Tobacco cartridge flavoring and cooling filter tip and preparation method thereof

A technology of filters and pods, applied in e-liquid filter elements, tobacco, applications, etc., can solve the problems of low reduction of characteristic fragrance, no flavoring and cooling, high-temperature cracking and distortion of spices, etc., to achieve outstanding style and taste, Lower flue gas temperature, excellent sensory experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

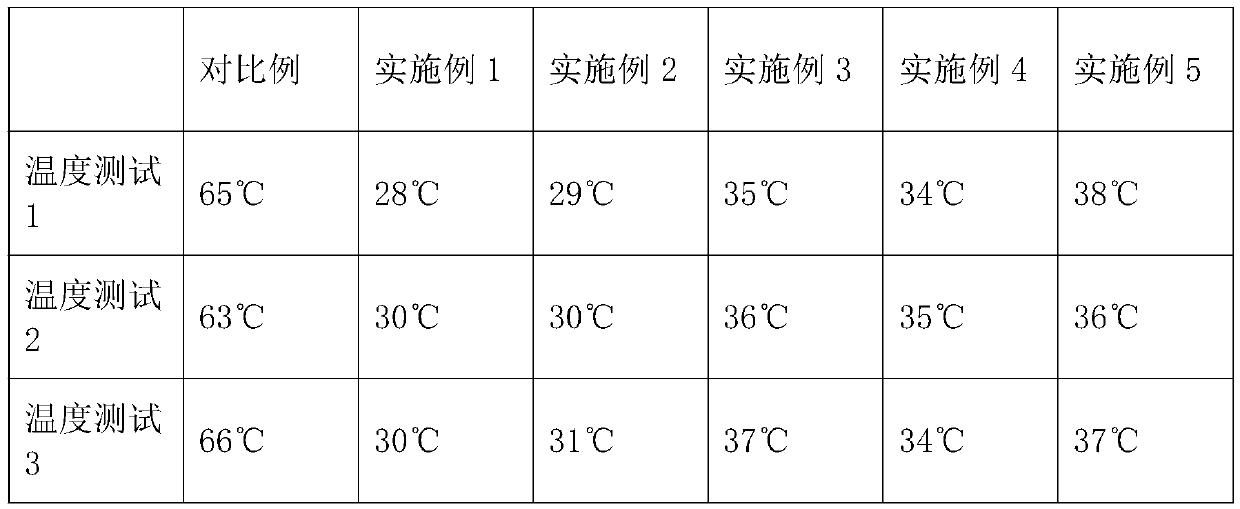

Embodiment 1

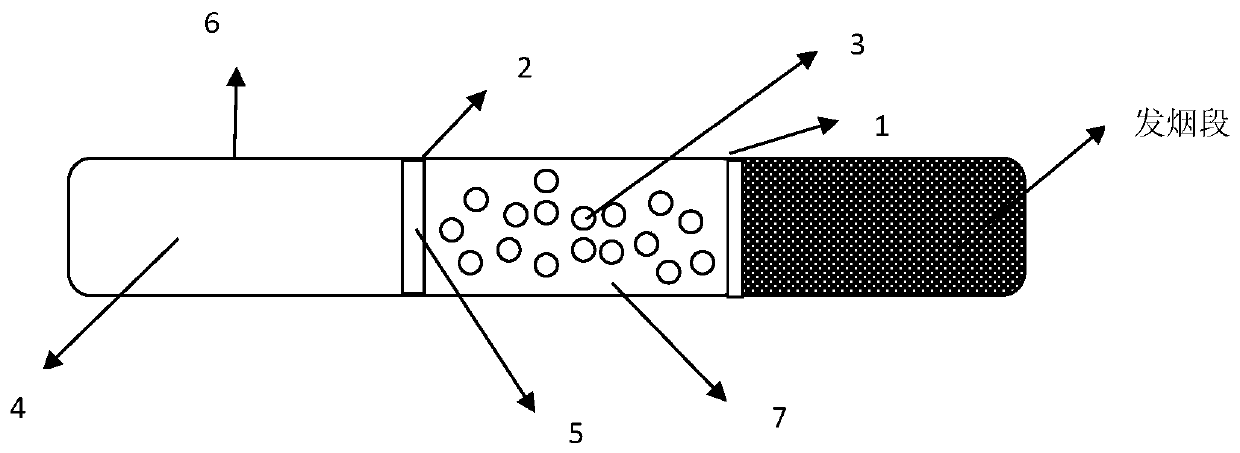

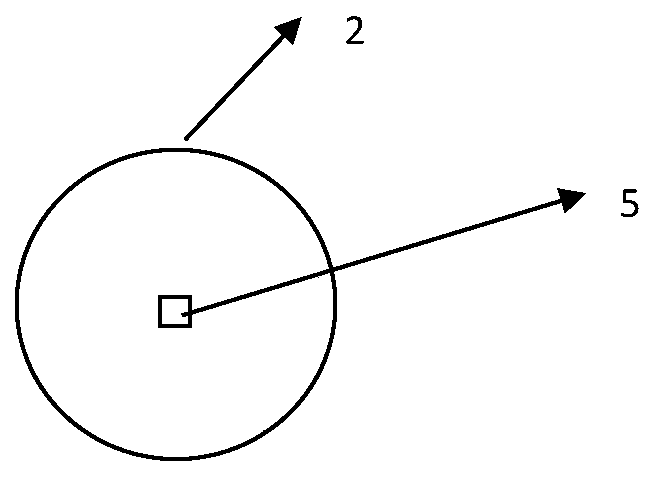

[0044] A cartridge flavoring and cooling filter, comprising a paper tube 6, a sealing filter 1, a spacer filter 2 and a filter, the sealing filter 1 and the spacer filter 2 are sequentially fixed in the paper tube 6 Thus, the paper tube 6 is divided into a sealing part, a partition part and a fragrance chamber 7, and the fragrance substance 3 is filled in the fragrance chamber. Fragrance substance 3 is a slow-release micro-fragrance ball, which can melt and release fragrance above 50°C. The interval filter 2 is provided with a plurality of circular through holes 5 , and the fragrance substance 3 cannot pass through the through holes 5 .

[0045] Both the sealing filter piece 1 and the spacer filter piece 2 are circular and fixed vertically in the paper tube 6 . The paper tube 6 is a round tube with an ignition point above 500°C.

[0046] The manufacturing method of the filter comprises the following steps: step 1: preparing the paper tube 6, sealing filter 1, spacer filter 2 an

Embodiment 2

[0048] Fragrance substance 3 is a gel fragrance, which can melt and release fragrance above 50°C. All the other are identical with embodiment 1.

Embodiment 3

[0050] Fragrance substance 3 is a solid particle fragrance, which can melt and release fragrance above 50°C. All the other are identical with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap