Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Exchange coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exchange coefficient. [iks′chānj ‚kō·i‚fish·ənt] (fluid mechanics) A coefficient of eddy flux in turbulent flow, defined in analogy to those coefficients of the kinetic theory of gases.

Device and method for measuring heat exchange coefficient of interface in hot stamp process

ActiveCN103033530ARealize the test of interface heat transfer coefficientAvoid incomingMaterial heat developmentSheet steelMeasurement device

The invention discloses a device for measuring a heat exchange coefficient of an interface between a high-temperature steel plate and a die in a hot stamp process. The device comprises a pressure applying device and a measurement device, wherein the pressure applying device comprises a pressurization device, an upper workbench and a lower workbench, wherein the pressurization device is connected with the upper workbench and the lower workbench respectively; the measurement device comprises an upper fixture, a lower fixture and a test sample fixing fixture; the upper fixture is fixed on the upper workbench; the lower fixture is fixed on the lower workbench; and the test sample fixing fixture is arranged between the upper fixture and the lower fixture. The invention also discloses a method for measuring the heat exchange coefficient of the interface between the high-temperature steel plate and the die in the hot stamp process. By the device and the method, the limitation to samples with the thickness being more than 30mm in the prior art is avoided; the heat exchange coefficient of the interface between the steel plate and the die in the hot stamp process can be measured; and by an elastic energy storage element, stabilization of interface pressures between a boron steel test sample and an upper die and between the boron steel test sample and a lower die can be guaranteed.

Owner:TENGZHOU PROD QUALITY SUPERVISION & INSPECTION INST

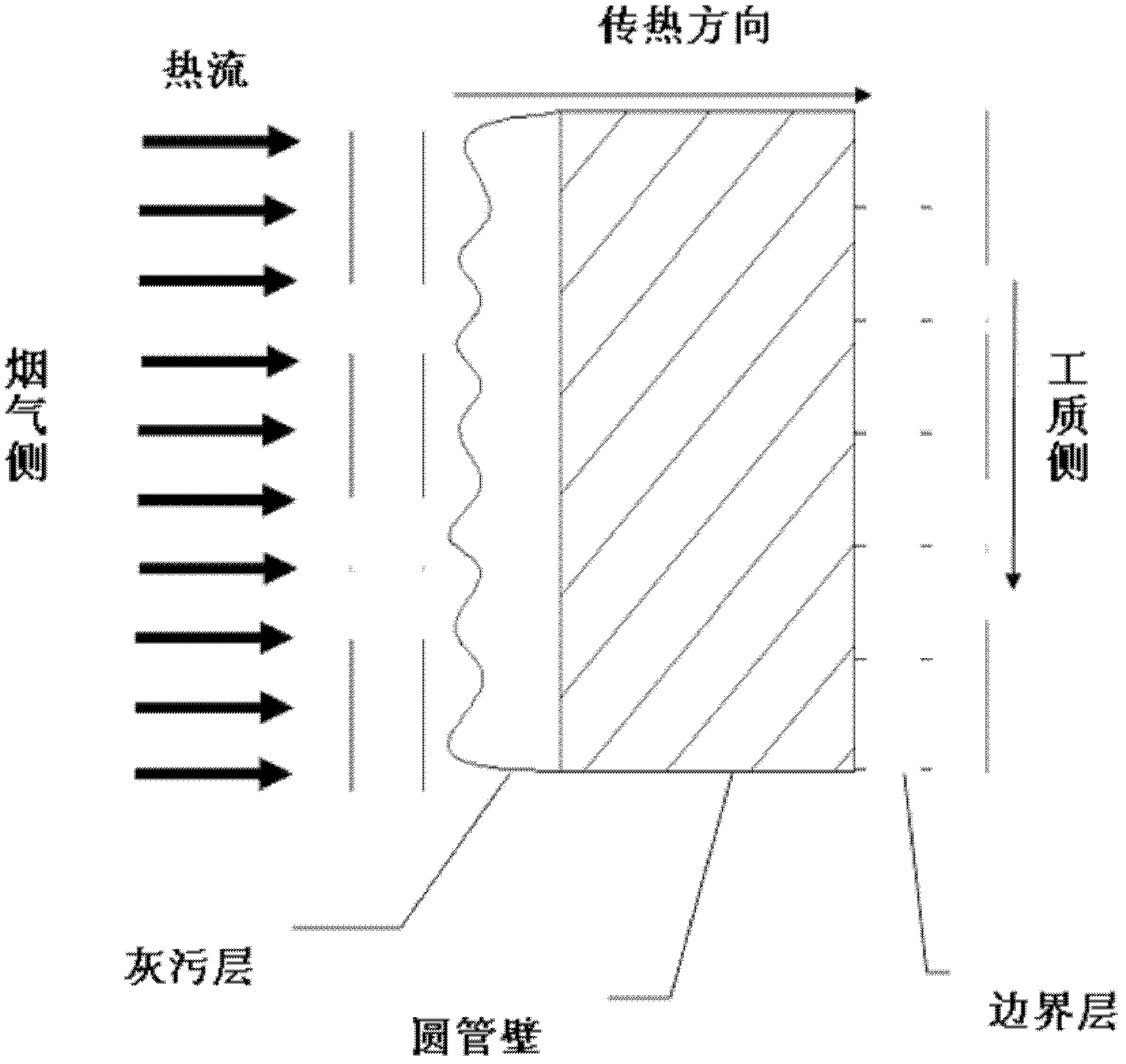

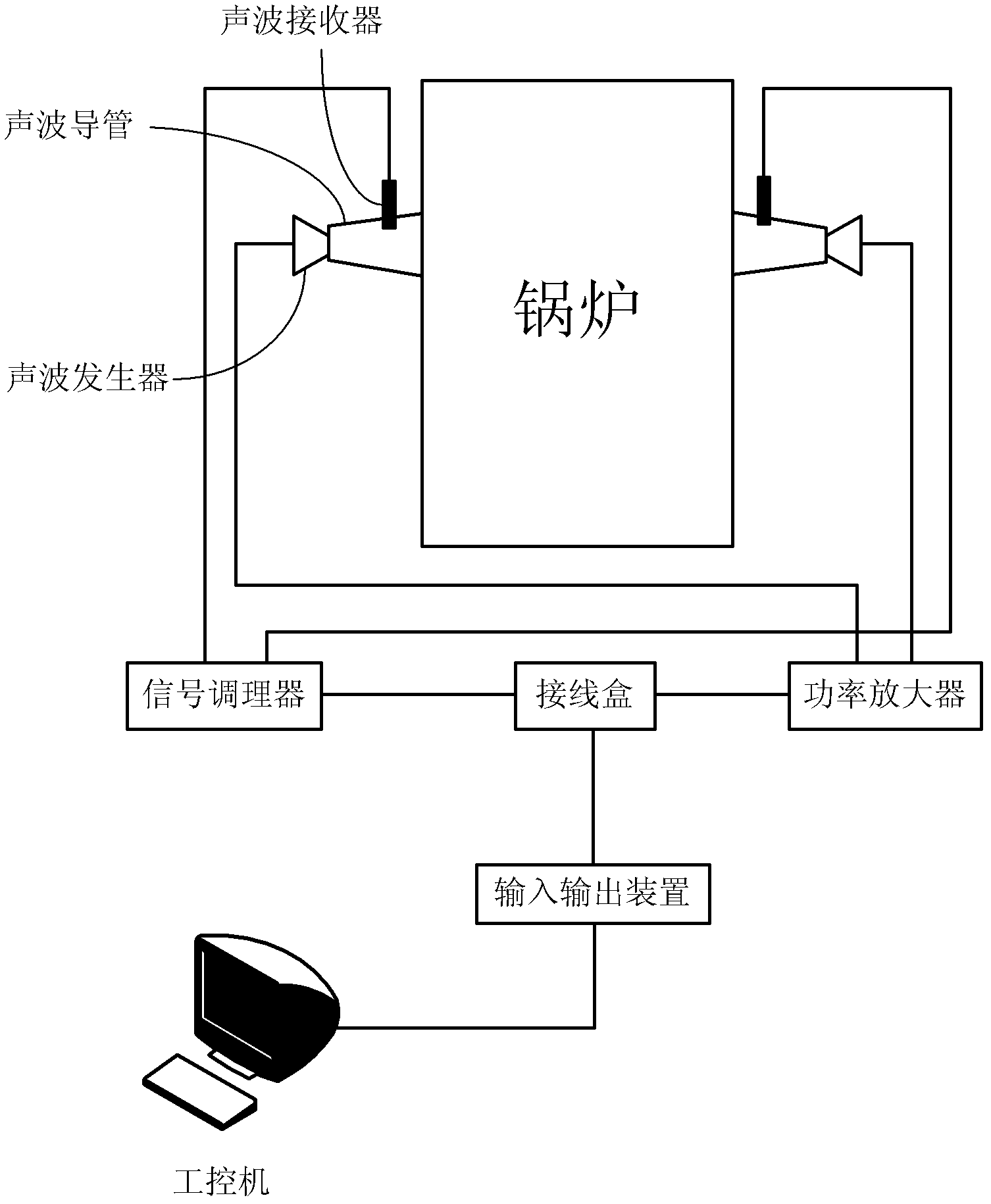

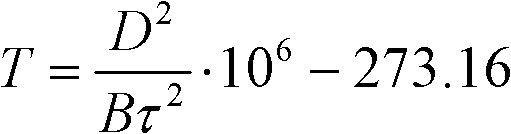

Method and device for monitoring ash dirt on convection heating surface of boiler

InactiveCN102353720AAvoid economic lossEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHearth

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

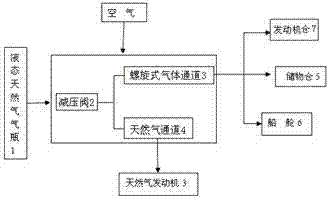

Liquefied natural gas latent heat energy reuse system of liquefied natural gas boat

InactiveCN103043204AIncrease resistanceImprove heat transfer coefficientAuxillariesVessel ventillation/heating/coolingGas solidHot weather

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap