Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Niobium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Niobium, formerly known as columbium, is a chemical element with the symbol Nb (formerly Cb) and atomic number 41. Niobium is a light grey, crystalline, and ductile transition metal. Pure niobium has a hardness similar to that of pure titanium, and it has similar ductility to iron. Niobium oxidizes in the earth's atmosphere very slowly, hence its application in jewelry as a hypoallergenic alternative to nickel. Niobium is often found in the minerals pyrochlore and columbite, hence the former name "columbium". Its name comes from Greek mythology, specifically Niobe, who was the daughter of Tantalus, the namesake of tantalum. The name reflects the great similarity between the two elements in their physical and chemical properties, making them difficult to distinguish.

Mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals

The invention relates to a mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals, and belongs to the fields of mineral process engineering and comprehensive recycling of resources. The mineral separation method for recycling iron, rare earth, fluorite and niobium from iron tailings of associated multi-metal minerals comprises the following steps: carrying out low intensity magnetic separation and high intensity magnetic separation pre-concentration by taking bayan obo tailings as raw materials, then carrying out fluid bed roasting on obtained pre-concentrated concentrates, and carrying out low intensity magnetic separation operation on roasted minerals obtained by roasting so as to obtain weak-magnetism concentrates and rare-earth-containing weak-magnetism tailings; and carrying out rare earth flotation operation on the weak-magnetism tailings to obtain rare earth flotation concentrates and rare earth flotation tailings finally, then carrying out acid leaching process on the rare earth flotation tailings to obtain niobium-enriched slag and acid pickling tailings, and meanwhile, carrying out fluorite flotation operation on pre-concentrated strong-magnetism tailings to obtain fluorite flotation concentrates and fluorite flotation tailings. By the method, fluorite concentrates, iron core concentrates, rare earth concentrates and the niobium-enriched slag are obtained finally, and thus, the bayan obo tailings are utilized comprehensively.

Owner:NORTHEASTERN UNIV LIAONING

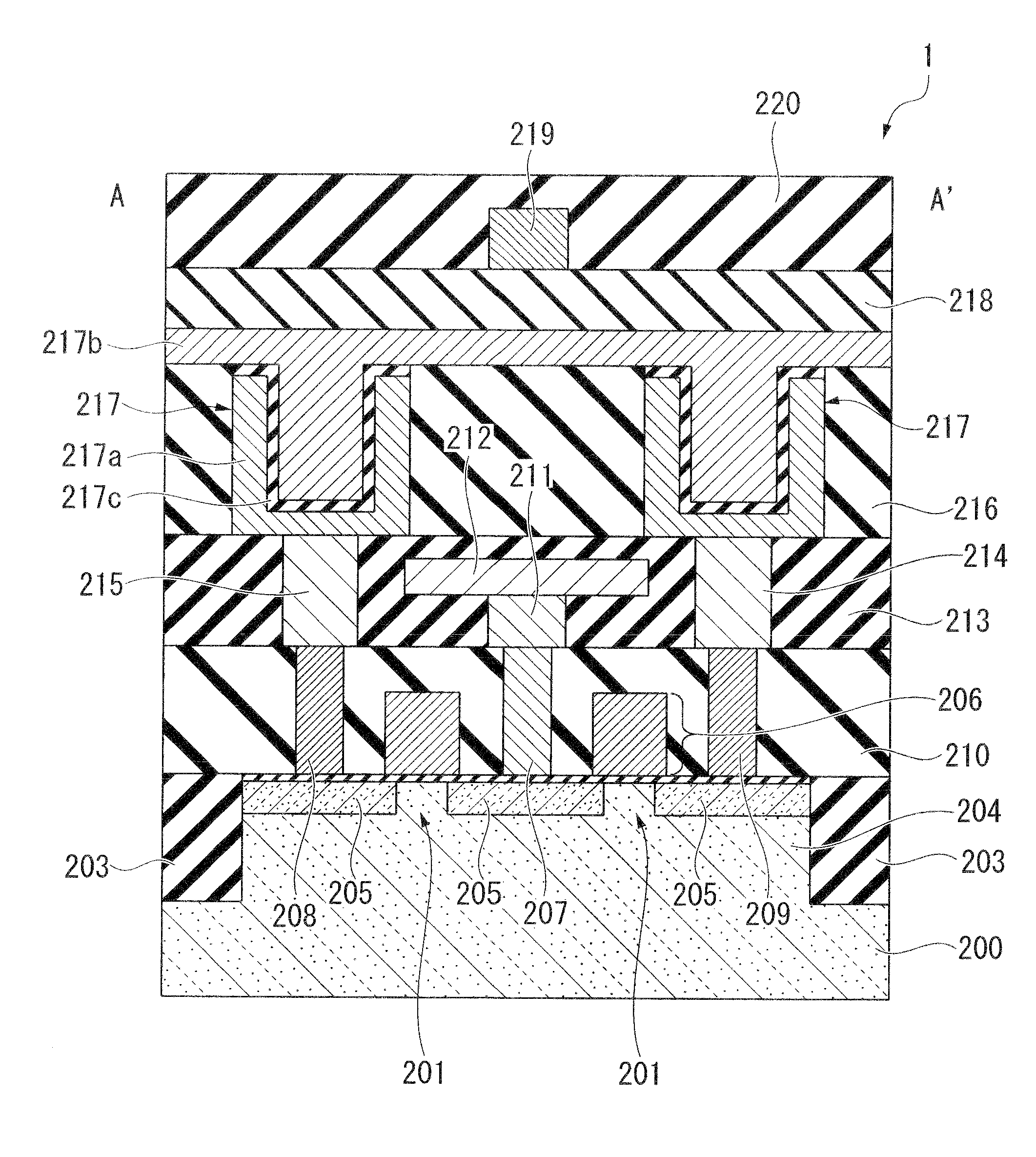

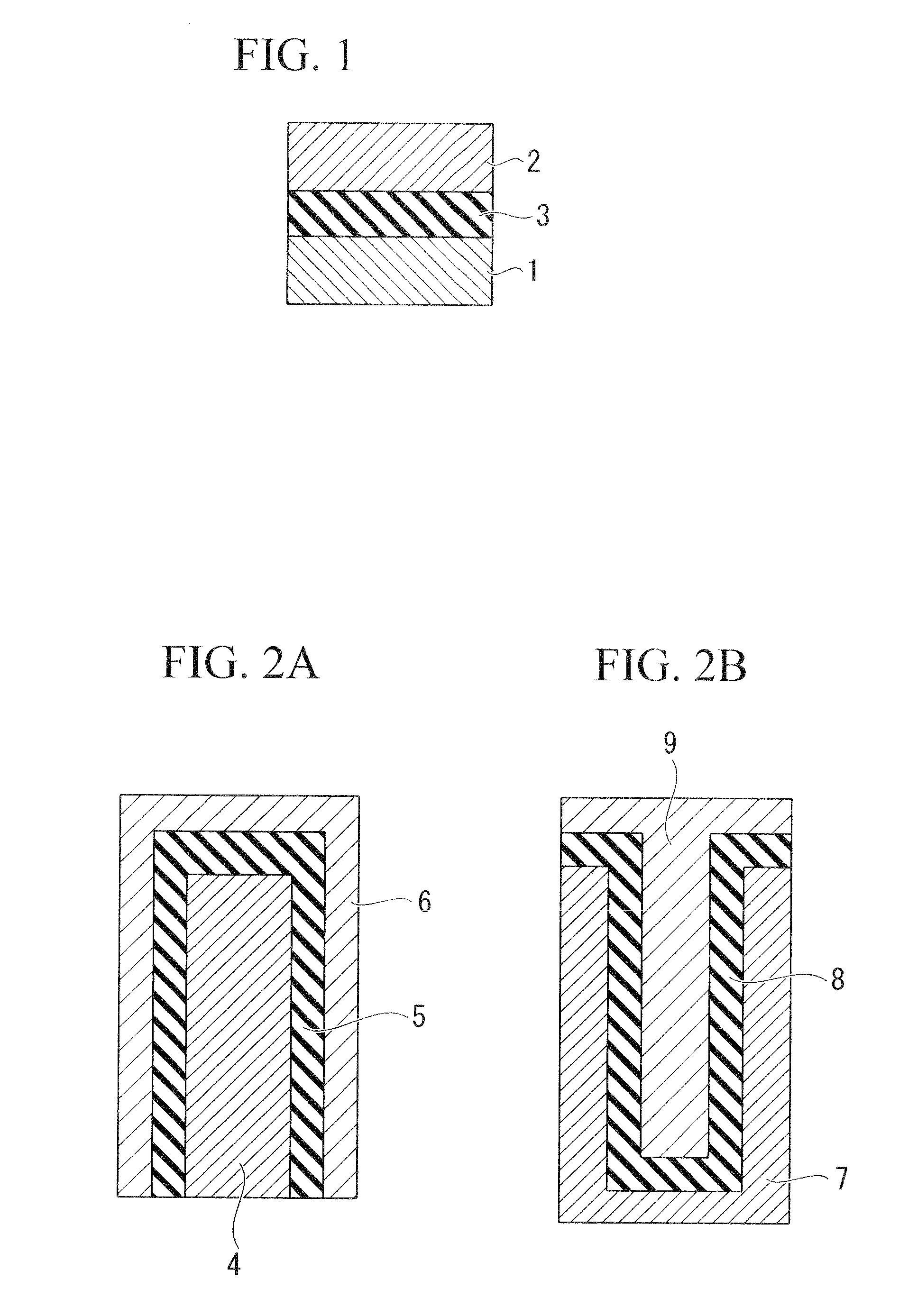

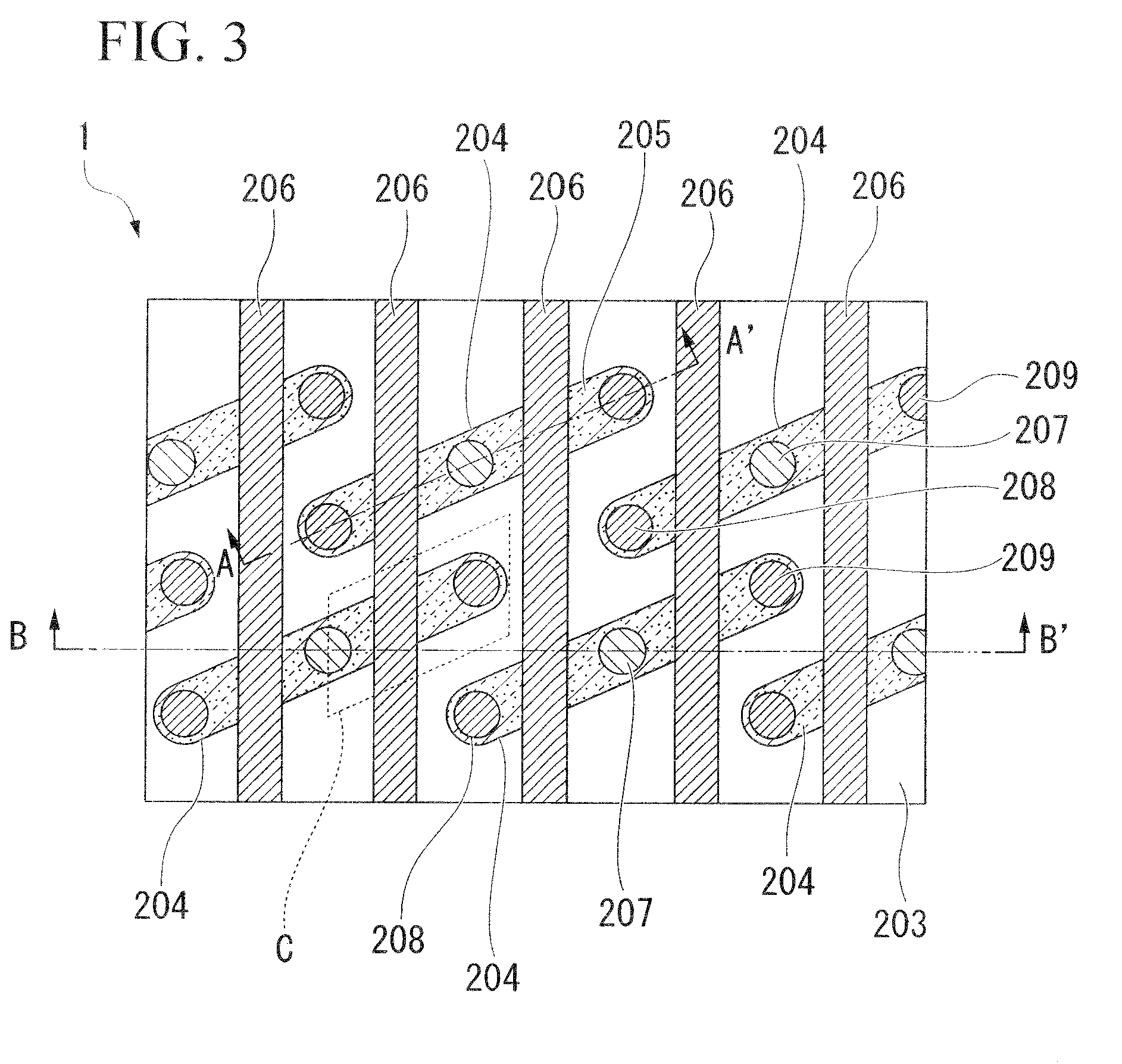

Insulation film for capacitor element, capacitor element and semiconductor device

Owner:ELPIDA MEMORY INC

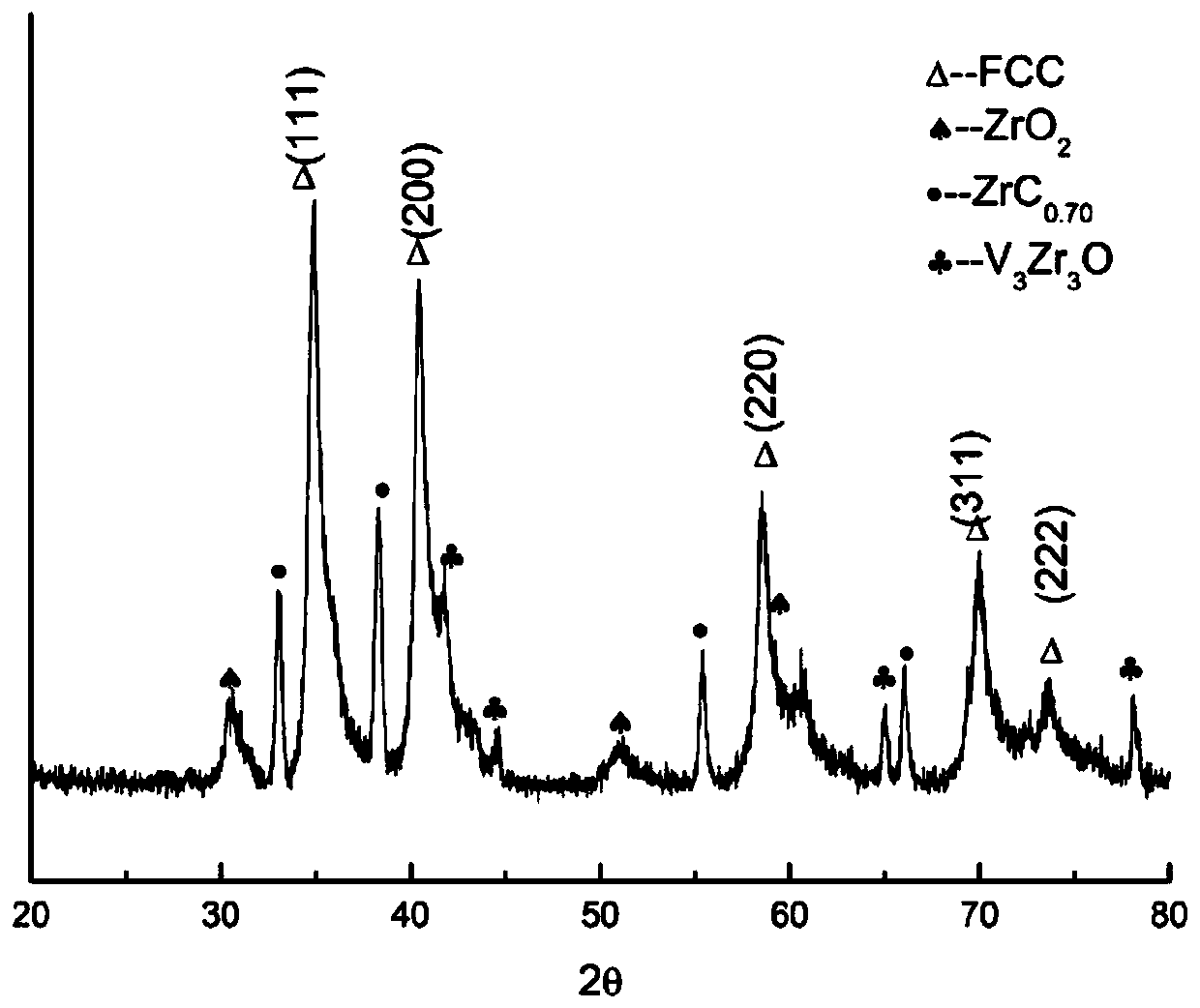

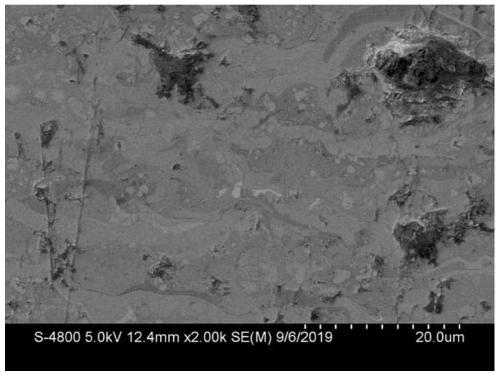

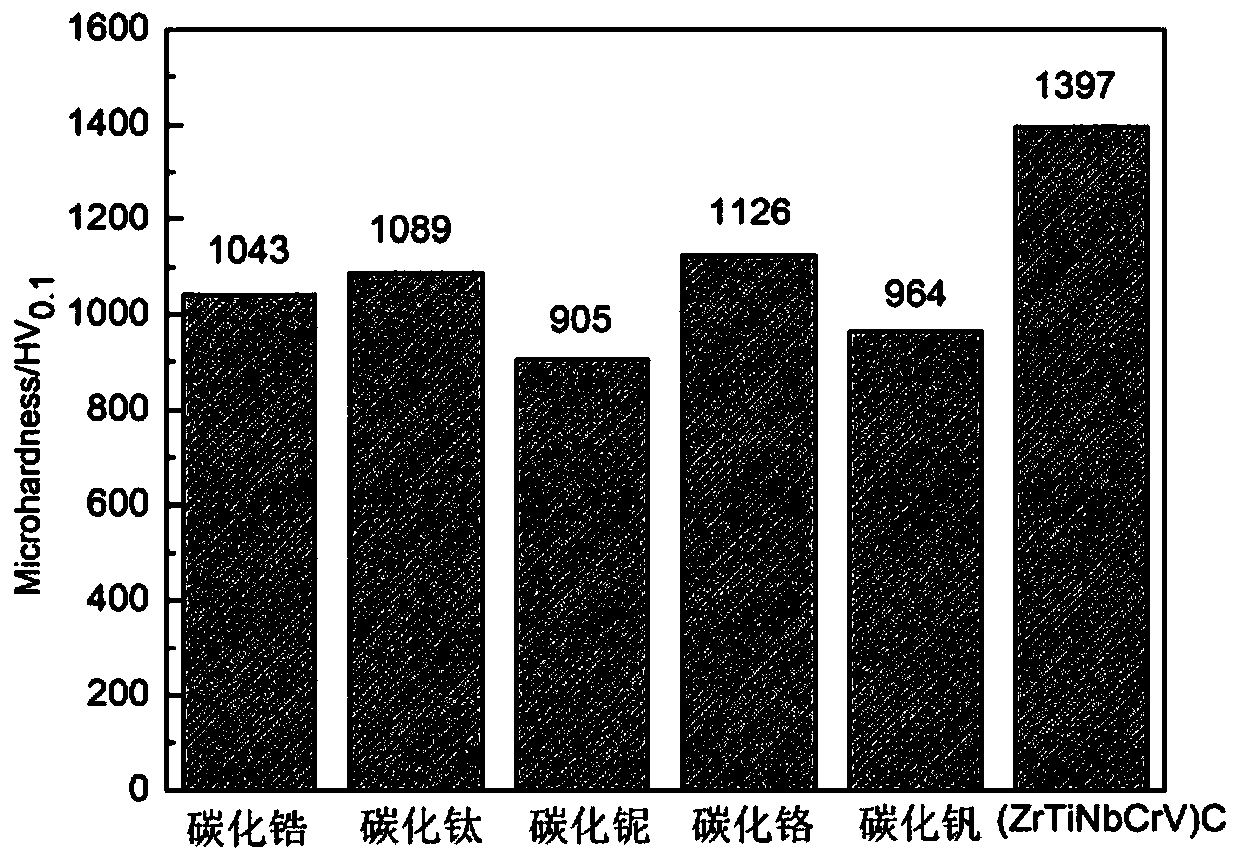

Preparation method of high-entropy ceramic coating

Owner:HEBEI UNIV OF TECH

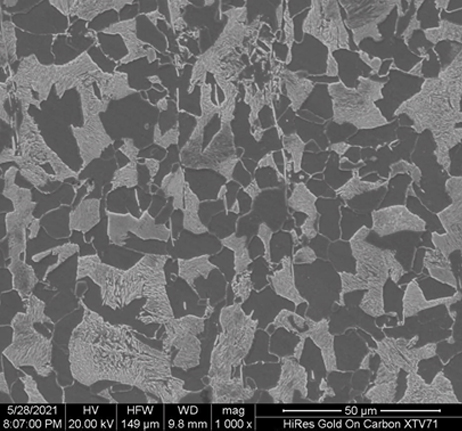

High heat input welding resistant building steel and production method thereof

ActiveCN114150228AImprove welding effectGood anti-fatigueHeat treatment process controlProcess efficiency improvementNiobiumHeat cycling

Owner:NORTHEASTERN UNIV

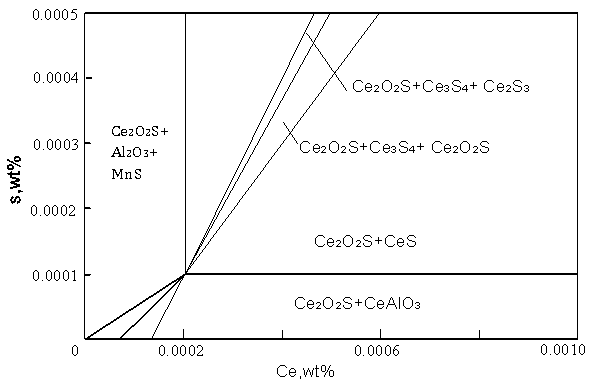

Smelting method for rare-earth microalloyed steel

Owner:内蒙古中天宏远稀土新材料股份公司

Separable pick-shaped cutter

InactiveCN104989400AHigh reuse rateImprove wear resistanceSlitting machinesCutting machinesNiobiumCarbide

A separable pick-shaped cutter comprises a cutting pick body and a cutting pick head, wherein the cutting pick body and the cutting pick head are detachable, the cutting pick head is inserted into the top of the cutting pick body and is in shaft and steel ball fit with the cutting pick body, and steel balls under the action of bolts and compression springs are evenly arranged around the top of the cutting pick body; anti-abrasion layers are arranged on the surface of the cutting pick body and the surface of the cutting pick head, and the anti-abrasion layers are made of metal carbides compounded from chrome, vanadium and niobium metal powder and nonmetal boron and carbon compounds. According to the separable pick-shaped cutter, the cutter can rotate in the stress direction of a conical spiral surface, the cutting pick head can rotate alone under the condition that generated cutting resistance is small, and eccentric wear of a carbide bit is effectively prevented; furthermore, due to the fact that the cutting pick body and the cutting pick head are two separated parts, the cutting pick head can be replaced, the reusing rate of the cutting pick body can be increased, and resources can be saved; due to the fact that the anti-abrasion layers are arranged on the surface of the cutting pick body and the surface of the cutting pick head to effectively protect the cutting pick body and the cutting pick head, the anti-abrasion performance of the cutting pick body and the cutting pick head is improved.

Owner:ANQING HUAQI MACHINERY ACCESSORIES CO LTD

Preparation method of niobium-zirconium 10 alloy tube

InactiveCN104561575ANo segregationImprove tissue uniformityNiobiumDehydrogenation

Owner:BAOJI TIANBO METAL MATERIAL

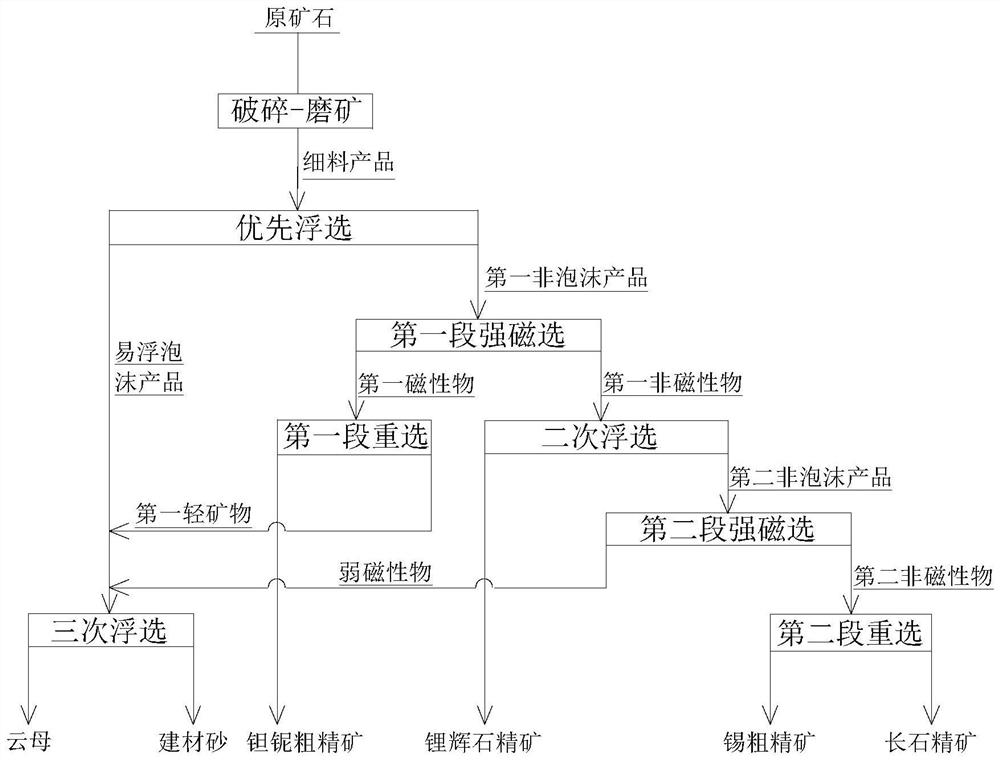

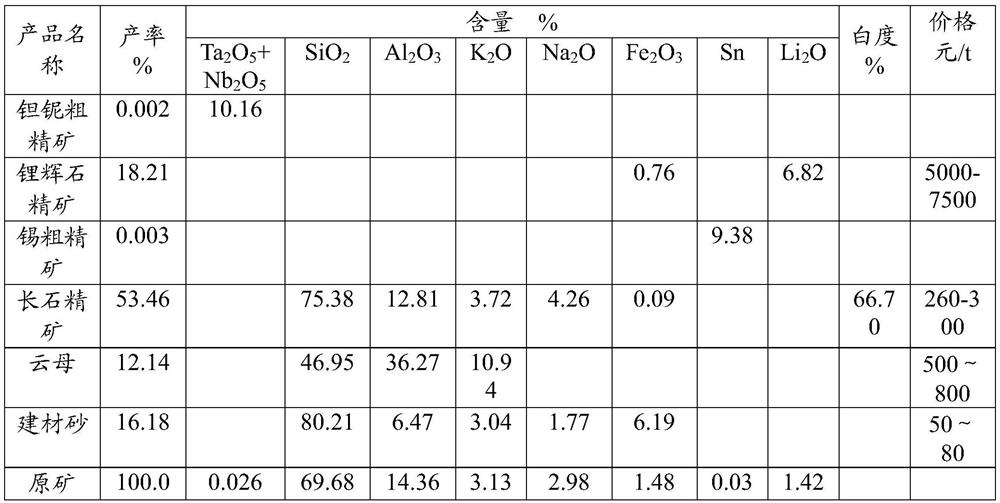

Comprehensive utilization method of pegmatite containing tantalum niobium, cassiterite, feldspar and spodumene

PendingCN114588998AImprove recycling ratesTake advantage ofHigh gradient magnetic separationFlotationNiobiumMagnetic separation

Owner:SHANDONG HUATE MAGNET TECH

Material formula for diamond bit

InactiveCN108746592AReduce manufacturing costHigh tensile strengthTransportation and packagingMetal-working apparatusNiobiumSilicon dioxide

Owner:如皋千骏工具有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap