Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Boron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron is a chemical element with the symbol B and atomic number 5. Produced entirely by cosmic ray spallation and supernovae and not by stellar nucleosynthesis, it is a low-abundance element in the Solar system and in the Earth's crust. Boron is concentrated on Earth by the water-solubility of its more common naturally occurring compounds, the borate minerals. These are mined industrially as evaporites, such as borax and kernite. The largest known boron deposits are in Turkey, the largest producer of boron minerals.

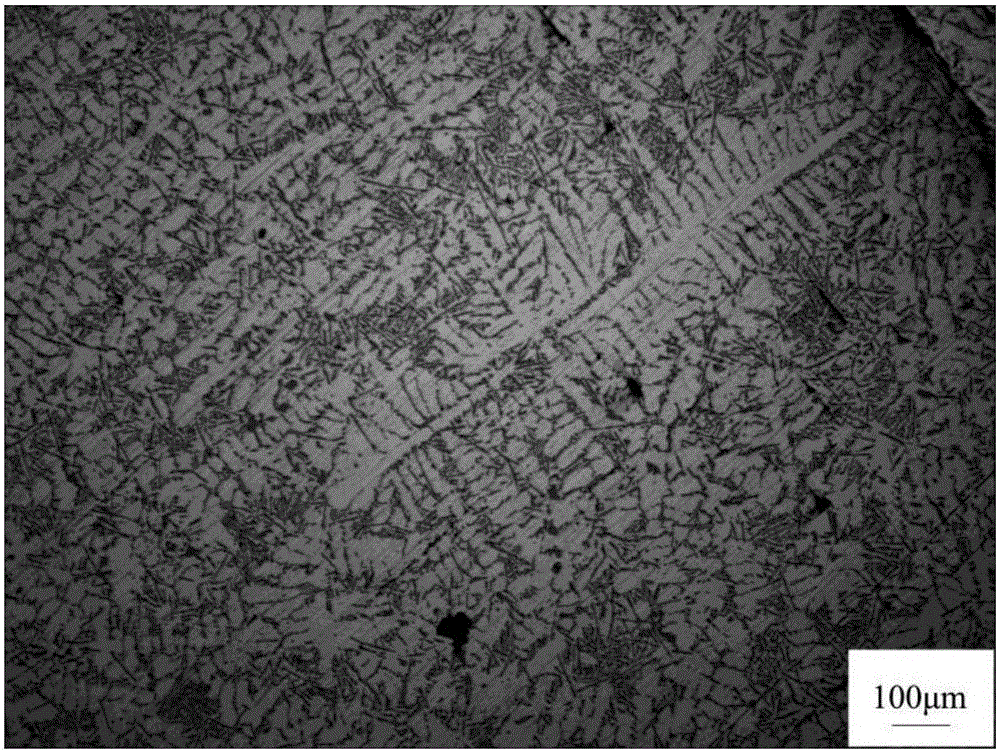

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

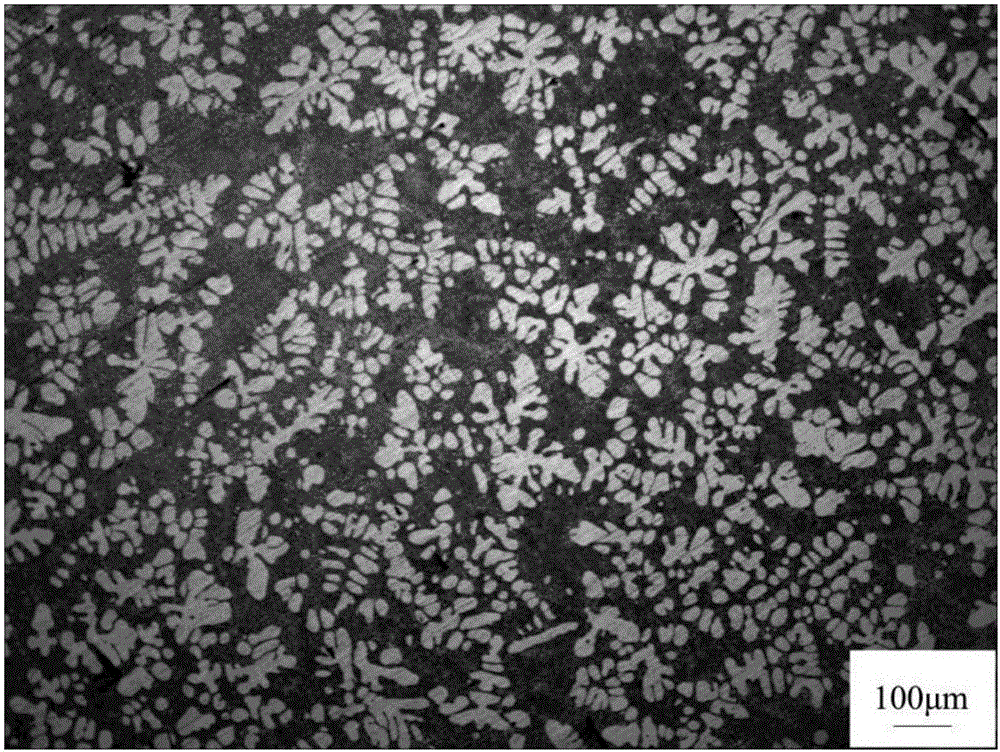

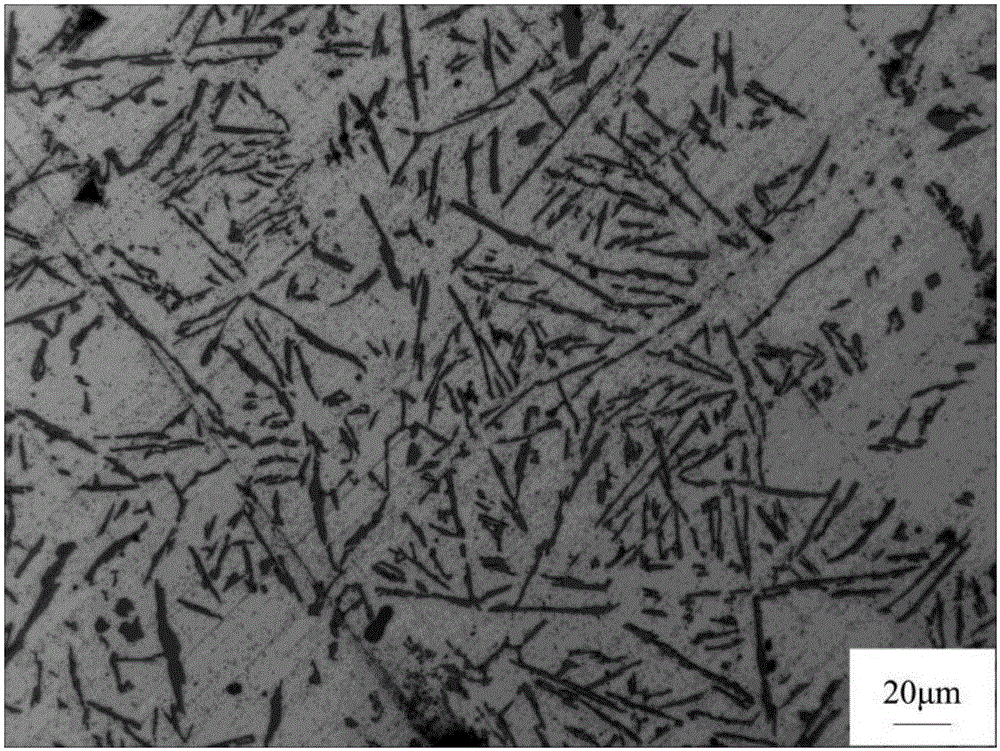

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

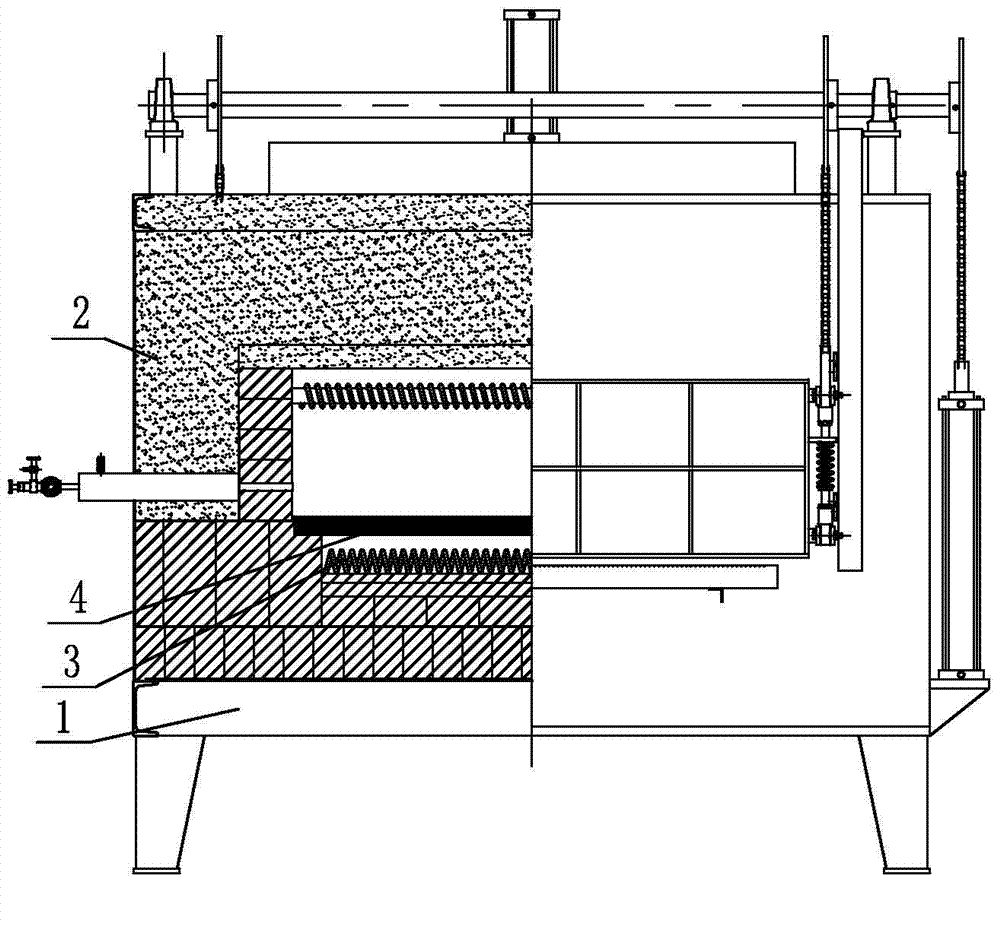

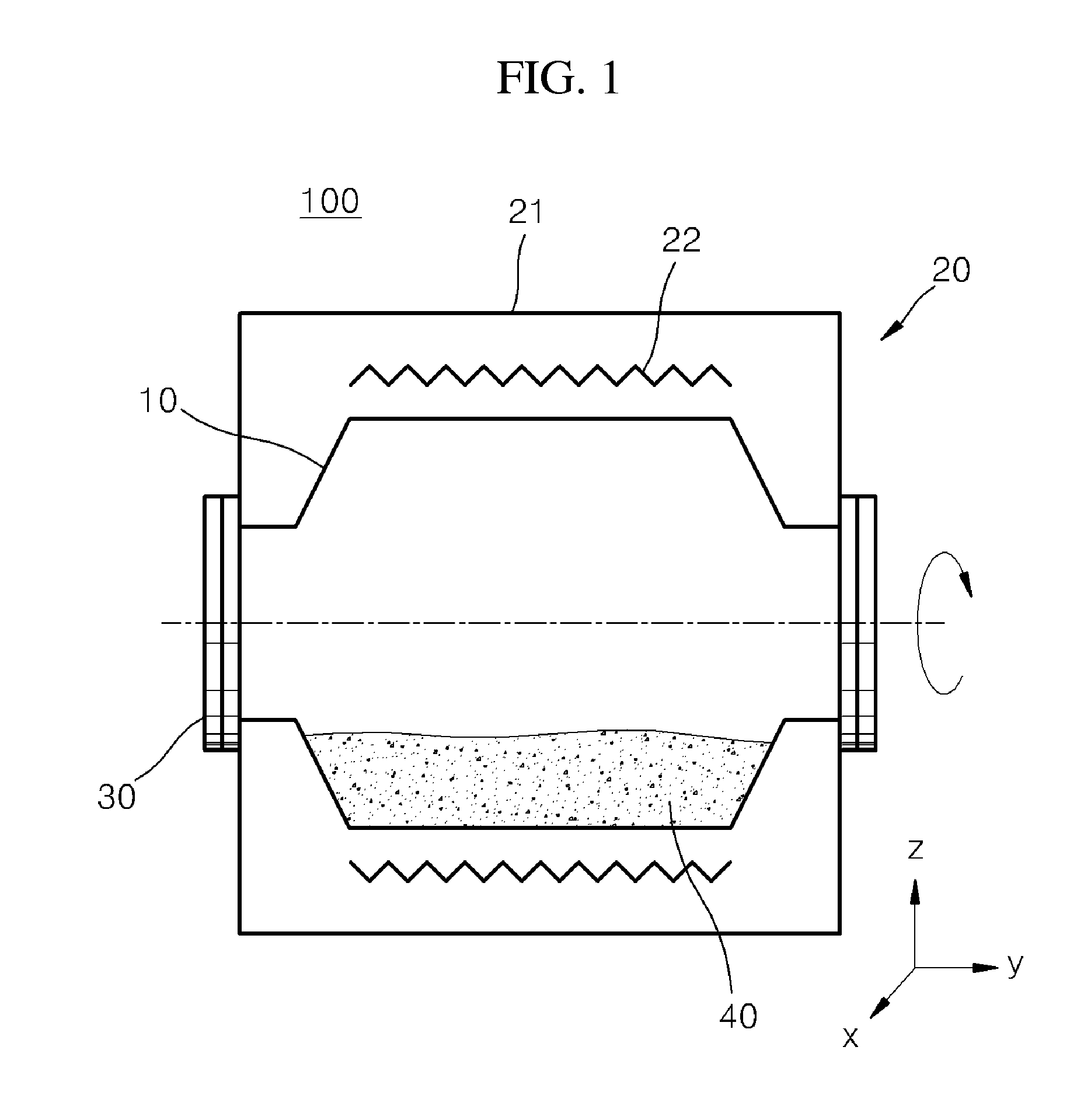

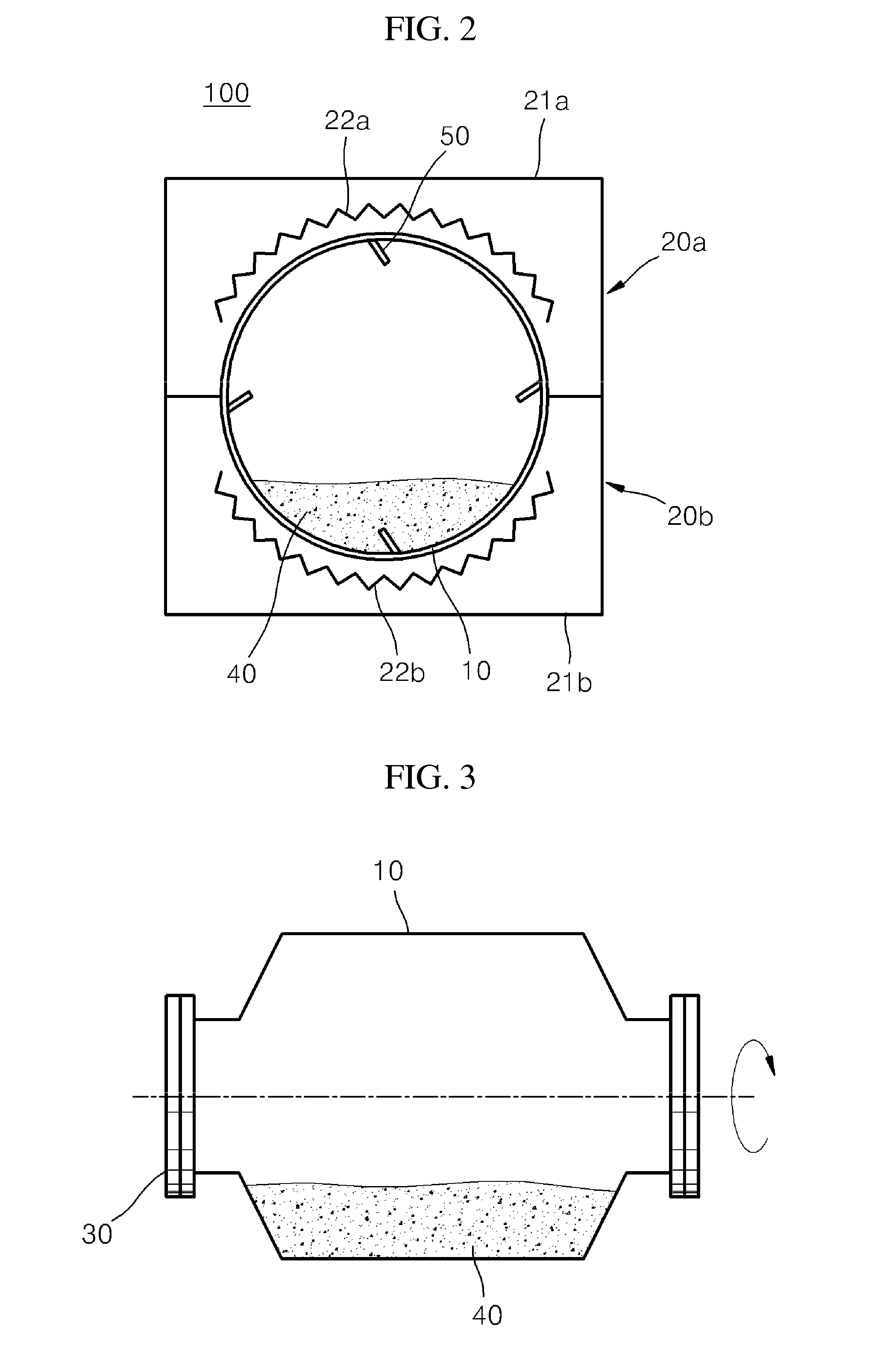

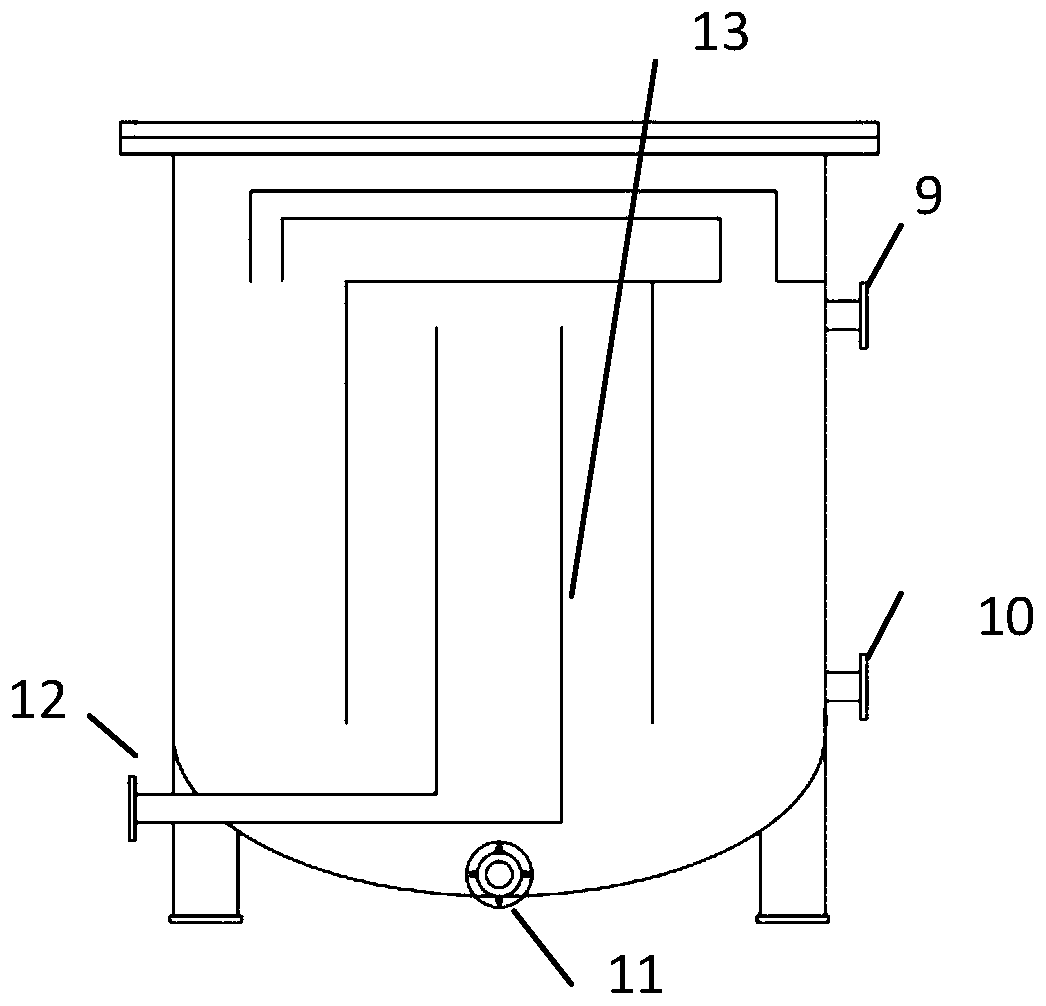

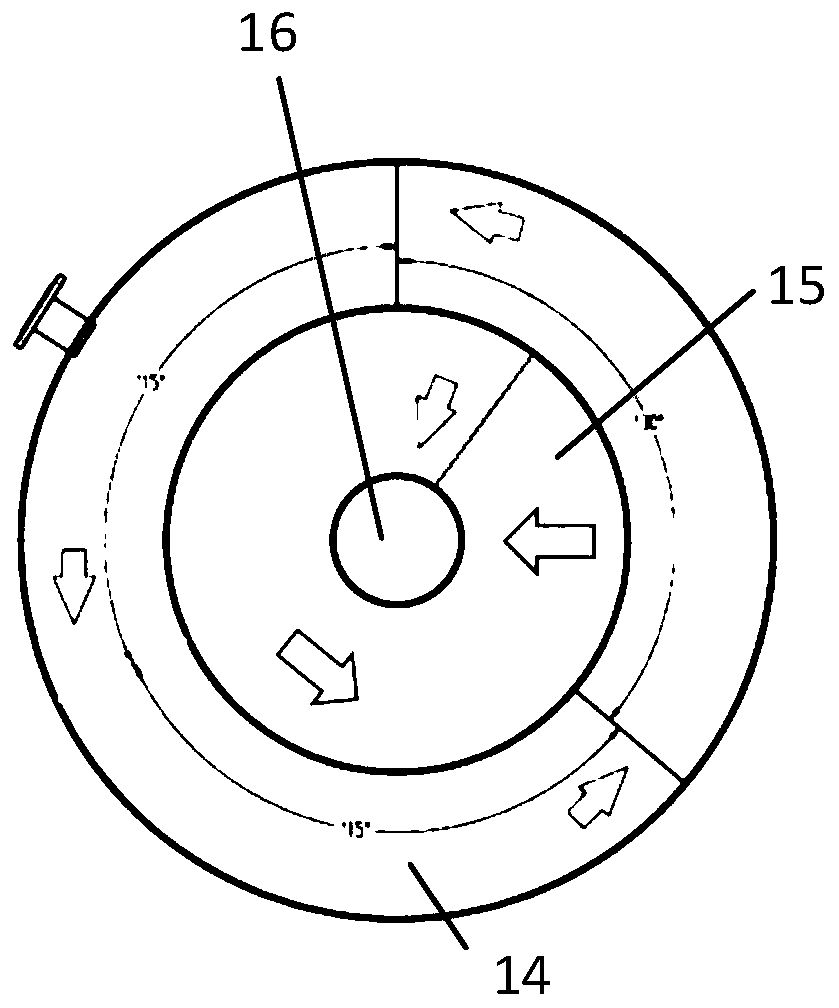

Device and method for measuring heat exchange coefficient of interface in hot stamp process

ActiveCN103033530ARealize the test of interface heat transfer coefficientAvoid incomingMaterial heat developmentSheet steelMeasurement device

The invention discloses a device for measuring a heat exchange coefficient of an interface between a high-temperature steel plate and a die in a hot stamp process. The device comprises a pressure applying device and a measurement device, wherein the pressure applying device comprises a pressurization device, an upper workbench and a lower workbench, wherein the pressurization device is connected with the upper workbench and the lower workbench respectively; the measurement device comprises an upper fixture, a lower fixture and a test sample fixing fixture; the upper fixture is fixed on the upper workbench; the lower fixture is fixed on the lower workbench; and the test sample fixing fixture is arranged between the upper fixture and the lower fixture. The invention also discloses a method for measuring the heat exchange coefficient of the interface between the high-temperature steel plate and the die in the hot stamp process. By the device and the method, the limitation to samples with the thickness being more than 30mm in the prior art is avoided; the heat exchange coefficient of the interface between the steel plate and the die in the hot stamp process can be measured; and by an elastic energy storage element, stabilization of interface pressures between a boron steel test sample and an upper die and between the boron steel test sample and a lower die can be guaranteed.

Owner:TENGZHOU PROD QUALITY SUPERVISION & INSPECTION INST

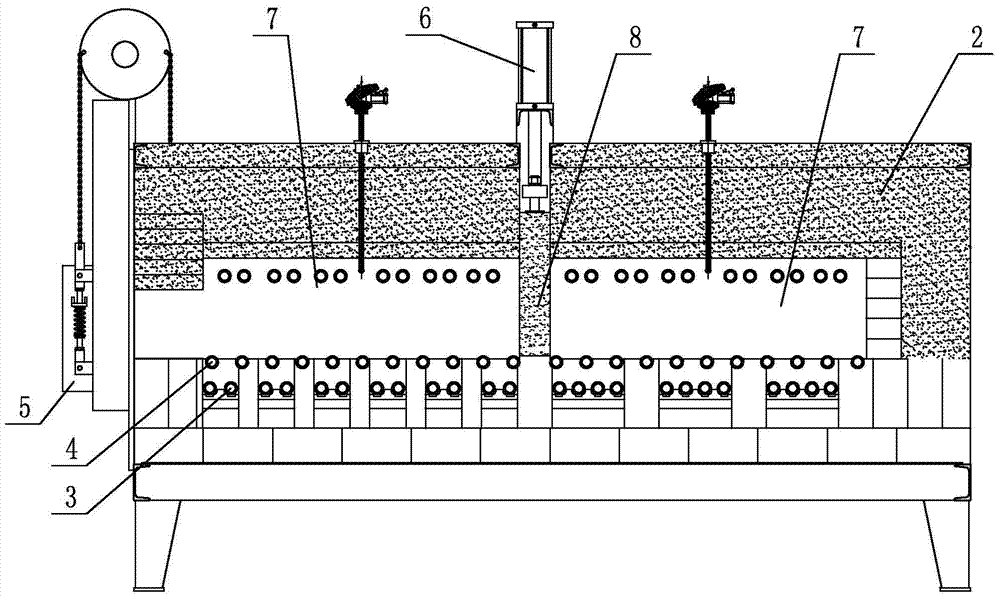

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

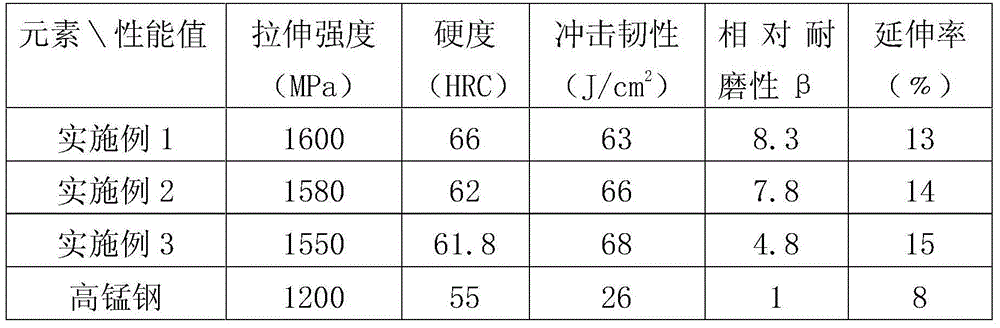

Boron-bearing chromium molybdenum nickel wear-resistant alloy and preparation method thereof

Owner:GUANGXI UNIV

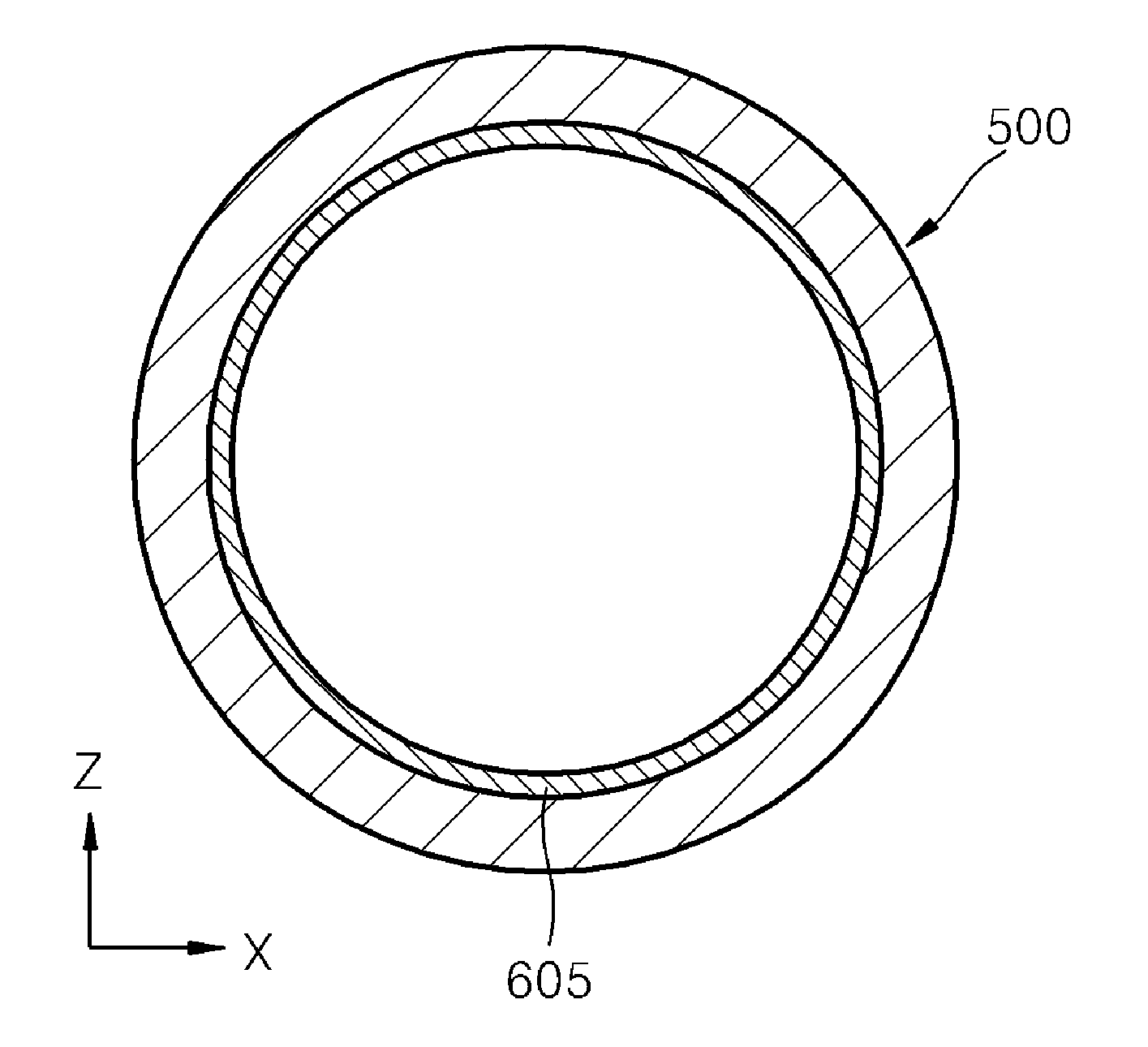

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS20140096858A1High hardnessLow melting pointHeat treatmentsLiquid surface applicatorsPowder mixtureAlloy

Owner:KMT CO LTD

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

Boron-phosphorus alloy cast iron used in air compressor cylinder block and its manufacturing process

InactiveCN102268587AImprove wear resistanceImprove tensile propertiesProcess efficiency improvementElectric furnaceAlloyCylinder block

Owner:ZHUJI HUAJIA AIR COMPRESSOR

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

Method for preparing laser cladding layer through double-layer organic coating iron-based alloy powder

ActiveCN105081313AWith metallic lusterControl gas compositionMetallic material coating processesDistillationSlurry

The invention discloses a method for preparing a laser cladding layer through double-layer organic coating iron-based alloy powder. 15%-19% of chromium, 2%-9% of nickel, 0.05%-0.15% of boron, 0.1%-0.7% of silicon, carbon less than 0.3% and the balance iron are selected; and then rosin accounting for 0.06%-0.2% of the total weight of the iron-based alloy powder and industrial starch accounting for 0.15%-0.4% of the total weight of the iron-based alloy powder are selected. The selected rosin is added to absolute ethyl alcohol, and the iron-based alloy powder is added to the absolute ethyl alcohol with the dissolved rosin; and rosin film coated iron-based alloy powder is prepared through drying by distillation, drying and breaking. Then, the industrial starch is added to pure water to be heated and stirred to obtain an even pasty solution, and the rosin film coated iron-based alloy powder is put in the pasty industrial starch; secondary mixed slurry is obtained; and the double-layer organic coating iron-based alloy powder can be obtained through stirring, drying by distillation and breaking. The laser cladding layer of the powder is flat in surface, has metal luster and is high in comprehensive quality.

Owner:NANHUA UNIV

Mixing technology for lead, boron and polyethylene

A process for mixing lead-boron polyethylene related to the material mixing process of radioactive masking material comprising the steps of, mixing lead and boron evenly, high speed mixing and plasticizing of polyethylene in heated mixer, and mixing the lead-boron mixture with polyethylene in heated mixer evenly. The process according to the invention realizes simple operation process, less pollution, even product mixing, thus can be widely applied into the mixing process for lead-containing material.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Rubber composition used for treads of middle-large-size automobile tires

ActiveCN107759860AIncrease elasticityImprove wear resistanceSpecial tyresVulcanizationPolymer science

Owner:ZHAOQING JUNHONG CO LTD

High-temperature-resistant high-performance rare earth permanent magnet material

InactiveCN105374488AHigh temperature resistance and high performanceImprove stabilityInorganic material magnetismRare-earth elementTemperature resistance

Owner:南通长江电器实业有限公司

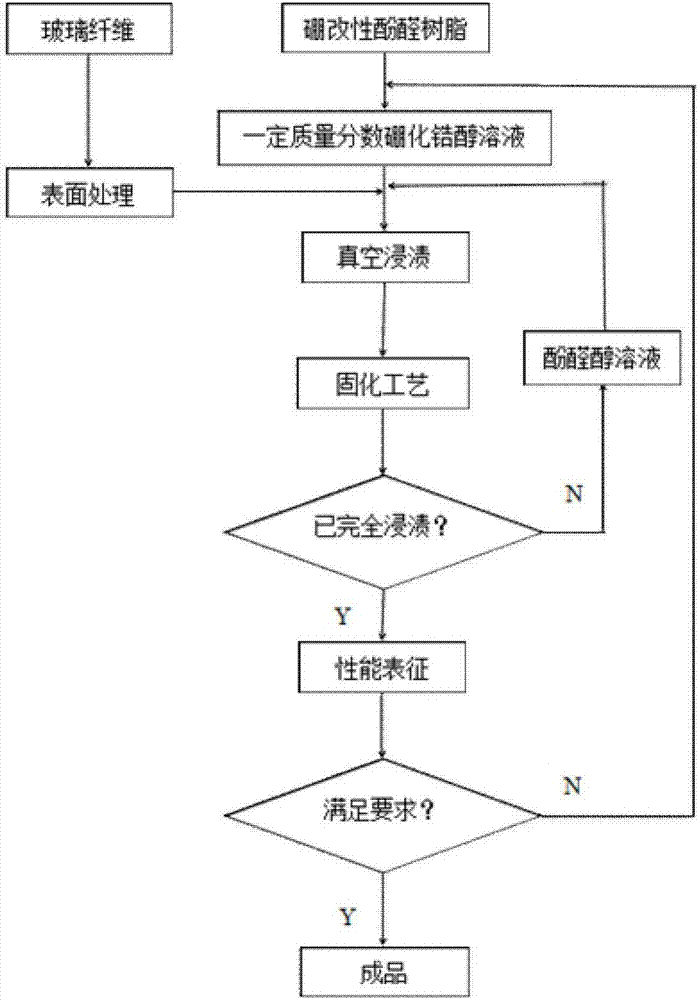

Preparation method of phenolic resin impregnation glass fiber composite material

Owner:BEIJING JIAOTONG UNIV

Aluminum-lanthanum-boron-strontium intermediate alloy for cast aluminum-silicon alloy and preparation method of aluminum-lanthanum-boron-strontium intermediate alloy

InactiveCN106191490AGood metamorphic effectAvoid reactionSilicon alloyCastability

Owner:SOUTHEAST UNIV

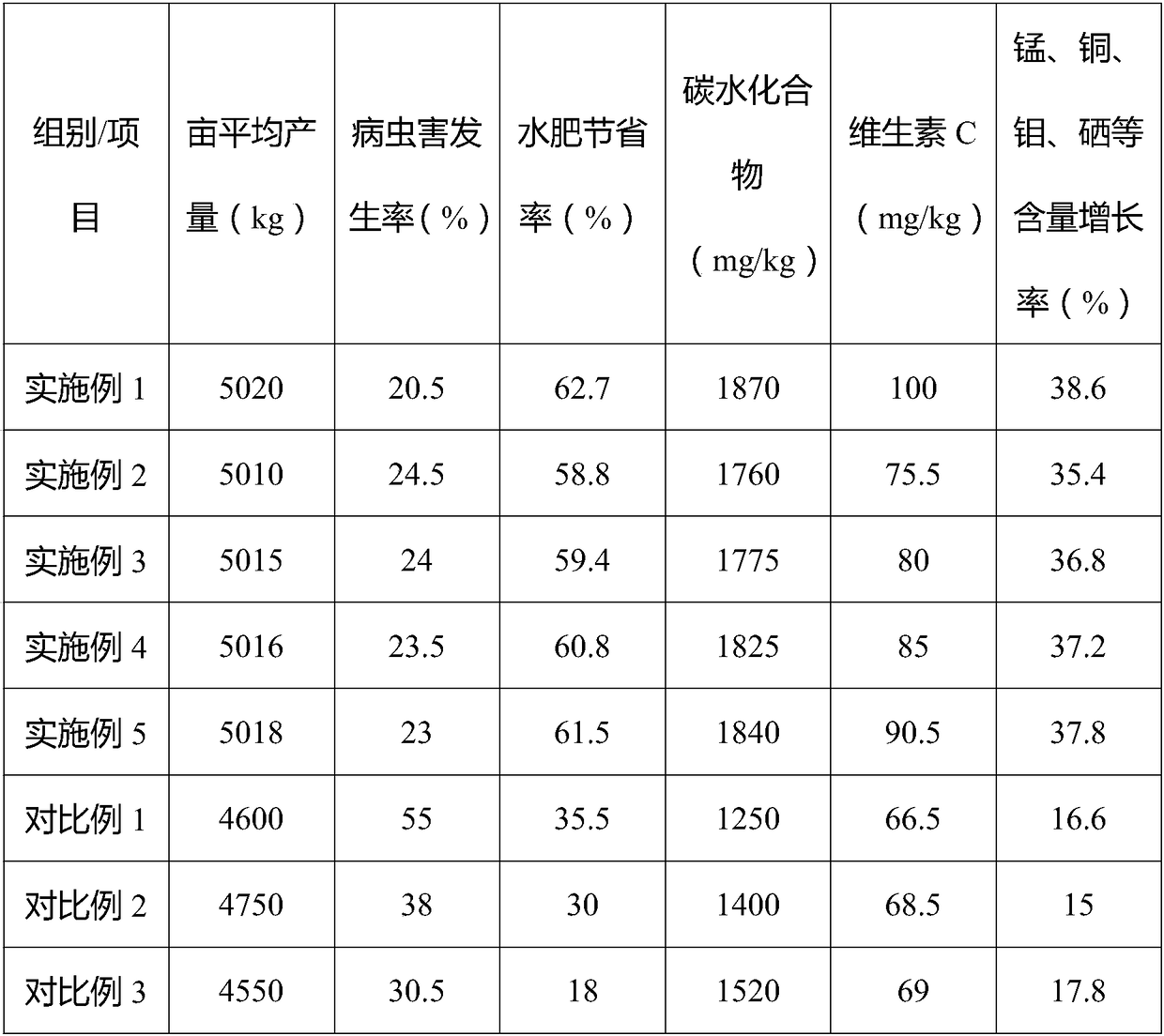

Planting method for beet rich in various trace elements

InactiveCN108739144AReduce volatilityReduce churnBio-organic fraction processingExcrement fertilisersPlant cellManganese

Owner:FOSHAN RIKEWEI FOOD TECH RES INST GENERAL PARTNER

High-efficiency environment-friendly composite fertilizer specially used for lotus drought plantation

Owner:太仓市林港农场专业合作社

Selective hydrogenation catalyst

ActiveCN103566942AEasy to prepareShort preparation cycleMetal/metal-oxides/metal-hydroxide catalystsRefining by selective hydrogenationNickel saltAlloy catalyst

The invention provides a selective hydrogenation catalyst. The selective hydrogenation catalyst is prepared by a method comprising the following steps: firstly, evenly mixing a soluble nickel salt solution with the mixed sol of an aluminum compound and a titanium compound to obtain a mixed solution; secondly, dropwise adding a metal boron hydride to the mixed solution in an inert atmosphere at a temperature ranging from 0 to 30 DEG C, stirring, and finally, obtaining an amorphous alloy catalyst with the composite sol as the carrier. The catalyst provided by the invention is characterized in that the preparation method of the catalyst is simple, the step of preparing a solid carrier is omitted, the preparation period is short and the cost is low, and the catalyst can be reused; and moreover, the catalyst is high in catalyst activity and good in selectivity, and has a good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

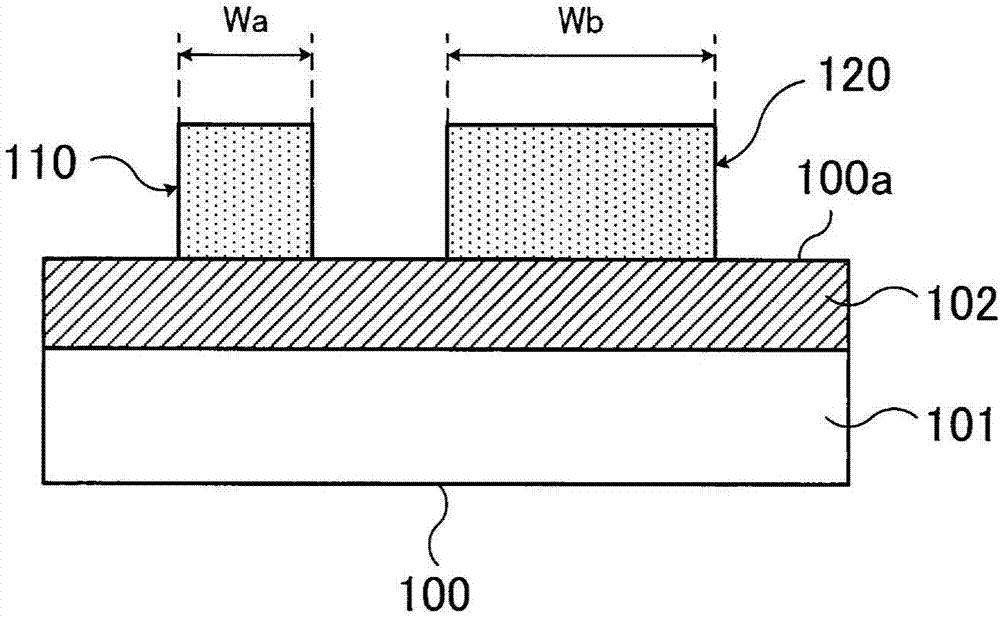

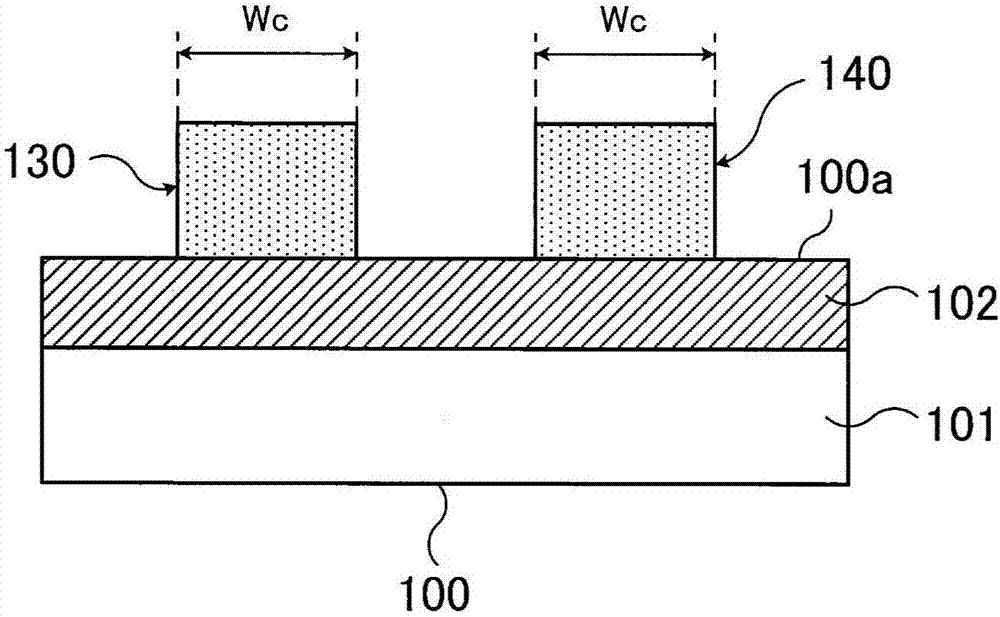

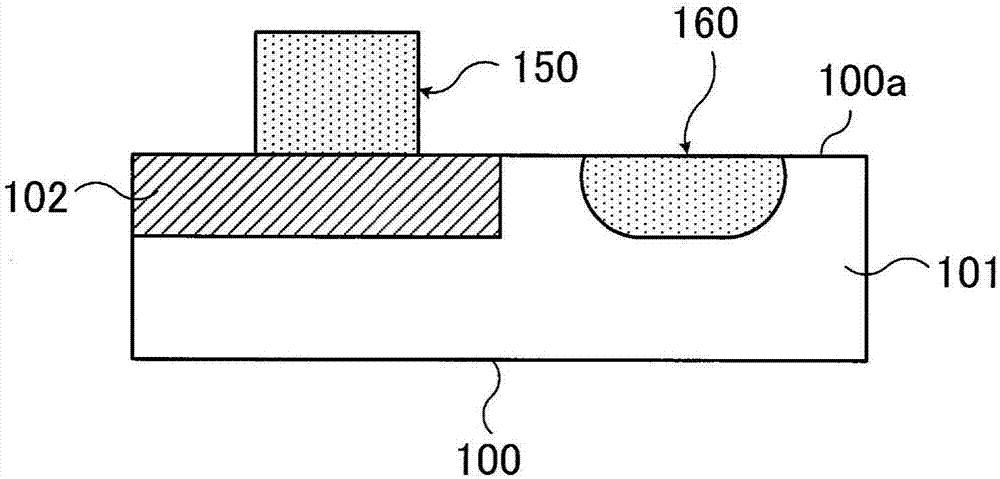

Semiconductor device and semiconductor device fabrication method

ActiveCN107104134AInhibition of poor performanceTransistorSemiconductor/solid-state device detailsPower semiconductor deviceBoron

Owner:UNITED SEMICON JAPAN CO LTD

Treatment system and method for mixed waste liquid of drilling wastewater and fracturing flowback fluid

InactiveCN110078251AAchieve re-useWell mixedWater contaminantsScale removal and water softeningLiquid wasteIon exchange

Owner:PETROCHINA CO LTD

Special magnesium alloy material for vehicle crankshaft and preparation method thereof

The invention discloses a special magnesium alloy material for a vehicle crankshaft and a preparation method thereof. The special magnesium alloy material for the vehicle crankshaft comprises the following components in percentage by weight: 4.0-7.0% of silicon, 3.7-5.8% of copper, 2.5-4.0% of lithium, 0.4-0.6% of tungsten, 0.5-0.9% of chromium, 0.04-0.07% of titanium, 0.02-0.07% of boron, 0.001-0.004% of nickel, 0.001-0.003% of vitriol, 0.001-0.003% of zirconium, and the balance of magnesium. The high-performance magnesium alloy material with higher strength and hardness is prepared through selecting the specific formula, has the advantages of lightness and wear resistance, is excellent in heat dissipating capacity, and can satisfy the quality requirement of the vehicle crankshaft.

Owner:YUYAO WANZHEN HARDWARE FACTORY

Method for producing 23MnB steel based on converter flow path

ActiveCN102409134AReduce acid soluble aluminum contentLight weightManufacturing convertersTitaniumOxygen

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Setting agent used after wool stretch and refinement

InactiveCN106702736AGuaranteed stabilityImprove oxidation efficiencyAnimal fibresPolystyreneButanone

Owner:HUZHOU PINCHUANG INCUBATOR

Robust binder, which is independent from the influence of catalytically active substances, for use in the crude oil and natural gas industry

ActiveUS9920237B2Extend time gelation timeExtended opening timeFluid removalDrilling compositionDouble bondHydrolysis

Owner:EPG ENGINEERED NANOPROD GERMANY

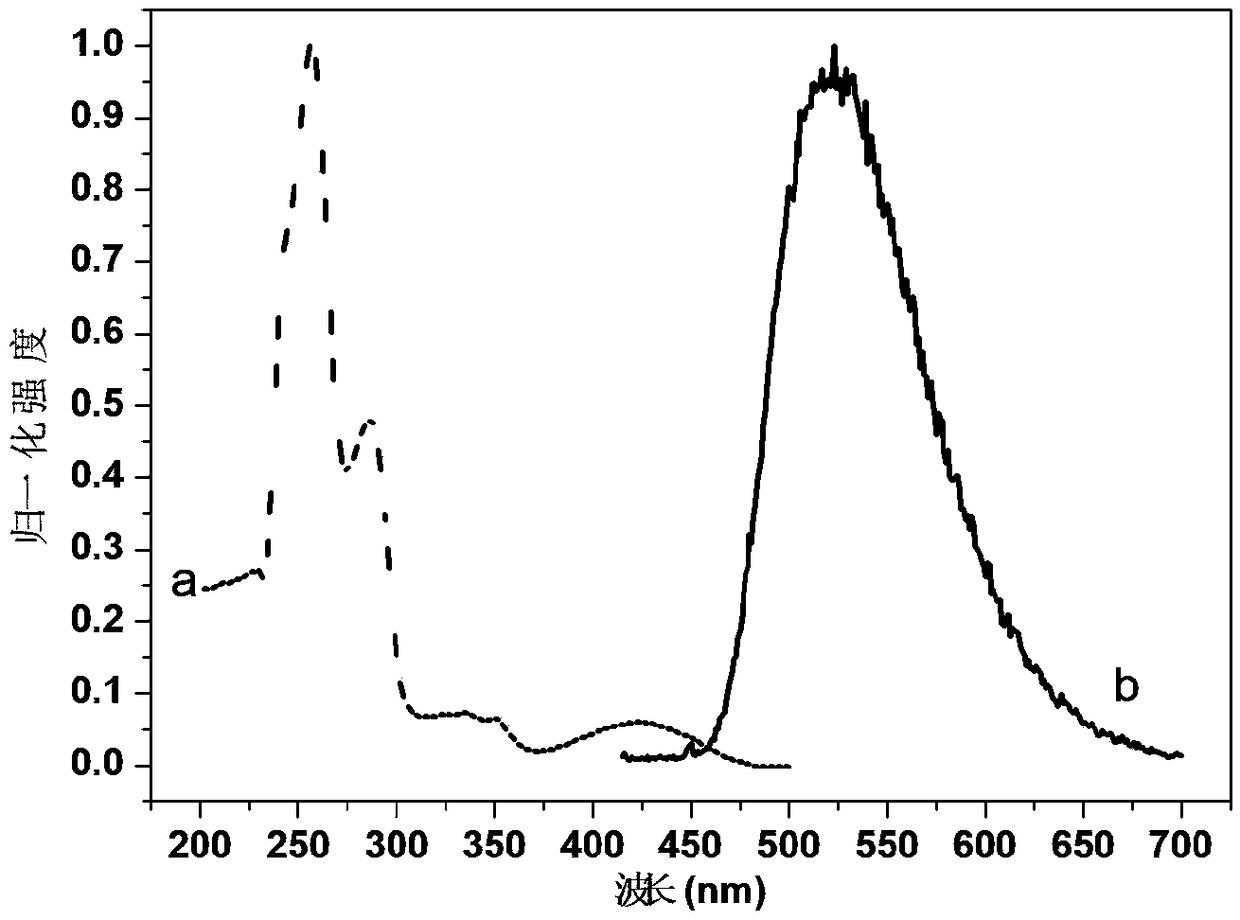

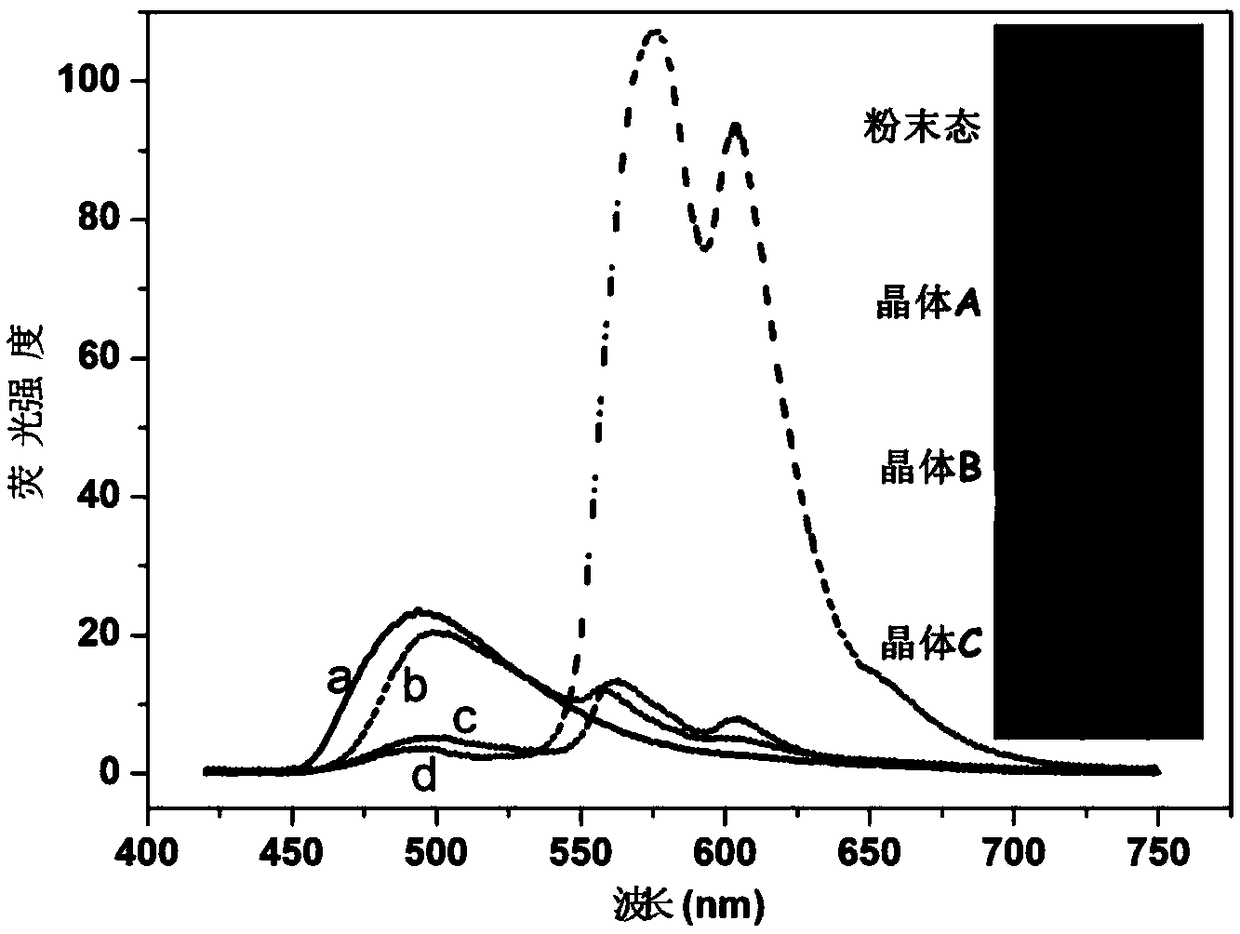

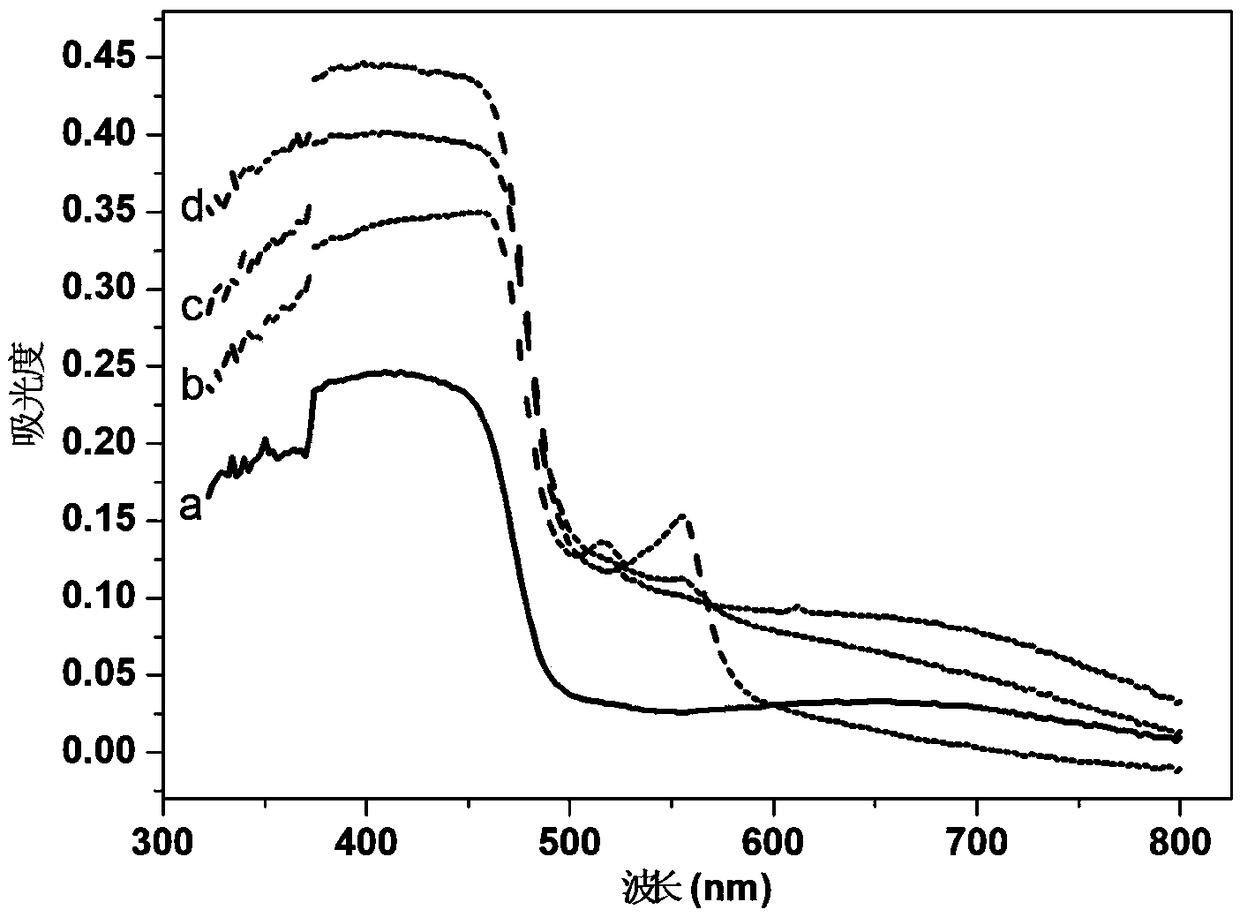

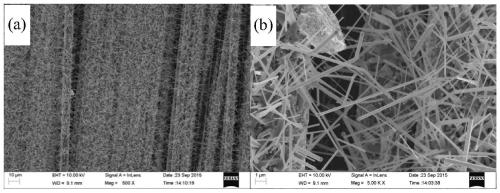

Tetra-coordinated octahydroxyquinoline boron compound, preparation method and application of compound

ActiveCN108774255AHigh fluorescence quantum yieldGood chemical stabilityOrganic chemistry methodsInksFluorescenceColor printing

Owner:SHAANXI NORMAL UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap