Boiler waste heat recovery device

A recovery device and boiler waste heat technology, applied in preheating, feed water heaters, fluid heaters, etc., can solve the problems of flue gas energy waste and achieve the effect of increasing the inlet water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

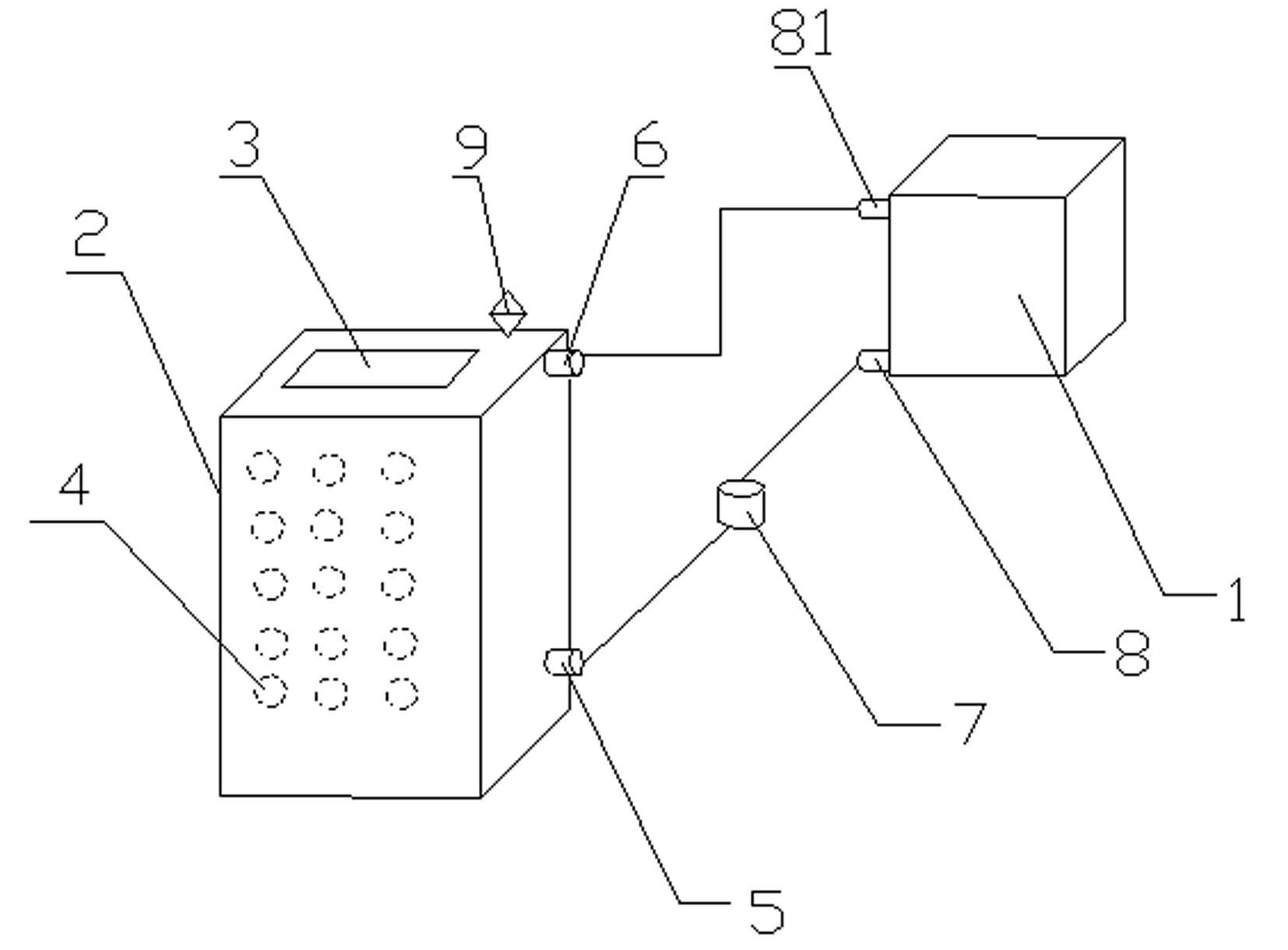

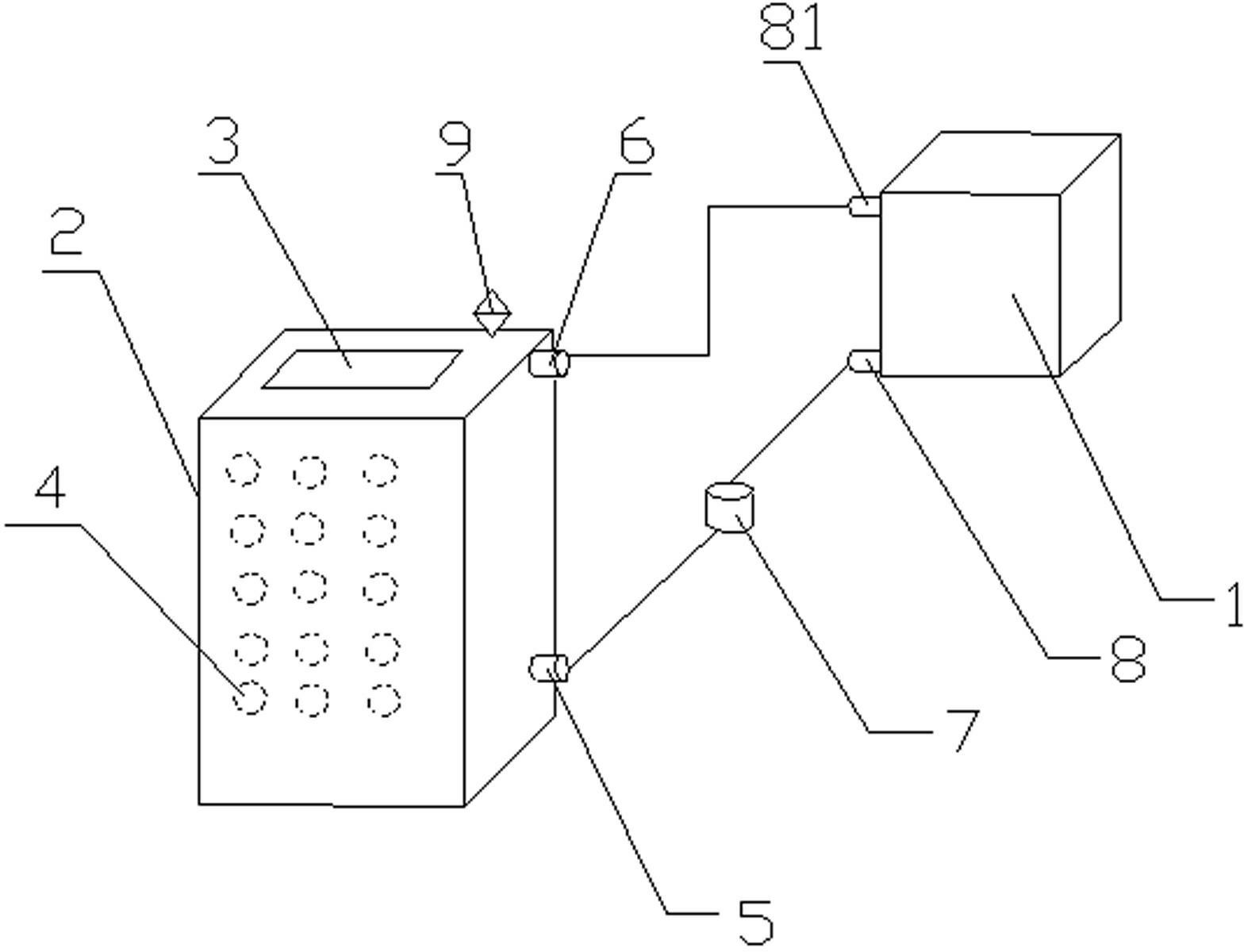

[0017] Such as figure 1 As shown, the boiler waste heat recovery device according to the embodiment of the present invention includes a boiler return tank 1 and a heat absorption tank 2 installed on the flue; the heat absorption tank 2 is provided with a There are a plurality of heat-absorbing steel pipes 4 inside the heat-absorbing tank 2, and a water inlet 5 and a water outlet 6 are arranged on the outer wall of the heat-absorbing tank 2, and the water inlet 5 and the water outlet 6 are respectively connected to the The boiler return water tanks 1 are connected.

[0018] The water inlet 5 is connected to a circulating water pump 7 through a pipeline, and the other end of the circulating water pump 7 is connected to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap