Method for matching cured tobacco leaves by using tobacco leaf beating and re-drying module

A technology of threshing and re-baking and module grouping, which is applied in the field of tobacco, can solve the problems of not considering the impact of existing cognition and discrimination results, and achieve the effect of accurate classification and combination, saving time and manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Huili area module leaf-threshing assembly method:

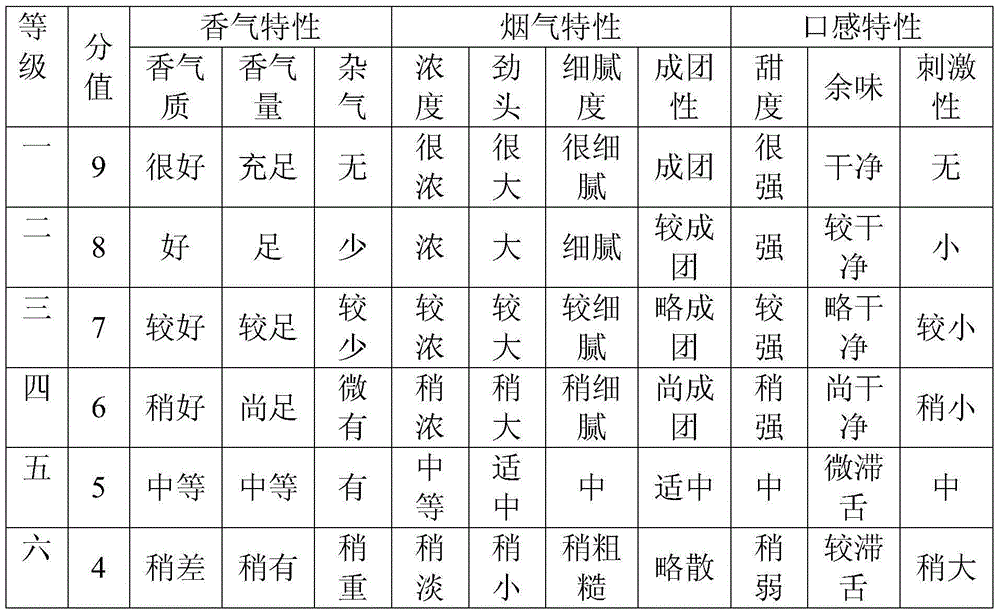

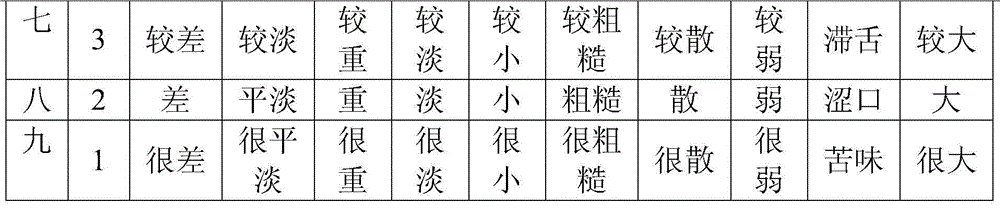

[0044] Through sensory evaluation, according to the modeling requirements of the aroma module, smoke module and taste module, 62 tobacco leaf modeling samples of the aroma module, 70 tobacco leaf modeling samples of the smoke module, and 54 tobacco leaf modeling samples of the taste module were collected. Each sample is 500g. The modeling samples were dried in an oven at 40°C for 2 hours, crushed and passed through a 60-mesh sieve. After scanning the modeling sample on the near-infrared spectrometer, the near-infrared spectrum of the modeling sample is obtained, and the spectrum acquisition range is 12000-4000cm –1 , resolution 8cm –1 , the number of scans is 64 times. The method of combining WT and SNV is used to preprocess the spectrum, and the method of singular value decomposition is used to analyze the –1 And 6200~9300cm –1 The spectral data matrix in the two regions is subjected to principal component calculati

Embodiment 2

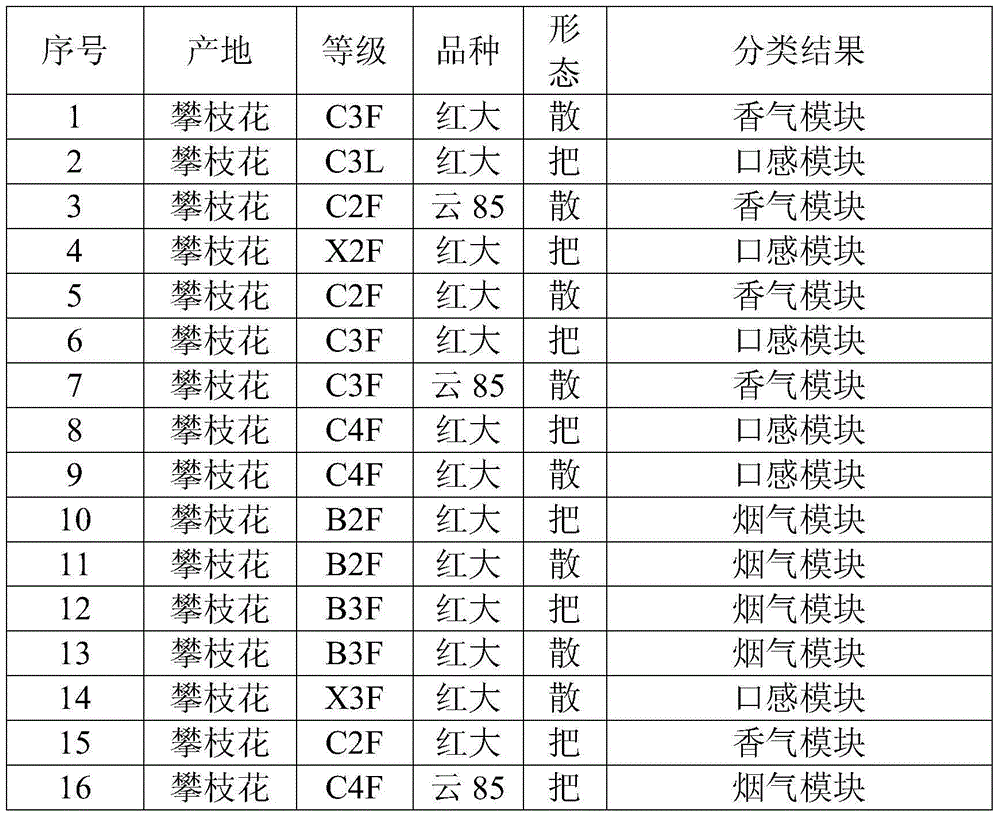

[0050] The combination method of module leaf threshing in Panzhihua area:

[0051] Through sensory evaluation, according to the modeling requirements of aroma module, smoke module and taste module, 52 tobacco leaf modeling samples of aroma module, 95 tobacco leaf modeling samples of smoke module, and 74 tobacco leaf modeling samples of taste module were collected respectively. Each sample is 500g. The modeling samples were dried in an oven at 40°C for 2 hours, crushed and passed through a 60-mesh sieve. After scanning the modeling sample on the near-infrared spectrometer, the near-infrared spectrum of the modeling sample is obtained, and the spectrum acquisition range is 12000-4000cm –1 , resolution 8cm –1 , the number of scans is 64 times. The method of combining WT and SNV is used to preprocess the spectrum, and the method of singular value decomposition is used to analyze the –1 And 6200~9300cm –1 The spectral data matrix in the two regions is subjected to principal compo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap