Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "Smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smoke is a collection of airborne solid and liquid particulates and gases emitted when a material undergoes combustion or pyrolysis, together with the quantity of air that is entrained or otherwise mixed into the mass. It is commonly an unwanted by-product of fires (including stoves, candles, internal combustion engines, oil lamps, and fireplaces), but may also be used for pest control (fumigation), communication (smoke signals), defensive and offensive capabilities in the military (smoke screen), cooking, or smoking (tobacco, cannabis, etc.). It is used in rituals where incense, sage, or resin is burned to produce a smell for spiritual or magical purposes. It can be a flavoring agent and preservative for various foodstuffs.

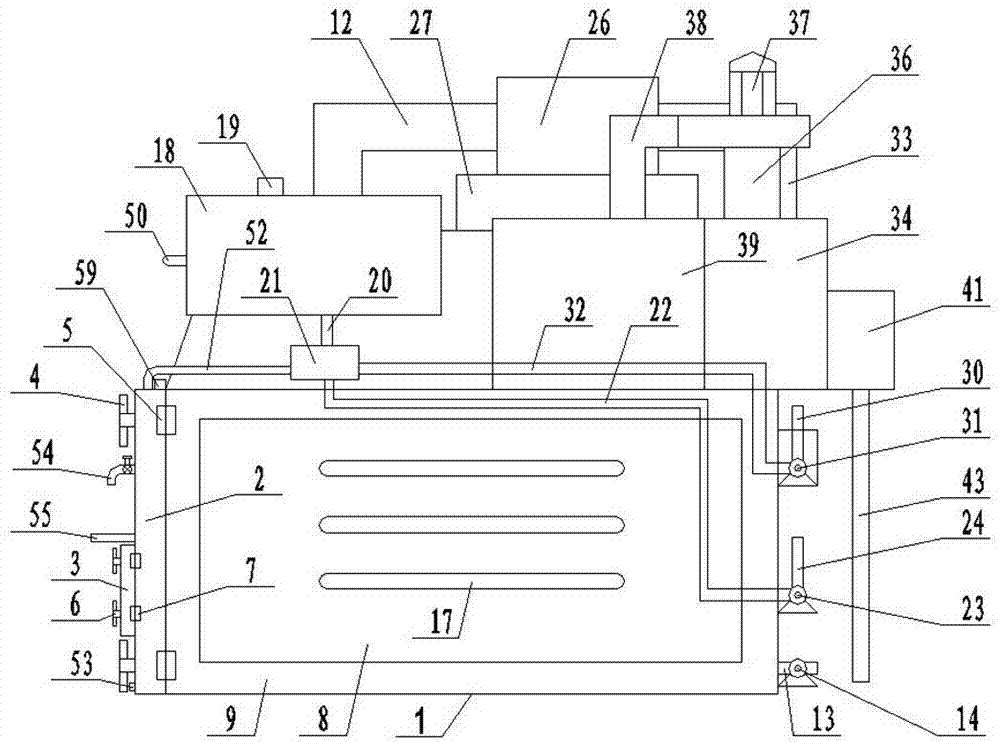

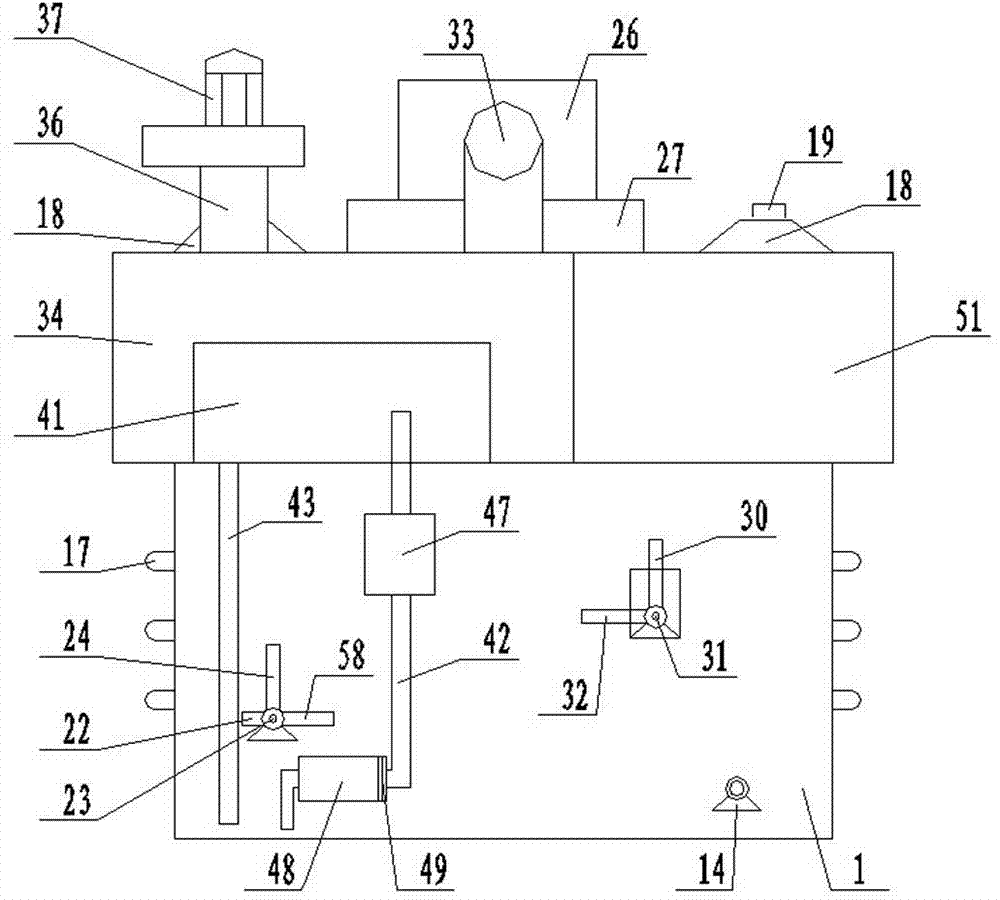

Device technology configuration method for treating house refuses by using rotary cement kiln

The invention provides a device technology configuration method for treating house refuses by using a rotary cement kiln, comprising a pre-treatment device technology configuration method and an incineration device technology configuration method, wherein the whole process of the crushing treatment of the house refuses is implemented by using the pre-treatment device technology configuration method, and a whole incineration process is carried out on the crushed house refuses by using the incineration device technology configuration method; the incineration device technology configuration comprises a double-layer power-driven flap valve, an L-shaped incinerator, a double-layer heavy punch flap valve, a vibrating conveyor and a bucket elevator; and partial tertiary air captured from a tertiary air tube of a rotary kiln enters into the L-shaped incinerator through an air intake tube and high temperature incineration is carried out on the house refuses in the incinerator, smoke generated when incineration passes through an air discharging tube and then is converged with the tertiary air tube, a loop formed by the air intake tube and the air discharging tube of the L-shaped incinerator is provided with a second high-temperature electric butterfly valve and a third high-temperature electric butterfly valve, and a first high-temperature electric butterfly valve is arranged on the tertiary air tube. Harmful gases such as dioxin can be inhibited by high-temperature environment which is generated by using the rotary cement kiln.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Asphalt mixture regenerating heating stirring roller

The invention discloses an asphalt mixture regenerative heating rod and mixing roller, and belongs to the concrete stirring technical field. The invention has a tilted roller supporting frame, a rolling ring, a roller and a roller driving device, wherein, the rolling ring is sleeved on the roller and supported by a rolling wheel arranged on the roller supporting frame, a burner is arranged at the lower end of the roller, a material outlet is arranged on the roller at the lower part of the burner, a material inlet is arranged at the other end of the roller, and a smoke outlet is arranged on the roller; wherein, an inner screening tube is sleeved inside the roller positioned at the material inlet end, and the inner screening tube is connected with the roller, the outer peripheral wall of the inner screening tube is composed of a screening mesh, a circular filtering mesh is sealed at the end part on the inner side of the inner screening tube, the material inlet is communicated with the inner screening tube, and an asphalt nozzle is arranged inside the roller positioned below the burner at the outlet end. The invention has compact and rational structure and high heat exchange efficiency, does not require secondary breakup of the waste asphalt mixture, can directly heat the block shape waste asphalt mixture for recycling; and the regenerated asphalt mixture can be directly utilized.

Owner:HENAN ROADY ROAD MACHINERY

Method for effectively restraining generation of sulfur trioxide and waste acid in smelting smoke

InactiveCN107144144AInhibitionReduce corrosionIncreasing energy efficiencyWaste heat treatmentSulfateSmelting process

Owner:CENT SOUTH UNIV

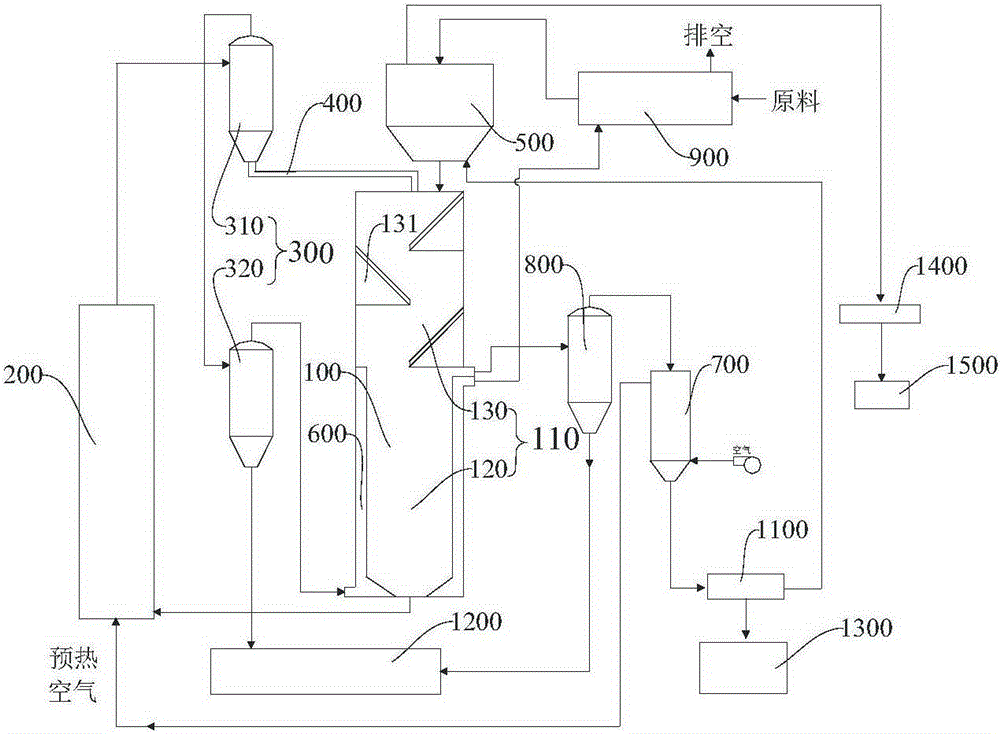

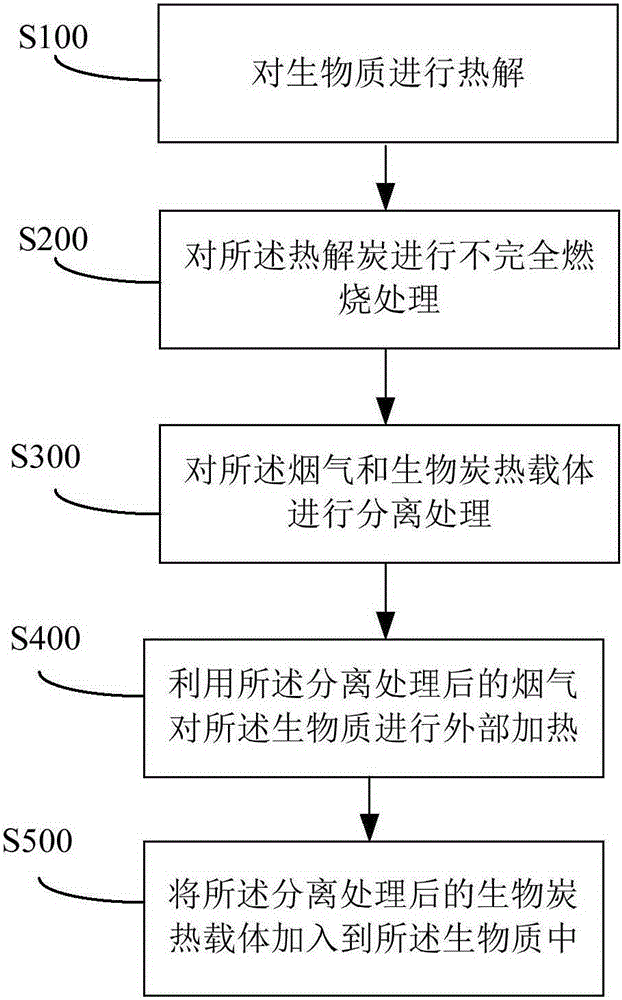

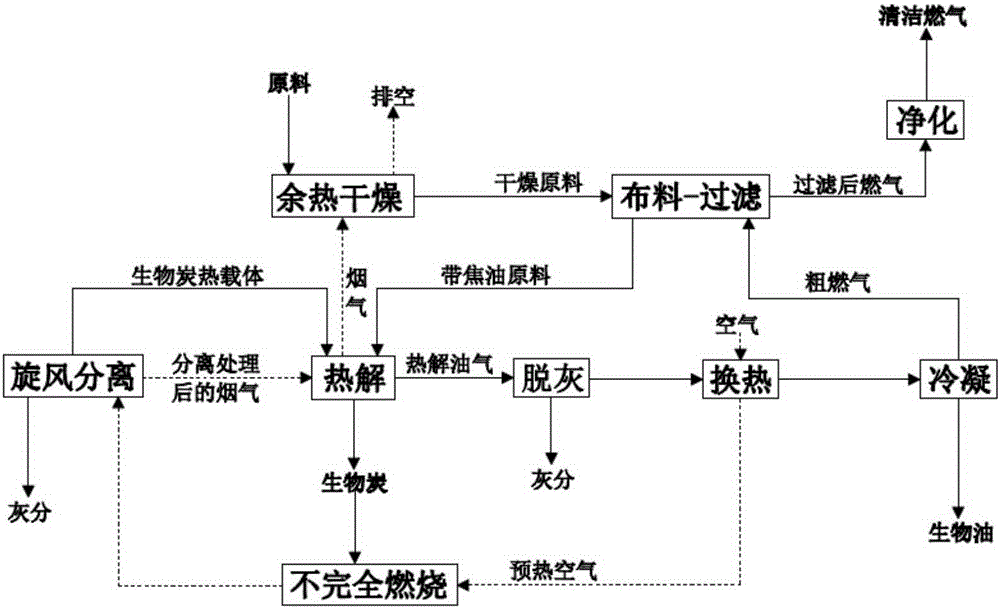

Biomass pyrolysis system and biomass pyrolysis method

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

Tamping coke oven machine side furnace door and furnace top smoke catching method and device

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for analyzing quicklime composition

InactiveCN101109738AEasy to operateAccurate analysisWeighing by removing componentChemical analysis using combustionDissolutionWater mass

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

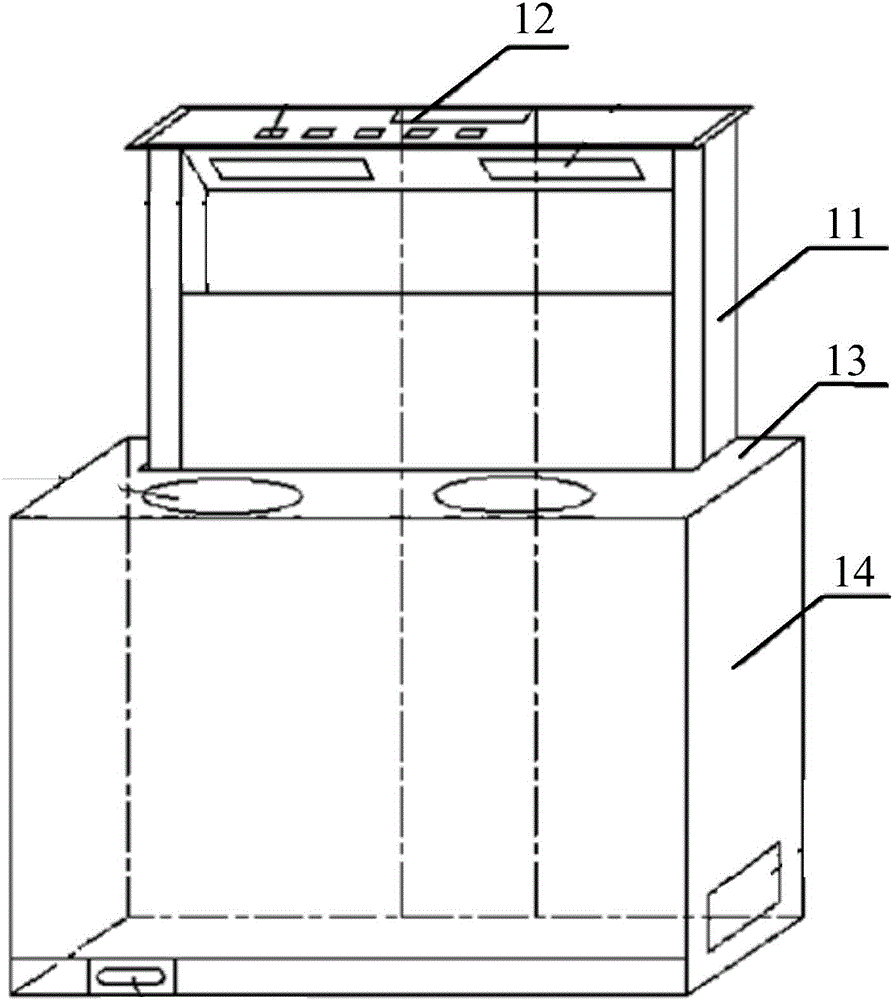

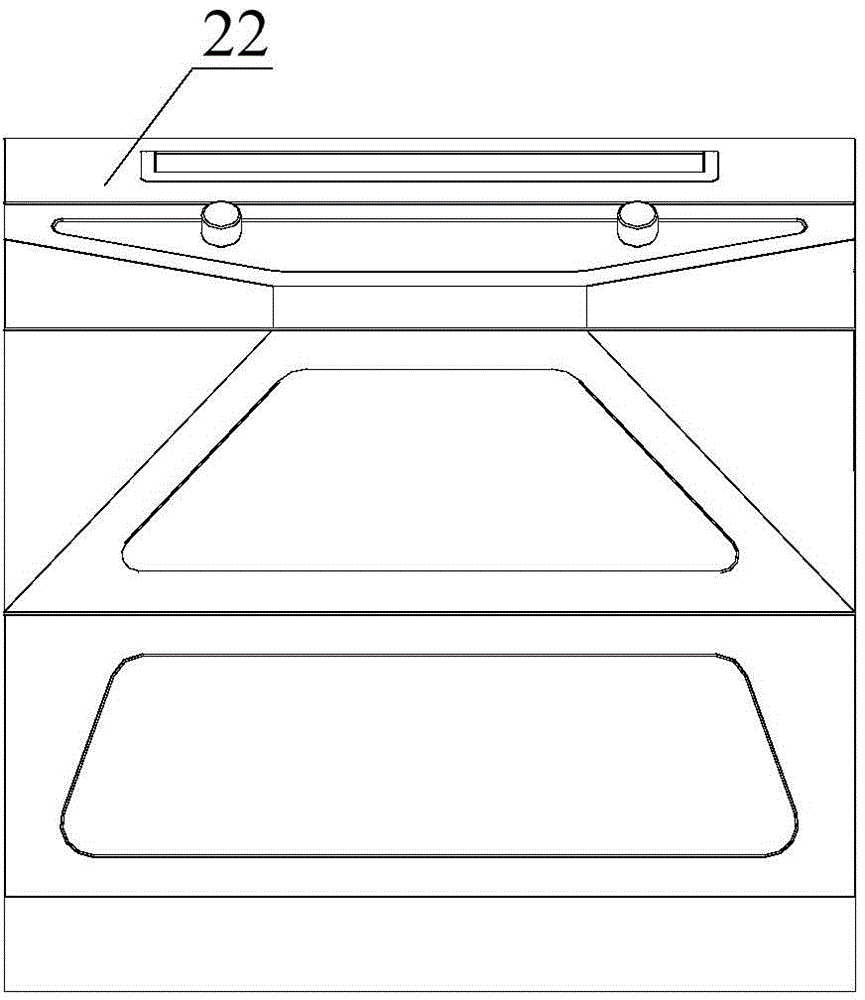

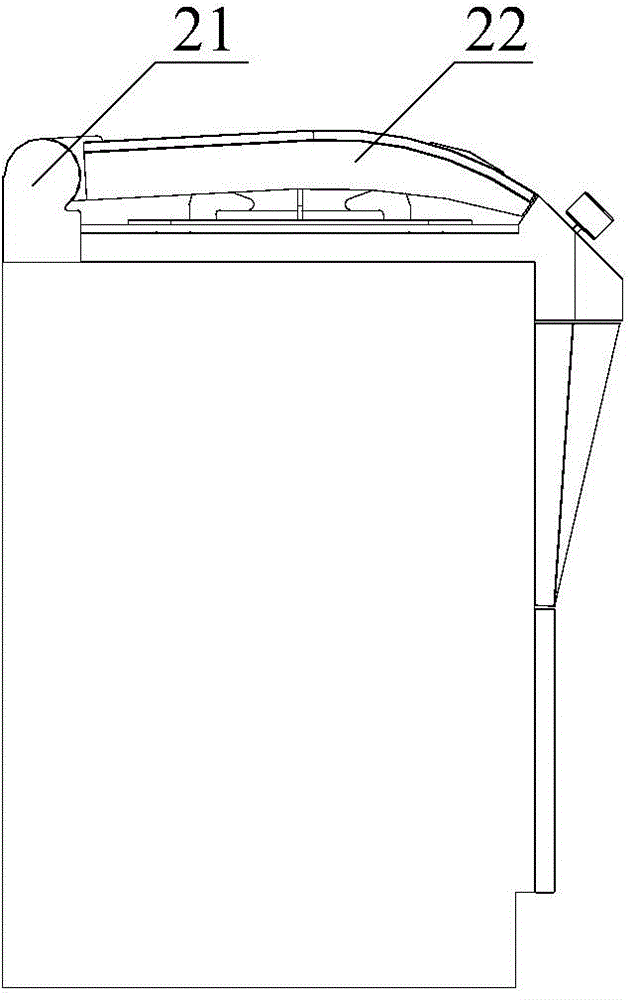

Flipping type integrated cooker

InactiveCN104456681AKeep clean and hygienicRealize the function of oil smokeDomestic stoves or rangesLighting and heating apparatusIndustrial engineeringCooker

Owner:ZHEJIANG AOTIN ELECTRIC APPLIANCE

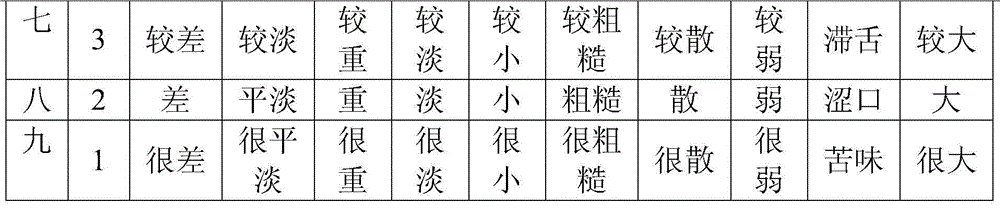

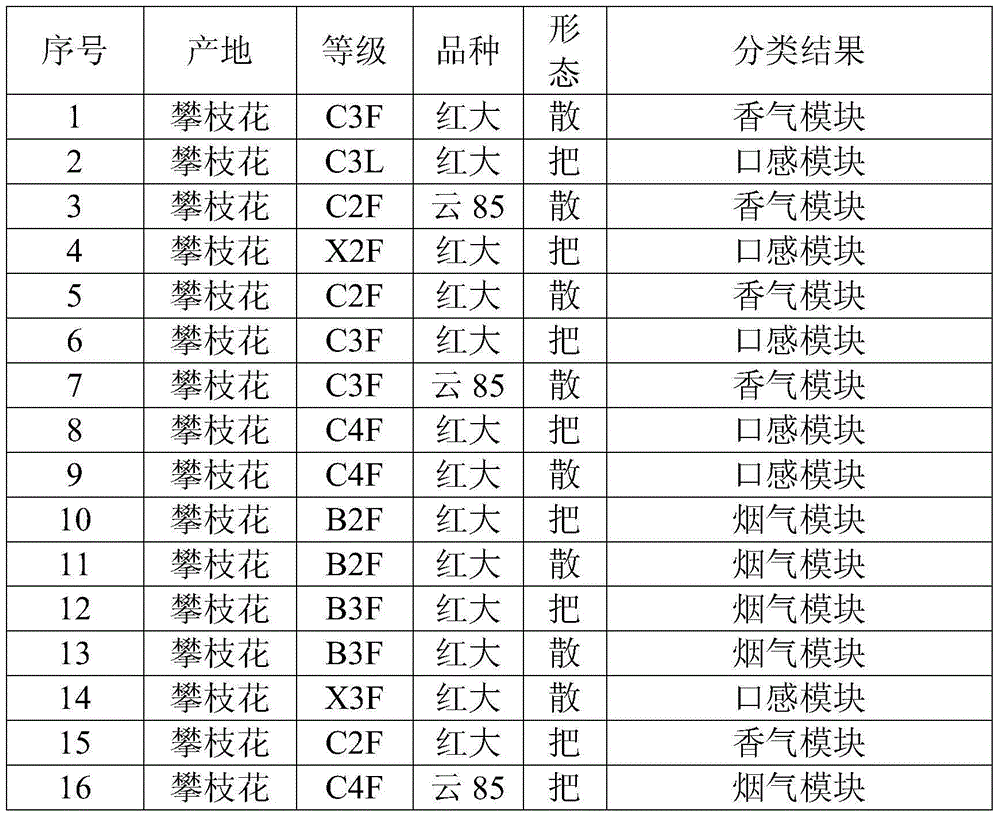

Method for matching cured tobacco leaves by using tobacco leaf beating and re-drying module

ActiveCN104568825AComposition to achieveShorten the timeMaterial analysis by optical meansModel sampleDecomposition

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

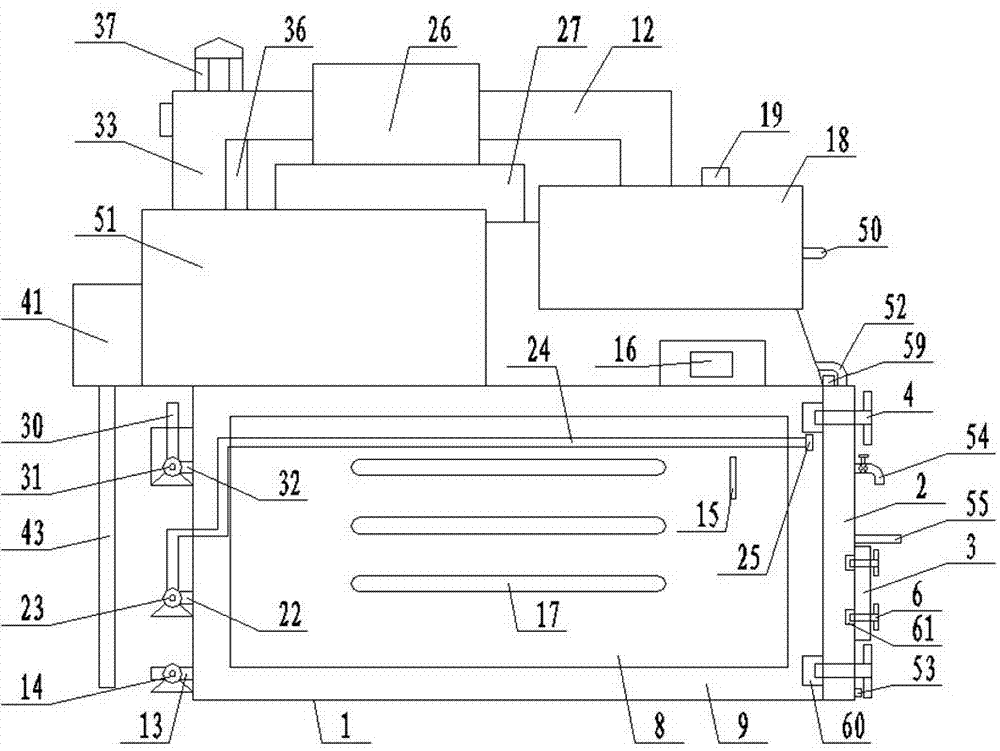

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

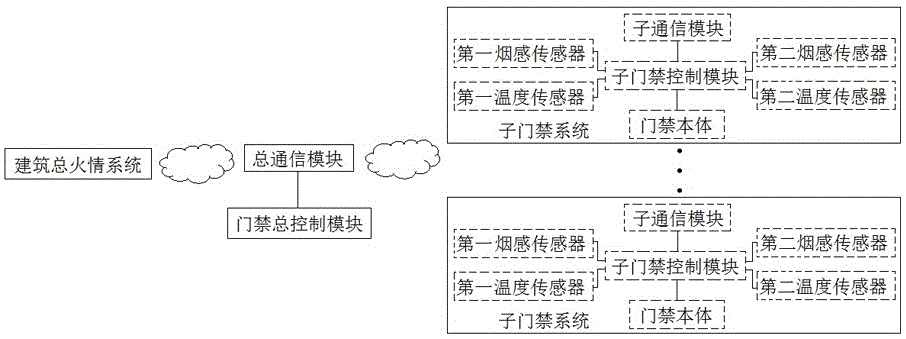

Intelligent fire escape access control system

InactiveCN106530463AImprove securityPrevent openingIndividual entry/exit registersAutomatic controlSystem architecture design

Owner:JIANGSU JINMI INTELLIGENT TECH CO LTD

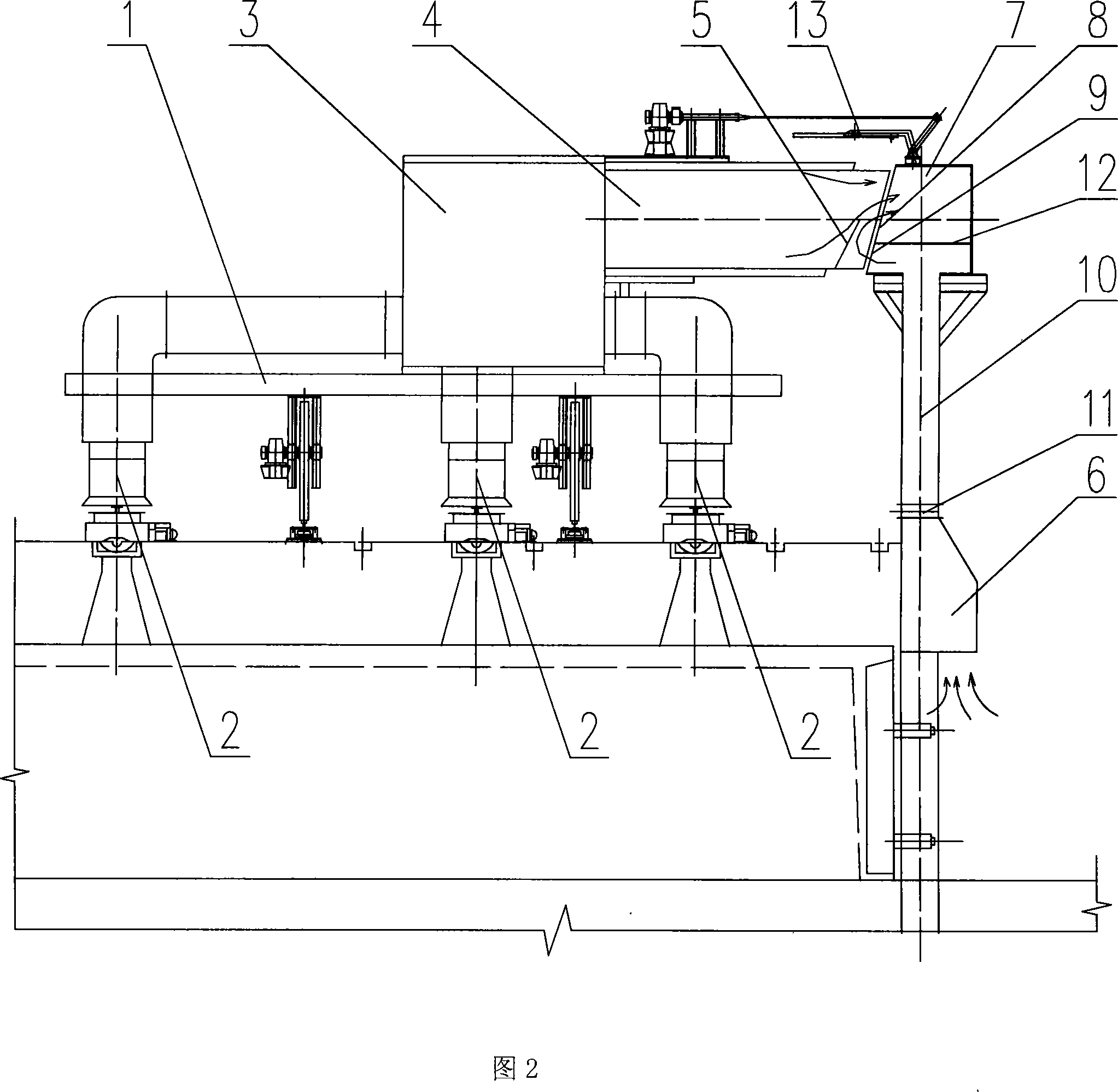

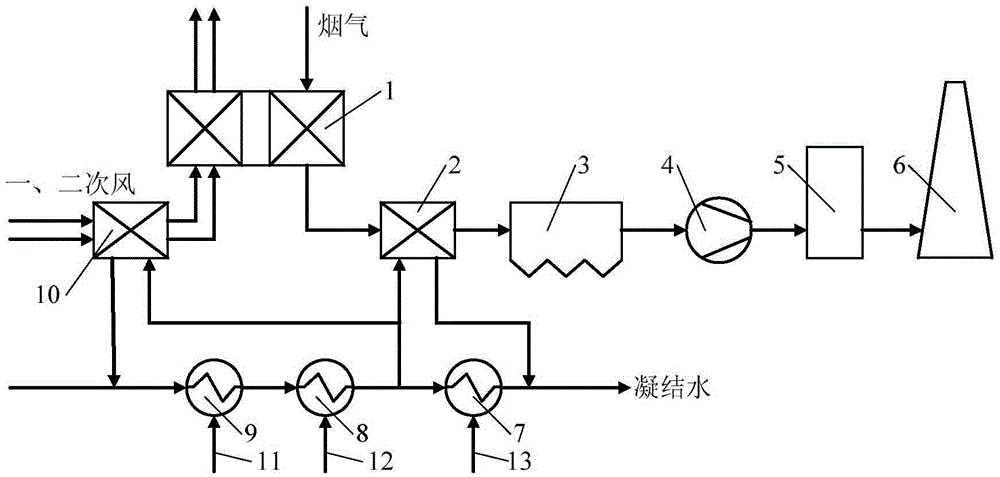

System and method for indirectly heating air heater through extracted low-level steam in waste heat cascade utilization mode

InactiveCN104534439AIncrease energy levelImprove economyCombustion processIndirect carbon-dioxide mitigationWater pipeSmoke

The invention provides a system and method for indirectly heating an air heater through extracted low-level steam in a waste heat cascade utilization mode. The system comprises a gas-gas heater arranged between a boiler rear smoke channel air preheater and an electric dust remover, the air heater arranged in front of an air side inlet of the air preheater and a circulating water pipe for connecting the gas-gas heater and the air heater and condensation water, primary cold air and secondary cold air in the air heater are heated through the condensation water at an outlet of a No.7 low-pressure heater, return water of an outlet of the air heater is returned to an inlet of a No. 8 low-pressure heater, the flow of the condensation water of the No.7 low-pressure heater and the No. 8 low-pressure heater is increased, the flow of No.8 extracted steam and No.7 extracted steam is increased, and the purpose of indirectly heating the air heater through the No.8 extracted steam and the No.7 extracted steam is achieved; part of condensation water led out by an inlet of a No.6 low-pressure heater is conveyed to the gas-gas heater to absorb heat and is led back to a regenerative system through an outlet of the No.6 low-pressure heater, the flow of the condensation water of the No.6 low-pressure heater is decreased, the flow of the No.6 extracted steam is decreased accordingly, a part of the squeezed out No.6 extracted steam is conveyed to a steam turbine to conduct acting, and the economical efficiency of a unit is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

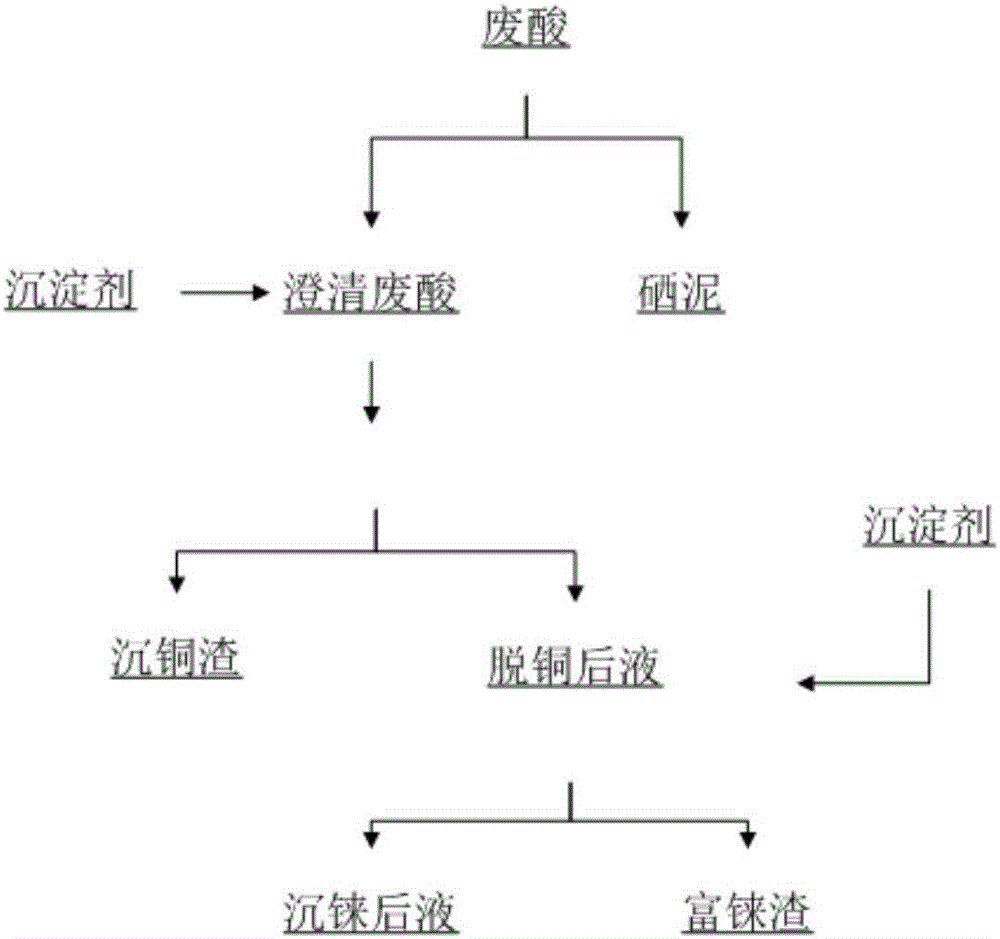

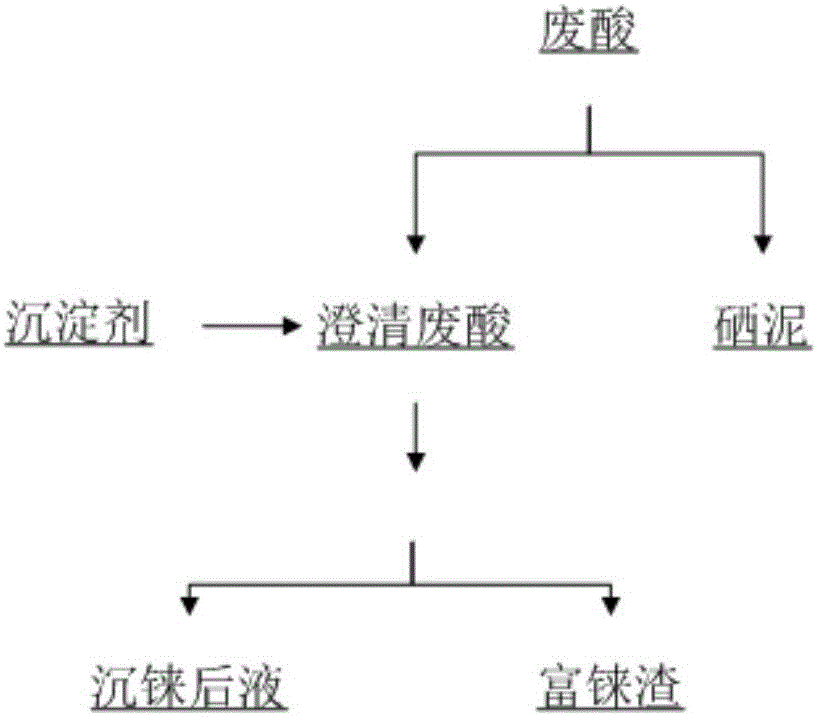

Method for recycling rhenium from copper smelting smoke washing waste acid

Owner:YANGGU XIANGGUANG COPPER

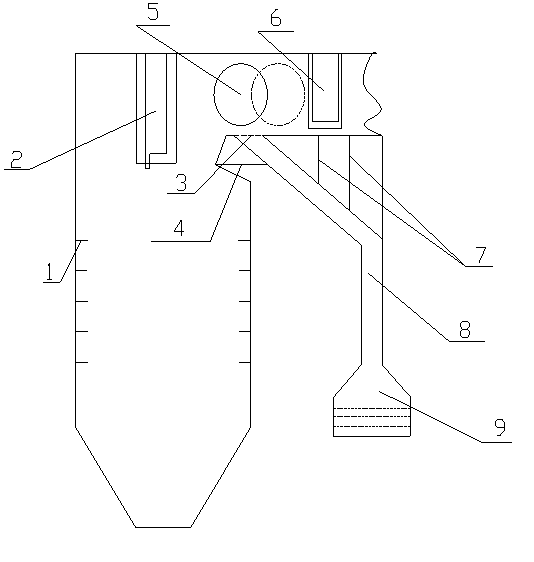

Cascading type rectifier used for SCR denitration device

ActiveCN101642678AReduce weightSave materialDispersed particle separationEngineeringMechanical engineering

The invention discloses a cascading type rectifier used for SCR denitration device, comprising an upper rectifying plate and a lower rectifying plate that are laminated together; wherein the upper rectifying plate is provided with a plurality of regular spread rectifying holes I penetrating the upper rectifying plate body, the lower rectifying plate is provided with rectifying holes II which correspond to the rectifying holes I and penetrates the lower rectifying plate body, the rectifying holes I and the rectifying holes II are partially laminated in vertical direction, and the laminated partforms a plurality of rectifying channels vertically penetrating the rectifier body. The rectifier is formed by adopting the upper and lower rectifying plates, and a plurality of rectifying channels are formed through overlap of the rectifying holes opened on the upper and lower rectifying plates in different directions, thus not only the effect of uniform smoke movement is achieved but also manufacturing cost can be saved.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

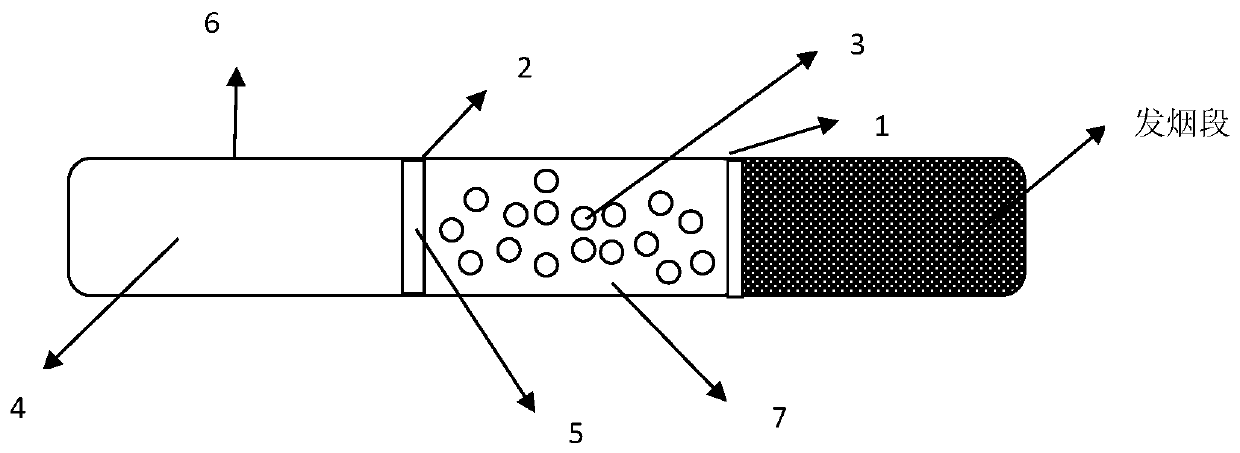

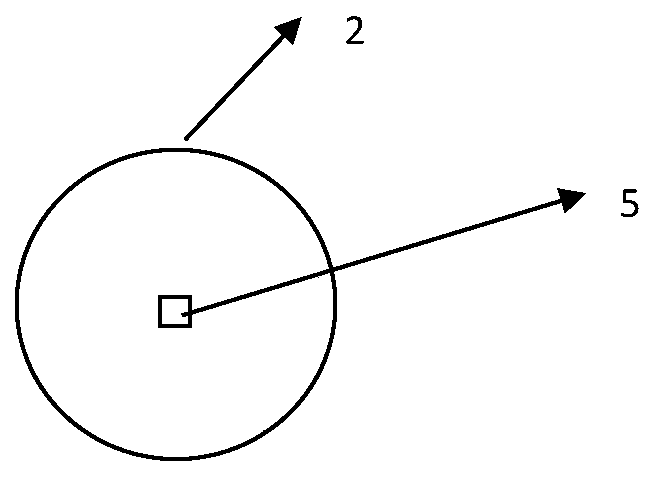

Smoking Article Warning Device

InactiveUS20100313900A1Increase exposureSkin of to easilyCigar manufactureTobacco pipesEmberProximate

A user engageable device disposed within the tobacco burning path of a smoking article's ember at a pre-selected point. The device may include a visual and / or audible and / or olfactory warning component which alerts the user in response to a proximate ember. This provides one or a combination of a visual, audible, or olfactory alert to the user that the ember has reached a predetermined point. The device is preferably in the form of a sleeve frictionally engageable around the smoking article, but can also may be engaged upon or impregnated into a wrapper of the article's cylinder. Alternatively, the sleeve type device may be disposed within the wrapper. Alternatively the indicator material may also be in the form of selectively placed integrated or stick-on patches.

Owner:HEATH CELEVATORON C

Straw carbonization furnace

InactiveCN103497773AAchieve recyclingHigh heat conversion efficiencyBiofuelsEnergy inputCombustion chamberCarbonization

Owner:YANCHENG CHENGXIN MACHINERY MFG

Anti-dripping flame-retardant finishing method for high-tenacity polyester

Owner:DONGHUA UNIV +1

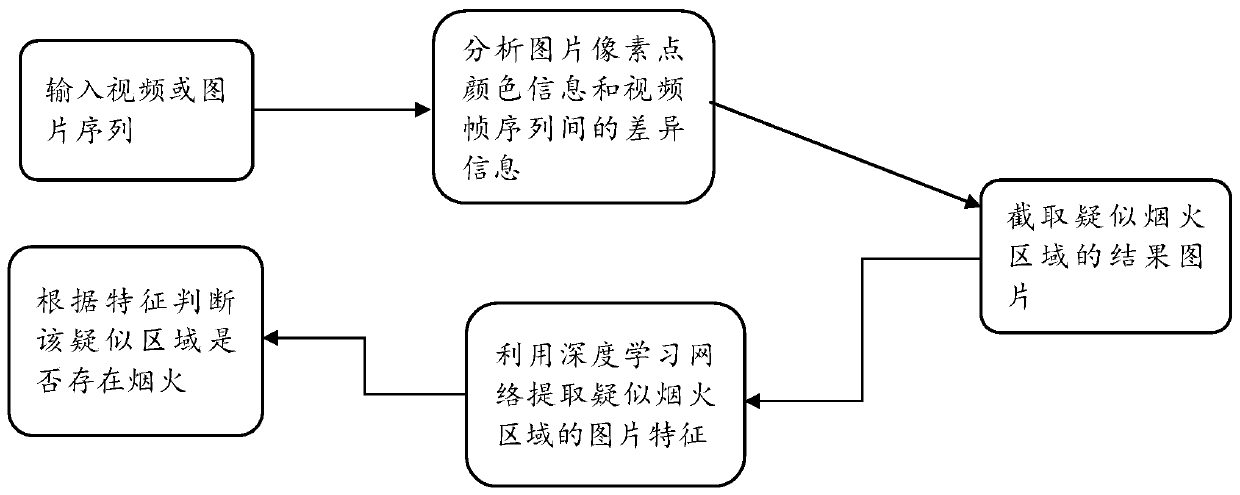

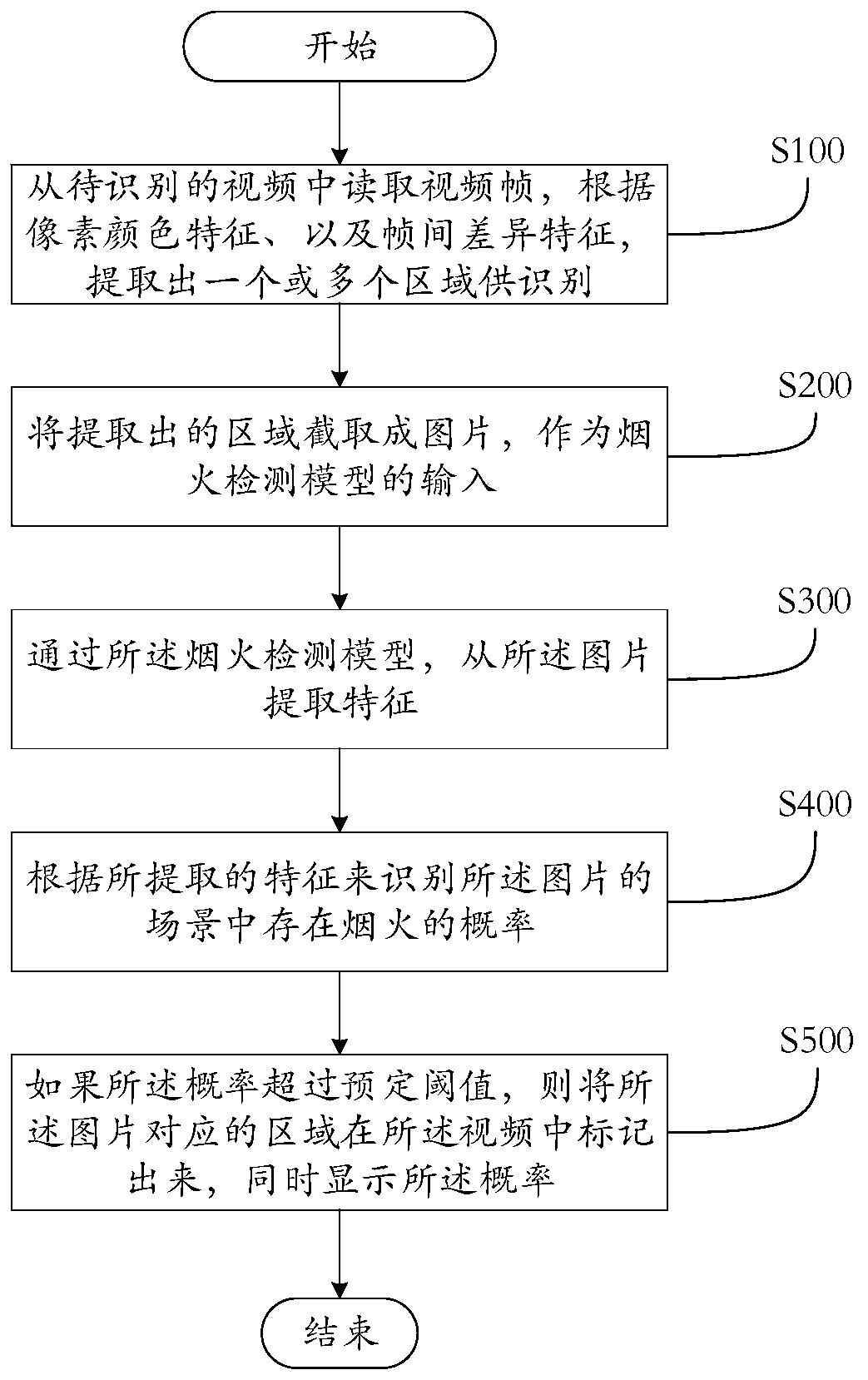

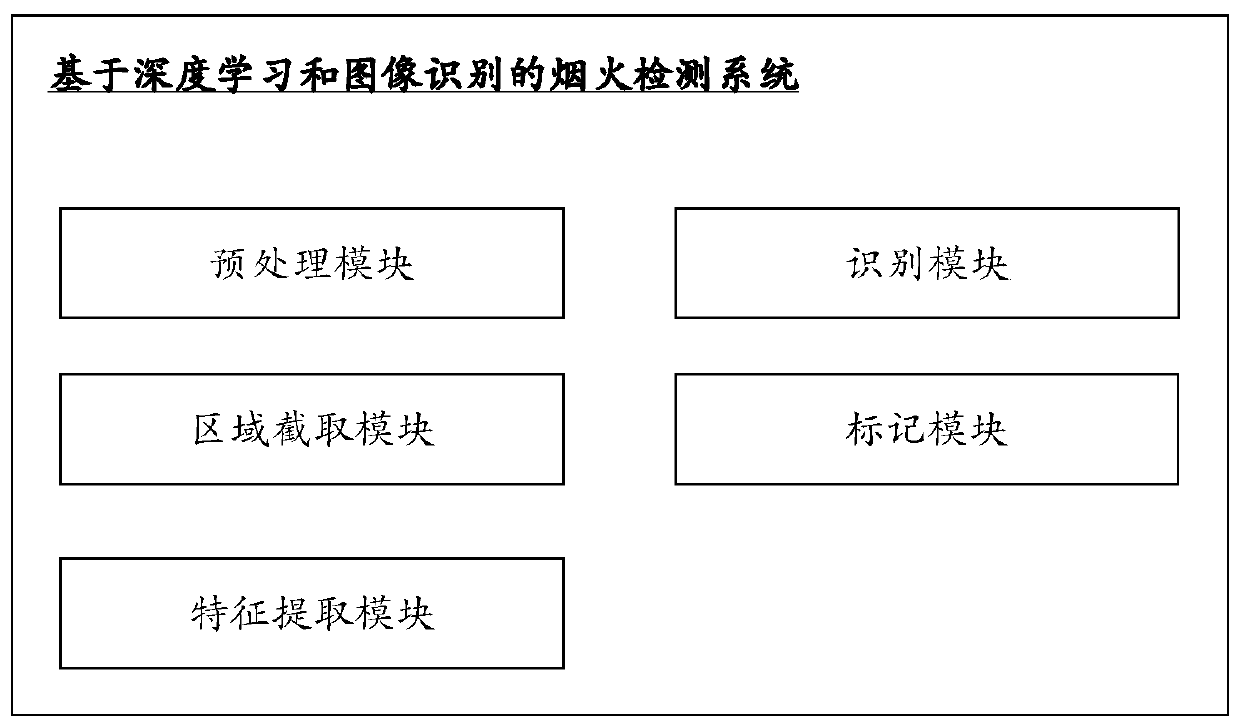

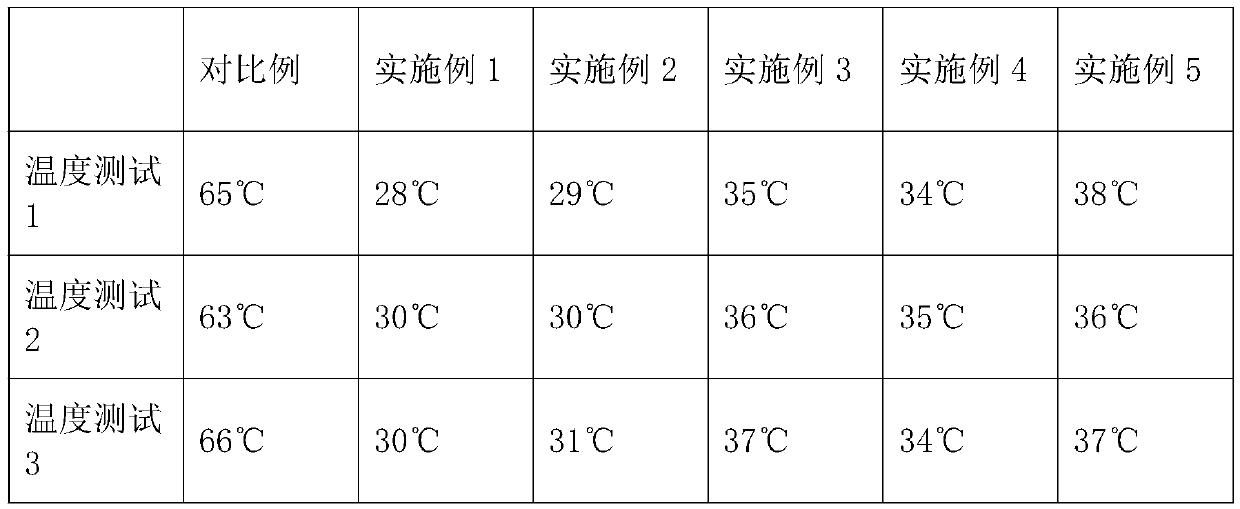

A smoke and fire detection method and system based on deep learning and image recognition

ActiveCN109815863AImprove efficiencyEasy to detectImage analysisCharacter and pattern recognitionPattern recognitionInter frame

Owner:BEIJING UNIV OF POSTS & TELECOMM

Tunnel kiln brick-making method

ActiveCN104279865AReduce pollutionReduce consumptionFurnace typesIncreasing energy efficiencyAlkaneTunnel kiln

The invention provides a tunnel kiln brick-making method. A tunnel kiln comprises a preheating section, a sintering section, a cooling section, a fuel and combustion-assisting air conveying system, a temperature control system, a heat exchange system and a smoke discharging system. The tunnel kiln brick-making method includes that a mixture of smoke containing polluting gas like pyrolytic gas, volatile gas gas and alkane generated by the preheating section and combustion-assisting air is fed into the sintering section to be mixed with fuel for mixed combustion, wherein the polluting gas is fully oxidized and finally generate carbon dioxide, water and the like along with combustion smoke to be cooled through a heat exchanger and then discharged. Hot air generated by the cooling section directly enters the preheating section to serve as preheated air, or the hot air generated by the cooling section together with normal-temperature air is heated through the heat exchanger to be preheated air so as to achieve the objective of waste heat recycling. By the tunnel kiln brick-making method, energy utilization rate of the tunnel kiln in the prior art is increased further, pollution, to surrounding environment, of discharged smoke is reduced, and effect of energy conservation and emission reduction is realized.

Owner:DALIAN UNIV OF TECH

Flue gas white smoke removal equipment for intelligent production factory of rubber plant

Owner:山东保蓝环保有限公司

Fireproof door with smoke-proof function

Owner:TIANJIN LONGJIA SPECIAL DOOR & WINDOW

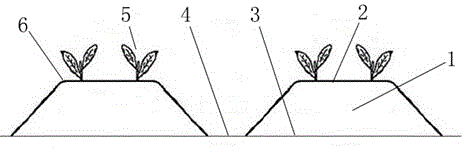

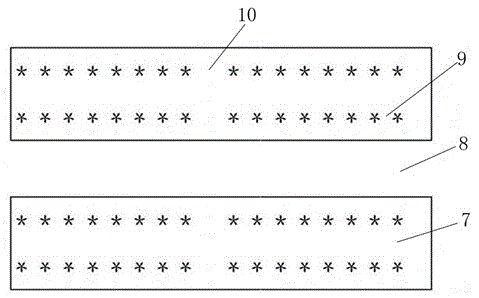

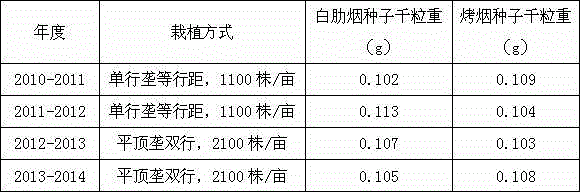

Southward propagation generation-adding breeding method for flattop ridge twin-row high density plantation of tobaccos

InactiveCN104584839AGuaranteed seed qualityAchieving the goal of southern multiplication plus generation multiplicationFertilising methodsPlant cultivationHigh densityNitrogen

Owner:HUBEI TOBACCO SCI RES INST

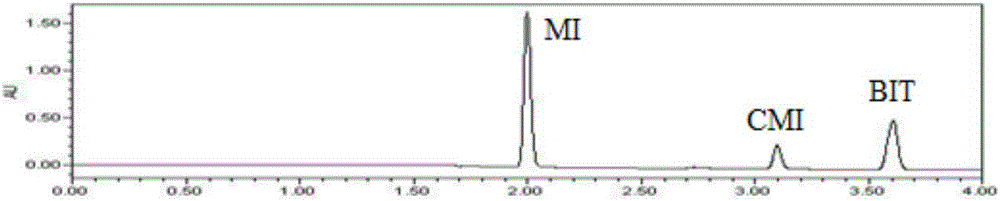

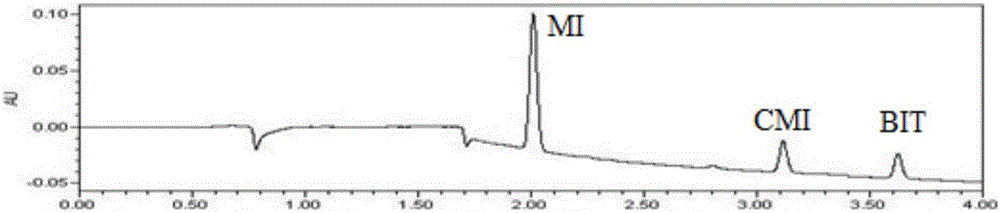

Method for rapid determination of isothiazolinone compounds in water-based adhesive for cigarettes

Owner:CHINA TOBACCO GUIZHOU IND

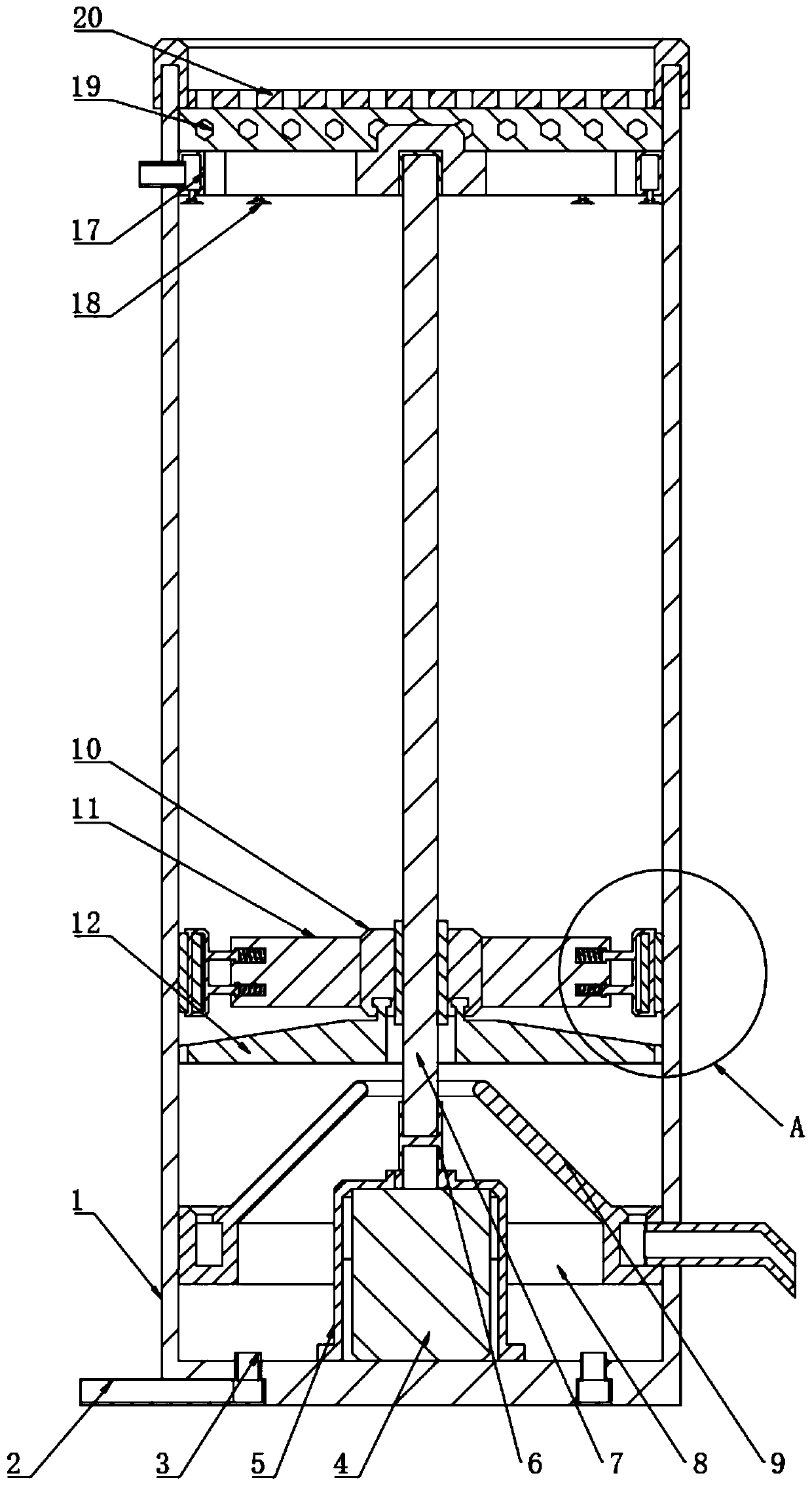

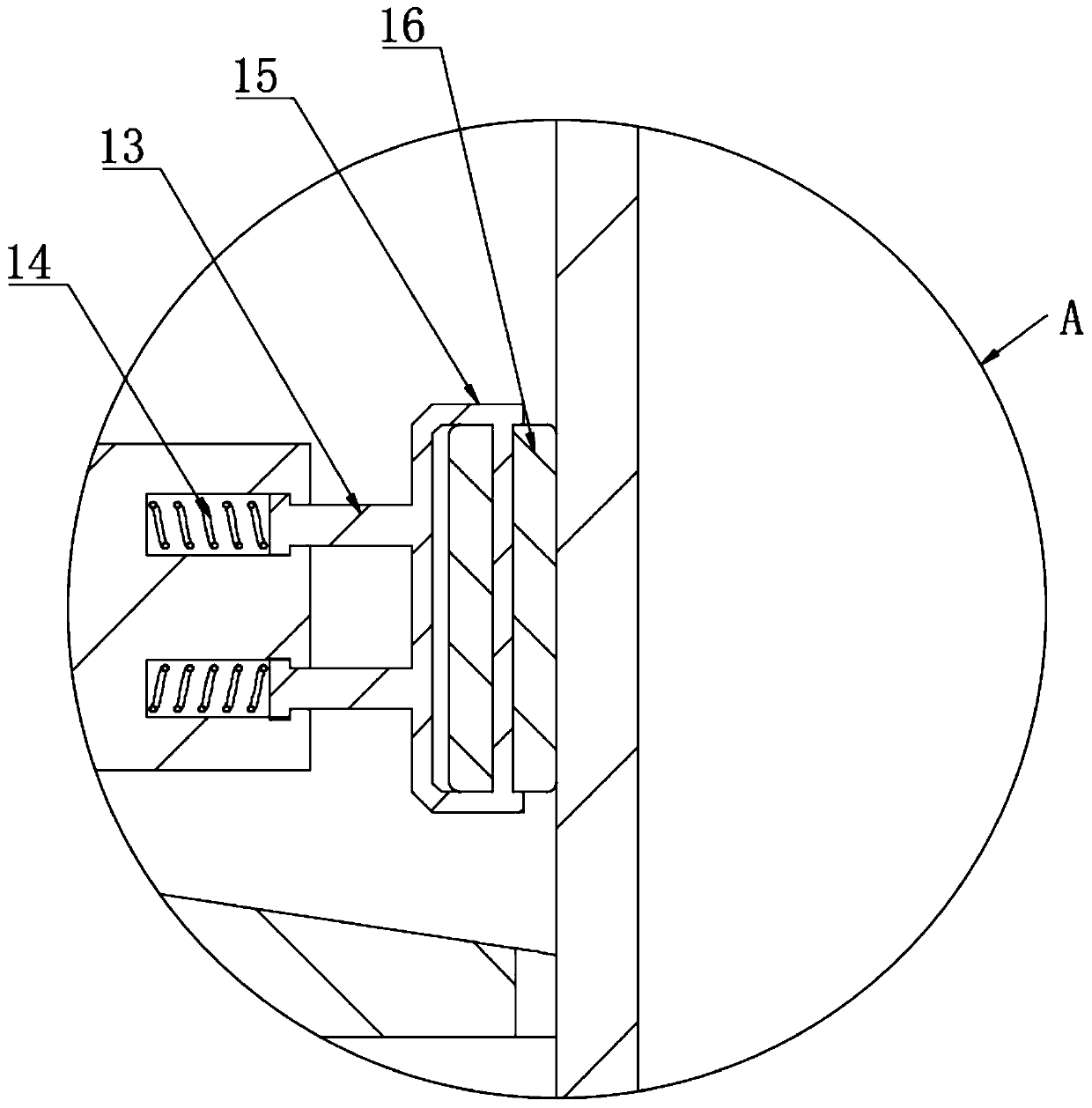

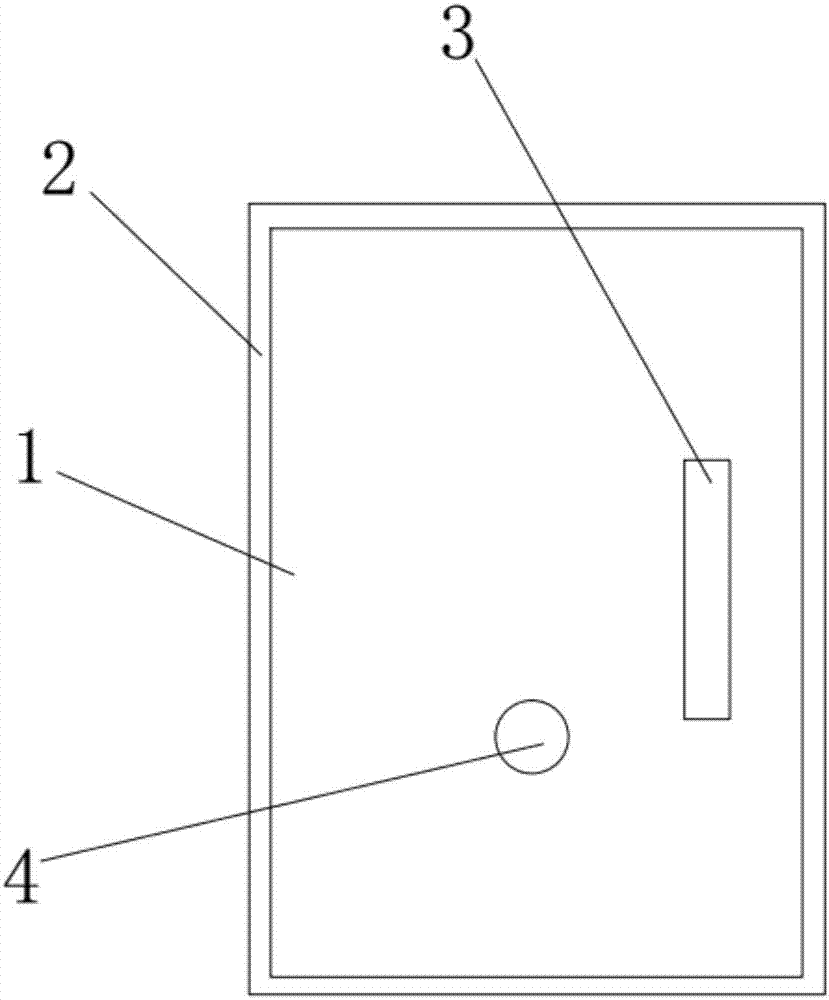

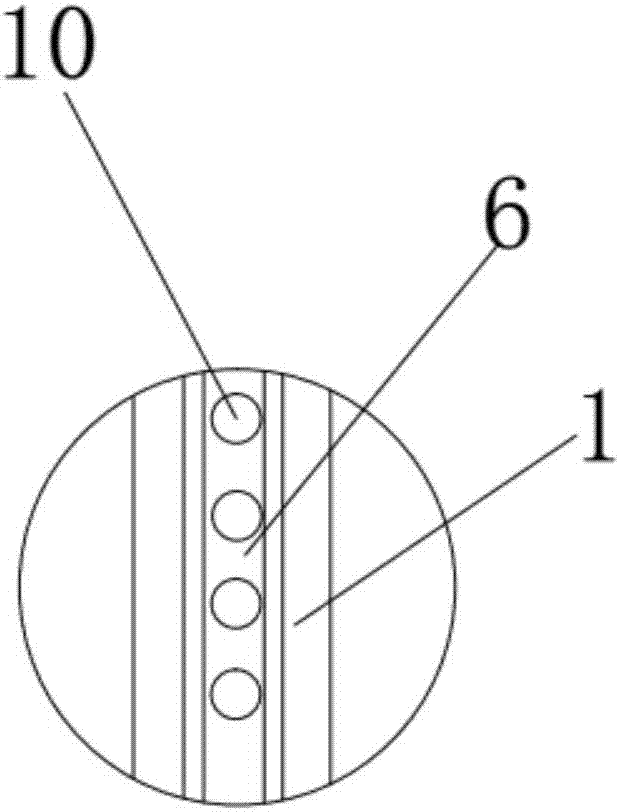

Smoke cleaner device for tractor

InactiveCN103195544AAvoid pollutionSimple structureExhaust apparatusSilencing apparatusExhaust pipeAtmosphere

The invention discloses a smoke cleaner device for a tractor. The smoke cleaner device is connected on a smoke exhaust pipe of the tractor and comprises a cleaner shell, a smoke inlet pipe is communicated at the bottom of the cleaner shell, a smoke exhaust pipe is communicated at the top of the cleaner shell, a first-level cleaning baffle plate and a second-level cleaning baffle are sequentially fixed in the cleaner shell from top to bottom, a first-level cleaning filter core is arranged between the top face of the cleaner shell and the first-level cleaning baffle plate, a second cleaning filter core is arranged between the first-level cleaning baffle plate and the second-level cleaning baffle plate, a third cleaning filter core is arranged between the second-level cleaning baffle plate and the bottom face of the cleaner shell, and smoke exhaust holes are respectively reserved on the first-level cleaning baffle plate and the second-level cleaning baffle plate. By mounting the smoke cleaner device at a smoke exhaust hole of the tractor, smoke exhausted from the tractor can be filtered for several times, so that dust, grains and the like in the smoke are filtered and prevented from being exhausted to the air to pollute the atmosphere, and the smoke cleaner device is simple in structure and convenient to use.

Owner:CHANGYI XINGYUAN FOUNDING CO LTD

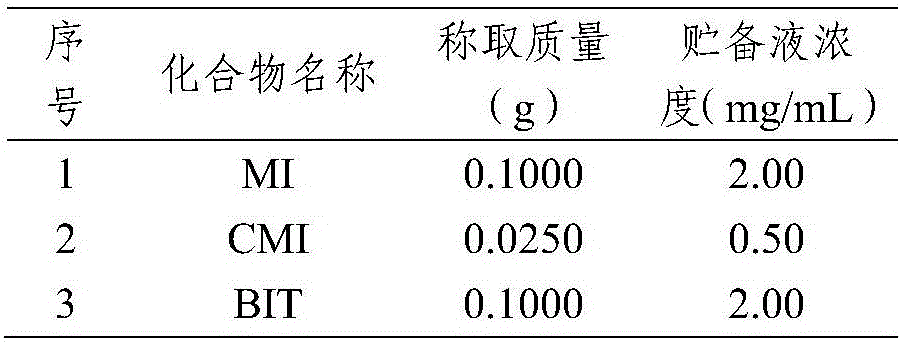

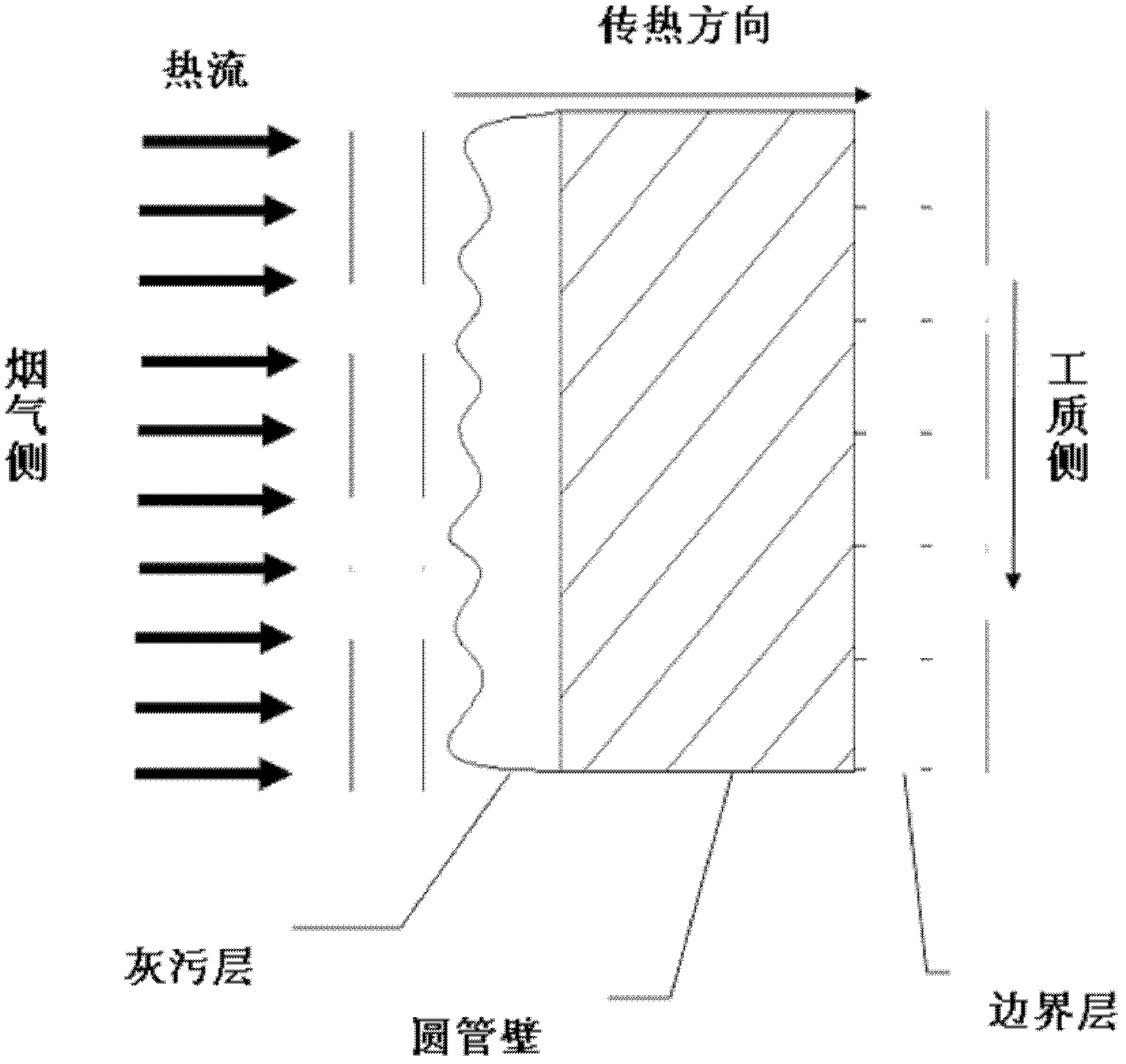

Method and device for monitoring ash dirt on convection heating surface of boiler

InactiveCN102353720AAvoid economic lossEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringHearth

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

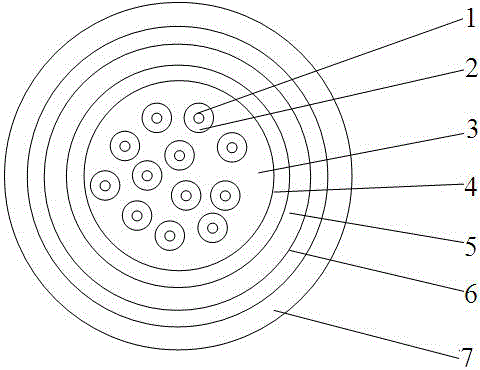

Marine low-smoke halogen-free low-toxicity frame-retardant fire-resistant soft optical cable and manufacturing method thereof

InactiveCN104570250AImprove transmission performanceFibre mechanical structuresLow smoke zero halogenPolyolefin

Owner:JIANGSU ZHONGTIAN TECH CO LTD

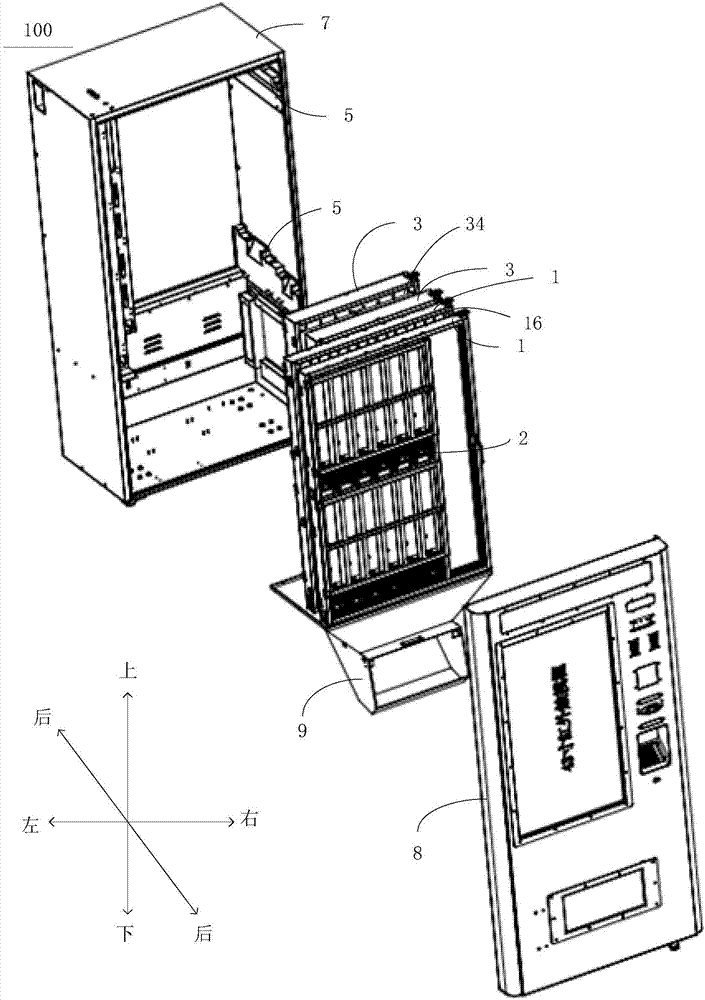

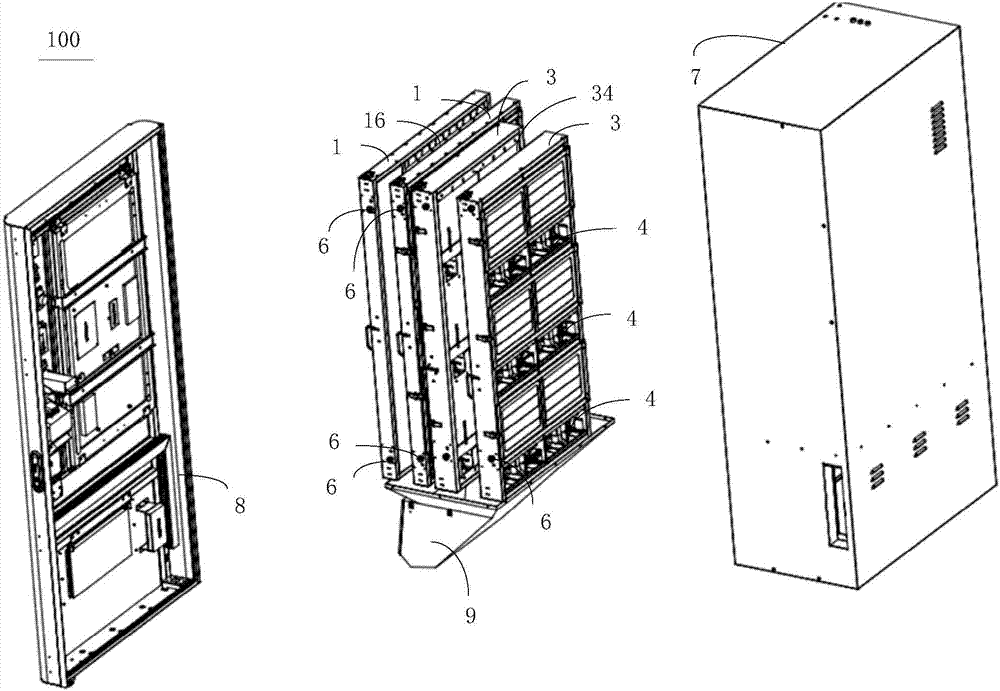

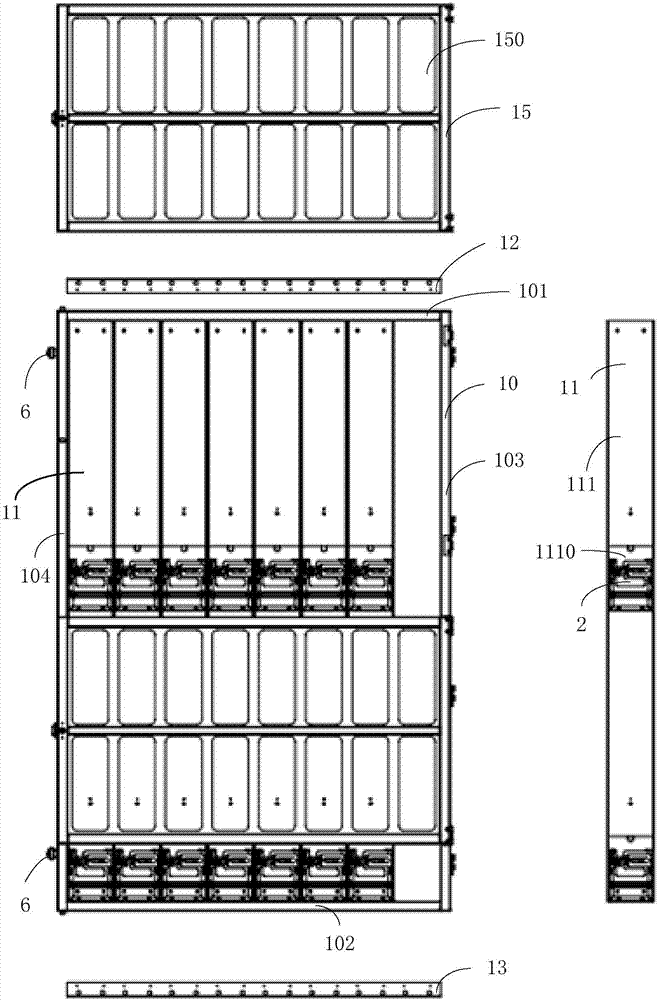

Automatic tobacco seller

PendingCN107993344AStable cigarettesSmall sizeCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringUltimate tensile strength

Owner:SHENZHEN GENUINE INNOVATIVE TECH CO LTD

Range hood with fixed visual detection system and oil smoke concentration detection method

PendingCN109373377ADomestic stoves or rangesLighting and heating apparatusImaging equipmentVisual perception

The invention discloses a range hood with a fixed visual detection system. The system is provided with a smoke machine main body and fixed type visual detection modules, wherein the fixed type visualdetection modules are used for detecting the size of the oil smoke, and the fixed visual detection modules are assembled on the small machine main body. According to the fixed vision detection modulesof the range hood, the collected initial images are processed and serialized, the initial image of the rear frame and the initial image of the front frame are sequentially processed, and the currentkitchen range hood oil smoke concentration at the moment where the initial image of each rear frame is located is obtained. According to the oil smoke concentration detection method, the initial images of the front frame and the rear frame collected by imaging equipment are used as the basis and are processed by the fixed type visual detection modules, and the initial image is a gray scale image.The non-contact real-time detection of the oil smoke concentration can be achieved, and the device has the advantages of high accuracy, real-time performance and the like.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

System for relieving scorification of convection heated surface of boiler

ActiveCN102798130AExtended run timeGuaranteed cleanlinessLighting and heating apparatusCombustionSlag

Owner:DONGFANG ELECTRIC CORP LTD

Efficient pure aluminum alloy environment-friendly refining agent and preparation method thereof

Owner:谢石华

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap