Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Battery pack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A battery pack is a set of any number of (preferably) identical batteries or individual battery cells. They may be configured in a series, parallel or a mixture of both to deliver the desired voltage, capacity, or power density. The term battery pack is often used in reference to radio-controlled hobby toys and battery electric vehicles.

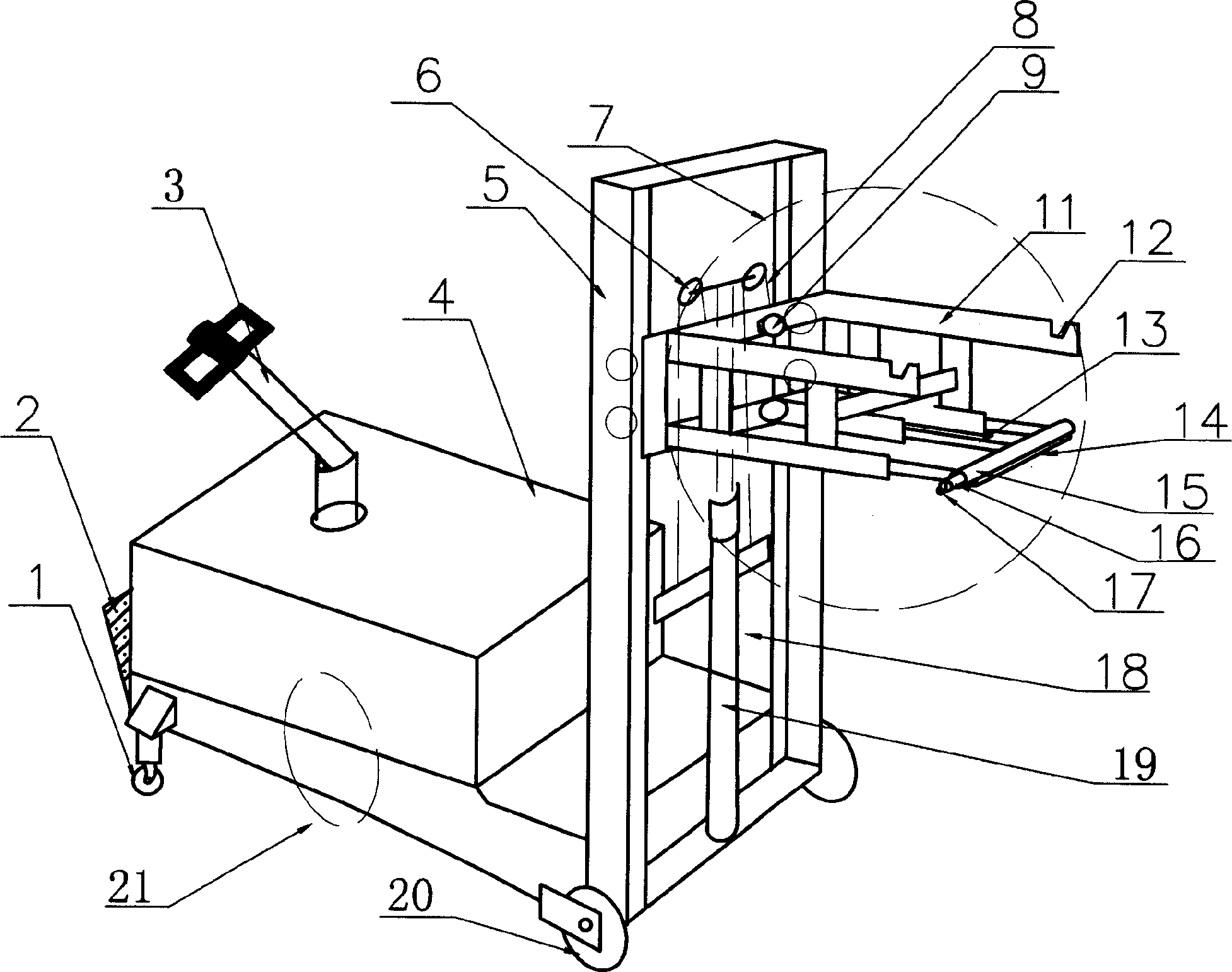

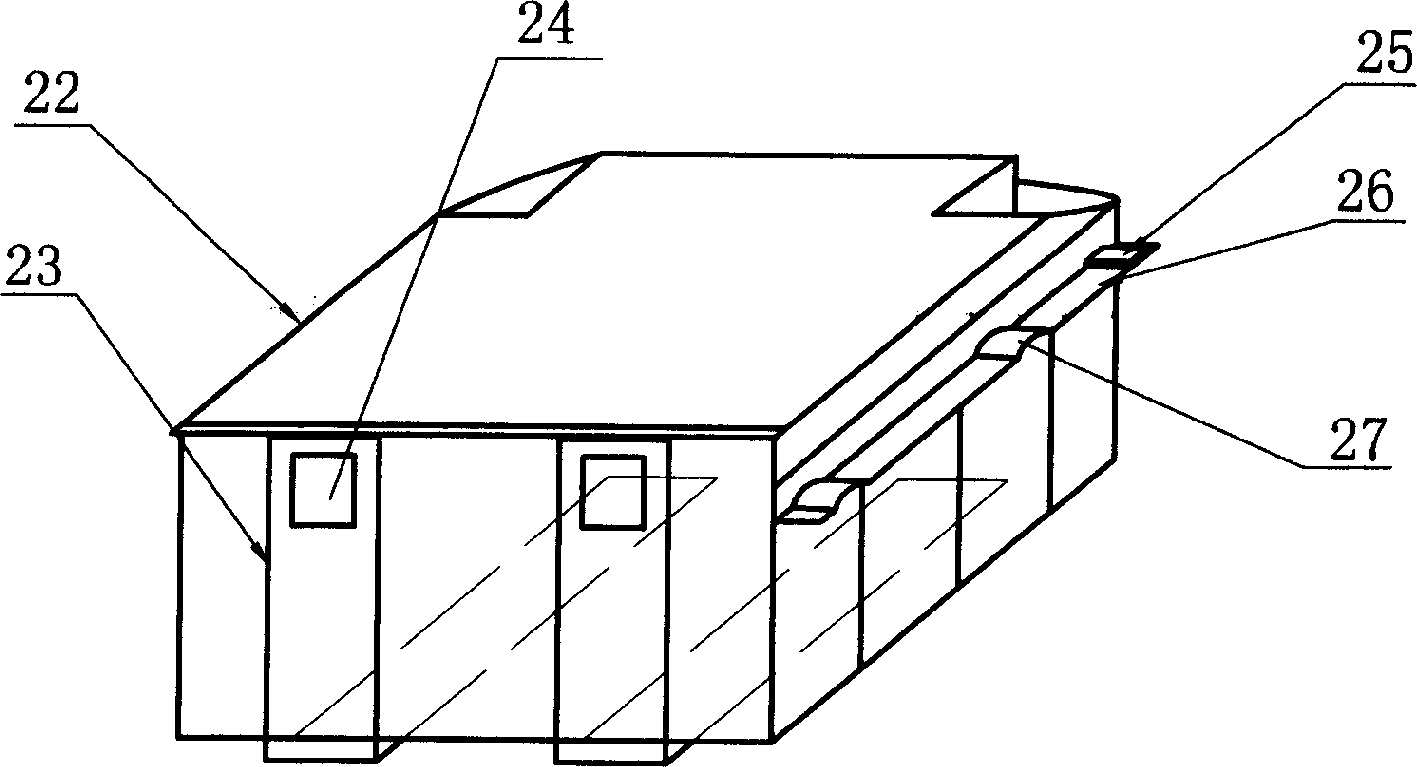

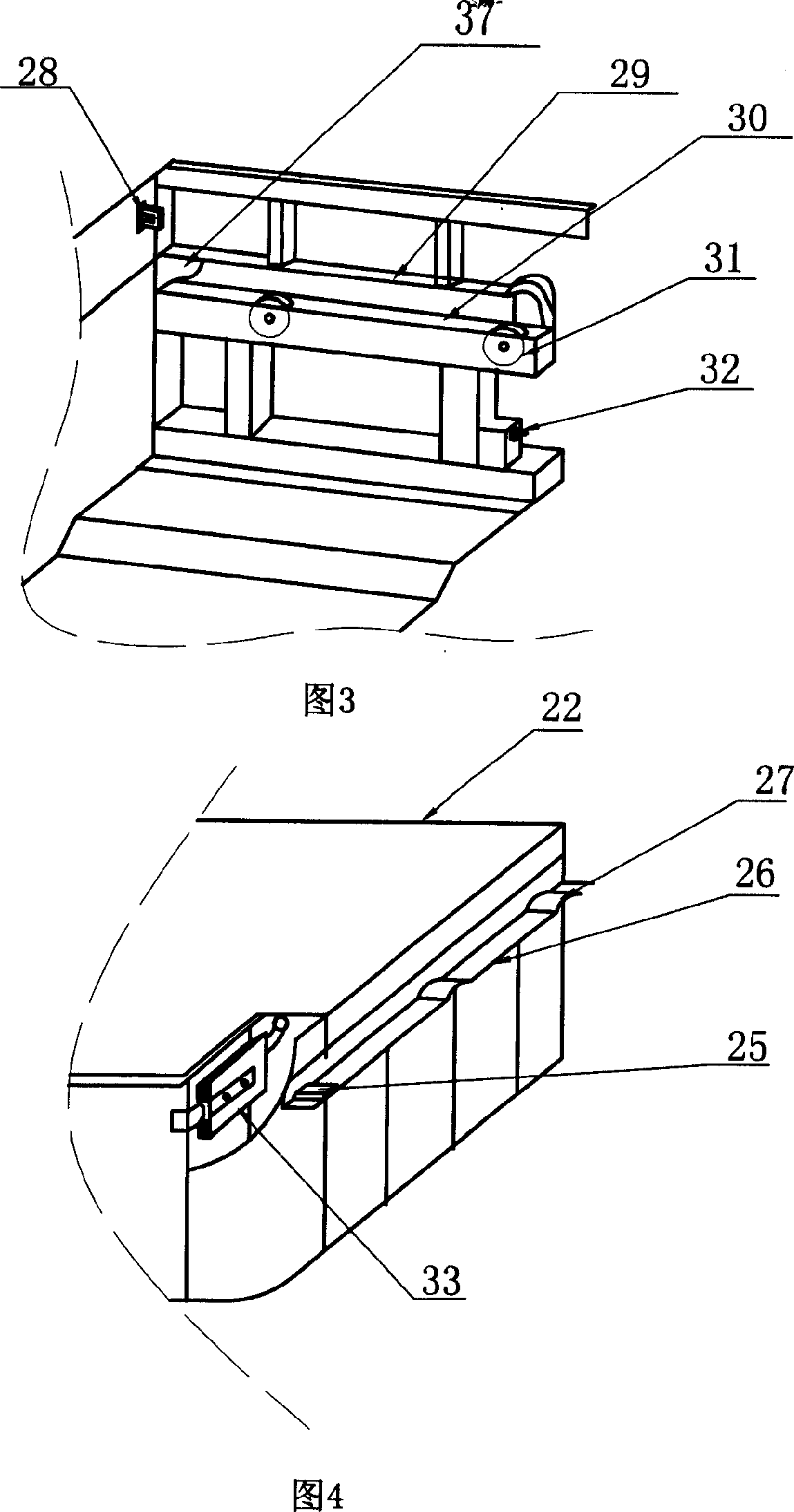

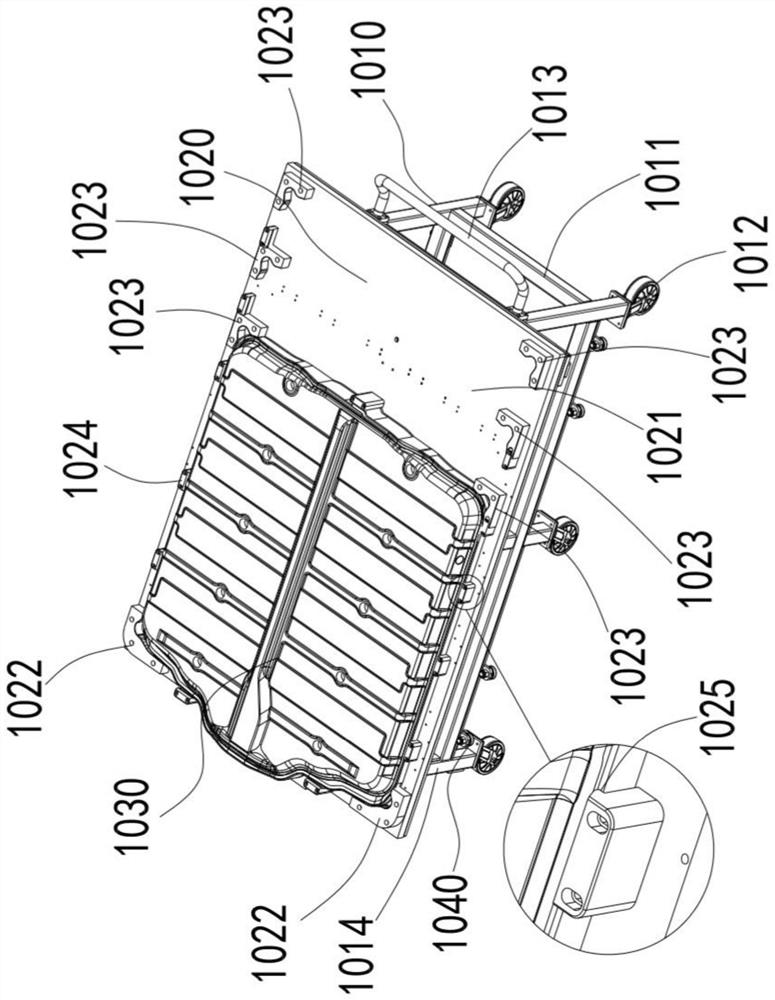

Electric car battery set unloading vehicle, and its track type battery holder and built-in type battery holder

InactiveCN1789048AEasy loading and unloadingImprove convenienceElectric propulsion mountingElectric vehicle charging technologyBogieElectrical battery

Owner:万向电动汽车有限公司

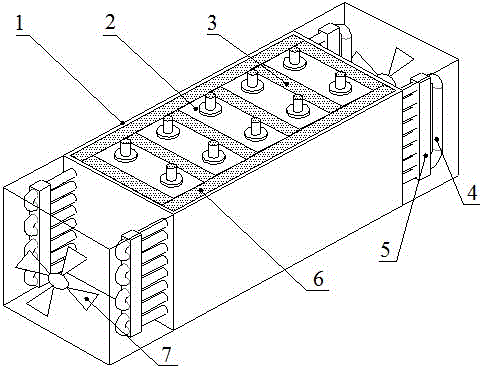

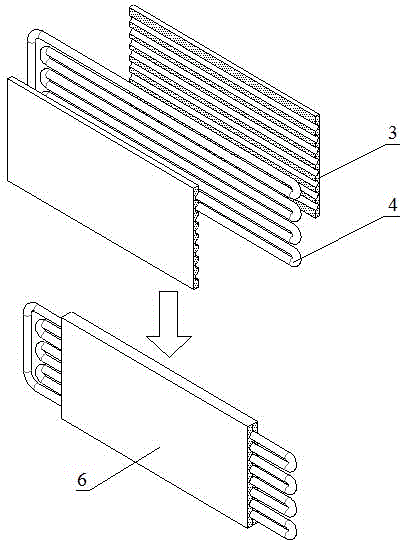

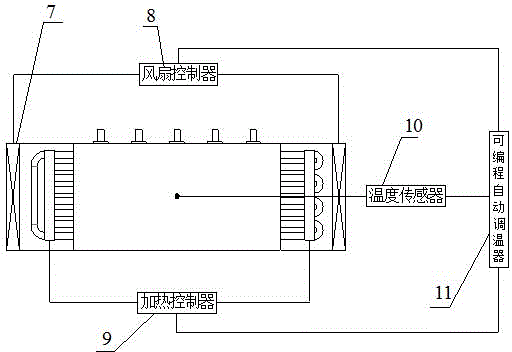

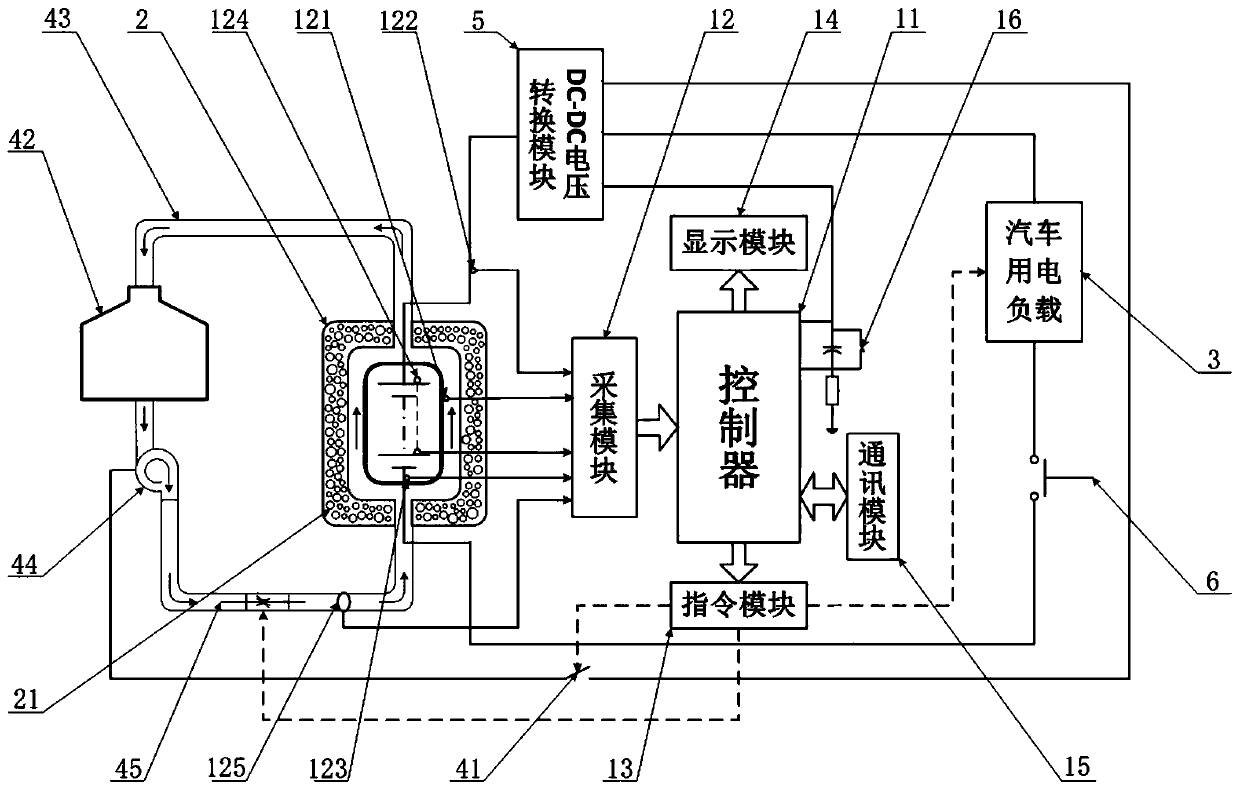

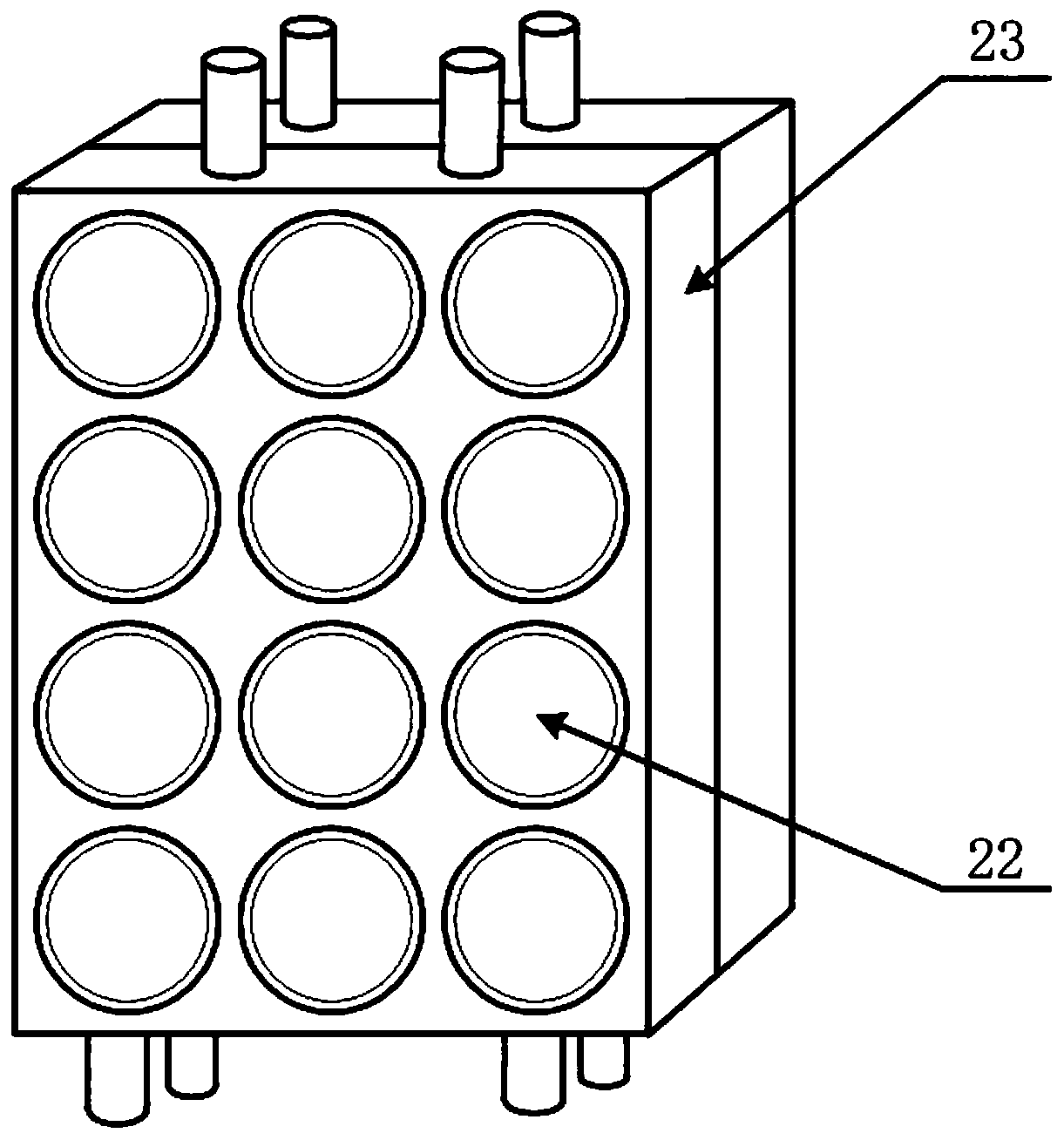

Power battery thermal management system with functions of efficient heat dissipation and efficient heating

InactiveCN106033827AEfficient dischargeAchieve temperature control effectSecondary cellsBatteriesAutomotive batteryElectrical battery

Owner:广东万锦科技股份有限公司

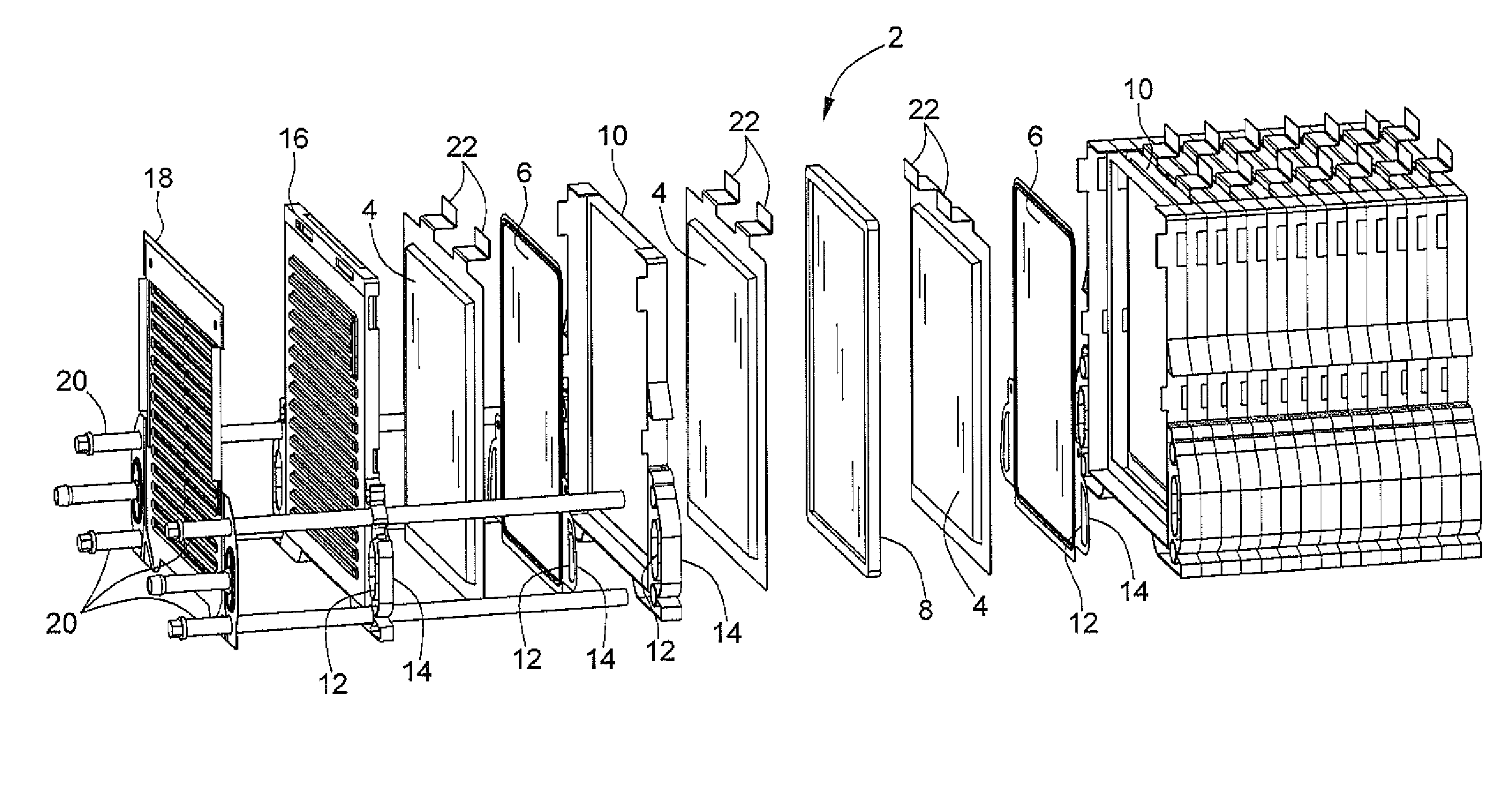

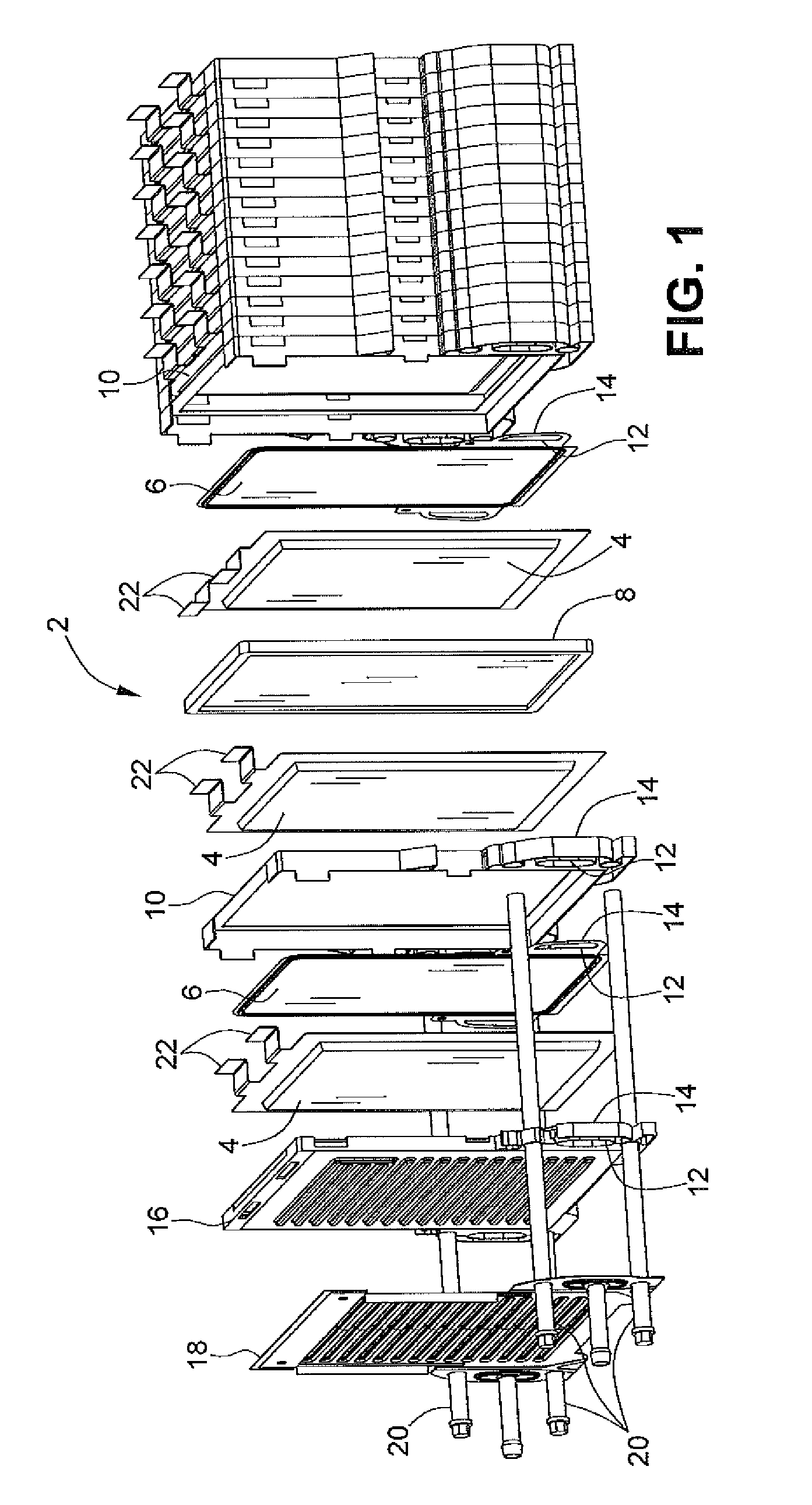

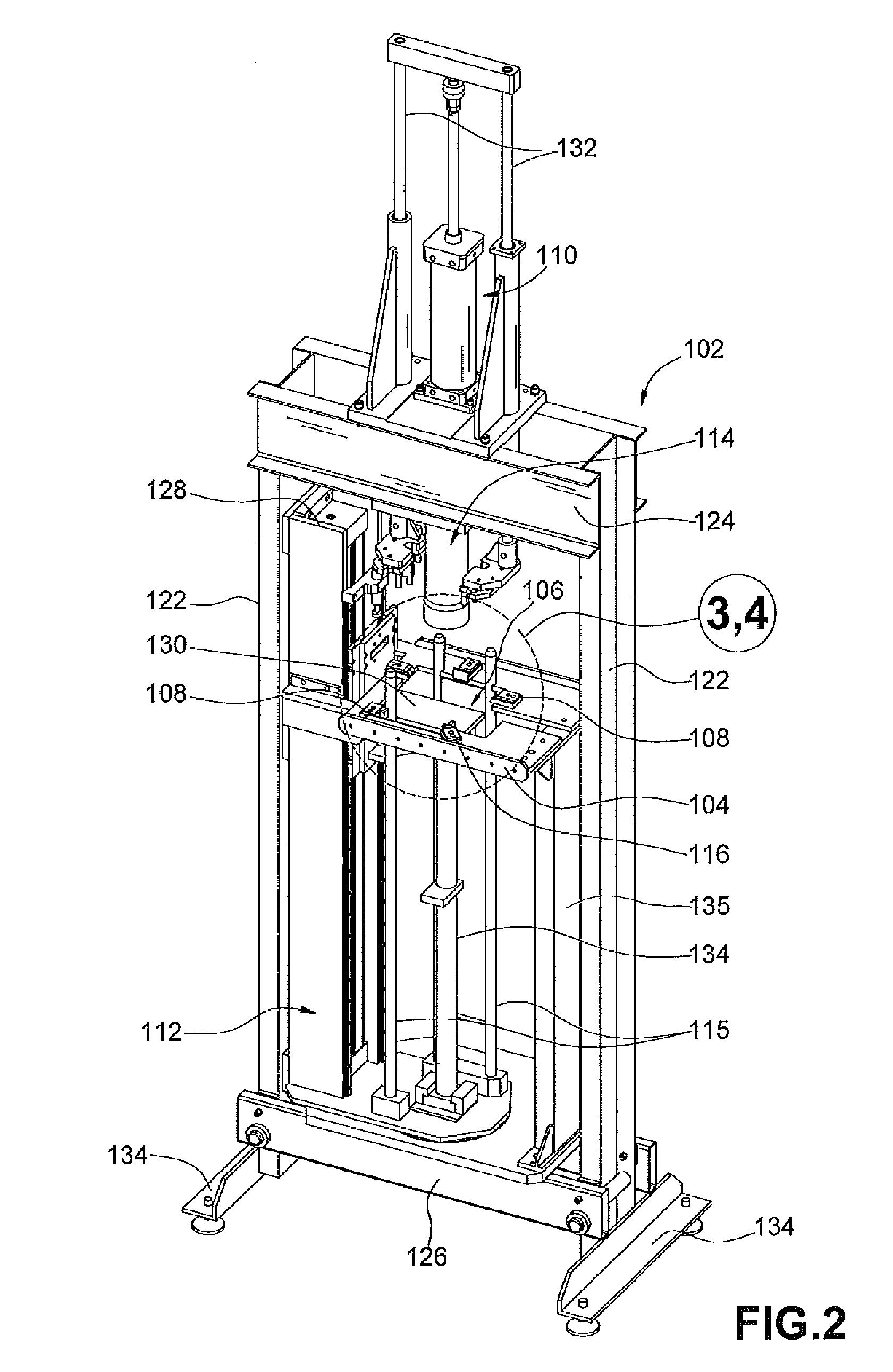

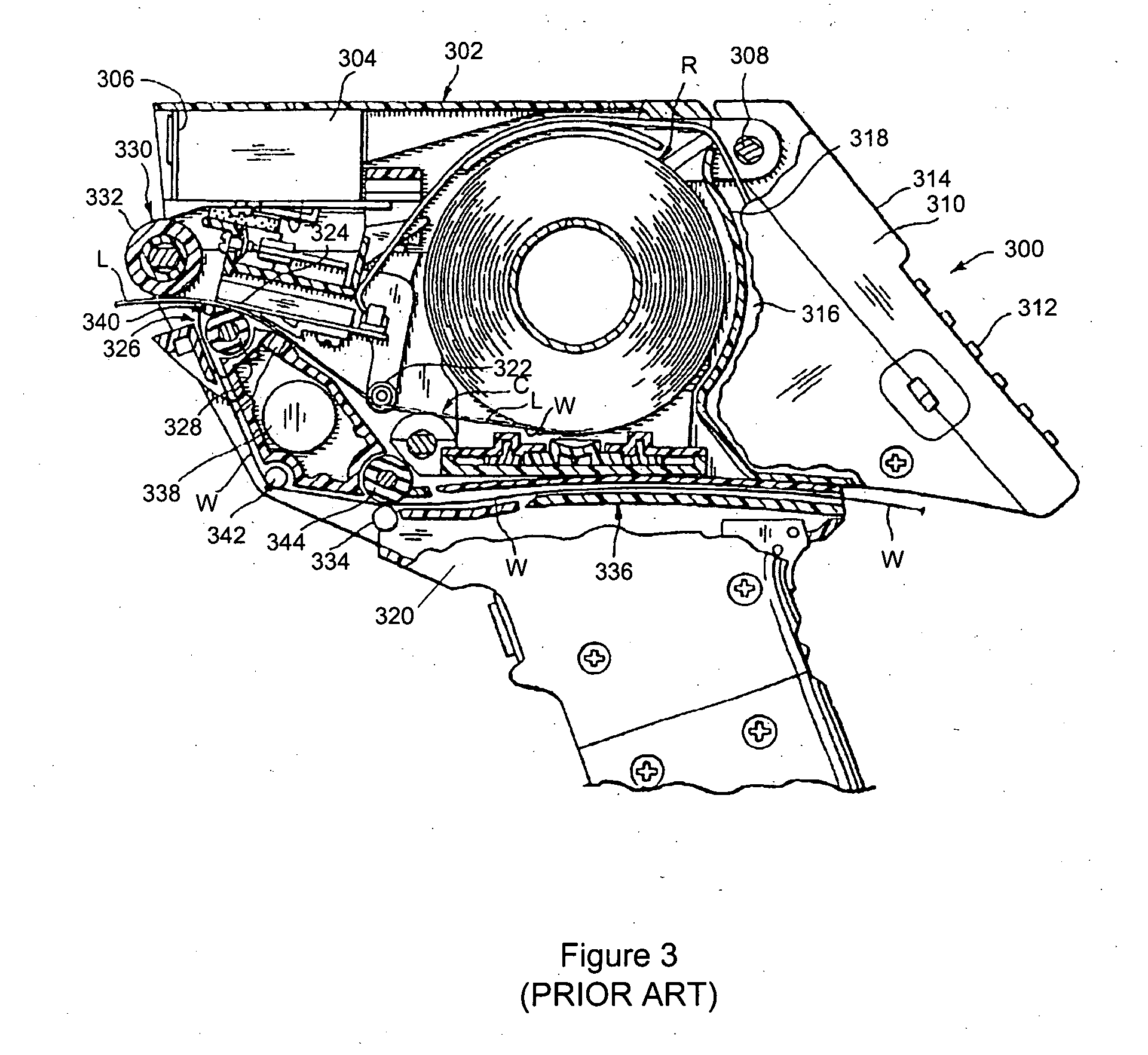

Press apparatus

InactiveUS20100306995A1Maintaining dimensional qualityAssembling battery machinesElectrode carriers/collectorsEngineeringBattery pack

Owner:GM GLOBAL TECH OPERATIONS LLC

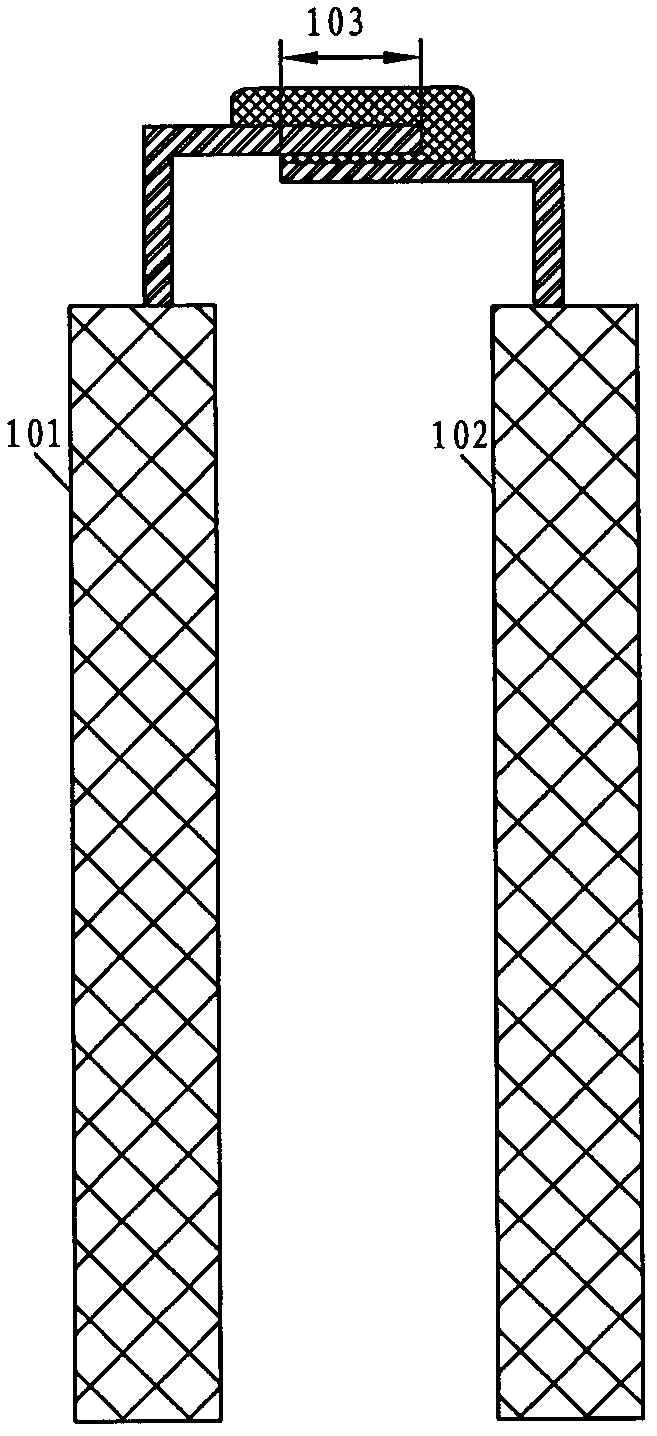

Lithium ion polymer battery pack assembling structure and assembling method

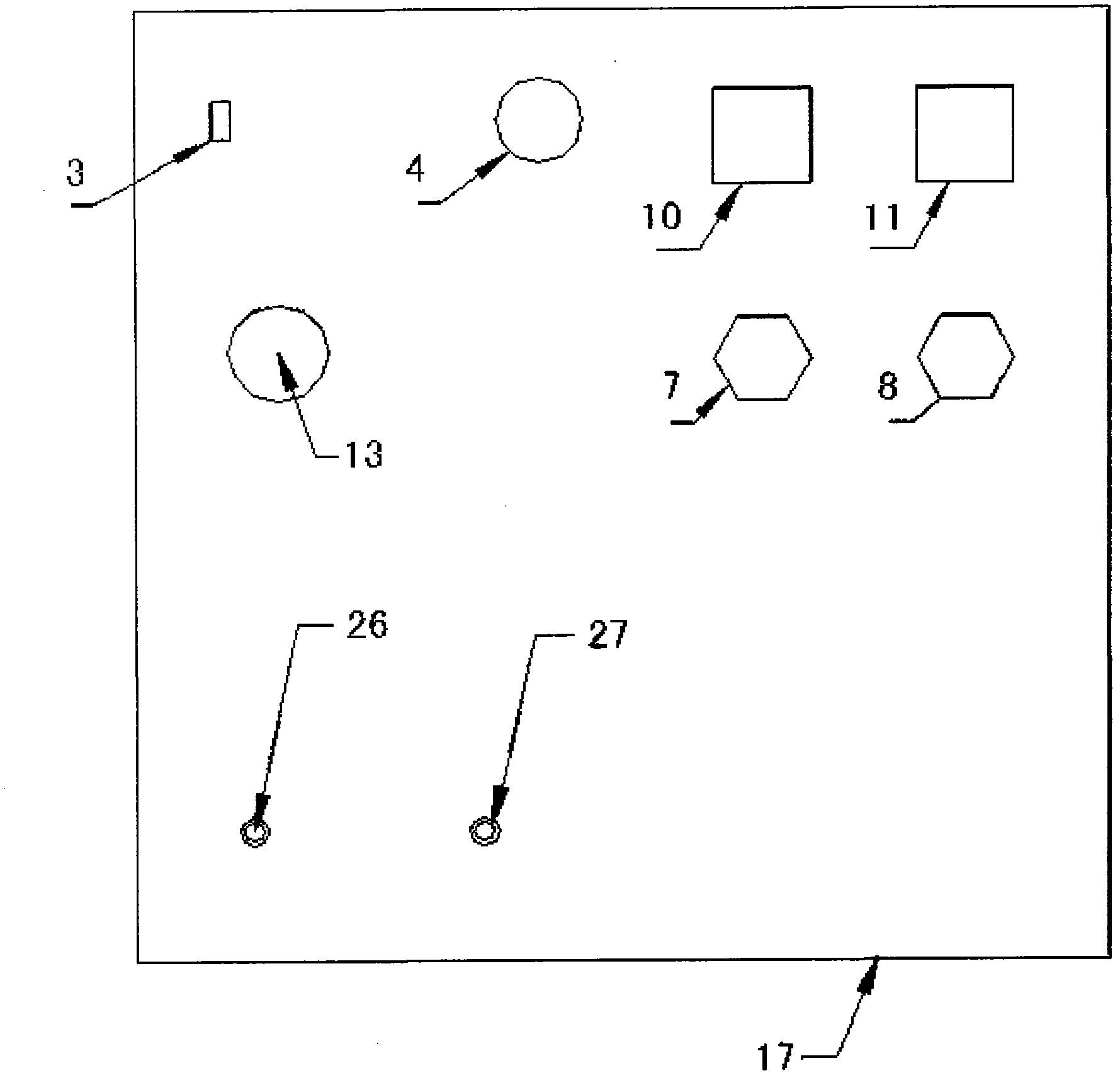

The invention discloses a lithium ion polymer battery pack assembling structure and an assembling method, which relate to a battery pack assembling structure and an assembling method. A lithium ion polymer battery is used in combination with a shell, it is difficult to replace a single battery in a battery pack once the single battery goes wrong, and the traditional assembling structure has no space for battery deformation and has a short service life. The lithium ion polymer battery pack assembling structure is characterized in that: adjacent batteries are isolated by an assembling bracket which is cuboid, a rectangular battery accommodating chamber is formed on the middle part of the assembling bracket, a side frame part of the assembling bracket is arranged on the periphery of the battery accommodating chamber which is matched with a battery groove, the side frame part is matched with a battery fixing part, and the height of the assembling bracket is greater than the thickness of the battery; and connection holes are formed on the four corners of the assembling bracket, lugs of the battery extend outside the side frame part of the assembling bracket, and the positive and negative lugs of the battery are bent and overlapped. The assembling bracket is arranged out of the battery pack for protection, a welding mode is avoided to prevent welding defective products, assembling and dismantling are convenient, the defective battery can be conveniently exchanged, the expansion factor of the battery is taken into consideration, and the service life of the product is prolonged.

Owner:WOLONG ELECTRIC GRP CO LTD +1

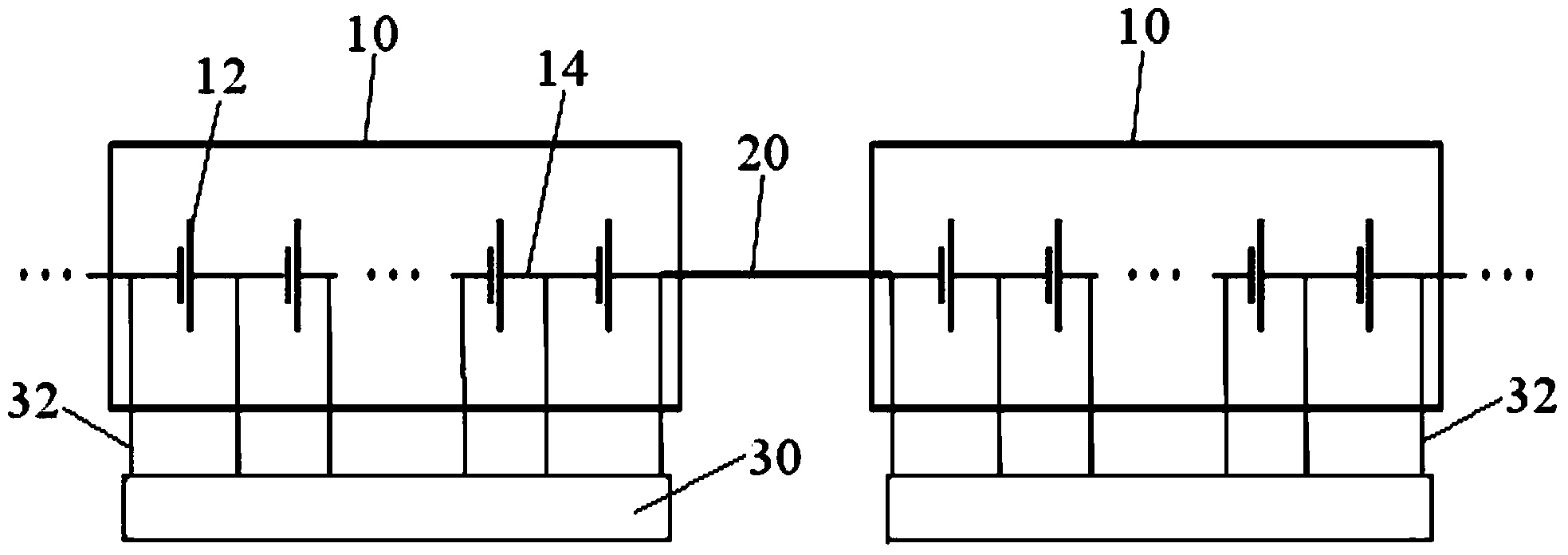

Solar cell module

InactiveCN104868841APhotovoltaicsPhotovoltaic energy generationElectrical resistance and conductanceElectrical battery

The invention relates to a solar cell module. The solar cell module comprises at least two battery packs. The battery packs are connected in series. Each battery pack comprises at least two battery piece tandems which are connected in parallel. Each battery piece tandem comprises at least two battery pieces which are connected in series. In the same battery piece tandem, two adjacent battery units are overlapped and connected in series. By using the solar cell module, the adjacent battery pieces are overlapped and connected so that arrangement of the battery pieces in the battery piece tandem is tight and an area which does not generate power is small. Besides, the adjacent battery pieces are overlapped and connected so that a conductive contact area is large and resistor losses are reduced.

Owner:GCL SYST INTEGRATION TECH CO LTD +2

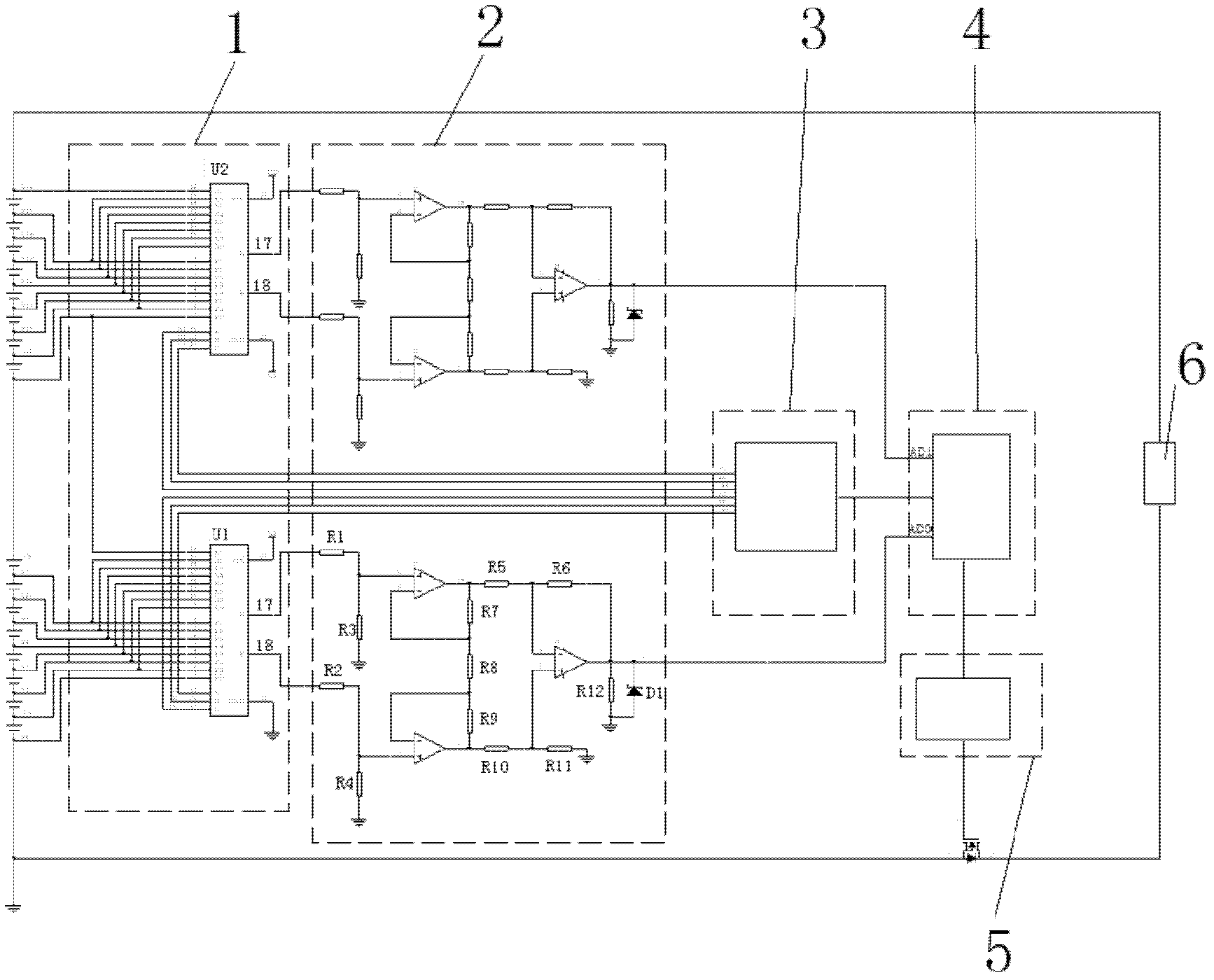

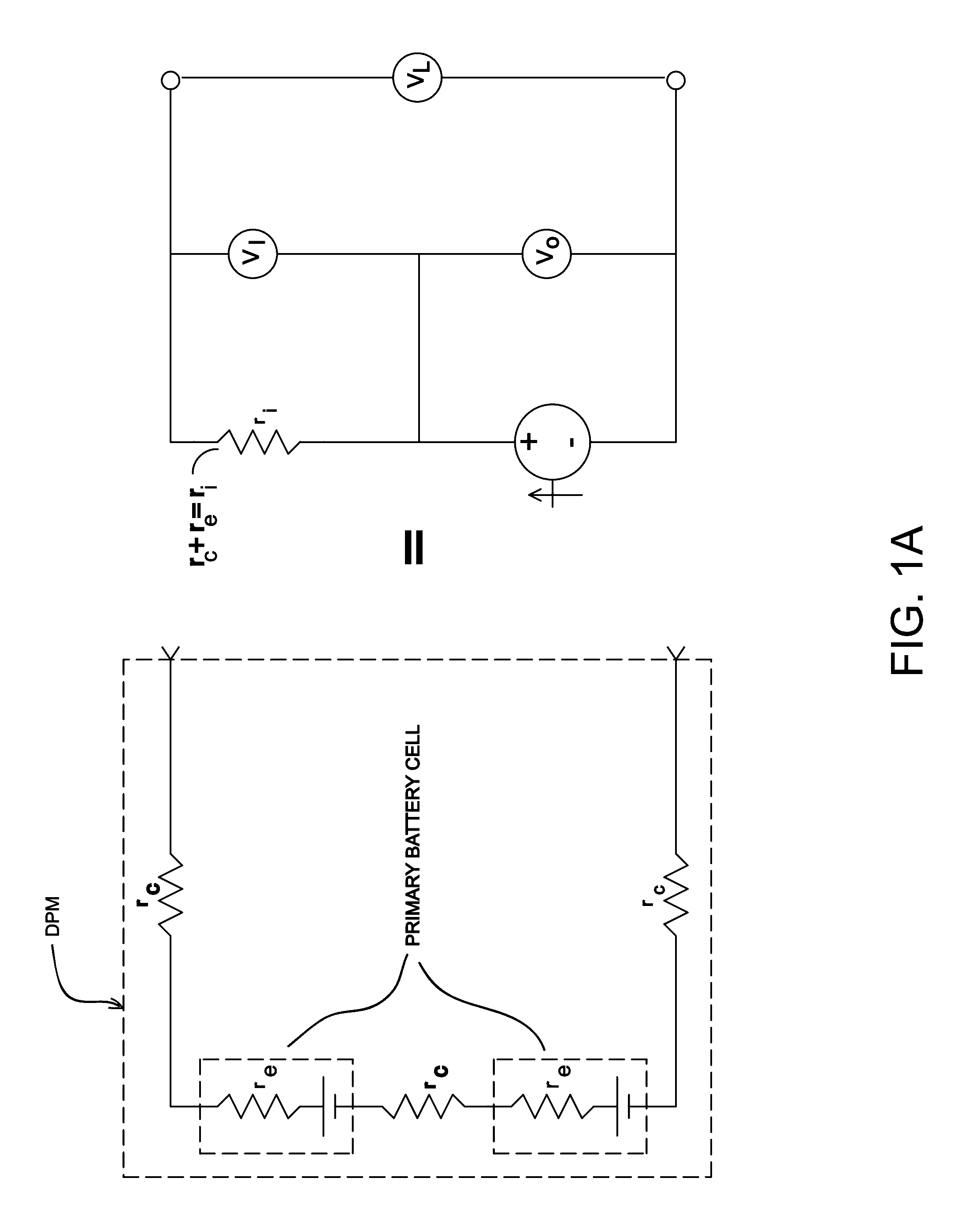

Device and method of testing an internal resistance of a battery pack

ActiveUS20110101986A1High measurement accuracyCurrent/voltage measurementElectrical testingElectrical resistance and conductanceInternal resistance

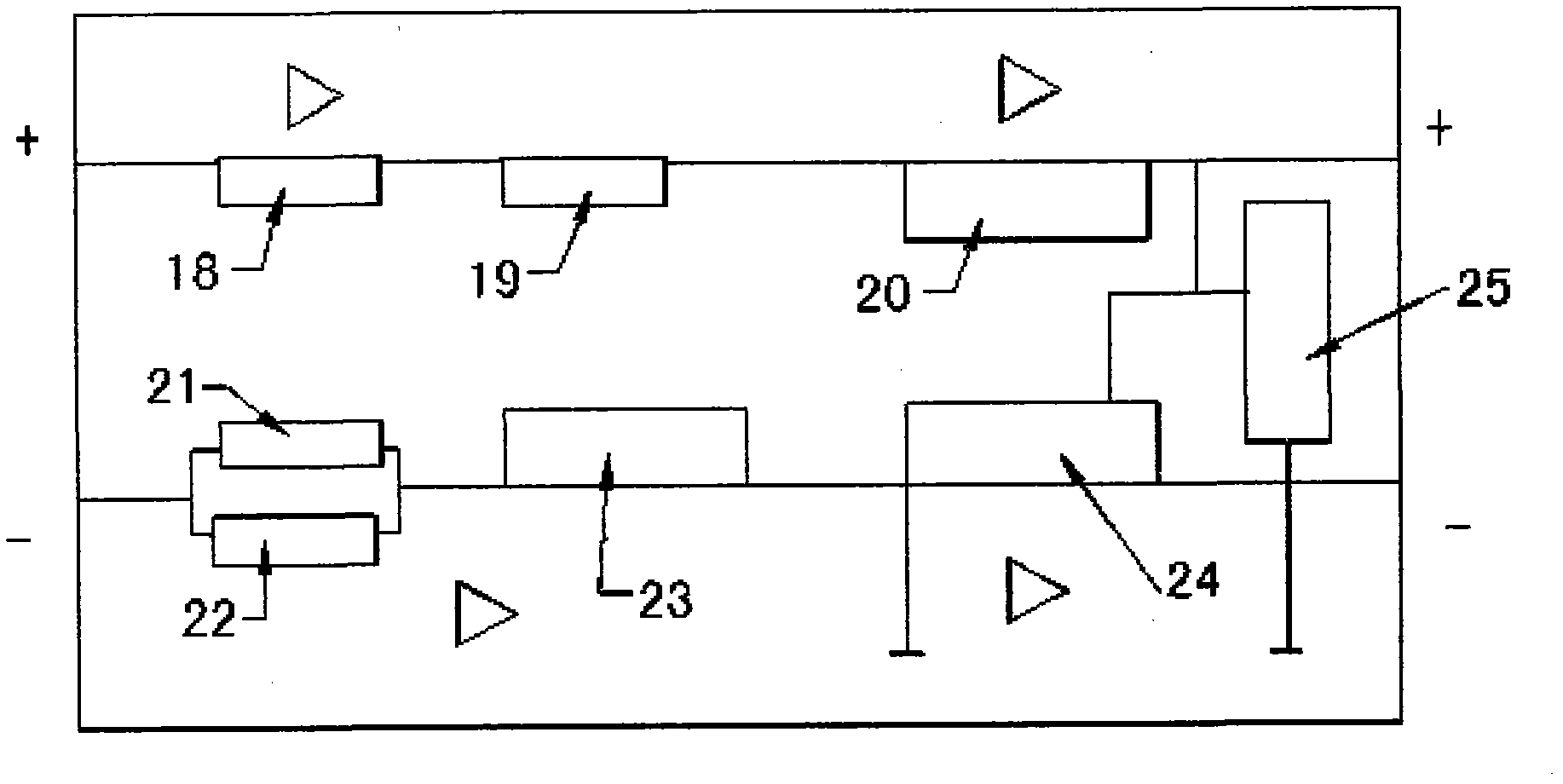

An internal resistance testing device includes an excitation source and a battery pack, an adjustable resistance R, a sampling unit, and a control unit. The excitation source and the battery pack form a loop circuit. The adjustable resistance R may be located at the loop circuit formed by the excitation source and the battery pack. The sampling unit samples the voltage between two sides of the battery pack, the voltage between two sides of the adjustable resistance R, and the value of the adjustable resistance R. The control unit calculates internal resistance of the battery pack according to the signal value collected by the sampling unit. The internal resistances of different voltage-ranges the battery pack are determined by adjusting the value of the adjustable resistance R to cause the actual excitation voltage to be equal to the range voltage of the sampling unit. The voltage between two sides of the adjustable resistance R is made equal to the range voltage of the sampling unit by adjusting the value of the adjustable resistance R, which effectively improves measurement accuracy of the internal resistance.

Owner:BYD CO LTD

Power unit and safety circuit having the same

ActiveUS20090051226A1Accurate graspEnsure safetyDc network circuit arrangementsBatteries circuit arrangementsElectricityElectrical connection

A power unit including a plurality of series-connected battery modules and a safety circuit.A service plug is inserted from the side of a terminal board of a battery pack, thereby establishing an electrical connection among battery modules. A connector is provided on a back of a terminal cover by way of a projecting section, and a second safety switch is activated by attachment of a terminal cover and insertion of the connector to the terminal board, thereby establishing an electrical connection among the battery modules. Even when the service plug is attached at the time of completion of maintenance without attachment of the terminal cover, the battery modules are still kept in an unconnected state by means of a second switch, and energization, which would otherwise arise with exposed terminals, is prevented.

Owner:GRUPO PETROTEMEX DE C V +1

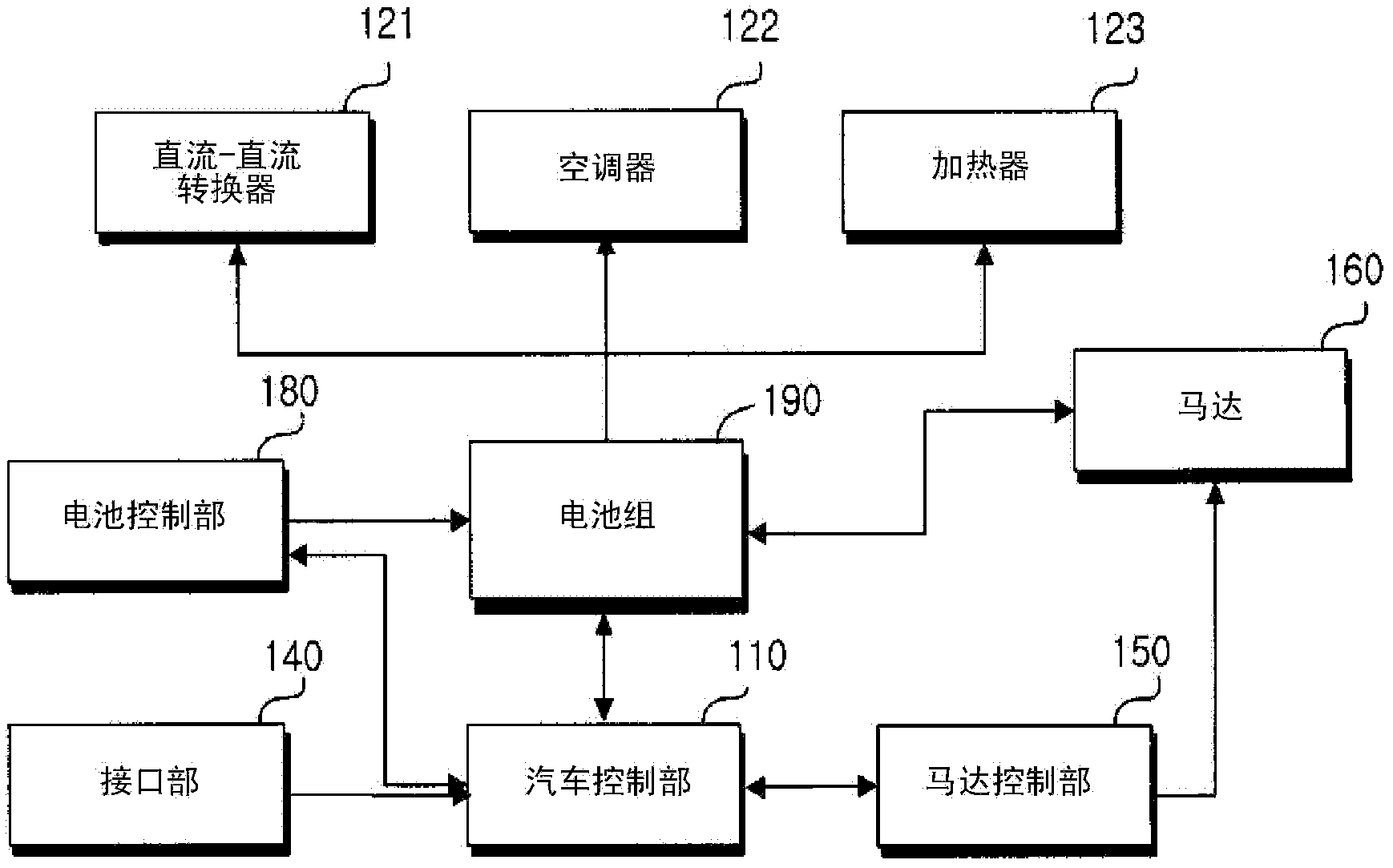

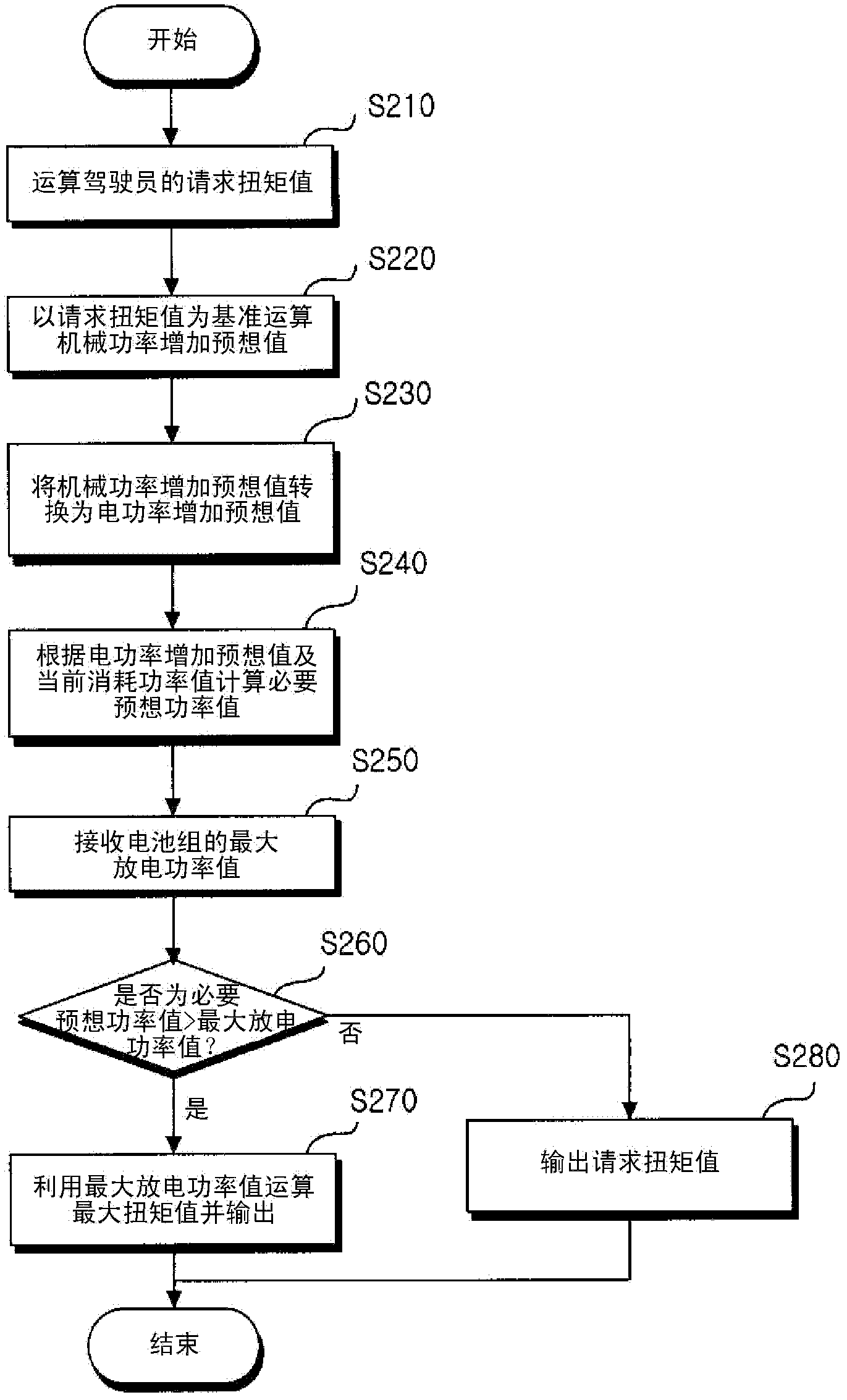

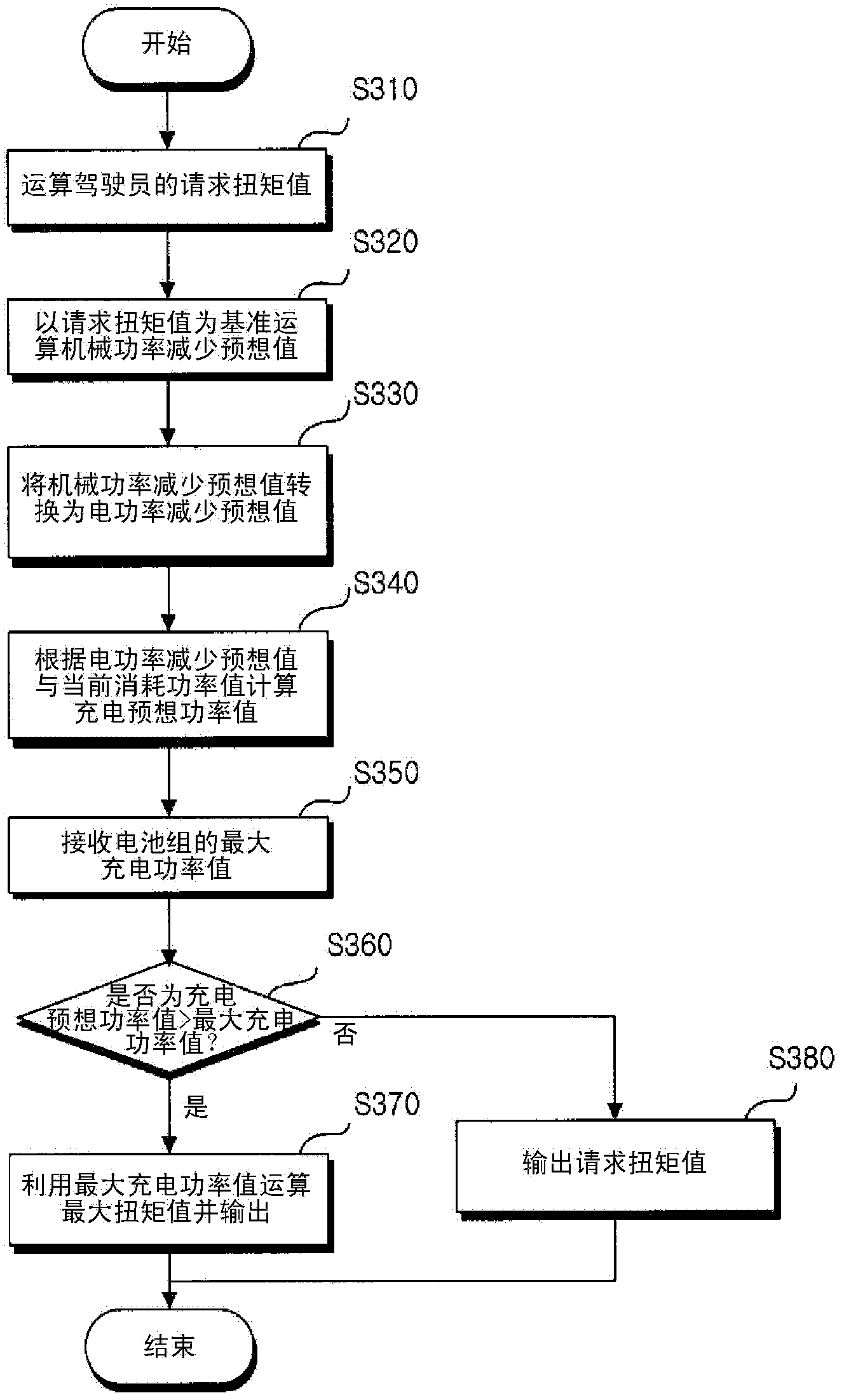

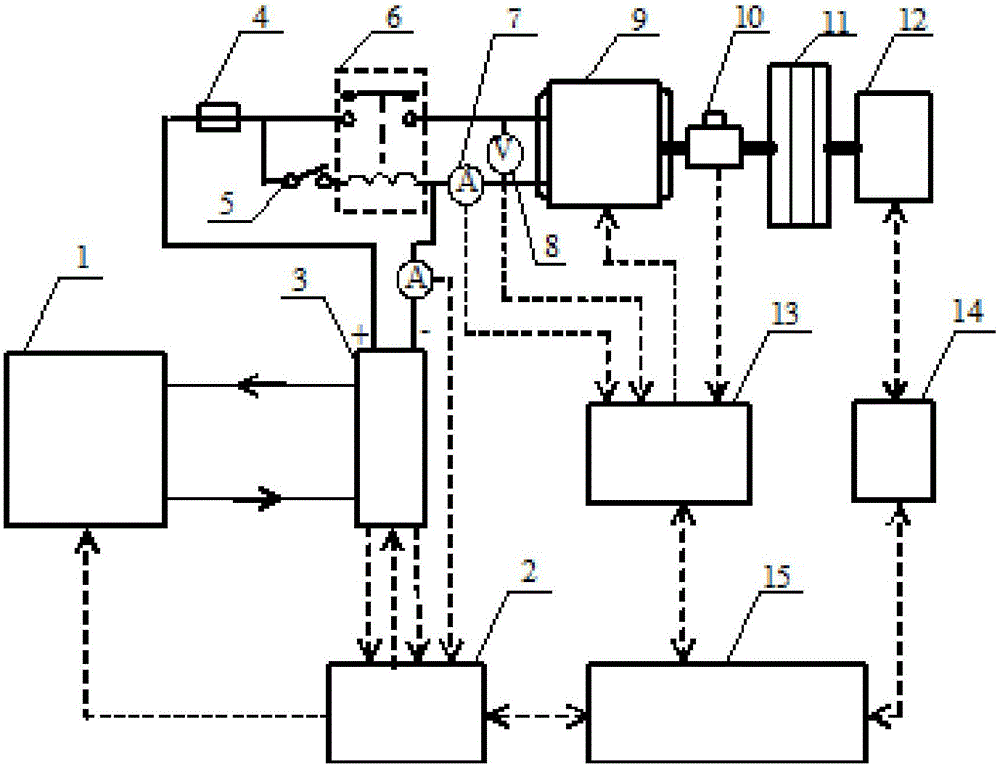

Electric car and control method thereof

InactiveCN102666184ALife Maintenance GuaranteePrecision Torque ControlSpeed controllerBatteries circuit arrangementsEngineeringElectric cars

Owner:LG ELECTRONICS INC

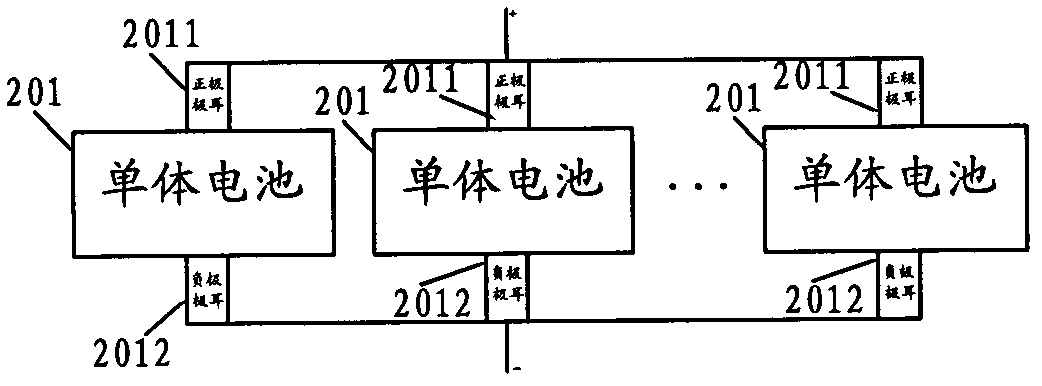

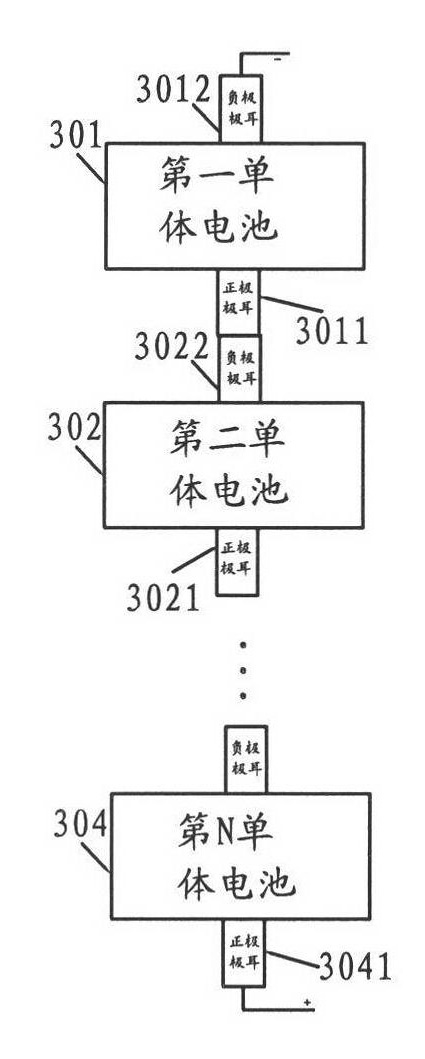

Lithium ion battery pack and soldering method for single batteries therein

ActiveCN102332611AAvoid bloatingFinal product manufactureCell component detailsBattery cellMaterials science

Owner:SHENZHEN GREPOW BATTERY CO LTD

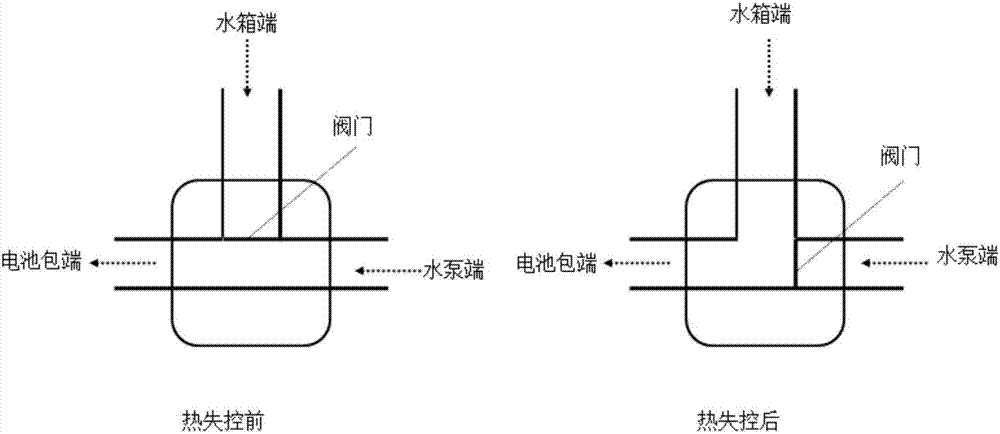

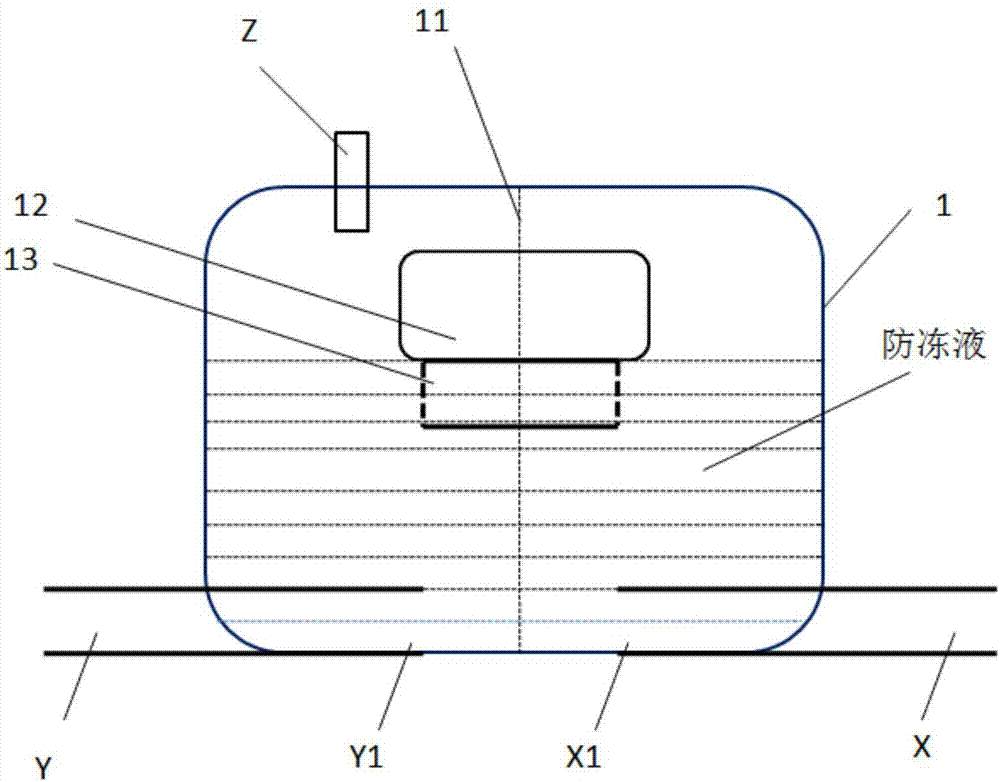

Thermal runaway control system for lithium ion battery pack of new energy automobile, and battery pack

ActiveCN107069140ALarge specific heat capacityAbsorb moreCell temperature controlVehicular energy storageNew energyElectrical battery

Owner:TIANJIN ENERGIES

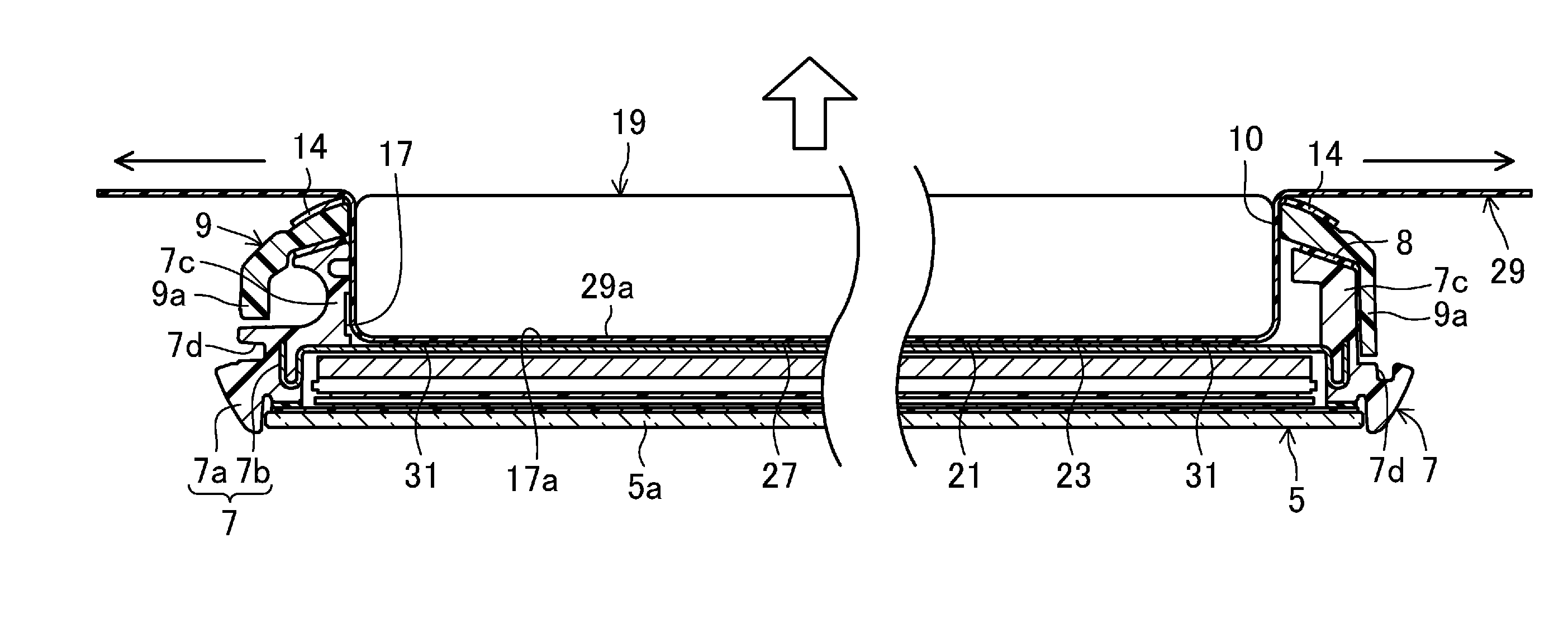

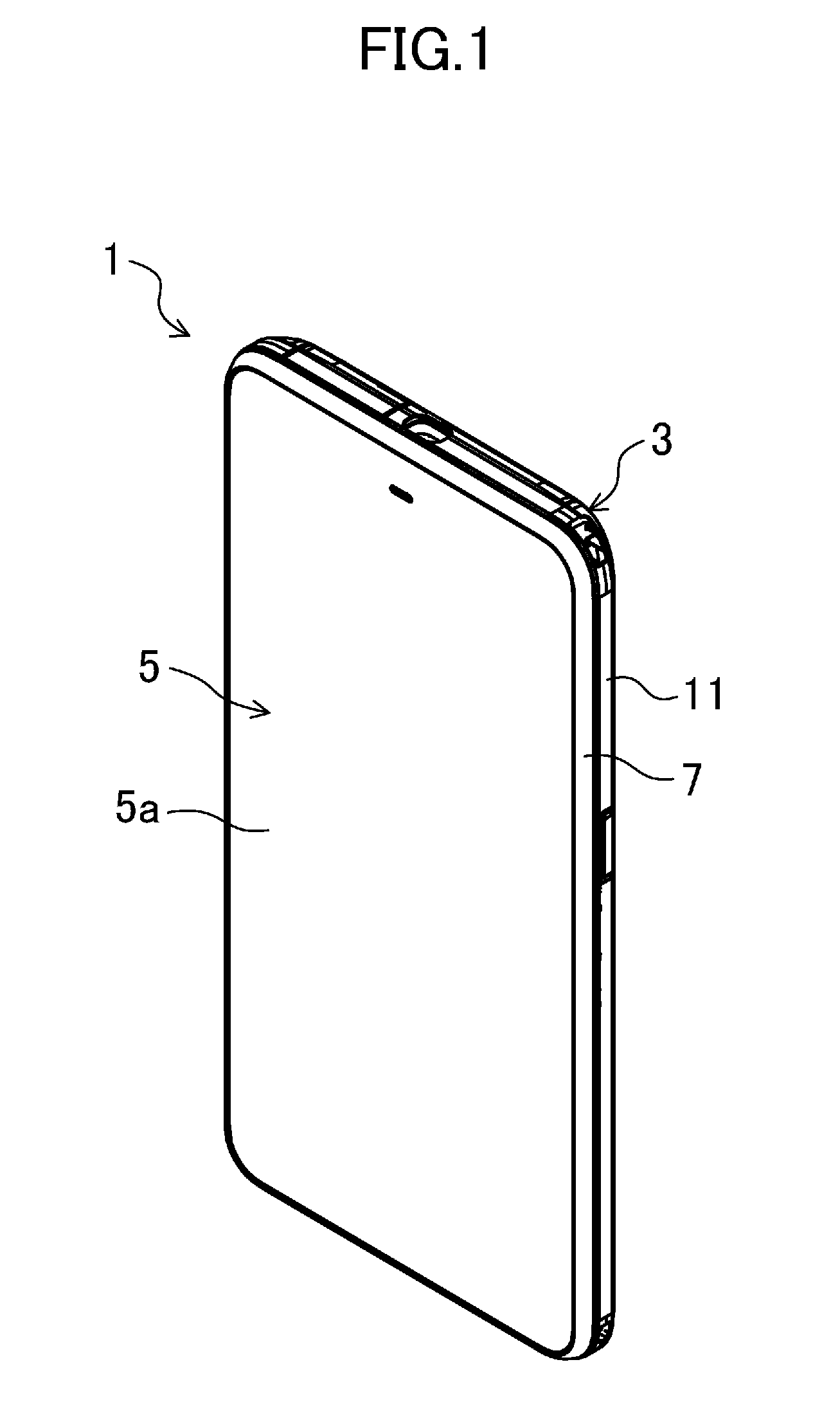

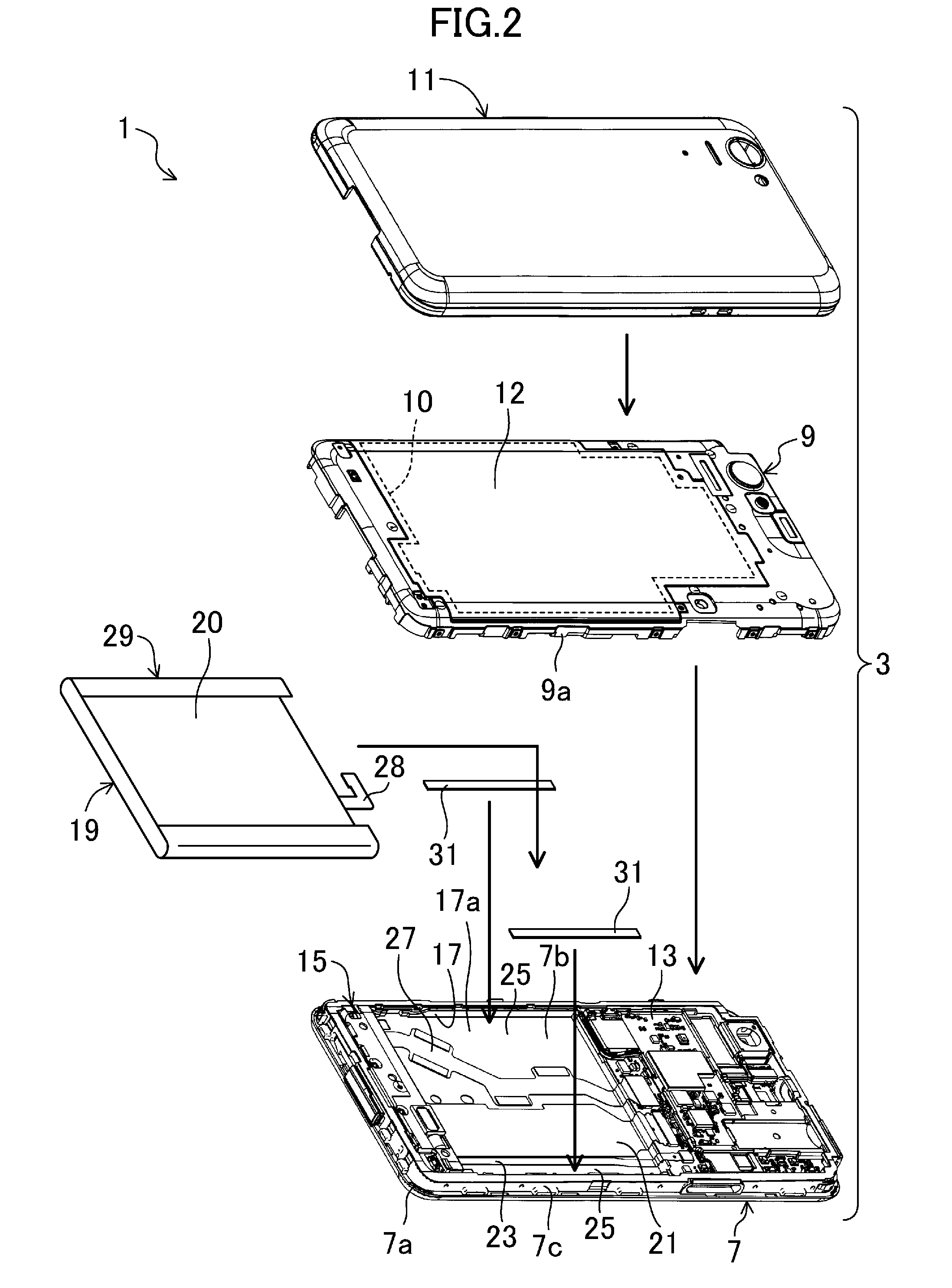

Mobile device

Owner:SHARP KK

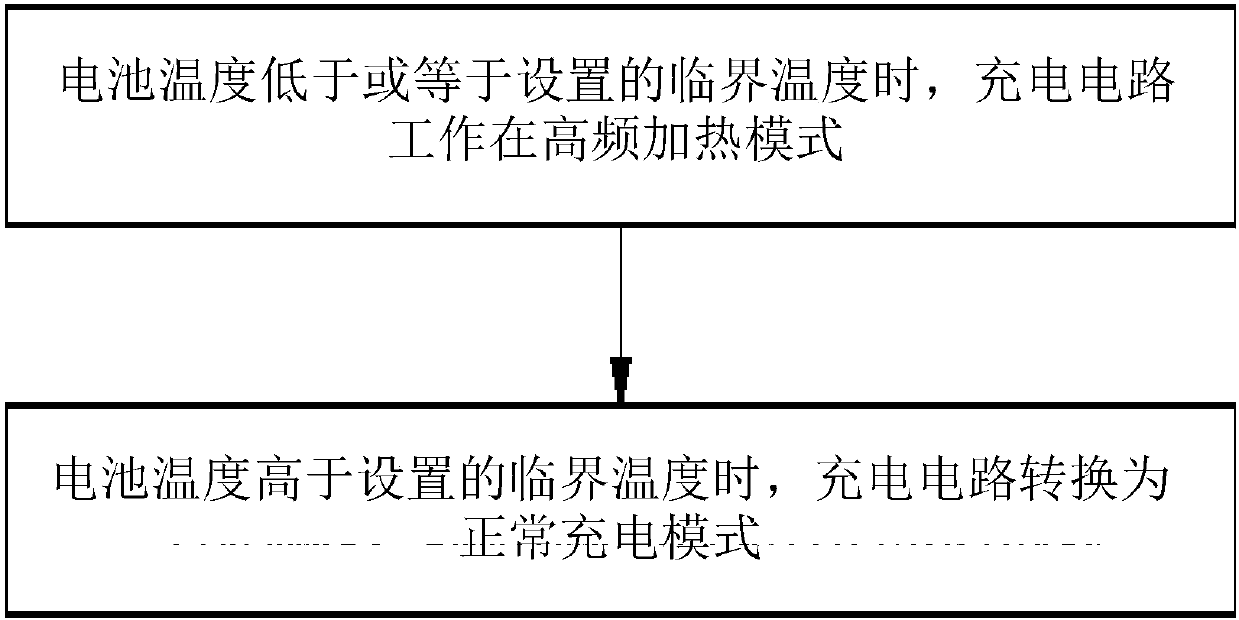

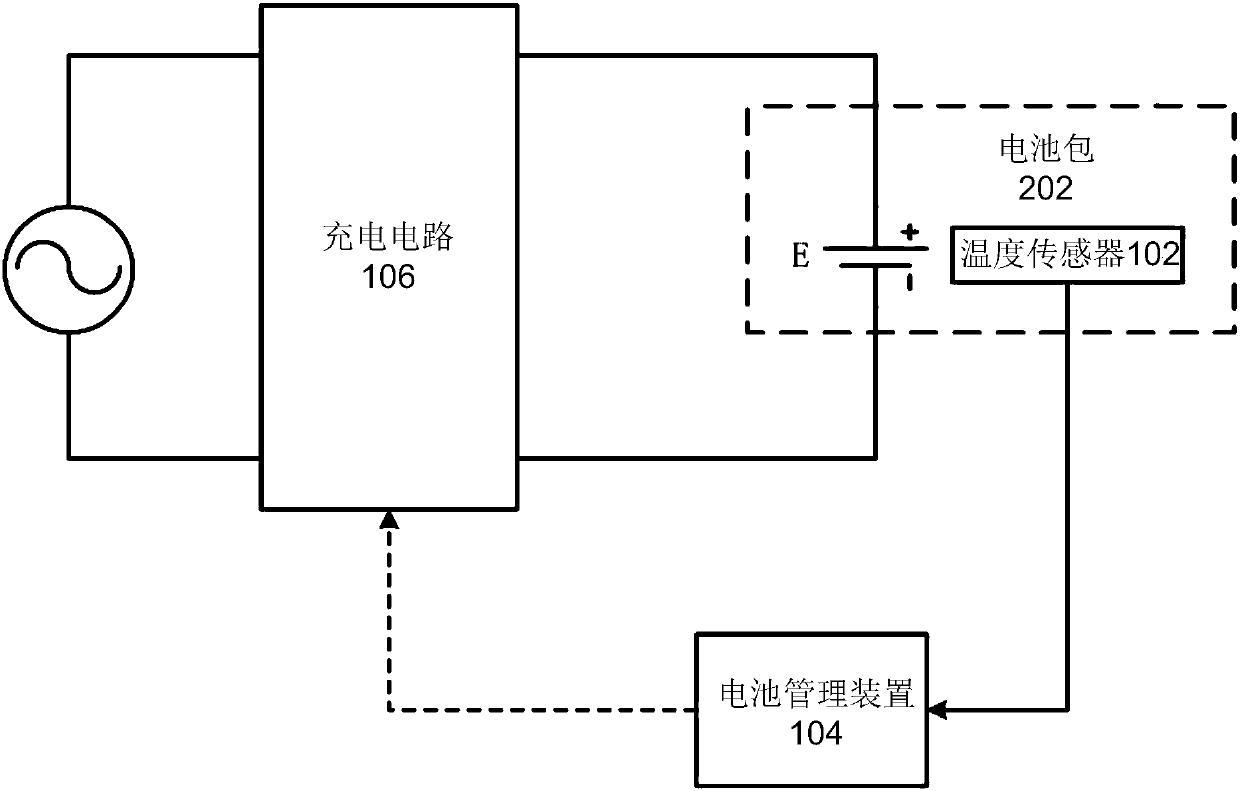

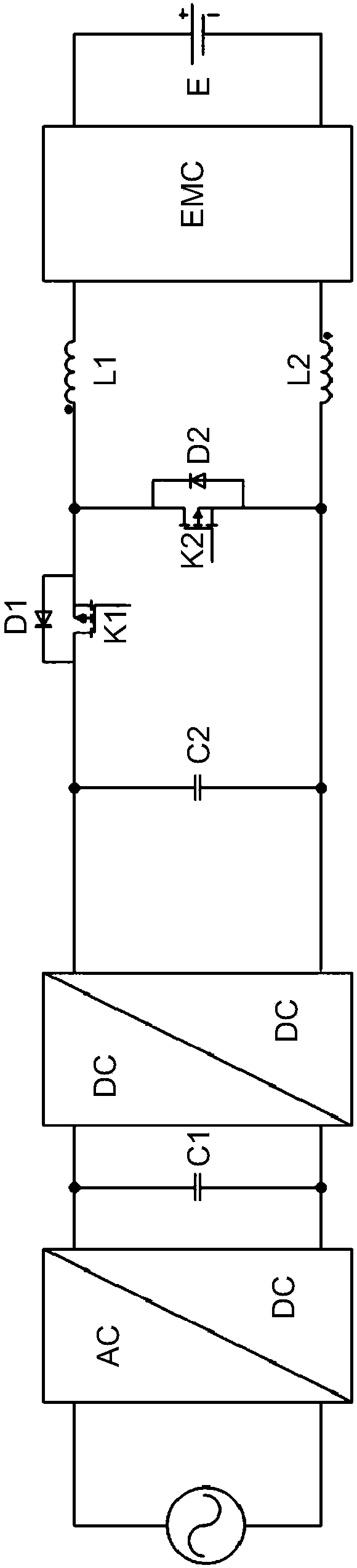

Heating circuit of battery

PendingCN107845840ADoes not affect the normal charging functionRealize low temperature heating functionBatteries circuit arrangementsSecondary cells charging/dischargingElectrical batteryInternal resistance

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

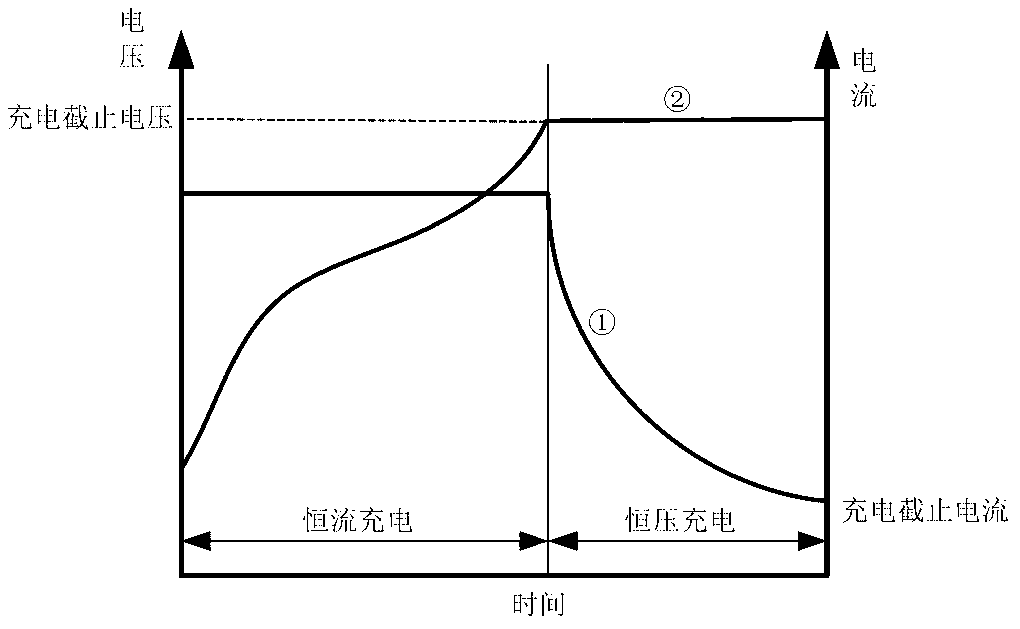

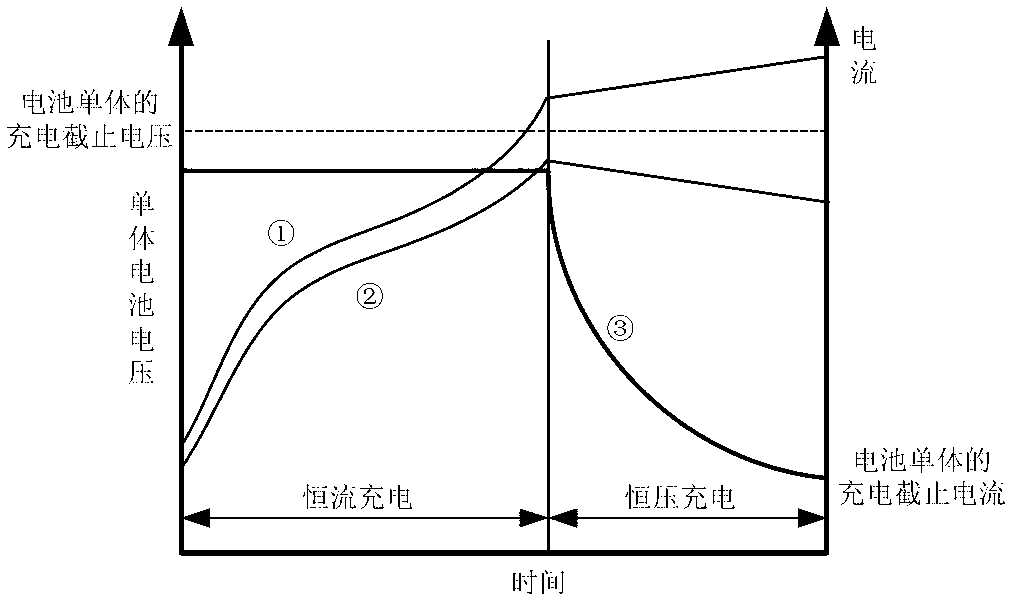

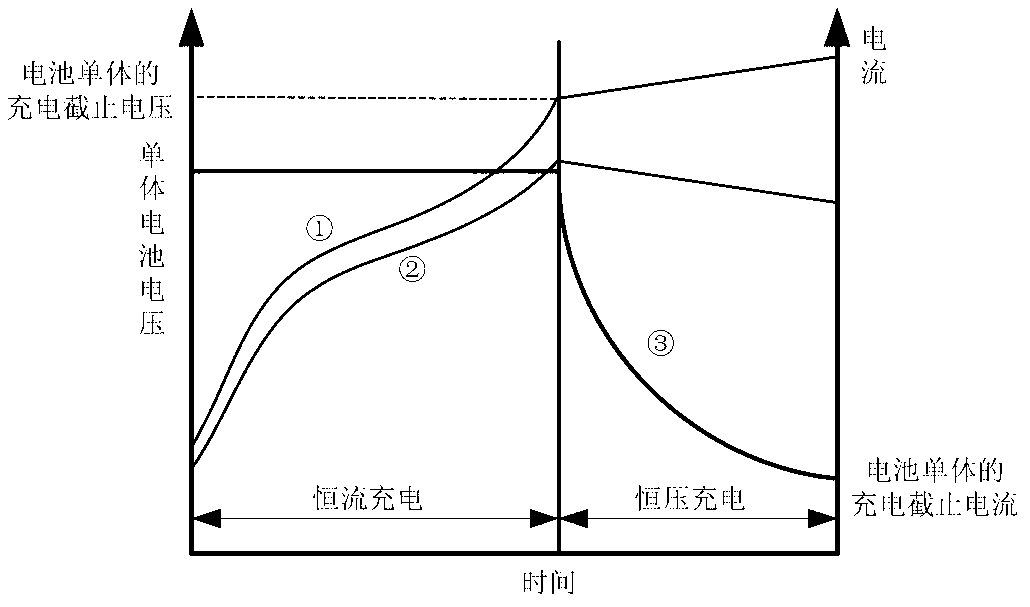

Battery pack charging method

InactiveCN103138022AEnsure safetyGuaranteed durabilitySecondary cells charging/dischargingClosed loop feedbackMonomer

Owner:TSINGHUA UNIV

Temperature pre-regulation system and method of power battery pack and thermal management system control method

ActiveCN110696680AReal-time monitoring of working currentAvoid misjudgmentCell temperature controlVehicular energy storagePower batteryDriver/operator

Owner:CHINA UNIV OF MINING & TECH +1

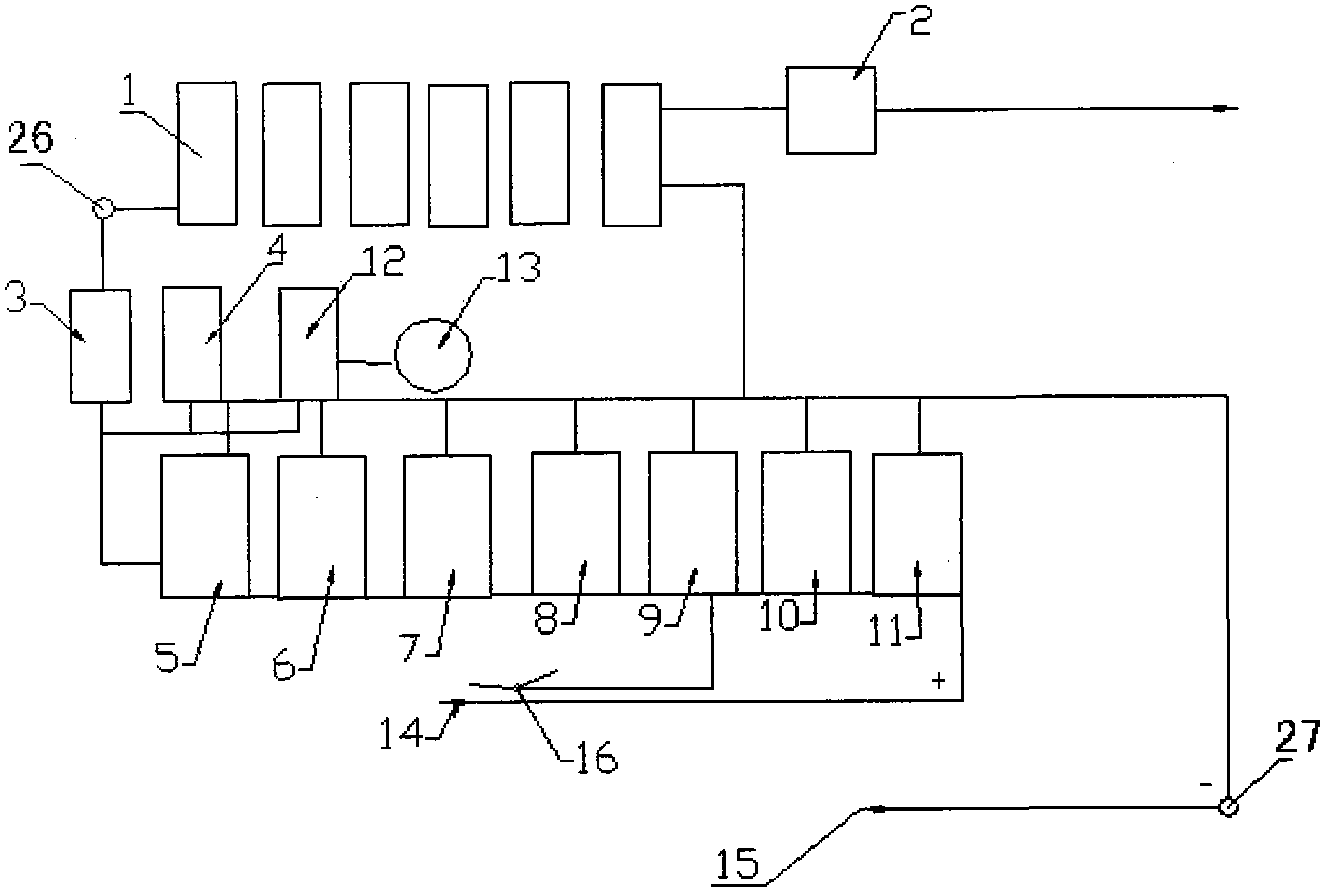

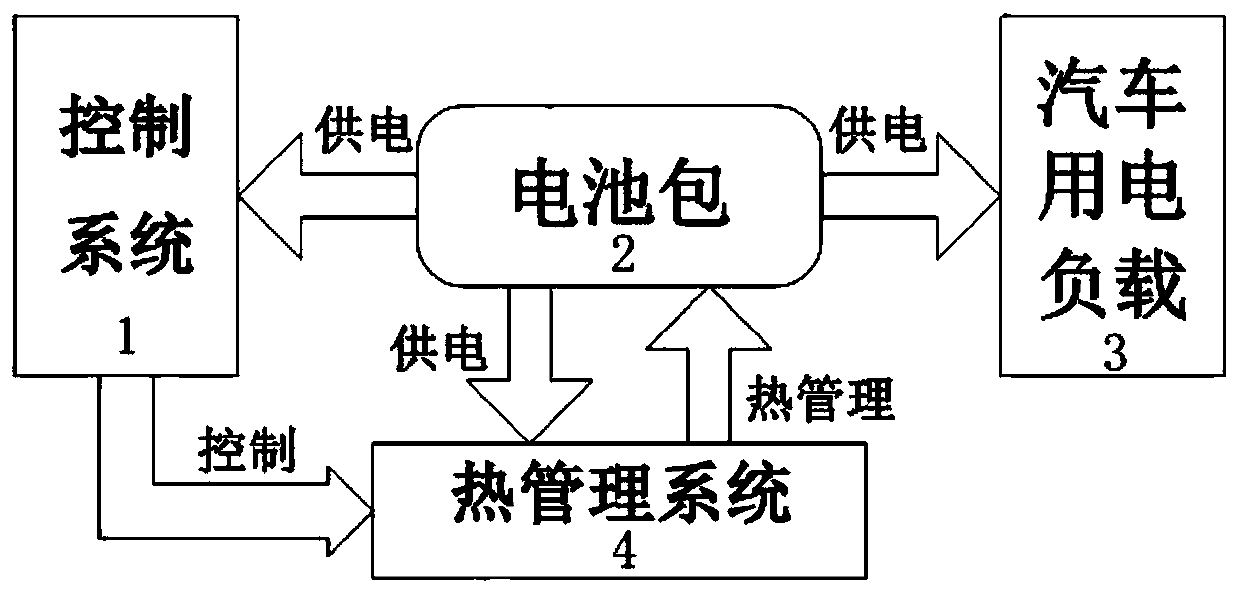

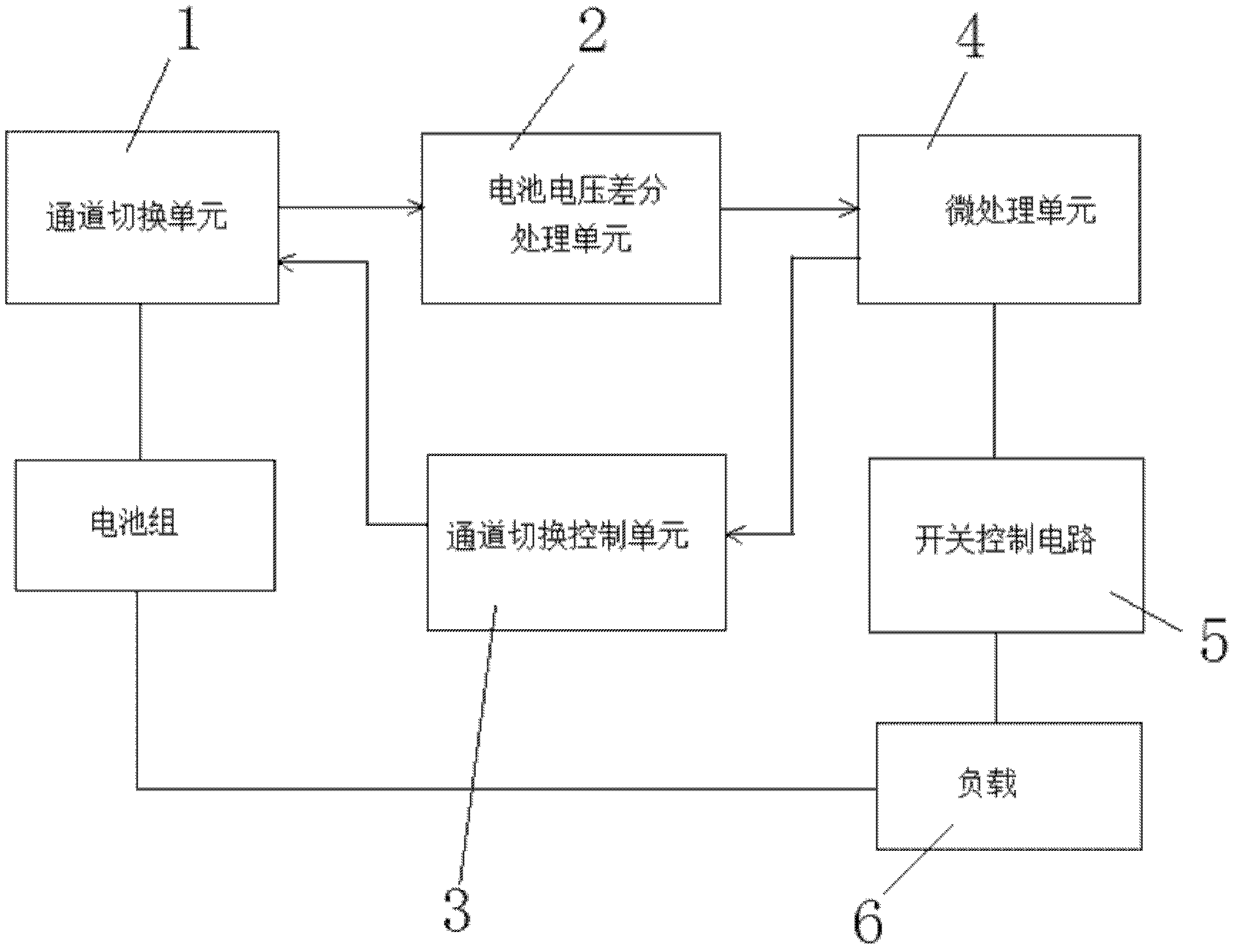

Intelligent energy management system of power battery pack

InactiveCN107425572ASafeguard and improve reliabilityImprove reliabilityCharging managementSecondary cells charging/dischargingPower batteryElectrical battery

The invention discloses an intelligent energy management system of a power battery pack. The intelligent energy management system comprises a main controller and a plurality of single battery intelligent management modules, wherein single batteries in the power battery pack are divided into a plurality of groups, each group is corresponding to each single battery intelligent management module and comprises at least one single battery, each single battery intelligent management module is used for monitoring a state of the single battery in the group, the abnormal single battery (group) is isolated when a monitoring result is abnormal, communication of the power battery pack is maintained, and the main controller is used for performing voltage regulation on total output voltage after control of each single battery intelligent management module and continuously outputting a preset stable current and total voltage. A failure battery is intelligently and automatically removed on line, the battery pack is enabled to still continuously and stably output a normal voltage and a normal current when the batteries in the whole group do not exceed a plurality of failure batteries in a certain proportion, so that the reliability and the availability of the power battery pack within planned backup time are guaranteed and improved, and the service lifetime of the battery pack is prolonged.

Owner:BEIJING SHENGFENG HELI SYST TECH CO LTD

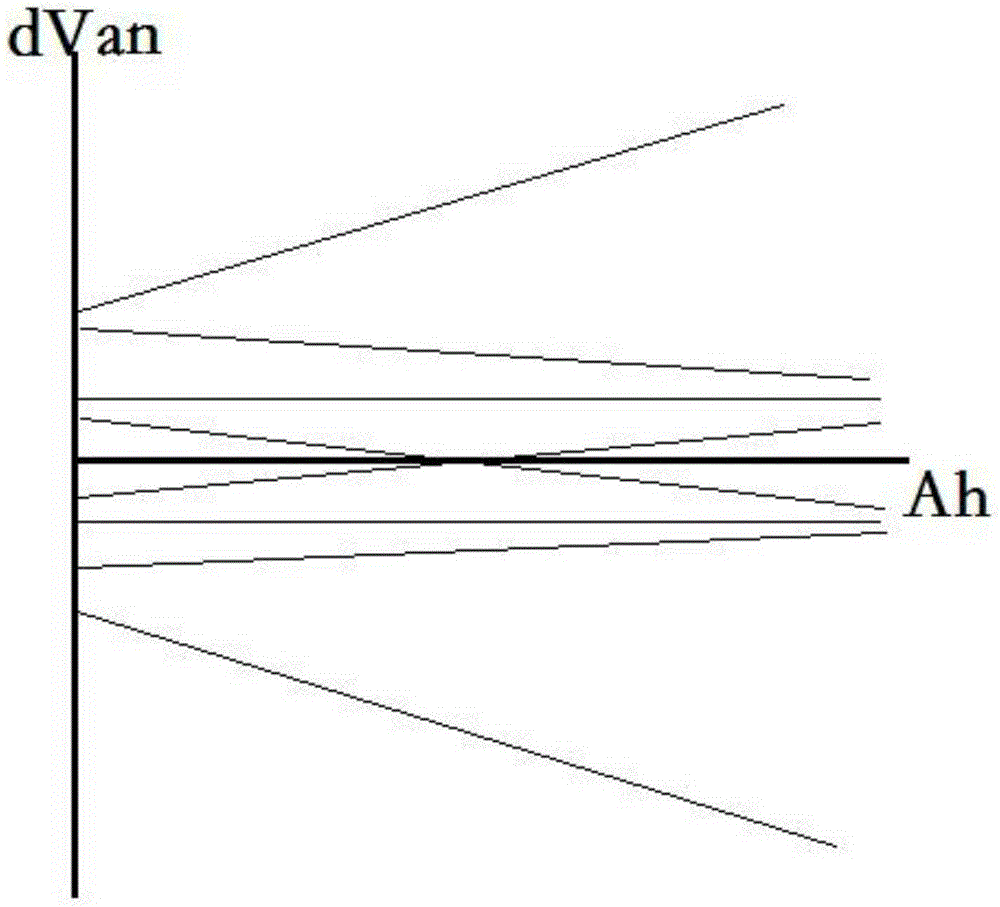

Battery pack active equalization method and battery pack active equalization device

ActiveCN105356533AHigh precisionReduce test errorBatteries circuit arrangementsSecondary cells charging/dischargingEqualizationPressure difference

Owner:HIGER

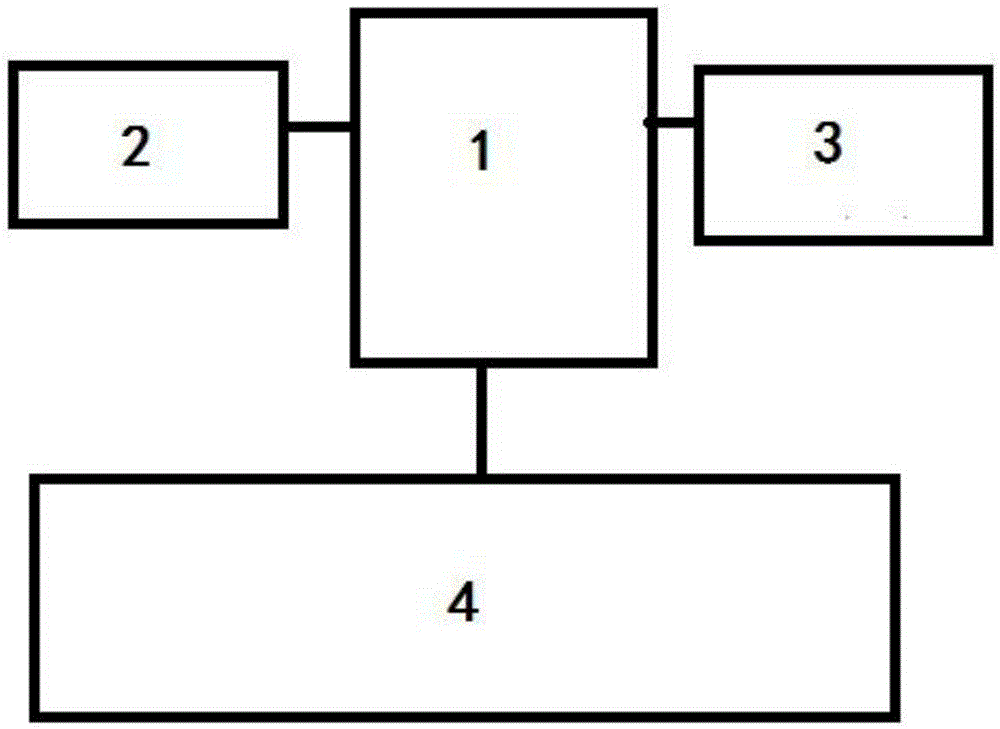

Multichannel battery sampling circuit and sampling method thereof

InactiveCN102495268AImprove detection accuracyImprove performanceCurrent/voltage measurementElectrical testingElectrical batteryPrice ratio

Owner:WUHU TIANYUAN AUTOMOBILE ELECTRON

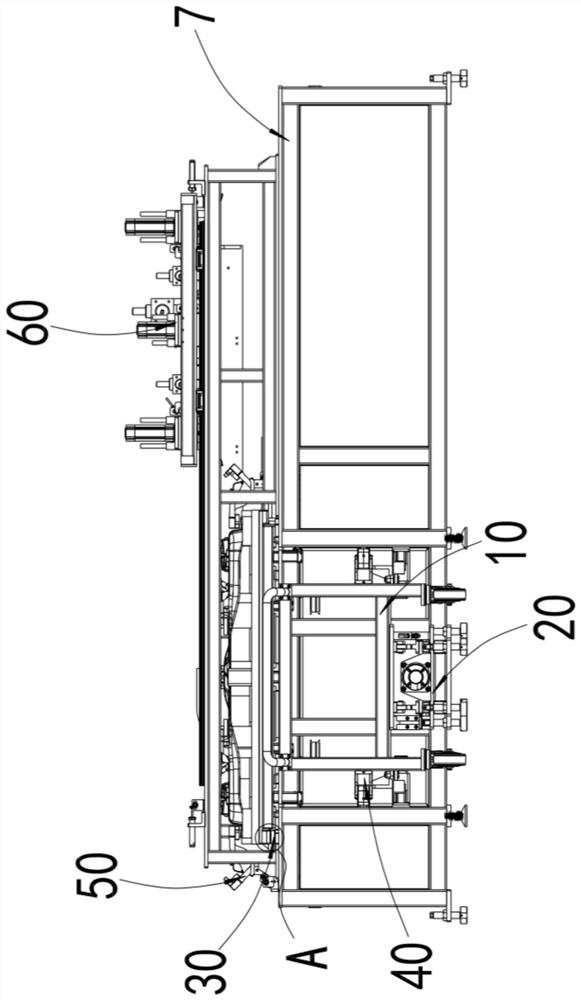

Electric vehicle three-system integrated test platform

InactiveCN105891631AAchieve balanceCompact structureDynamo-electric machine testingElectrical batteryDynamometer

Owner:BEIJING UNIV OF TECH

Method for detecting inner connecting resistor of power battery pack

ActiveCN104237643AEasy to calculateResistance/reactance/impedenceElectrical resistance and conductancePower battery

Owner:CONTEMPORARY AMPEREX TECH CO

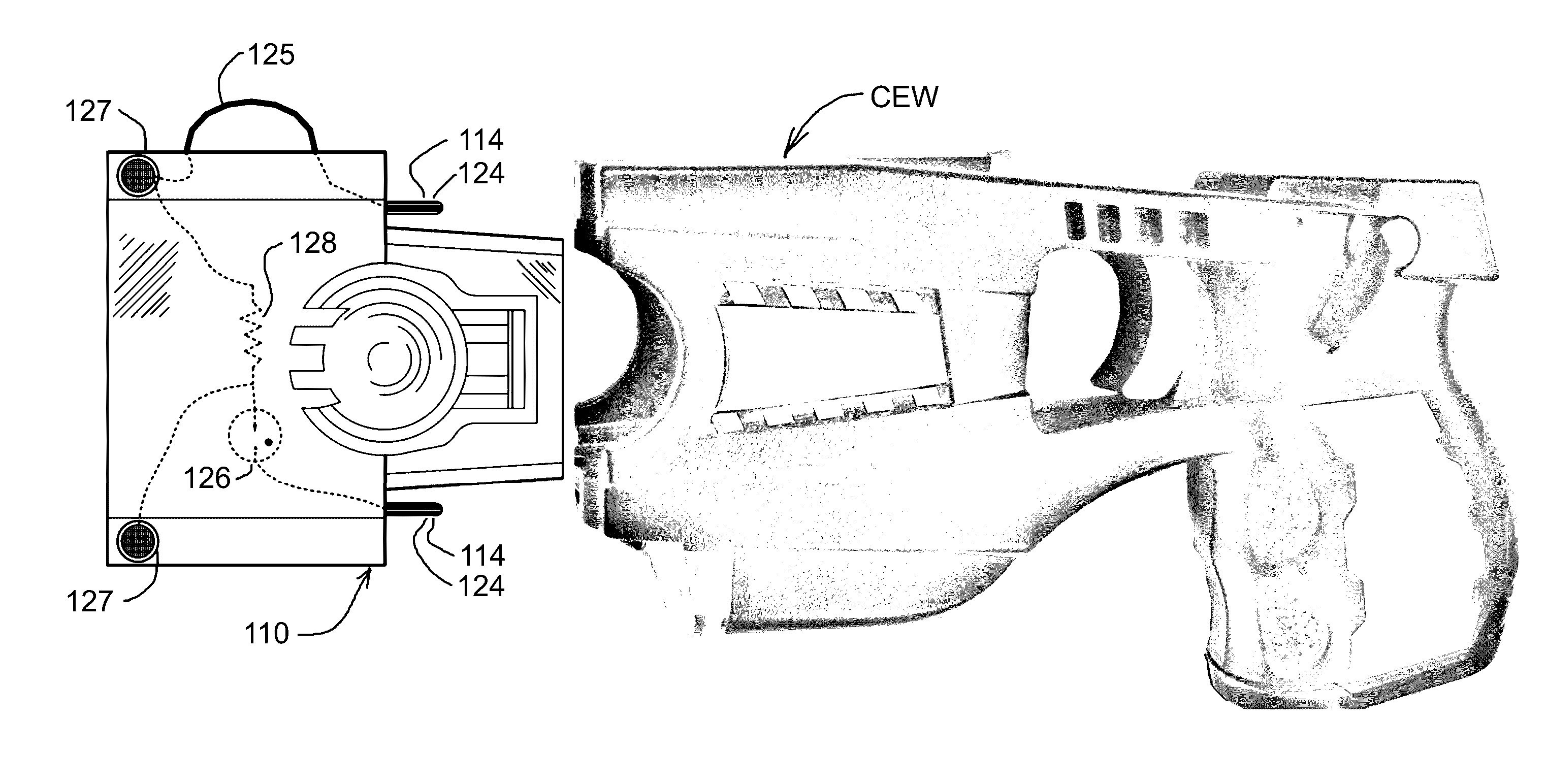

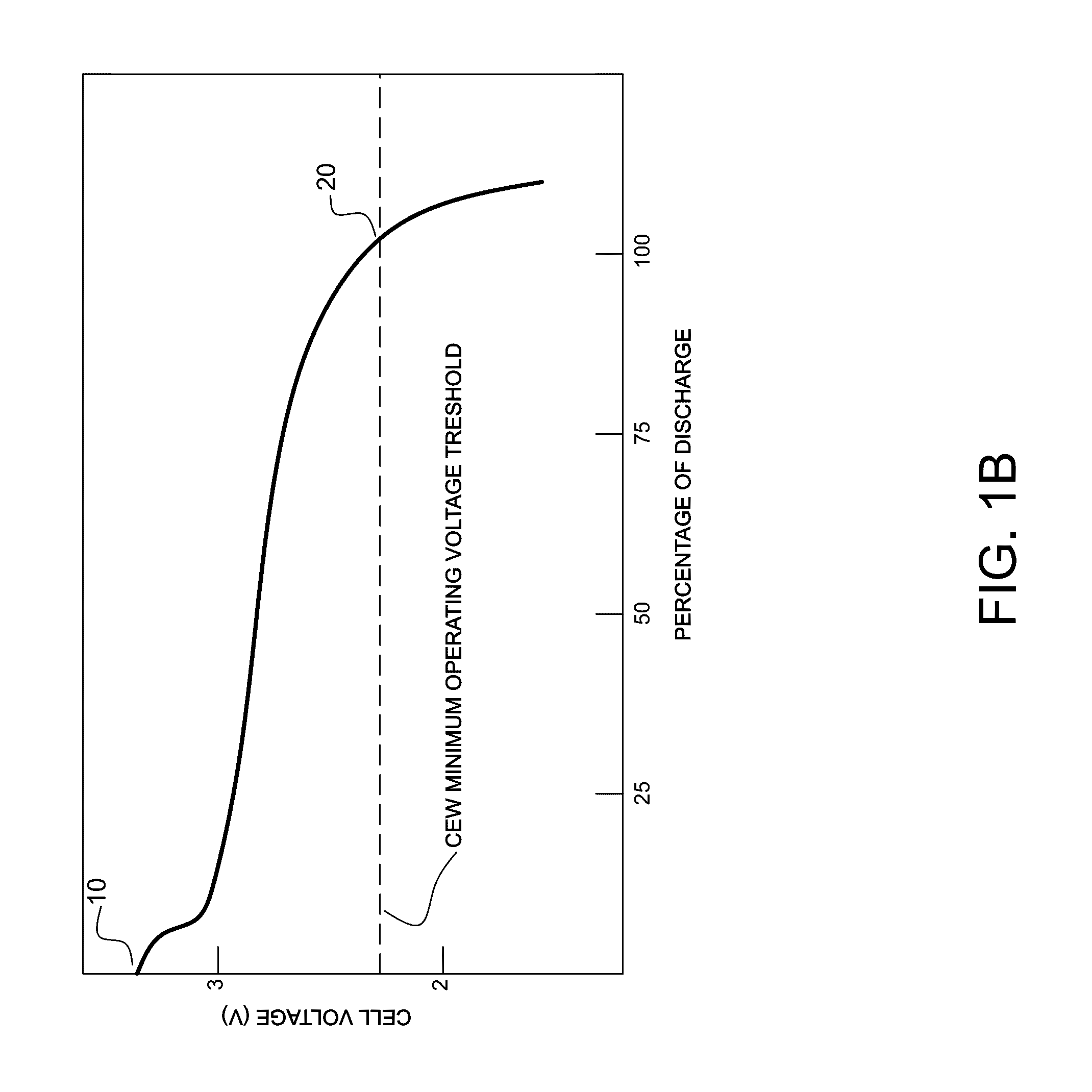

Apparatus and methods for evaluating cew energy cell performance

InactiveUS20170059661A1Evaluate performanceAmmunition testingElectrical testingAnalysis toolsEngineering

Owner:FOLDYNA IVO

Method for displaying information of battery pack based on mobile terminal

PendingUS20200393516A1Batteries data exchangeCircuit monitoring/indicationEngineeringComputer science

The present invention relates to a method for displaying information of a battery pack based on a mobile terminal. The battery pack is used to supply electric energy to an electric tool. The method includes: establishing wireless communication with the battery pack; acquiring status information of the battery pack; and displaying the status information on the mobile terminal according to the acquired status information. In this way, as long as a user carries a mobile terminal that wirelessly communicates with a battery pack, status information of the battery pack can be displayed. The operation manner is simple, convenient, and easy to realize, which improves user experience.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

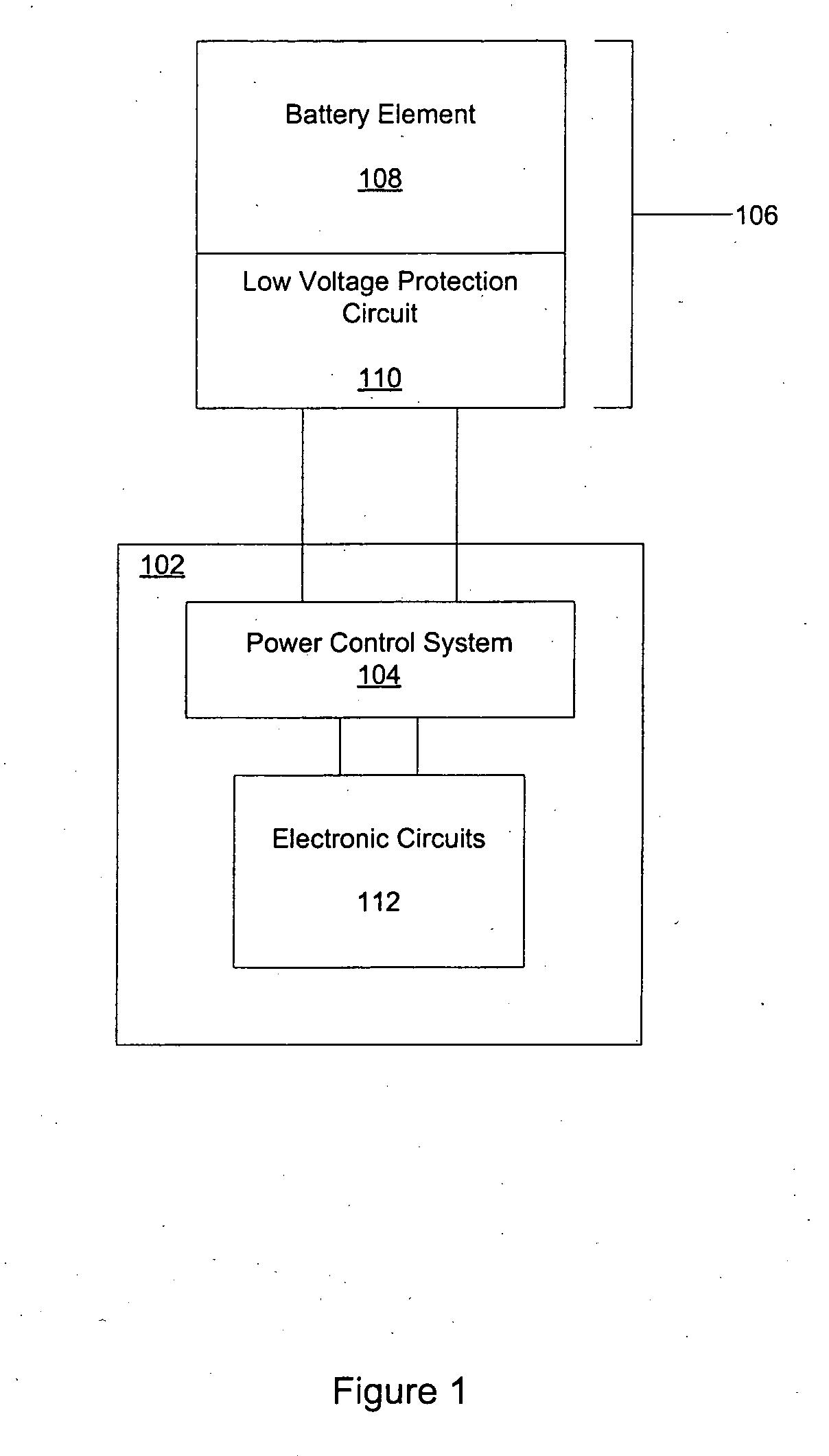

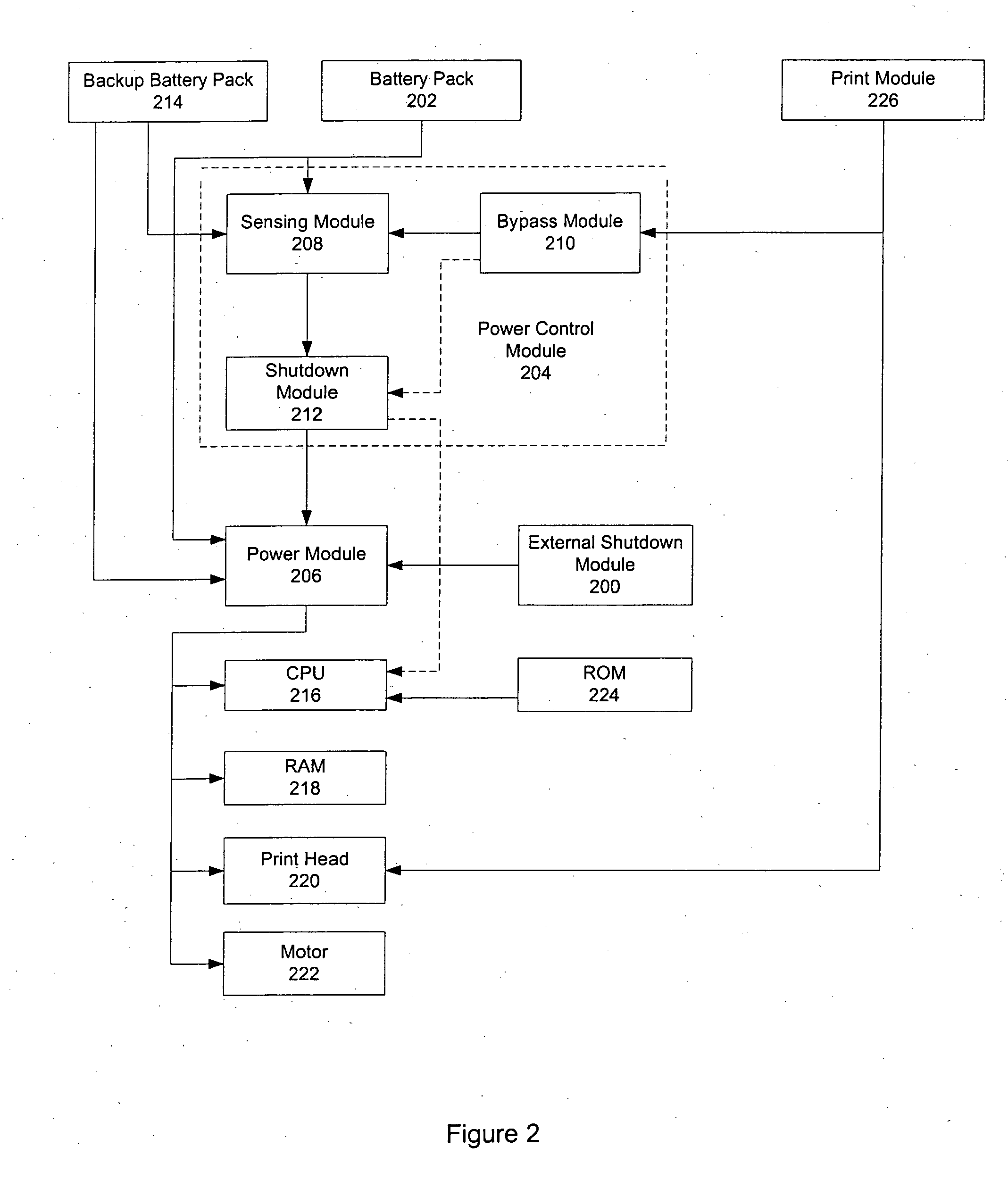

Power control circuits

InactiveUS20070090800A1Easy to controlGood removal effectElectric powerBattery overcurrent protectionElectricityPower control system

Owner:AVERY DENNISON CORP

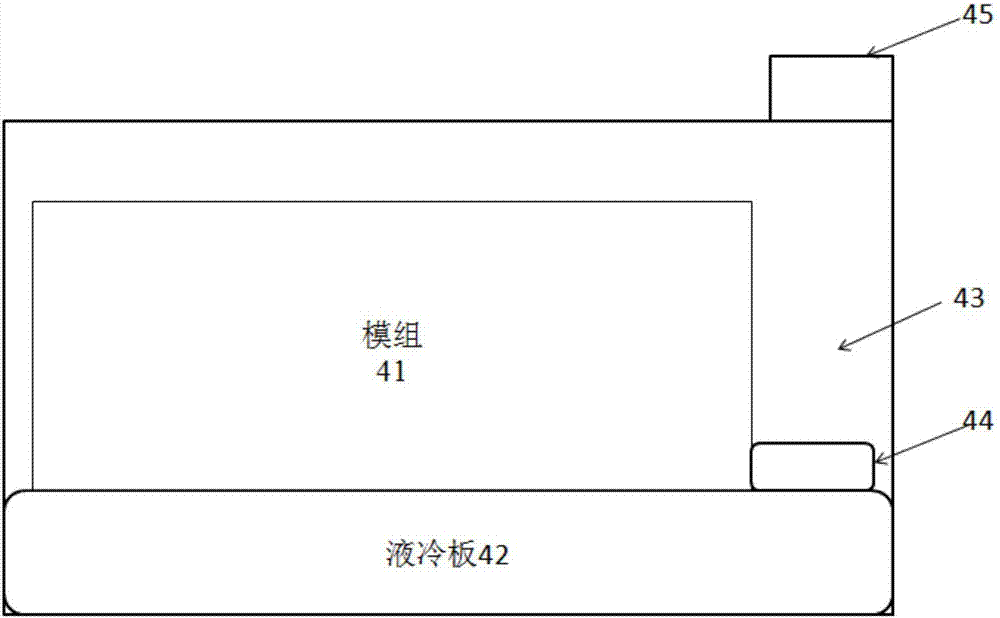

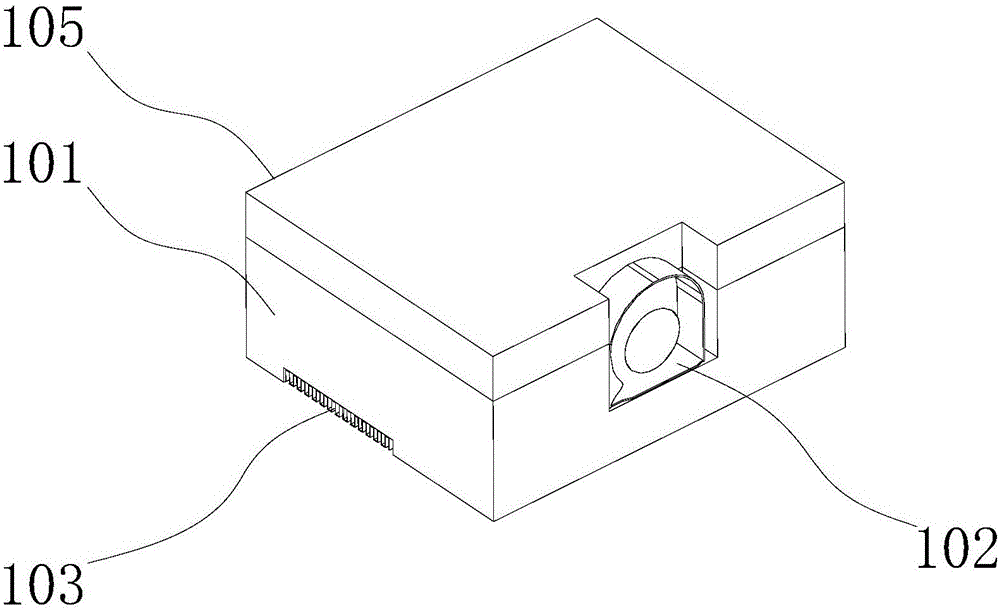

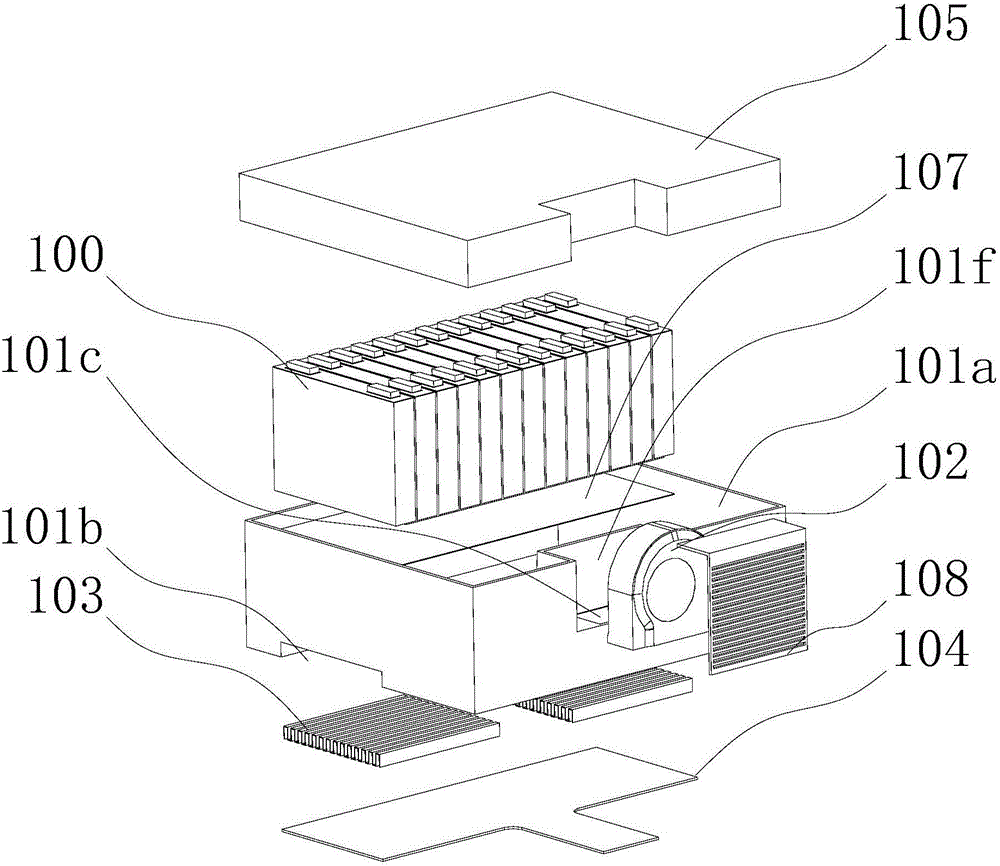

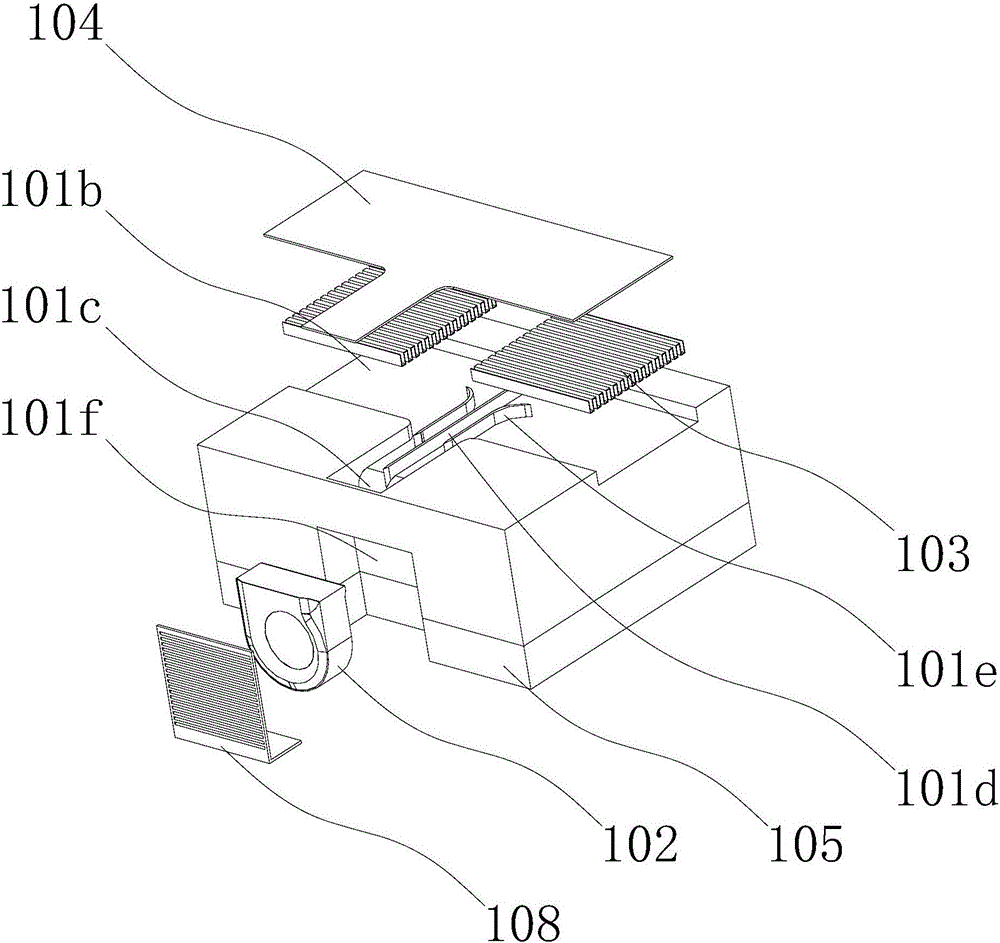

Battery pack

InactiveCN105977571APrevent water ingressAvoid dustBattery isolationSecondary cellsElectrical batteryHeat conducting

Owner:CONTEMPORARY AMPEREX TECH CO

Airtightness detection device and airtightness detection method

Owner:SUZHOU JEE INTELLIGENT EQUIP CO LTD

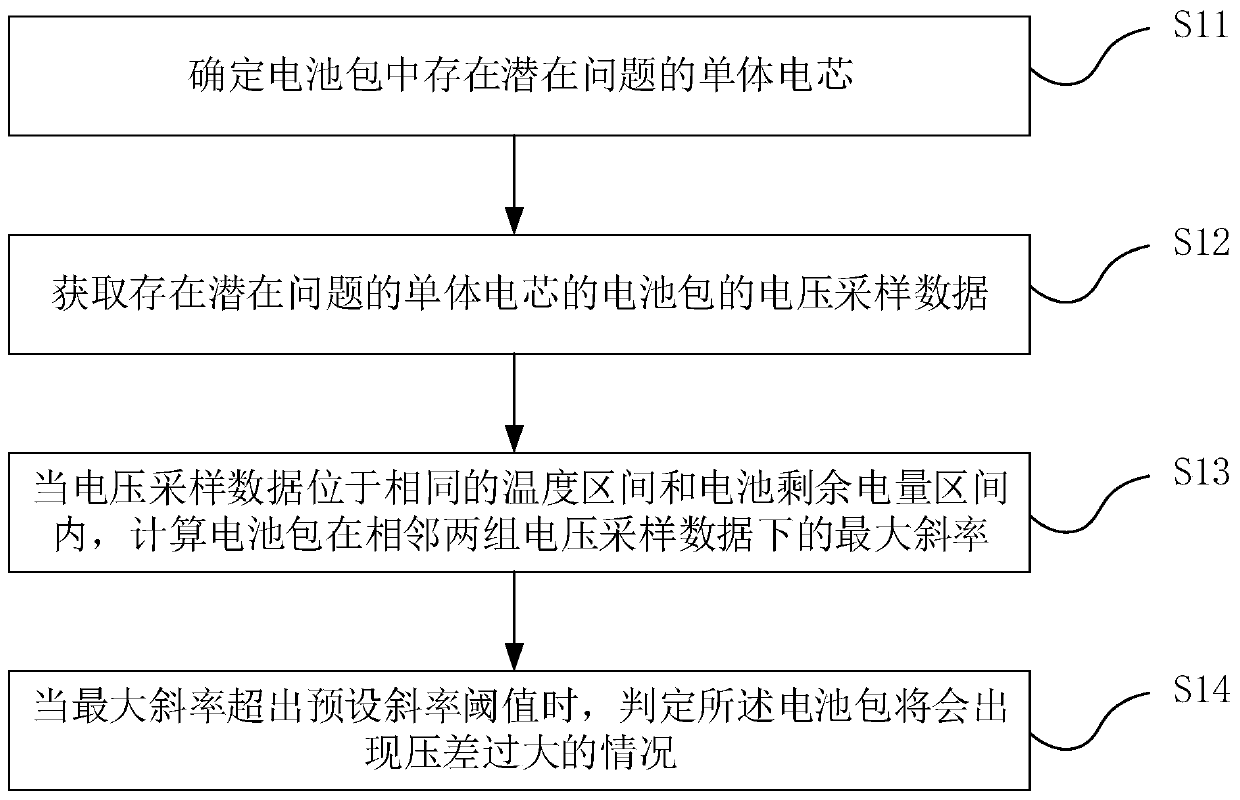

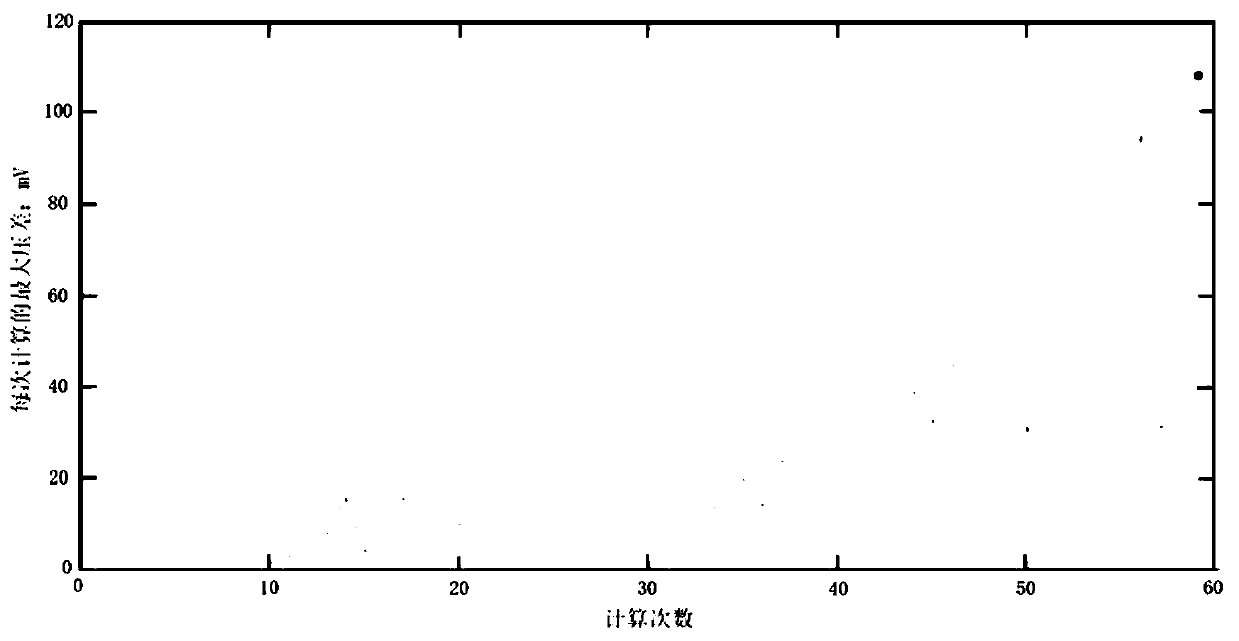

Method, device and equipment for predicting overlarge differential pressure of battery pack

Owner:北京四维智联科技有限公司

Electric automobile battery pack fixing device

PendingCN111976453AImprove replacement efficiencyQuick and effective fixationCharging stationsElectric propulsion mountingElectrical batteryAutomotive battery

Owner:CHERY COMML VEHICLE ANHUI

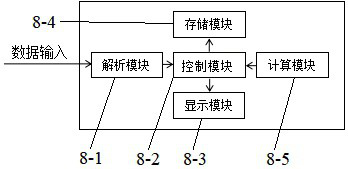

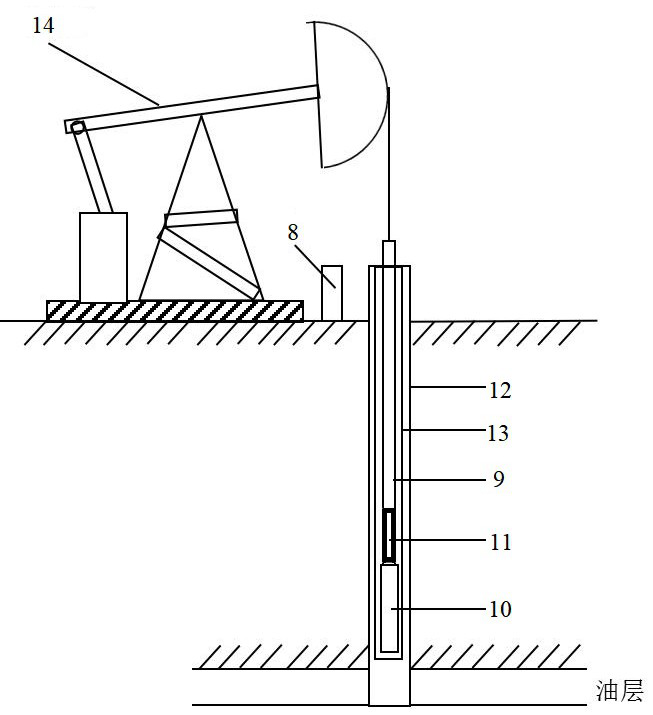

Real-time testing and wireless transmission device and method for sucker-rod pump indicator diagram of pumping well

PendingCN112682028ARealize real-time data collectionReceive in real timeSurveyConstructionsConvertersWireless transmission

Owner:PETROCHINA CO LTD

Metal/air battery system

ActiveCN108172949ASimple structureImprove reliabilityFuel and primary cellsInjection portBattery system

The invention provides a metal / air battery system, which comprises a metal / air battery pack provided with an electrolytic solution injection port and an electrolytic solution outlet, a liquid pump anda liquid storage unit, wherein the liquid inlet of the liquid pump is connected to the liquid storage unit, the liquid outlet of the liquid pump is connected to the electrolytic solution injection port of the metal / air battery pack, the electrolytic solution outlet of the metal / air battery pack is connected to the liquid storage unit to form a closed circuit, the liquid storage unit is provided with a heat dissipating component, the liquid storage unit is a container, the heat dissipating component comprises more than N groups of heat dissipating fins, N is a natural number of greater than orequal to 1, each group of the heat dissipating fins comprises one heat dissipating fin connected to the outer wall surface of the container or more than two heat dissipating fins arranged in parallelat intervals, and the fixed connection is that one end of the heat dissipating fin and the liquid storage unit outer wall are integrally fixed, and other end of the heat dissipating fin and the fixedliquid storage unit outer wall surface form a 10-90 DEG angle.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrode, nonaqueous electrolyte battery, battery pack and vehicle

ActiveCN108630908AImprove life characteristicsAlkali titanatesNegative electrodesBinding energyX-ray

The invention relates to an electrode, a nonaqueous electrolyte battery, a battery pack and a vehicle. The invention provides an electrode excellent in service performance. According to one approach,an electrode (3) is provided. The electrode (3) includes an active material-containing layer (3b). The active material-containing layer (3b) includes a Na-containing niobium-titanium composite oxide having an orthorhombic crystal structure. The active material-containing layer (3b) satisfies I2 / I1>=1. I1 is an intensity of a peak P1 appearing in a binding energy range of 289 eV to 292 eV in an X-ray photoelectron spectroscopy spectrum of the active material-containing layer (3b). I2 is an intensity of a peak P2 appearing in a binding energy range of 283 eV to 285 eV in the X-ray photoelectronspectroscopy spectrum of the active material-containing layer (3b).

Owner:KK TOSHIBA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap