System for relieving scorification of convection heated surface of boiler

A slagging and boiler technology, applied in the direction of lighting and heating equipment, to achieve the effect of increasing operating time, reducing impact and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

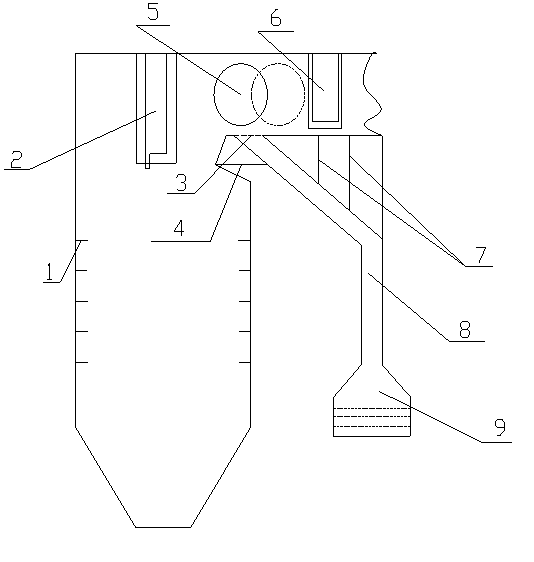

[0024] Such as figure 1 As shown, a system for alleviating slagging on the convective heating surface of a boiler includes a slagging device 5 arranged in the boiler flue, and the slagging device 5 is located at the windward front end of the convective superheater 6 at the top of the flue. The slag container 5 includes two symmetrically arranged disks and a straight pipe fixedly arranged between the disks, and the slag container 5 can roll along the axial direction of the flue.

[0025] The flue where the slag condenser 5 and the convection superheater 6 are located is arranged horizontally.

[0026] The part of the flue corresponding to the lower end of the slag condenser 5 is provided with a slag discharge port, and the lower end of the slag discharge port is provided with a slag conveying pipe 8, which is connected to the slag pool 9; Transport to the slag pool 9.

[0027] The slag discharge port is provided with a movable slag discharge baffle 3, which can be opened during

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap