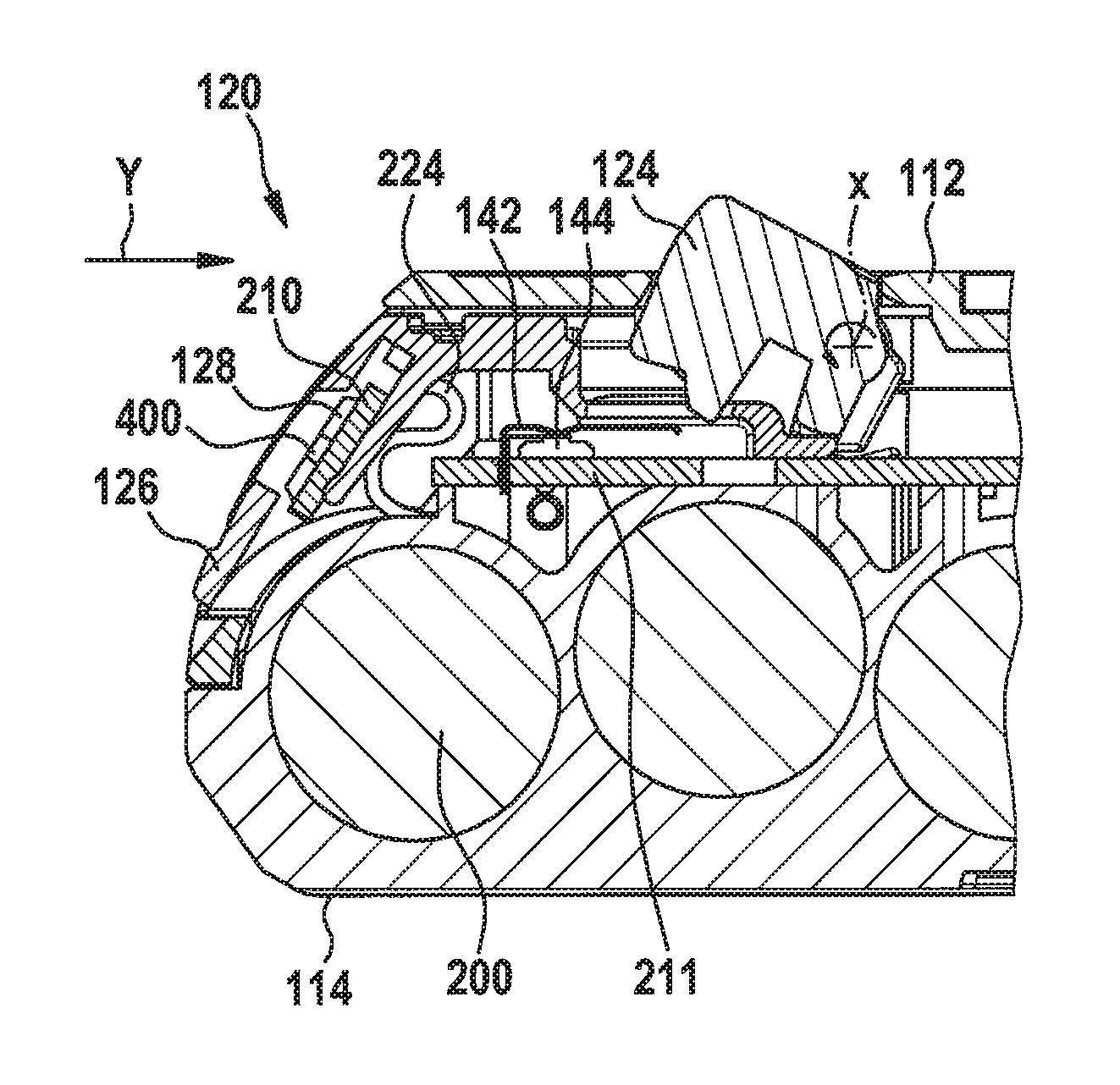

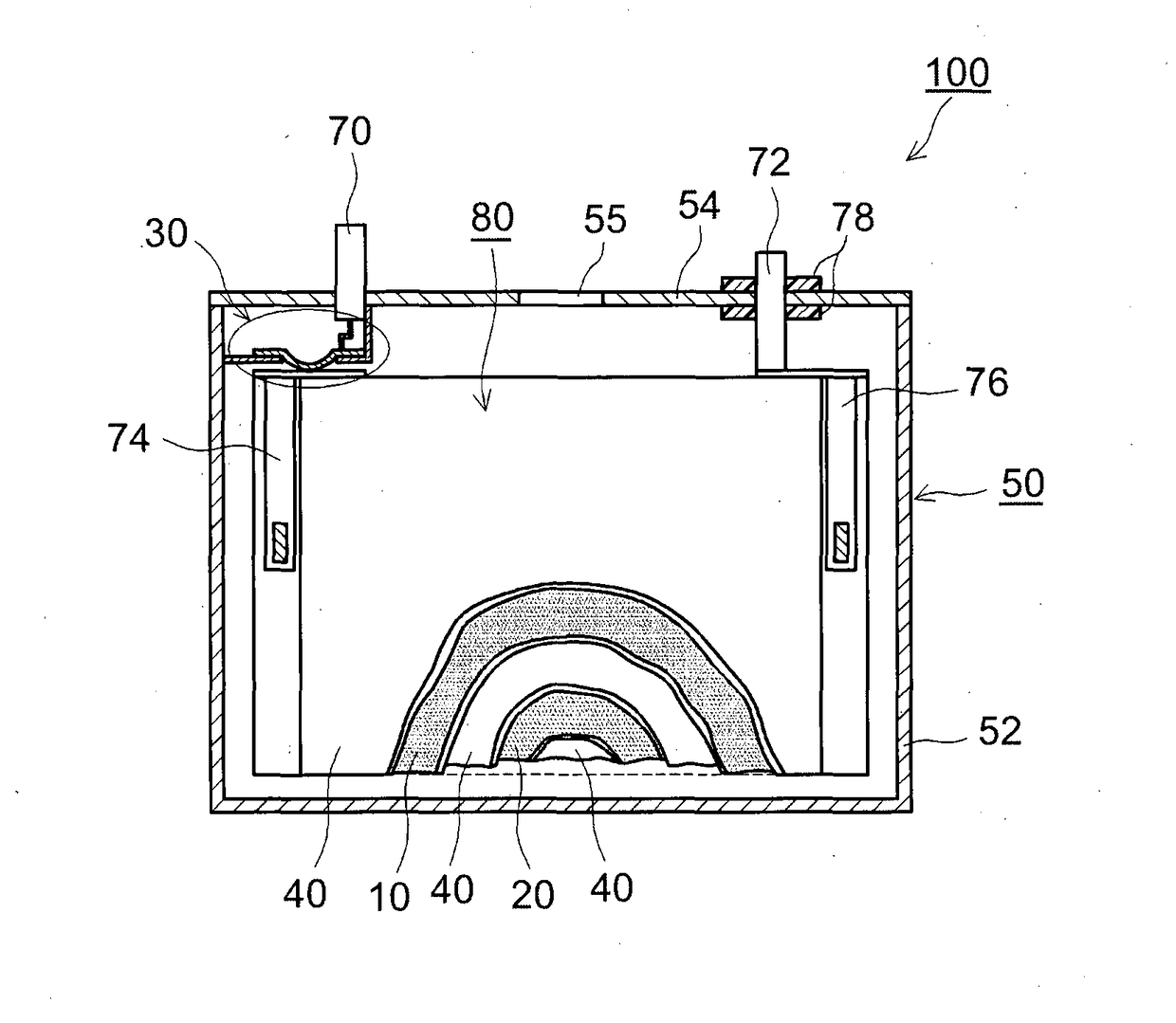

Press apparatus

InactiveUS20100306995A1Maintaining dimensional qualityAssembling battery machinesElectrode carriers/collectorsEngineeringBattery pack

Owner:GM GLOBAL TECH OPERATIONS LLC

Positive active material and nonaqueous electrolyte secondary battery

ActiveUS20060093914A1Large capacityStable structureActive material electrodesCobalt compoundsManganeseLithium manganese oxide

A positive active material including a compound expressed by a general formula LimMxM′yM″zO2 (here, M designates at least one kind of element selected from Co, Ni and Mn, M′ designates at least one kind of element selected from Al, Cr, V, Fe, Cu, Zn, Sn, Ti, Mg, Sr, B, Ga, In, Si and Ge, and M″ designates at least one kind of element selected from Mg, Ca, B and Ga. Further, x is designated by an expression of 0.9≦x<1, y is indicated by an expression of 0.001≦y≦0.5, z is indicated by an expression of 0≦z≦0.5, and m is indicated by an expression of 0.5≦m) and lithium manganese oxide expressed by a general formula LisMn2-tMatO4 (here, the value of s is expressed by 0.9≦s, the value of t is located within a range expressed by 0.01≦t≦0.5, and Ma indicates one or a plurality of elements between Fe, Co, Ni, Cu, Zn, Al, Sn, Cr, V, Ti, Mg, Ca, Sr, B, Ga, In, Si and Ge) are included, so that both a large capacity and the suppression of the rise of temperature of a battery upon overcharging operation are achieved.

Owner:MURATA MFG CO LTD

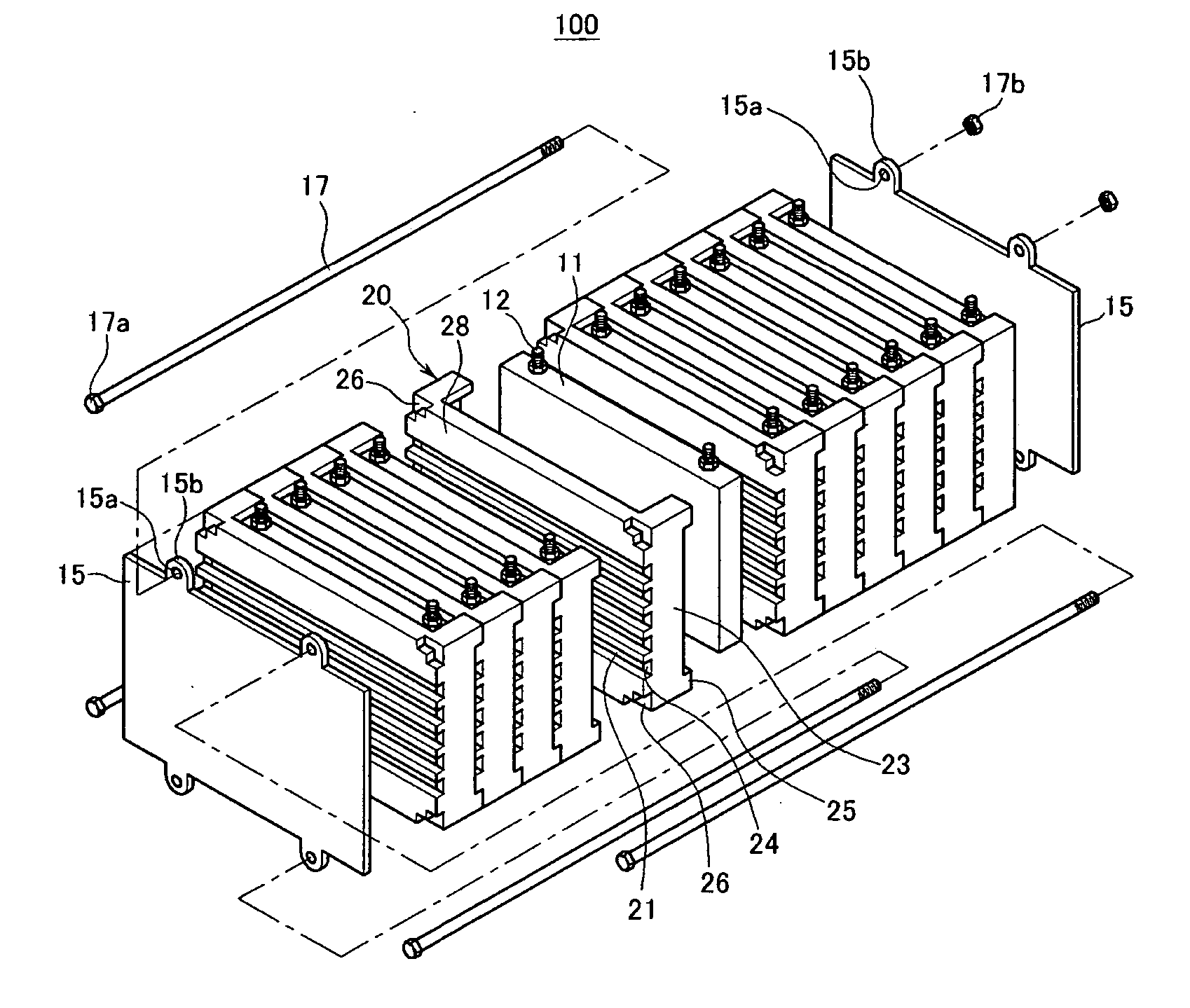

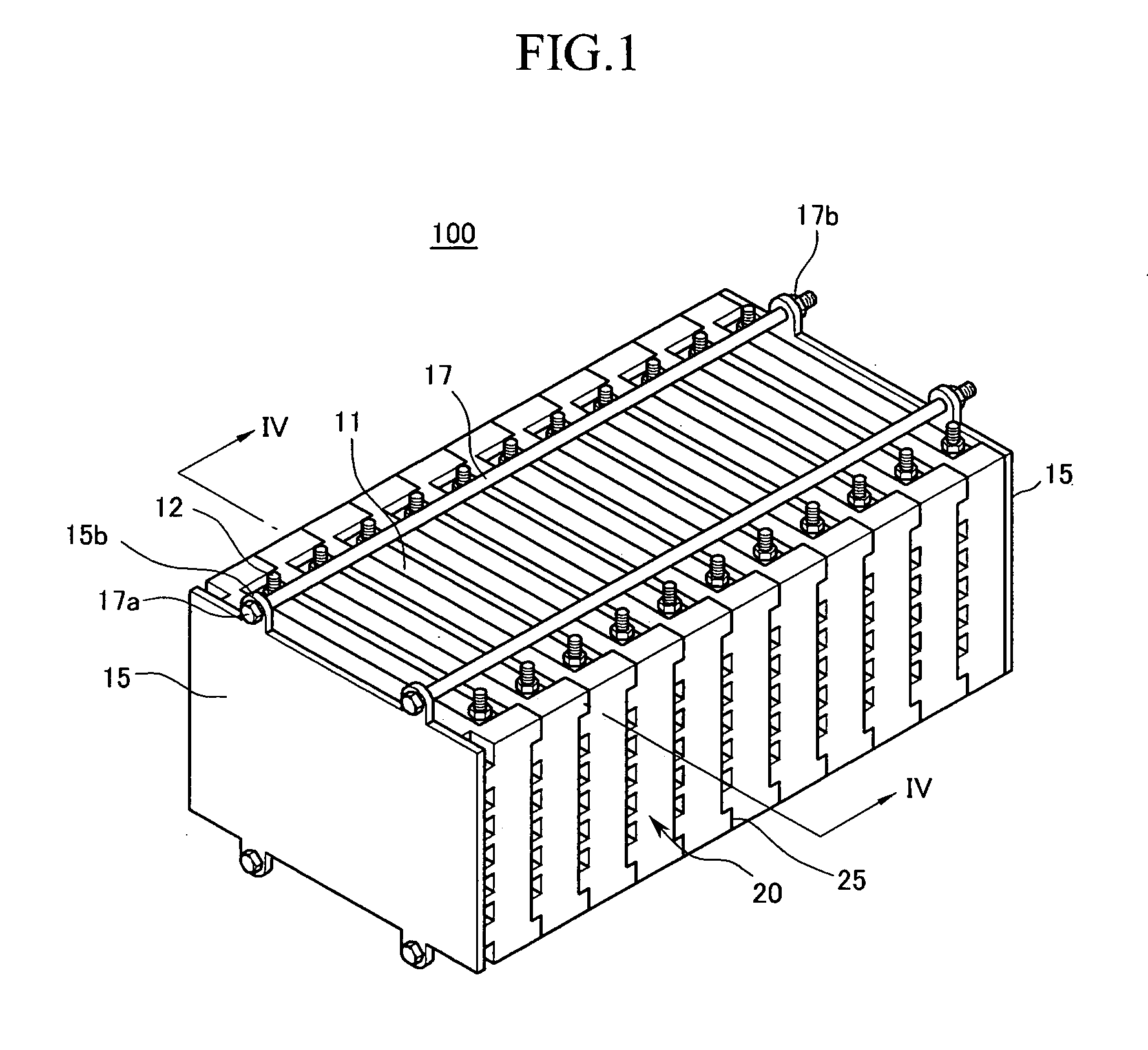

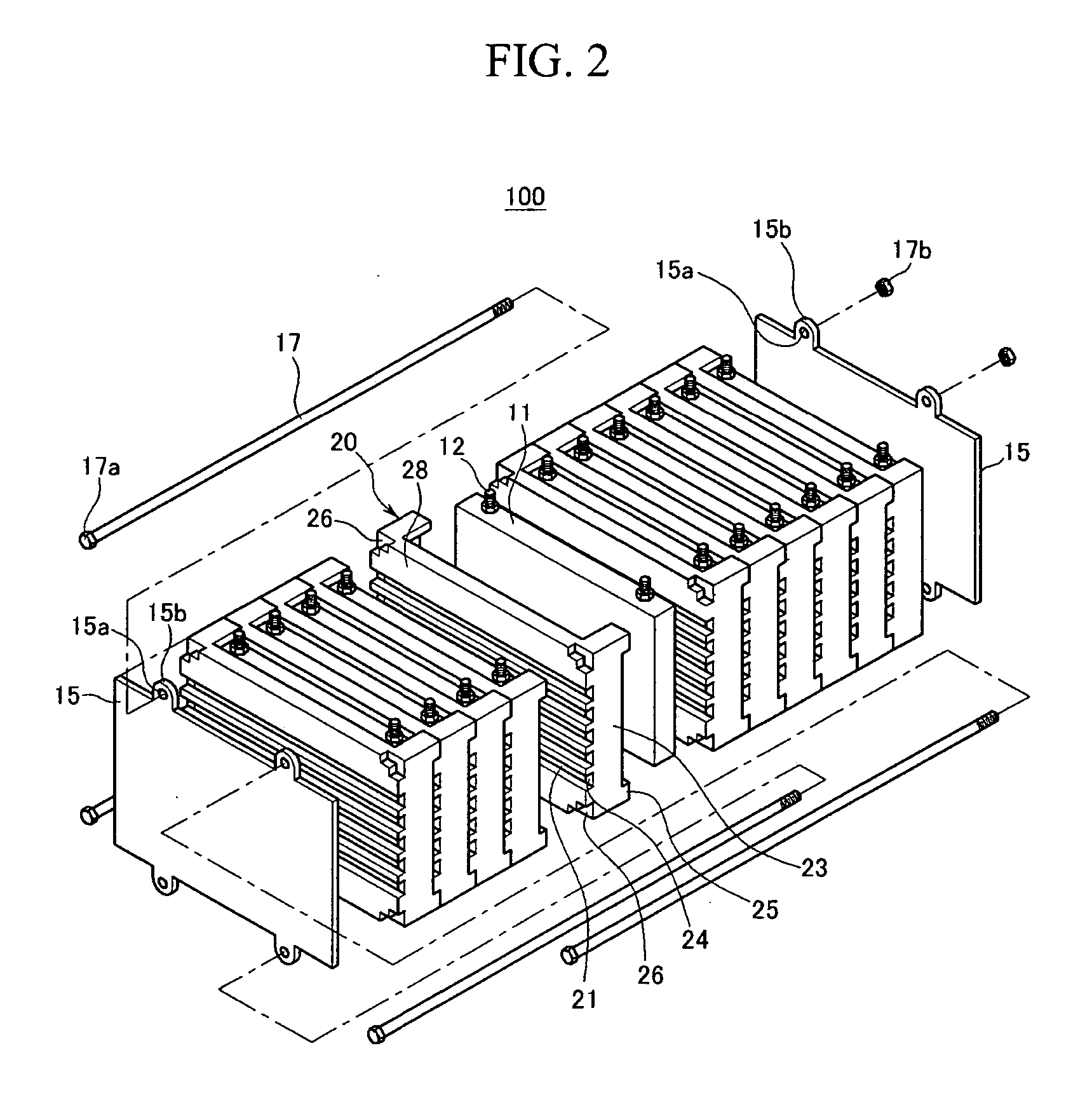

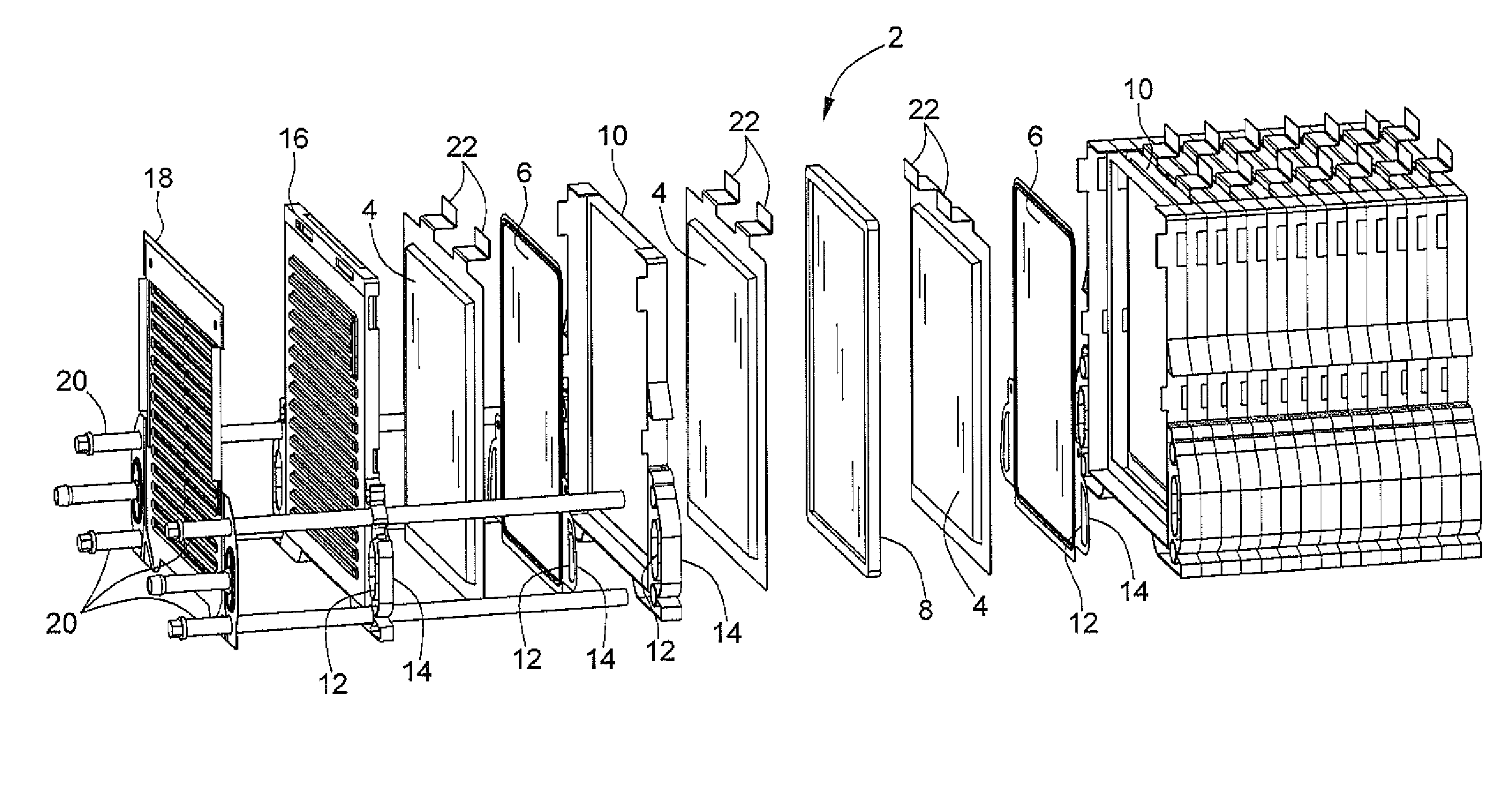

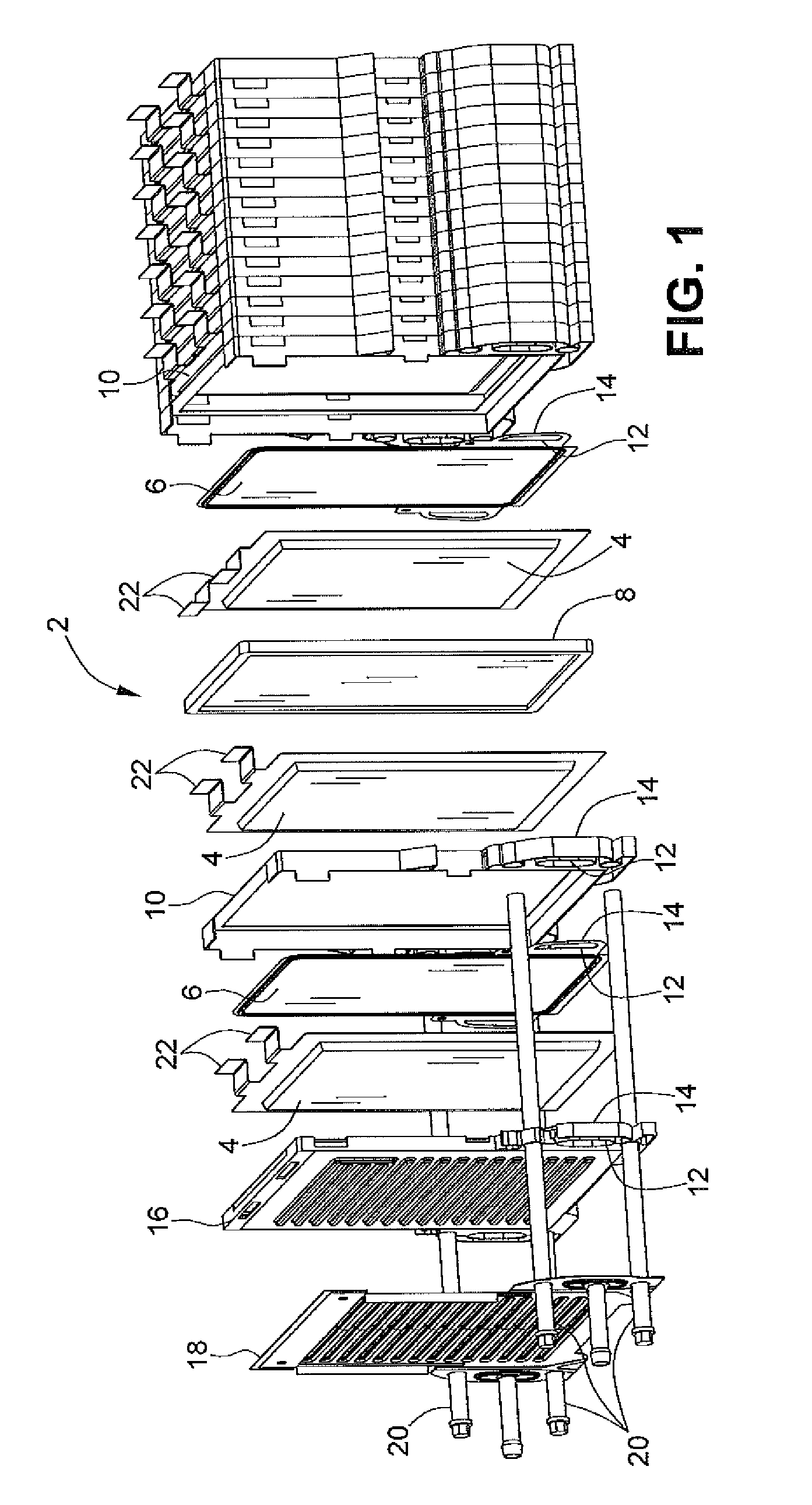

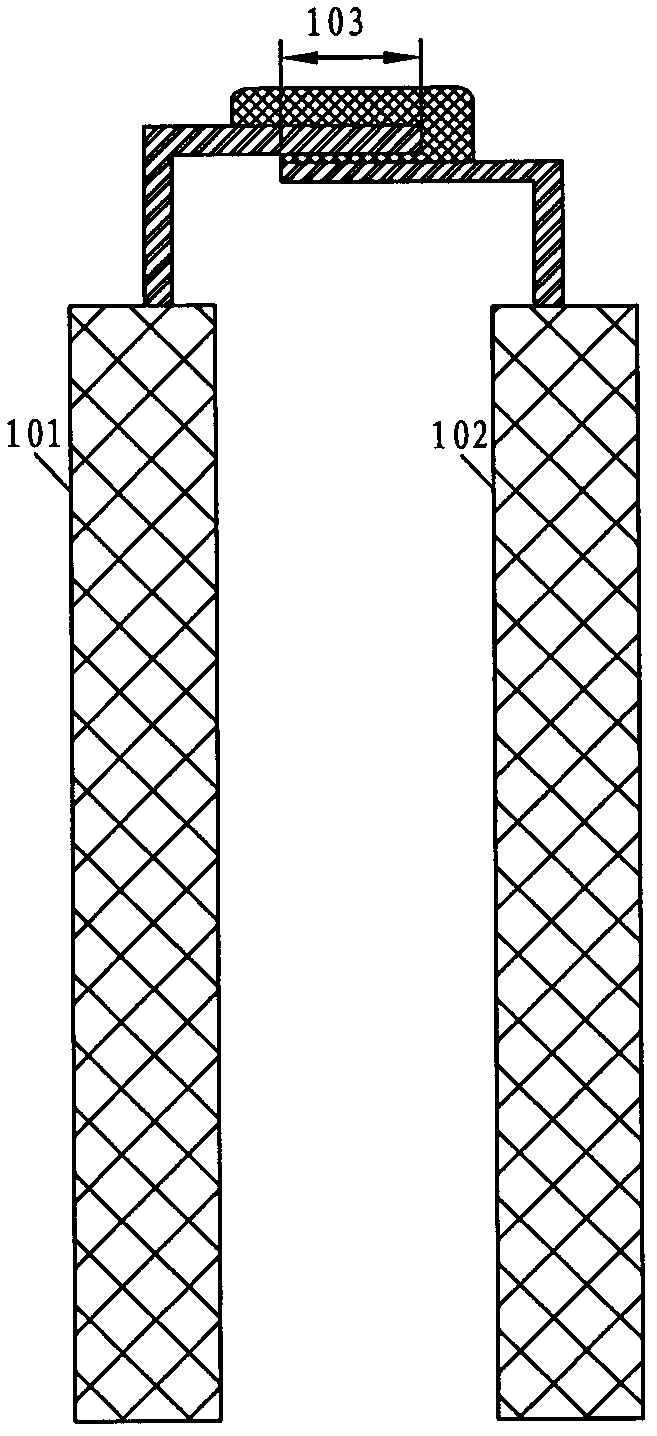

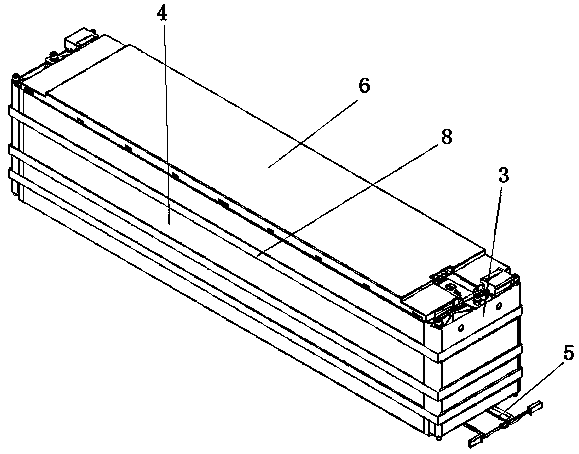

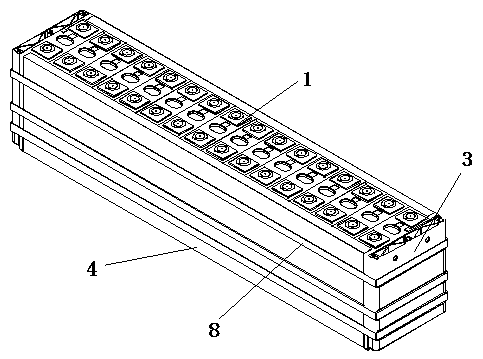

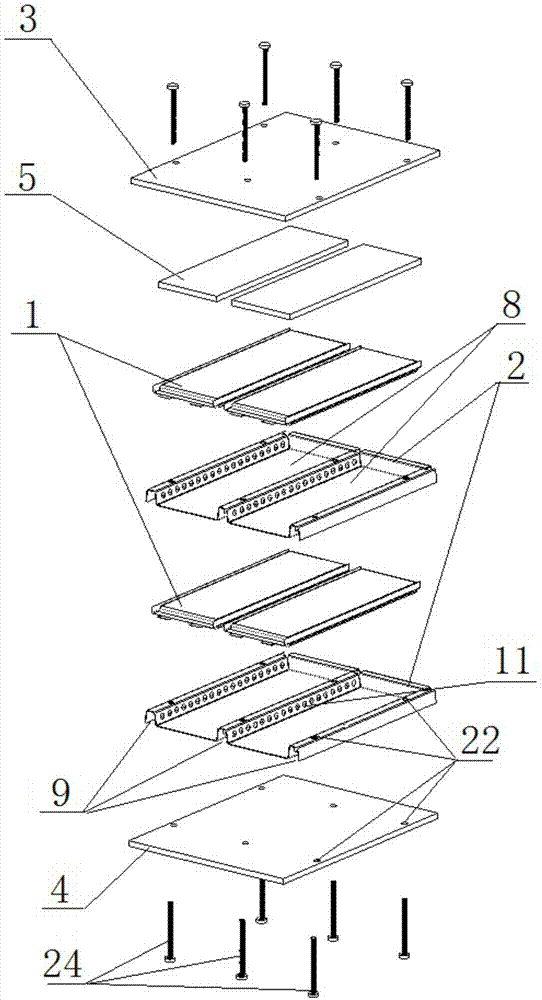

Power supply device, and vehicle and storage battery device equipped with power supply device

InactiveUS20150093607A1Avoid damagePrevent gas leakageSecondary cellsCell component detailsSafety valveBattery cell

A power supply device comprises a battery assembly formed by stacking secondary battery cells having safety valves for exhausting gas, end plates being arranged at both end faces of the battery assembly in the stacking direction, a gas duct guiding gas emitted from the safety valves in a prescribed gas exhaust passage, and fixing portions fixing both ends of the gas duct to the end plates in a position where the gas duct faces the safety valves. In a state in which the gas duct is fixed to the end plates in at least one of the fixing portion a fixing opening of a slit is formed extending in the direction parallel to the direction in which the secondary battery cells are stacked, and a fixing member is inserted into the slit fixing opening.

Owner:SANYO ELECTRIC CO LTD

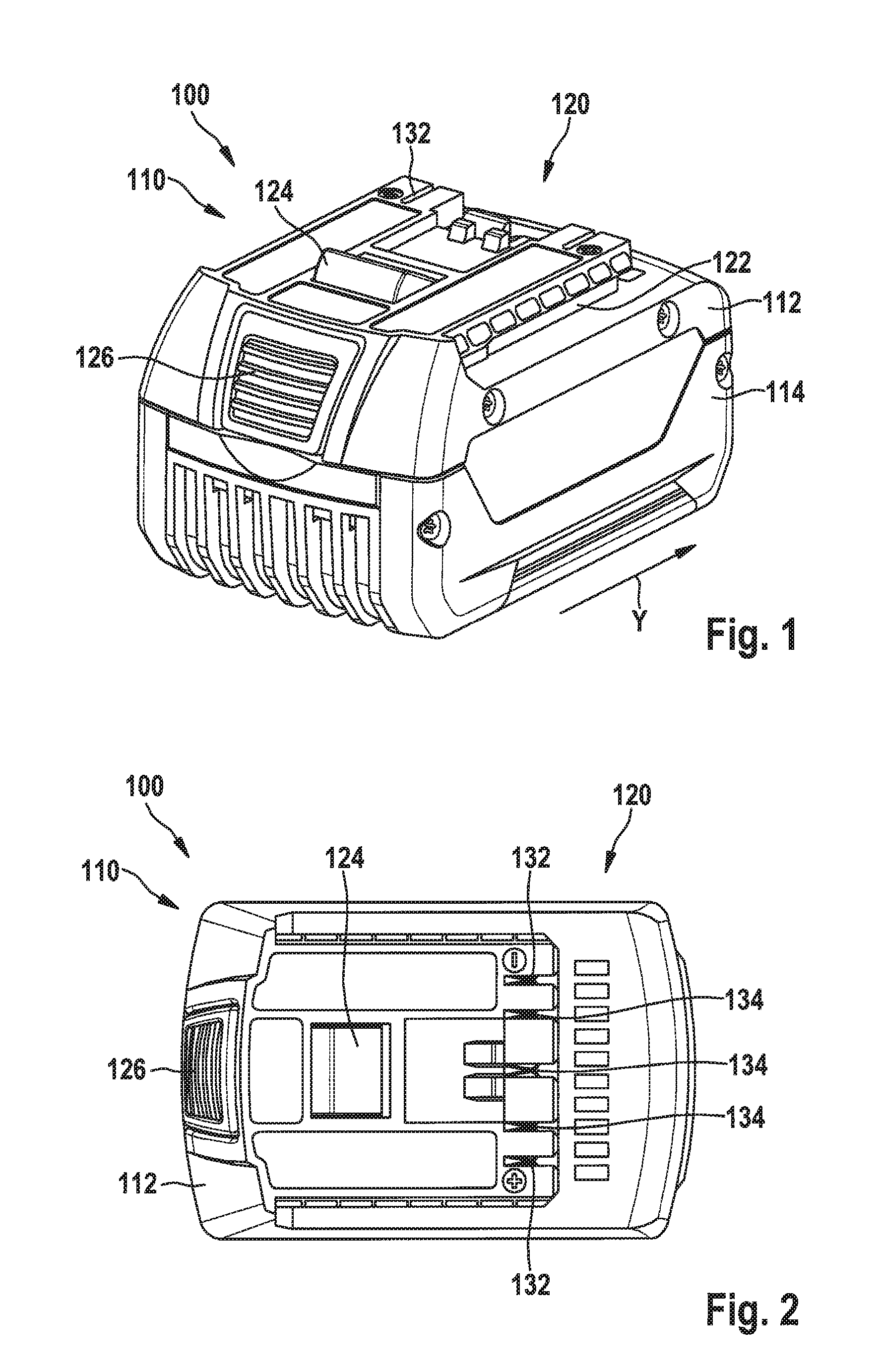

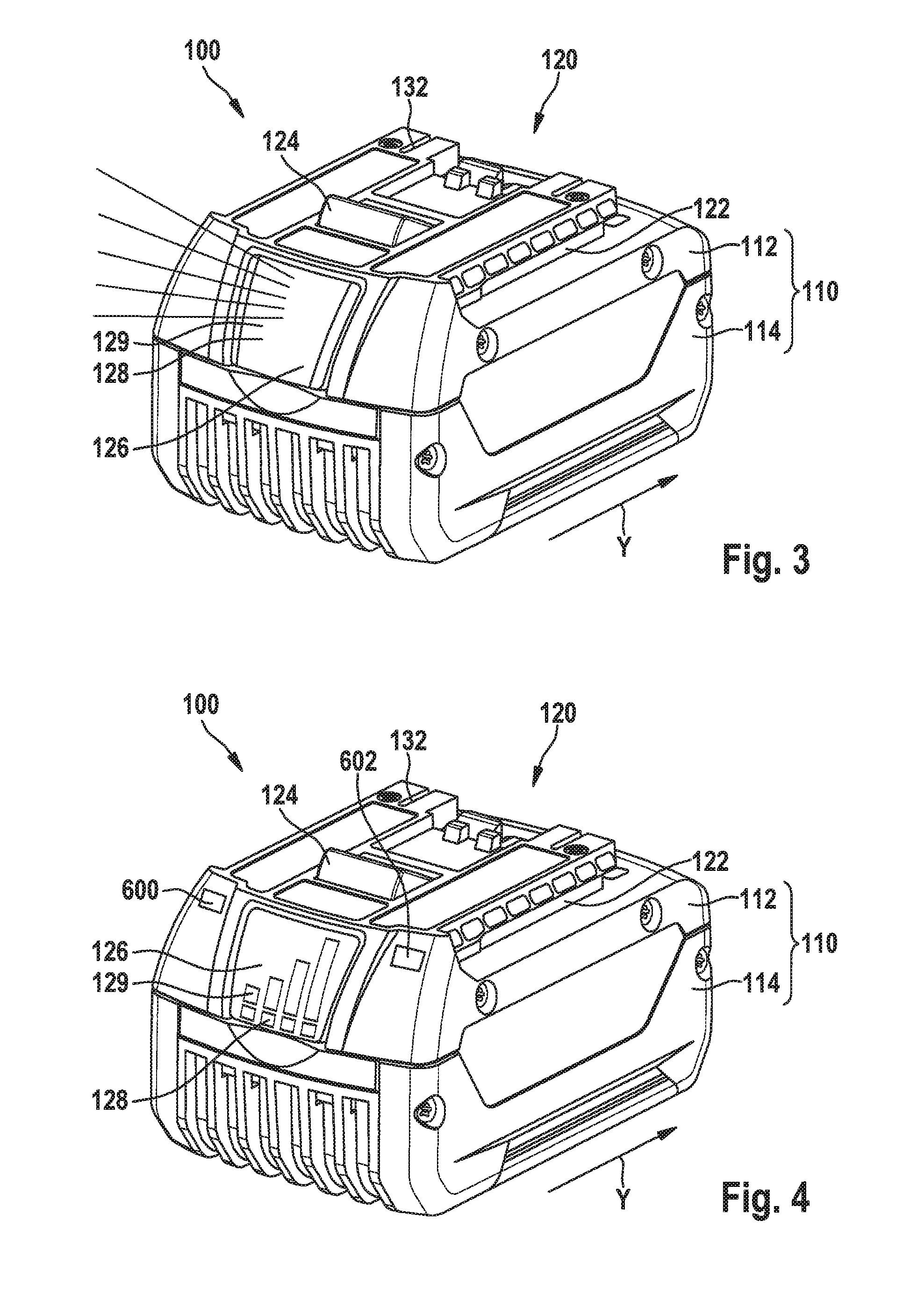

Rechargeable battery pack for a handheld power tool

ActiveUS20160172722A1Reduce chargeCircuit monitoring/indicationDifferent batteries chargingElectricityRechargeable cell

Owner:ROBERT BOSCH GMBH

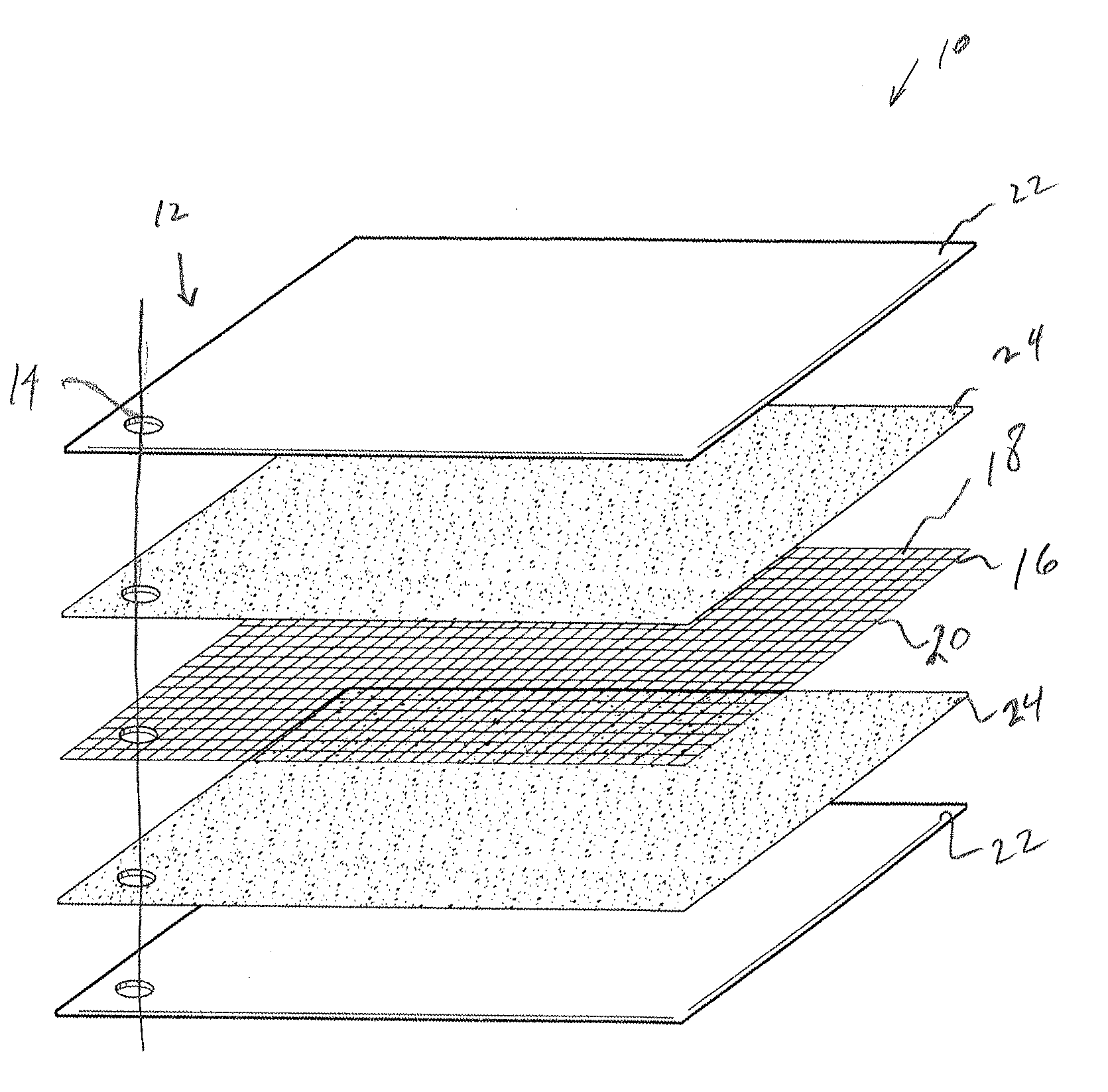

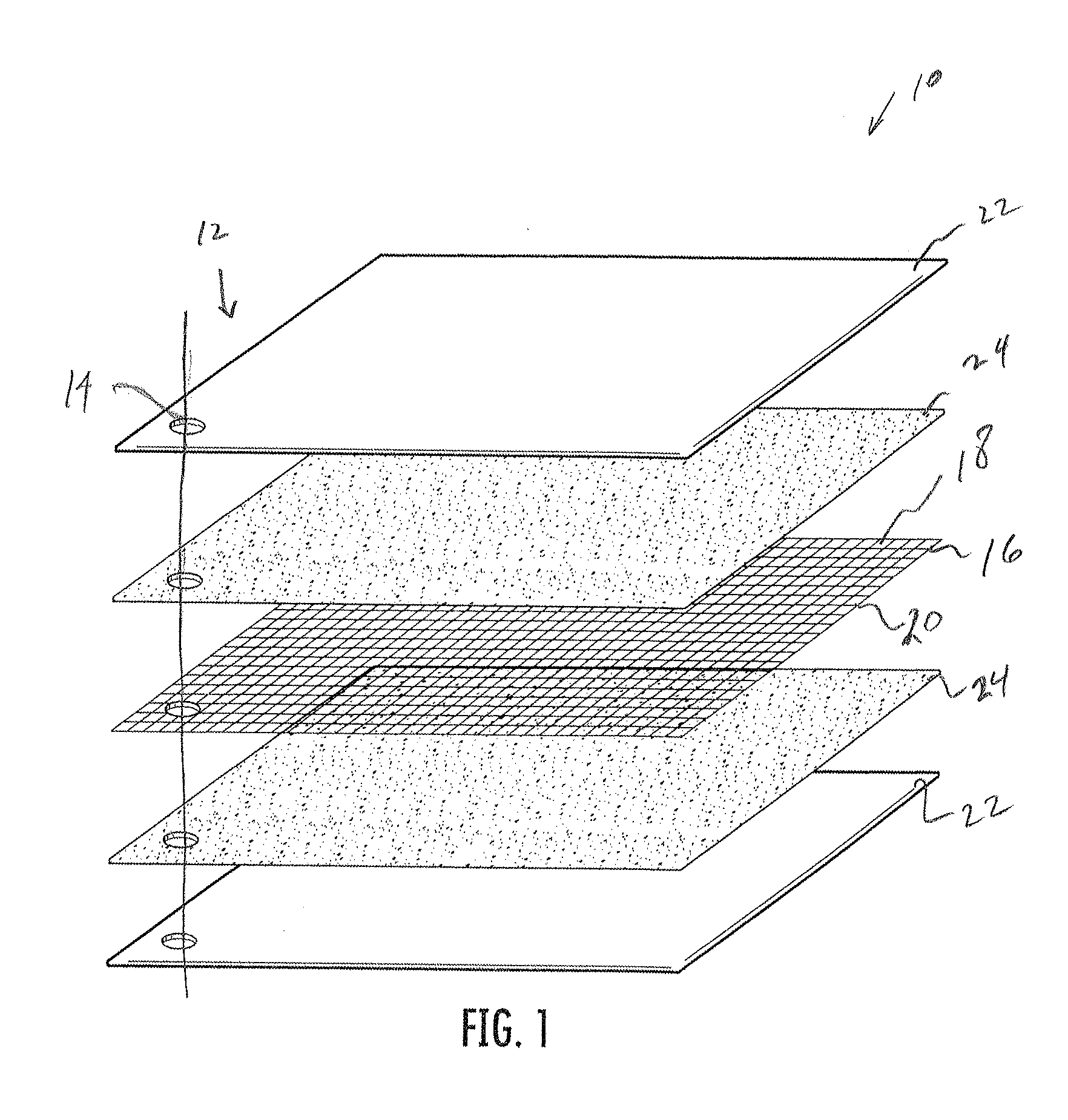

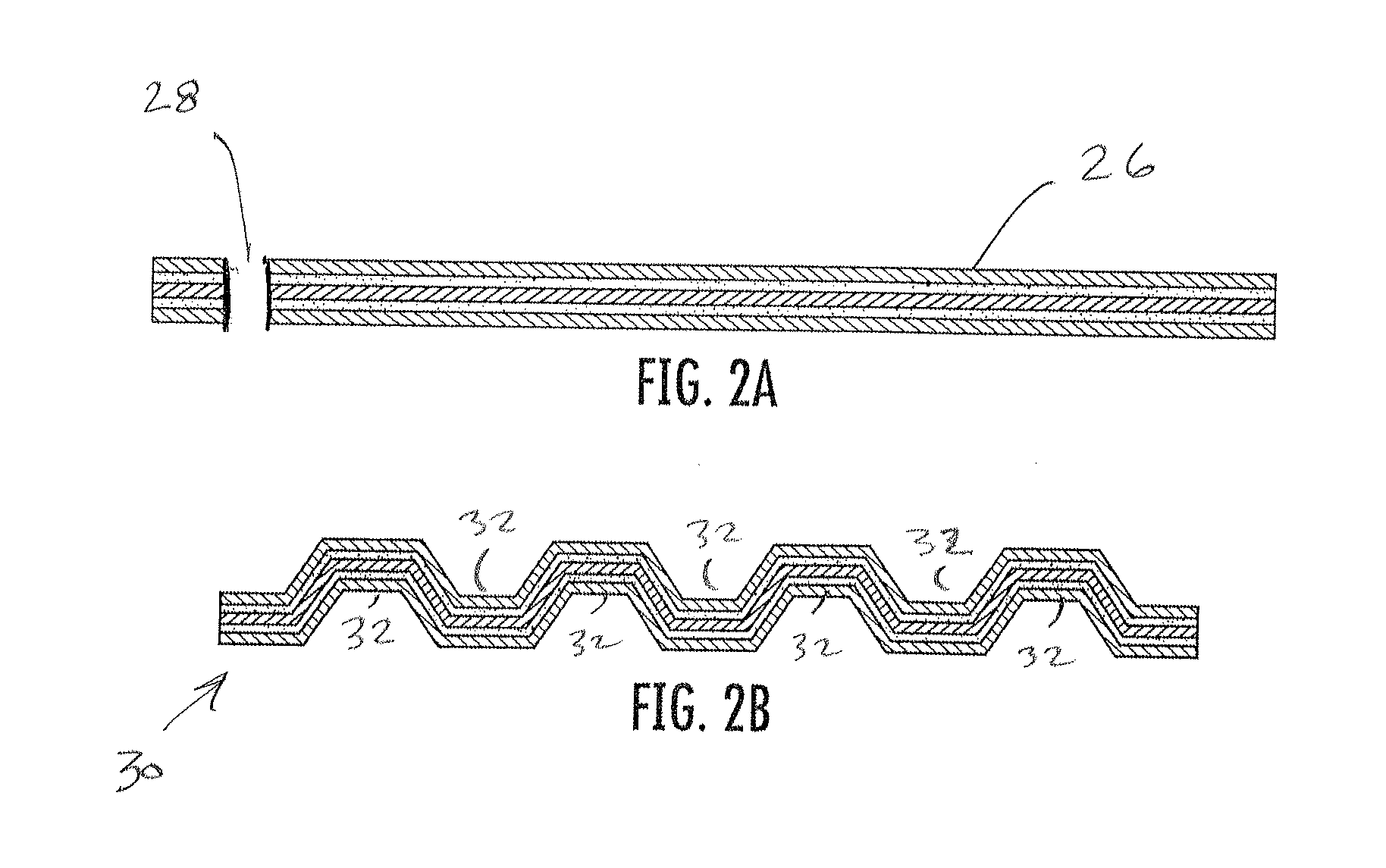

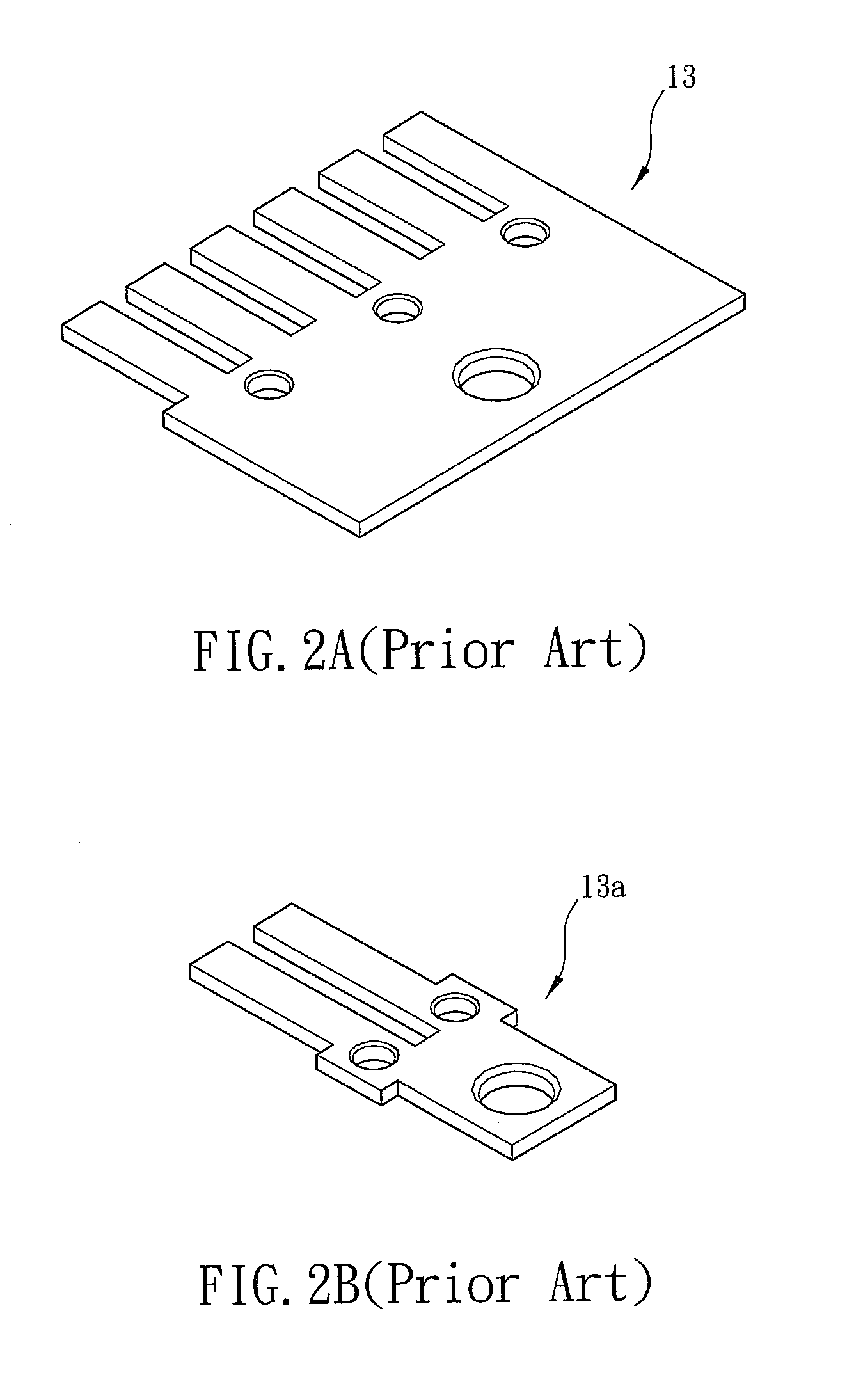

Fuel cell composite flow field element and method of forming the same

InactiveUS20110053052A1High thermalImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsFuel cellsGraphite

Owner:VPJP

Device and method of testing an internal resistance of a battery pack

ActiveUS20110101986A1High measurement accuracyCurrent/voltage measurementElectrical testingElectrical resistance and conductanceInternal resistance

An internal resistance testing device includes an excitation source and a battery pack, an adjustable resistance R, a sampling unit, and a control unit. The excitation source and the battery pack form a loop circuit. The adjustable resistance R may be located at the loop circuit formed by the excitation source and the battery pack. The sampling unit samples the voltage between two sides of the battery pack, the voltage between two sides of the adjustable resistance R, and the value of the adjustable resistance R. The control unit calculates internal resistance of the battery pack according to the signal value collected by the sampling unit. The internal resistances of different voltage-ranges the battery pack are determined by adjusting the value of the adjustable resistance R to cause the actual excitation voltage to be equal to the range voltage of the sampling unit. The voltage between two sides of the adjustable resistance R is made equal to the range voltage of the sampling unit by adjusting the value of the adjustable resistance R, which effectively improves measurement accuracy of the internal resistance.

Owner:BYD CO LTD

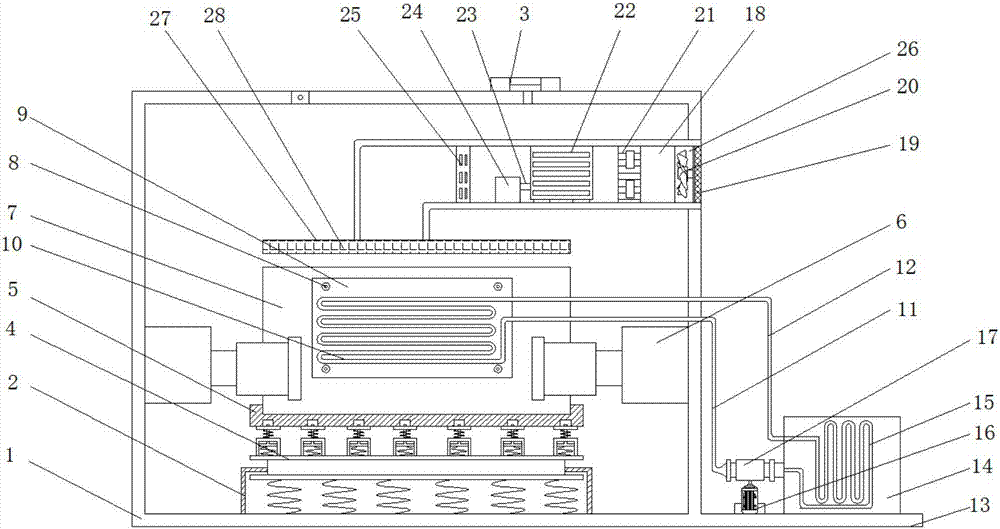

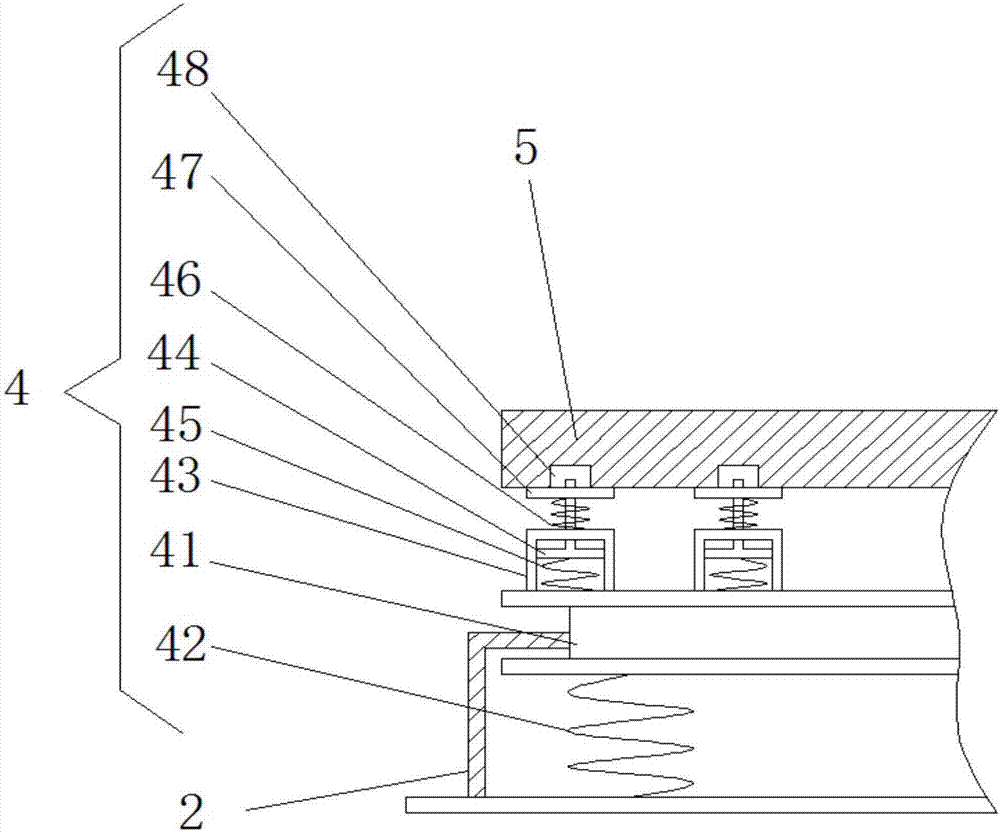

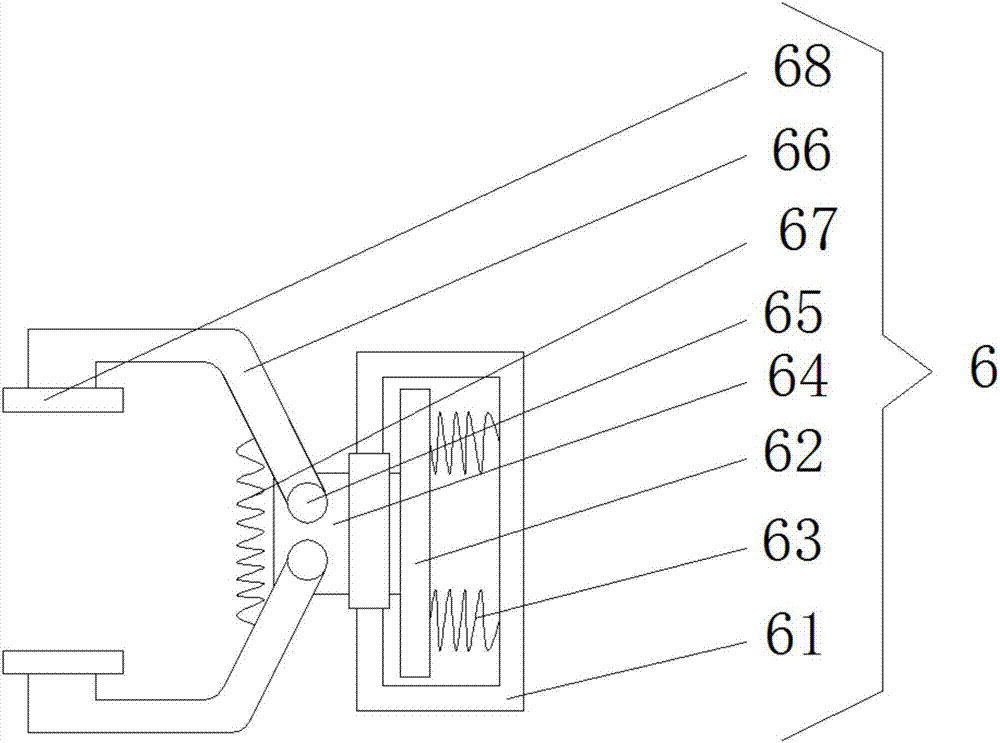

Automobile battery fixing device

InactiveCN107394083AAchieving oil-cooled car batteriesClamp firmlyElectric propulsion mountingSecondary cellsAutomotive batteryCooling effect

Owner:安吉天剑电器科技有限公司

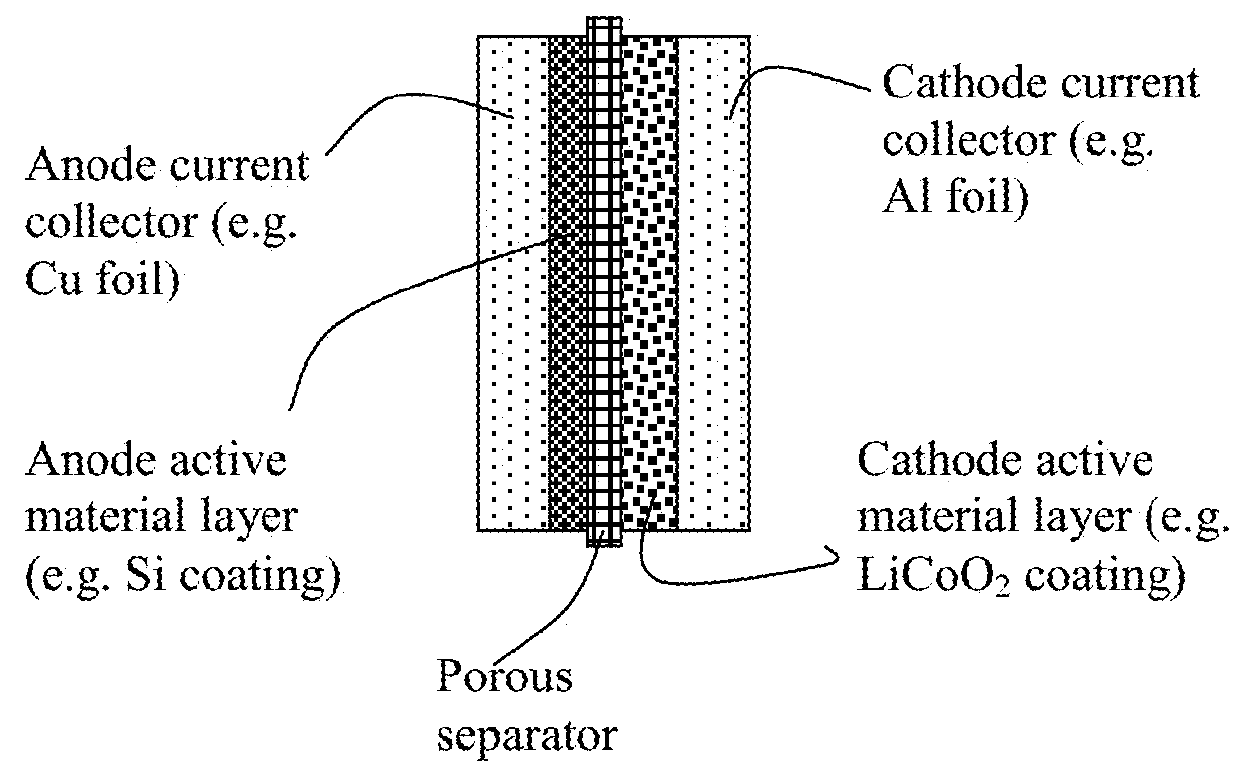

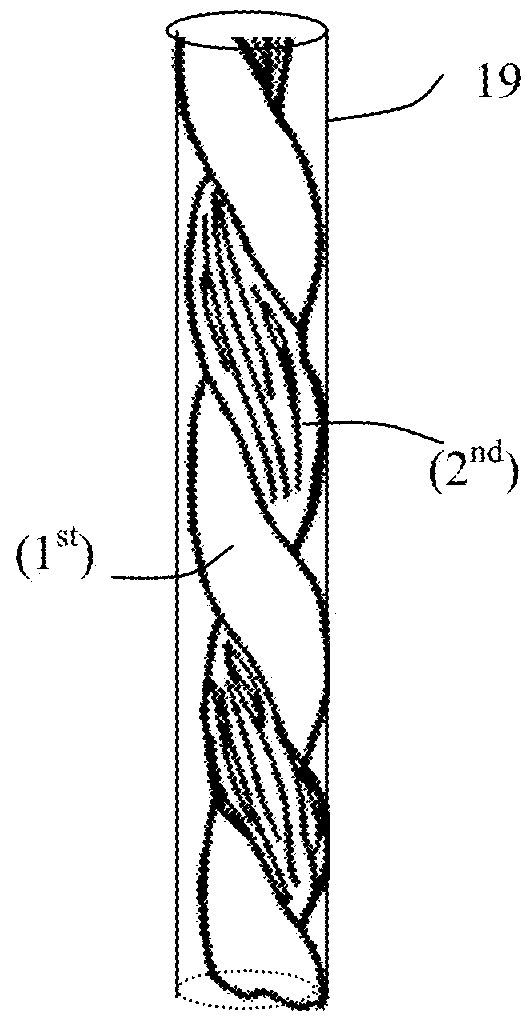

Process for producing flexible and shape-conformal rope-shape alkali metal batteries

ActiveUS10008747B1Maximize contact areaMaximize interfacial areaFinal product manufactureElectrode carriers/collectorsYarnMaterials science

Owner:GLOBAL GRAPHENE GRP INC

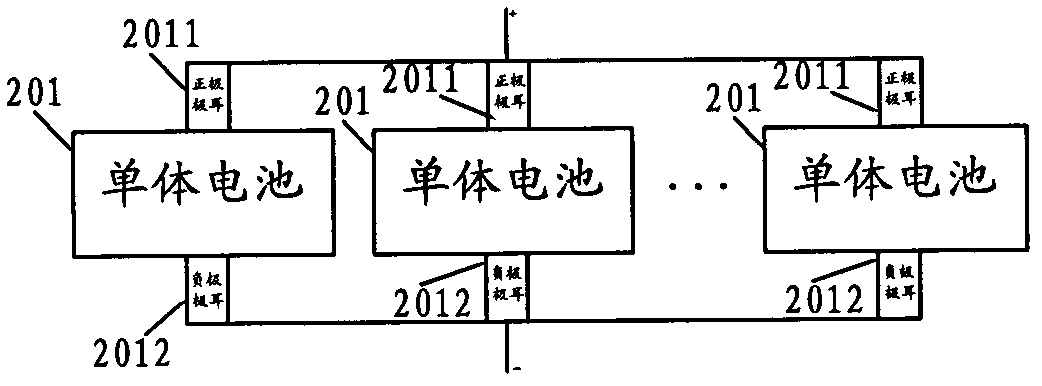

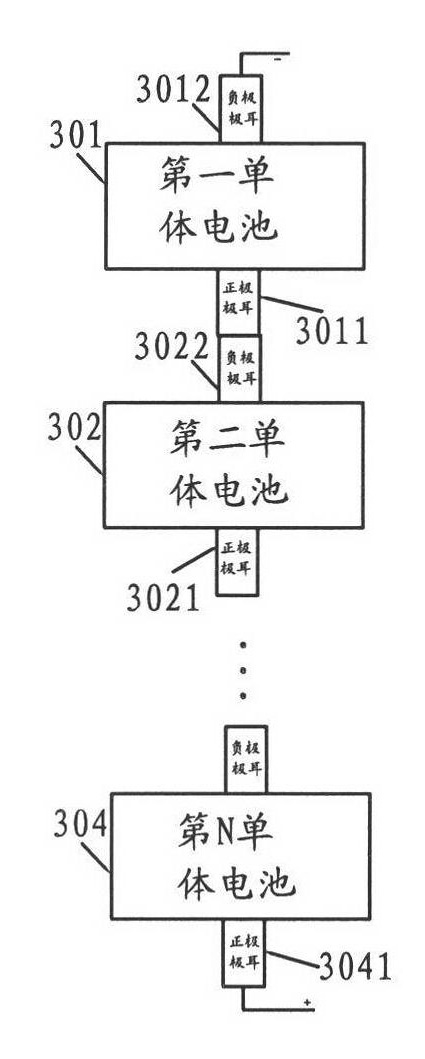

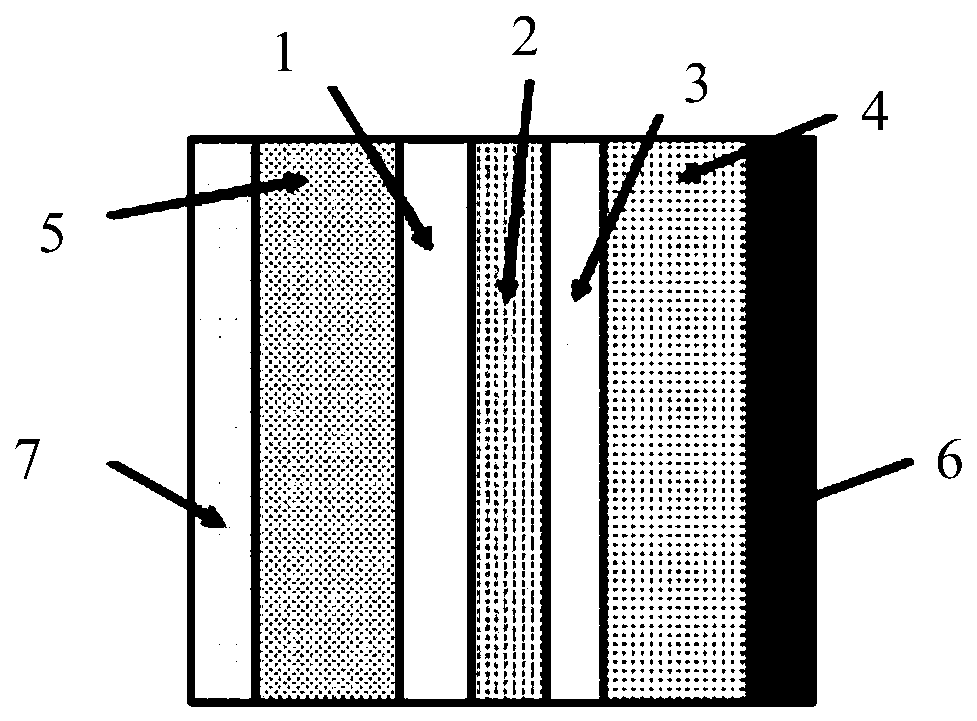

Lithium ion battery pack and soldering method for single batteries therein

ActiveCN102332611AAvoid bloatingFinal product manufactureCell component detailsBattery cellMaterials science

Owner:SHENZHEN GREPOW BATTERY CO LTD

Lithium supplementing diaphragm of lithium ion battery

Owner:复阳固态储能科技(溧阳)有限公司

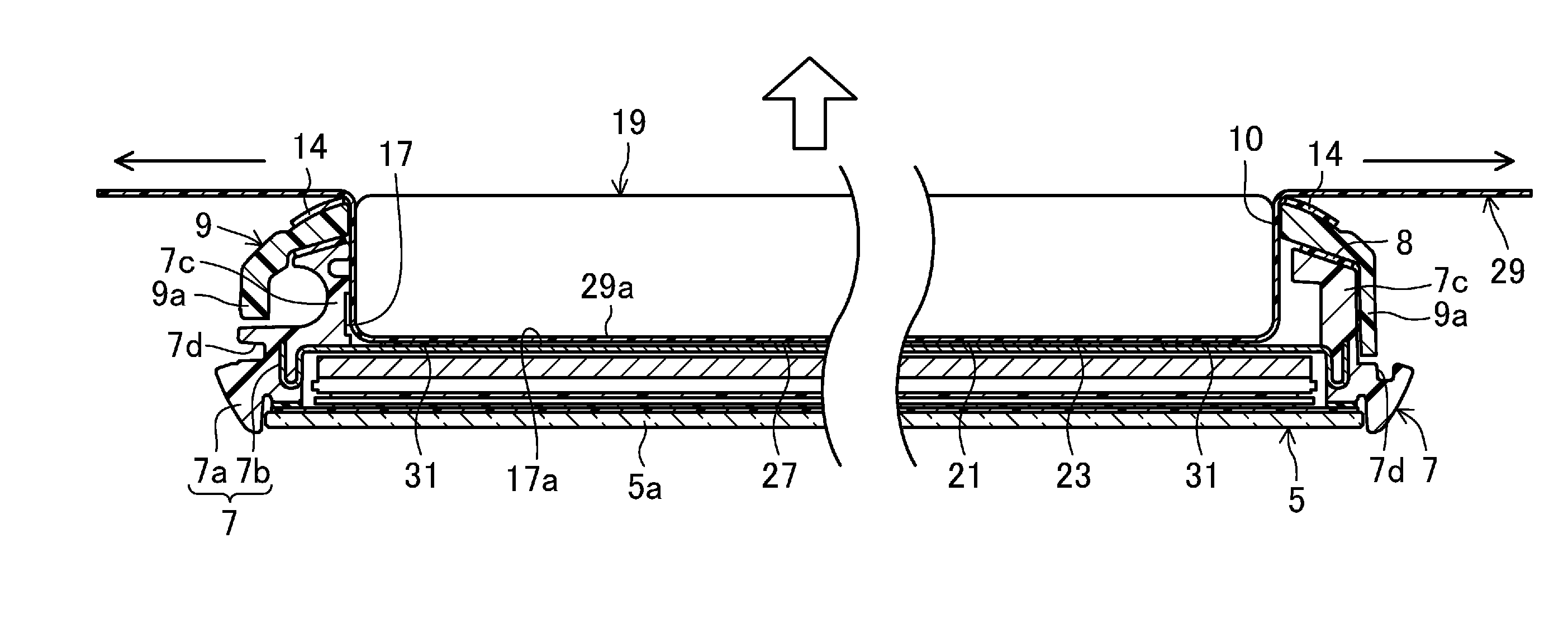

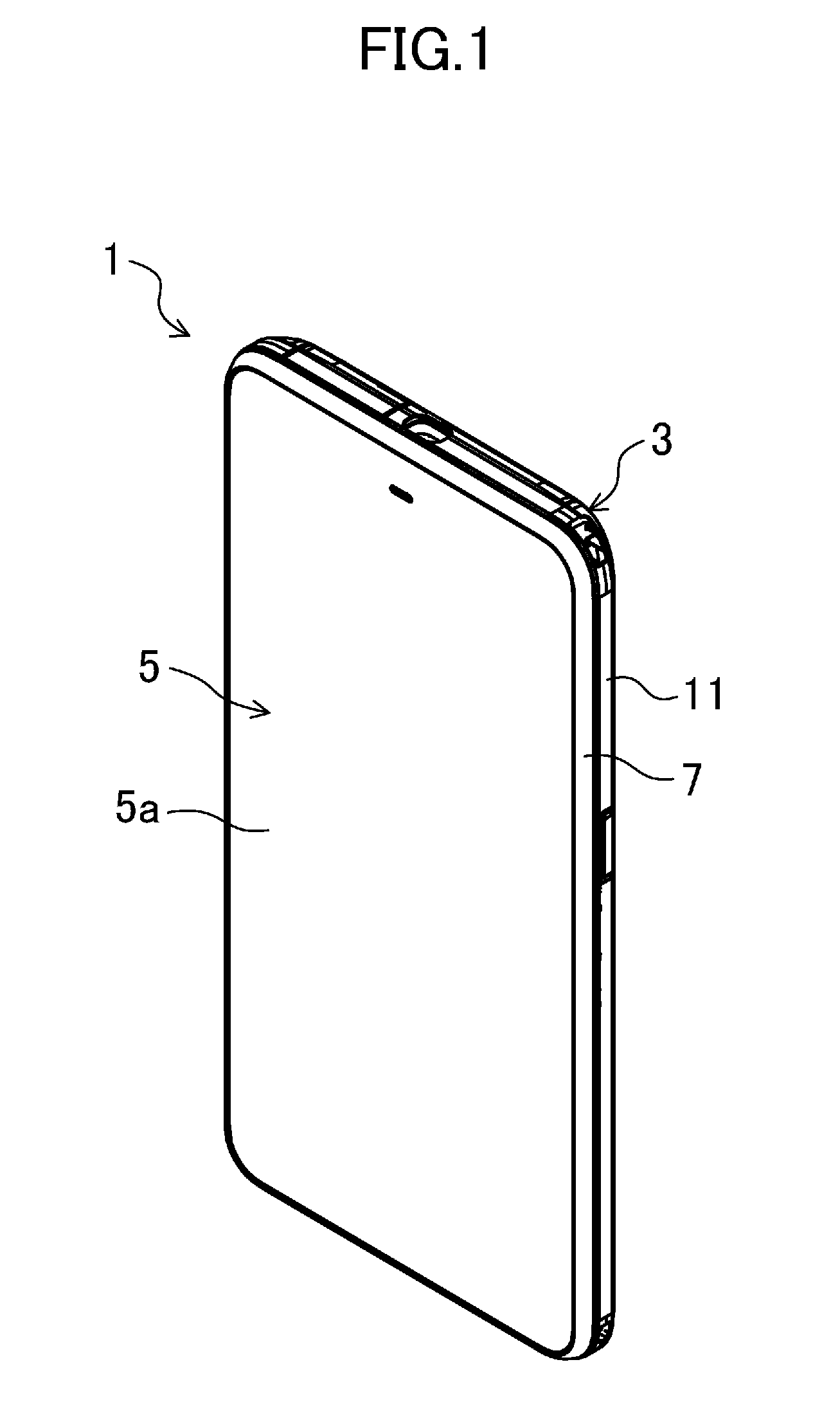

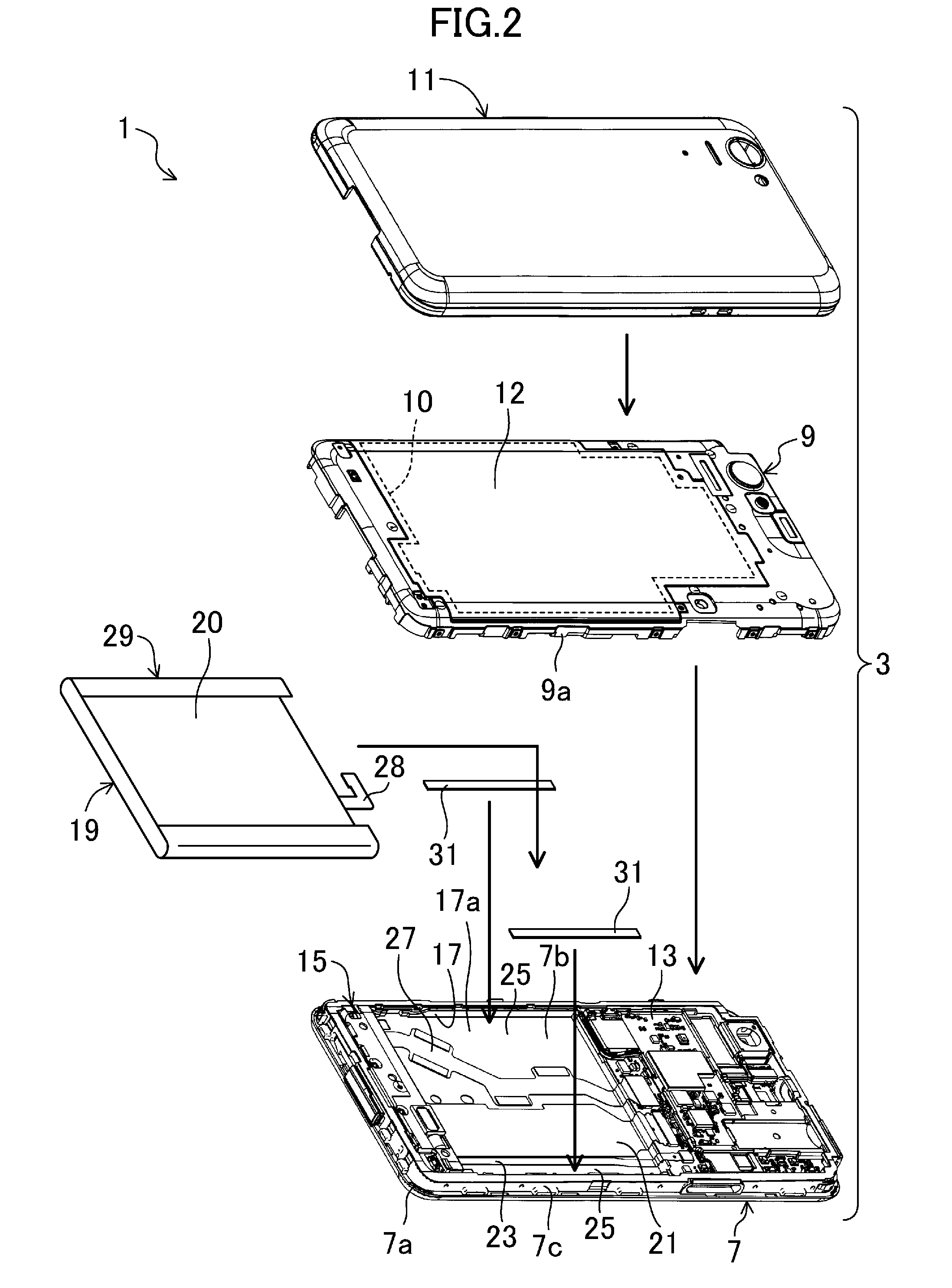

Mobile device

Owner:SHARP KK

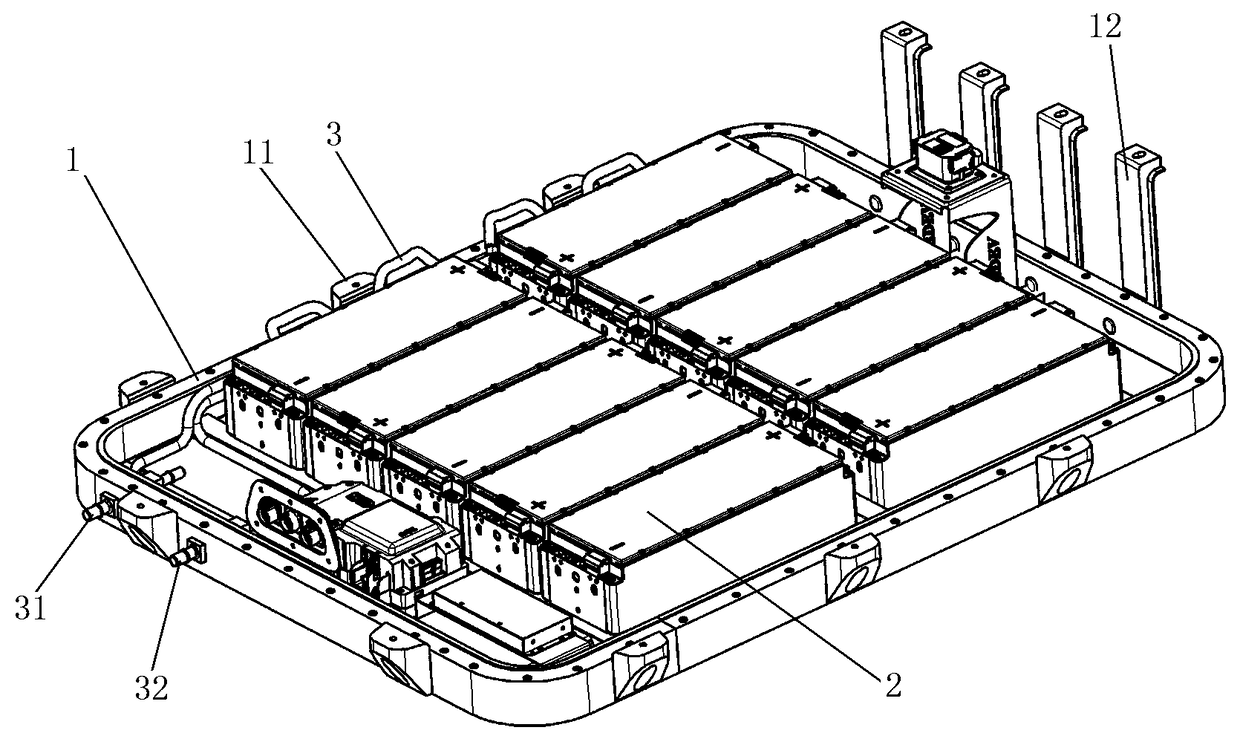

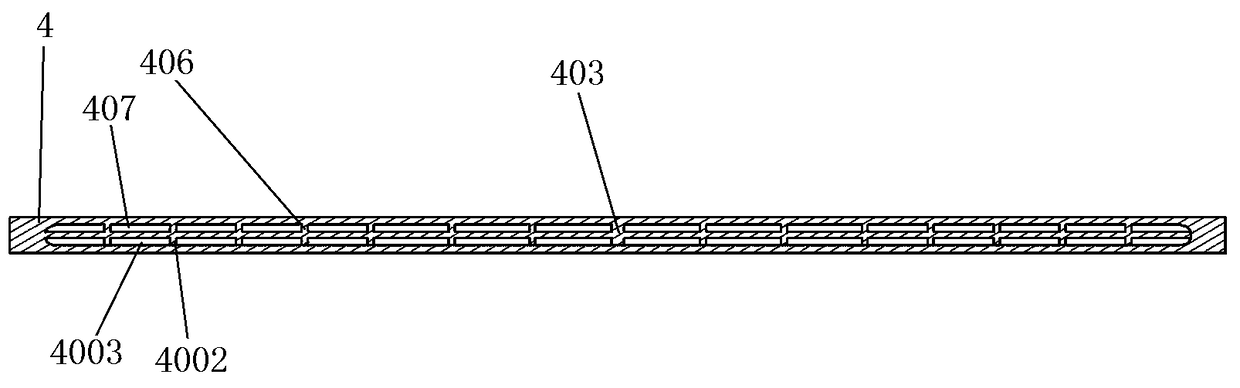

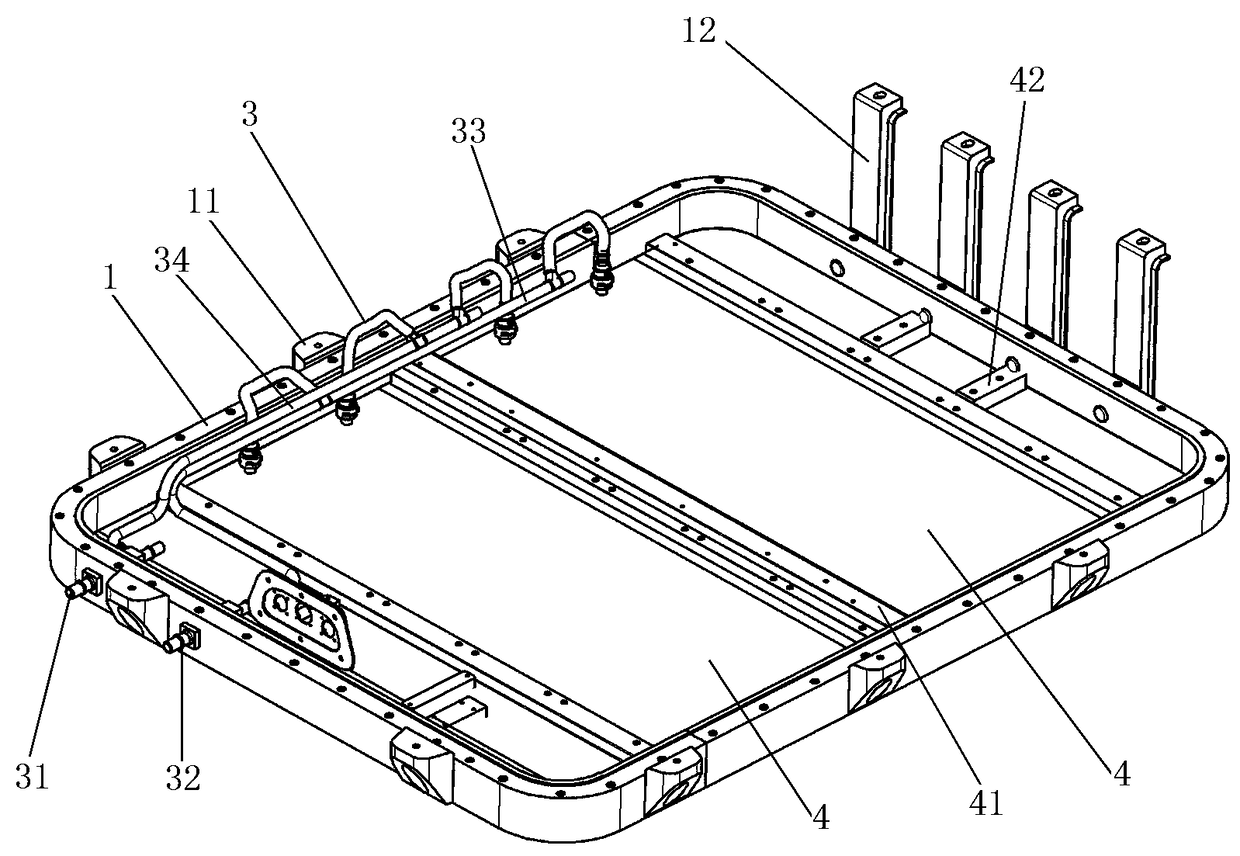

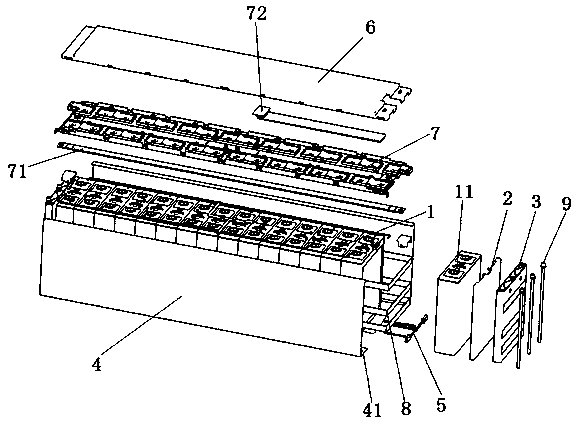

Electric vehicle, battery box body thereof, and battery box

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

Method for preparing high-temperature resistant microporous membrane

ActiveCN103811704AClearly definedEasy to understandCell component detailsPolymer sciencePolypropylene

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

Battery module

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

Light diffusing layer, light diffusing film, and light diffusing adhesive sheet

Owner:TOMOEGAWA PAPER CO LTD

Multilayer, microporous polyolefin membrane, and production method thereof

ActiveUS20160118639A1Improve permeabilityHigh strengthSemi-permeable membranesMembranesIn planePolymer science

Owner:TORAY IND INC

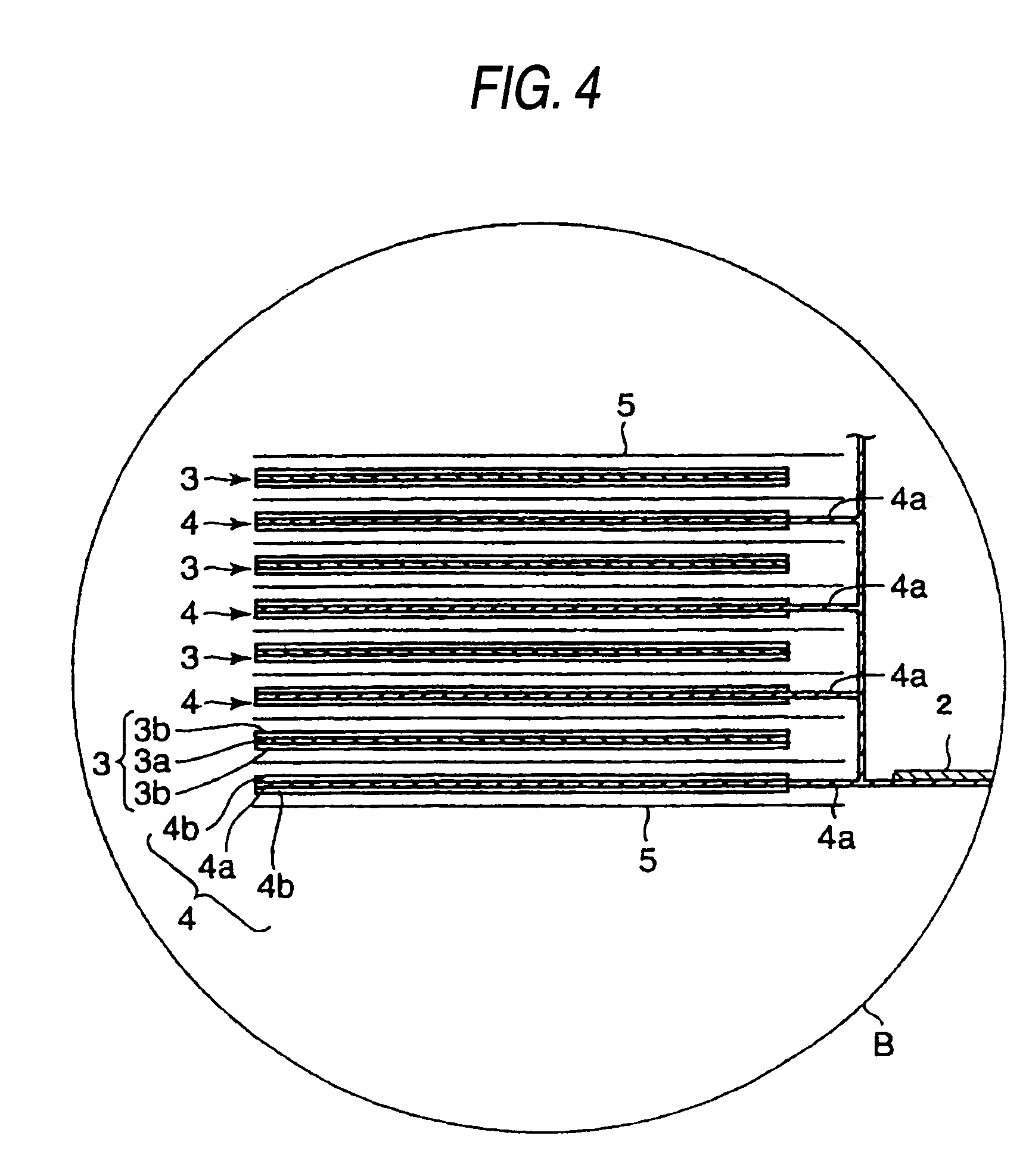

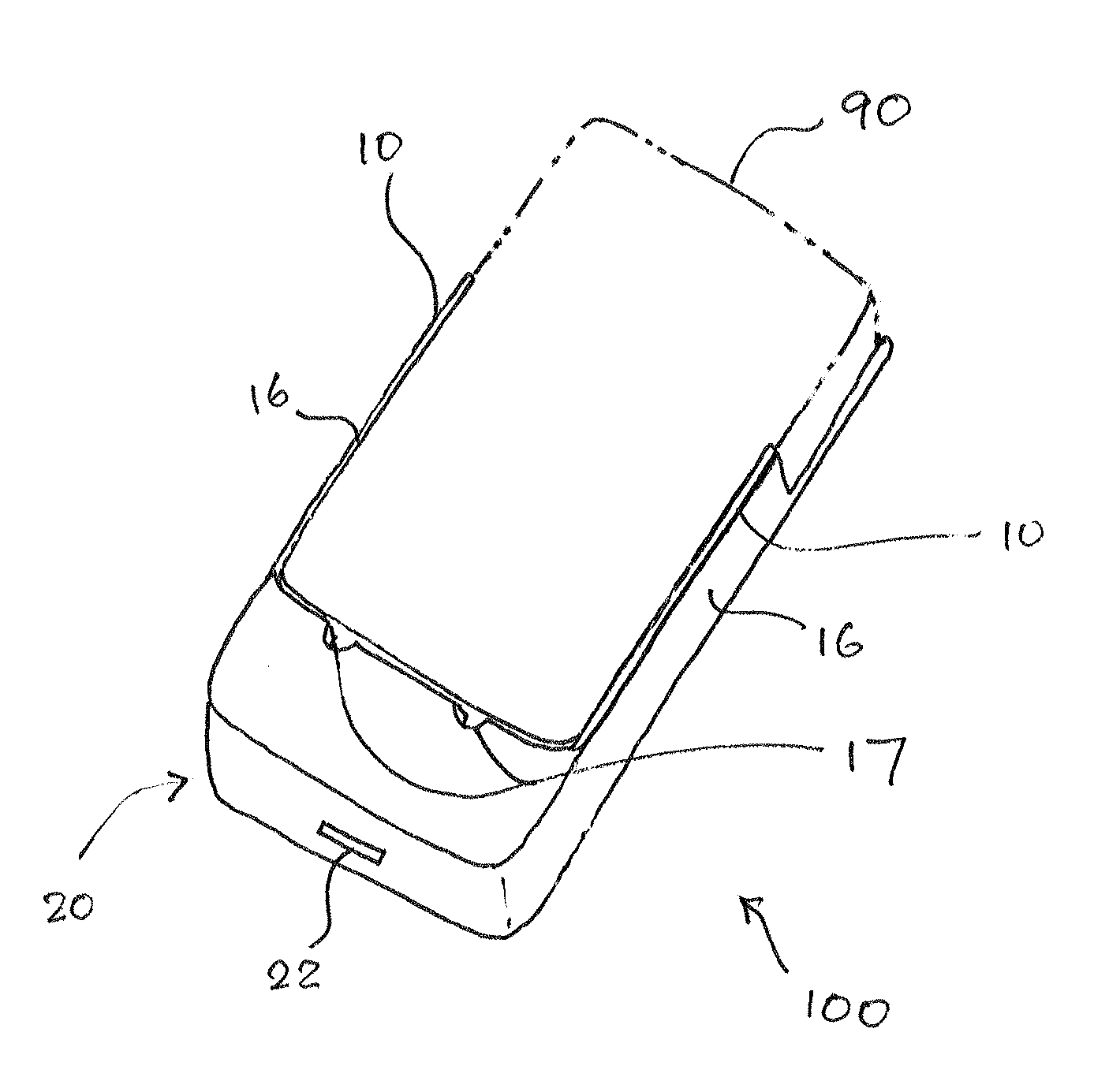

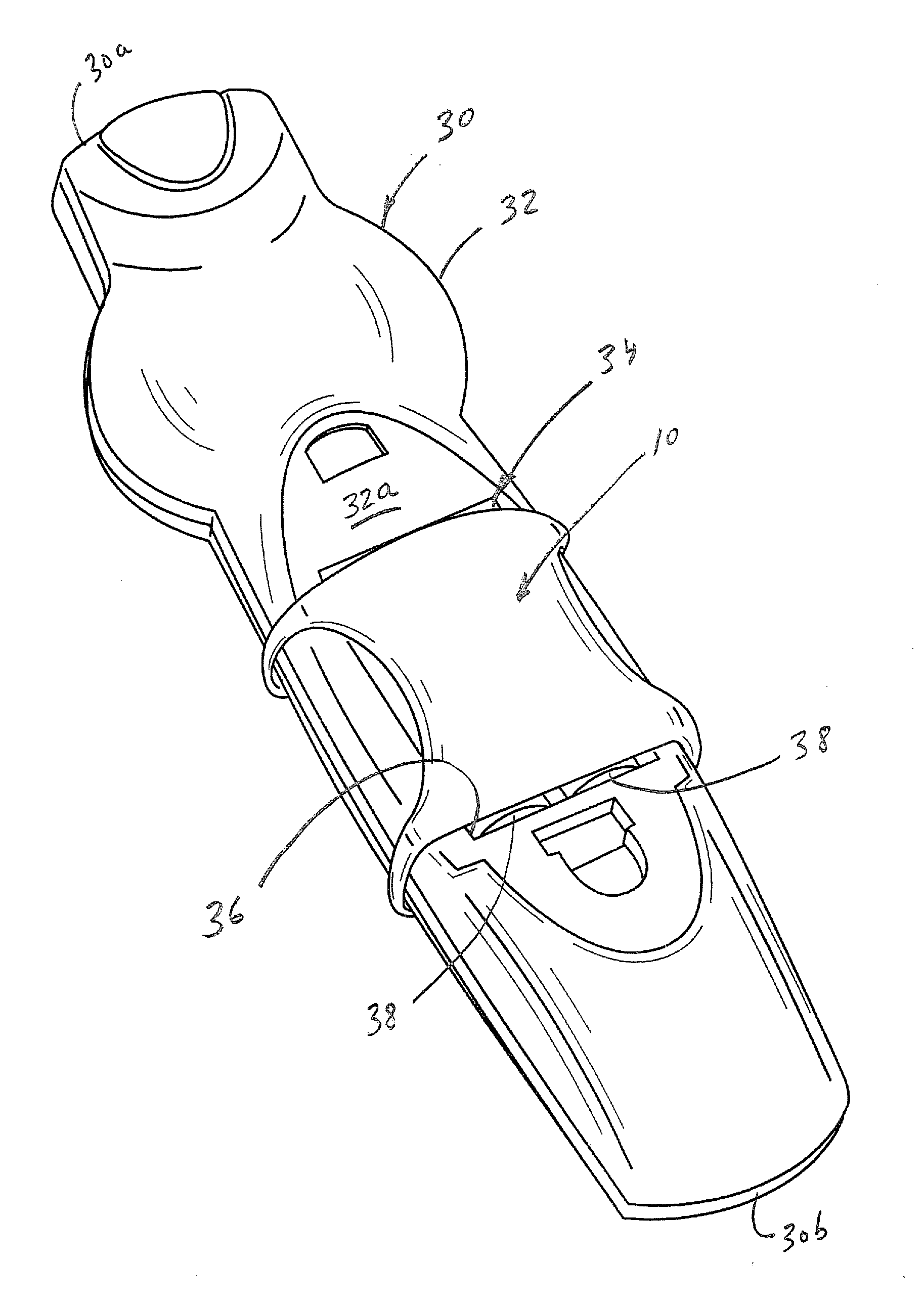

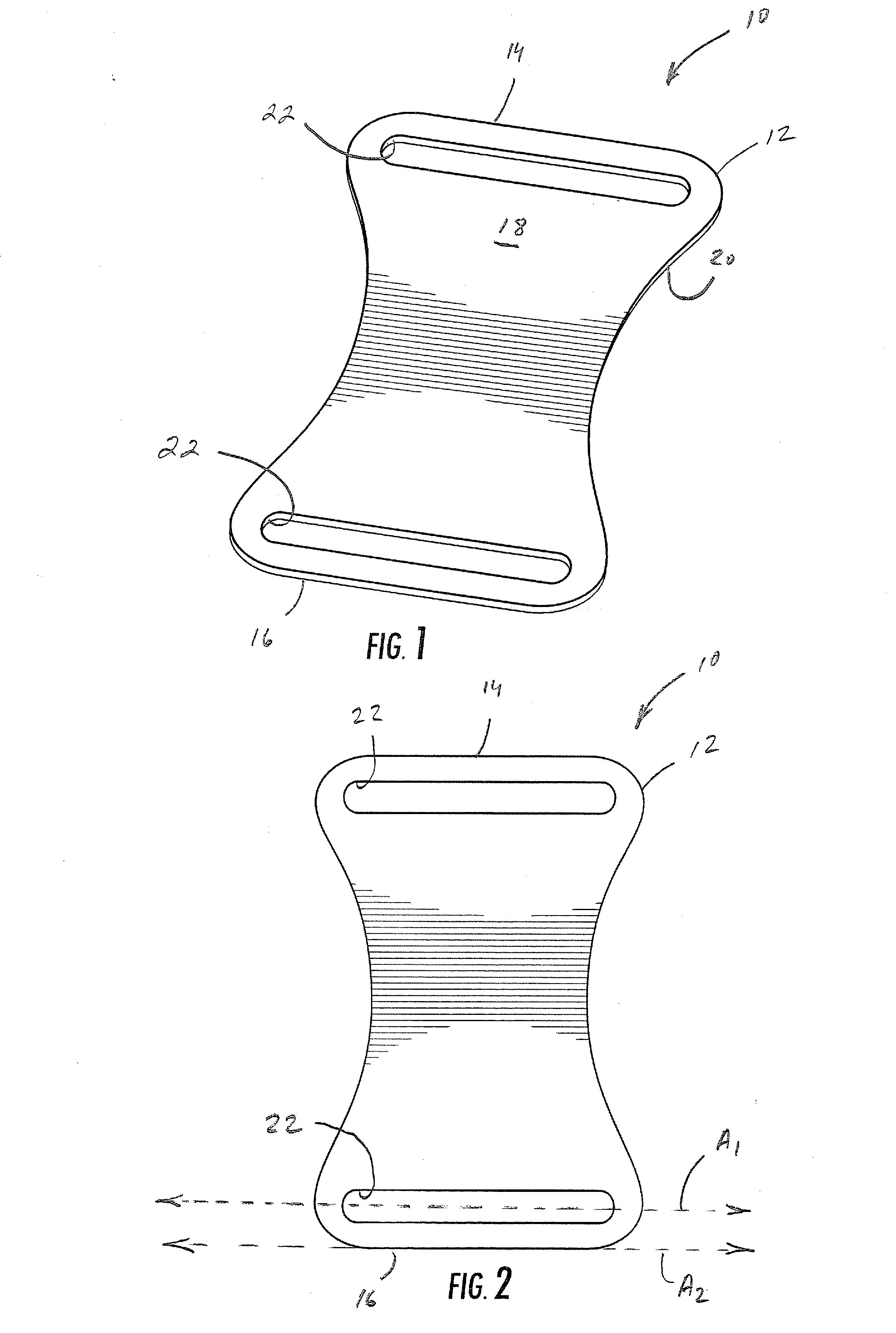

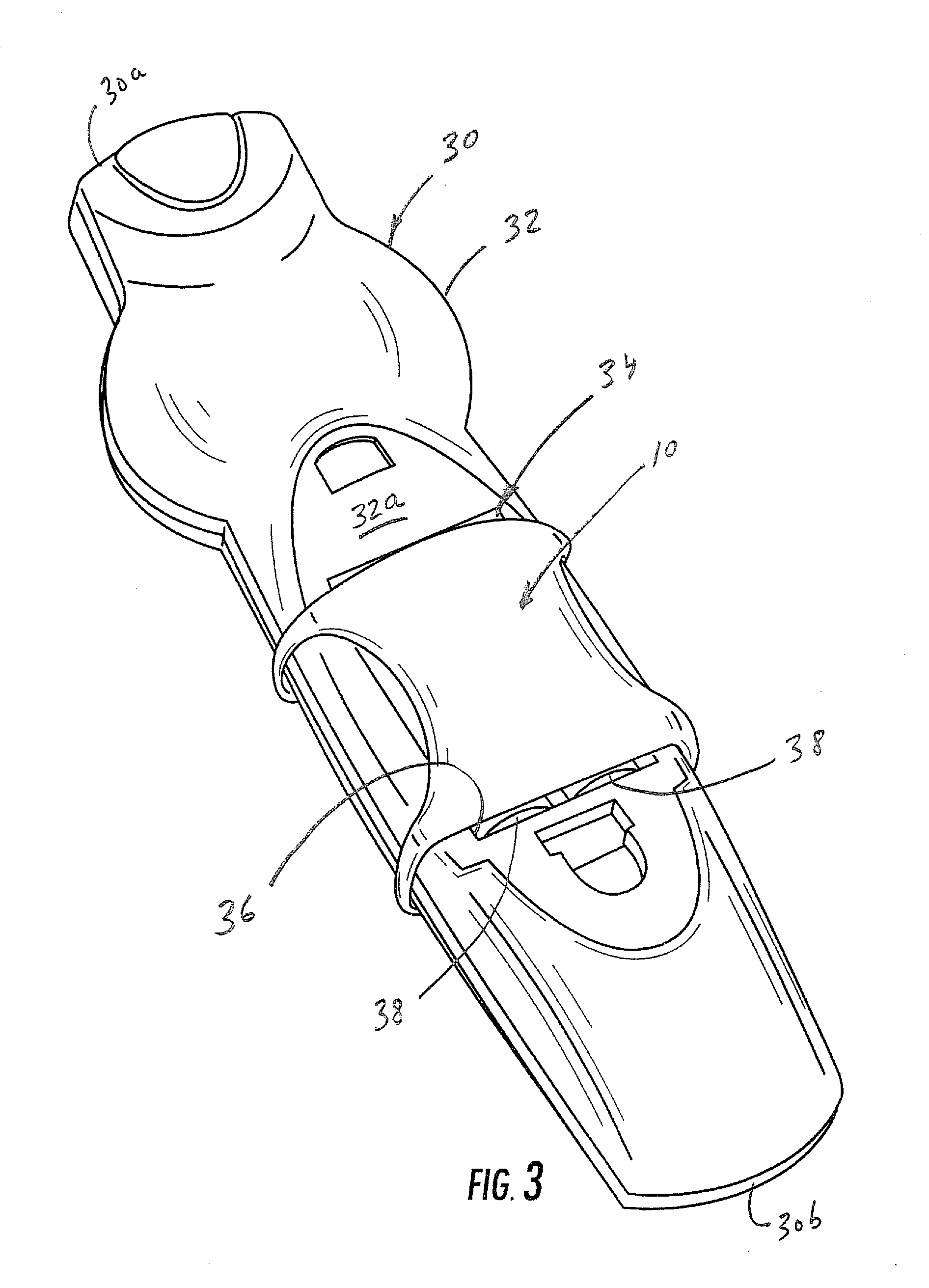

Flexible battery restraint for electronic devices

Owner:PROPEL IP

Nonaqueous secondary battery

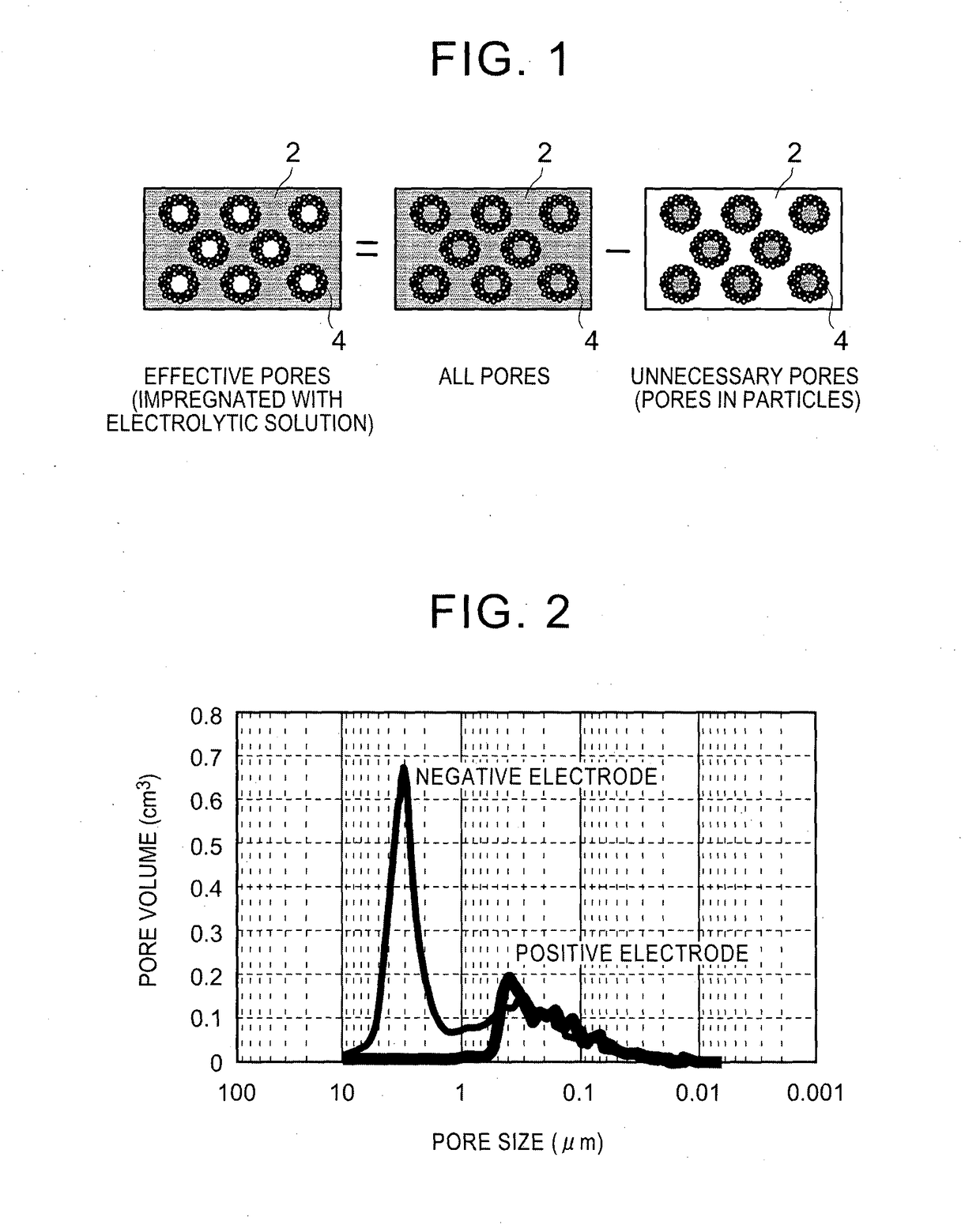

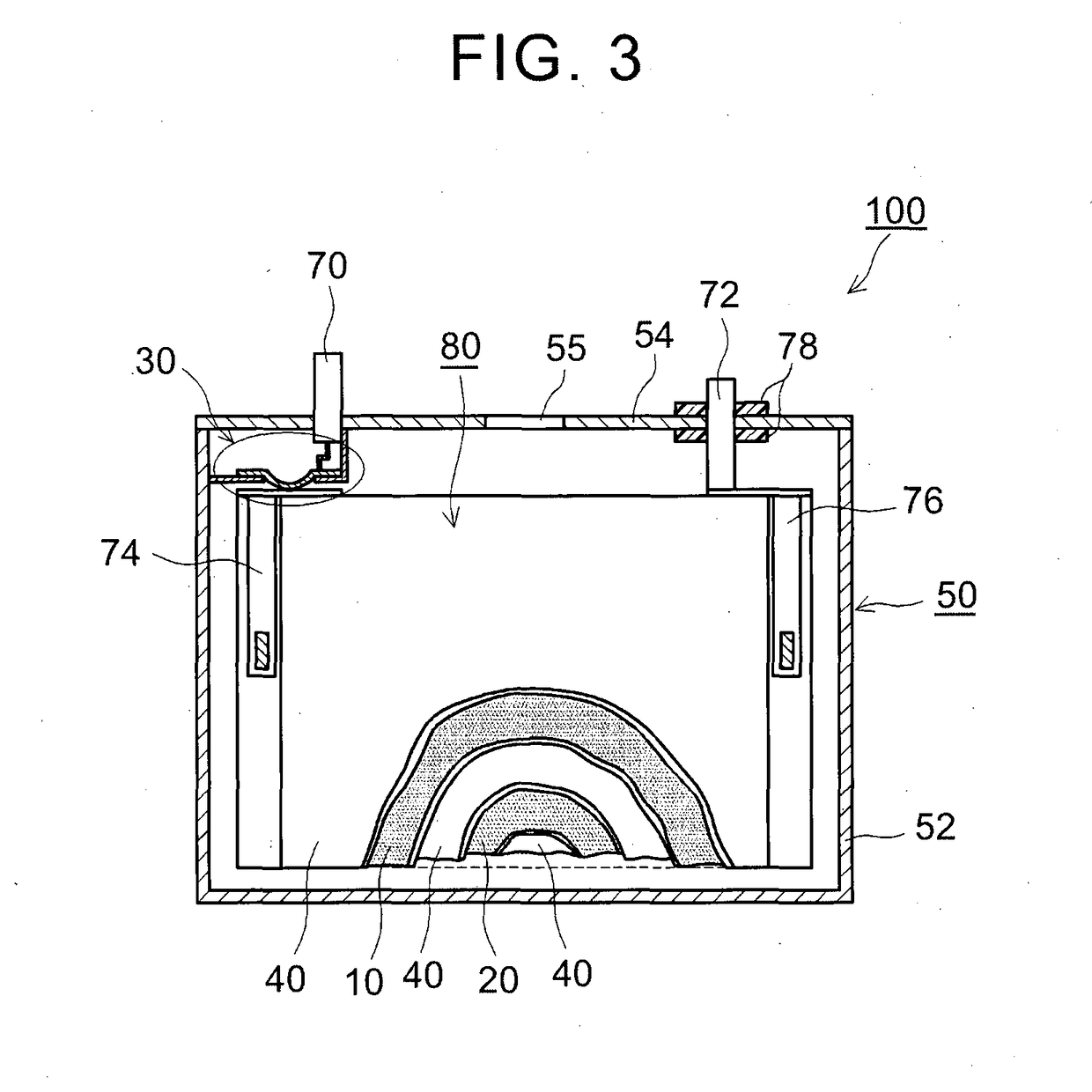

ActiveUS20170077486A1Accurate operationStable controlFinal product manufactureNegative electrodesEngineeringElectrode

Owner:TOYOTA JIDOSHA KK

High breathable polymer coated diaphragm as well as preparation method and application thereof

Owner:湖南烁普新材料有限公司

Fuel Cell System

InactiveUS20080008913A1Increased durabilityImprove reliabilityFuel cells groupingFuel cell auxillariesElectricityExhaust valve

The disclosure describes fuel cell systems including a fuel cell stack that generates electricity, an exhaust valve that externally vents a fuel gas from a fuel chamber of the fuel cell stack, and a controller that computes an estimated time to replace an oxidant gas in at least the fuel chamber with a newly supplied fuel gas, wherein at a time of starting-up the fuel cell system the controller maintains the exhaust valve in an open position for the estimated time. In some embodiments, the controller computes the estimated time as a summation of a first time T1 measured from the fuel cell start-up time to a time when contents of a supply conduit are replaced with fuel gas, a second time T2 measured from the when contents of a supply conduit are replaced with fuel gas to a time when contents of the fuel chamber are replaced with fuel gas, and a third time T3 measured from time when contents of the fuel chamber are replaced with fuel gas to a time when contents of the exhaust conduit are replaced with fuel gas. The disclosure further describes methods of operating a fuel cell system, particularly during fuel cell start-up.

Owner:NISSAN MOTOR CO LTD

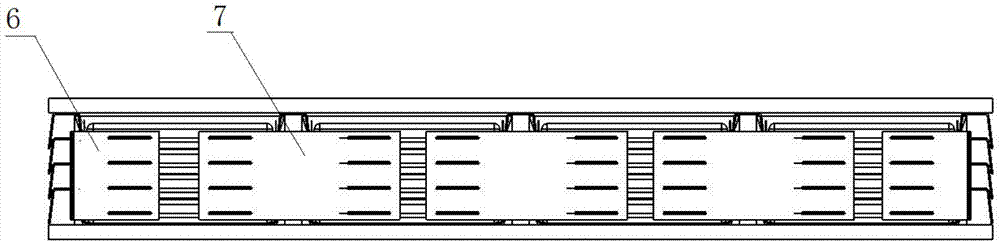

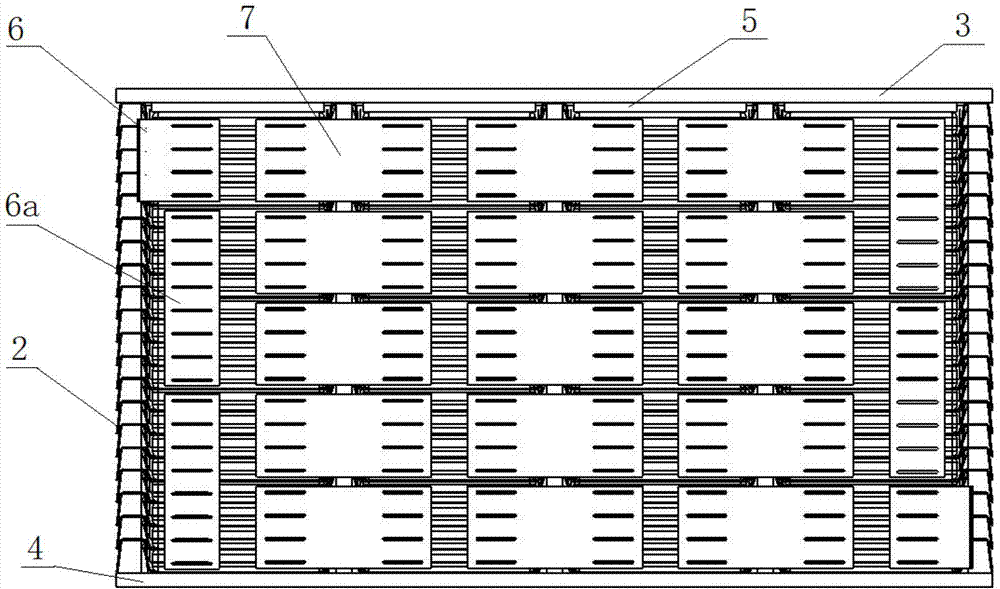

Soft package lithium ion battery module for electric vehicle

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

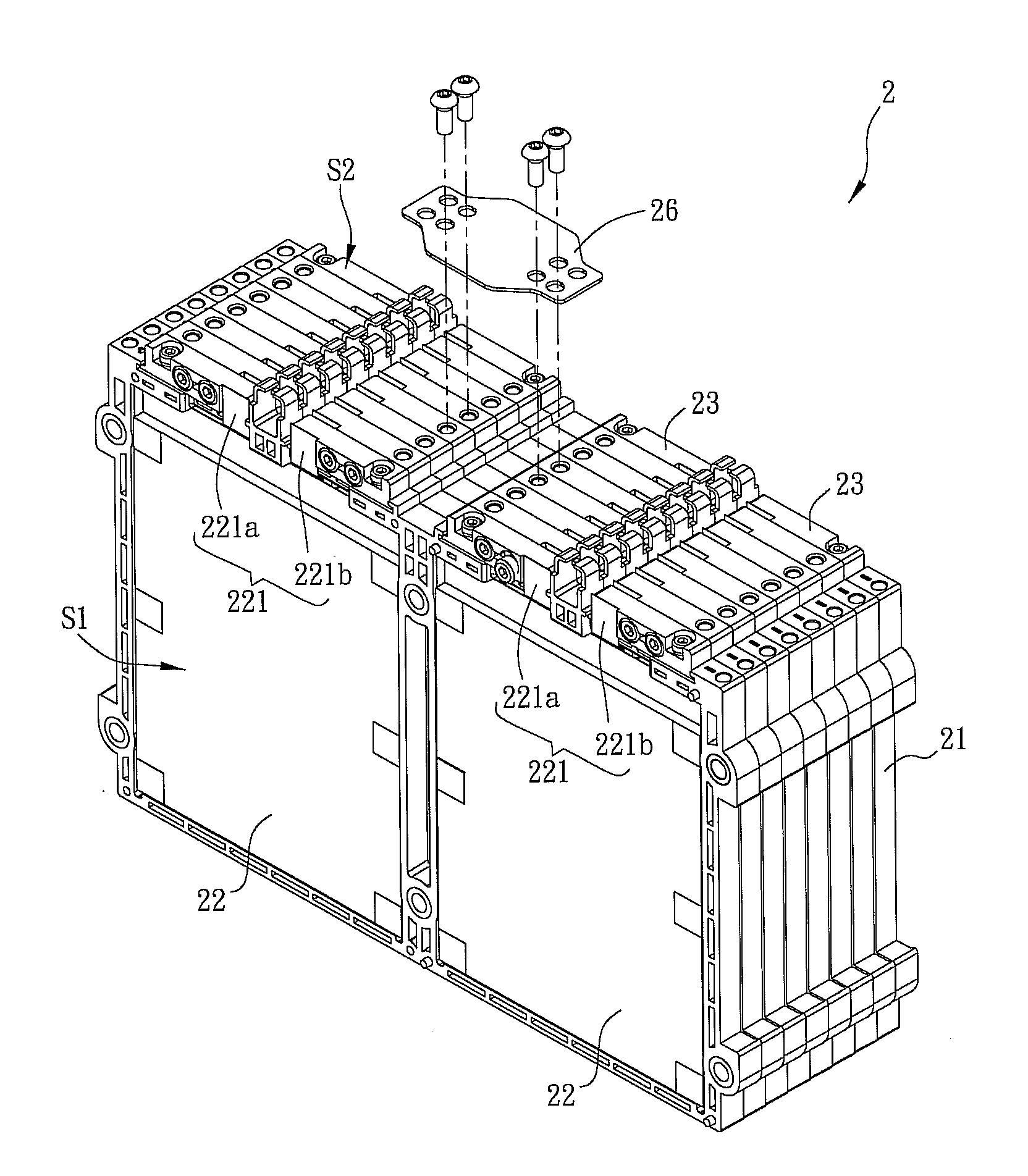

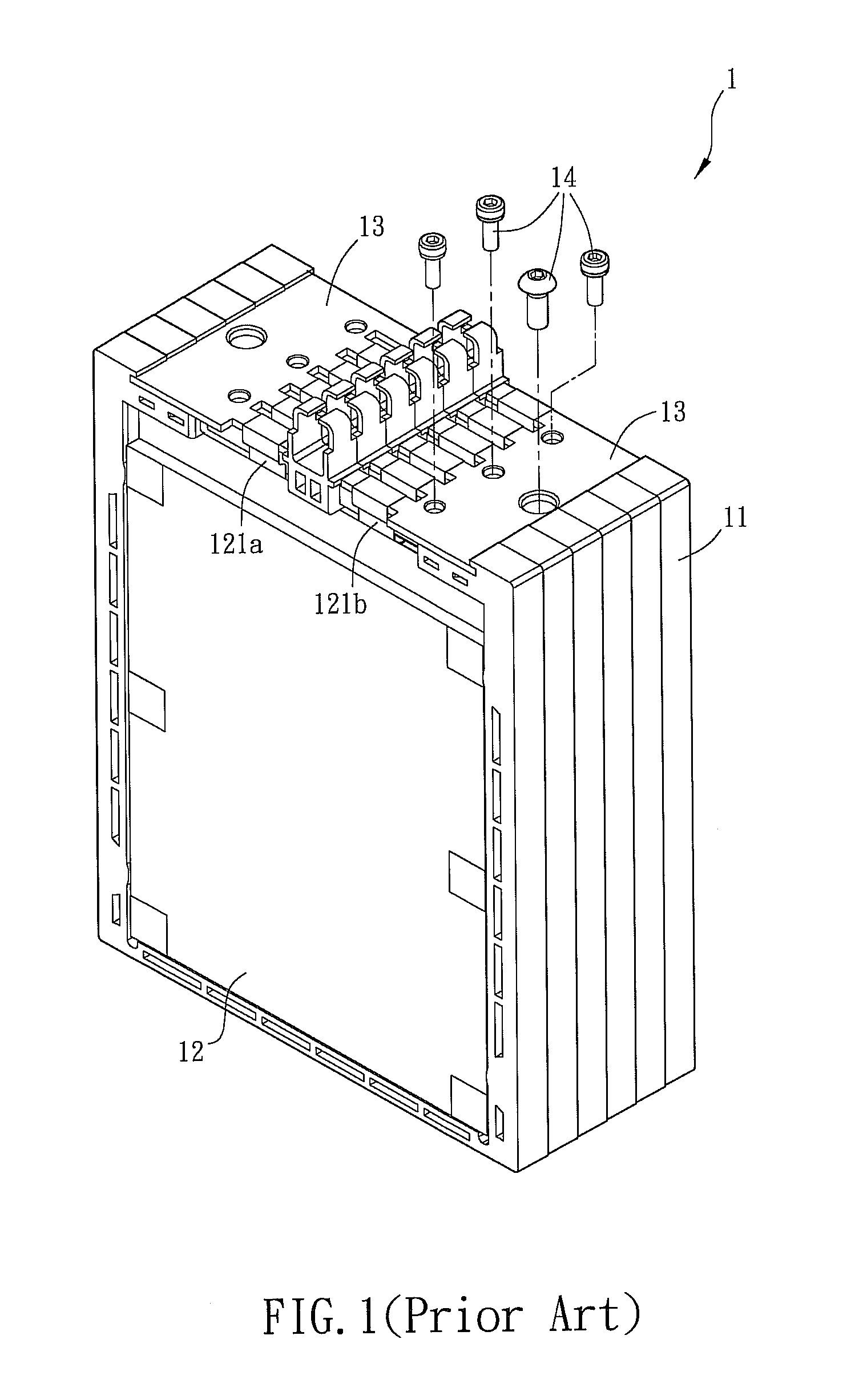

Battery module

InactiveUS20130011718A1Increasing assembling stabilityIncreasing assembling efficiencyPrimary cell to battery groupingCell component detailsElectrical conductor

Owner:DELTA ELECTRONICS INC

Process and corresponding apparatus for continuously producing gaseous hydrogen to be supplied to micro fuel cells and integrated system for producing electric energy

A process for the production of hydrogen for micro fuel cells, comprises the successive steps of: continuously supplying a catalytic bed with an aqueous solution of sodium borohydride, the catalytic bed being made of at least one metal chosen among cobalt, nickel, platinum, ruthenium with obtainment of hydrogen and of a by-product comprising sodium metaborate, continuously recovering the hydrogen thus obtained and supplying, with said hydrogen as it is as obtained, a micro fuel cell which transforms hydrogen into electric energy. An apparatus provides continuous supply of hydrogen to a micro fuel cell. An integrated system structured for continuously producing and supplying hydrogen to a micro fuel cell and for converting the continuously supplied hydrogen into electric energy.

Owner:STMICROELECTRONICS SRL

Fuel cell

InactiveUS20120009498A1Complex structureLow costFuel cells groupingCell component detailsCross-linkFuel cells

A fuel cell is provided with a separator that supports an electrolyte / electrode assembly sandwiched therebetween. The separator is provided with: first and second fuel gas supply parts in the center of which fuel gas supply holes are formed; first and second cross-link parts connected to the first and second fuel gas supply parts; and first and second surrounding support parts connected to the first and second cross-link parts. Each first surrounding support part is provided with a set of fuel gas exhaust passages that discharge fuel gas that has gone through a fuel gas passage and been used. The cross-sectional areas of the fuel gas exhaust passages are larger on the downstream sides than on the upstream sides, in terms of the direction of fuel gas flow.

Owner:HONDA MOTOR CO LTD

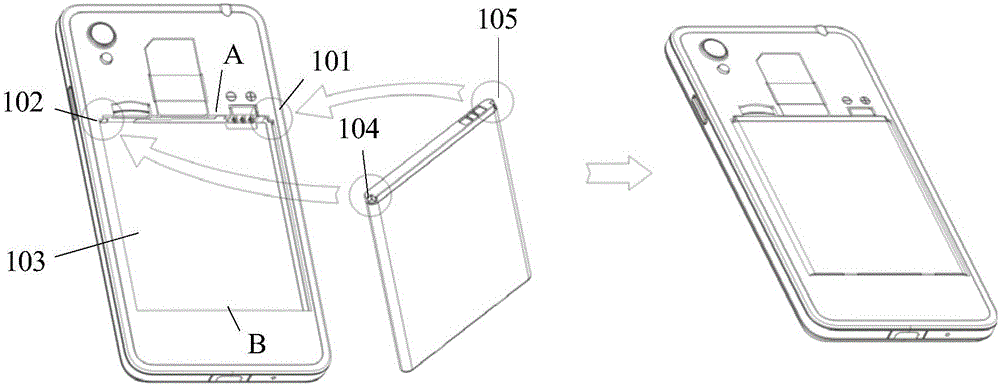

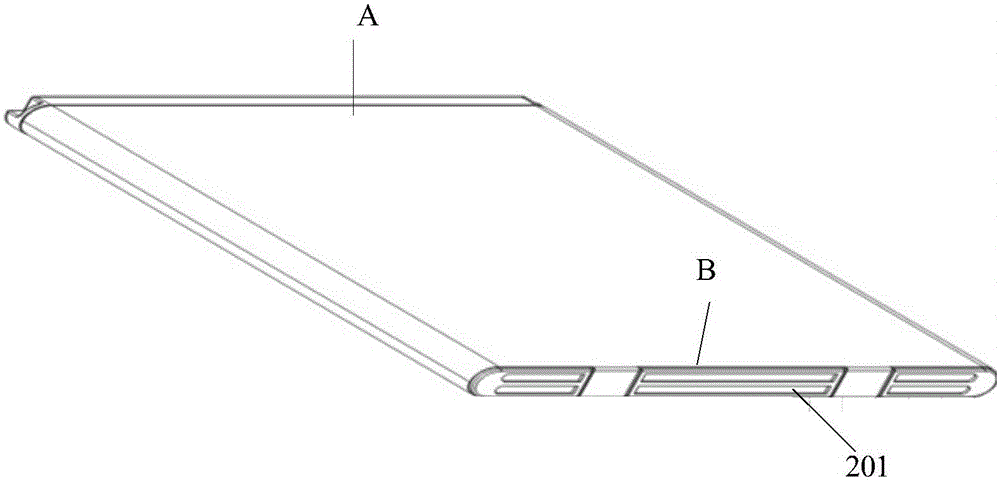

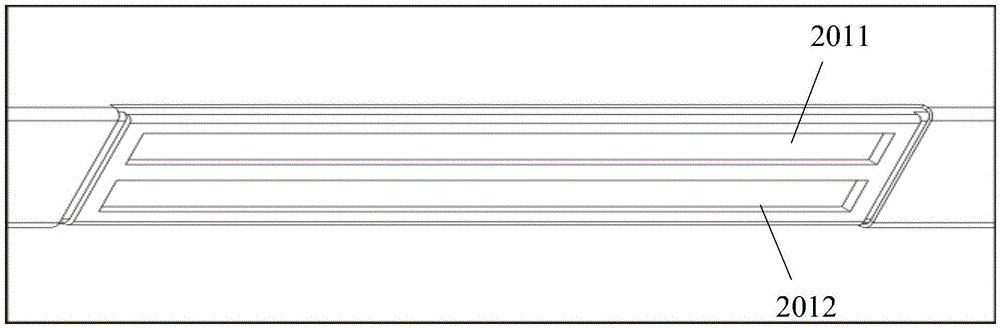

Battery, telescoping device, shell, and battery fixing system

ActiveCN105826491AImprove reliabilityReduce the number of abnormal power outagesCell component detailsTelephone set constructionsElectrical batteryElectrical and Electronics engineering

Owner:VIVO MOBILE COMM CO LTD

Battery separator

InactiveUS6586137B1Avoid breakingIncrease resistanceAlkaline accumulatorsCell component detailsYoung's modulusEngineering

Owner:NIPPON BAIRIIN

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap