Online waste removing system for waste discharge area of plate type SCR denitration catalyst calcinator

A denitration catalyst and calciner technology, applied in the field of kiln auxiliary facilities, can solve the problems of excessive dust and volatile matter, difficulty in exhaust gas extraction, product quality defects, etc., and achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

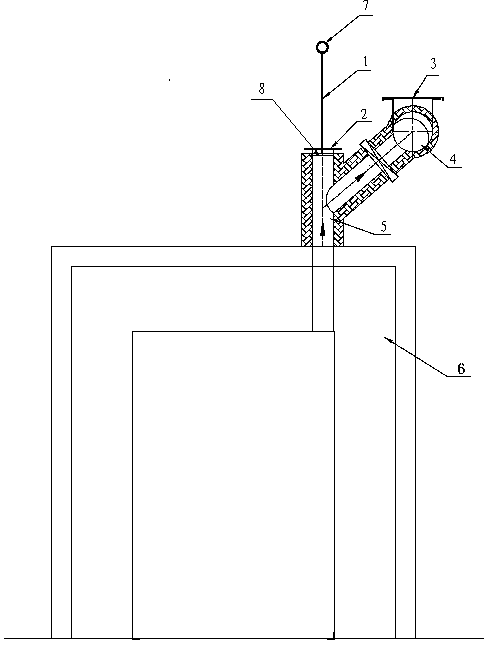

[0011] Such as figure 1 As shown, the online decontamination system for the waste area of the calcination furnace of the plate type SCR denitrification catalyst is composed of a furnace body 6 in the waste area of the calcination furnace, a vertical branch pipe 5 of the flue, a connecting branch pipe with a butterfly valve 4, a main exhaust pipe 3 and a fan. etc., the connection mode between the vertical branch pipe 5 of the flue and the connecting branch pipe where the butterfly valve 4 is set and the smoke exhaust main pipe 3 is a snap-fit connection. The vertical branch pipe 5 of the flue is set on the top of the furnace body 6 in the waste area of the calciner, and the smoke exhaust port on one side is connected to the main exhaust pipe 3 through the connecting branch pipe provided with the butterfly valve 4, and the top protrudes upwards to install a blind plate for installing a cleaner 2. Cleaner is made up of circular scraper 8, elevating rod 1 and handle 7, and c

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap