Full-load denitration device with urea fume pyrolysis function

A full-load, urea technology, applied in the direction of gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of low efficiency, high operating cost, high energy consumption, etc., achieve scientific and reasonable structure, meet the requirements of denitrification, and be widely popularized and applied Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

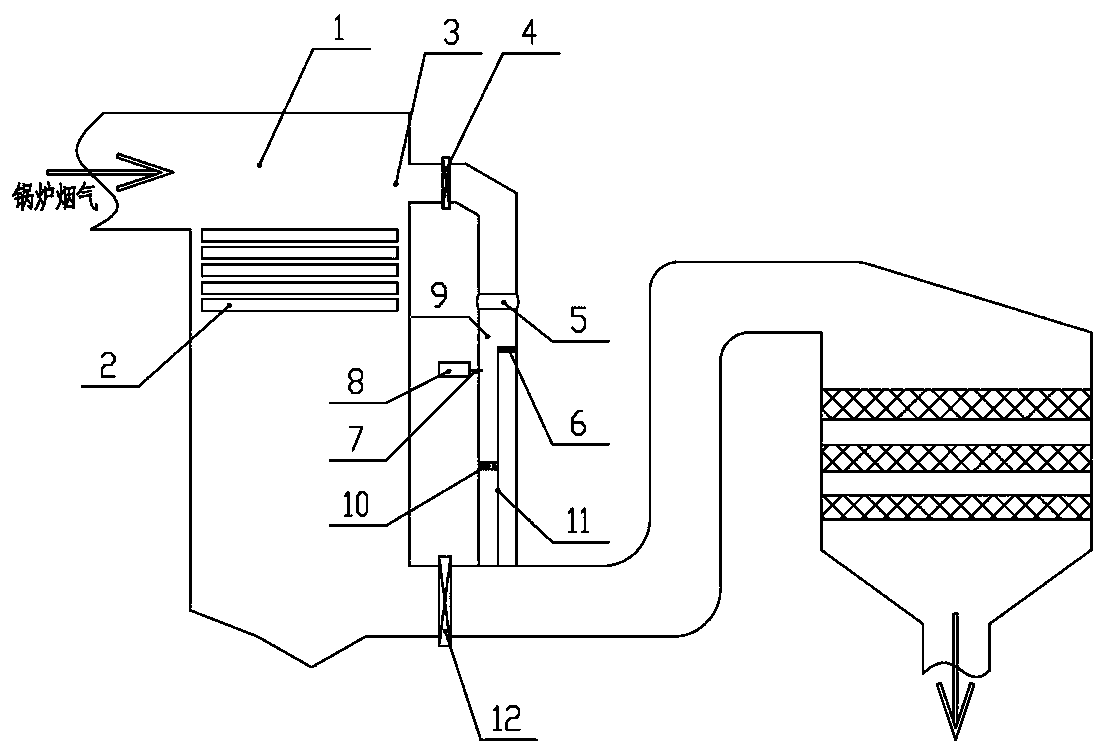

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0027] A full-load denitrification device with urea flue gas pyrolysis function, consisting of 1. tail flue steering chamber, 2. low-temperature superheater, 3. bypass flue inlet, 4. bypass flue adjustment door, 5. expansion Section, 6. Shut-off door, 7. Urea solution spray gun, 8. Urea solution metering and distribution device, 9. Bypass flue, 10. Bypass flue ammonia gas equalization device, 11. Bypass flue partition plate , 12, the main flue regulating door composition.

[0028] The full load denitrification device with urea flue gas pyrolysis function, its bypass flue, bypass flue adjustment door, urea solution metering and distribution device, urea solution spray gun, bypass flue ammonia gas equalization device Fixed connection, the bypass flue is equipped with expansion joints, urea solution metering and distribution devices

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap