Arrangement structure of tail flue of a double reheat boiler

A tail flue, secondary reheating technology, applied in valve configuration, lighting and heating equipment, combustion methods, etc., can solve problems affecting the safe operation of the water wall, the heat absorption deviation of the economizer tube group, and the temperature rise of the outlet smoke. High-level problems, to achieve the effect of being conducive to high-efficiency operation, solving high-temperature heat and easy deformation, and ensuring the effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0020] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

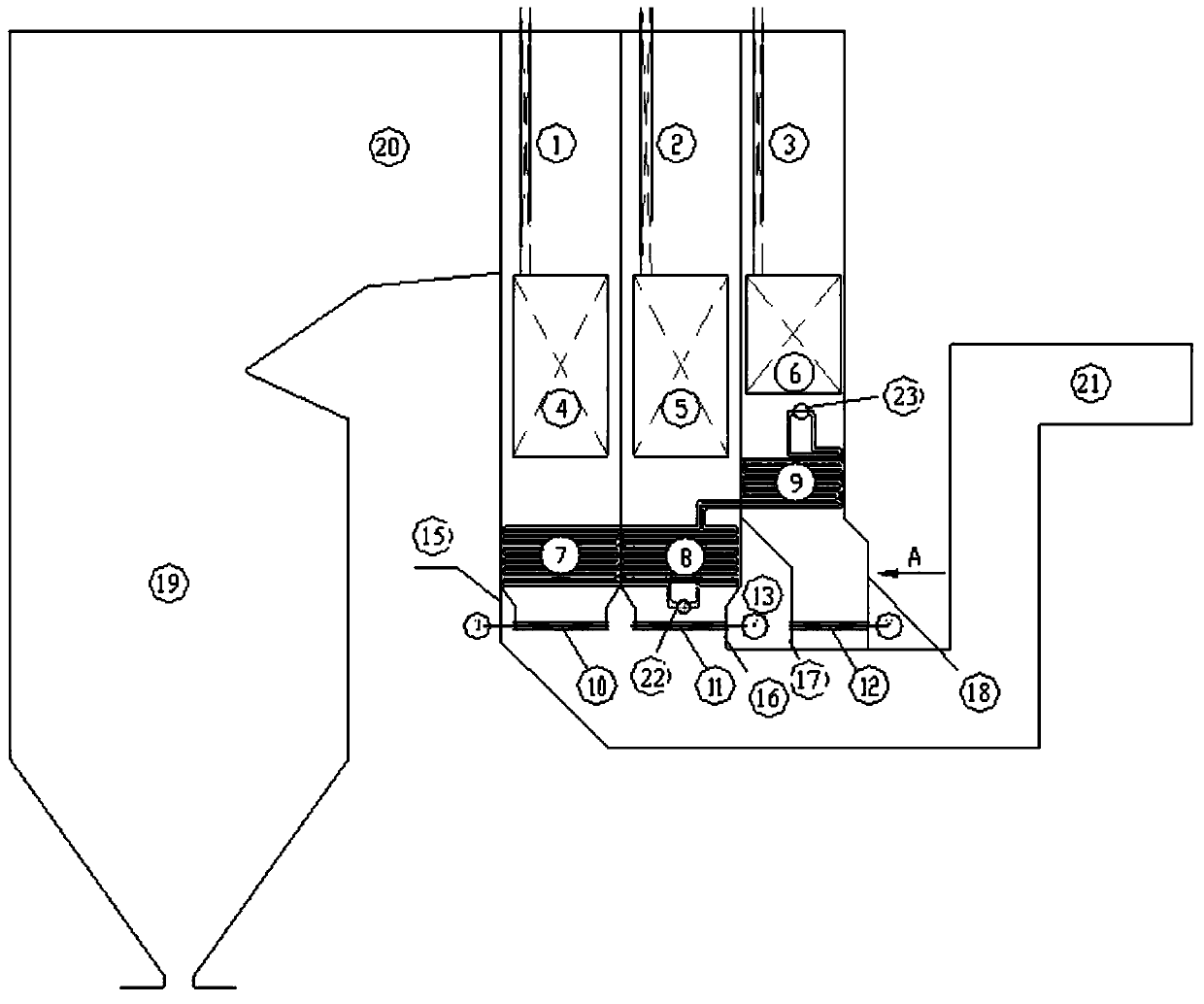

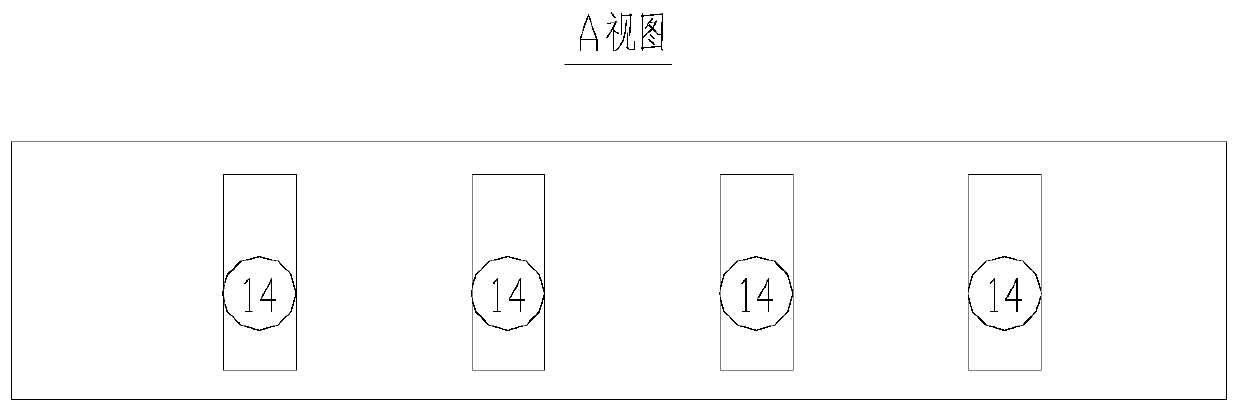

[0021] figure 2 A schematic structural diagram showing an arrangement structure of a tail flue of a double reheat boiler according to an exemplary embodiment of the present invention.

[0022] like figure 2 As shown, according to an exemplary embodiment of the present invention, the rear flue is divided into front flue 1, middle flue 2 and rear flue 3 from front to rear, and an economizer is arranged in the tail flue and is located in the front flue 1 The first low-temperature reheater 4, the seco

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap