Warm air furnace

A heating furnace and furnace body technology, which is applied in the field of heating furnaces, can solve the problems of inconvenient operation, inconvenient production, sales, inventory and delivery of heating furnaces, and can only be cleaned when it is stopped, so as to achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

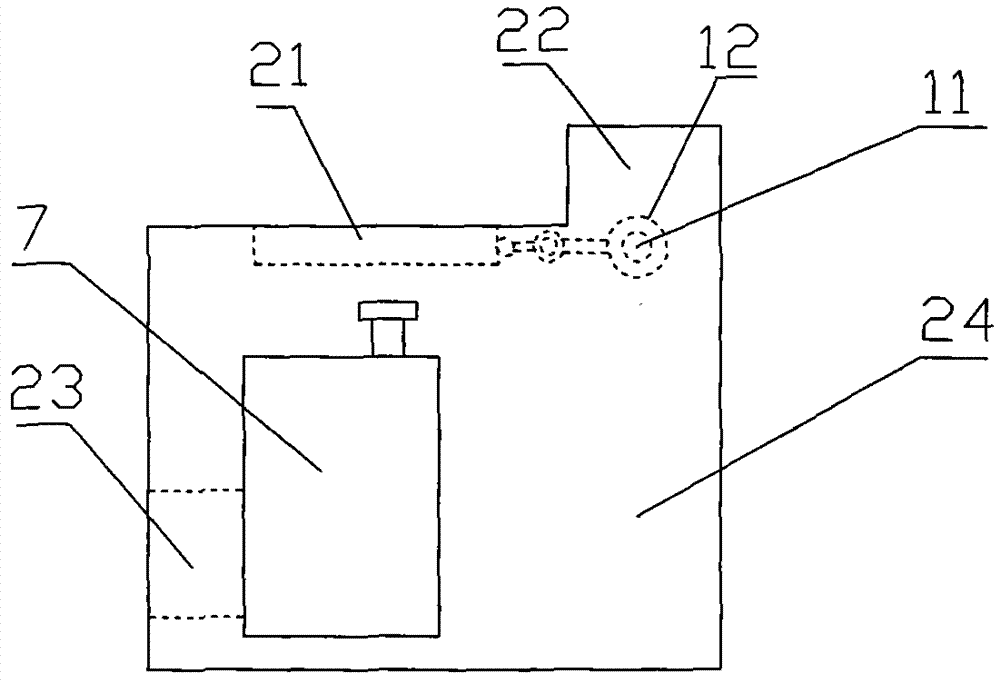

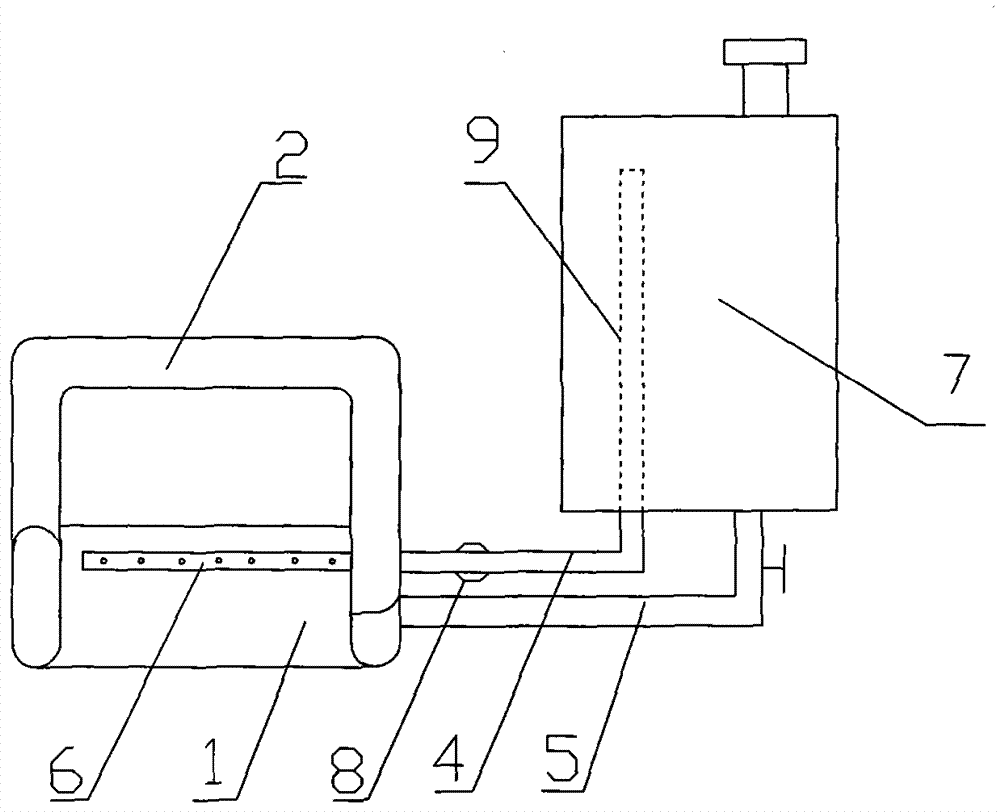

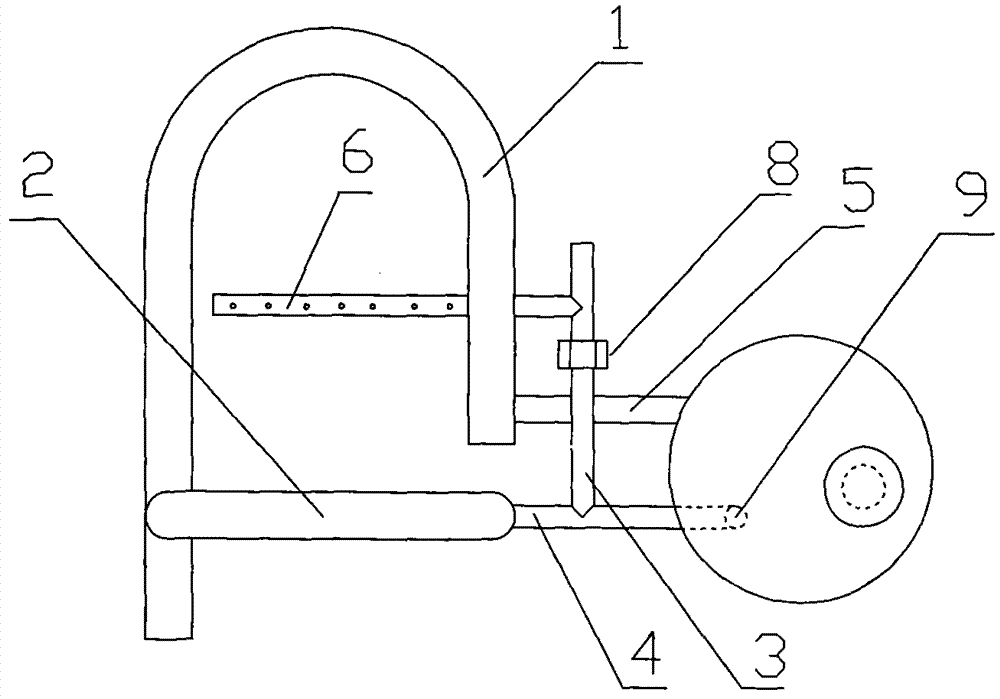

[0011] Such as Figure 1 to Figure 3 As shown, a heating furnace of the present invention includes a furnace body 24, the furnace body is provided with a stove mouth 21, a flue 22, a furnace 23 and a steam combustion-supporting device, the flue is provided with a flue heat-absorbing pipe 11, and the steam combustion-supporting device includes Heating pipe 1, steam bag 2, water tank 7, steam spray pipe 6, water tank 7 is located on the outside of body of heater 24, water tank 7 is communicated with heating pipe 1 by water inlet pipe 5, and steam bag 2 is connected with the guide in the water tank by steam pipe 4. Steam pipe 9 communicates, and described steam pipe 4 is communicated with side pipe 3, and side pipe 3 is positioned at the outside of body of heater 24, and side pipe 3 communicates with steam spray pipe 6 by connecting pipe nut 8, and steam spray pipe 6 passes through the body of heater 24. The through hole of the outer wall goes deep into the hearth 23 . When dismant

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap