Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

57 results about "Flue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flue is a duct, pipe, or opening in a chimney for conveying exhaust gases from a fireplace, furnace, water heater, boiler, or generator to the outdoors. Historically the term flue meant the chimney itself. In the United States, they are also known as vents for boilers and as breeching for water heaters and modern furnaces. They usually operate by buoyancy, also known as the stack effect, or the combustion products may be 'induced' via a blower. As combustion products contain carbon monoxide and other dangerous compounds, proper 'draft', and admission of replacement air is imperative. Building codes, and other standards, regulate their materials, design, and installation.

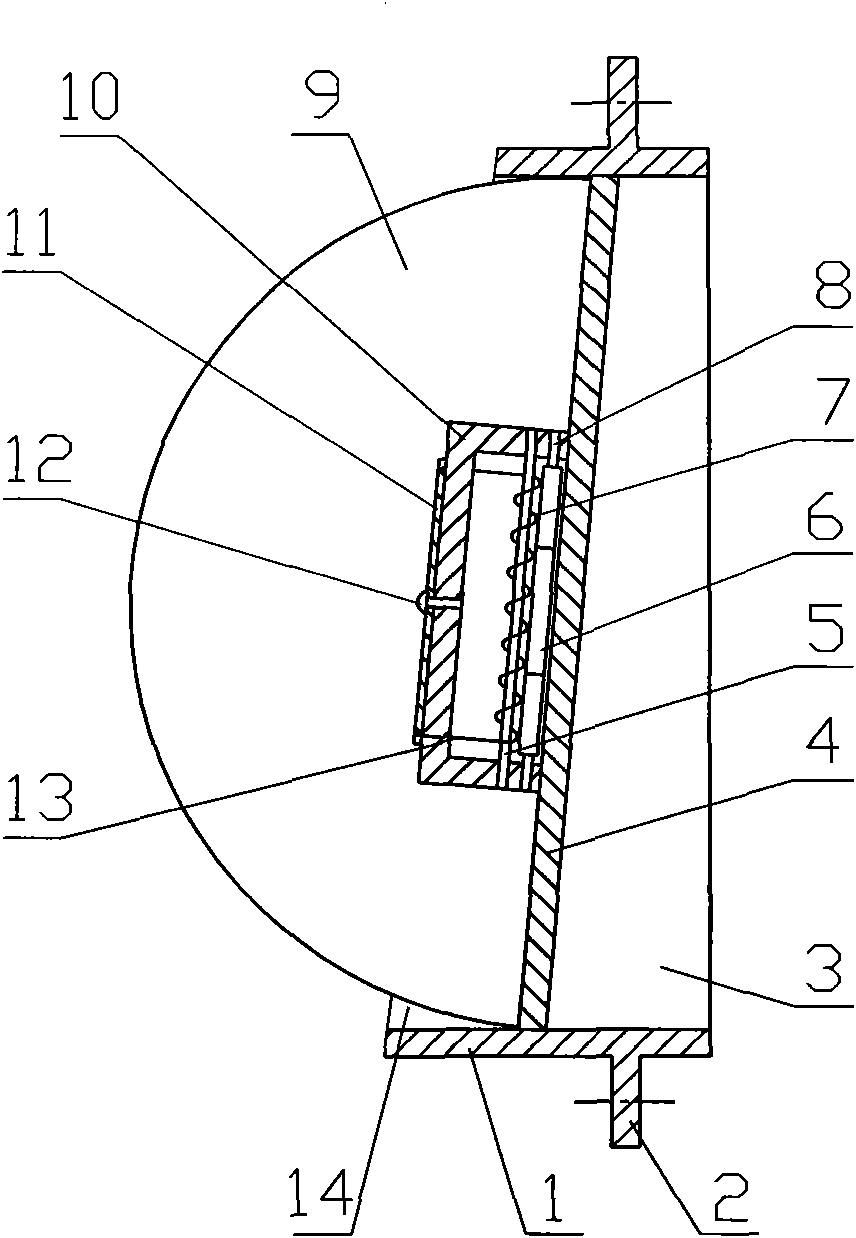

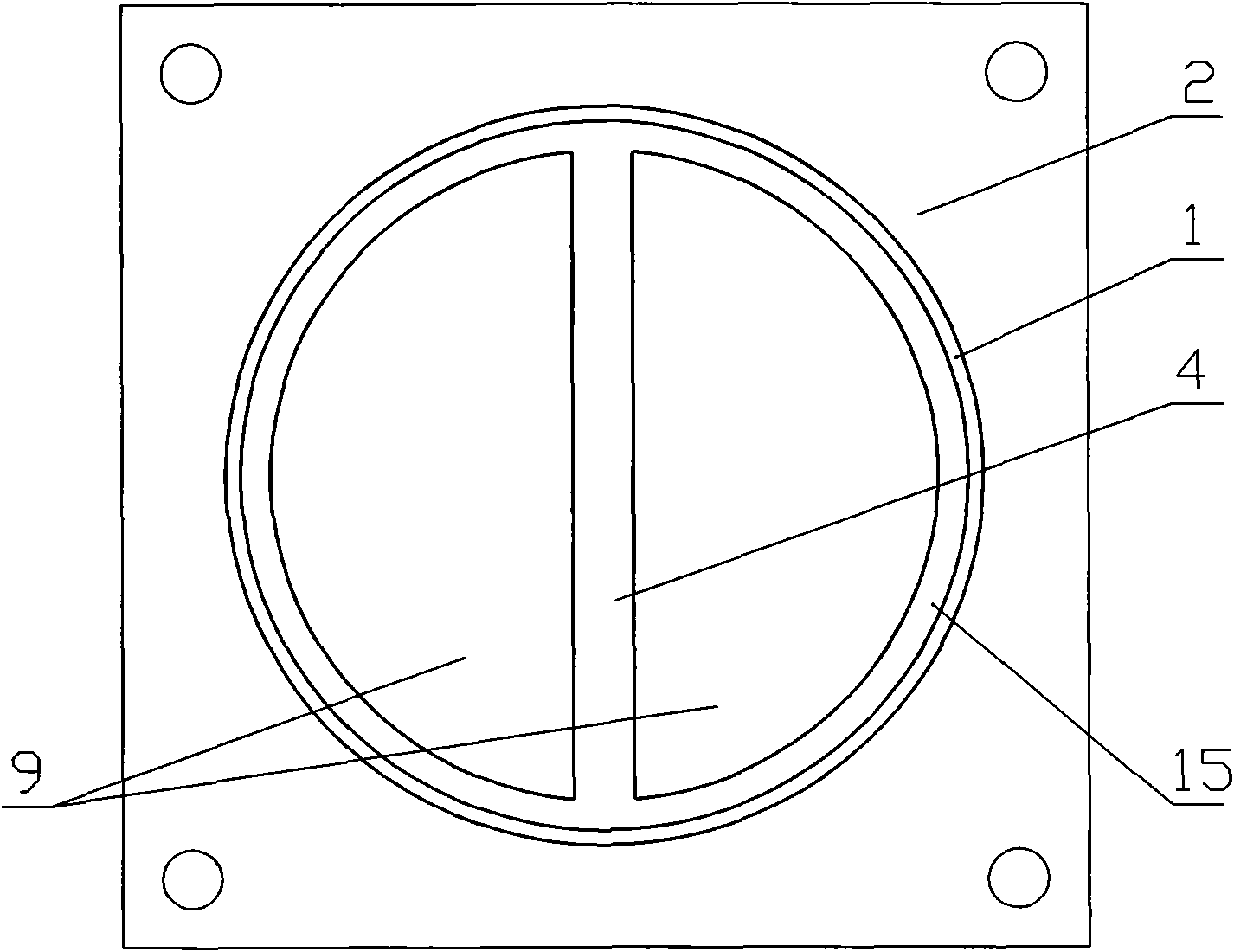

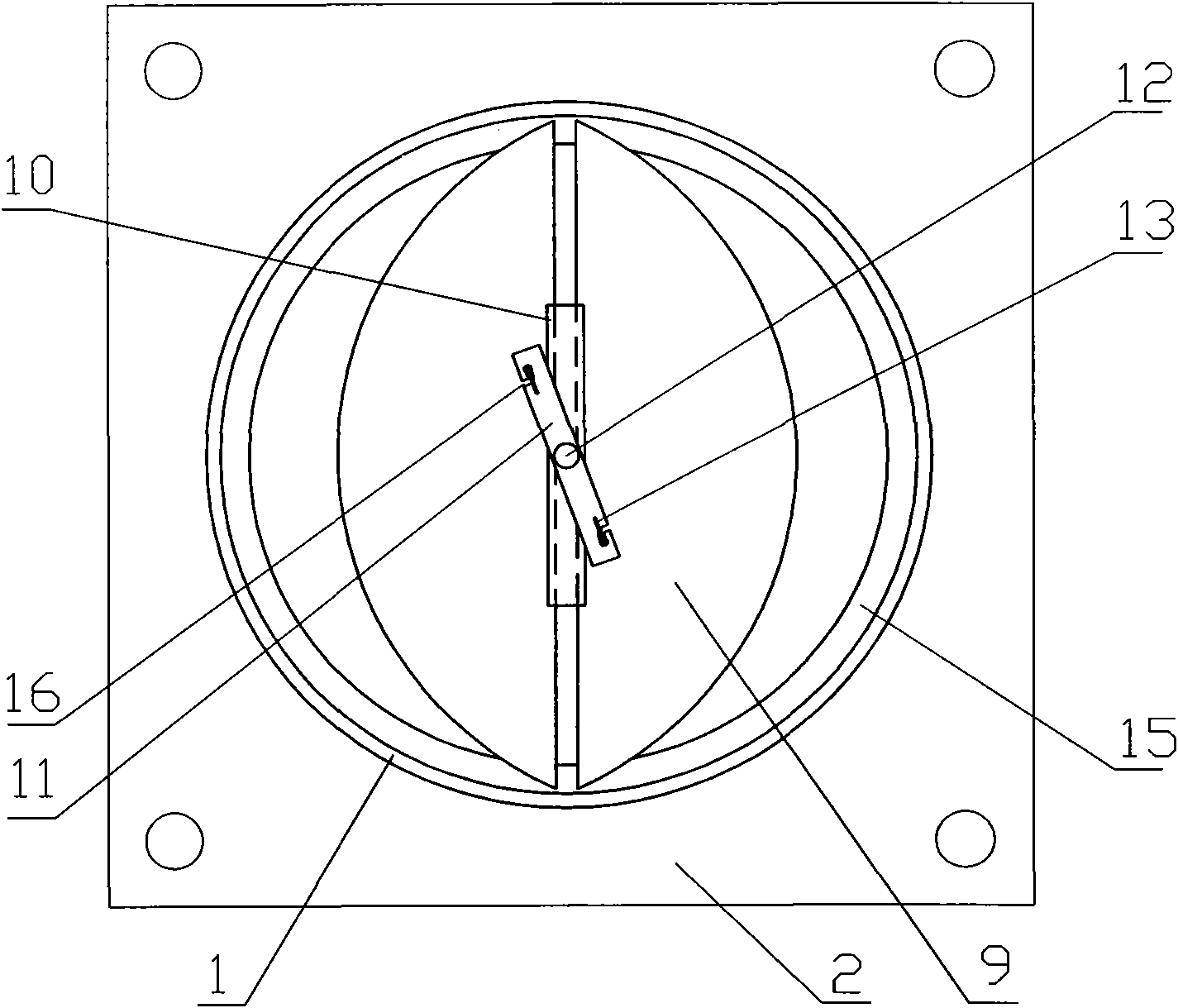

Check fire valve for flue

Owner:韩文强

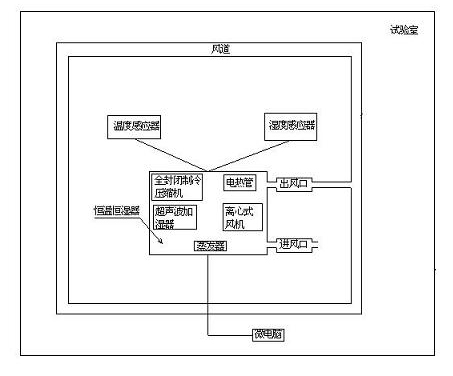

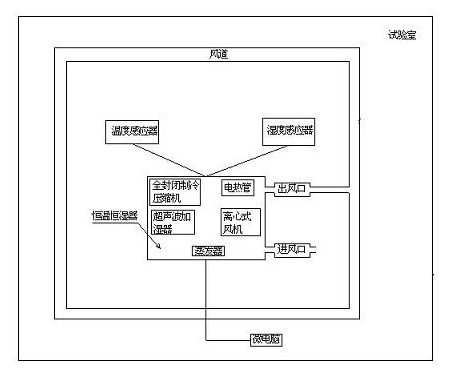

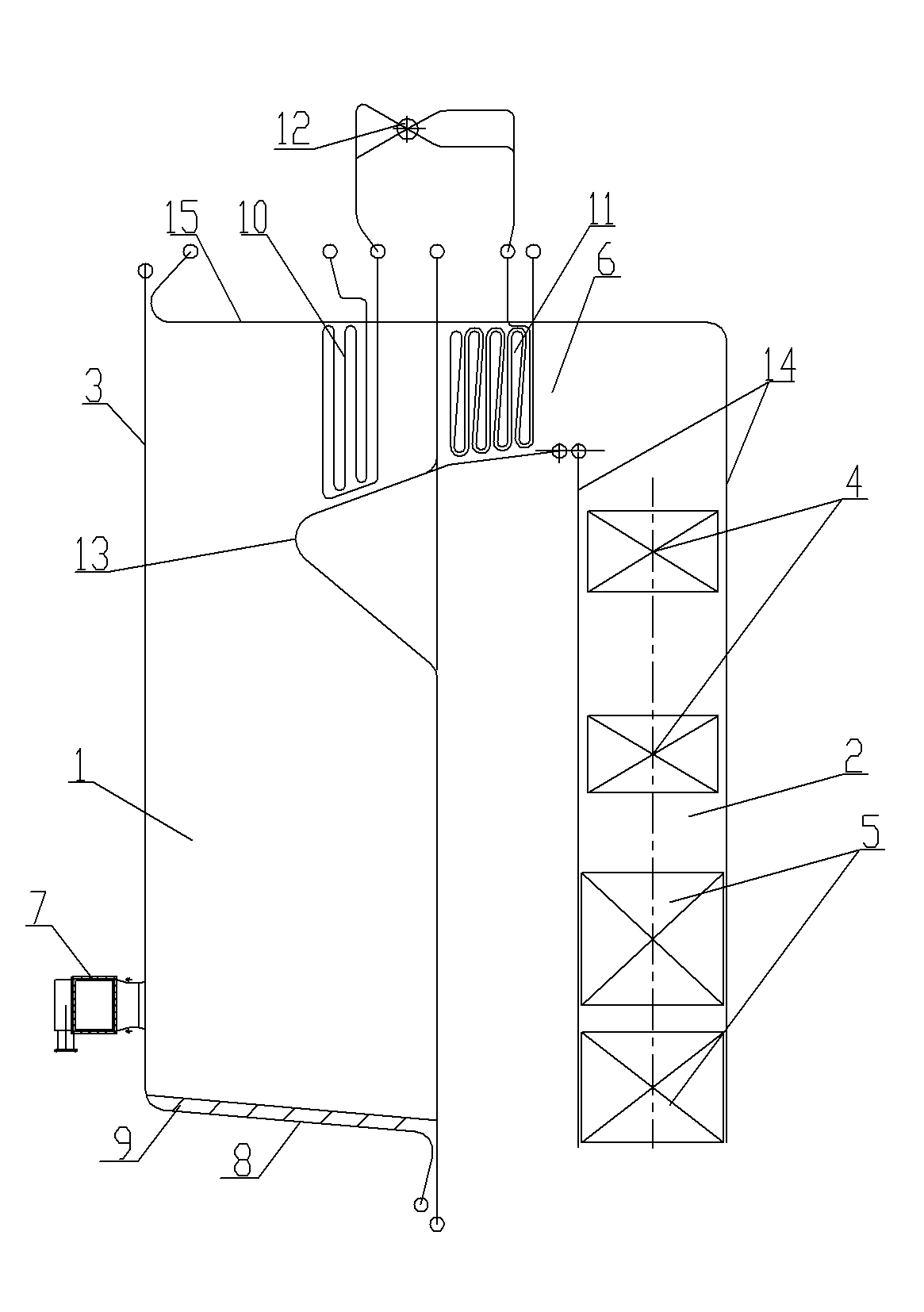

Concrete sample curing room

ActiveCN101947810AUniform temperatureUniform humidityCeramic shaping apparatusMicrocomputerThermodynamics

Owner:JSTI GRP INSPECTION & CERTIFICATION CO LTD

Air conditioner running control method and device and air conditioner system

ActiveCN106871366AEasy to operate and controlImprove ease of useMechanical apparatusLighting and heating apparatusTarget controlFlue

The invention provides an air conditioner running control method and device and an air conditioner system. An air conditioner comprises an outdoor unit shell, an air inlet, an air outlet and an air flue, wherein the air inlet and the air outlet are defined by the shell, and the air flue communicates with the air inlet and the air outlet and is internally provided with a draught fan and a heat exchanger. The running control method comprises the following steps that the voice of a target user using the target air conditioner is collected, the voice of the target user is subjected to voice recognition, and feature information of the target user is obtained; for various reference air conditions within the area range where the target air conditioner is located, a reference user matched with the feature information is inquired from users using the reference air conditioners, target control parameters are calculated according to historical control parameters set by the reference user, and then the target air conditioner is controlled through the target control parameters. According to the method, the air conditioner control operation can be simplified, and the using convenience of the air conditioner is improved.

Owner:MIDEA GRP CO LTD

Method for effectively restraining generation of sulfur trioxide and waste acid in smelting smoke

InactiveCN107144144AInhibitionReduce corrosionIncreasing energy efficiencyWaste heat treatmentSulfateSmelting process

Owner:CENT SOUTH UNIV

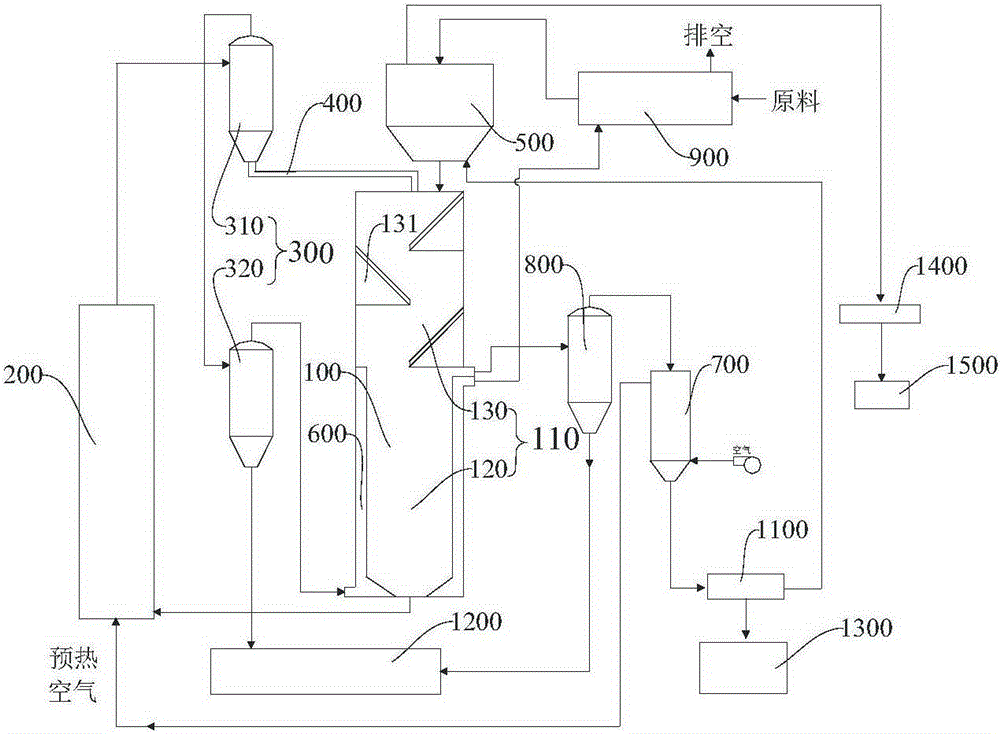

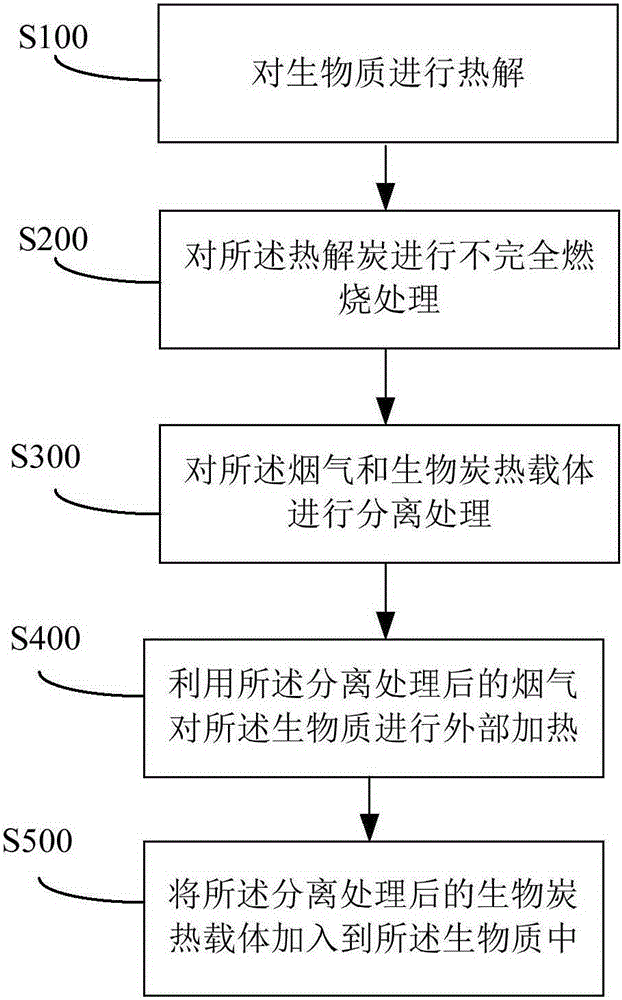

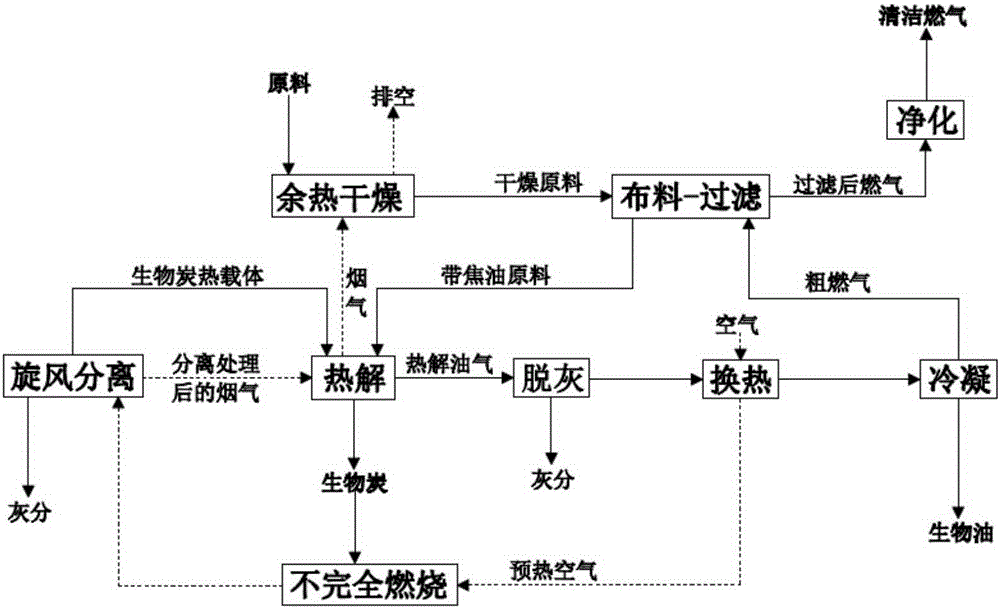

Biomass pyrolysis system and biomass pyrolysis method

ActiveCN105219417AEfficient pyrolysisLarge processing capacity per unit timeBiofuelsIndirect and direct heating destructive distillationCombustionHeat carrier

Owner:SHENWU TECH GRP CO LTD

Electronic cigarette

Owner:深圳市古可生物科技有限公司

Device for testing contamination characteristic of segmental temperature control coal burning boiler

InactiveCN102879415AImprove stabilityIncrease flexibilityMaterial thermal analysisTemperature controlCombustor

Owner:中国东方电气集团有限公司

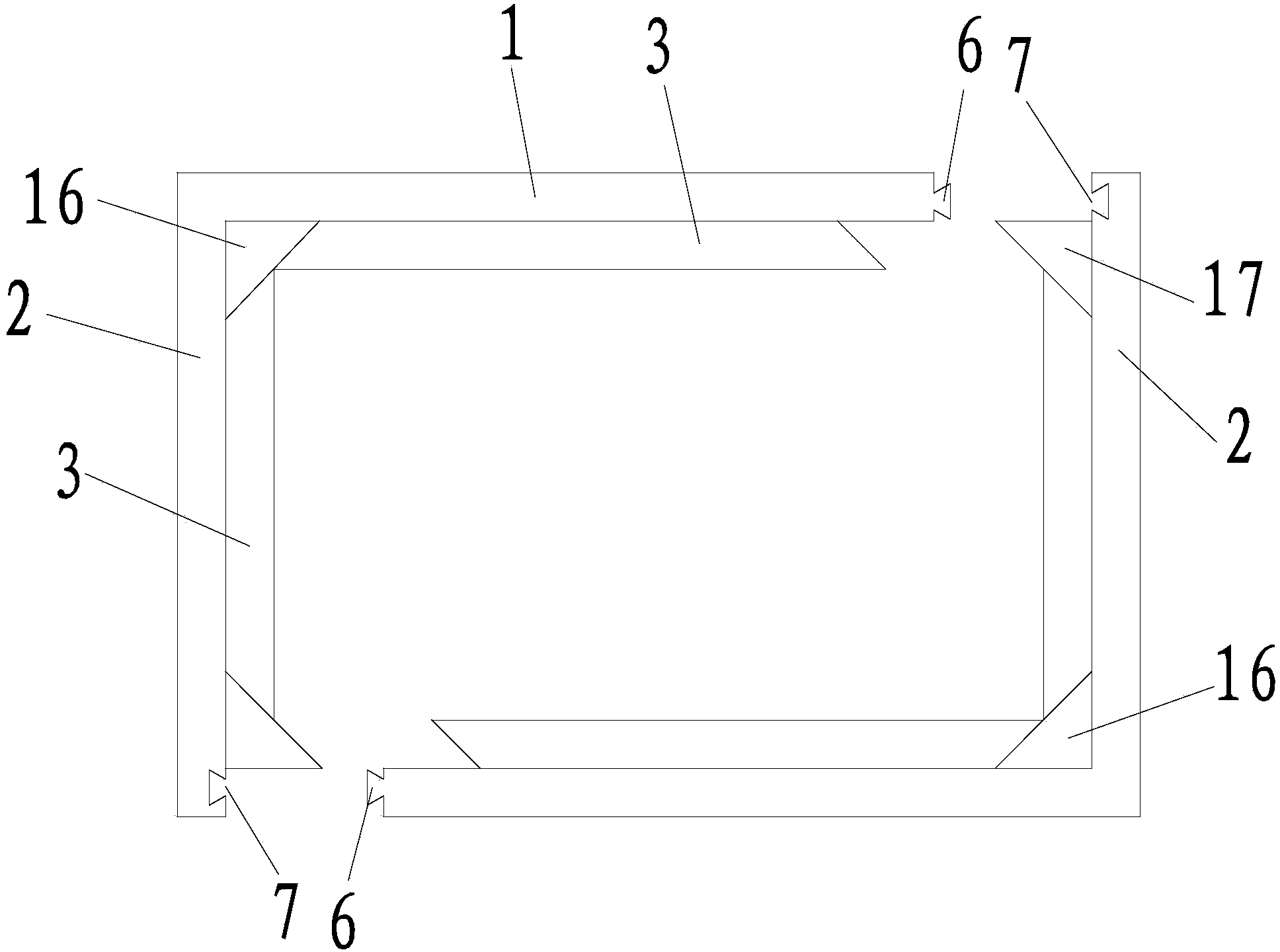

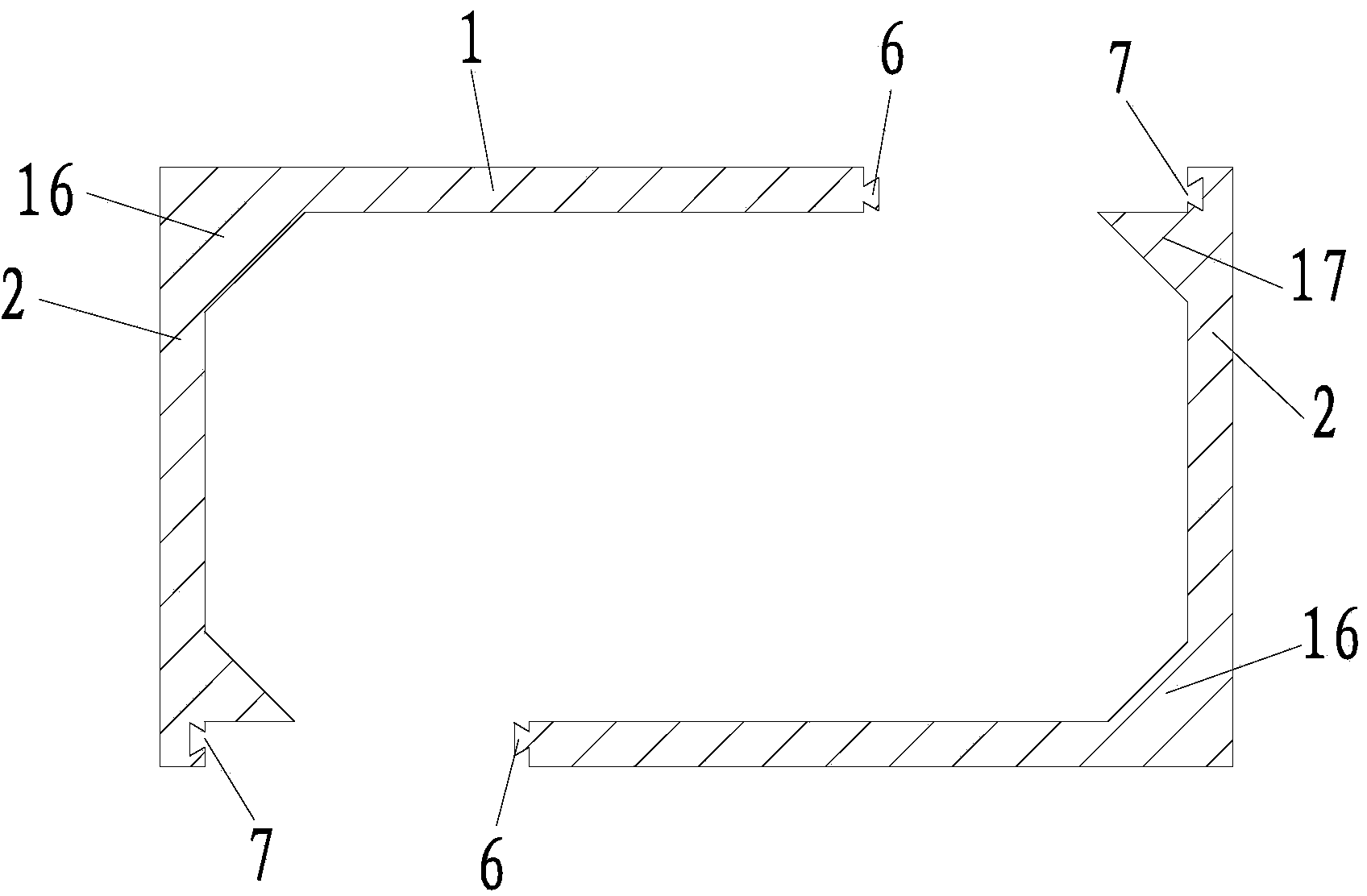

Assembled type flue

ActiveCN103821323AExcellent joint strengthEasy to transportVertical ductsEngineeringUltimate tensile strength

Owner:CSCEC STRAIT CONSTR & DEV +1

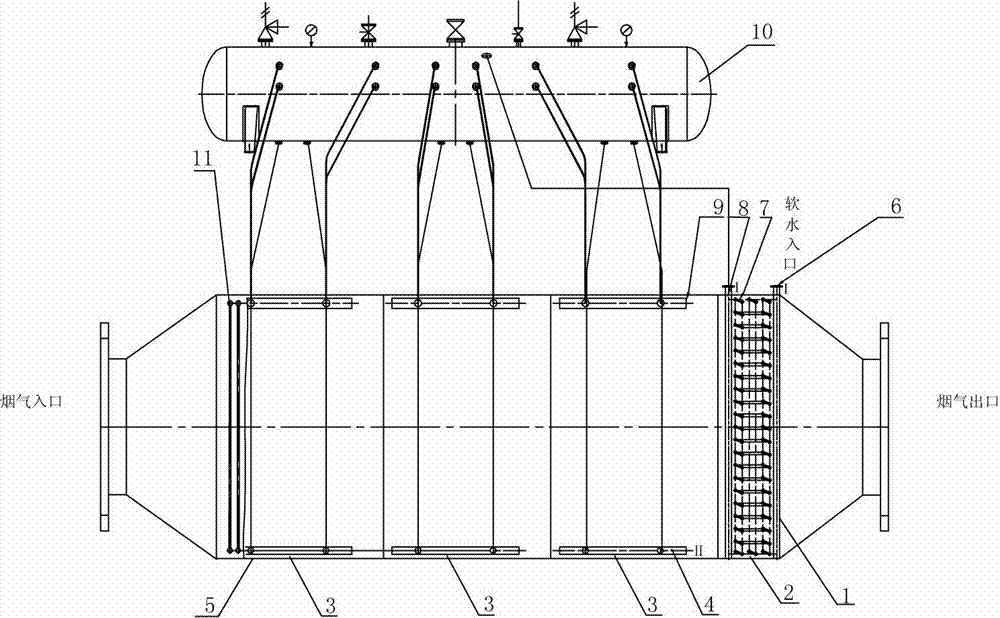

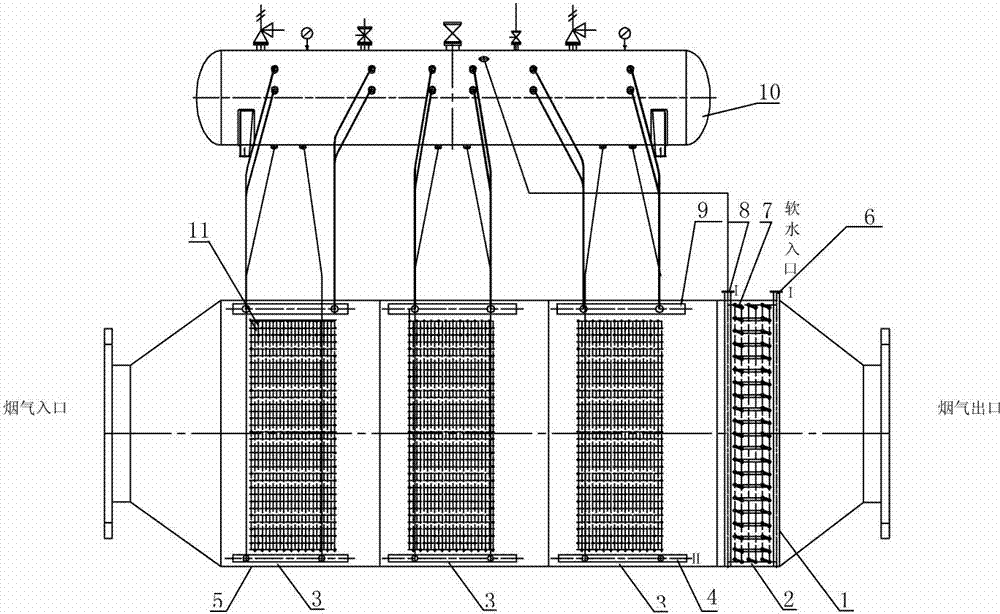

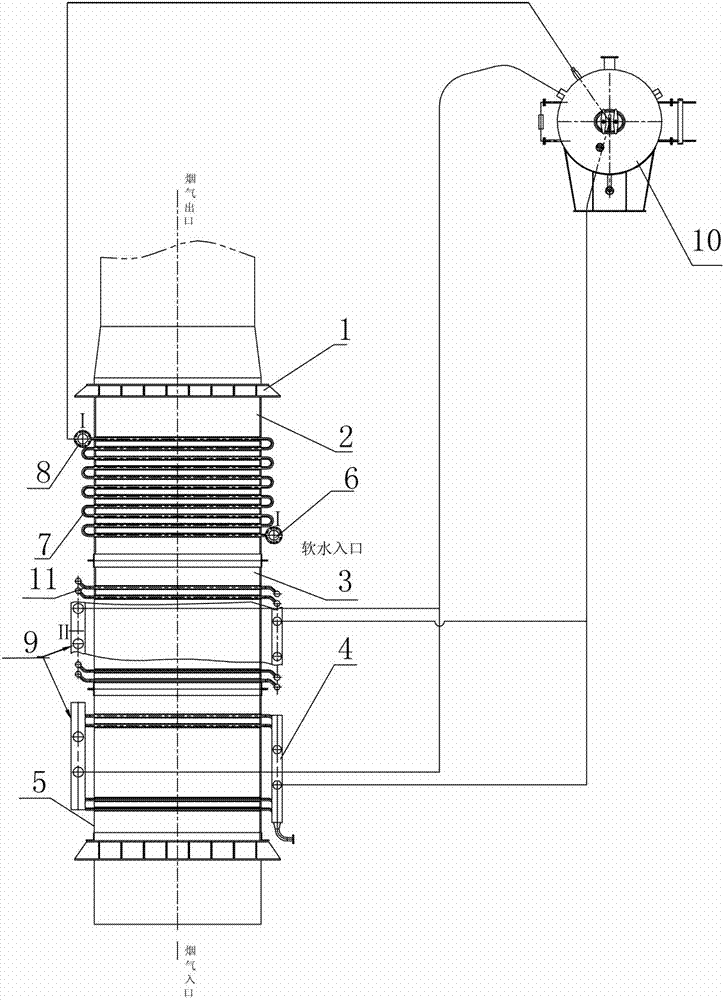

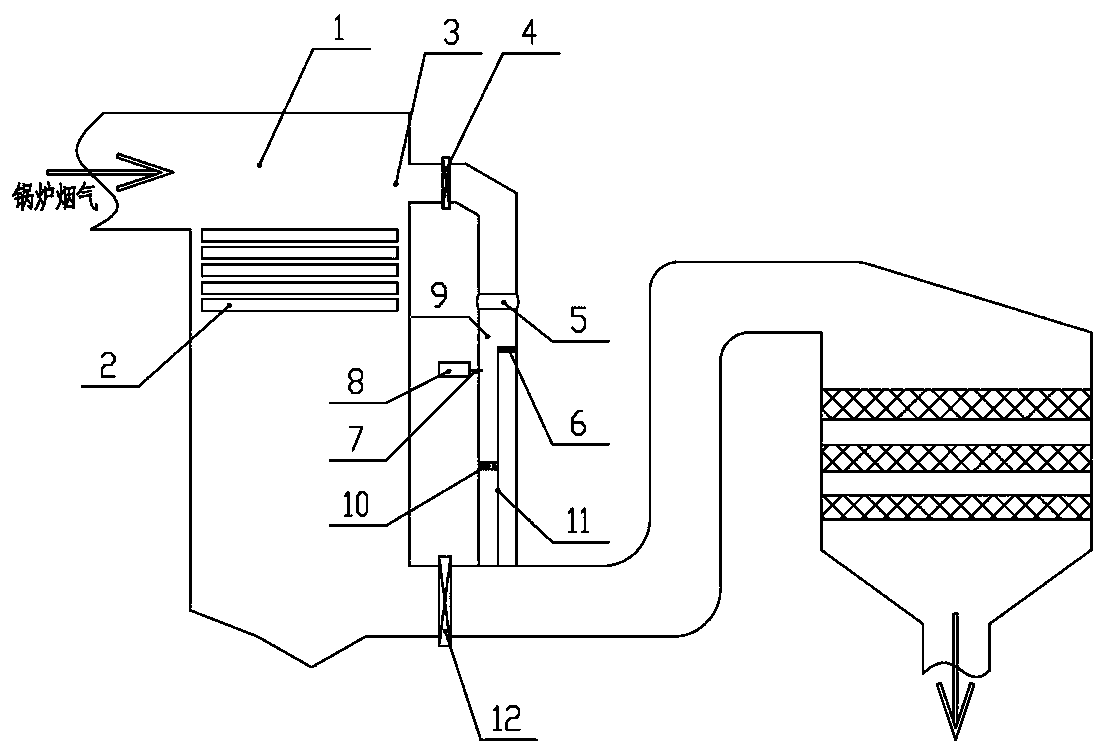

Radial heat tube-ordinary heat exchange tube combined type waste heat recovery device for flue tail gases

InactiveCN103292305ALower exhaust gas temperatureAvoid corrosionSteam generation using hot heat carriersFlue gasExhaust fumes

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP +1

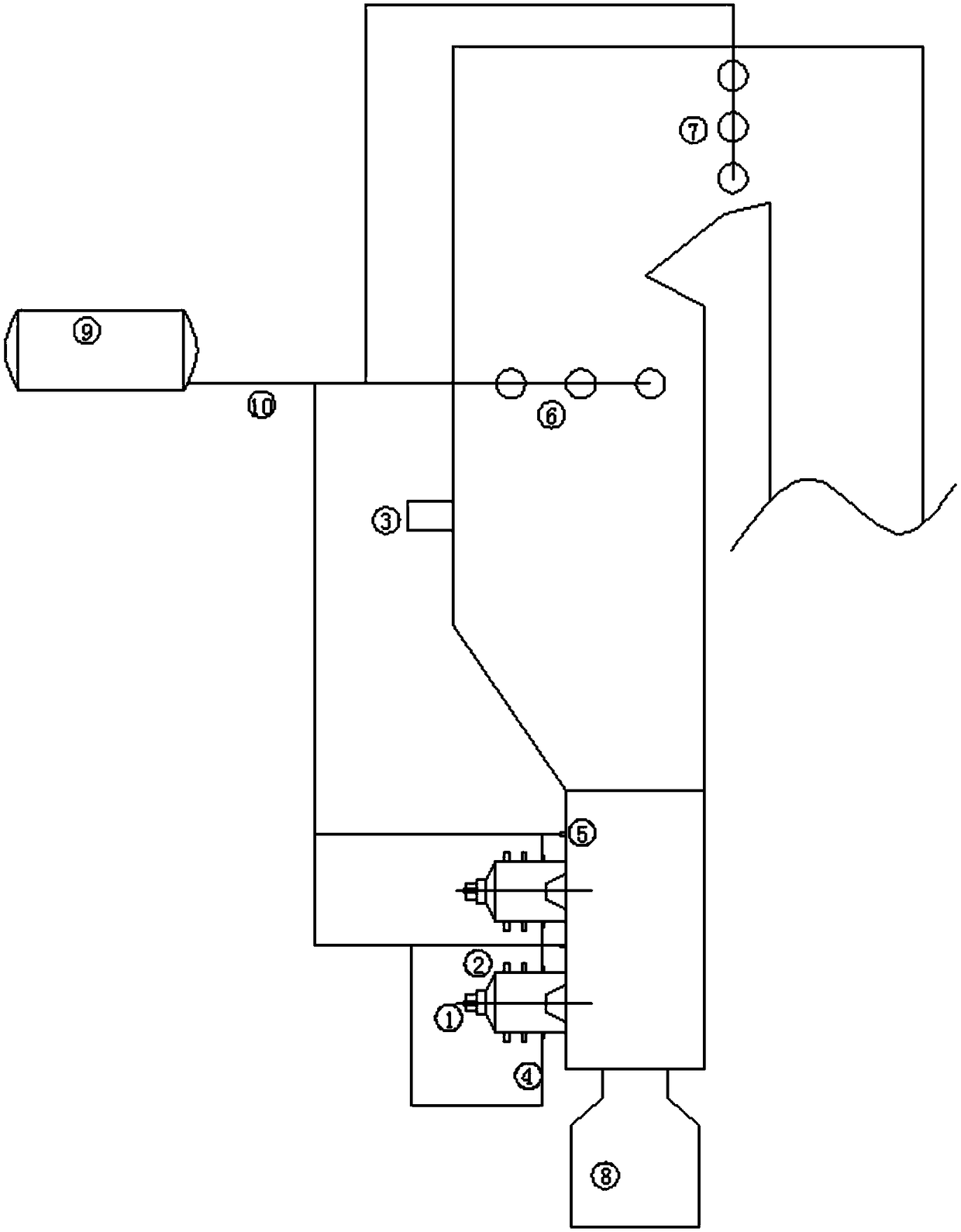

Cyclone furnace denitration system and method

PendingCN109058979AEmission reductionImprove economyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

Owner:CHINA HUANENG GRP CO LTD +1

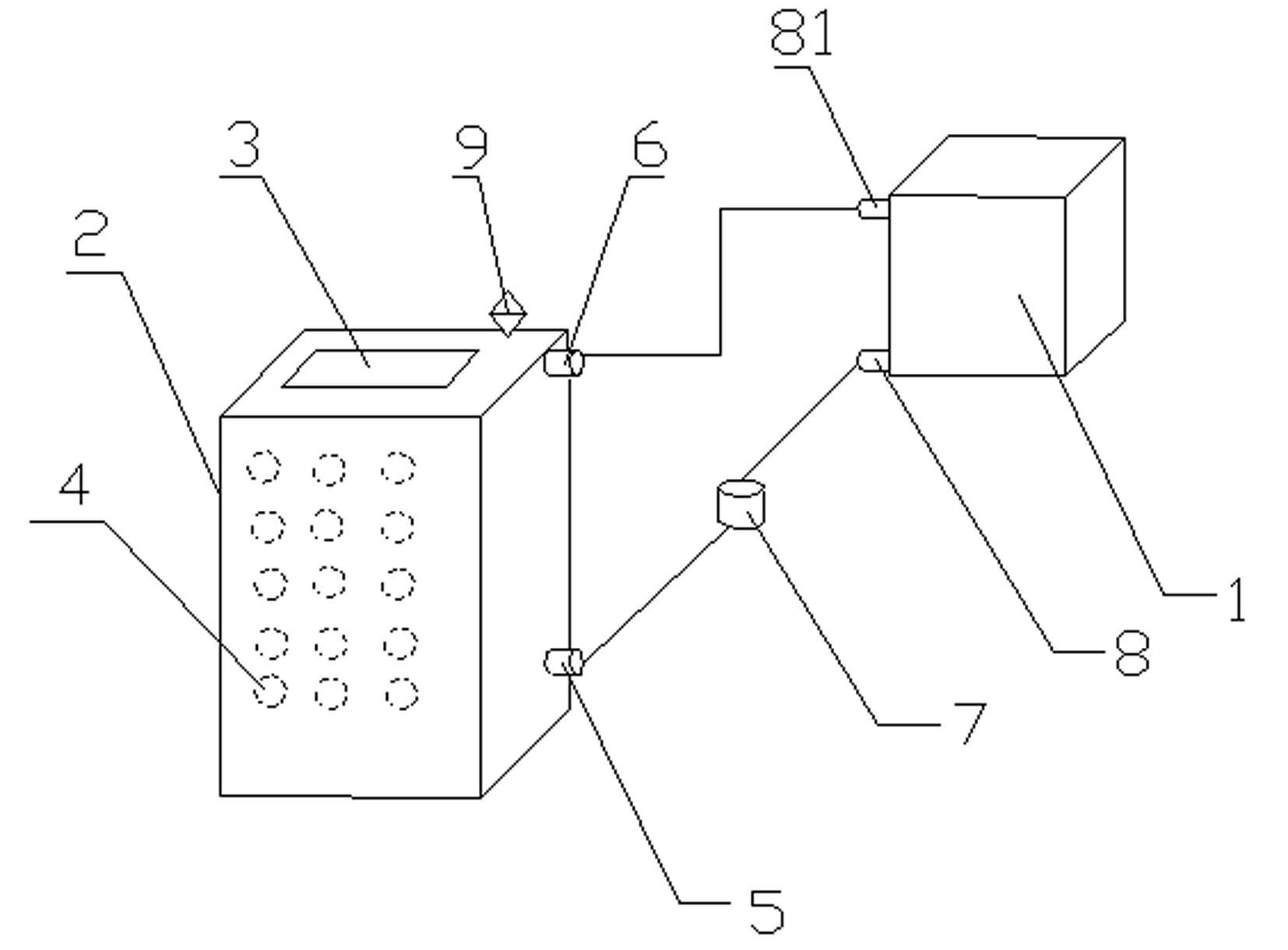

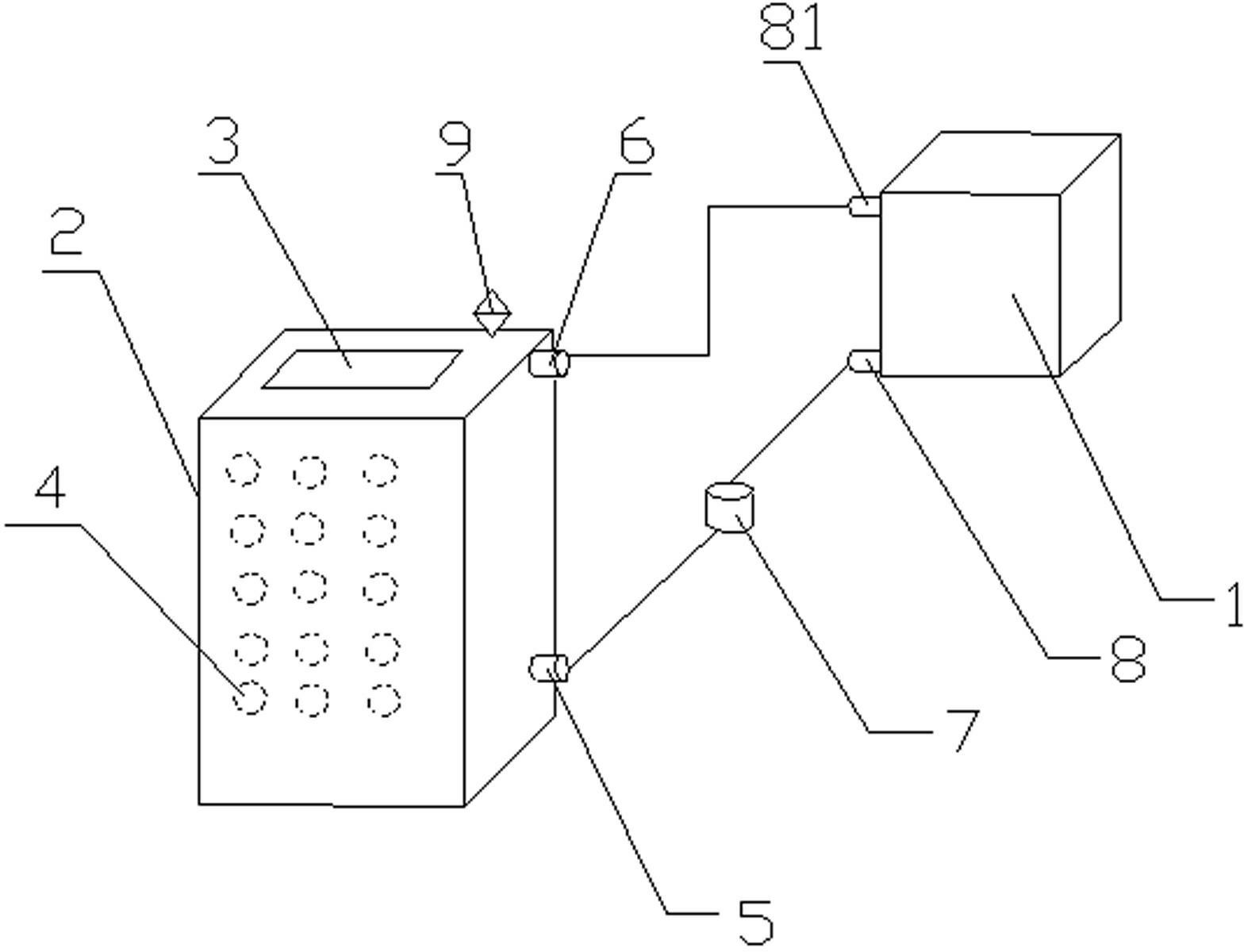

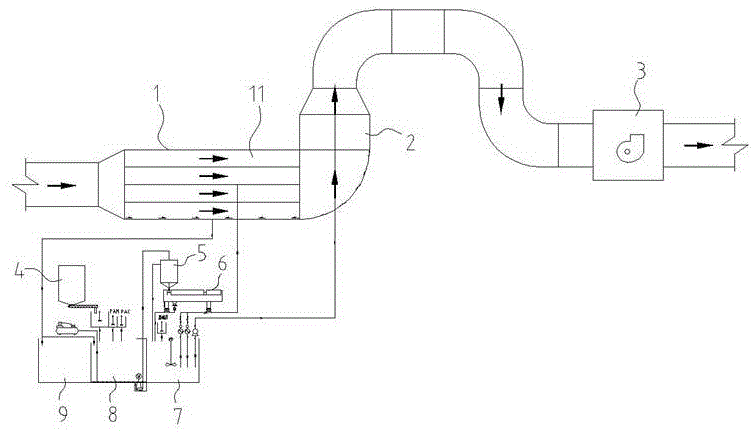

Flue gas desulfurization and denitration system and method

The invention discloses a flue gas desulfurization and denitration system and method, and belongs to the technical field of flue gas processing. The system comprises a pre-deduster, a rotating spray desulfurization and denitration system, an induced draft fan and a chimney, a circulating fluidized bed desulfurization system is arranged between the rotating spray desulfurization and denitration system and the induced draft fan, and a flue gas mixing axial adjustment damper is arranged between the rotating spray desulfurization and denitration system and the circulating fluidized bed desulfurization system; the system further comprises a booster conveying fan, a material conveying pump I and a material conveying pump II. Accordingly, the rotating spray desulfurization and denitration systemand the circulating fluidized bed desulfurization system are combined, step-by-step desulfurization and denitration on flue gas are achieved, and the desulfurization and denitration efficiency is high; due to step-by-step desulfurization and denitration, the system and method can be applied to desulfurization and denitration processing of the flue gas high in sulfur content and nitrate content, and the application range is high.

Owner:NANJING SHIBO ENVIRONMENTAL PROTECTION TECH CO LTD

Boiler waste heat recovery device

InactiveCN102287805ARealize secondary recycling and reuseRaise the water temperatureFluid heatersCombustion technology mitigationWaste heat recovery unitFlue gas

Owner:PENGLAI HUIYANG FOOD

Desulfurization wastewater zero discharging system and method based on waste heat reuse under low-load working condition

PendingCN107973475AIncrease temperatureSolve the problem of incomplete evaporationGas treatmentLighting and heating apparatusFlue gasEvaporation

Owner:DATANG ENVIRONMENT IND GRP

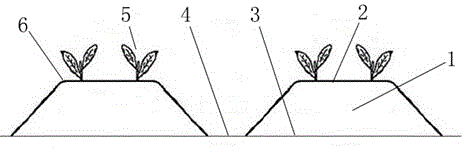

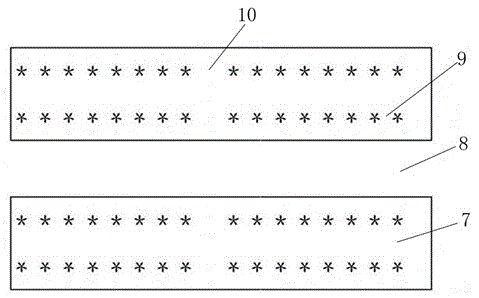

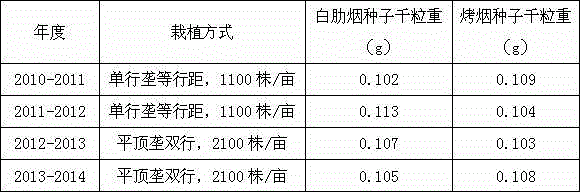

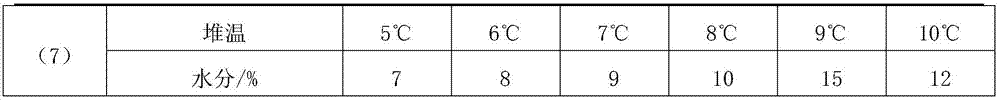

Southward propagation generation-adding breeding method for flattop ridge twin-row high density plantation of tobaccos

InactiveCN104584839AGuaranteed seed qualityAchieving the goal of southern multiplication plus generation multiplicationFertilising methodsPlant cultivationHigh densityNitrogen

Owner:HUBEI TOBACCO SCI RES INST

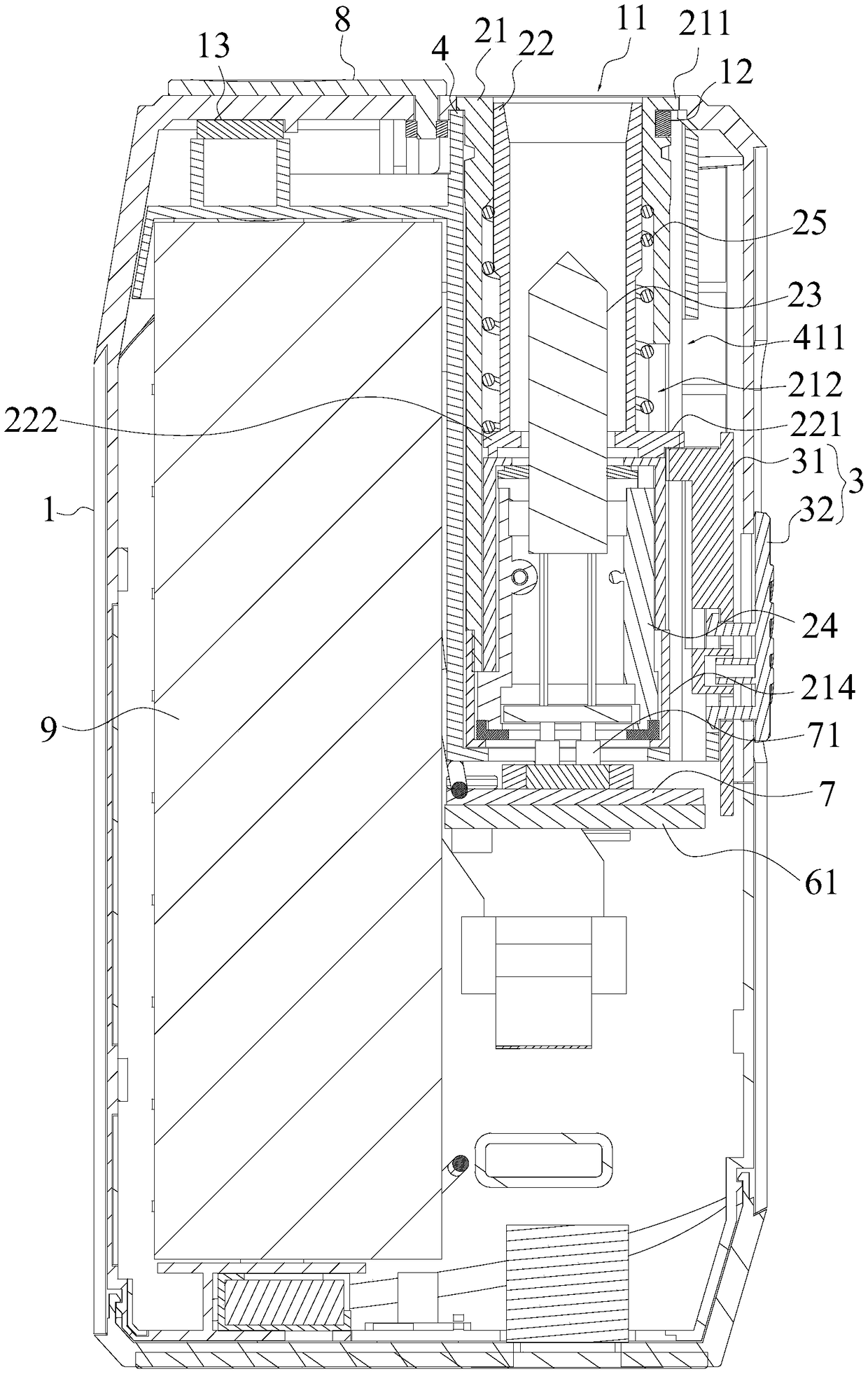

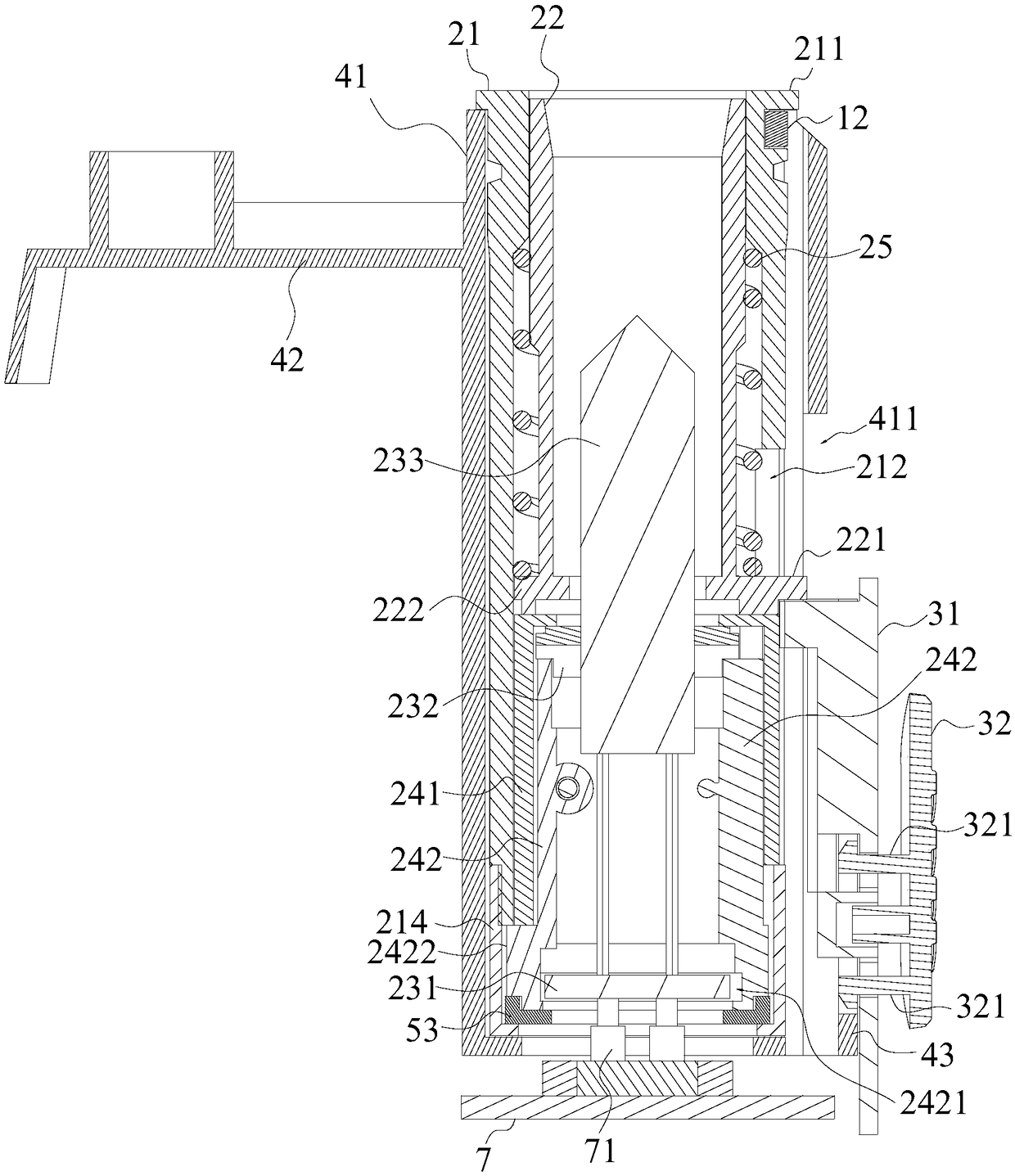

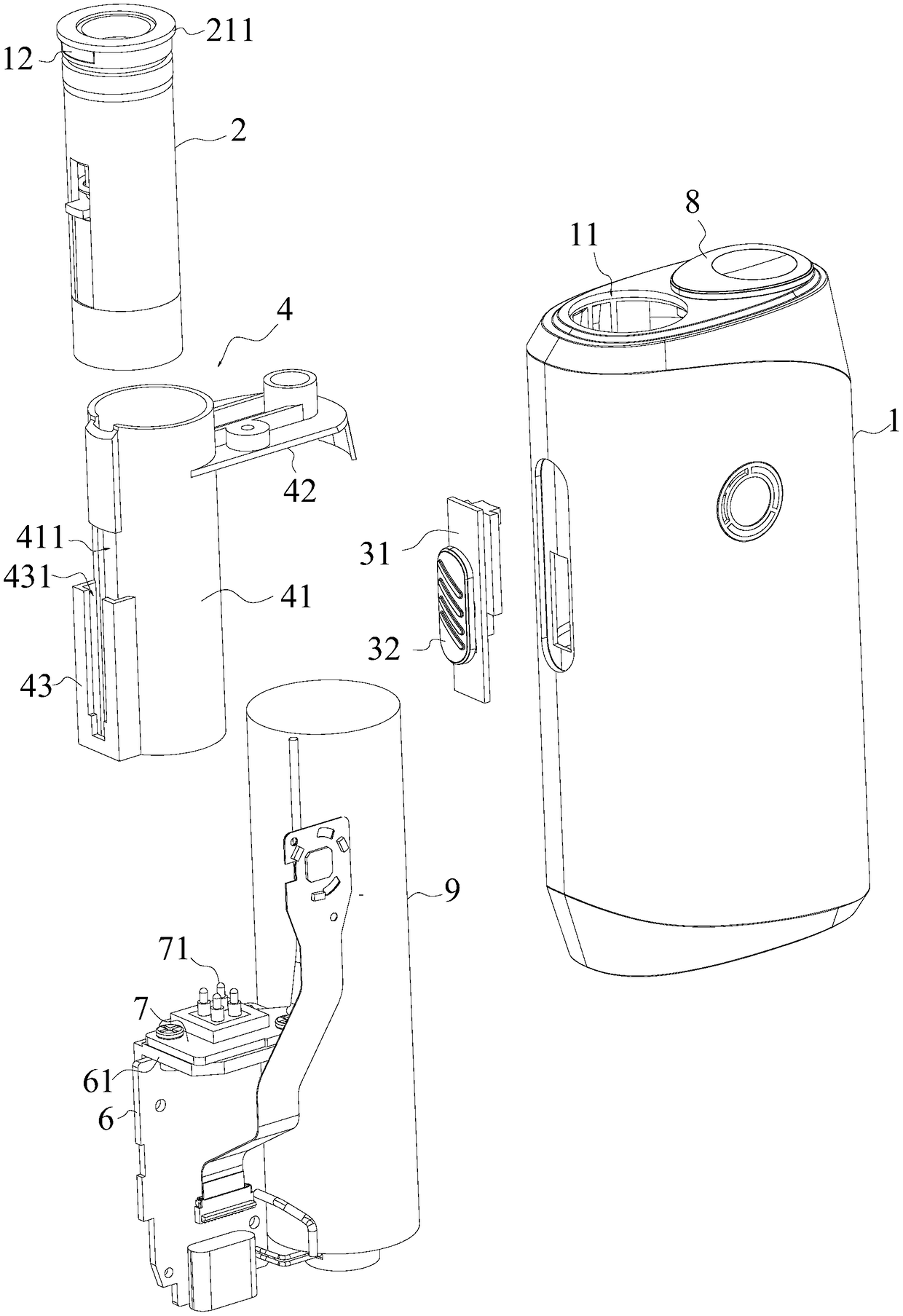

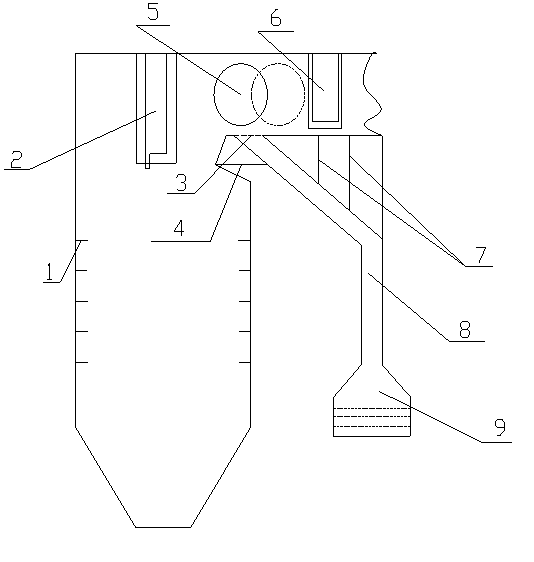

Long suction type acupuncture, bloodletting and thrombolysis all-in-one cupping device

ActiveCN108938060AControl the depth of penetration into the skinEasy to operateAcupuncturePneumatic massageAcupunctureNeedle puncture

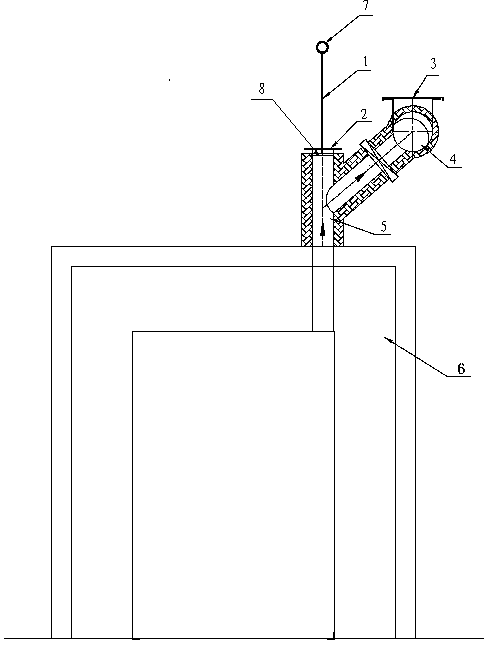

The invention provides a long suction type acupuncture, bloodletting and thrombolysis all-in-one cupping device, and relates to the technical field of physiotherapy equipment. The device comprises a transparent tank body, wherein the tank body is provided with an inlaid nut, the inlaid nut is provided with a rotating needle seat, the rotating needle seat is in threaded connection to the inlaid nut, the rotating needle seat is provided with an air flue and an air hole, the upper end of the rotating needle seat is provided with an air faucet, the lower end of the rotating needle seat is providedwith a blood pricking edge needle, the air hole is communicated with the air flue, and the air flue is communicated with the air faucet. The long suction type acupuncture, bloodletting and thrombolysis all-in-one cupping device has the advantages that needle pricking and pulling-out bloodletting work can be completed simultaneously, tool switching does not need to be carried out like traditionaloperation, and operation is fast and efficient.

Owner:FOSHAN YISANFENGHANG TECH CO LTD

System for relieving scorification of convection heated surface of boiler

ActiveCN102798130AExtended run timeGuaranteed cleanlinessLighting and heating apparatusCombustionSlag

Owner:DONGFANG ELECTRIC CORP LTD

Burner

A burner operating with flameless combustion, comprising a system for sucking the recycling flue gases directly from the combustion chamber by means of an ejector (1) fed with the comburent, a heat exchange system positioned between the recycling flue gases and the comburent, a system for injecting the fuel directly into the recycling flue gases, the latter comprising or not comprising the comburent with formation of a mixture of fuel-recycling flue gases-comburent in the zone around the outlet of the comburent ejector and following introduction of the mixture into the combustion chamber.

Owner:SOFINTER

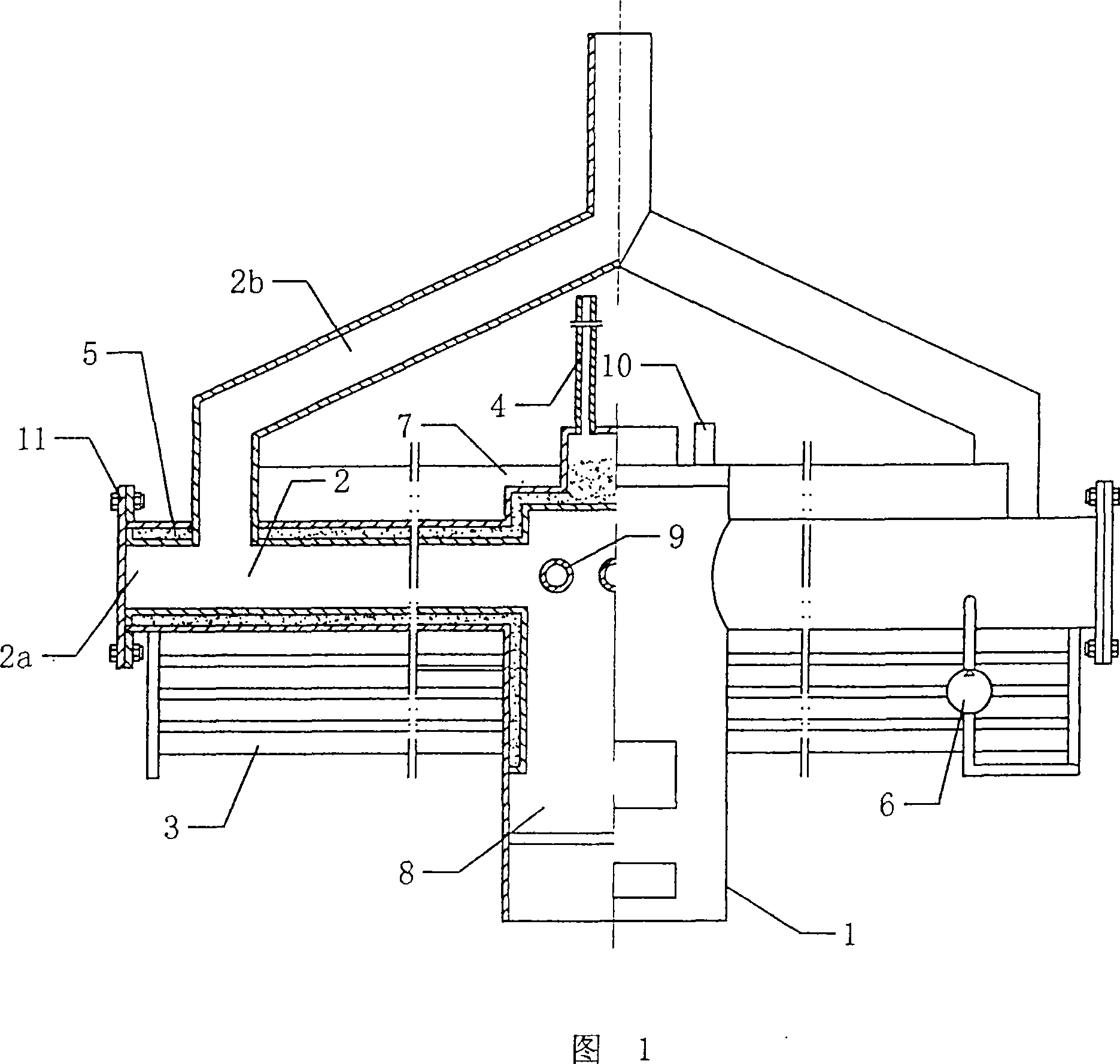

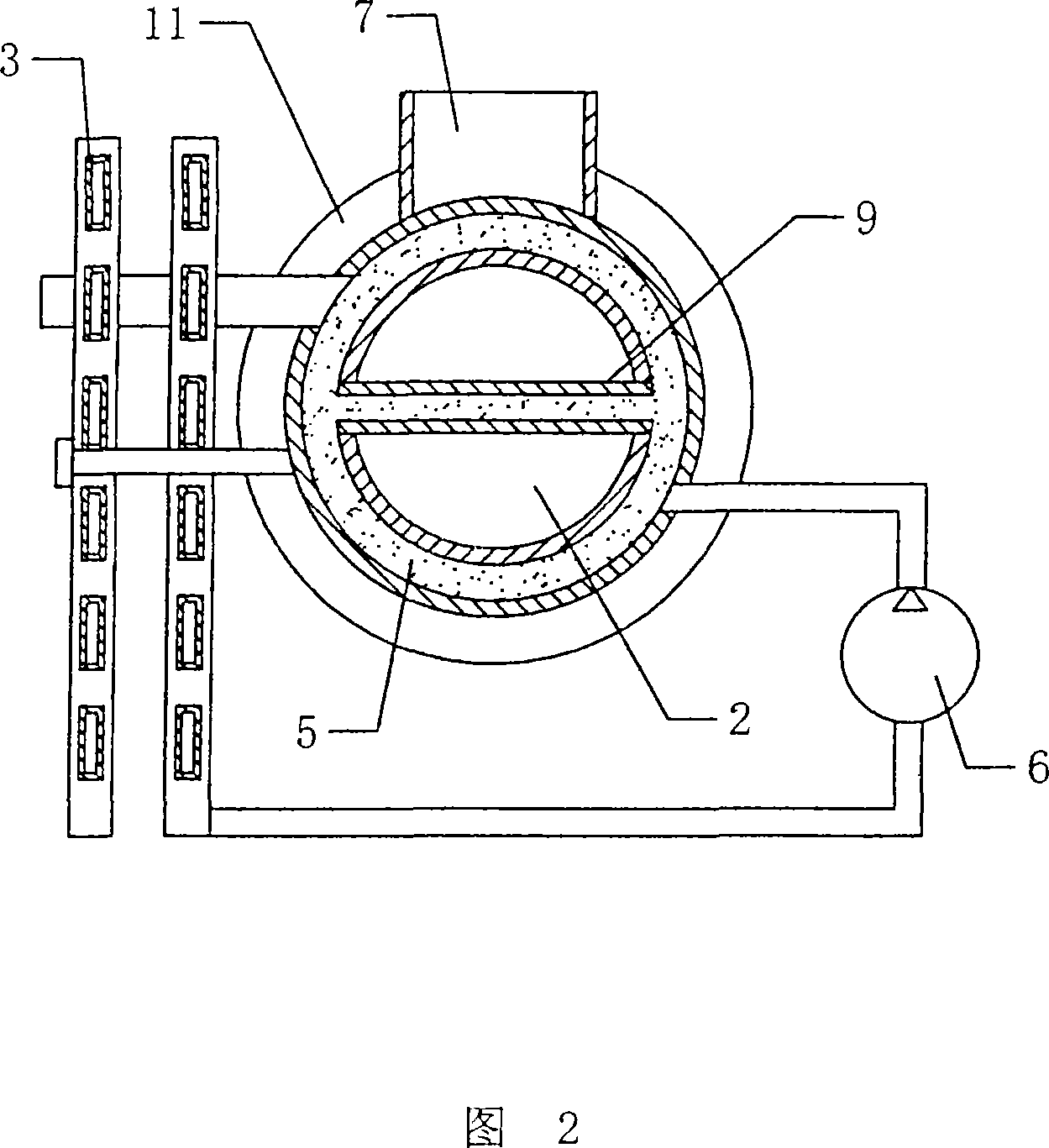

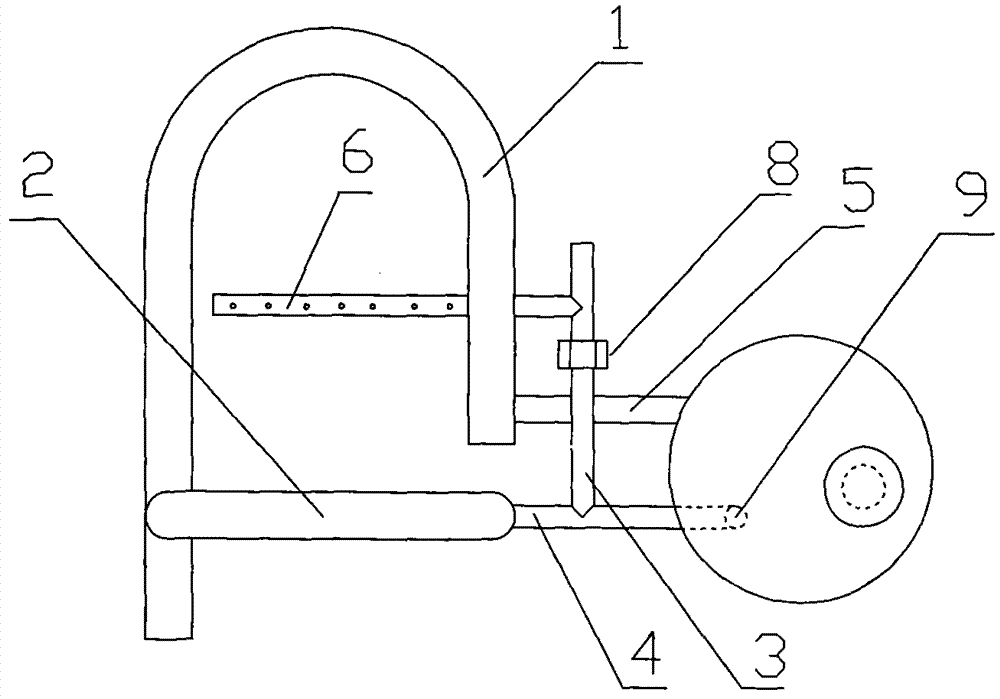

Lumber drying kiln

InactiveCN101144685AImprove thermal conductivityTemperature safetyHeating arrangementCombustion chamberHeat conducting

Owner:李祥文

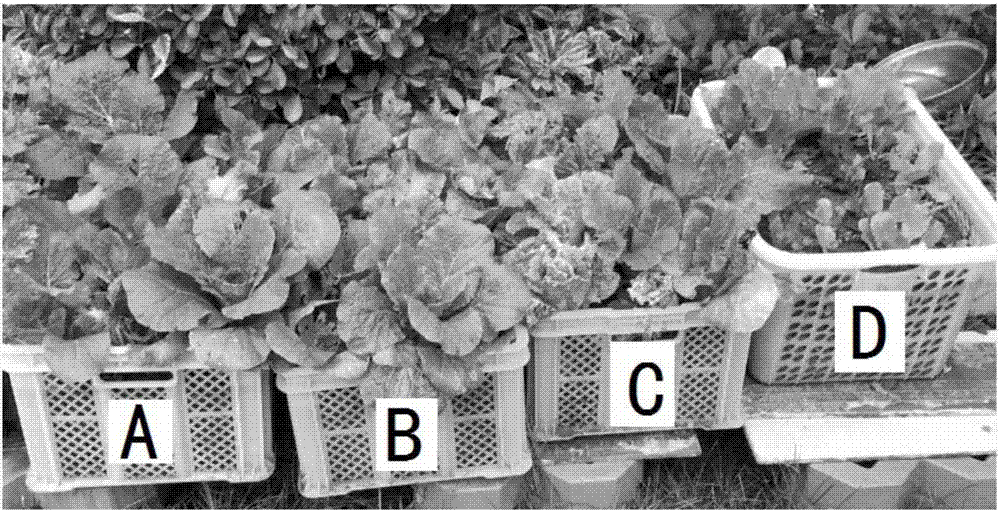

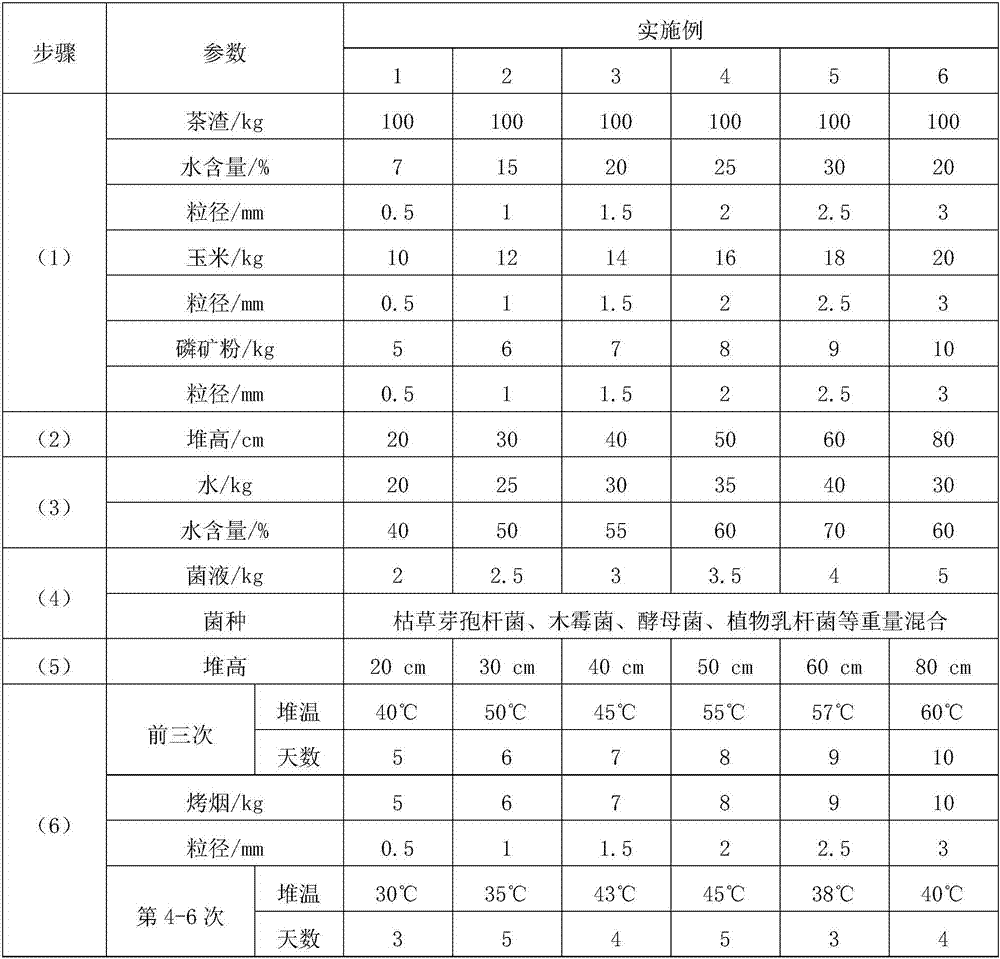

Tea-leaf organic fertilizer and preparation method thereof

InactiveCN107162837AHigh in NPKGood fertilizer effectBio-organic fraction processingOrganic fertiliser preparationPhosphatePotassium

Owner:MENGHAI TEA IND +1

High heating value gas boiler

Owner:WUXI HUAGUANG BOILER

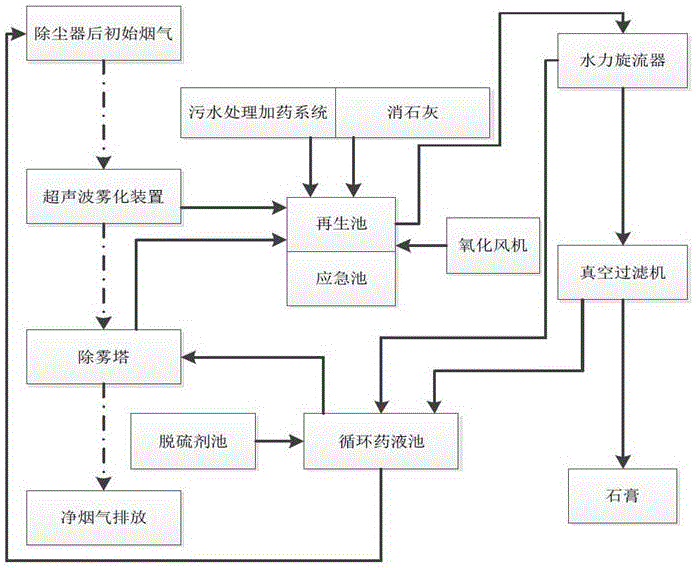

Thermal power plant ultrasonic atomization desulfurization-dust removal-ammonia escape prevention integrated system

InactiveCN107433115ALow concentration of sulfur dioxideReduce dust contentCombination devicesGas treatmentAutomatic controlEngineering

Owner:陈佐会

Warm air furnace

InactiveCN102777938AStove/ranges for heating waterNon-combustible gases/liquids supplyFlueEngineering

Owner:王新阳

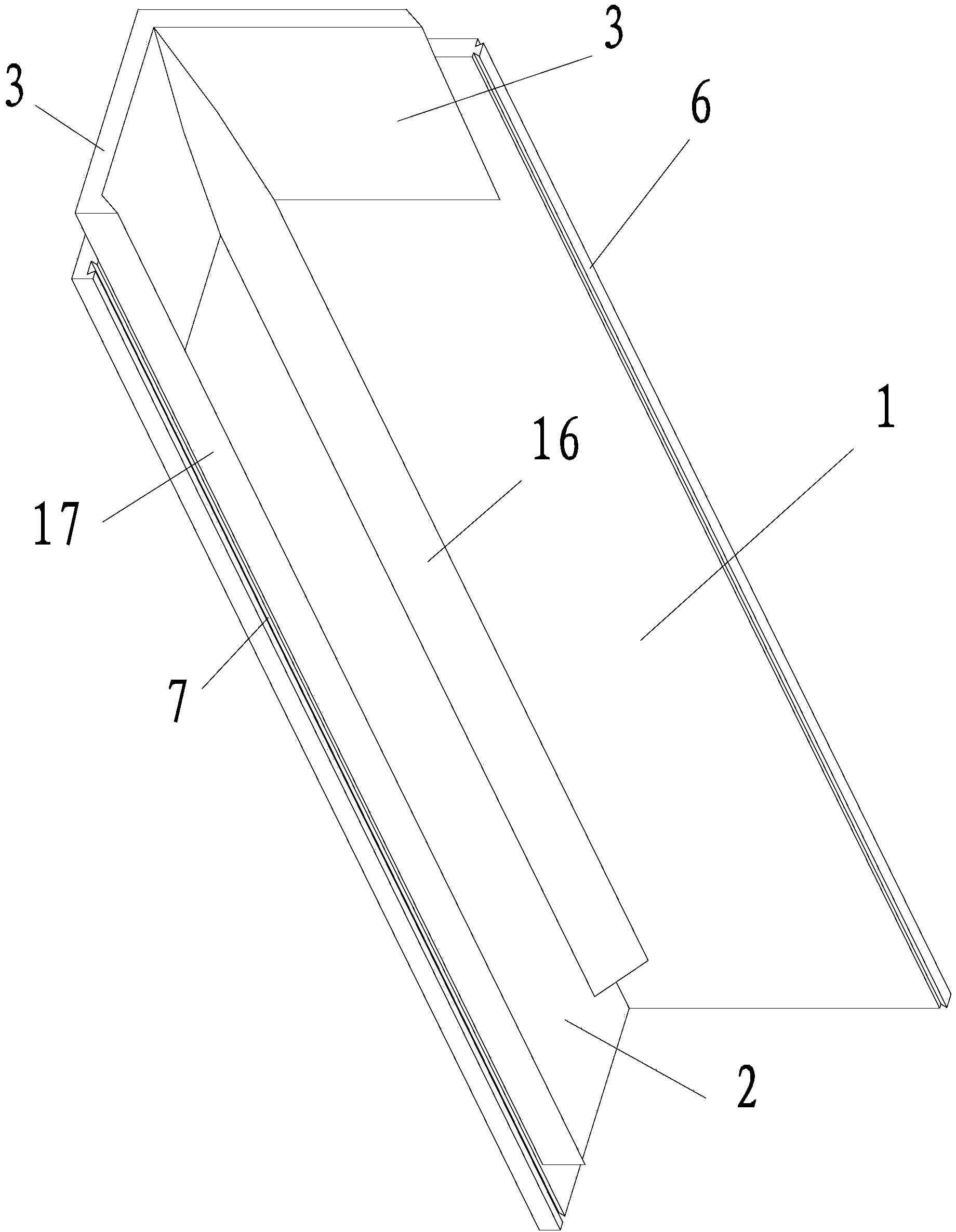

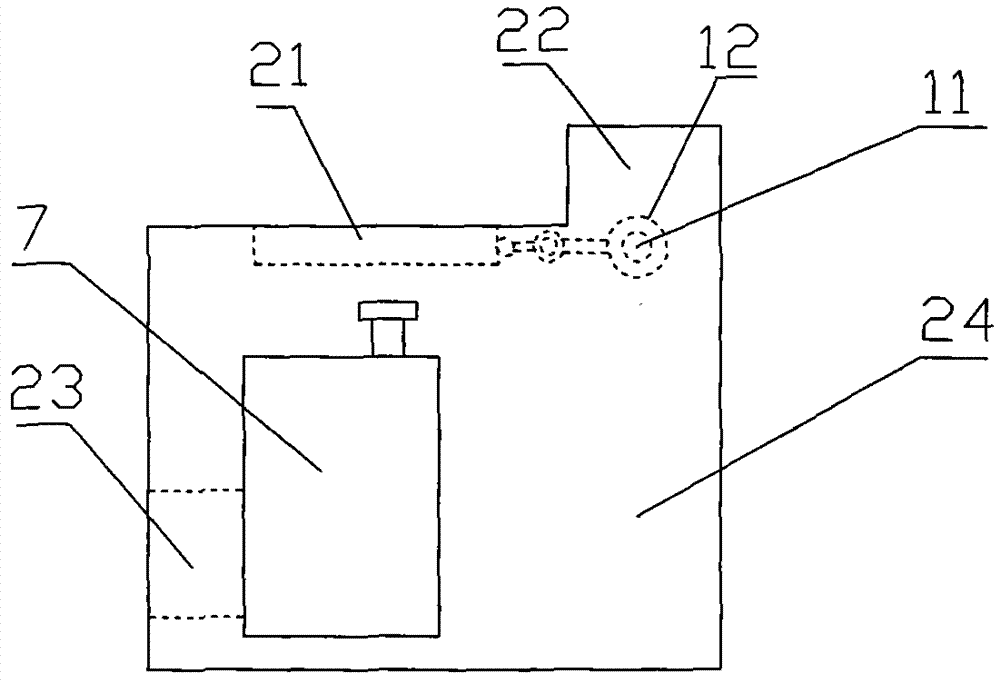

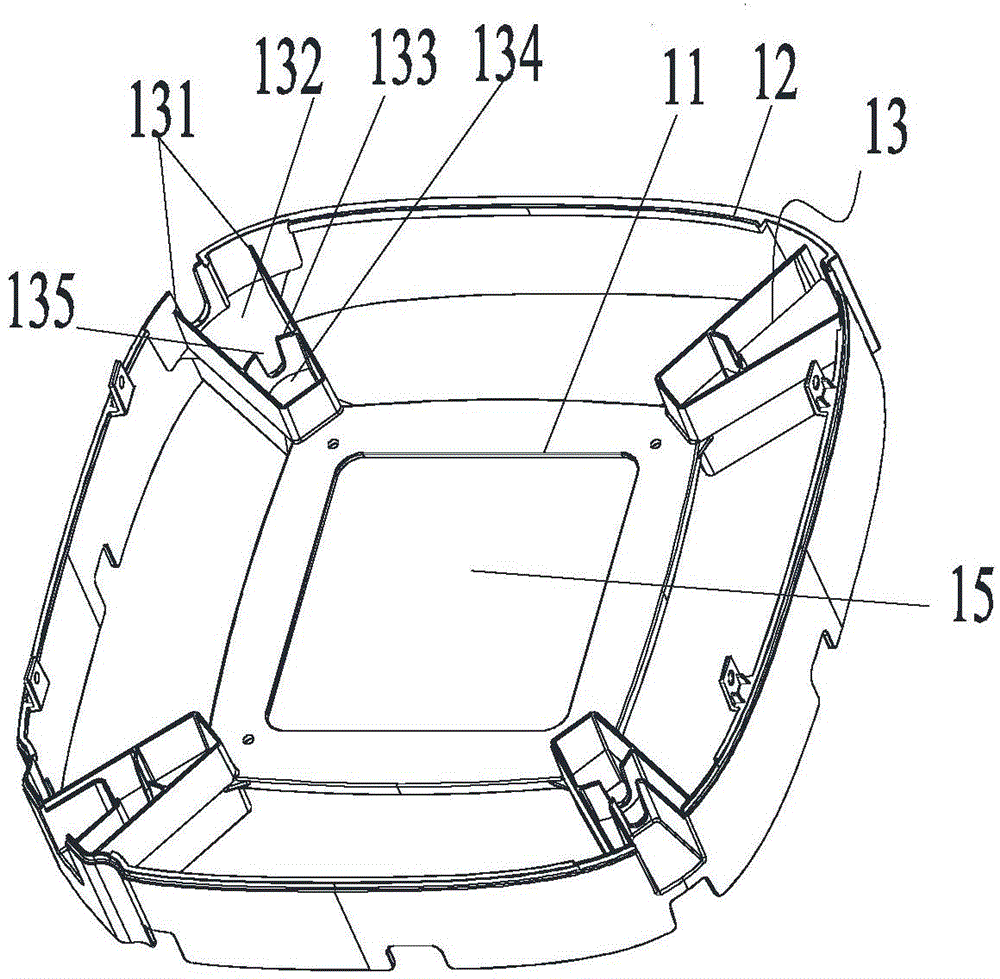

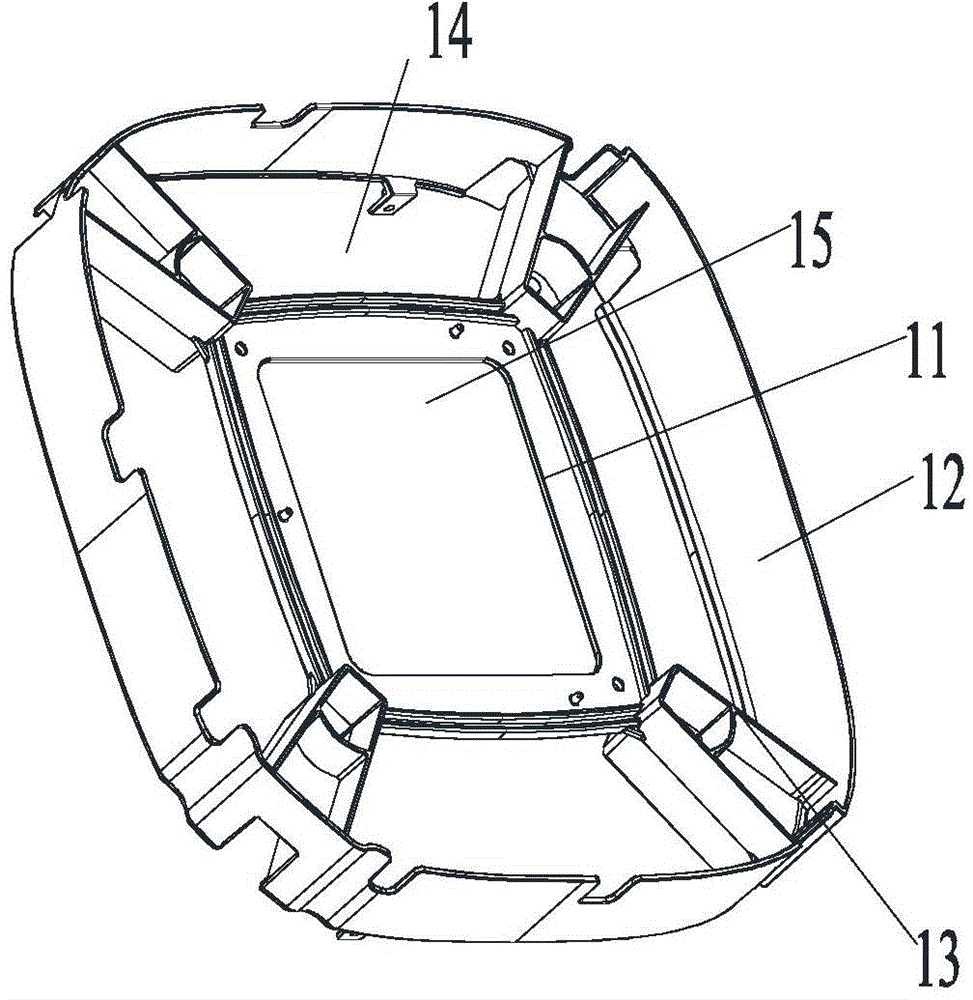

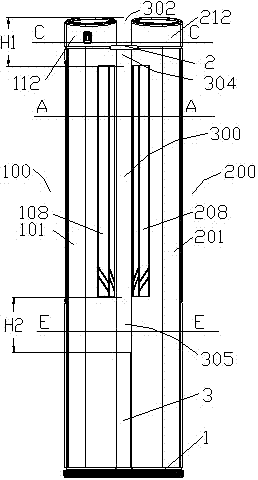

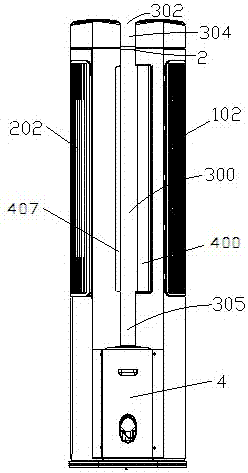

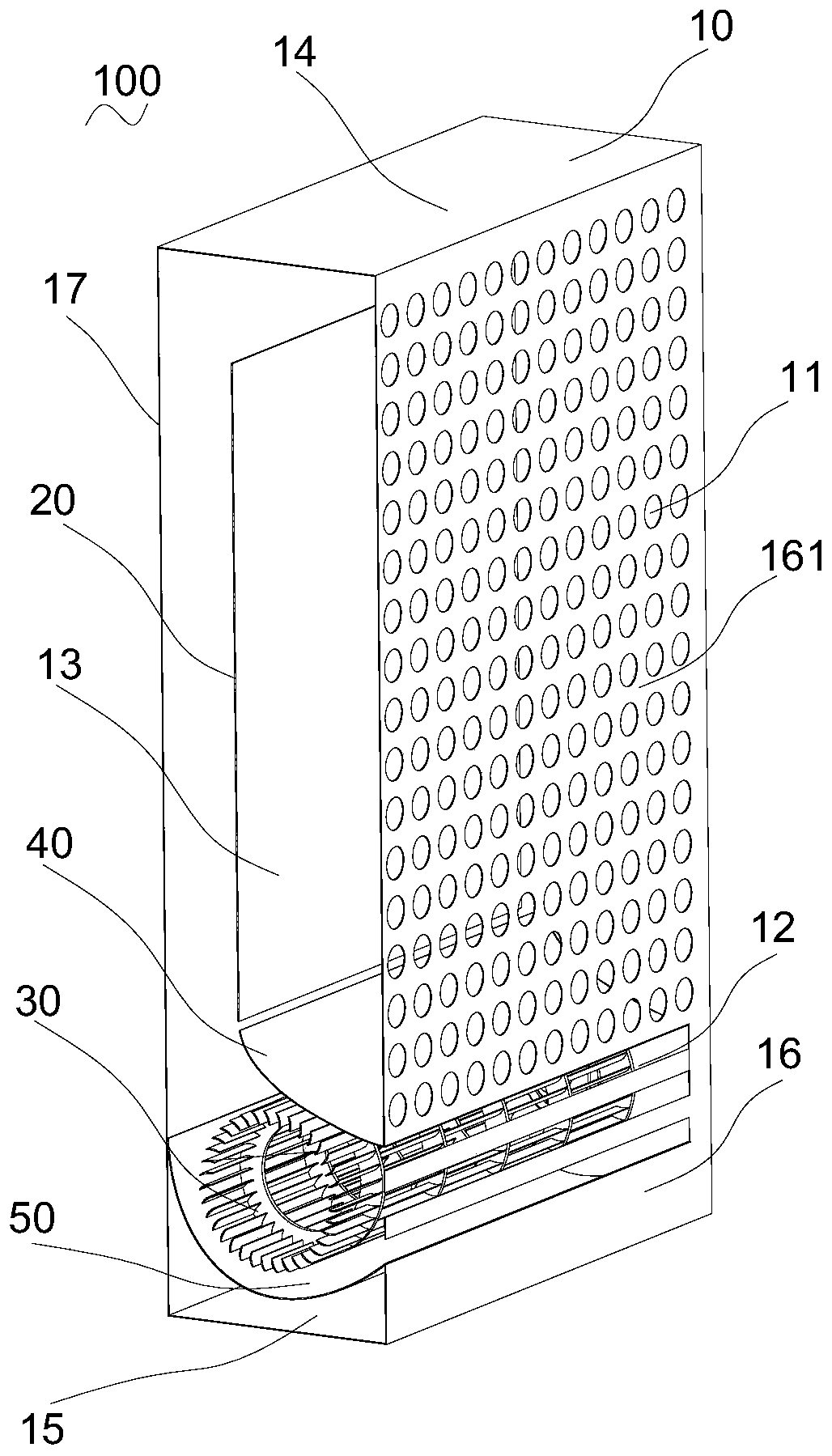

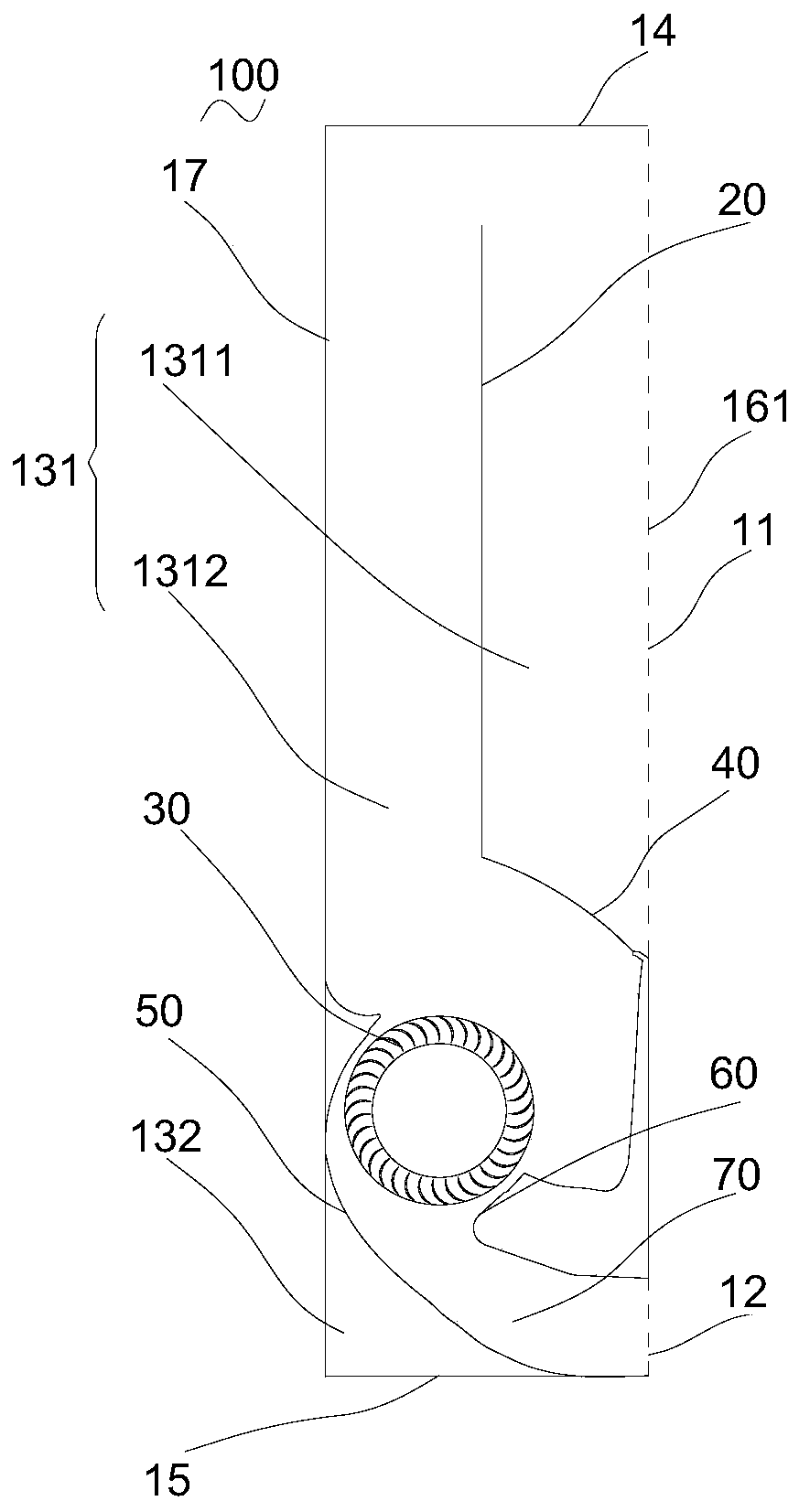

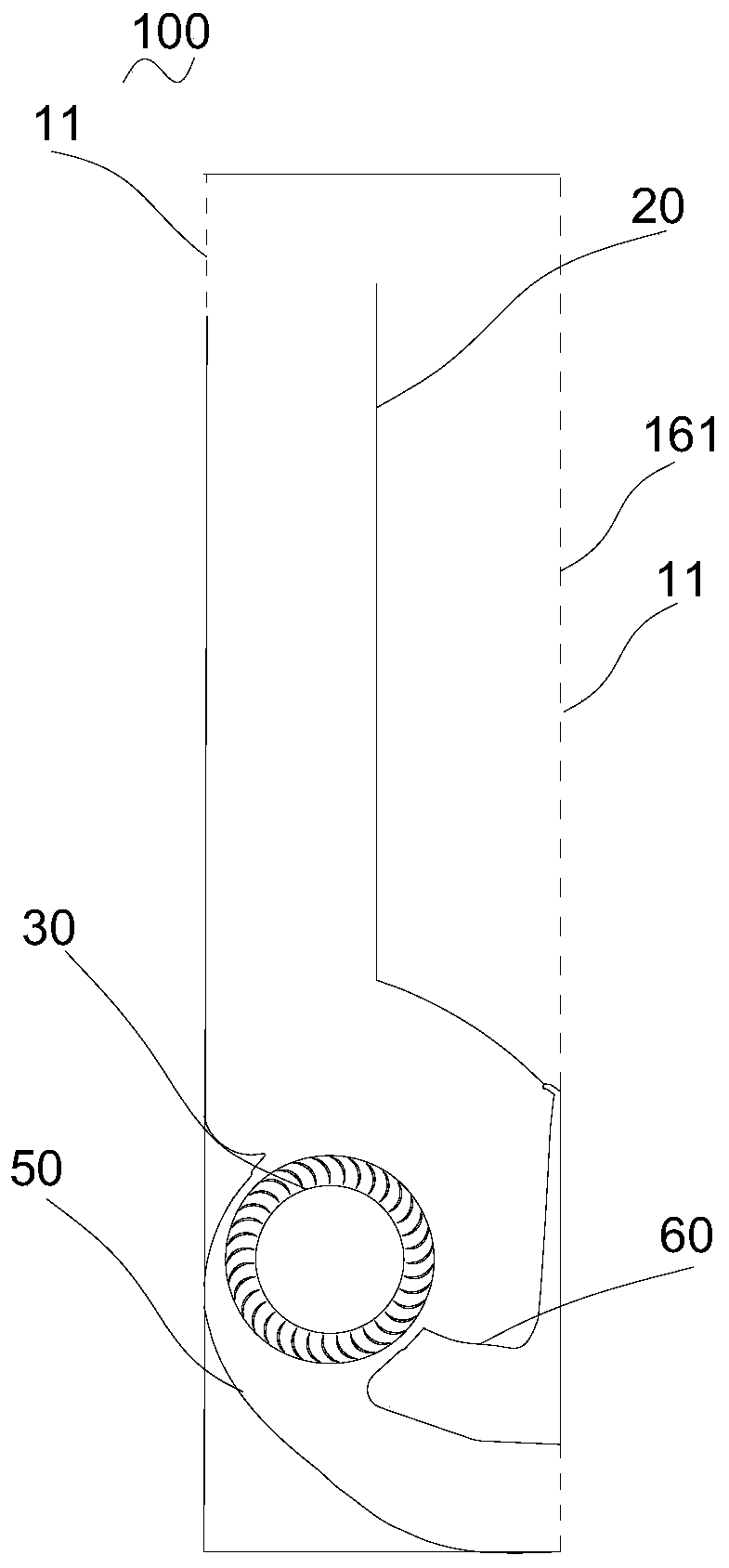

Support frame, base assembly and air purifier

ActiveCN105485888ALighting and heating apparatusSpace heating and ventilation detailsFlueEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Full-load denitration device with urea fume pyrolysis function

PendingCN108607358AAvoid pyrolysisReduced pyrolysis energy requirementsGas treatmentDispersed particle separationSuperheaterFuel oil

Owner:HUNAN DATANG ENERGY SAVING SCI & TECH CO LTD

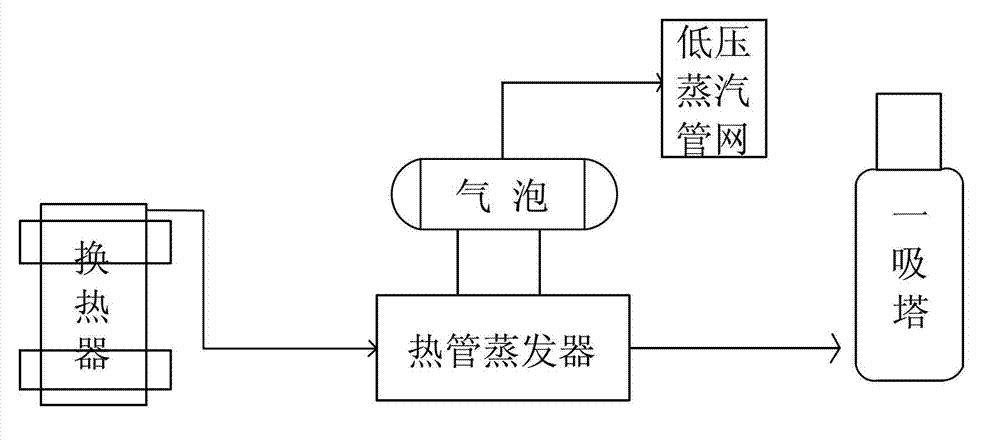

Device for recycling waste heat generated in procedure of acid making and conversion of sulphide ore

Owner:SHANDONG BOFENG LIZHONG CHEM

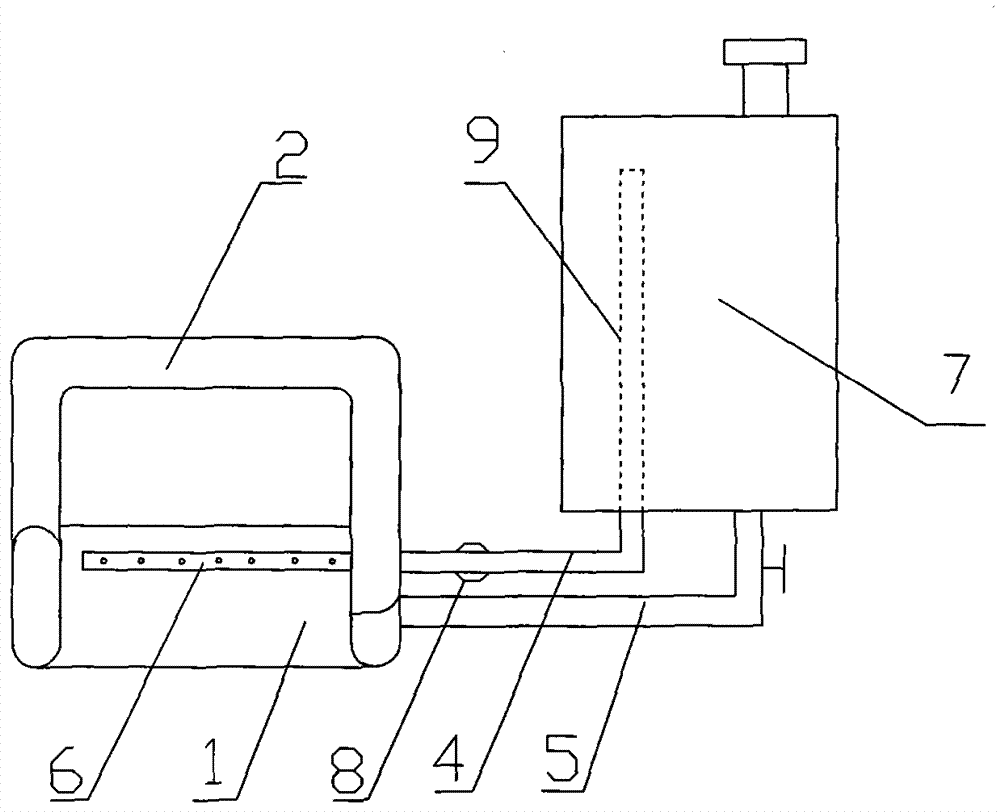

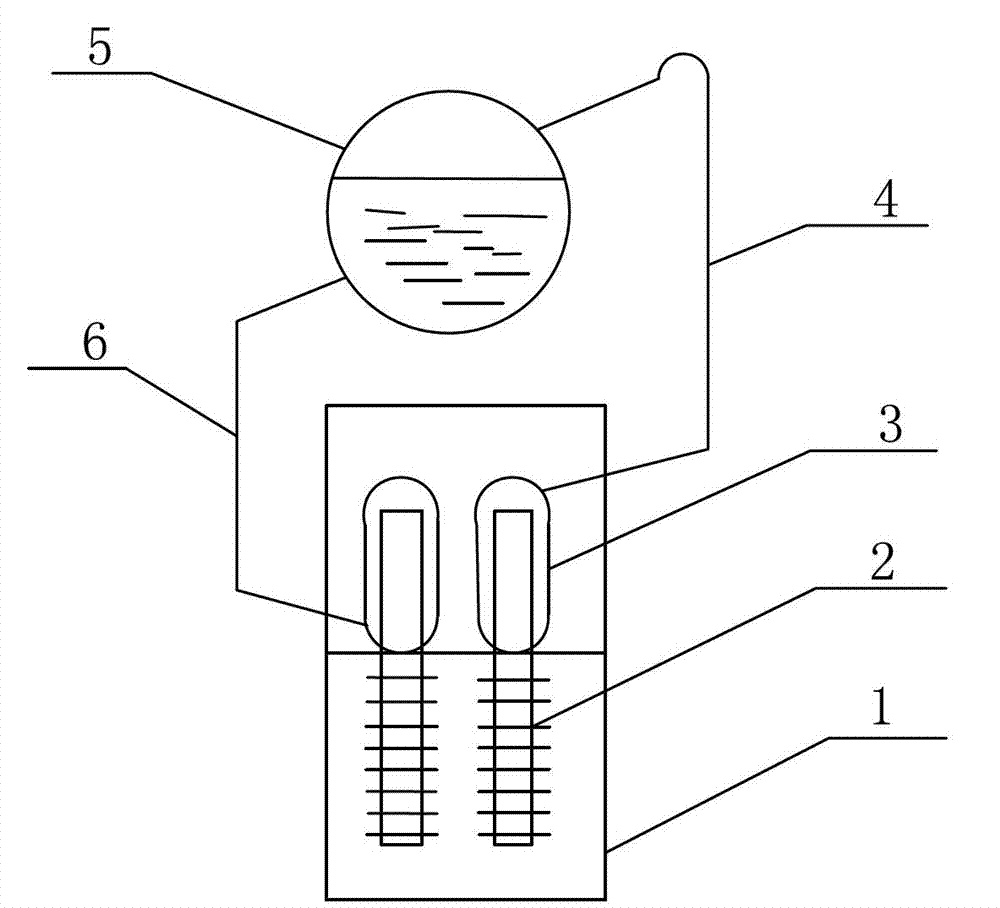

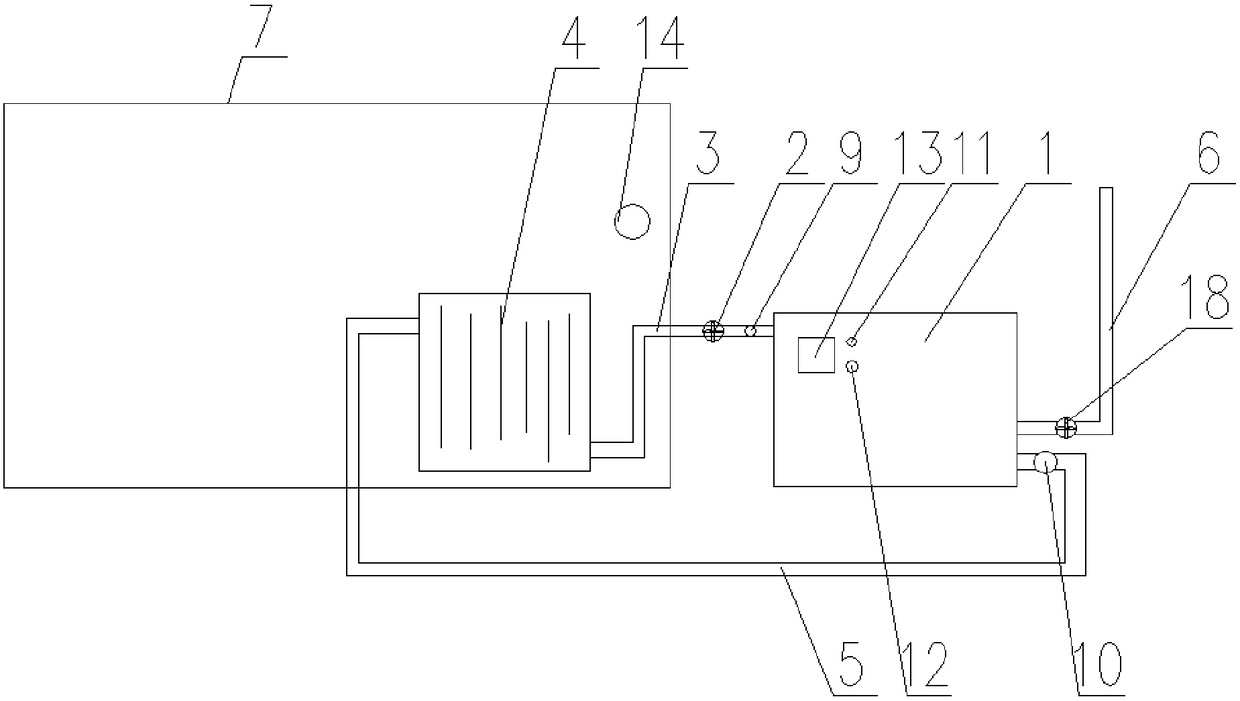

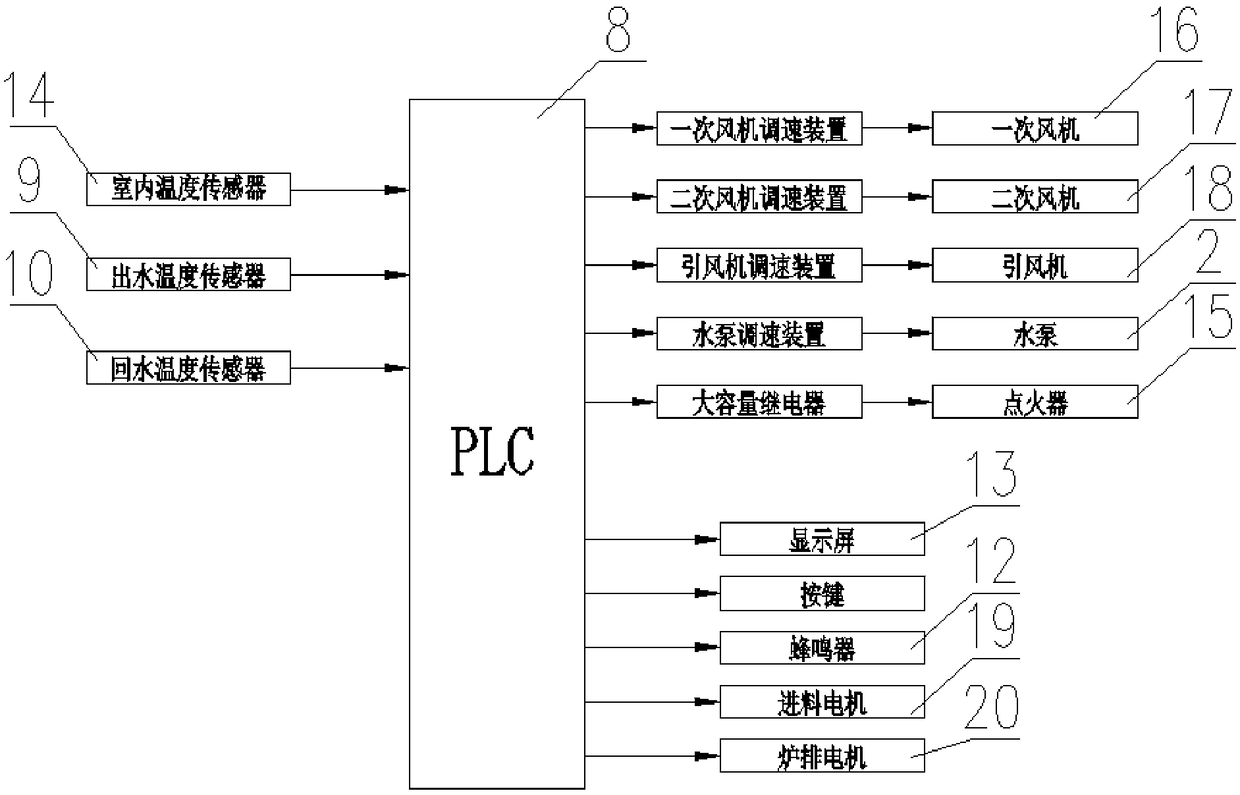

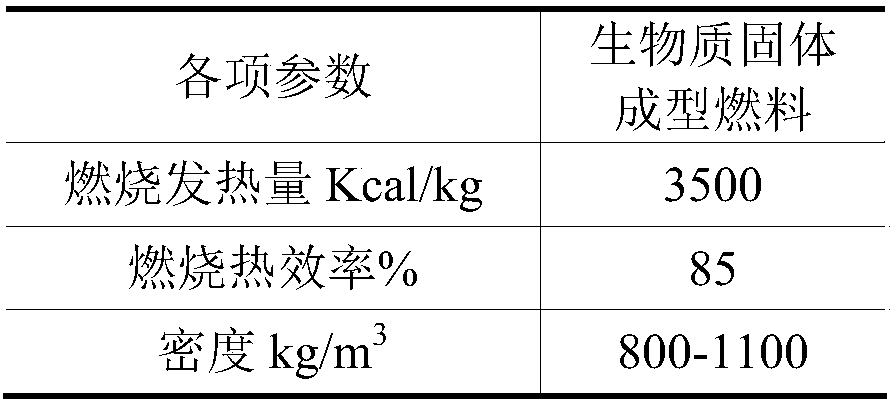

Biomass boiler intelligent heating device

InactiveCN108105829ARealize intelligent controlHeating fuelLighting and heating apparatusEconomic benefitsProcess engineering

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

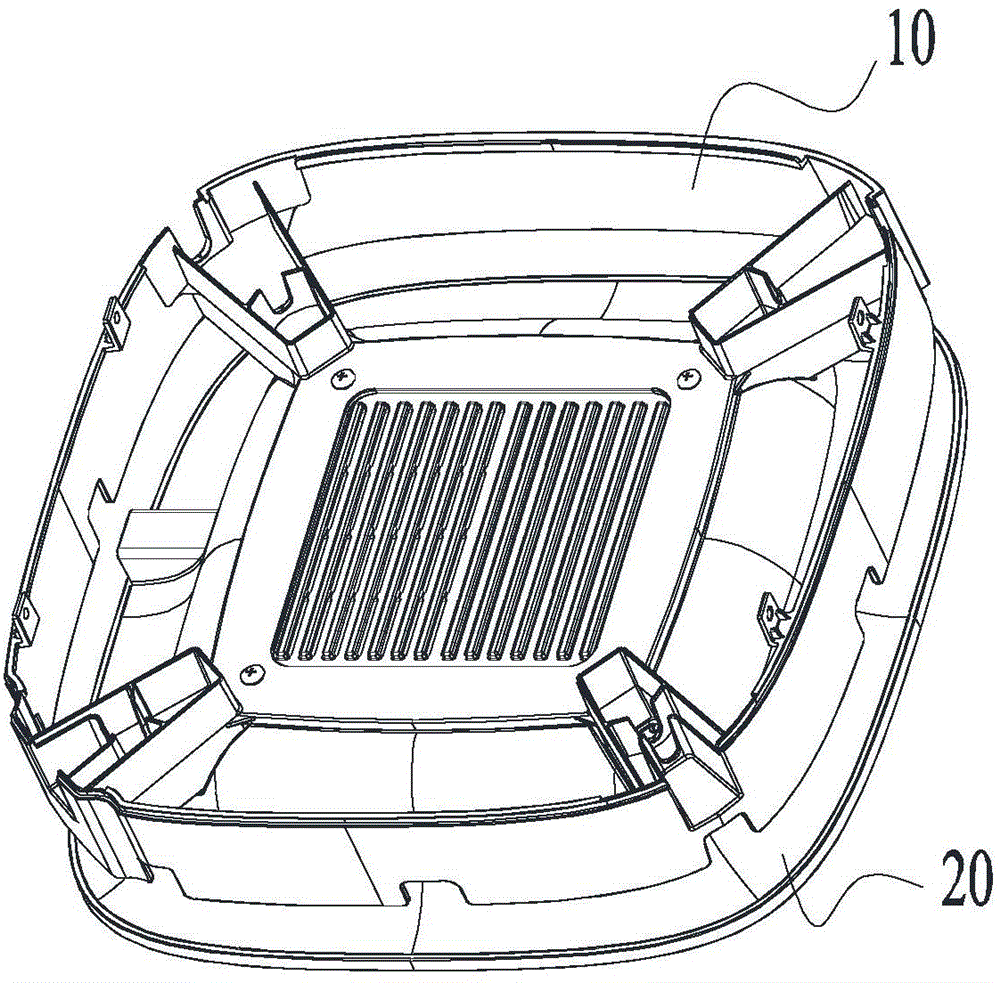

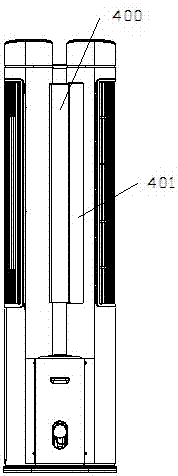

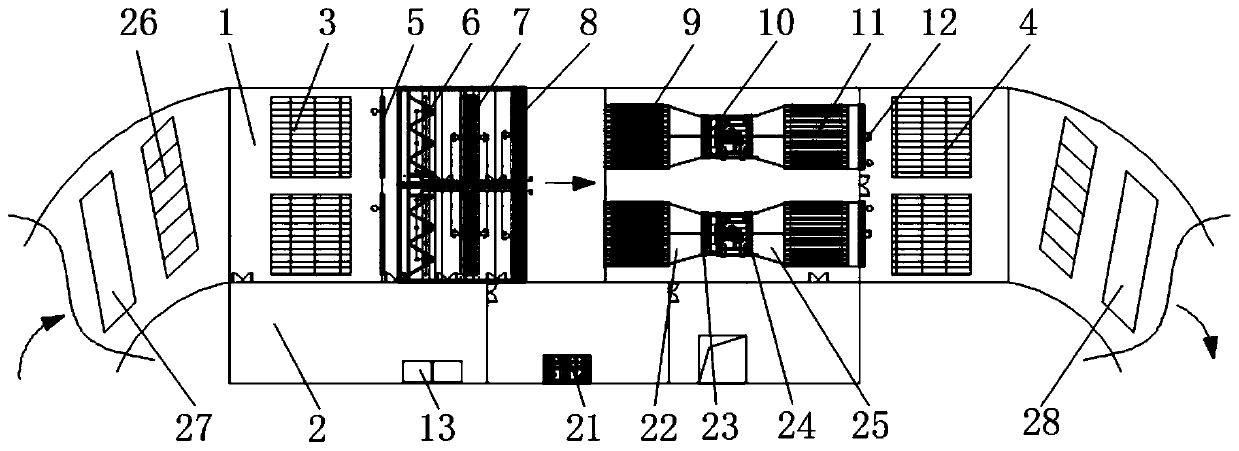

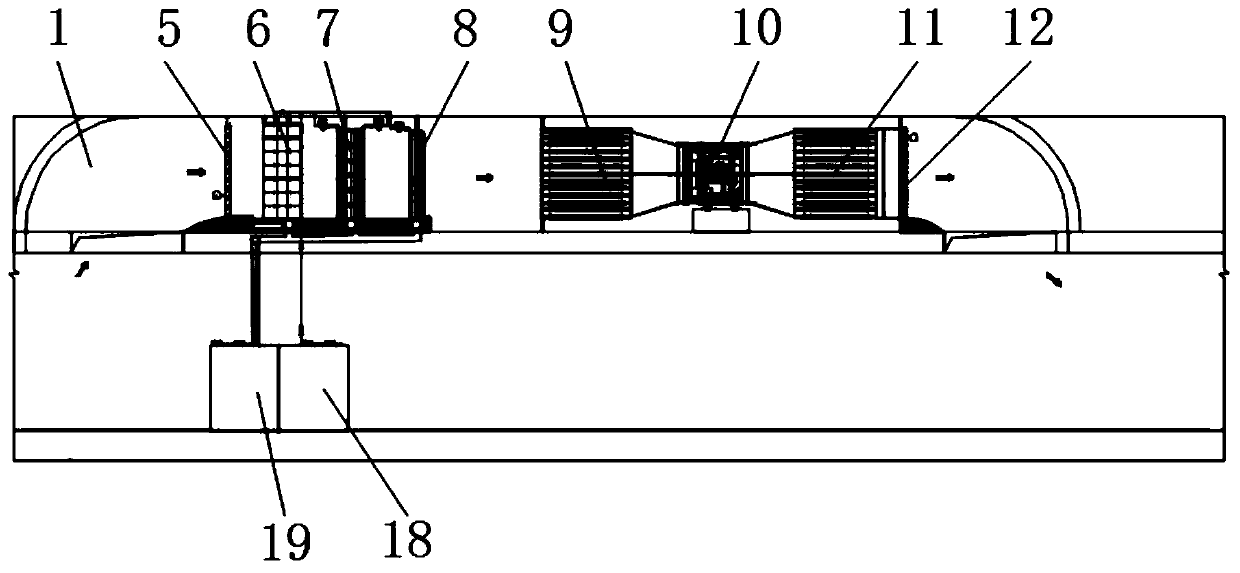

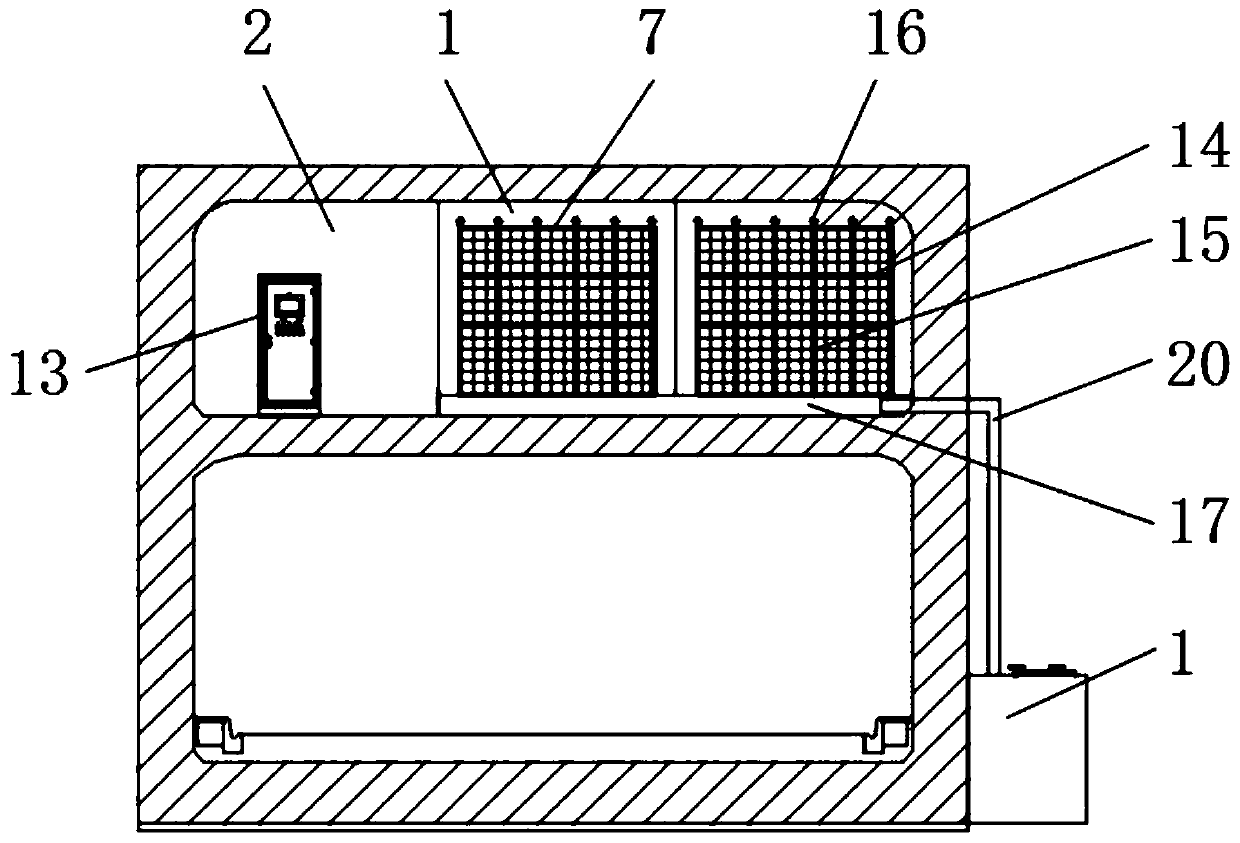

Dual-cross-flow jet flow air conditioner with adjustable air input amount and air conditioner indoor unit

The invention discloses a dual-cross-flow jet flow air conditioner with the adjustable air input amount and an air conditioner indoor unit. The indoor unit comprises at least two air conditioner bodies. A through air flue is formed between the first air conditioner body and the adjacent second air conditioner body, a rear end air induced opening is formed between the rear ends of the air conditioner bodies, an upper end air induced opening is formed between the upper ends of the air conditioner bodies, an air supply opening is formed between the front ends of the air conditioner bodies, and an air outlet of each air conditioner body is located in the through air flue; according to the first air conditioner body and the second air conditioner body, when a cross flow fan rotates, negative pressure generated in the through air flue enables air outside the first air conditioner body and the second air conditioner body to enter the through air flue through the rear end air induced opening and the upper end air induced opening, and the air supply opening supplies air in the through air flue. The air induced openings comprise the rear end air induced opening and the upper end air induced opening, the air induced range is widened, the air induced amount is greatly increased, the air induced effect is improved, and the output air of the air supply opening is more warm and comfortable. The air in the through air flue can be adjusted through a wind adjusting part, and the different air induced amount needs of a user can be met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Tunnel top flue mounting type air purification system

Owner:上海进贤机电科技有限公司

Online waste removing system for waste discharge area of plate type SCR denitration catalyst calcinator

InactiveCN104197726ADoes not affect product qualityAvoid secondary pollutionSolid removalWaste heat treatmentFlue gasExhaust fumes

Owner:HUBEI DABIESHAN FURNACE IND RES & DESIGN INST

Electric heater

PendingCN110094797AIncrease profitImprove experienceHeating fuelElectric heating systemEngineeringBuoyancy

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap