Method for detecting inner connecting resistor of power battery pack

A power battery pack and resistance detection technology, applied in the direction of measuring resistance/reactance/impedance, measuring devices, measuring electrical variables, etc., can solve problems such as reducing battery pack production efficiency, increasing production cost, and damaging battery pack products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

[0025] For ease of understanding, the internal connection resistance of the power battery pack to be tested will first be described below.

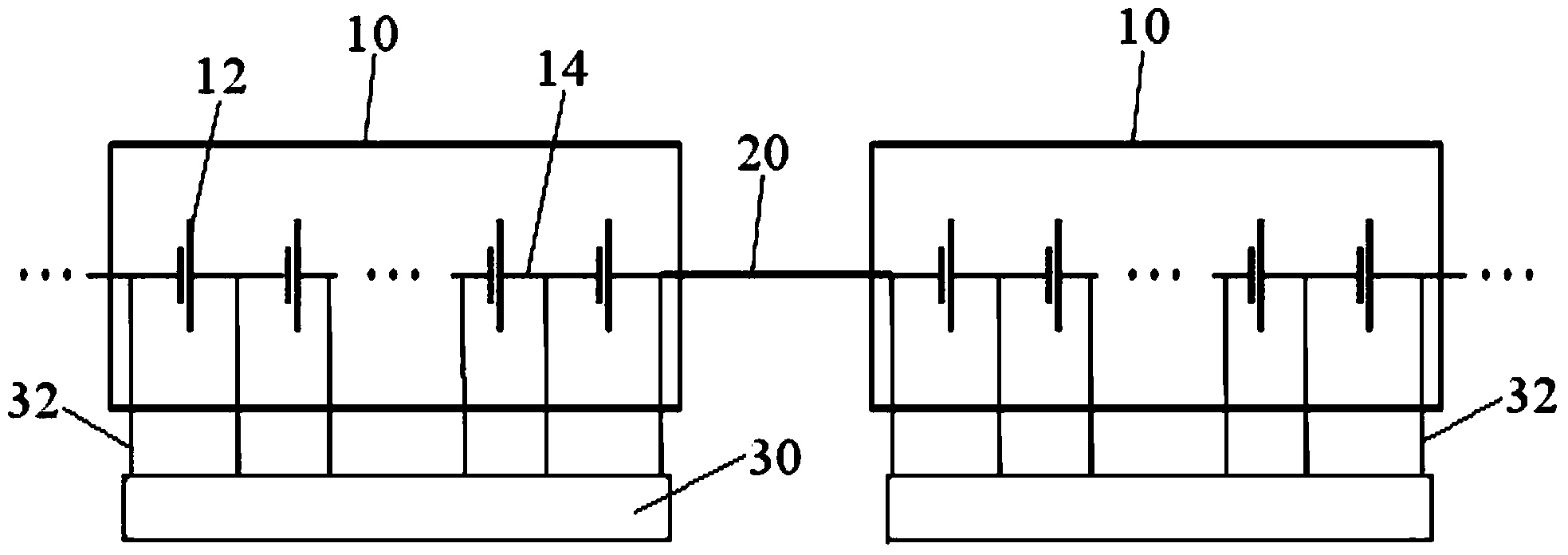

[0026] see figure 1 , the power battery pack to be tested contains a plurality of identical or different battery modules 10 , and each battery module 10 is provided with more than one single battery 12 . Since there is connection resistance (including the self-resistance of each connector and the contact resistance generated by different connection methods) on the connection route 20

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap