Lithium ion battery pack and soldering method for single batteries therein

A technology for lithium-ion battery packs and single cells, which is applied to battery pack components, welding equipment, non-aqueous electrolyte batteries, etc. Avoid the effect of bloating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

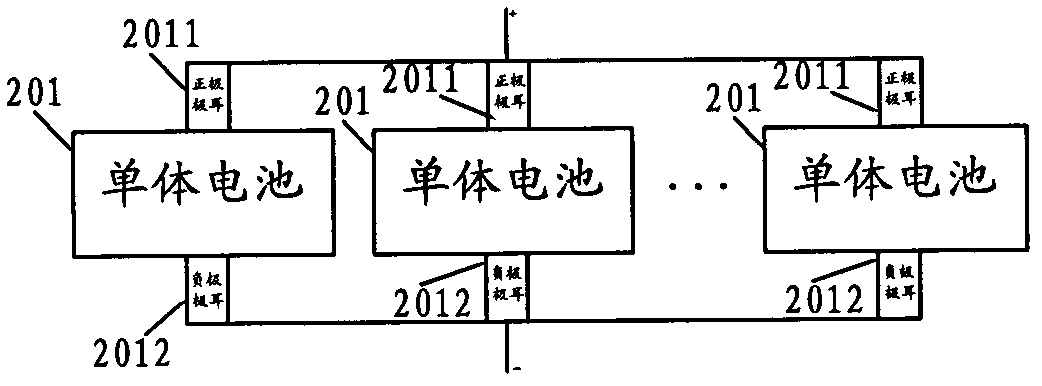

[0052] The lithium-ion battery pack provided in this embodiment is composed of a plurality of single cells. Each single cell can be as figure 2 The lithium-ion battery pack is formed by connecting in parallel with each other as shown: the positive tabs 2011 and the positive tabs 2011 of any two single batteries 201 are welded to each other, and the negative tabs 2012 and 2012 are welded to each other. Finally: the positive tabs 2011 of all single cells 201 serve as the positive poles of the lithium-ion battery pack, and the negative tabs 2012 of all single cells 201 serve as the negative poles of the lithium-ion battery pack to provide external power supply.

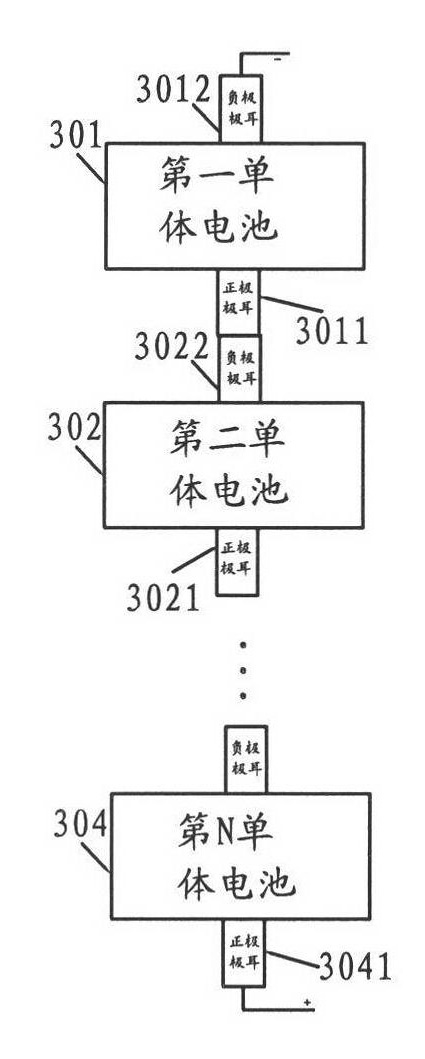

[0053] Each single battery can also be as image 3 The lithium-ion battery pack is formed in series with each other as shown: the positive pole tab 3011 of the first unit battery 301 is welded to the negative pole tab 3022 of the second unit battery 302, and the positive pole tab 3021 of the second unit battery 302 is con

Embodiment 2

[0069] Similar to Embodiment 1, the lithium-ion battery pack provided in this embodiment is composed of a plurality of single cells. Each single cell can be as figure 2 The lithium-ion battery packs shown are connected in parallel with each other. Each single cell can also be as image 3 The lithium-ion batteries shown are connected in series with each other.

[0070] In the lithium-ion battery pack of this embodiment, no matter whether it adopts a plurality of single cells connected in parallel or in series, the welding structure of any two interconnected tabs of any two single cells is as follows: Figure 4 shown.

[0071] The two mutually welded tabs of any two single cells are recorded as the first tab 4011 and the second tab 4021. The welding connection method of the first tab 4011 and the second tab 4021 mainly includes the following steps:

[0072] Step 501 : Pad a rigid plate 404 on the back of the horizontally bent sections of the first tab 4011 and the second tab 4

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap